High temperature resistant fibres

A high-temperature-resistant fiber technology, applied in the field of high-temperature-resistant fibers, can solve problems such as difficult to find, uncontrolled crystallization, and difficult melt formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Other features and aspects of the invention will be apparent from the claims and the following exemplary description, with reference to the accompanying drawings, in which:

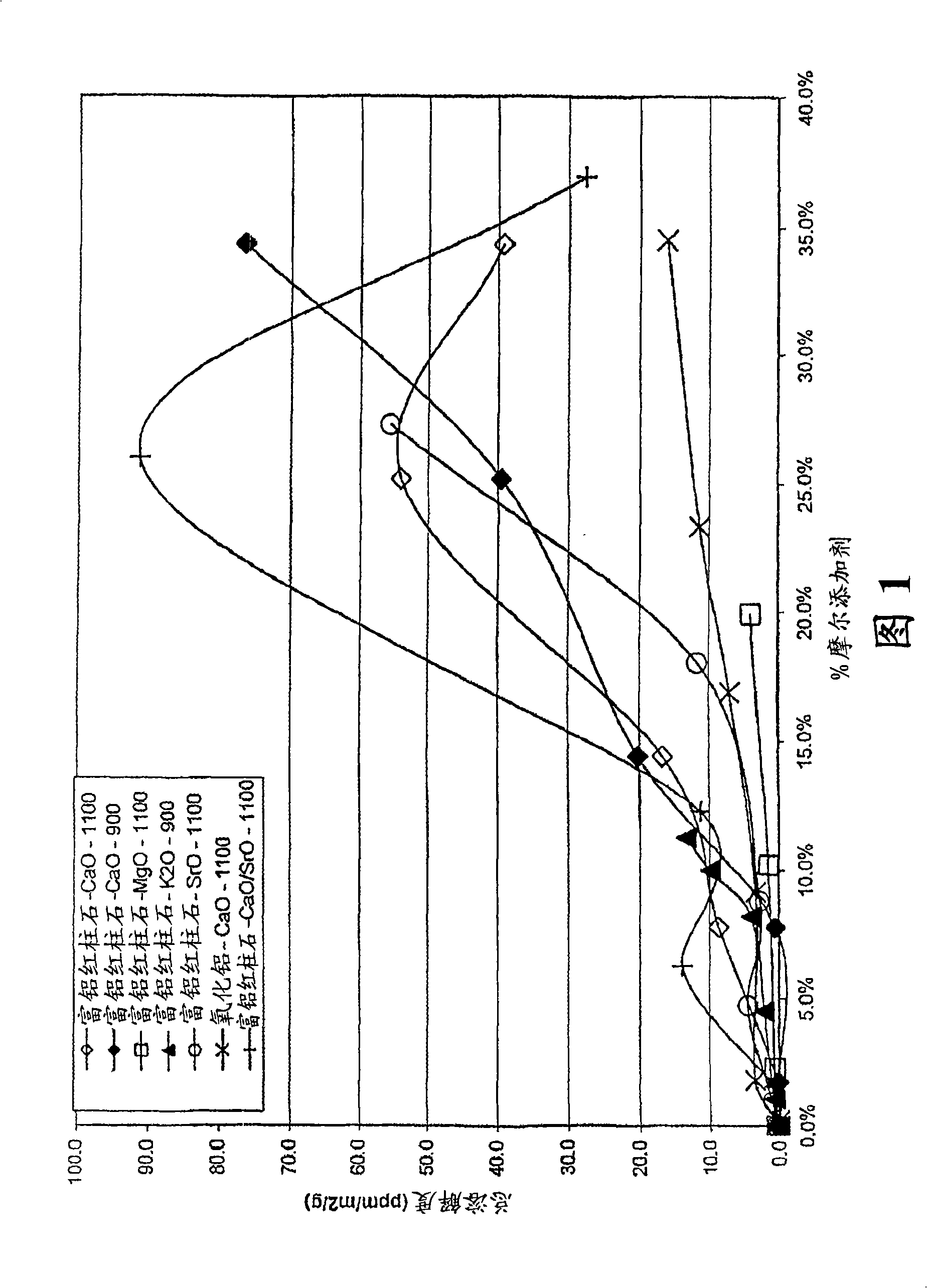

[0068] Figure 1 is a graph of the solubility in body fluids of a series of fibers including the fibers of the present invention.

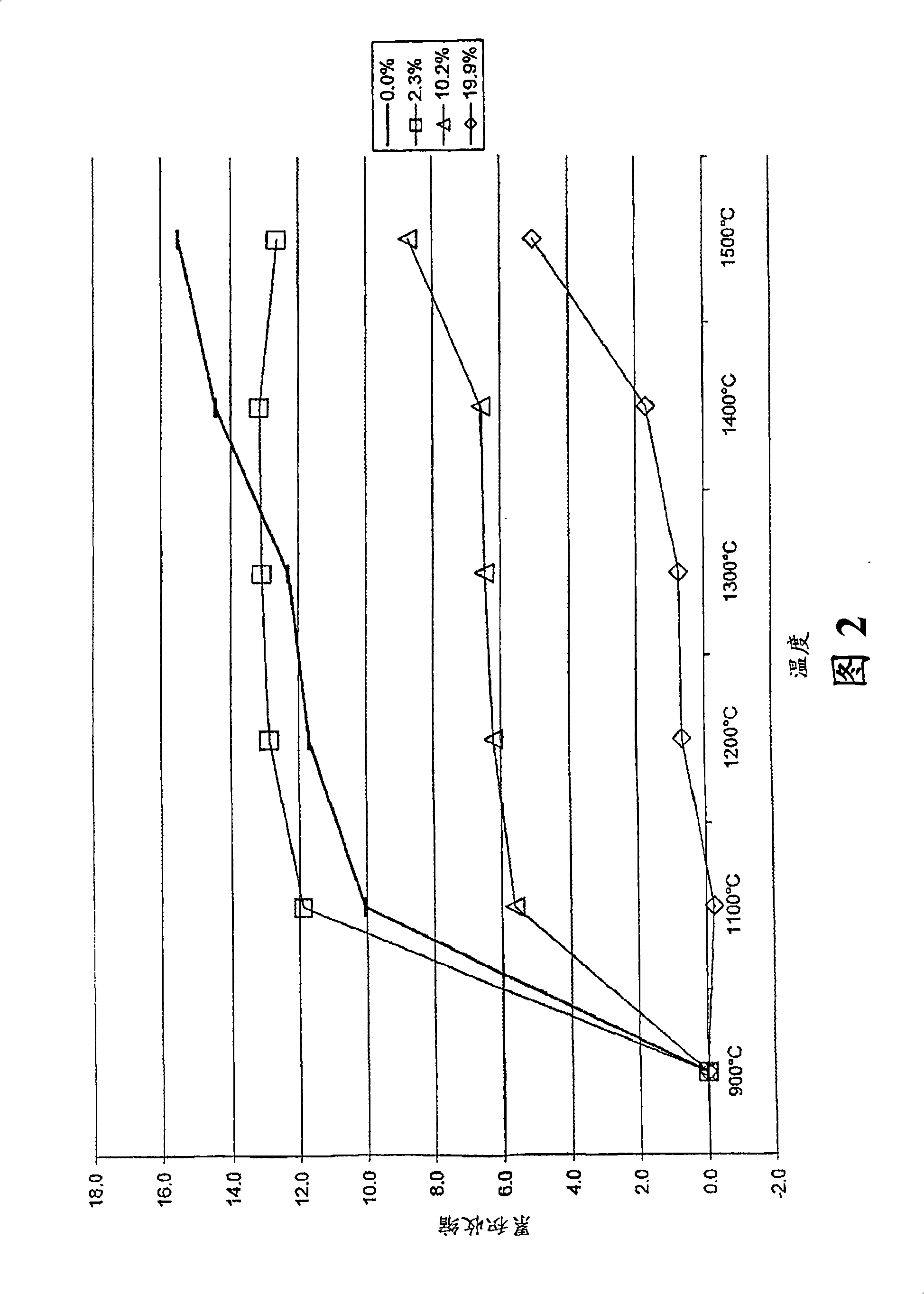

[0069] Figure 2 is a graph of shrinkage versus temperature for a series of MgO-modified mullite matrix composition fibers.

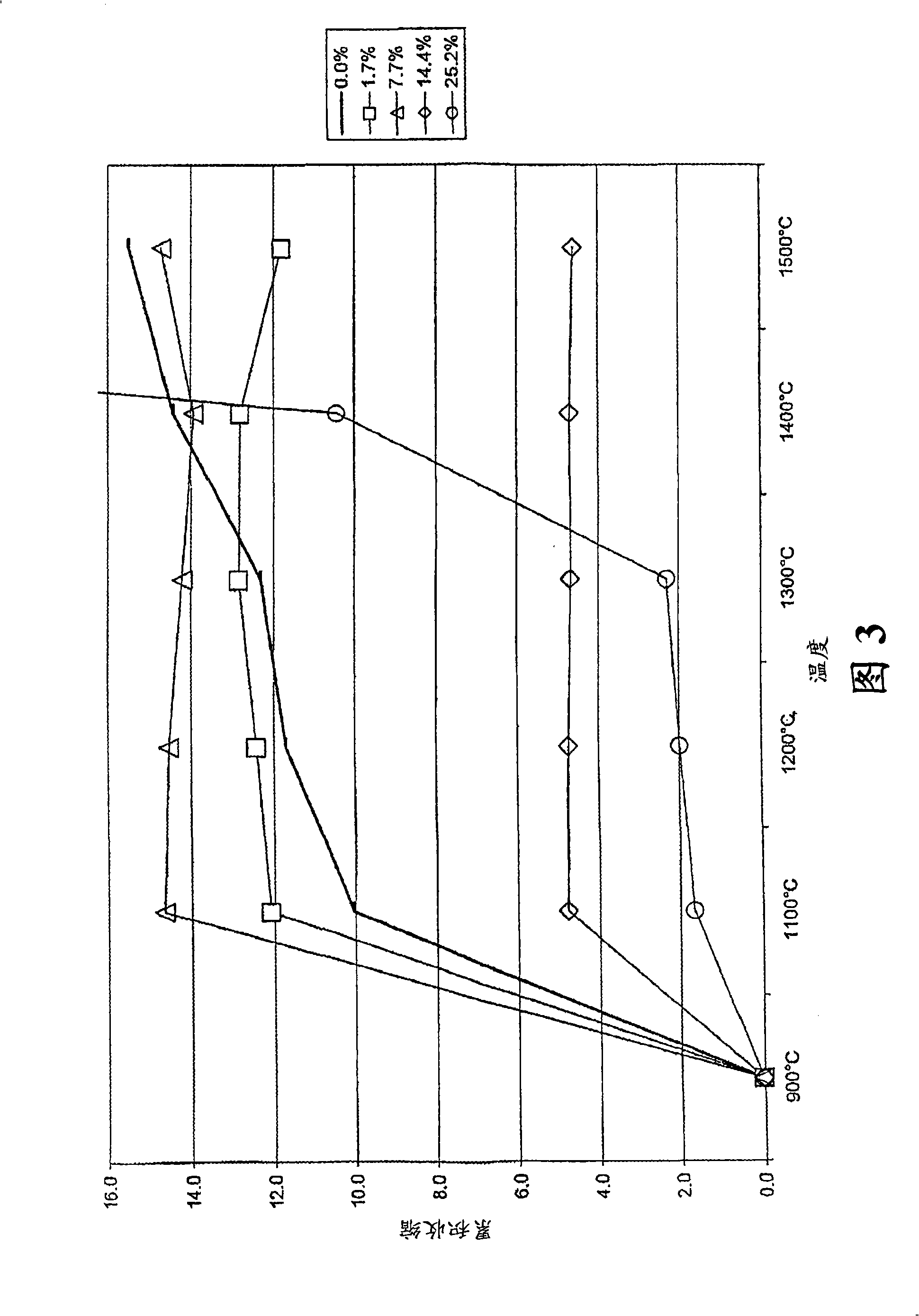

[0070] Figure 3 is a graph of shrinkage versus temperature for a series of CaO-modified mullite matrix composition fibers.

[0071] Figure 4 is a graph of shrinkage versus temperature for a series of SrO-modified mullite matrix composition fibers.

[0072] Figure 5 is a graph of shrinkage versus temperature for a series of CaO and SrO modified mullite matrix composition fibers.

[0073] Figure 6 is a graph of shrinkage versus temperature for a series of fibers of a CaO-modified alumina matrix composition.

[0074] Figure 7 is a graph showing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com