Production method and device for purification of low-concentration wet-process phosphoric acid by solvent extraction

A wet-process phosphoric acid and production method technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low extraction rate of low-concentration phosphoric acid, long production technology process, low impurity removal rate, etc., to achieve Improve economic added value, good effect, and improve the effect of purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

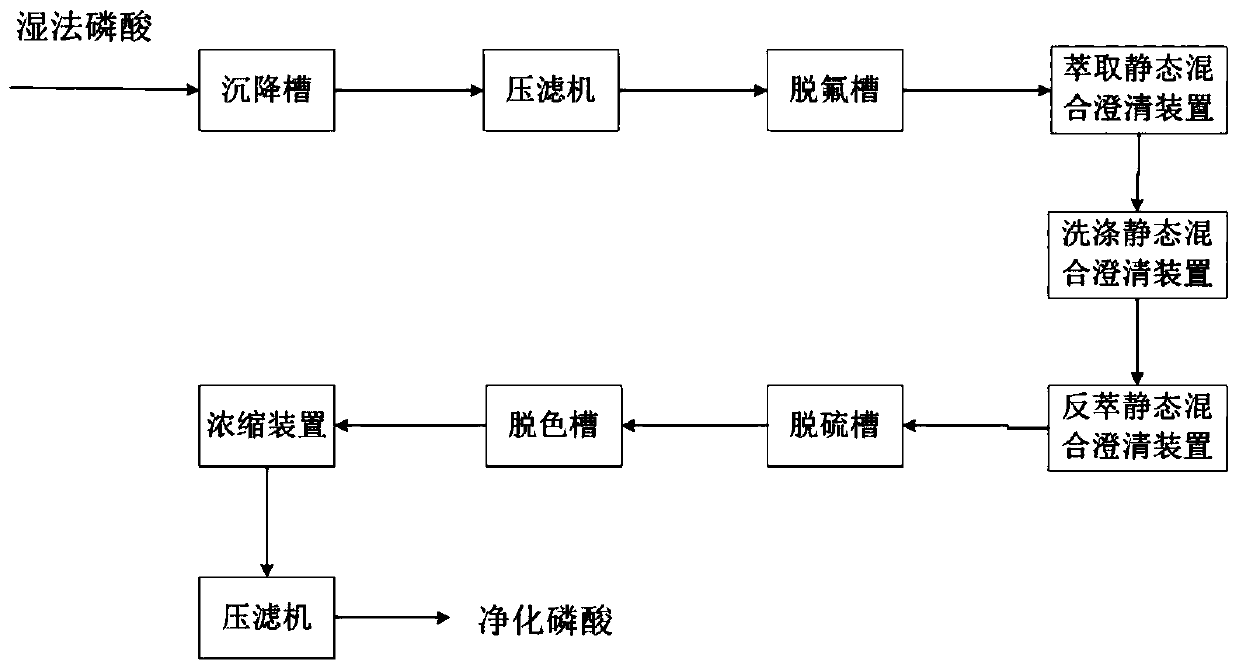

[0023] Embodiment 1: The technological process of 5000 tons / year purification wet-process phosphoric acid is as follows:

[0024] Concentration is 35wt%P 2 o 5 The raw material wet-process phosphoric acid is settled and filtered, and sodium carbonate is added to it, and at 65-85°C, the reaction generates Na 2 SiF 6 Precipitate and filter to obtain pretreated defluorinated raw phosphoric acid, which enters the raw acid tank of the purification section.

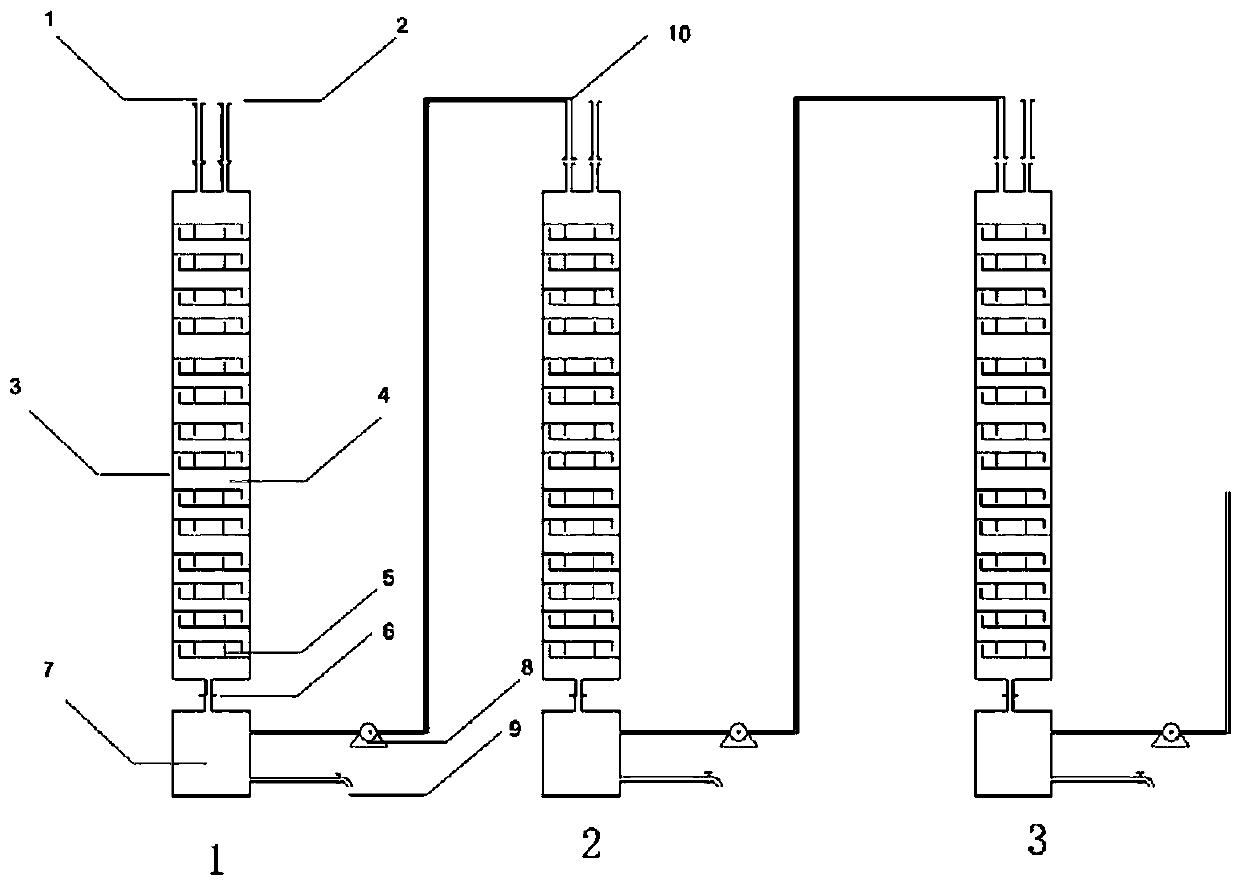

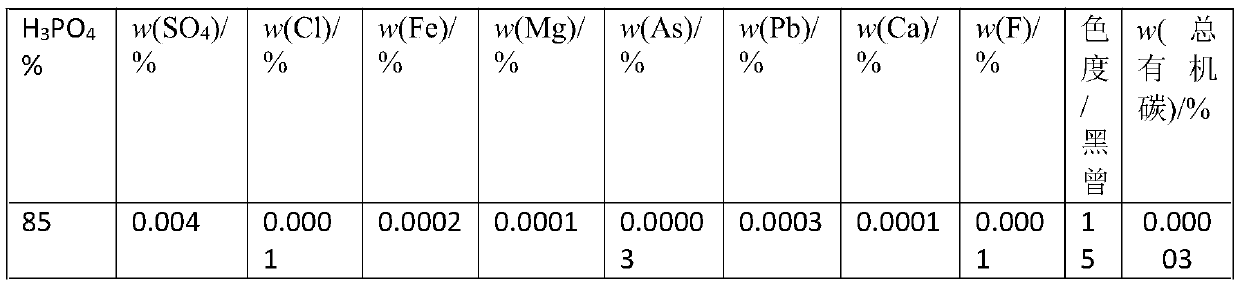

[0025] The pretreated raw material wet-process phosphoric acid and organic solvent (specific gravity 0.813) are metered by the pump respectively to control the two-phase phase ratio, and transported to the mixing chamber. At room temperature, the raw phosphoric acid and the organic solvent are fully mixed and contacted, and the phosphoric acid enters the organic phase to obtain an extracted organic phase with a specific gravity of 1.015, and most impurities enter the extraction acid. In the clarification chamber, the extrac...

Embodiment 2

[0028] Embodiment 2: embodiment 1: the technological process of 10000 tons / year purification wet-process phosphoric acid is as follows:

[0029] Concentration is 40wt%P 2 o 5 The raw material wet-process phosphoric acid is settled and filtered, and sodium carbonate is added to it, and at 70-90°C, the reaction generates Na 2 SiF 6 Precipitate and filter to obtain pretreated defluorinated raw phosphoric acid, which enters the raw acid tank of the purification section.

[0030] The pretreated raw material wet-process phosphoric acid and organic solvent (specific gravity 0.813) are metered by the pump respectively to control the two-phase phase ratio, and transported to the mixing chamber. At room temperature, the raw phosphoric acid and the organic solvent are fully mixed and contacted, and the phosphoric acid enters the organic phase to obtain an extracted organic phase with a specific gravity of 1.015, and most impurities enter the extraction acid. In the clarification cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com