Multifunctional environment-friendly emulsion as well as preparation method and application thereof

An emulsion and composite emulsion technology, applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., to achieve excellent film-forming properties, improved adhesion, and low volatile content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

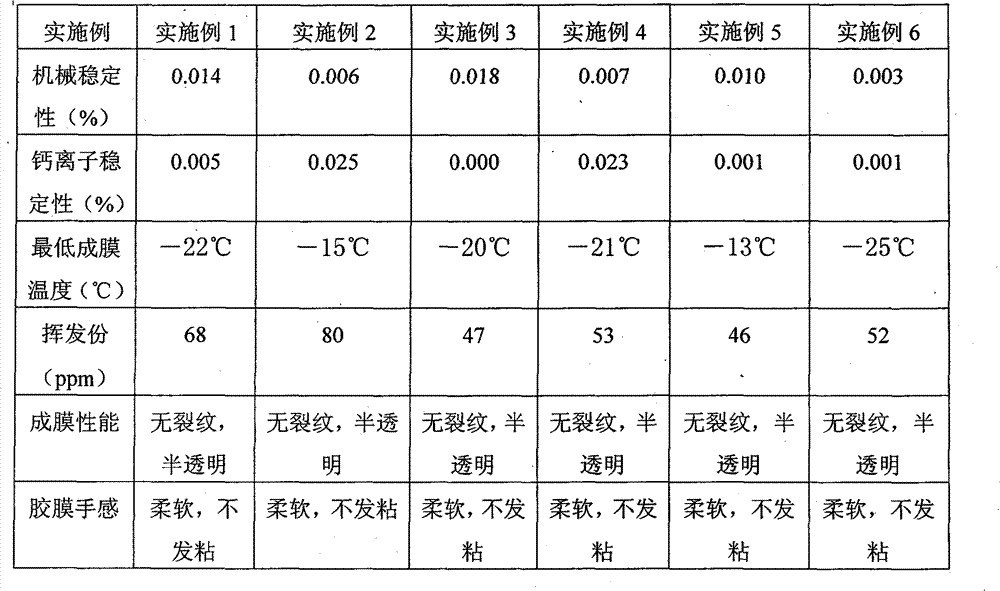

Examples

Embodiment 1

[0039] The preparation of organosilicon-acrylate / inorganic nanocomposite emulsion comprises the following steps:

[0040](1) Add 4.0(wt)% of copper oxide with a particle size of 82nm to water containing 55(wt)%, Dowfax 2A-1 emulsifier 0.15(wt)%, EDTA0.03(wt)% and ammonium persulfate 0.10 (wt)% in the reactor, vacuumize after stirring and dispersing, heat up to 75°C under nitrogen protection conditions, add 7.5(wt)% styrene monomer dropwise for 30 minutes, and keep warm for 15 minutes; obtain polymer-coated inorganic nanoparticle emulsion;

[0041] (2) In the emulsion of step (1), add dropwise water containing 49 (wt) %, 1.0 (wt) % sodium bicarbonate, 0.30 (wt) % Dowfax 2A-1, 0.45 (wt) % ammonium persulfate, 2.0 (wt)% methylol acrylamide, 3.0(wt)% acrylic acid aqueous solution and 81(wt)% methyl methacrylate acrylate 32(wt)%, hydroxyethyl acrylate 2.5(wt)%, acrylic acid A mixed monomer composed of 46.5 (wt)% of butyl ester, the dropwise addition time is 2.0 hours, and the tem...

Embodiment 2

[0048] The preparation of organosilicon-acrylate / inorganic nanocomposite emulsion comprises the following steps:

[0049] (1) Add 4.0 (wt)% of titanium dioxide with a particle size of 90nm to water containing 60 (wt)%, Dowfax 2A-1 emulsifier 0.15 (wt)%, EDTA0.05 (wt)% and ammonium persulfate 0.10 ( wt)% of the reactor, vacuumize after stirring and dispersing, heat up to 75°C under nitrogen protection conditions, add 5.0 (wt)% styrene monomer dropwise for 30 minutes, and keep warm for 15 minutes; obtain polymer-coated inorganic nano particle emulsion;

[0050] (2) in step (1) emulsion, add dropwise to comprise 44 (wt)% water, 1.15 (wt)% sodium carbonate, 0.25 (wt)% Dowfax 2A-1, 0.25 (wt)% ammonium persulfate, 1.0 ( wt)% methylol acrylamide, 4.0(wt)% acrylic acid aqueous solution and 82(wt)% methyl methacrylate acrylate 33(wt)%, hydroxyethyl acrylate 1.5(wt)%, butyl acrylate A mixed monomer composed of 41 (wt)% ester and 6.5 (wt)% ethyl acrylate, added dropwise for 2.5 hours a...

Embodiment 3

[0057] The preparation of organosilicon-acrylate / inorganic nanocomposite emulsion comprises the following steps:

[0058] (1) Add 6.0 (wt)% of silver oxide with a particle size of 82nm to water containing 60 (wt)%, Dowfax 2A-1 emulsifier 0.20 (wt)%, EDTA0.06 (wt)% and ammonium persulfate 0.10 (wt)% in the reactor, vacuumize after stirring and dispersing, heat up to 80°C under nitrogen protection conditions, add 15(wt)% styrene monomer dropwise for 30 minutes, and keep warm for 15 minutes; obtain polymer-coated inorganic nanoparticle emulsion;

[0059] (2) In the emulsion of step (1), add dropwise water containing 46 (wt) %, 0.3 (wt) % sodium bicarbonate, 0.15 (wt) % Dowfax 2A-1, 0.5 (wt) % ammonium persulfate, 3.0 (wt) % of a mixture of methylol acrylamide and methylenebisacrylamide with a mass ratio of 2:1, 2.0 (wt) % of methacrylic acid in water and 70 (wt) % of methyl methacrylate acrylate 30(wt)%, 2.0(wt)% of hydroxyethyl acrylate, 38(wt)% of butyl acrylate, a mixed mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com