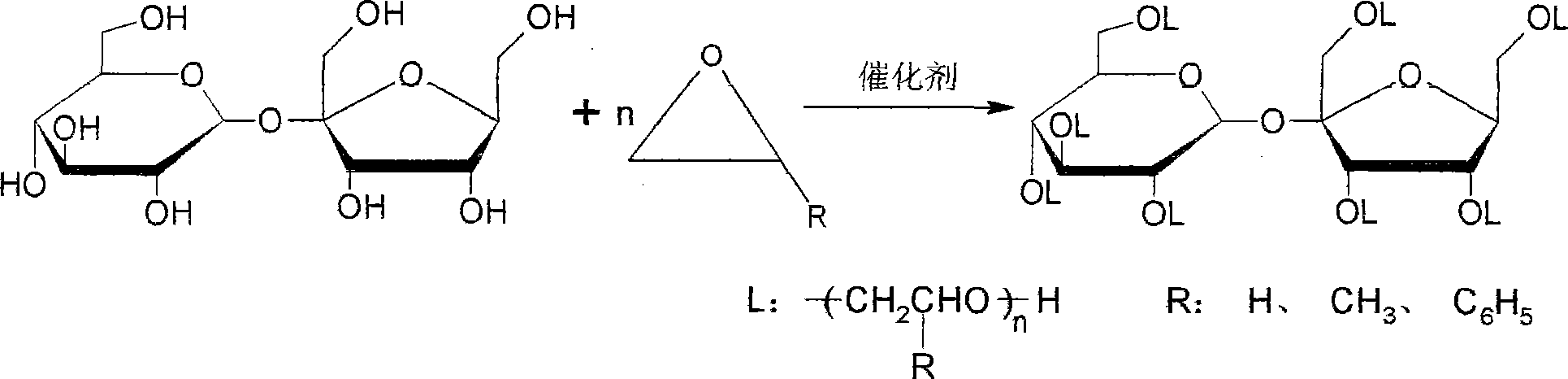

Catalyst for synthesizing polyether glycol from sucrose and oxidized olefin and preparation method thereof

A technology of polyether polyol and oxidized olefin, which is applied in the field of mixed metal complex catalysts, can solve the problems of long activation time, single organic ligand, catalytic efficiency not reaching ideal catalytic activity, etc., and achieve high catalytic efficiency, no Effect of pyrophoric hygroscopicity and apparent hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 4.08 grams of analytically pure ZnCl 2 Make a 1mol / L solution, then take K 3 Co(CN) 5Cl6.83 g is made into a 1mol / L solution with distilled water; at constant temperature, first add organic matter isopropanol and dioxane to the reactor, and then add the above-mentioned solution to the reactor under rapid stirring to mix and react , where the amount of material added is: Zn 2+ : [Co(CN) 5 Cl] 3- =1.2:1 (molar ratio); Virahol: dioxane=1:1 (volume ratio); every mole of [Co(CN) 5 Cl] 3- Add 13.0 liters of organic matter, and age at room temperature for 1 to 2 hours after the reaction is complete. Then the solution is suction filtered to obtain a filter cake, which is washed 2 to 3 times with a mixed solution of isopropanol and dioxane organic matter, and then washed 2 to 3 times with deionized water, and then heated in an oven at 50 to 60°C Vacuum-dried to constant weight, the obtained powder was pressed into tablets, then ground, and finally sieved into 100 me...

Embodiment 2

[0026] Weigh 4.08 grams of analytically pure ZnCl 2 Make a 1mol / L solution, then take K 3 Co(CN) 5 Cl6.83 g is made into a 1mol / L solution with distilled water; at constant temperature, first add organic matter isopropanol and dioxane to the reactor, and then add the above-mentioned solution to the reactor under rapid stirring to mix and react , where the amount of material added is: Zn 2+ : [Co(CN) 5 Cl] 3- =1.2:1 (molar ratio); Virahol: dioxane=3:1 (volume ratio); every mole of [Co(CN) 5 Cl] 3- Add 13.0 liters of organic matter, and age at room temperature for 1 to 2 hours after the reaction is complete. Then the solution is suction filtered to obtain a filter cake, which is washed 2 to 3 times with a mixed solution of isopropanol and dioxane organic matter, and then washed 2 to 3 times with deionized water, and then heated in an oven at 50 to 60°C Vacuum-dried to constant weight, the obtained powder was pressed into tablets, then ground, and finally sieved into 100 m...

Embodiment 3

[0029] Weigh 4.08 grams of analytically pure ZnCl 2 Make a 1mol / L solution, then take K 3 Co(CN) 5 Cl6.83 g is made into a 1mol / L solution with distilled water; at constant temperature, first add organic matter isopropanol and dioxane to the reactor, and then add the above-mentioned solution to the reactor under rapid stirring to mix and react , where the amount of material added is: Zn 2+ : [Co(CN) 5 Cl] 3- =1.2:1 (molar ratio); Virahol: dioxane=1:3 (volume ratio); every mole of [Co(CN) 5 Cl] 3- Add 13.0 liters of organic matter, and age at room temperature for 1 to 2 hours after the reaction is complete. Then the solution is suction filtered to obtain a filter cake, which is washed 2 to 3 times with a mixed solution of isopropanol and dioxane organic matter, and then washed 2 to 3 times with deionized water, and then heated in an oven at 50 to 60°C Vacuum-dried to constant weight, the obtained powder was pressed into tablets, then ground, and finally sieved into 100 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com