Preparation method of white zirconia ceramic

A technology of zirconia ceramics and zirconia, which is applied in the field of ceramic materials and its preparation, can solve the problem of poor bonding and adhesion between coatings and zirconia substrates, reducing the strength and fracture toughness of zirconia ceramics, and failing to meet high whiteness and high Shading and other issues, to achieve the effect of improving anti-aging performance, reducing light transmittance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

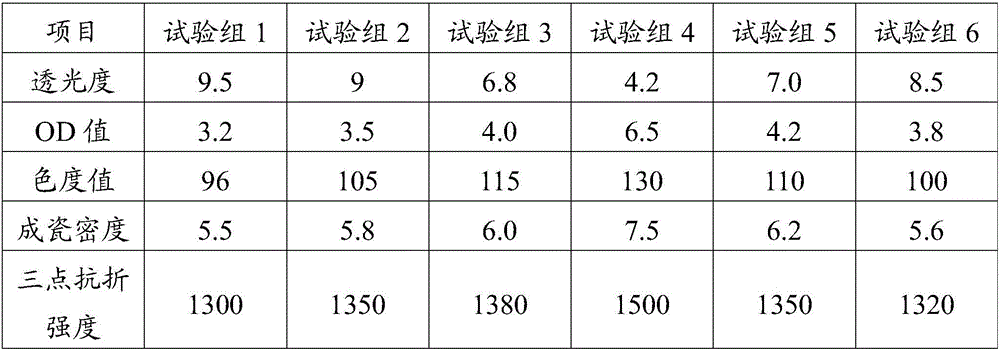

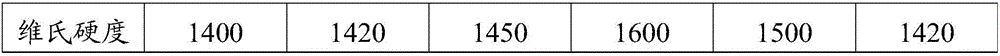

Examples

Embodiment 1

[0043] An embodiment of the white zirconia ceramic material composition of the present invention, the white zirconia ceramic material composition in this embodiment contains the following components in mass percentage: 0.01% of aluminum oxide, 20% of magnesium oxide, and 15% of calcium oxide %, strontium oxide 20%, barium oxide 0.01%, yttrium oxide 8%, and the balance is zirconium oxide containing hafnium oxide; in the zirconium oxide containing hafnium oxide, the amount of hafnium oxide in the zirconium oxide containing The mass percentage is 20%.

[0044] The white zirconia ceramic material composition of the present embodiment is a powder, and the D50 particle size of the powder is 3um, and the specific surface area is 5m 2 / g.

Embodiment 2

[0046] An embodiment of the white zirconia ceramic material composition of the present invention, the white zirconia ceramic material composition in this embodiment contains the following components in mass percentage: 5% of aluminum oxide, 15% of magnesium oxide, 1% of calcium oxide %, strontium oxide 10%, barium oxide 20%, yttrium oxide 7%, and the balance is zirconium oxide containing hafnium oxide; in the zirconium oxide containing hafnium oxide, the amount of hafnium oxide in the zirconium oxide containing The mass percentage content is 5%.

[0047] The white zirconia ceramic material composition of the present embodiment is a powder, and the D50 particle size of the powder is 2.5um, and the specific surface area is 8m 2 / g.

Embodiment 3

[0049] An embodiment of the white zirconia ceramic material composition of the present invention, the white zirconia ceramic material composition in this embodiment contains the following components in mass percent: 8% alumina, 6% magnesium oxide, and 8% calcium oxide. %, strontium oxide 3%, barium oxide 5%, yttrium oxide 6%, and the balance is zirconium oxide containing hafnium oxide; in the zirconium oxide containing hafnium oxide, the amount of hafnium oxide in the zirconium oxide containing The mass percentage is 15%.

[0050] The white zirconia ceramic material composition of the present embodiment is a powder, and the D50 particle size of the powder is 2um, and the specific surface area is 12m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com