Lithium ion battery hard carbon negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of poor cycle stability, voltage hysteresis, and low initial efficiency of hard carbon negative electrodes, and improve electrochemical performance. Avoid voltage hysteresis and improve energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of lithium ion battery hard carbon negative electrode material of the present invention is: make TiO 2 Ultrasonic dispersion with lithium salt mixture and metal lithium powder in solvent 1 to obtain dispersion 1; dissolve allyl phenolic resin in solvent 2 to obtain solution 2; slowly add dispersion 1 to solution 2 and stir evenly After heating and solidifying, a mixture is obtained; and the mixture is carbonized at a high temperature under the protection of an inert atmosphere to obtain a hard carbon negative electrode material for a lithium ion battery. In order to avoid the reaction between the metal lithium powder and the solvent, solvent one and solvent two in this application are all weakly polar organic solvents or non-polar organic solvents, including n-heptane, n-hexane, cyclohexane, carbon disulfide, tetrachloride One or more of carbon, xylene, toluene, benzene, ether, ethyl acetate, n-pentane, n-butanol, dioxane, acetone, and isopropanol...

Embodiment 1

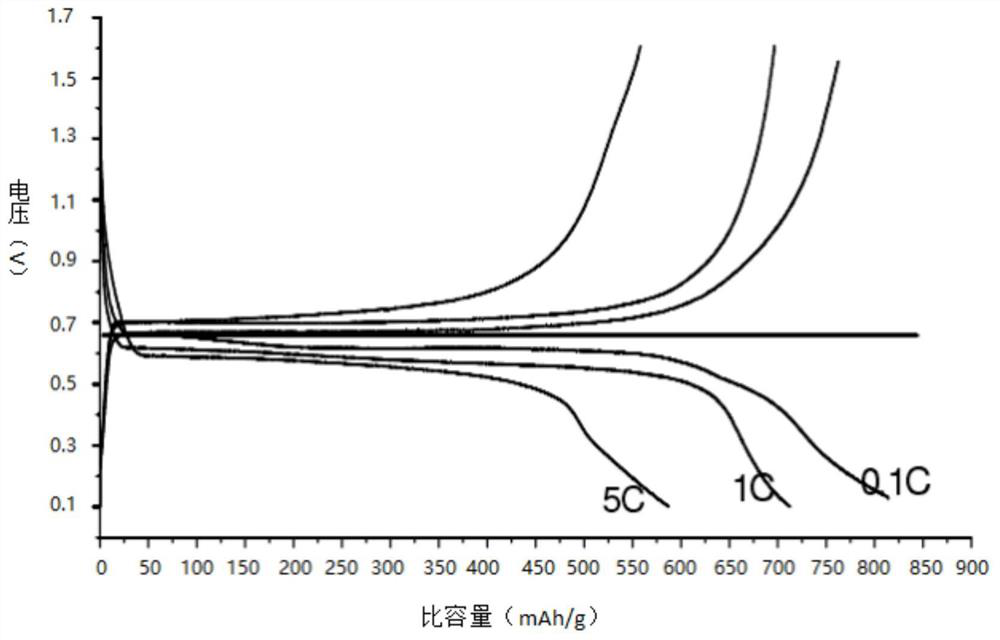

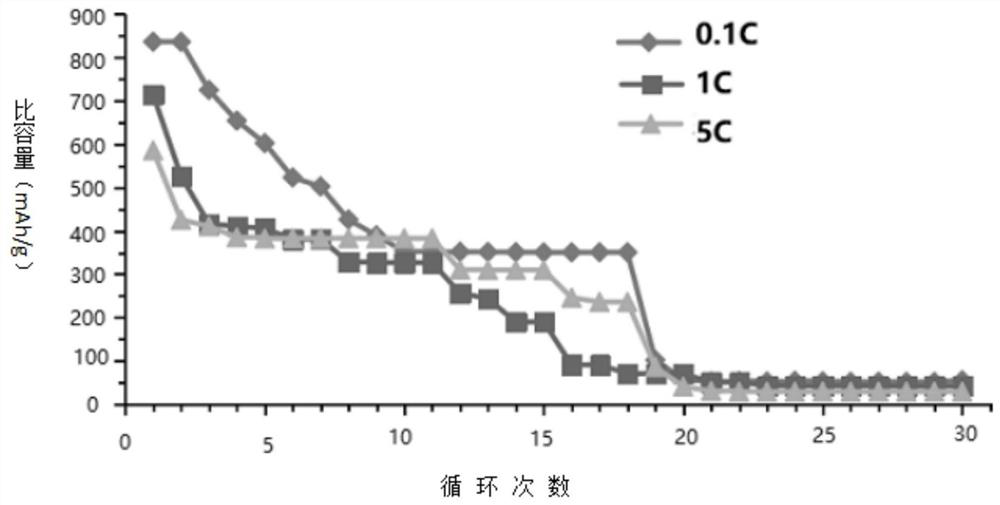

[0026] Take 15g of lithium metal powder and ultrasonically disperse it in carbon disulfide to obtain dispersion solution 1; then take 85g of allyl phenolic resin and dissolve it in carbon disulfide to obtain solution 2. The input amount of carbon disulfide is advisable to fully disperse metal lithium powder and dissolve allyl phenolic resin. While stirring, pour the dispersion into Solution 2 to make it fully mixed. Then put the mixture into a mold, heat up to 195°C at a rate of 8°C / min, and keep warm for 2 hours; then heat up to 245°C at a speed of 3°C / min, and keep warm for 4 hours. The solidified mixture was transferred to a high-temperature carbonization furnace, fed with nitrogen for protection, then raised to 1000°C at a rate of 30°C / min, kept for 3 hours, and then naturally cooled to below 80°C under the condition of continuously feeding nitrogen, Open the oven to cool down naturally. That is, a hard carbon negative electrode material for a lithium ion battery is obta...

Embodiment 2

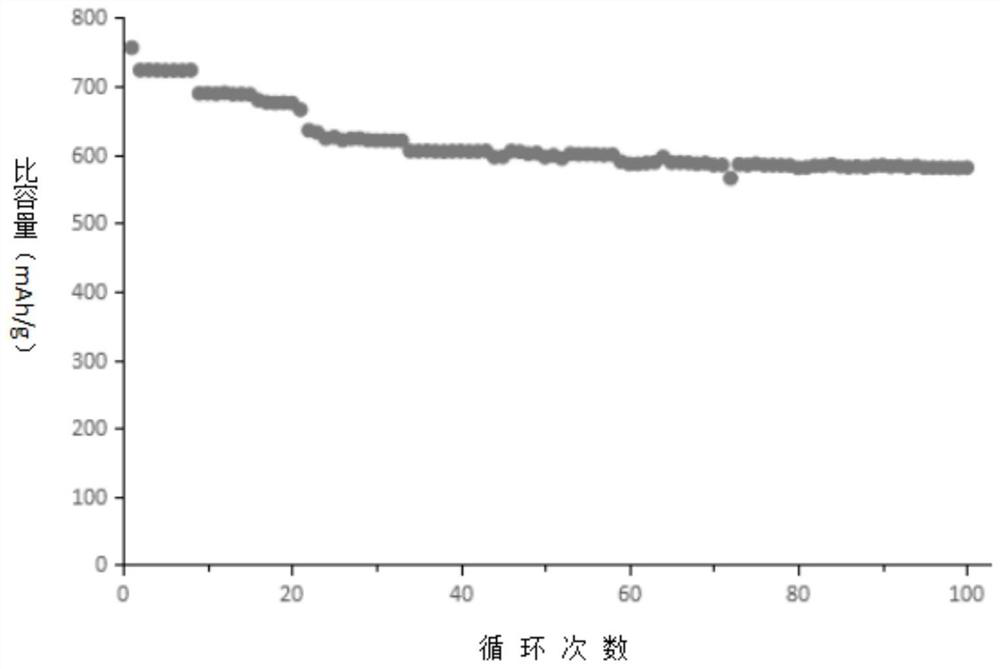

[0029]Melt a certain amount of lithium acetate into absolute ethanol, then calculate the amount of tetrabutyl titanate according to the Ti 0.72g, Ti:Li molar ratio of 1:0.83, add it to the previously prepared solution, stir well and turn it into a constant temperature Solvothermally react at 180°C for 24 hours in a drying oven; then centrifuge and wash the bottom sediment until the pH is neutral, and directly disperse metal lithium powder into carbon disulfide without drying to obtain dispersion 1. All the other steps are the same as in Example 1. Use the ground powder to assemble a button battery. The first charge and discharge specific capacity measured at 1C rate is 756.4mAh / g. After 100 cycles, the specific capacity is still as high as 580.9mAh / g. image 3 shown. Compared with Example 1, adding a small amount of lithium titanate can significantly improve the electrochemical performance of the hard carbon material synthesized by metal lithium and allyl phenolic resin, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com