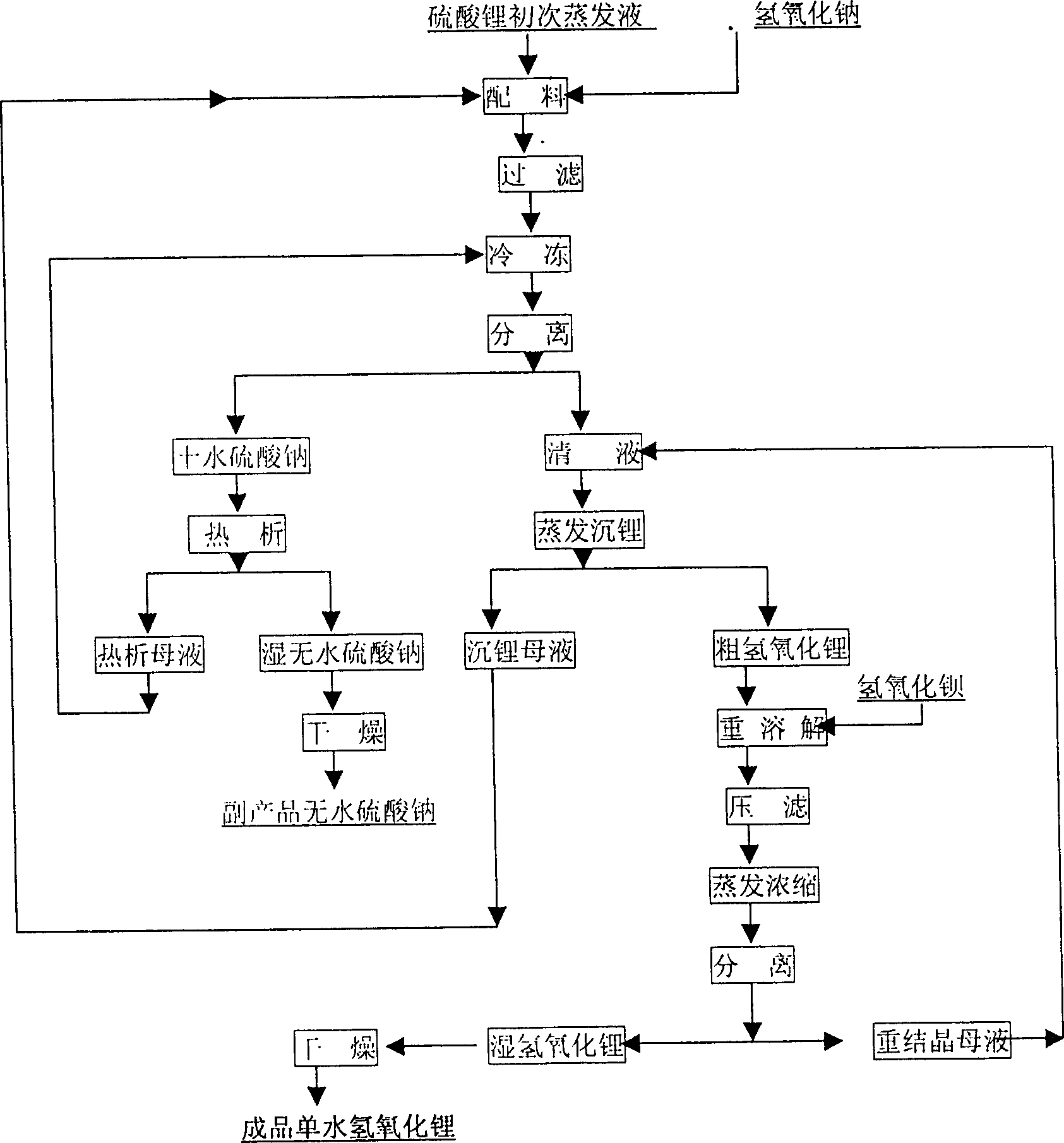

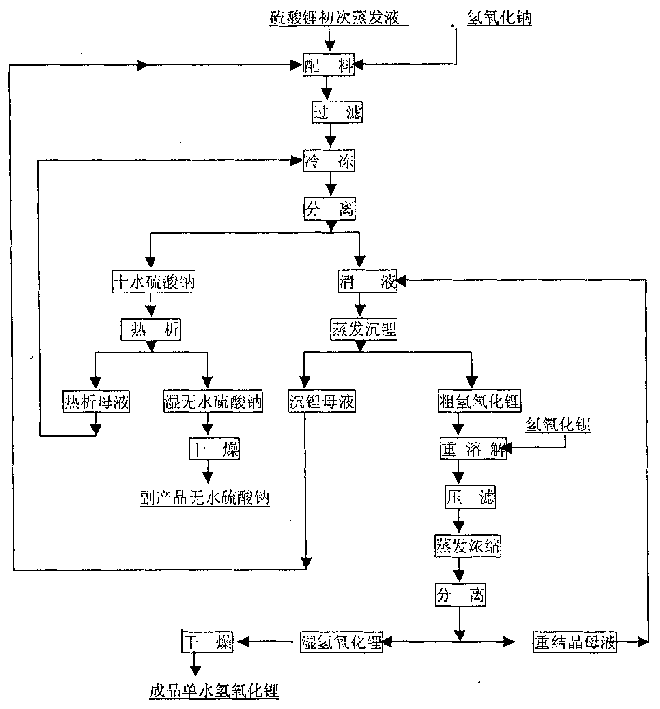

Production process of lithium hydroxide monohydrate

A lithium hydroxide, production process technology, applied in the direction of lithium oxide;/hydroxide, lithium sulfate/sulfite, sulfate/bisulfate preparation, etc., can solve the problem of reducing production costs, long process routes, Reduce lithium loss and other issues, achieve high guiding significance, shorten the process route, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, with reference to figure 1 :

[0040] 1. The front-end production process of lithium sulfate solution from lithium concentrate through roasting, acidification, pulping, leaching and preliminary concentration still uses the existing production process. The lithium sulfate solution produced in the middle is directly used in the new process.

[0041] 2. Ingredients (prefabricated liquid): Li which has been preliminarily evaporated 2 O concentration in the 45 ~ 55g / l concentrate, and Li 2 The crude mother liquor with an O concentration of 55-65g / l, according to the expected Li 2 O content 50g / l preparation. Add sodium hydroxide, keep heating, and adjust the pH value to 12-14, heat to 90-95°C, stand still for a period of time, and discharge. The still feed liquid is pumped into the plate-and-frame filter press to filter, and various impurities such as Ca, Fe, Mn, etc. are removed, which is the prefabricated liquid, which flows to the intermediate storage t...

Embodiment 2

[0073] Embodiment 2 is basically the same as Embodiment 1, but the temperature control index of the freezing and crystallizing tank solution is: -5~-1°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com