Dyeing method for polysulfonamide yarns

A dyeing method and technology of sulfone fiber, applied in the direction of dyeing method, fiber type, dry-cleaning fiber products, etc., can solve the problems of low genuine product rate, poor hand feeling of aramid sulfone fiber, high cost, and solve color difference and crease. , The effect of good product quality and short foam life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: the preparation of cleaning agent

[0054] Each raw material is taken by weighing the raw material data of Example 1 corresponding to Table 1. Wherein in Table 1, EL-60 emulsifier, chemical name: castor oil ethylene oxide condensate, alias: castor oil polyoxyethylene ether, English name: Emulsifier EL-60, is provided by Hai'an Petrochemical Factory of Jiangsu Province.

[0055] Castor Oil Ethylene Oxide Condensate, Lauryl Polyoxyethylene Ether, Sodium Lauryl Sulfate, Lauryl Dimethyl Betaine, Cocamidopropyl Hydroxysultaine, Sodium Polymethacrylate , polyvinylpyrrolidone, sodium citrate, sodium silicate and bentonite are added to water, heated to 40°C, stirred and mixed evenly, and the detergent can be prepared.

Embodiment 2

[0056] Embodiment 2: the preparation of cleaning agent

[0057] Each raw material is taken by weighing the raw material data of Example 2 corresponding to Table 1.

[0058] Castor Oil Ethylene Oxide Condensate, Lauryl Polyoxyethylene Ether, Sodium Lauryl Sulfate, Lauryl Dimethyl Betaine, Cocamidopropyl Hydroxysultaine, Sodium Polymethacrylate , polyvinylpyrrolidone, sodium citrate, sodium silicate and bentonite are added to water, heated to 60°C, stirred and mixed evenly, and the detergent can be prepared.

Embodiment 3

[0059] Embodiment 3: the preparation of detergent

[0060] Each raw material is taken by weighing the raw material data of Example 3 corresponding to Table 1.

[0061] Castor Oil Ethylene Oxide Condensate, Lauryl Polyoxyethylene Ether, Sodium Lauryl Sulfate, Lauryl Dimethyl Betaine, Cocamidopropyl Hydroxysultaine, Sodium Polymethacrylate , polyvinylpyrrolidone, sodium citrate, sodium silicate and bentonite are added to water, heated to 50°C, stirred and mixed evenly, and the detergent can be prepared.

[0062] Table 1: Cleaning agent raw material list Unit: kg

[0063] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

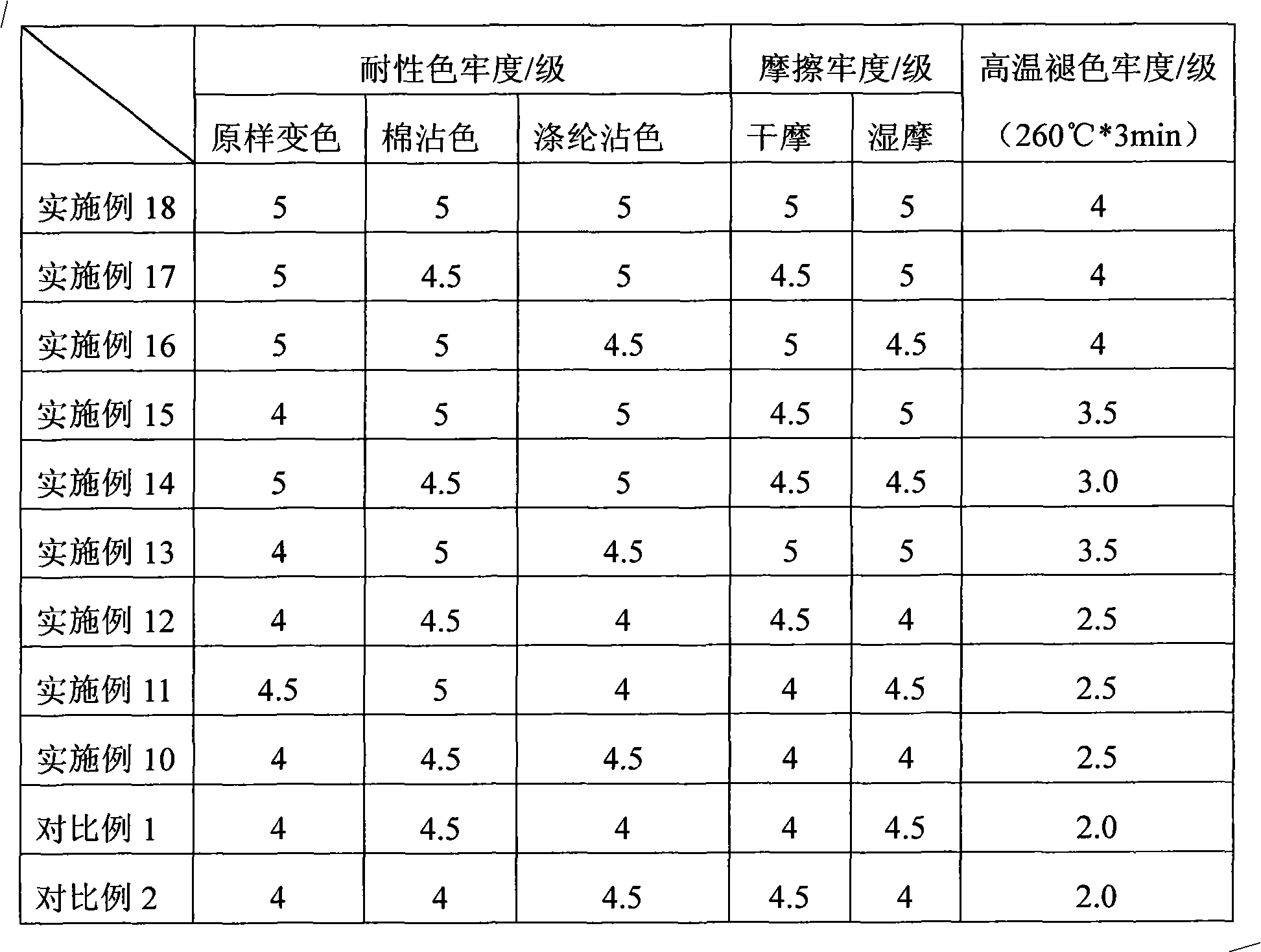

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com