Ignition drug for lifesaving solid oxygen and preparation method thereof

A technology of igniting powder and powder, which is applied to explosives processing equipment, explosives, offensive equipment, etc. It can solve the problems of poor quality consistency, large density difference, and low production efficiency, and achieve strong consistency, large impact, and improved production. The effect on quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

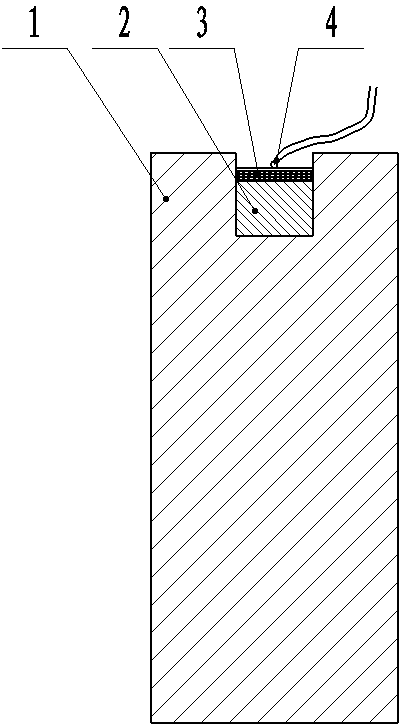

Image

Examples

Embodiment 1

[0027] Sodium chlorate 43%, potassium perchlorate 21.5%, iron powder 14%, titanium powder 5%, cobalt chloride 9%, ferric oxide 5%, barium peroxide 2%, mica powder 0.5%, and the above materials are proportionally After weighing, add it to a mortar, mix it by hand with a glass ball stick or use an automatic mixer, and pass it through a 40-mesh sieve. Add 5% distilled water to the mixed material, and mix evenly for the second time. Put the igniter powder mixed for the second time into the concave drug groove of the powder column, compact it, and evenly spread 0.03g / cm2 on the surface of the igniter powder 2 Titanium metal powder is pressed manually or by a press through a limit pressure rod. The density of the igniter for life-saving oxygen fixation after compression is 1.55g / cm 3 . After the powder column is dried in an oven at 80°C, an electric ignition head is assembled. Take three rounds and keep them warm in incubators at -20°C, 25°C, and 80°C for 6 hours, and then use t...

Embodiment 2

[0029] Sodium chlorate 40%, potassium perchlorate 21.5%, iron powder 14%, titanium powder 8%, cobalt chloride 8%, ferric oxide 6%, barium peroxide 1.7%, mica powder 0.8%, the above materials are mixed in proportion After weighing, add it to a mortar, mix evenly with a glass ball stick, and pass through a 40-mesh sieve. Add 4% distilled water to the mixed material, and mix evenly for the second time. Put the igniter powder mixed for the second time into the concave drug groove of the powder column, compact it, and evenly spread 0.04g / cm2 on the surface of the igniter powder 2 Metal titanium powder is manually pressed through the limit pressure rod. The density of the igniter for life-saving oxygen fixation after compression is 1.60g / cm 3 . After the powder column is dried in an oven at 80°C, it is equipped with a mechanical impact primer. Take three rounds and keep them warm in incubators at -20°C, 25°C, and 80°C for 6 hours, then pull out the plug, and the striker hits the...

Embodiment 3

[0031] Sodium chlorate 32%, potassium perchlorate 29.5%, iron powder 14%, titanium powder 8%, cobalt chloride 8%, ferric oxide 4.5%, barium peroxide 3%, mica powder 1%, and the above materials are proportionally After weighing, add it to a mortar, mix evenly with a glass ball stick, and pass through a 40-mesh sieve. Add 4.5% distilled water to the mixed material, and mix evenly for the second time. Put the igniter powder mixed for the second time into the concave drug groove of the powder column, compact it, and evenly spread 0.05g / cm2 on the surface of the igniter powder 2 Metal titanium powder is manually pressed through the limit pressure rod. The density of the igniter for life-saving oxygen fixation after compression is 1.65g / cm 3 . After the powder column is dried in an oven at 80°C, an electric ignition head is assembled. Take three rounds and keep them warm in incubators at -20°C, 25°C, and 80°C for 6 hours, and then use the battery to ignite, which can reliably ig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com