A non-priming charge detonator

A technology of primary explosives and detonators, which is applied to weapons accessories, fuzes, offensive equipment, etc., can solve the problems of being unable to get rid of primary explosives, reduce the chemical stability of high explosives, and reduce production safety, so as to achieve large heat release and reliable operation of detonators , fast burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

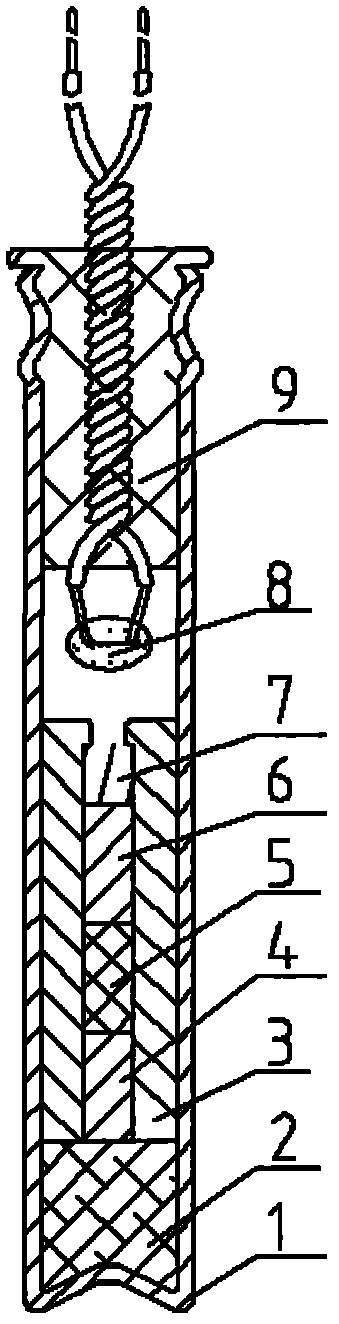

[0038] Example 1: Instantaneous detonator, figure 1

[0039] Such as figure 1 , 1 is a detonator shell, made of steel, copper clad or aluminum, with an outer diameter of 5.7 mm to 8.0 mm, a length of 50 mm to 60 mm, and a thickness of 0.10 mm to 0.38 mm. From the bottom of the detonator to the top, there are mixture 2 of Hesuojin and Taian (the mass ratio of the two is Taian: Hesuojin = 80:20, and the particle diameter is 0.15mm~0.30mm), a closed metal tube at one end 3, and the bottom of the metal tube High explosive 4, high explosive 5 in the middle of the metal tube, high high explosive 6 on the upper part of the metal tube, exciting powder 7, bridge wire type electric ignition powder head 8, and plastic plug 9.

[0040] During production, firstly pack 0.15g to 0.35g of the high explosive 2 mentioned above in the detonator shell, and the density after compaction is 1.2g / cm 3 ~1.6g / cm 3 .

[0041] 3 is a closed steel pipe at one end, which is formed by multiple punching...

example 2

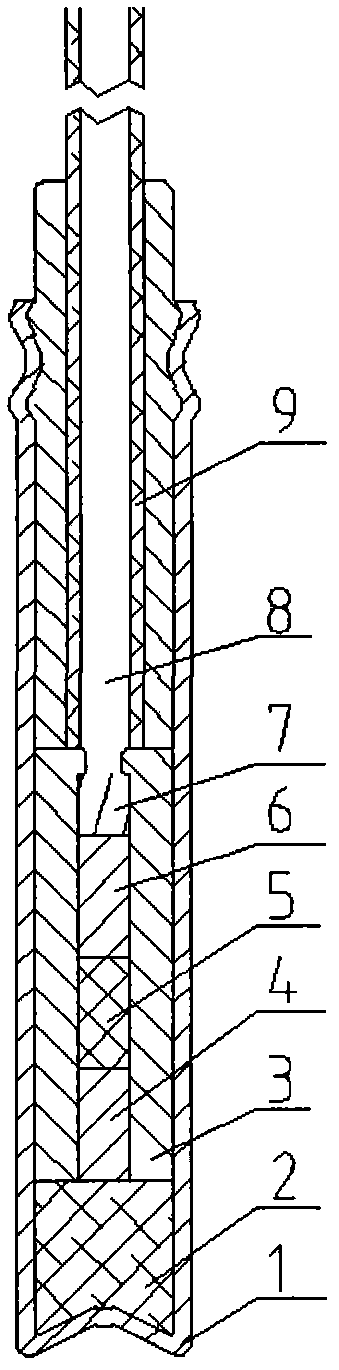

[0044] Example 2: non-electric plastic nonel type prompt detonator, figure 2

[0045] To the steel inner tube being pressed into the detonator shell, the assembly process is the same as example 1, except that plastic nonel tube 8 and stopper 9 are stuck on the detonator shell.

example 3

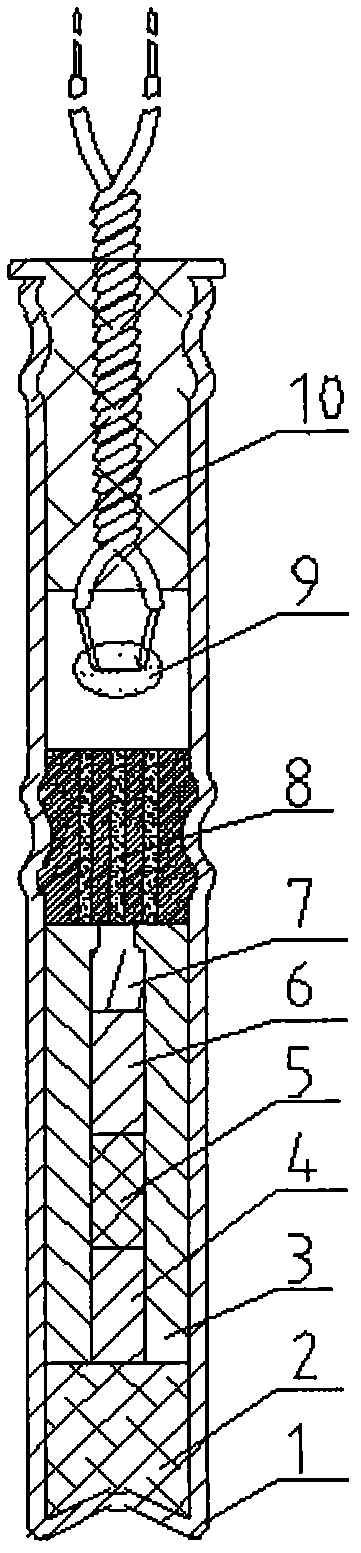

[0046] Example 3: lead core delay type millisecond delay electric detonator, image 3

[0047] The length of the detonator shell is 65mm-75mm. To press the steel inner tube into the detonator shell, the assembly process is the same as in Example 1. Afterwards, the lead core extension body is pressed into the detonator shell, and then the lead core is clamped outside the detonator shell to fix the lead core. On the lead core delay, stick the gunpowder head plug 10 again, promptly make the lead core delay form millisecond delay electric detonator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com