Organic phase electrolyte and application thereof in negative electrode of redox flow battery

An organic phase and electrolyte technology, applied in the direction of regenerative fuel cells, can solve the problems of high price, complicated preparation process, low solubility, etc., and achieve the effect of improving energy density, low electrochemical potential, and increasing cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

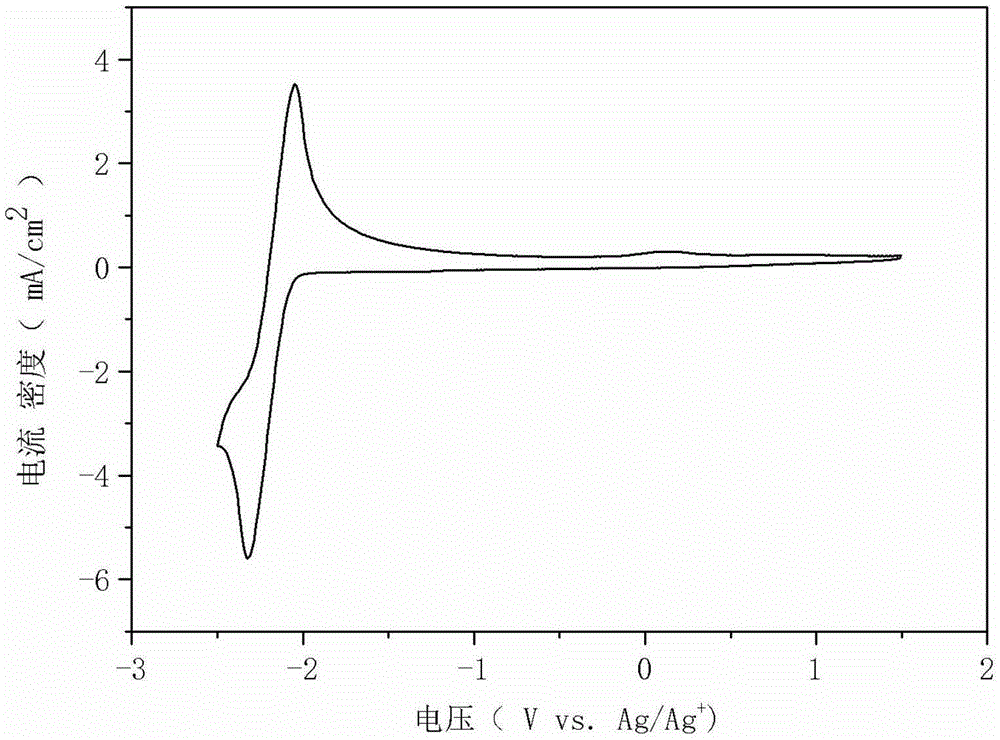

[0026] Weigh benzophenone and tetraethylammonium hexafluorophosphate and dissolve them in acetonitrile to prepare 25ml electrolyte solution. The molar concentrations of benzophenone and tetraethylammonium hexafluorophosphate in acetonitrile are 0.01mol / L and 0.1mol / L, respectively. After passing the above electrolyte into nitrogen to remove oxygen, test it with a three-electrode system to obtain the cyclic voltammetry curve of the benzophenone electrolyte. The reference electrode, the counter electrode and the working electrode are respectively Ag / Ag + electrode, graphite electrode and glassy carbon electrode.

Embodiment 2

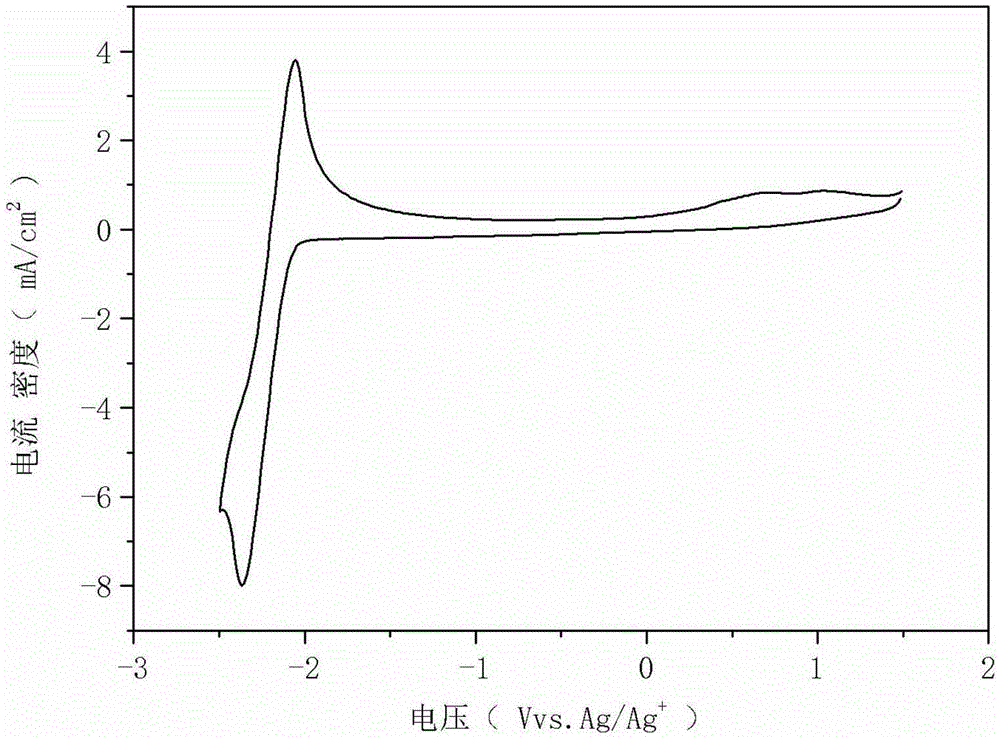

[0028] Weigh benzophenone and tetraethylammonium tetrafluoroborate and dissolve them in acetonitrile to prepare 30ml electrolyte solution. The molar concentrations of benzophenone and tetraethylammonium tetrafluoroborate in acetonitrile were 0.01 mol / L and 0.03 mol / L, respectively. After passing the above electrolyte solution into nitrogen to remove oxygen, it is tested with a three-electrode system to obtain a cyclic voltammetry curve of the benzophenone electrolyte solution. The reference electrode, counter electrode and working electrode are Ag / Ag + electrode, graphite electrode and glassy carbon electrode.

Embodiment 3

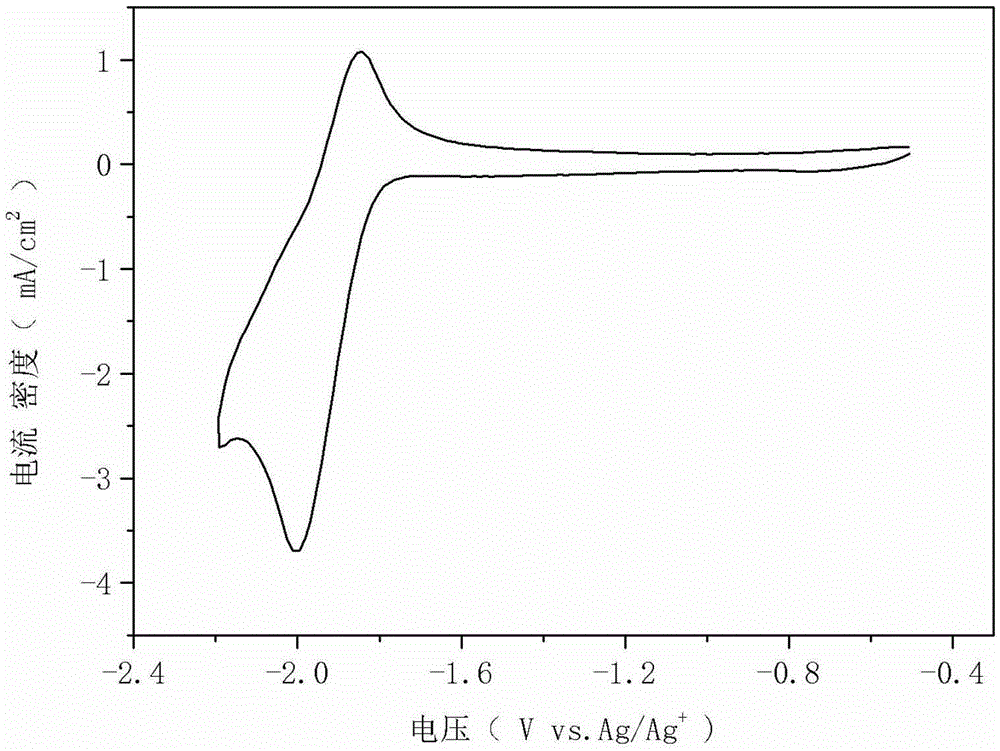

[0030] Weigh anthrone and tetraethylammonium tetrafluoroborate and dissolve them in acetonitrile to prepare 25ml electrolyte solution. The molar concentrations of anthrone and tetraethylammonium tetrafluoroborate in acetonitrile are 0.01 mol / L and 0.3 mol / L, respectively. After passing the above electrolyte solution into nitrogen to remove oxygen, it is tested with a three-electrode system to obtain the cyclic voltammetry curve of the anthrone electrolyte solution. The reference electrode, counter electrode and working electrode are Ag / Ag + electrode, graphite electrode and glassy carbon electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com