Demoulding agent

A technology of release agent and defoamer, which is applied in the field of water-soluble release agent for warm forging and hot forging, can solve the problems of affecting the release performance, damage the health of operators, affect the size and accuracy of castings, etc., and achieve high-temperature adhesion performance. Good, not easy to scratch the mold surface, prevent mold temperature from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

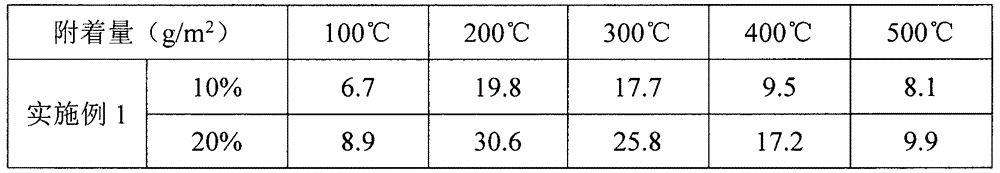

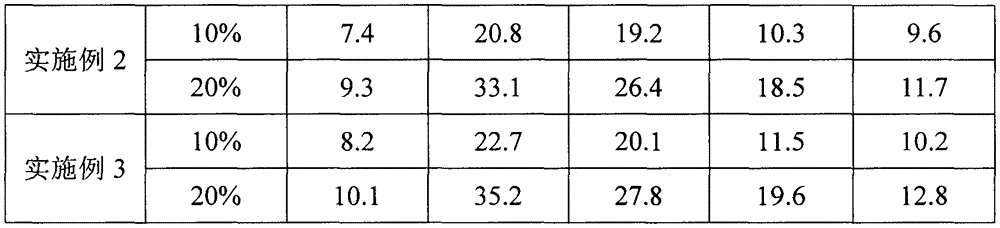

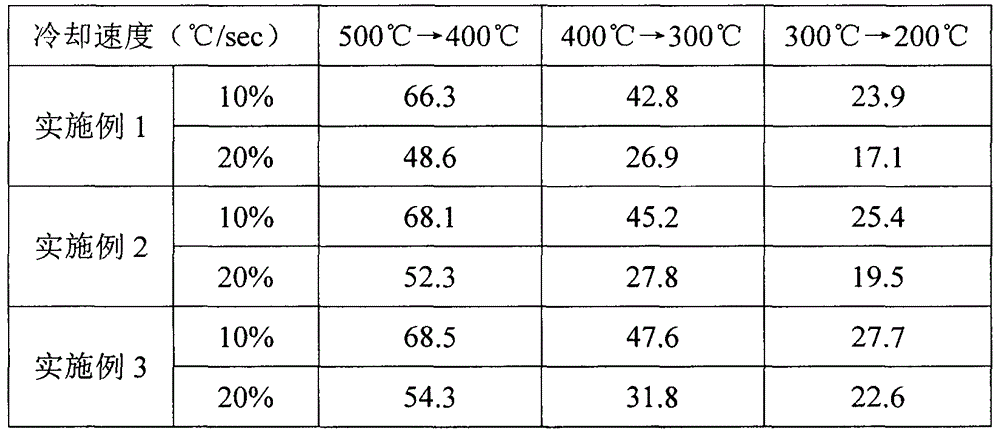

Embodiment 1

[0023] The release agent of the present embodiment is made from the following raw materials in weight percentage: 16% of organic dibasic acid, 12% of sodium hydroxide, 2% of sodium polymethacrylate, 0.3% of isomeric decanol polyoxyethylene ether, polypropylene Amide 0.2%, polyisobutylene succinic anhydride 1%, silicone resin 1.5%, defoamer 0.1%, water 66.9%.

Embodiment 2

[0025] The release agent of the present embodiment is made from the following raw materials in weight percentage: 18% of organic dibasic acid, 14% of sodium hydroxide, 2% of sodium polymethacrylate, 0.8% of isomeric decanol polyoxyethylene ether, polypropylene Amide 0.5%, polyisobutylene succinic anhydride 2%, silicone resin 2%, defoamer 0.2%, water 60.5%.

Embodiment 3

[0027] The release agent of the present embodiment is made from the following raw materials in weight percentage: 15% of organic dibasic acid, 13.5% of sodium hydroxide, 2.5% of sodium polymethacrylate, 0.5% of isomeric decanol polyoxyethylene ether, polypropylene Amide 0.35%, polyisobutylene succinic anhydride 1.5%, silicone resin 1.5%, defoamer 0.15%, water 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com