Polytetrafluoroethylene product surface treatment agent and preparation method thereof

A technology of surface treatment agent and polytetrafluoroethylene, which is applied in the field of fluororesin surface treatment agent and its preparation, can solve the problems of poor product quality, different corrosion depths, and volatile solvents, so as to solve the problems of safe production and reduce material consumption , the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

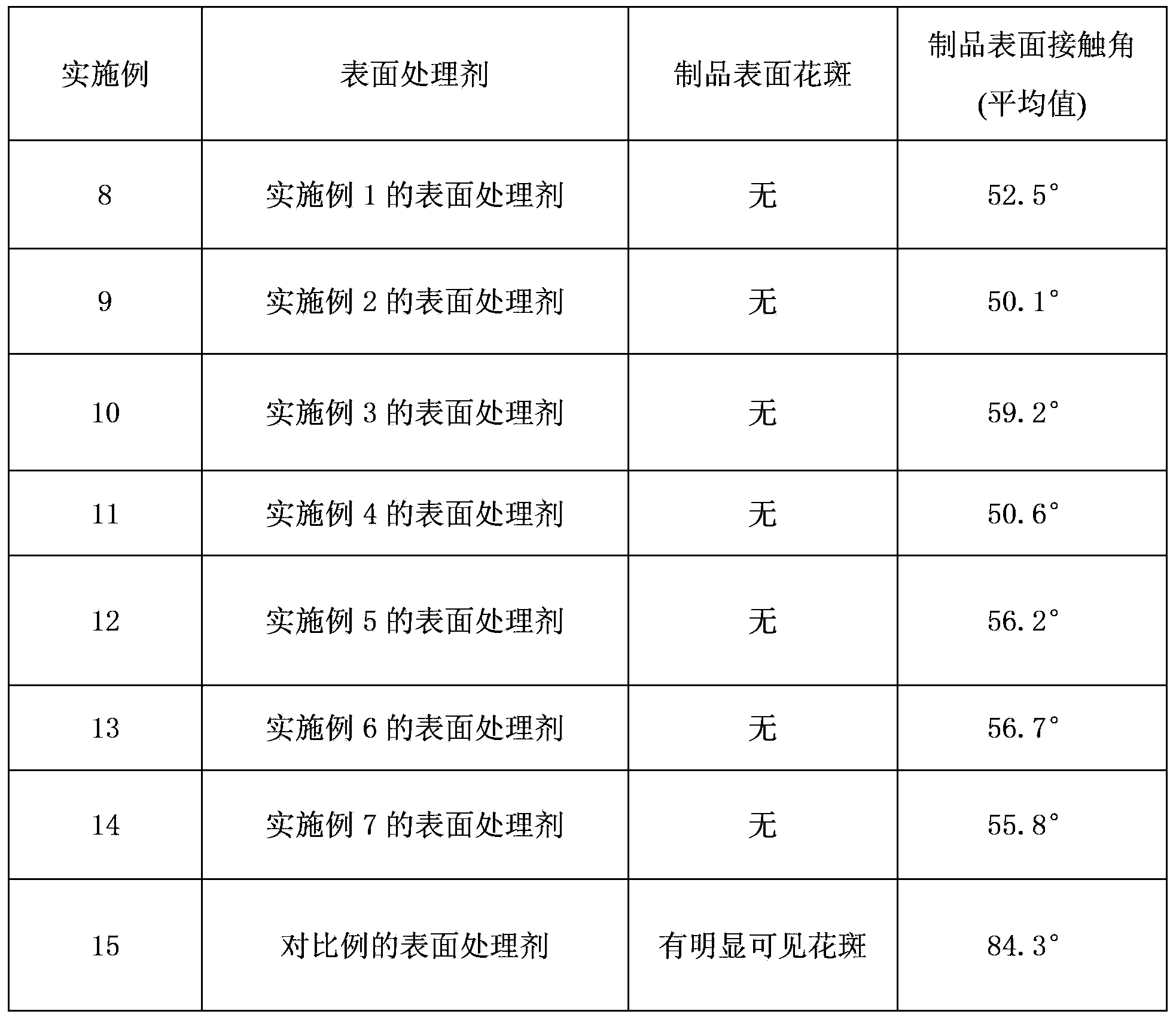

Examples

Embodiment 1

[0030] A polytetrafluoroethylene product surface treatment agent, its composition is as follows:

[0031] Naphthalene 55.7 g

[0033] Ethylene glycol dimethyl ether 800 grams

[0034] The preparation method is as follows:

[0035] According to the ratio, add ethylene glycol dimethyl ether and naphthalene into a 1-liter four-necked flask with stirring, start stirring to stir the naphthalene until it is completely dissolved, and obtain a solution containing naphthalene; Dry nitrogen, add the required metal sodium according to the proportion to react, control the temperature of the reaction liquid at 30°C, stir and react for 3 hours, cool, turn off the stirring and turn off the nitrogen, pour the prepared surface treatment agent into the glass filled with nitrogen Store in a bottle, sealed and protected from light.

Embodiment 2

[0037] A polytetrafluoroethylene product surface treatment agent, its composition is as follows:

[0038] Naphthalene 200g

[0040] Tetraethylene glycol dimethyl ether 700 grams

[0041] The preparation method is as follows:

[0042] Add tetraethylene glycol dimethyl ether and naphthalene into a 1-liter four-necked flask with stirring according to the proportion, start stirring to stir the naphthalene until it is completely dissolved, and obtain a solution containing naphthalene; Dry nitrogen, add the required metal sodium according to the proportion to react, control the temperature of the solution at 80°C, stir the reaction for 5 hours and end the reaction, cool down, turn off the stirring and turn off the nitrogen, pour the prepared surface treatment agent into the nitrogen filled Store in a glass bottle, sealed and protected from light.

Embodiment 3

[0044] A polytetrafluoroethylene product surface treatment agent, its composition is as follows:

[0045] Naphthalene 100g

[0047] Diethylene glycol dimethyl ether 700g

[0048] The preparation method is as follows:

[0049] Add diethylene glycol dimethyl ether and naphthalene into a 1-liter four-necked flask with stirring according to the proportion, start stirring to stir the naphthalene until it is completely dissolved, and obtain a solution containing naphthalene; Dry nitrogen, add the required metal sodium to react according to the proportion, control the temperature of the solution at 80°C, stir the reaction for 10 hours and end the reaction, cool down, turn off the stirring and turn off the nitrogen, pour the prepared surface treatment agent into the nitrogen filled Store in a glass bottle, sealed and protected from light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com