Patents

Literature

161results about How to "Channel short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

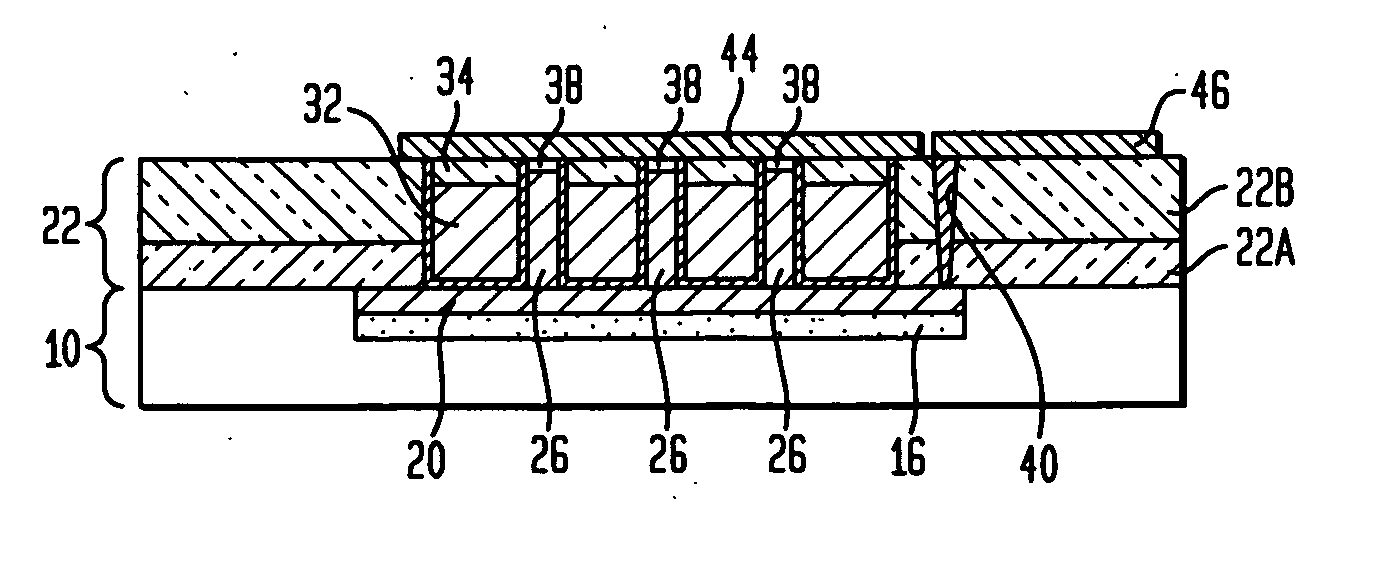

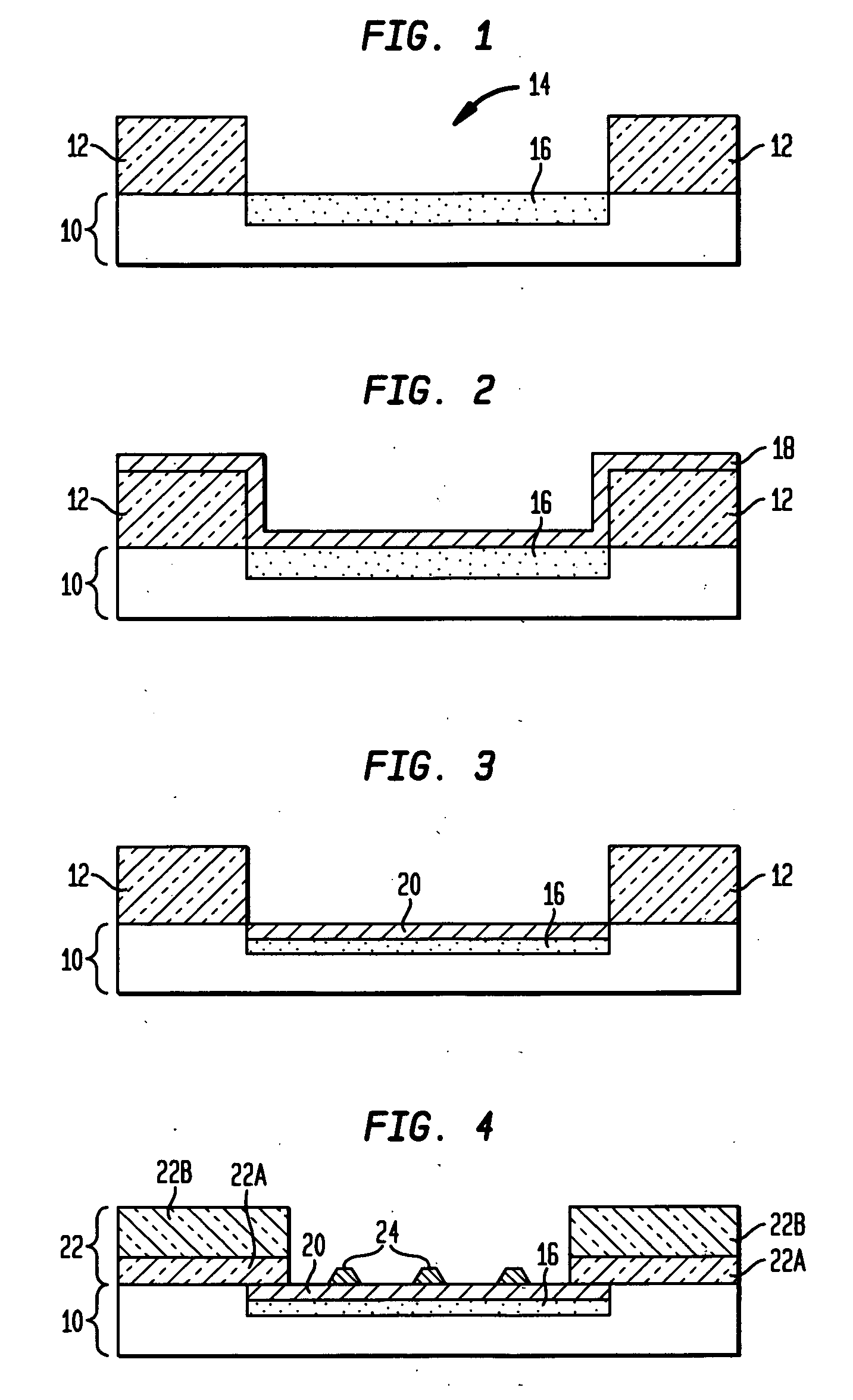

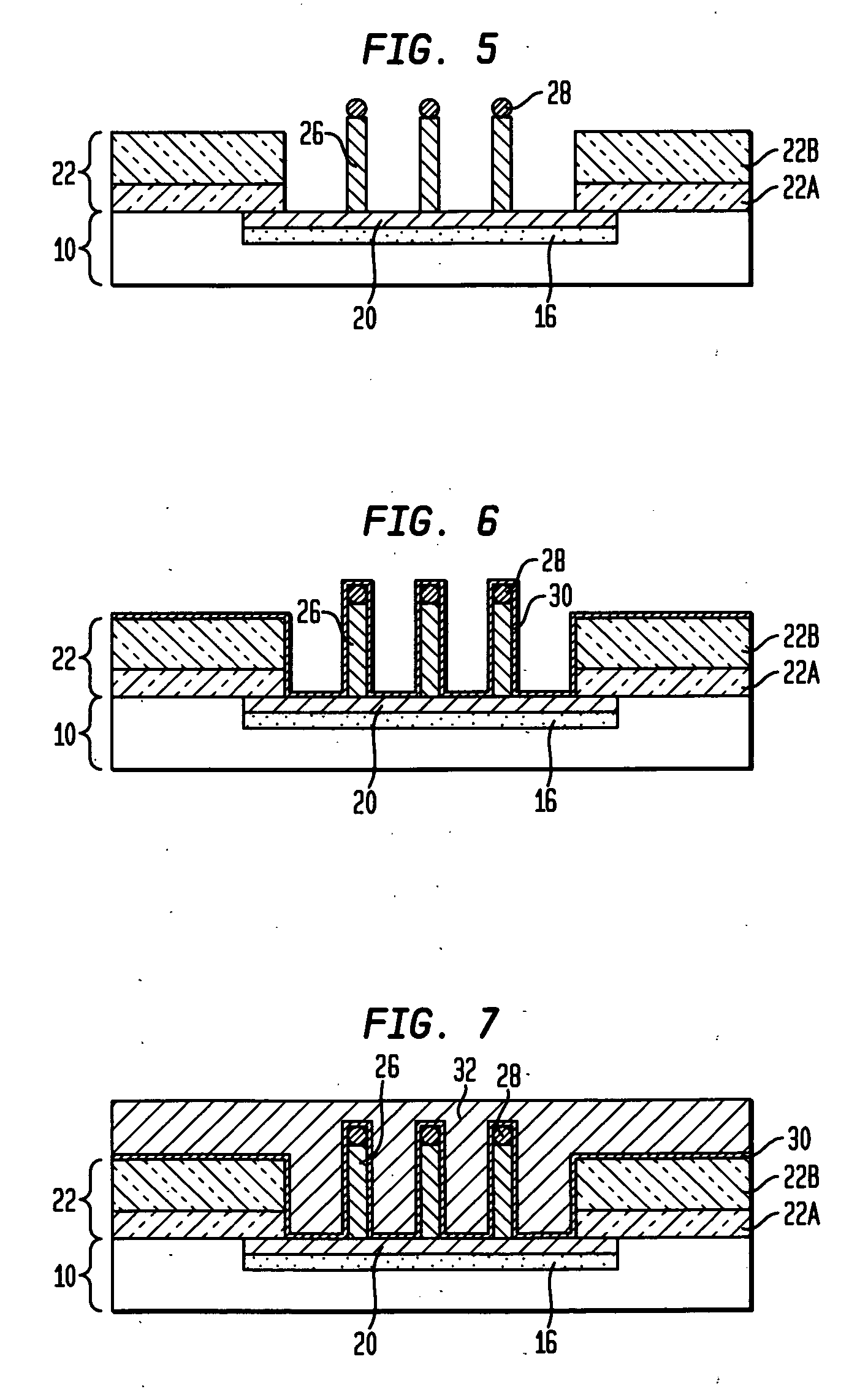

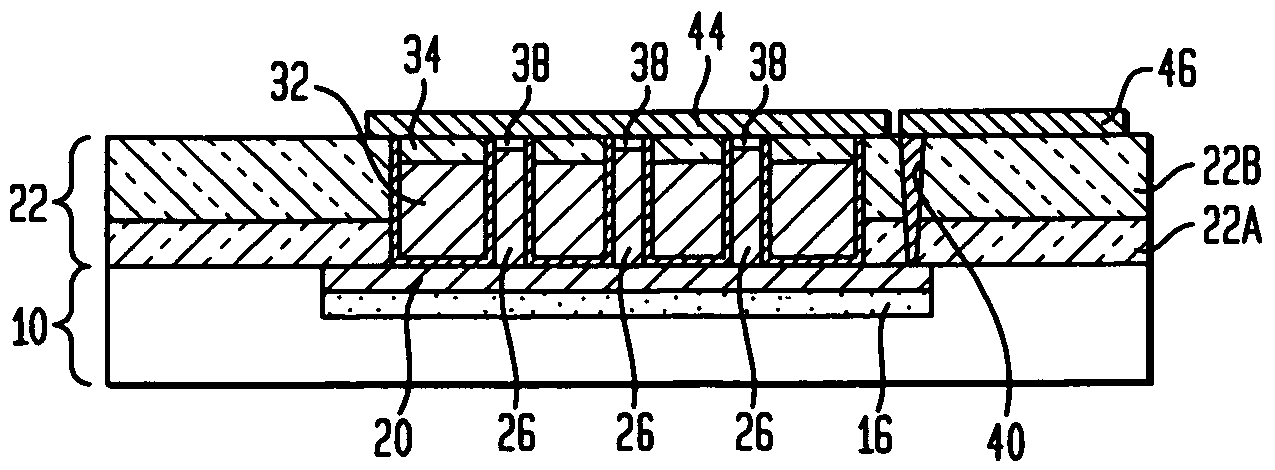

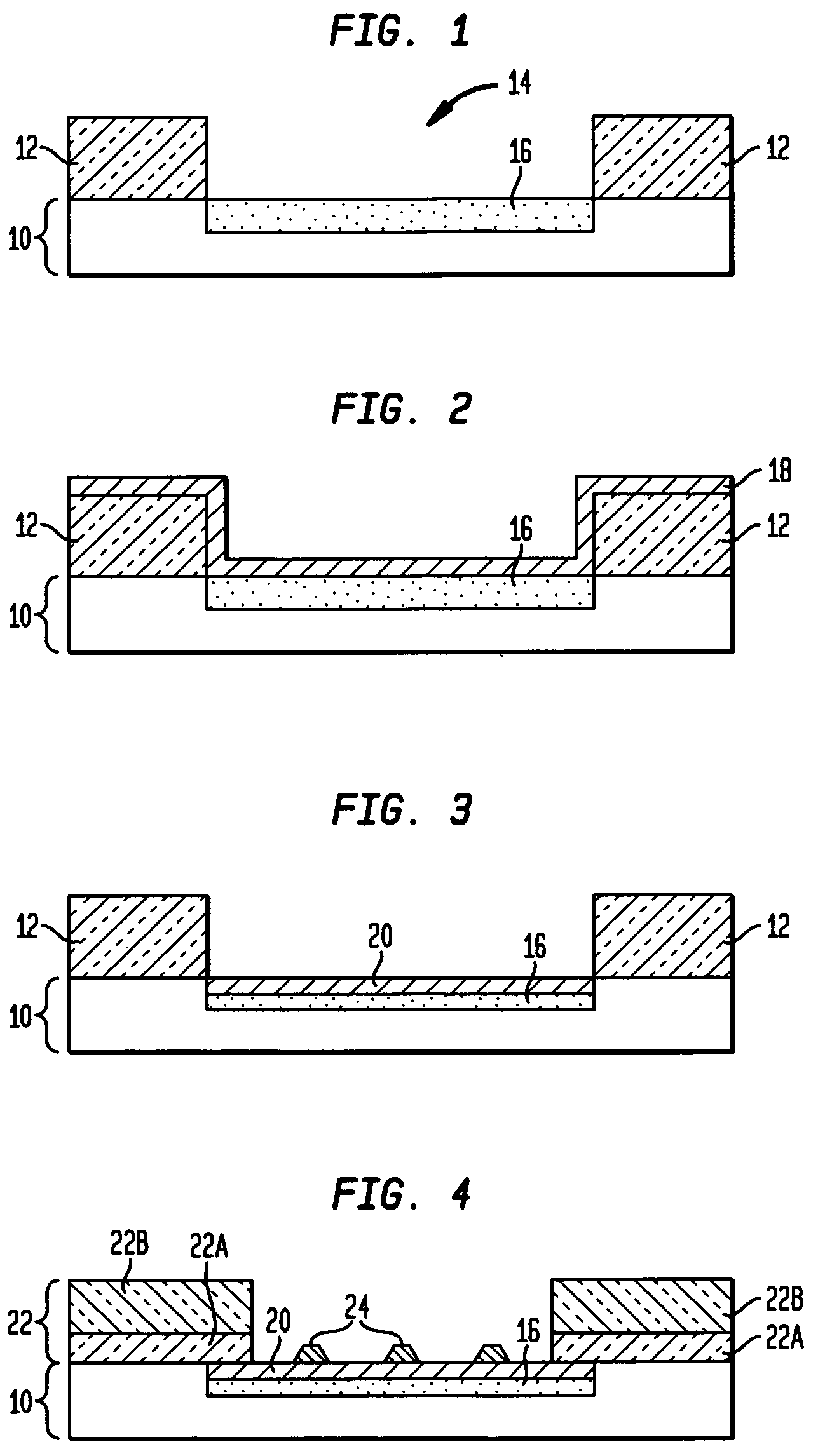

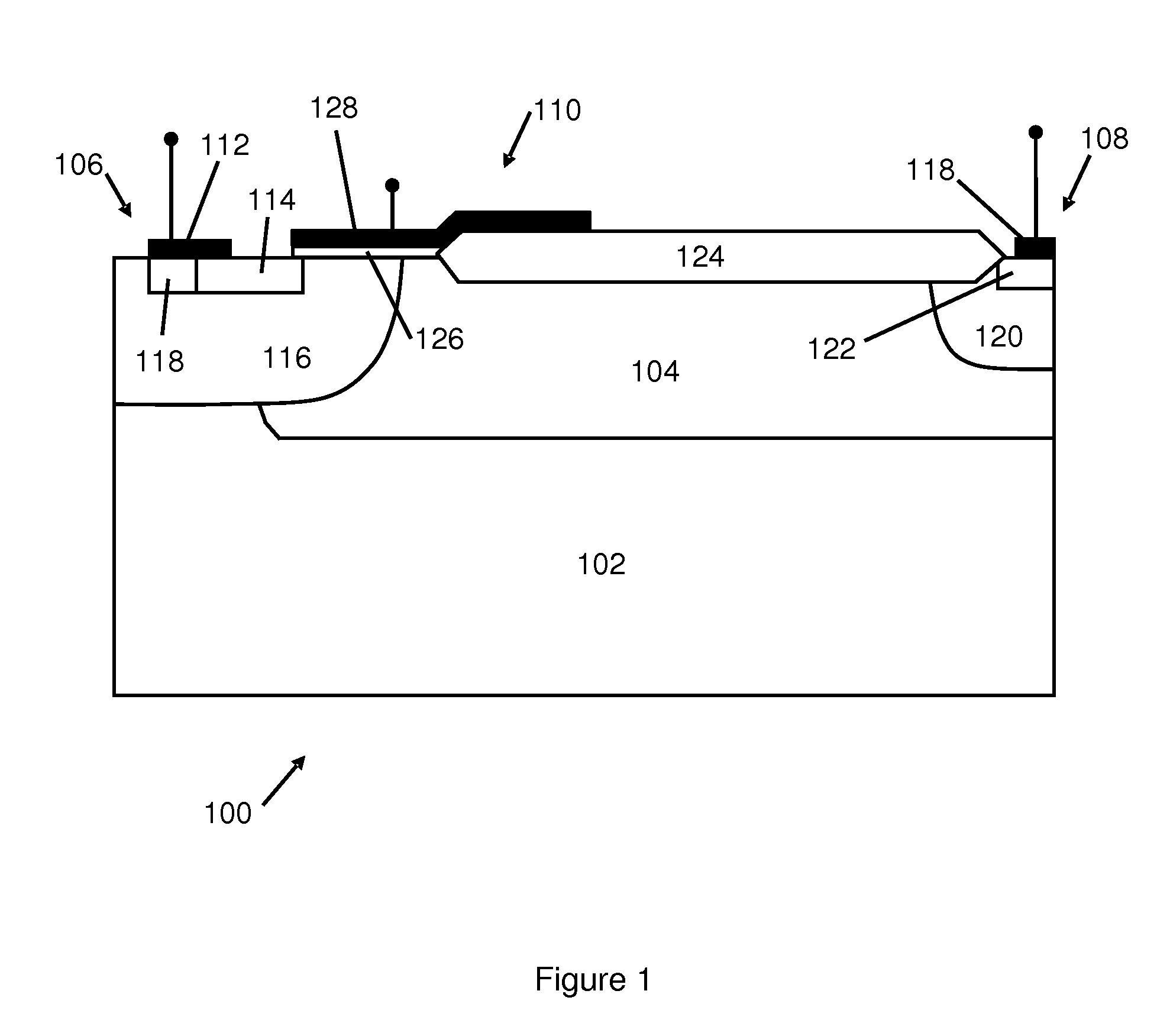

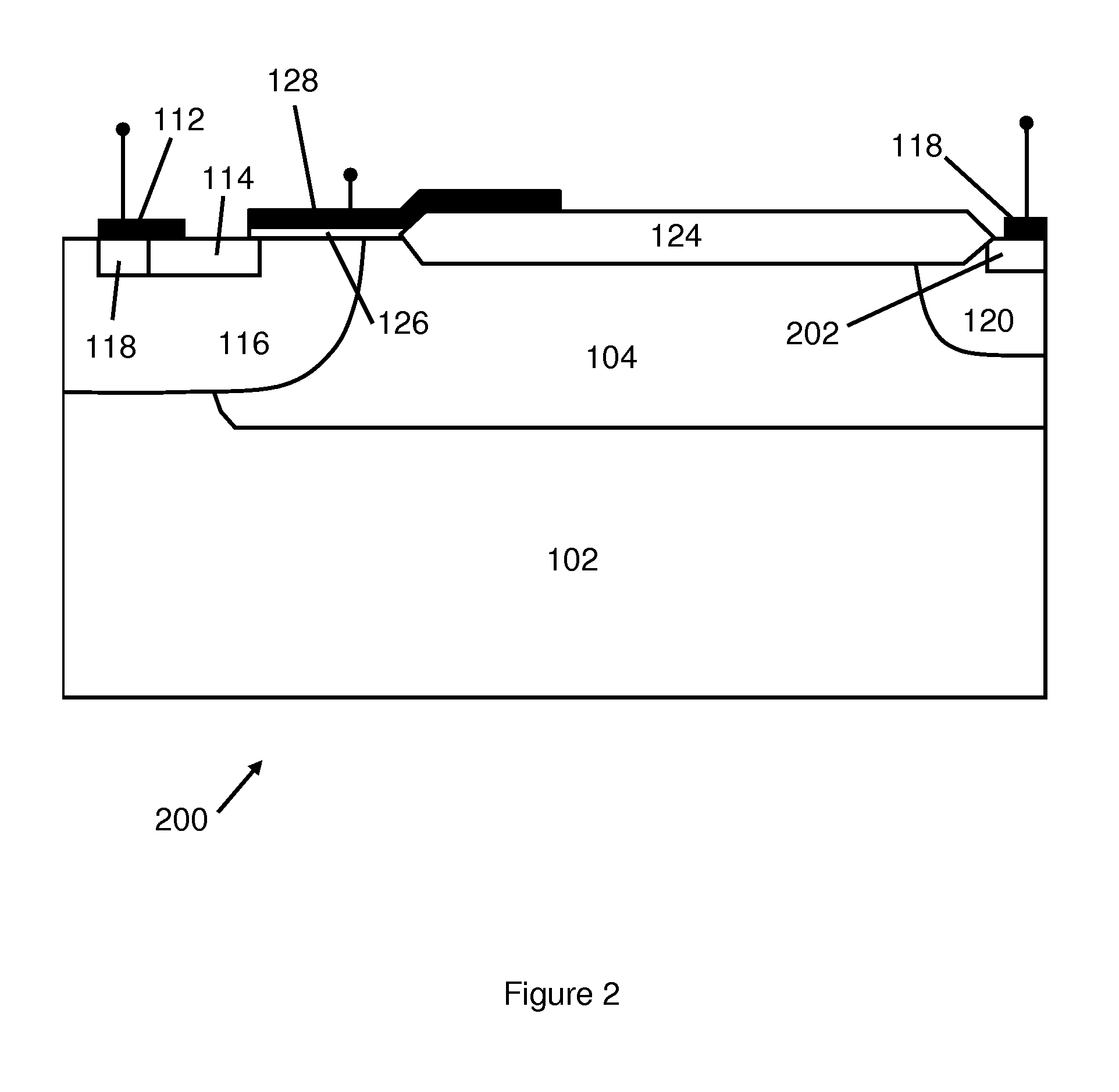

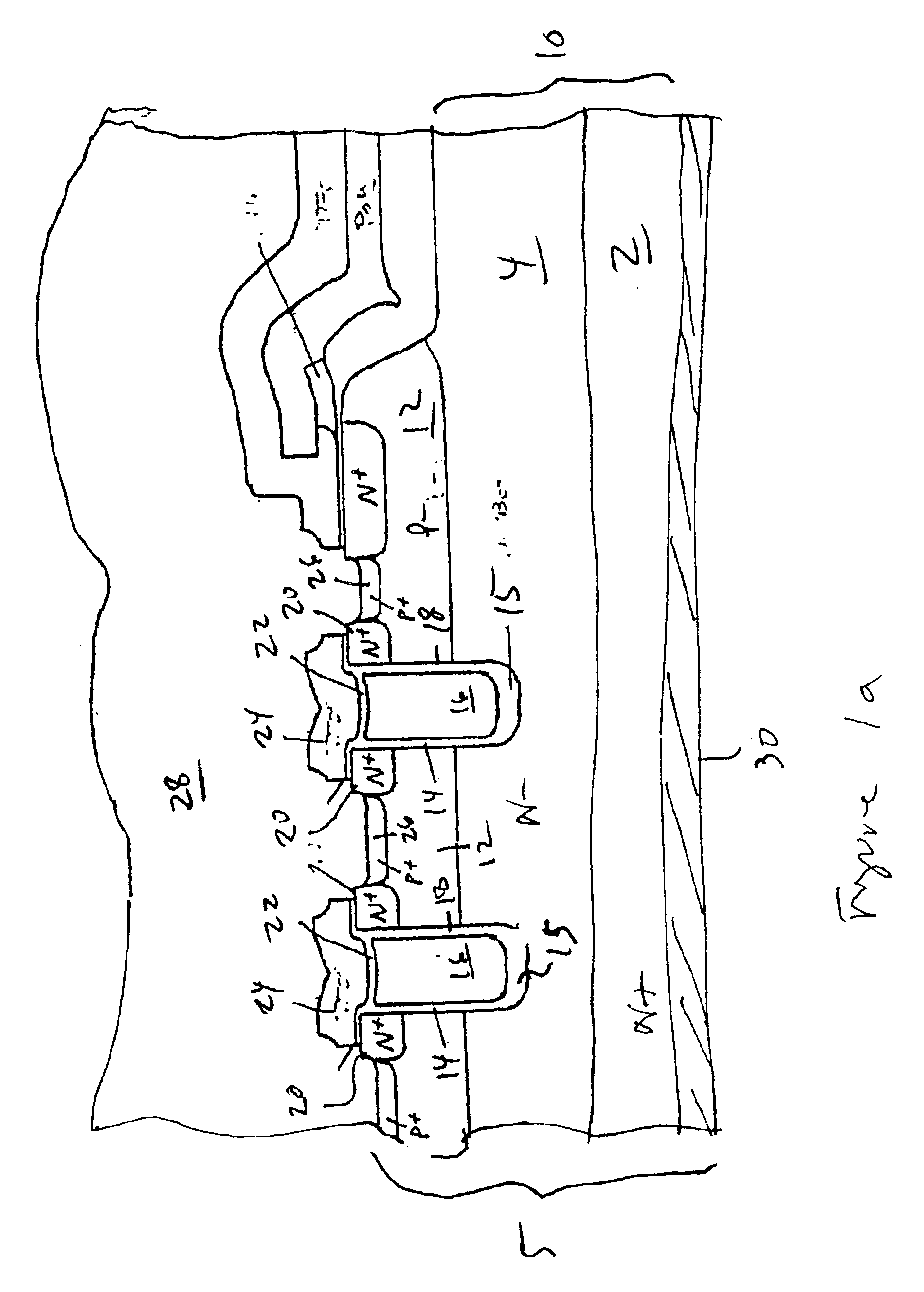

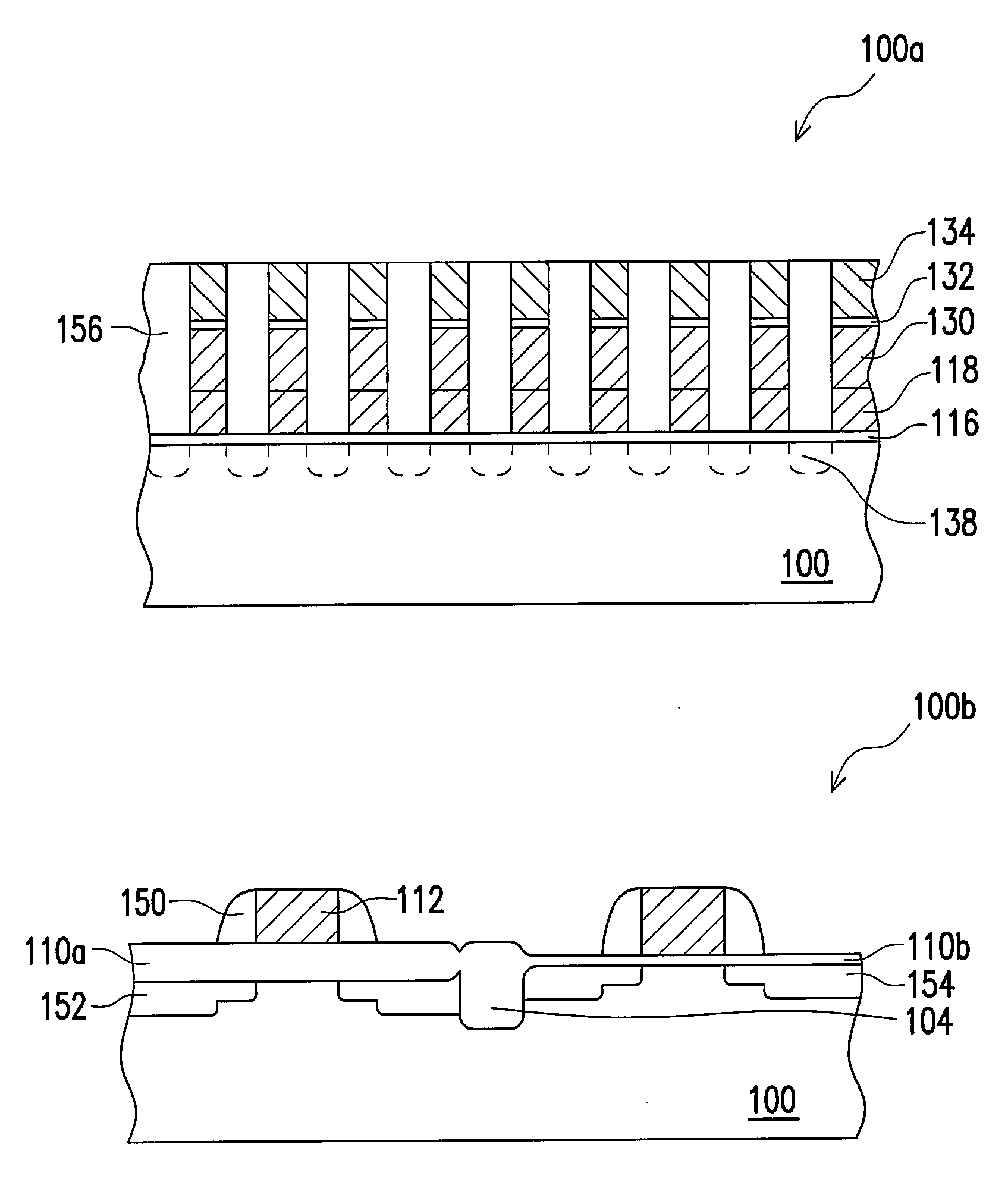

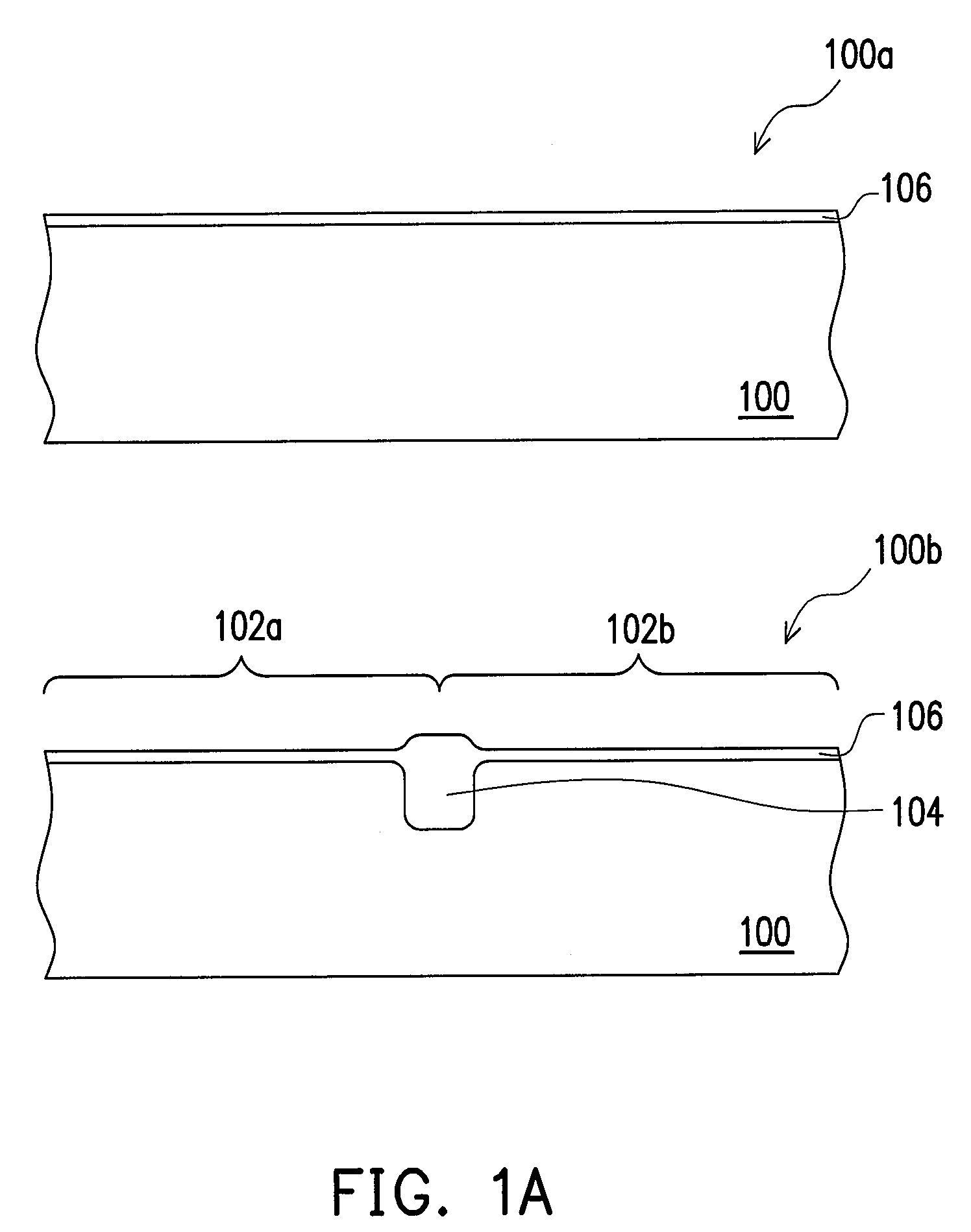

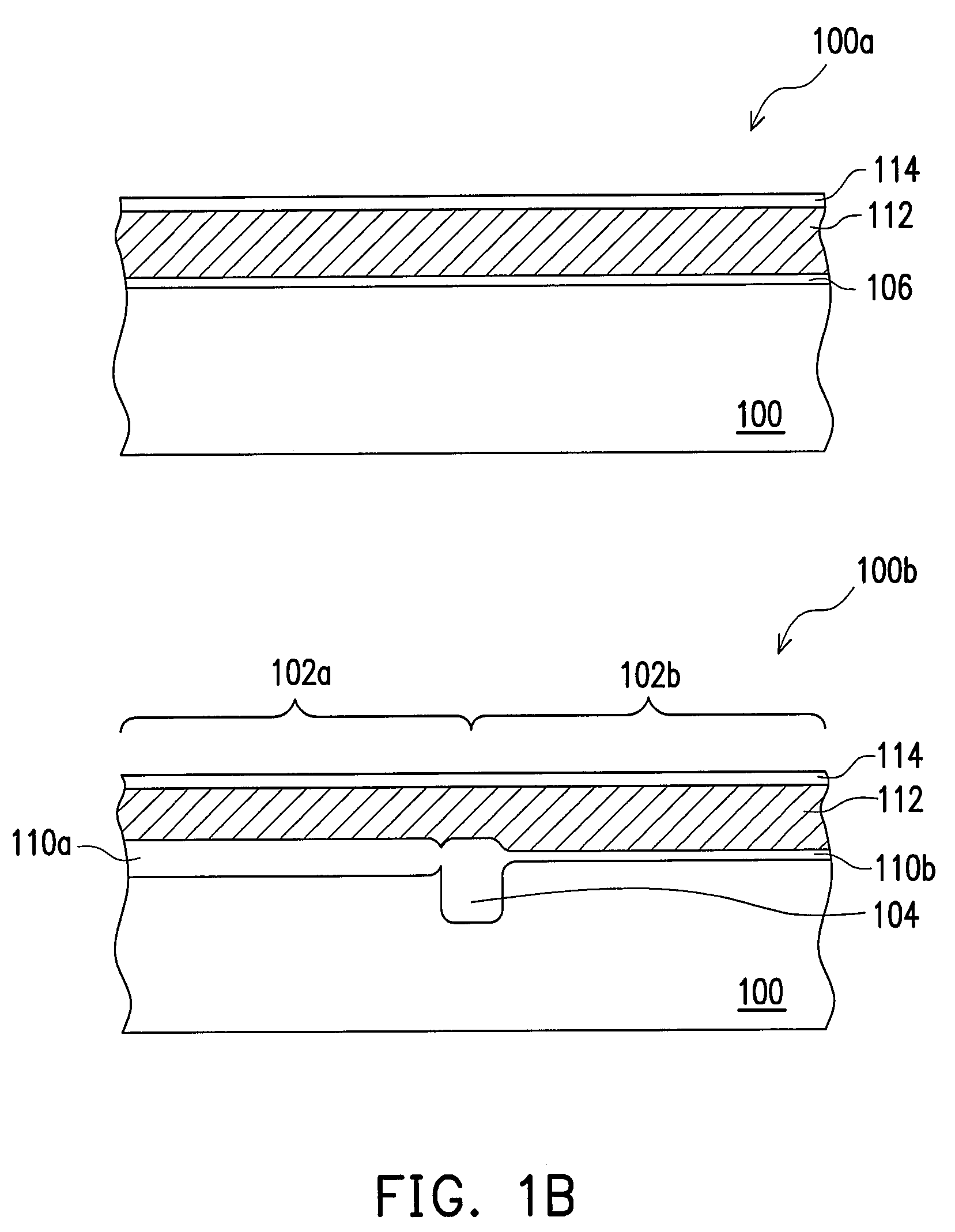

Vertical FET with nanowire channels and a silicided bottom contact

ActiveUS20060273389A1Reduce access series resistanceReduce overlap capacitanceNanoinformaticsSolid-state devicesCapacitanceAND gate

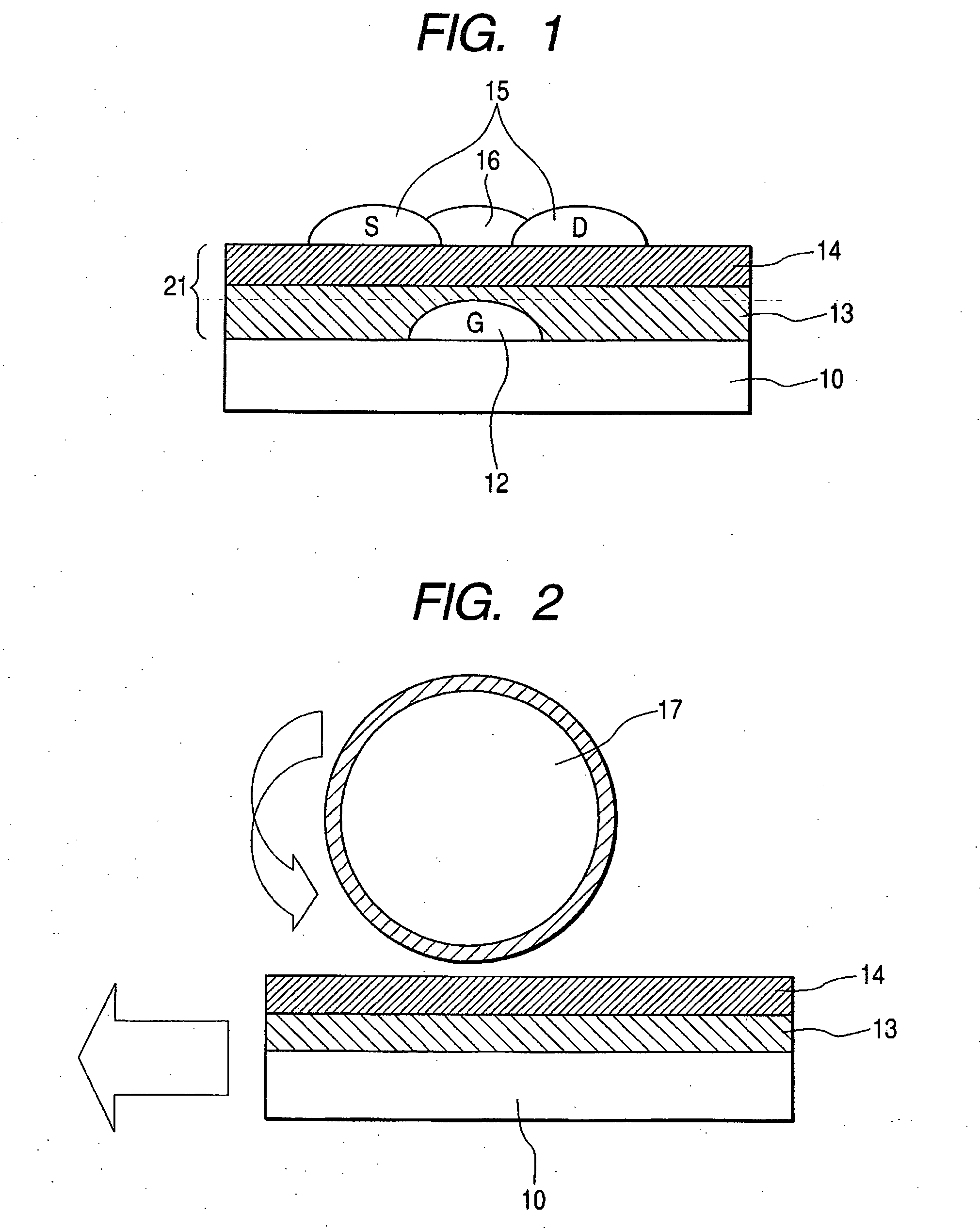

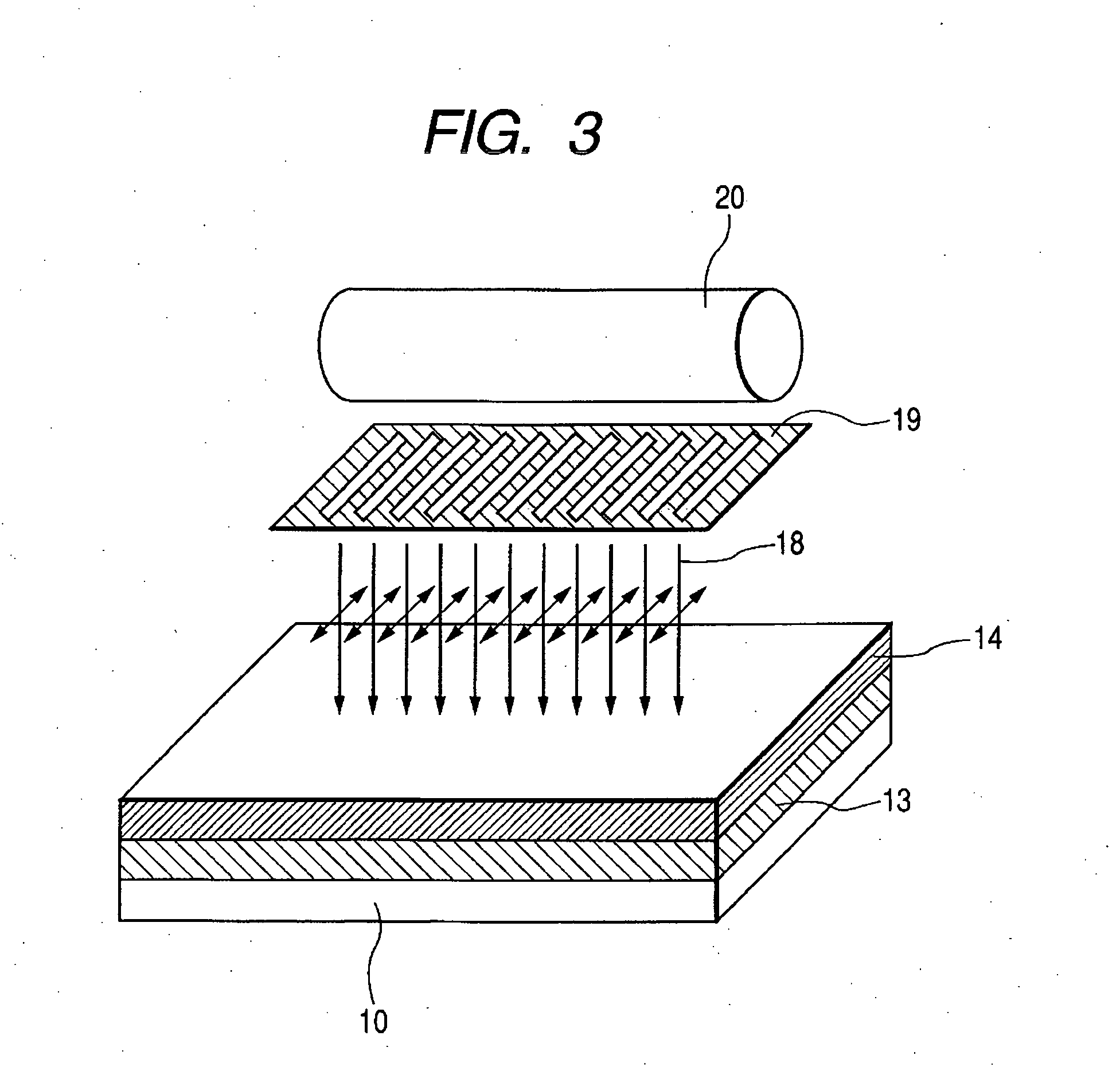

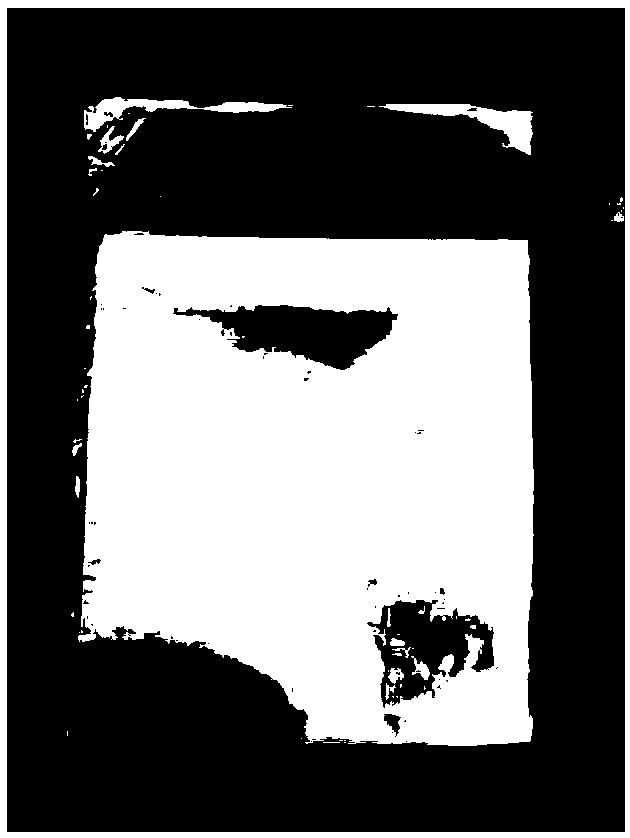

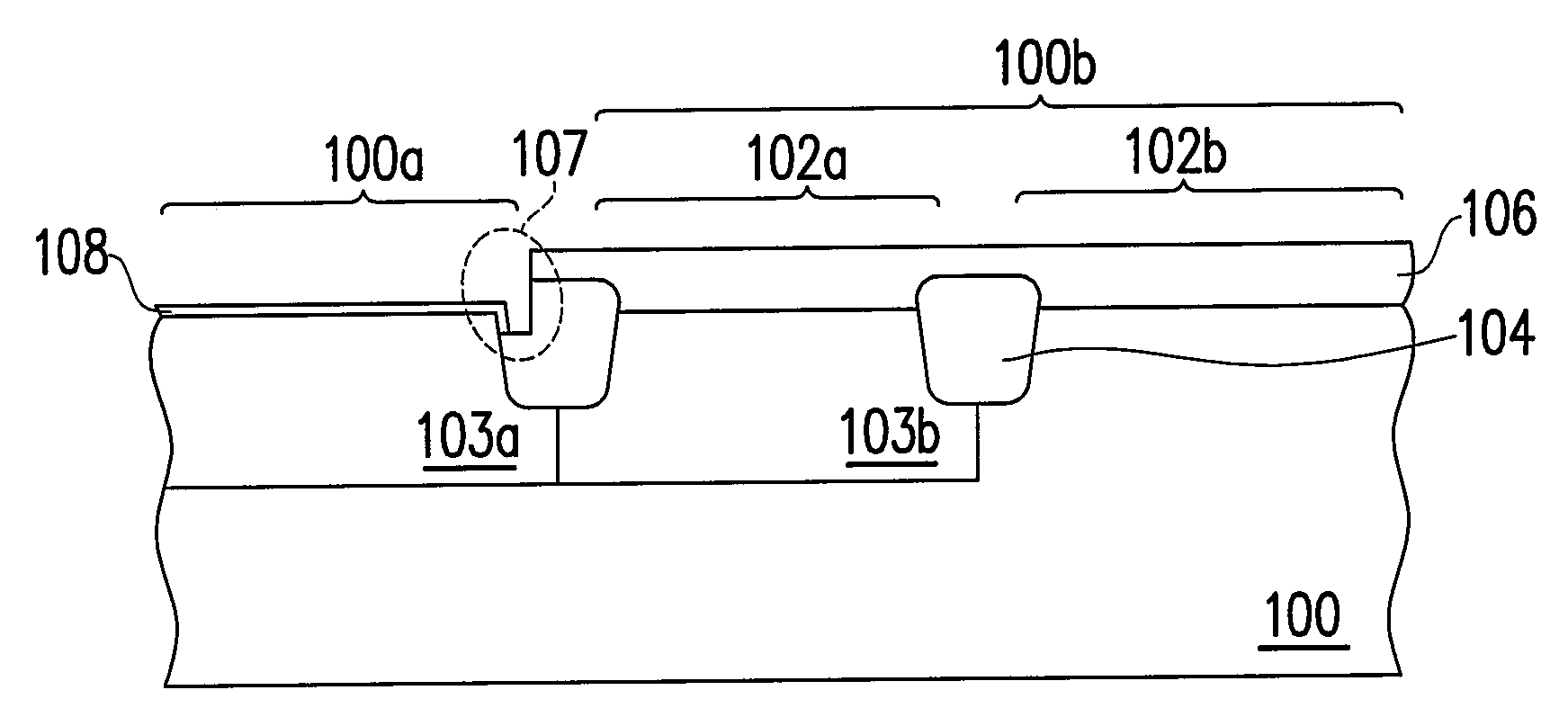

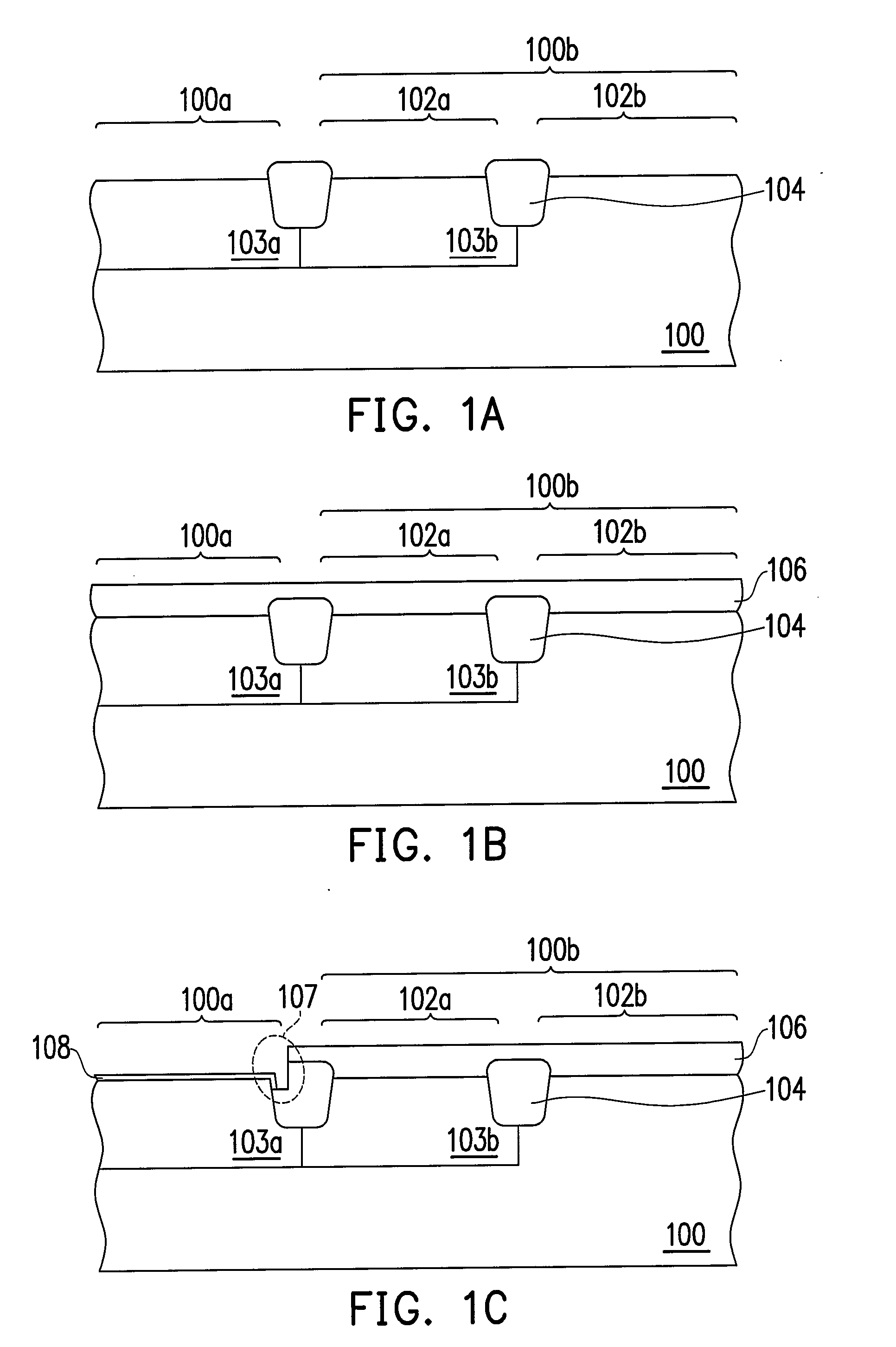

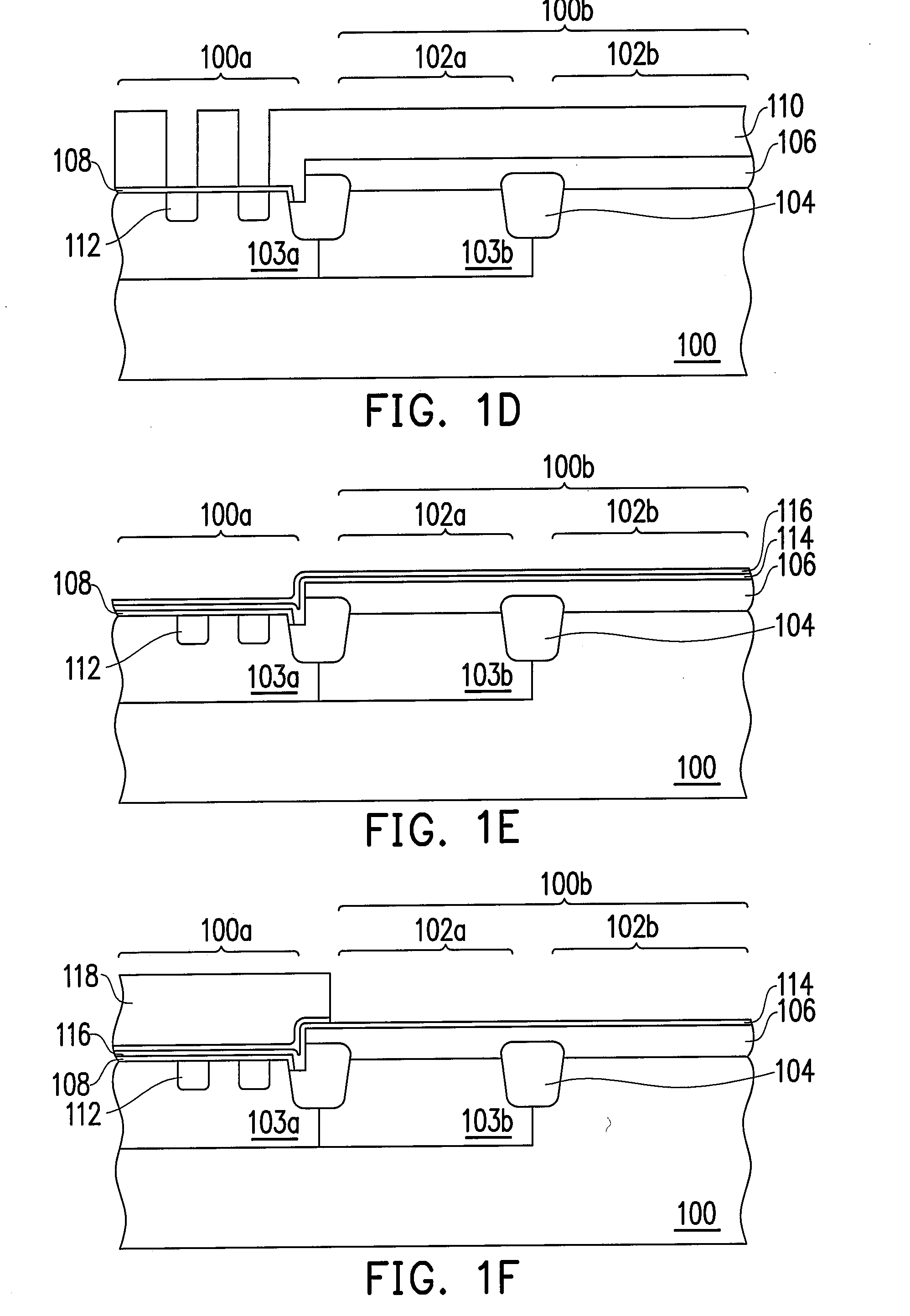

A vertical FET structure with nanowire forming the FET channels is disclosed. The nanowires are formed over a conductive silicide layer. The nanowires are gated by a surrounding gate. Top and bottom insulator plugs function as gate spacers and reduce the gate-source and gate-drain capacitance.

Owner:GLOBALFOUNDRIES US INC

Vertical FET with nanowire channels and a silicided bottom contact

ActiveUS7230286B2Reduce resistanceGood short channel characteristicsTransistorNanoinformaticsCapacitanceNanowire

A vertical FET structure with nanowire forming the FET channels is disclosed. The nanowires are formed over a conductive silicide layer. The nanowires are gated by a surrounding gate. Top and bottom insulator plugs function as gate spacers and reduce the gate-source and gate-drain capacitance.

Owner:GLOBALFOUNDRIES U S INC

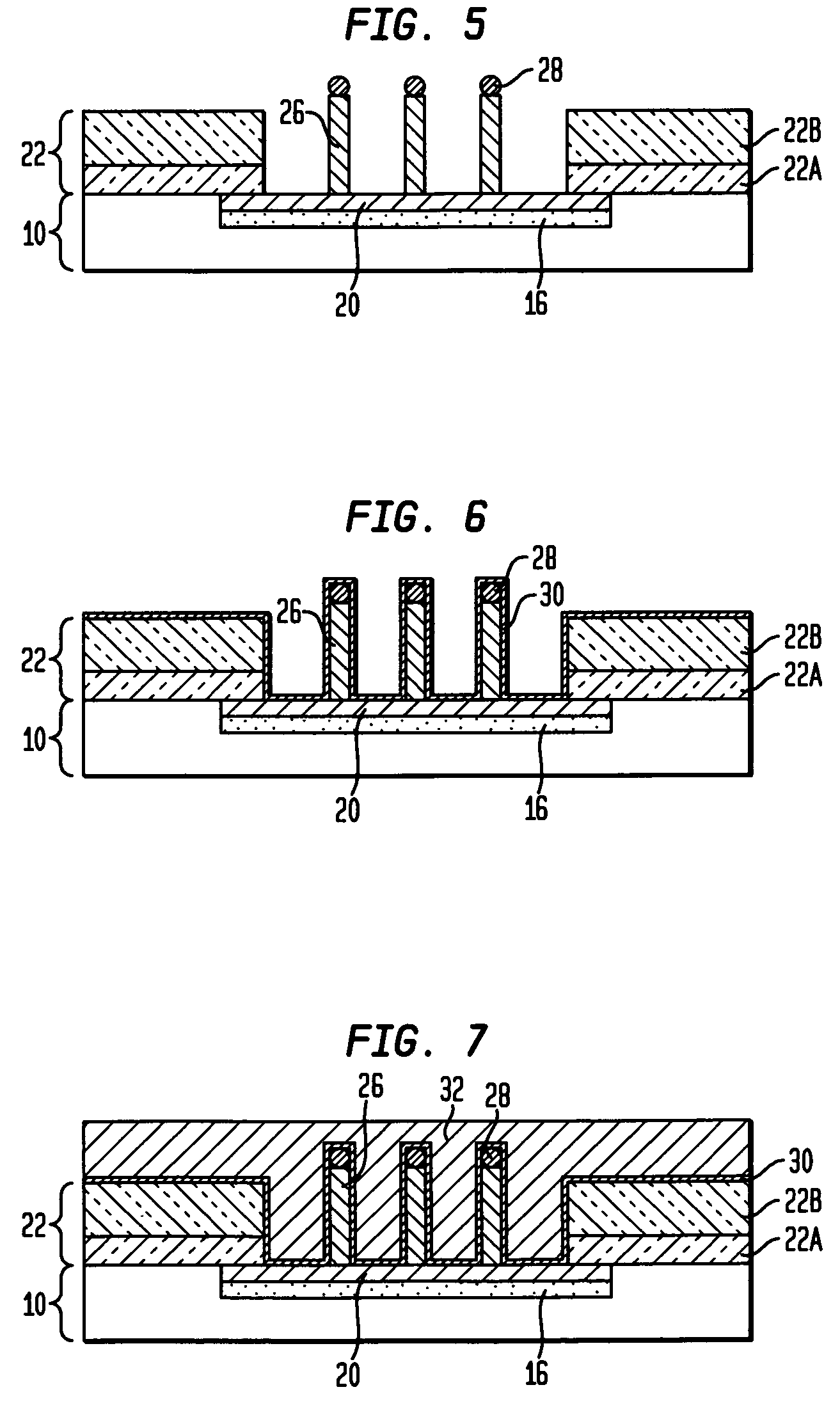

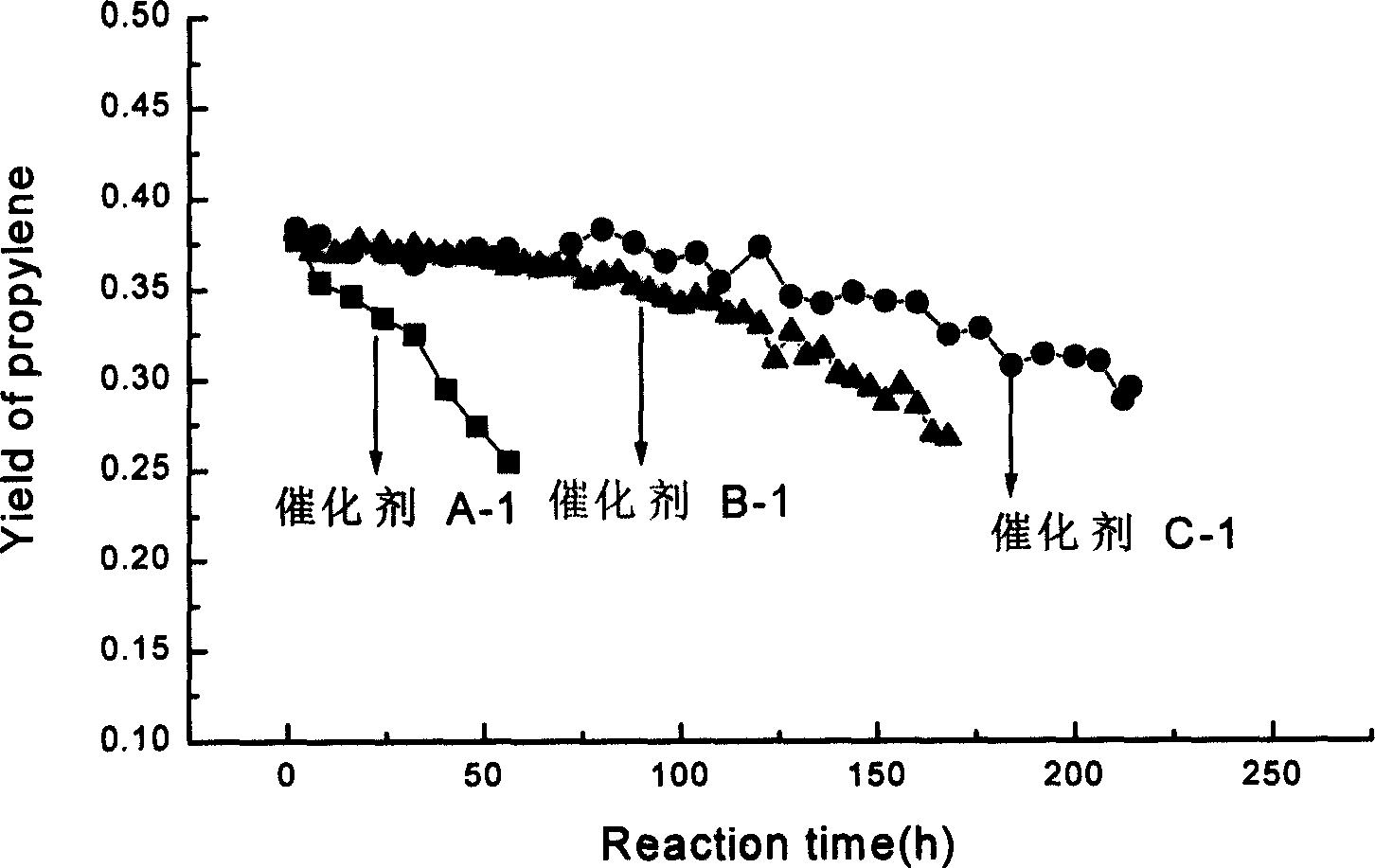

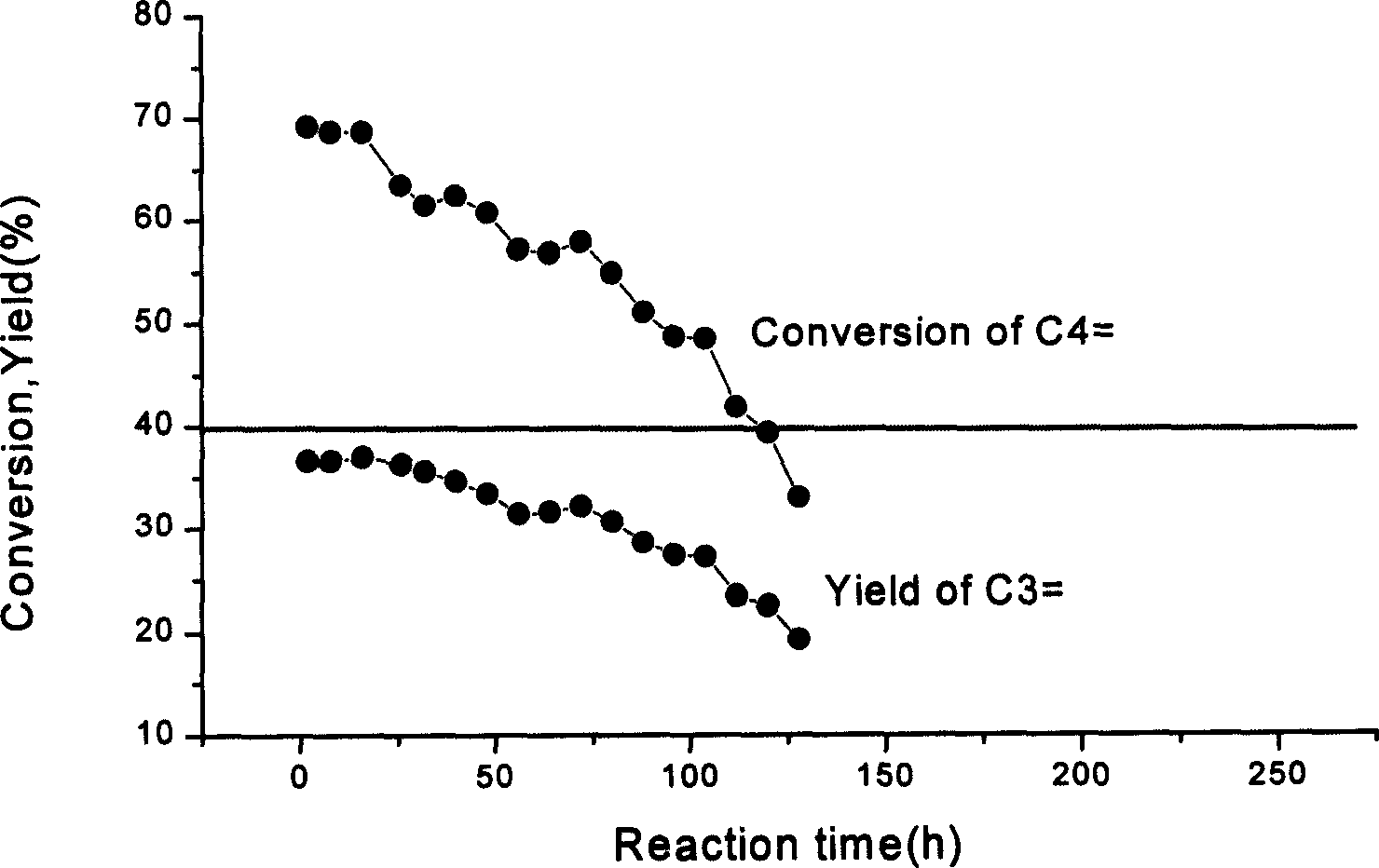

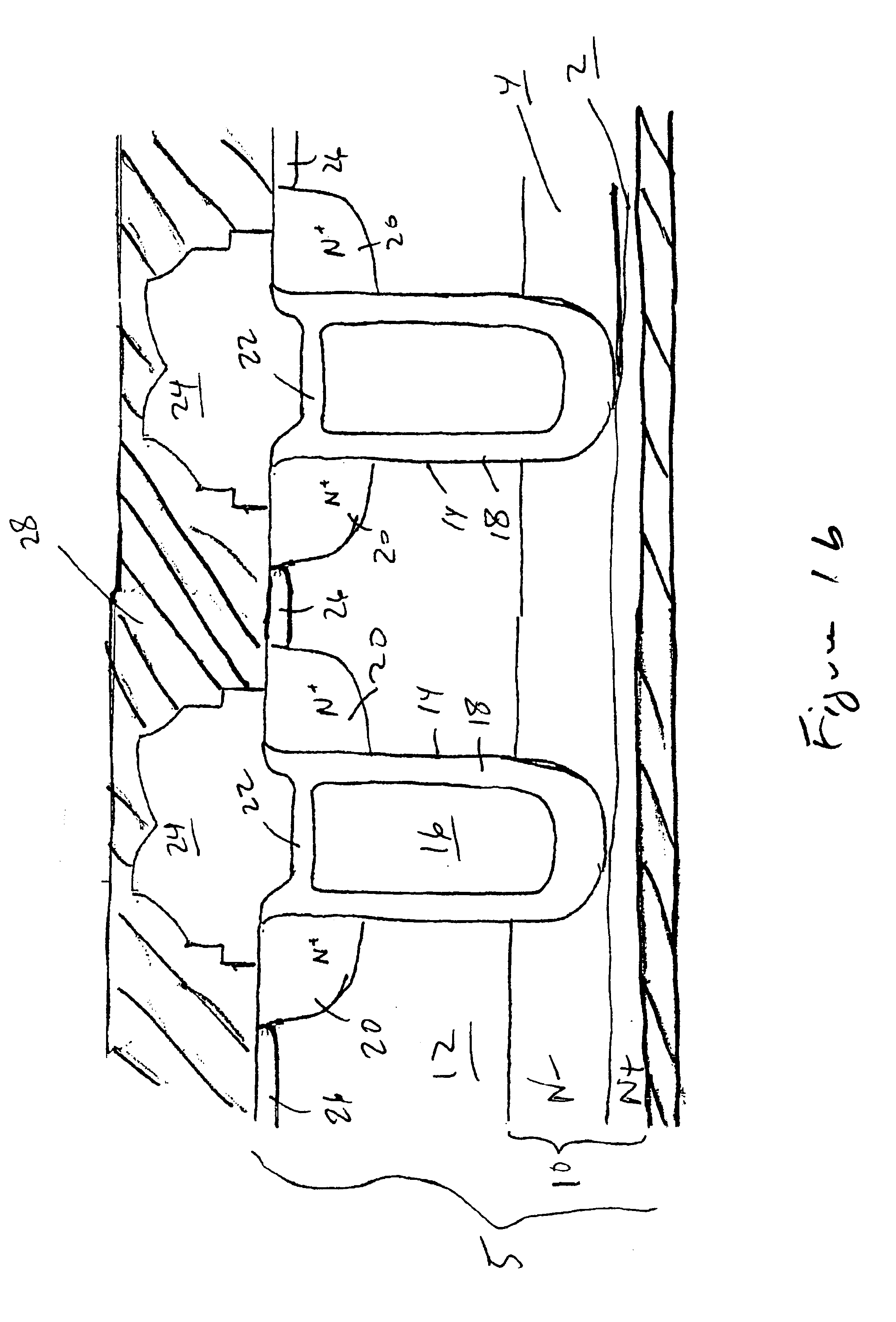

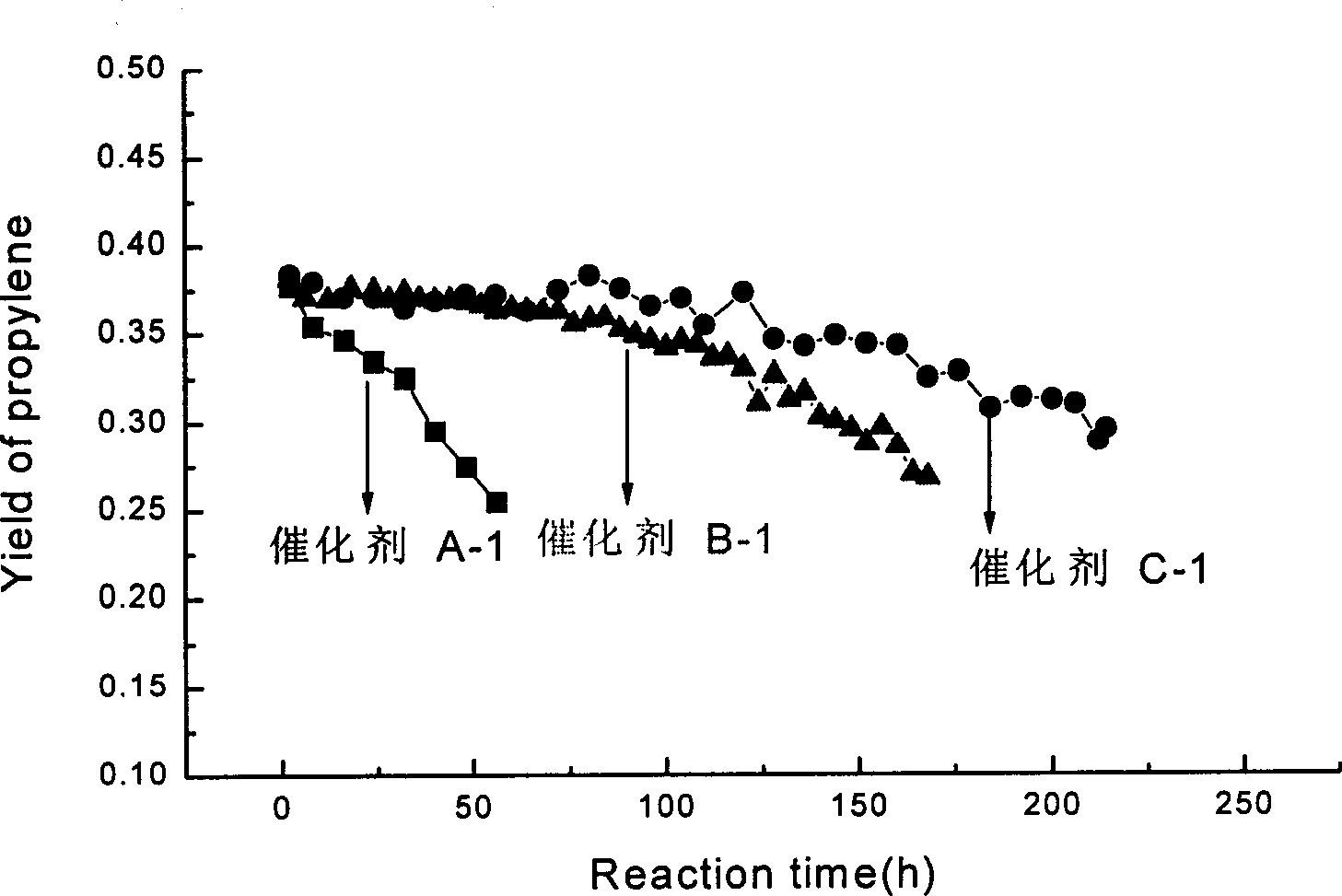

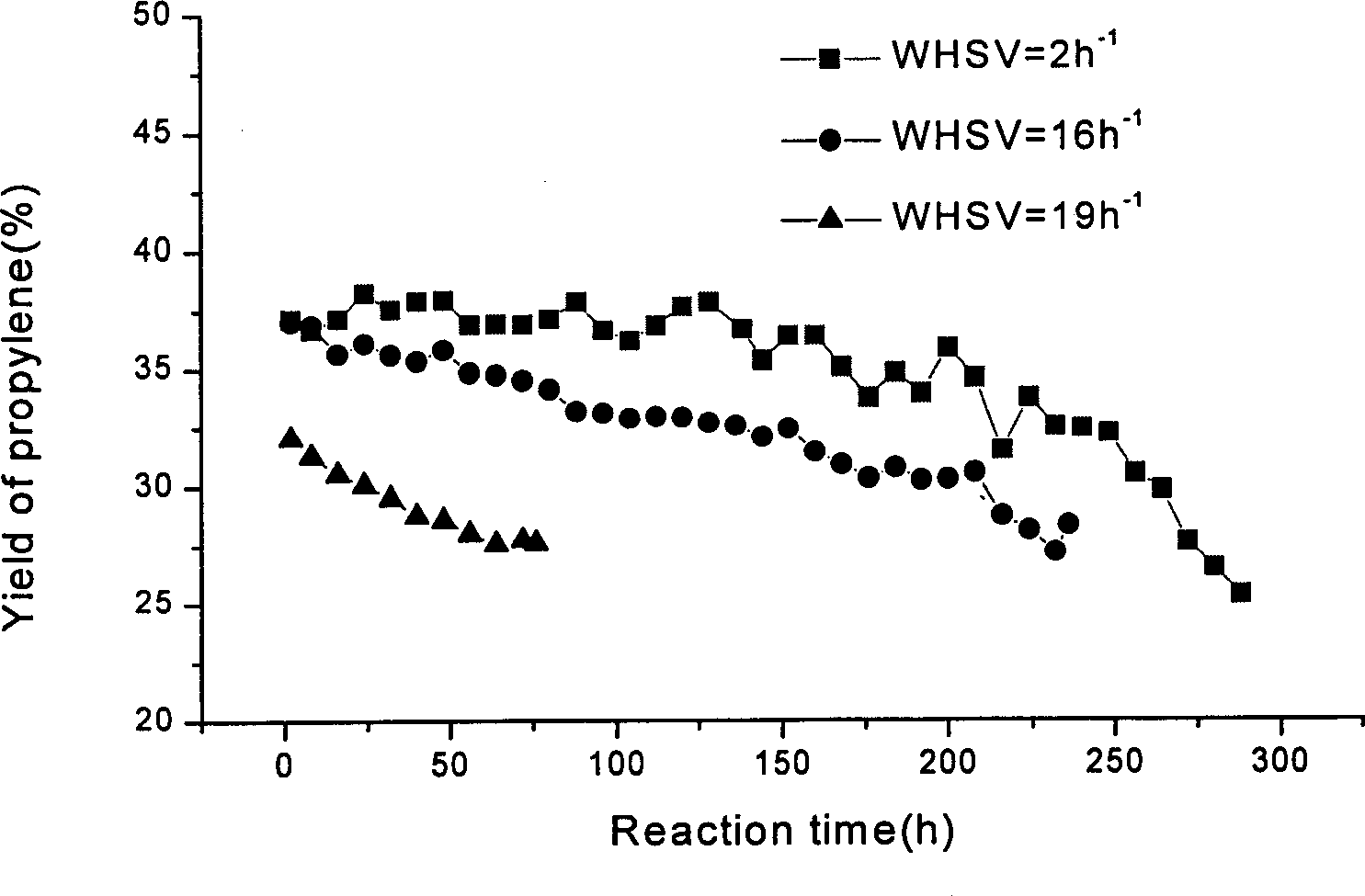

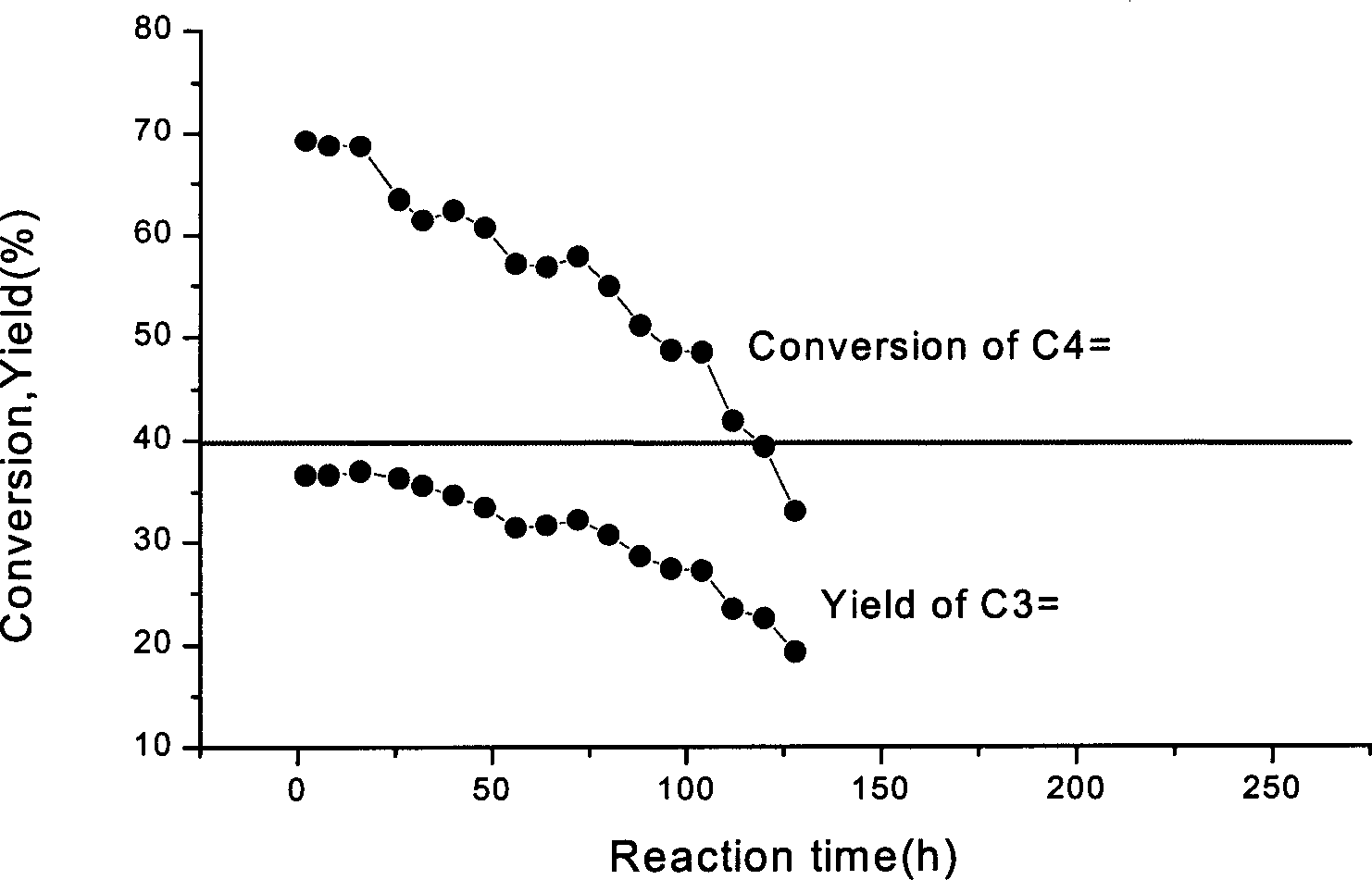

Method for producing propene for C4 and more olefin catalytic cracking

ActiveCN1611472AIncreased diffusion resistanceSize diffusion resistanceChemical recyclingHydrocarbon by hydrocarbon crackingMolecular sieveAluminium

The invention relates to a kind of method for manufacturing propylene by catalytic cracking alkene of no less than tetra carbon, which mainly solves the short catalyst regeneration period problem and the stability problems uninvolved in previous technique. The invention uses minor crystalline grain and molecular sieve with high silicon-aluminium ratio as the catalyst for catalytic cracking with alkene that no less than tetra carbon to manufacture propylene. According to the technique scheme that described above, the invention can solve the problems mentioned above excellently, and can be used in industrial production of manufacturing propylene by catalytic cracking with alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

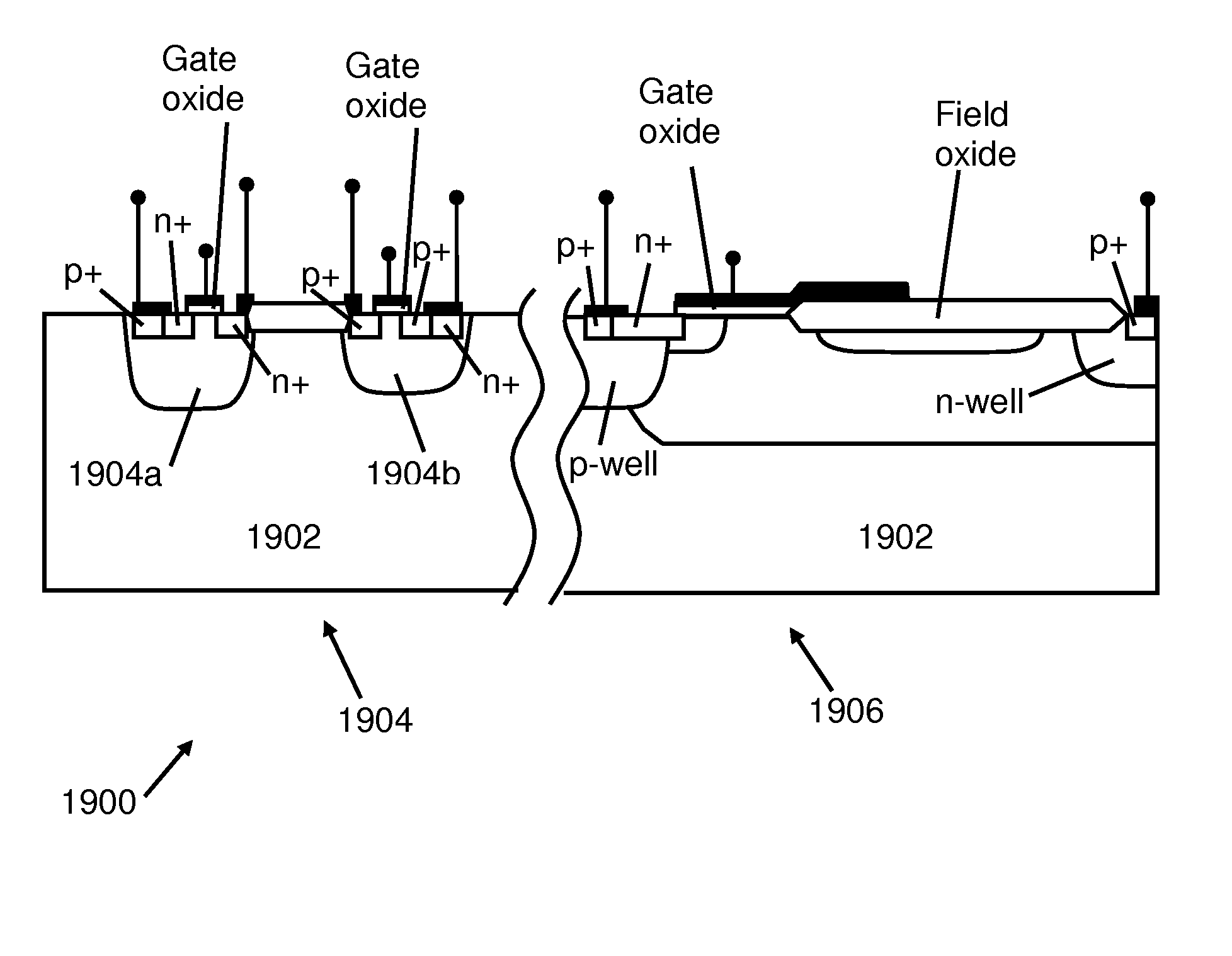

Power semiconductor devices and fabrication methods

InactiveUS20130069712A1Uniform on-state behaviourChannel shortSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceEngineering

We describe a RESURF semiconductor device having an n-drift region with a p-top layer and in which a MOS (Metal Oxide Semiconductor) channel of the device is formed within the p-top layer.

Owner:POWER INTEGRATIONS INC

Aromatization catalyst and clean gasoline producing process

InactiveCN1488723AHigh yieldFacilitated DiffusionRefining to change hydrocarbon structural skeletonMolecular sieveAromatization

The present invention relates to an aromatization catalyst and production process of clean gasoline. Said invention adopts hydrofining and aromizing two-stage catalyst combined process to make the FCC gasoline with high sulfur content and high olefin content into clean gasoline. Said invented aromatization catalyst adopts small-grain molecular sieve catalyst, and makes the aromatization catalyst undergo the process of hydrothermal treatment and can make the strong acid quantity of said catalyst be reduced. Said invention can raise yield of gasoline, and can obtain high-quality clean gasoline product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic transistor and manufacturing method thereof

InactiveUS20060157692A1Channel shortImprove electrical characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingBottom gateEngineering

There is provided an organic transistor having a bottom gate structure, composed of a substrate, a gate electrode, a gate insulating layer, source and drain electrodes and an organic semiconductor layer, wherein the gate insulating layer is formed so as to have a low surface energy in a portion thereof in proximity to the source and drain electrodes and a relatively high surface energy in a portion in proximity to the gate electrode, and consist of different compositions in a layer thickness direction, whereby an organic transistor has a short channel and high electric characteristics; as well as a method of manufacturing the organic semiconductor.

Owner:CANON KK

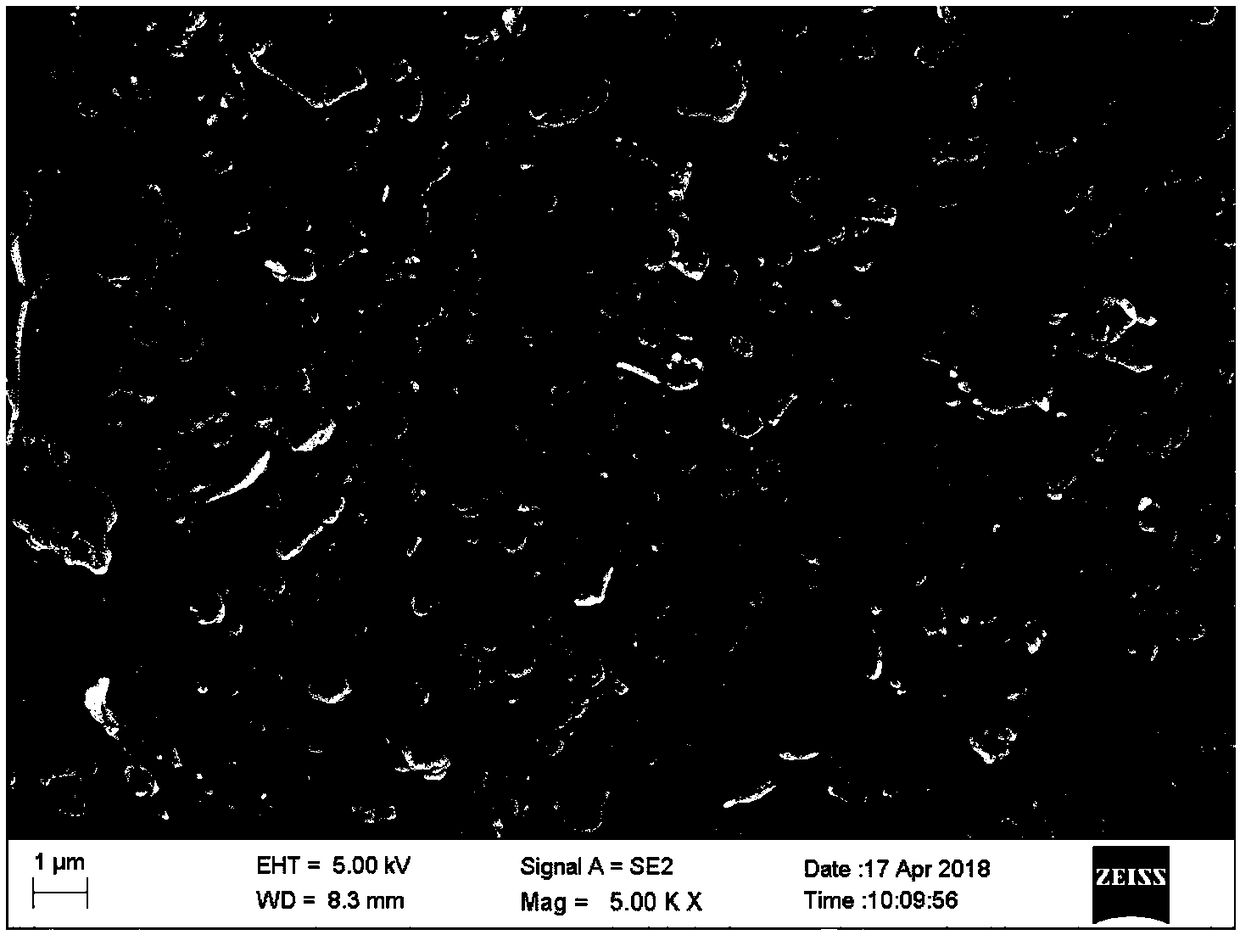

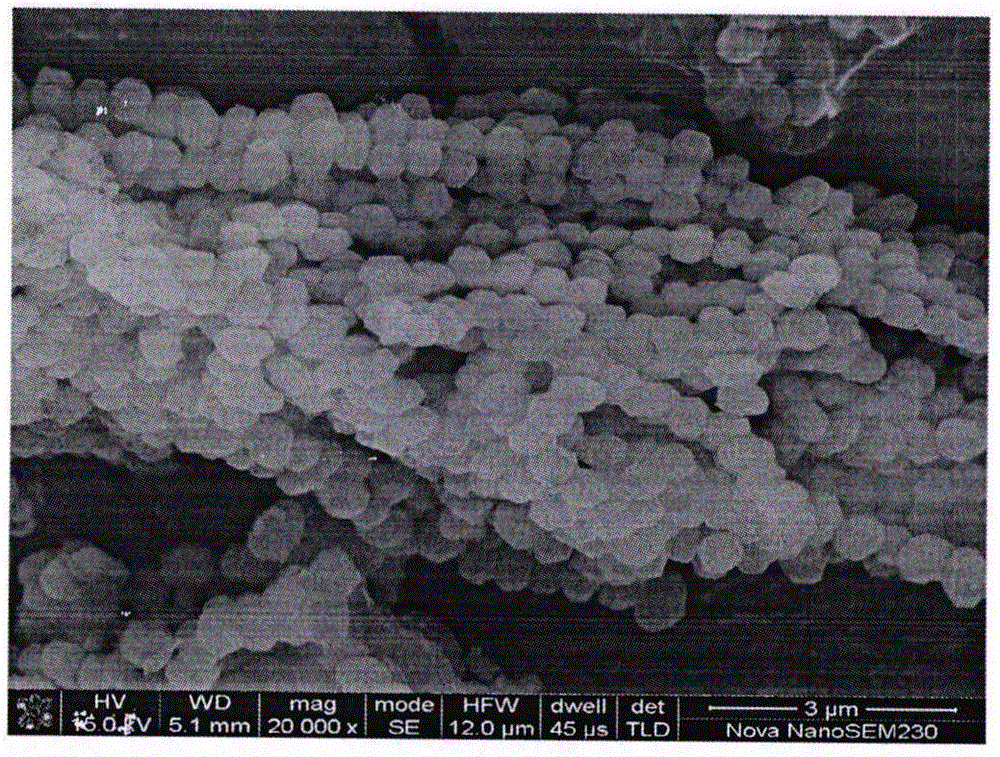

Preparation method and application of carbon-based metal organic frame (MOF) compound derivative material

The invention discloses preparation method and application of a carbon-based metal organic frame (MOF) compound derivative material, and belongs to the technical field of preparation of a functional nanometer material. The preparation method comprises the steps of placing a carbon fiber / polyacrylonitrile (PAN) thin film in an MOF precursor solution, achieving self-assembly of different morphologies of an MOF on different substrates at a room temperature, mixing the obtained product and an appropriate amount of melamine, and then performing thermal reduction on in-situ catalytic growth carbon nanotube (CNT) in an inert atmosphere to obtain the carbon-based MOF derivative material. The function nanometer material prepared by the method has the physical characteristics of high conductivity, rapid ion transmission passage, good flexibility, favorable self-support structure and the like and shows long service lifetime, high-capacity electric storage performance and excellent electrochemicalstability during energy storage and conversion; and the preparation process of the whole material is simple, no toxic product during reaction is generated, and the material is green and environmental-friendly and is suitable for industrial production on a large scale.

Owner:NANJING UNIV OF TECH

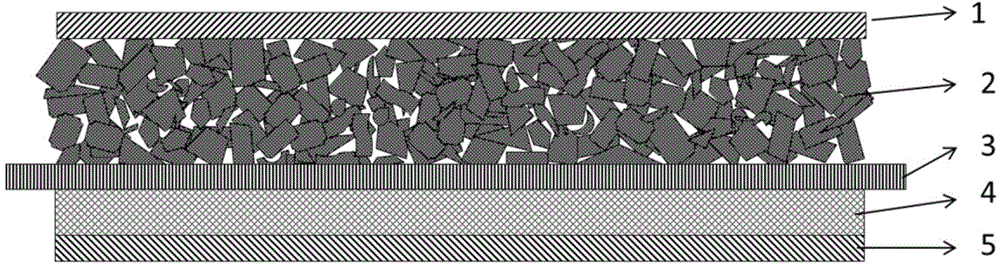

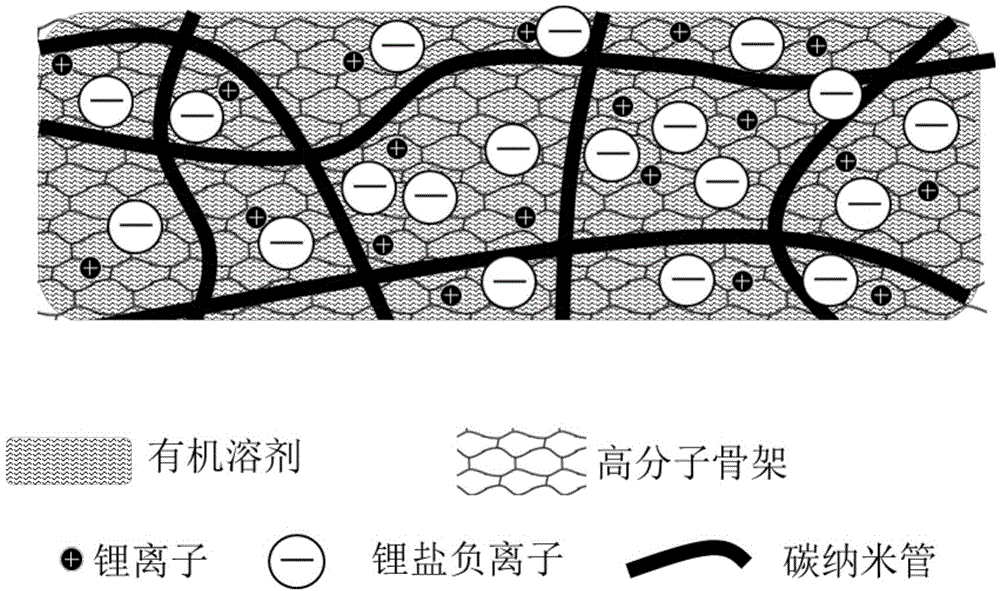

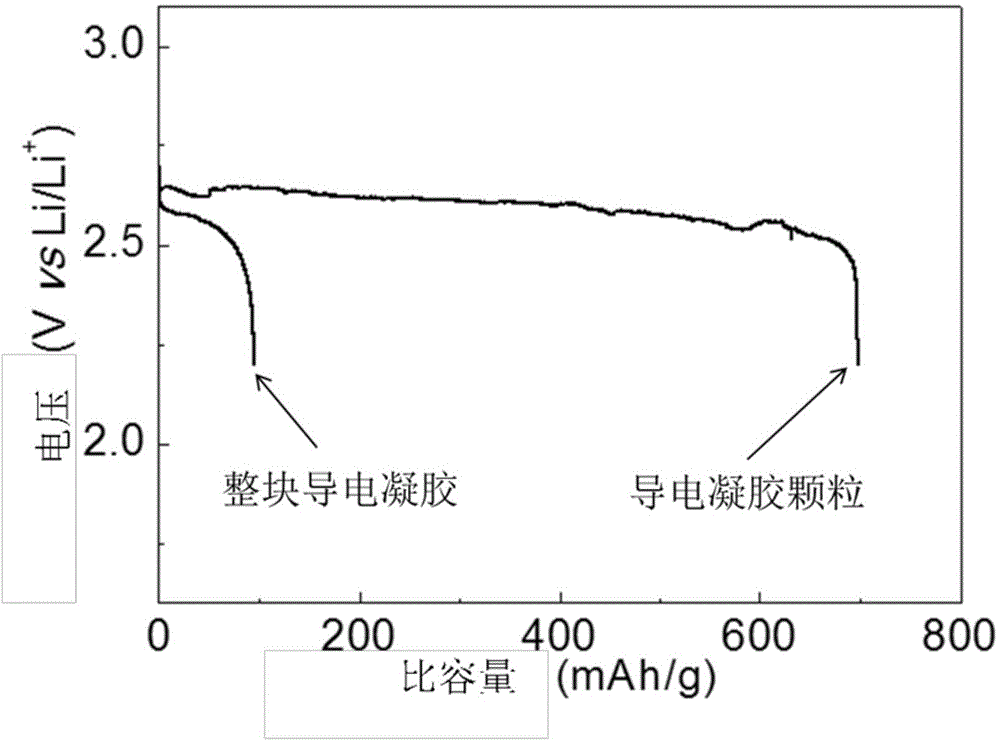

Air positive electrode constructed by conductive gel particles and lithium air battery

ActiveCN104659375AEasy and quick passFast deliveryFuel and primary cellsCell electrodesSolid structureLithium–air battery

The invention discloses an air positive electrode constructed by conductive gel particles and a lithium air battery. The air positive electrode is characterized by being of a full-solid structure and comprising particles with arbitrary shapes, wherein the particles are prepared from conductive gel, gaps are formed among the particles, electrons and ions can be simultaneously conducted by conductive gel, and the size range of the particle sizes of the particles is 10-500 microns; the particles are stacked to form a laminated structure, and the thickness of the laminated structure is 50 microns to 5 millimeters. A battery cell of the lithium air battery is of a multi-layer winding type structure or a multi-layer laminating type structure and is formed by winding and laminating a plurality of repetitive units, and each repetitive unit comprises the air positive electrode. A rapid gas dispersion channel is formed in the air positive electrode and can be prepared to be relatively thick, so that the problem that oxygen is difficult to diffuse is effectively solved, and the air positive electrode can be truly input into actual application.

Owner:HUAZHONG UNIV OF SCI & TECH

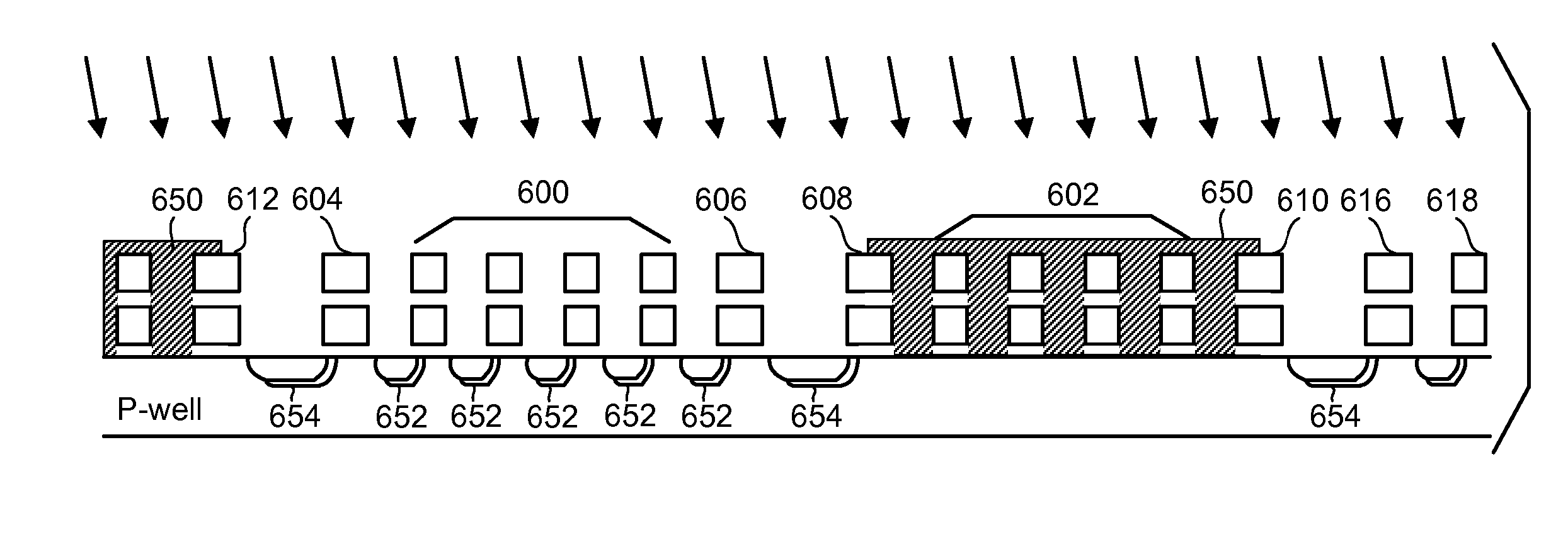

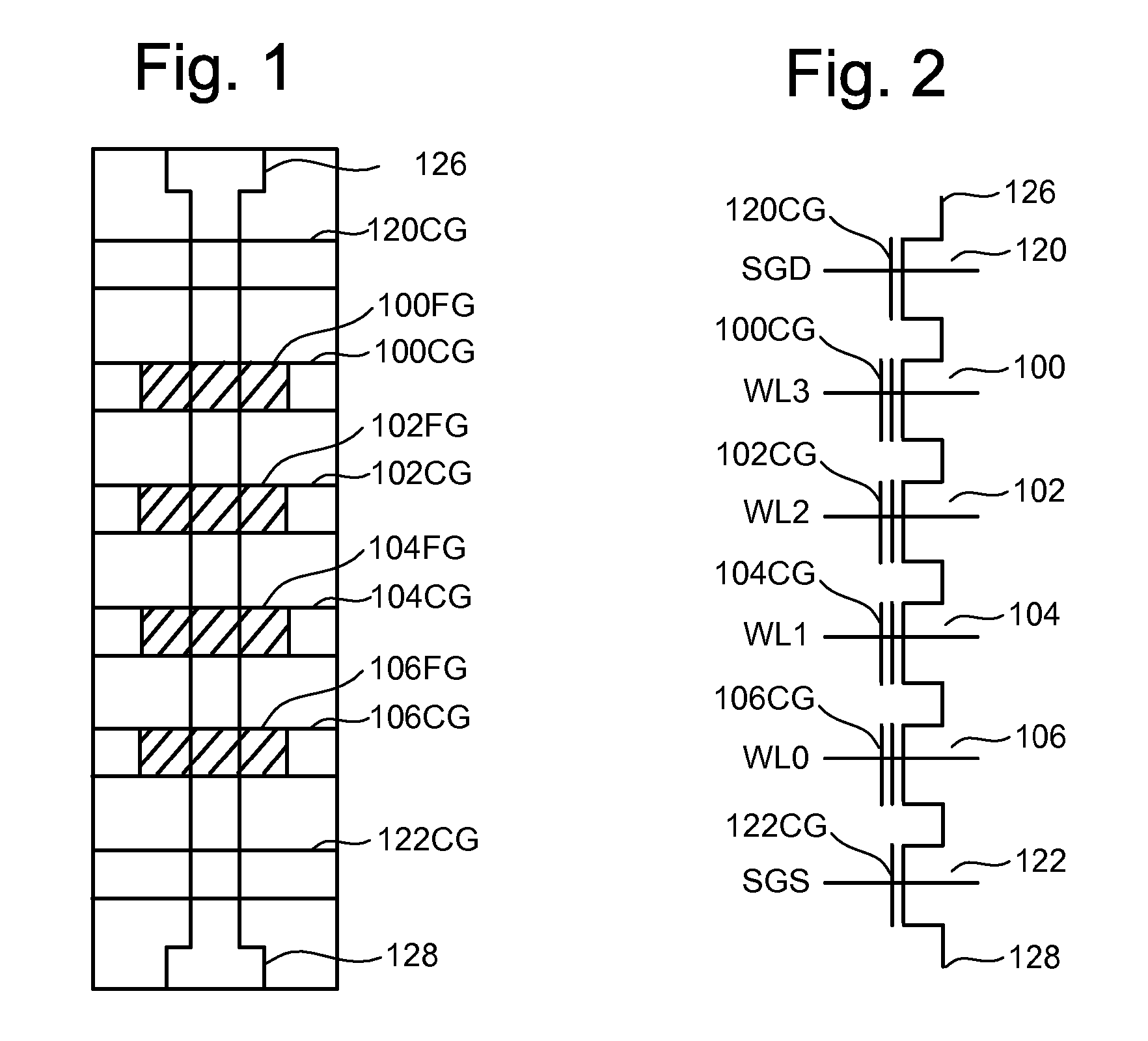

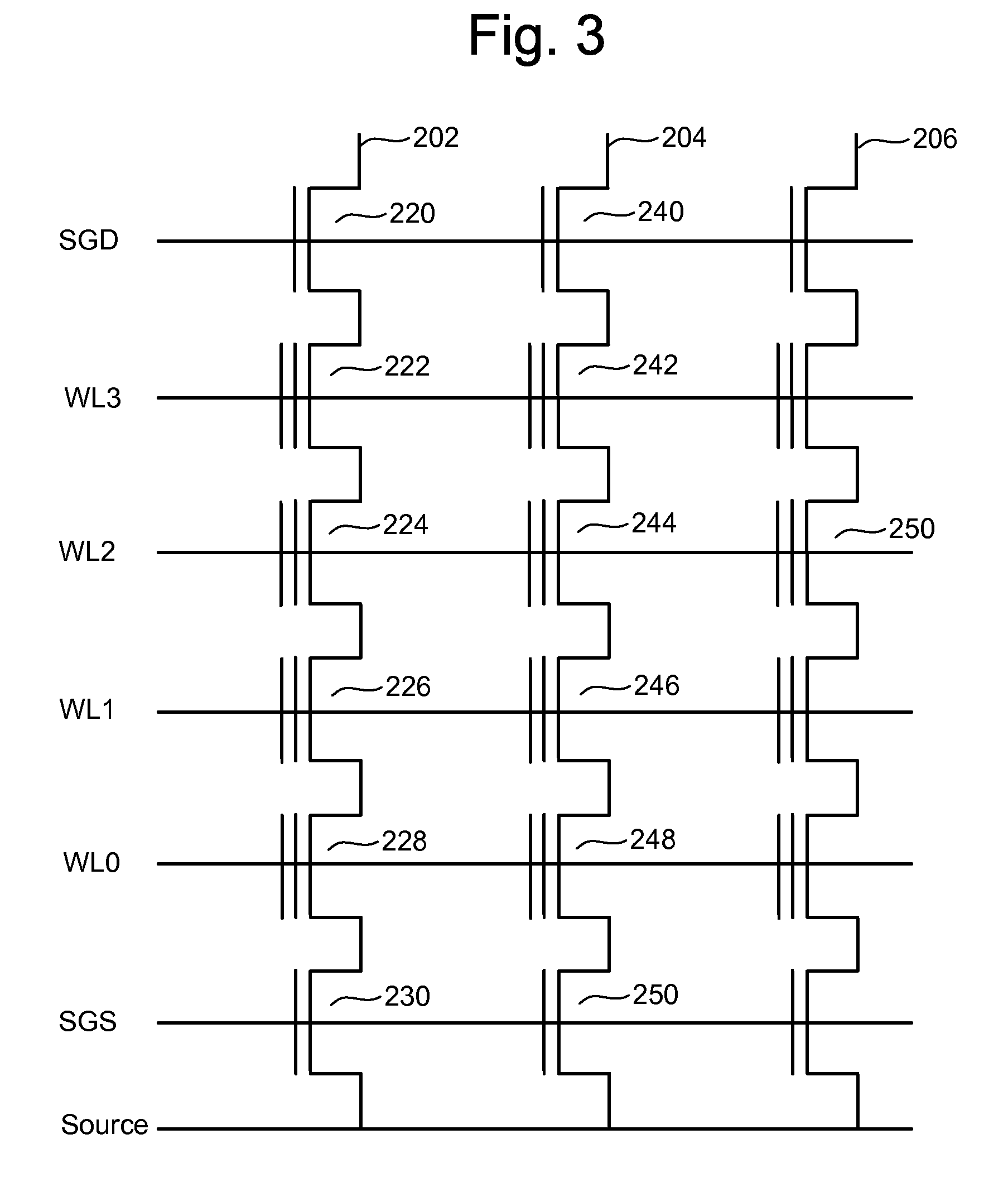

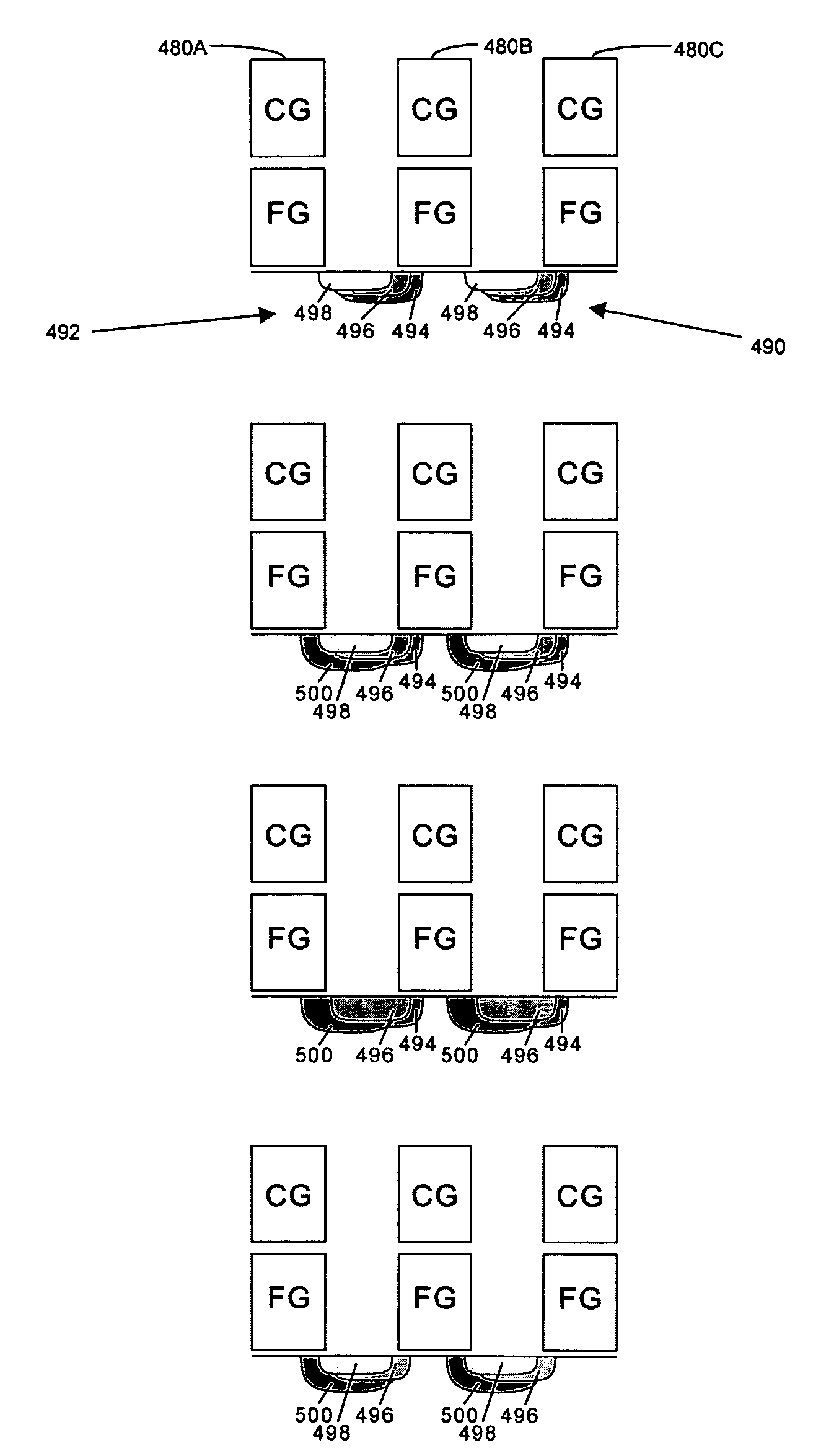

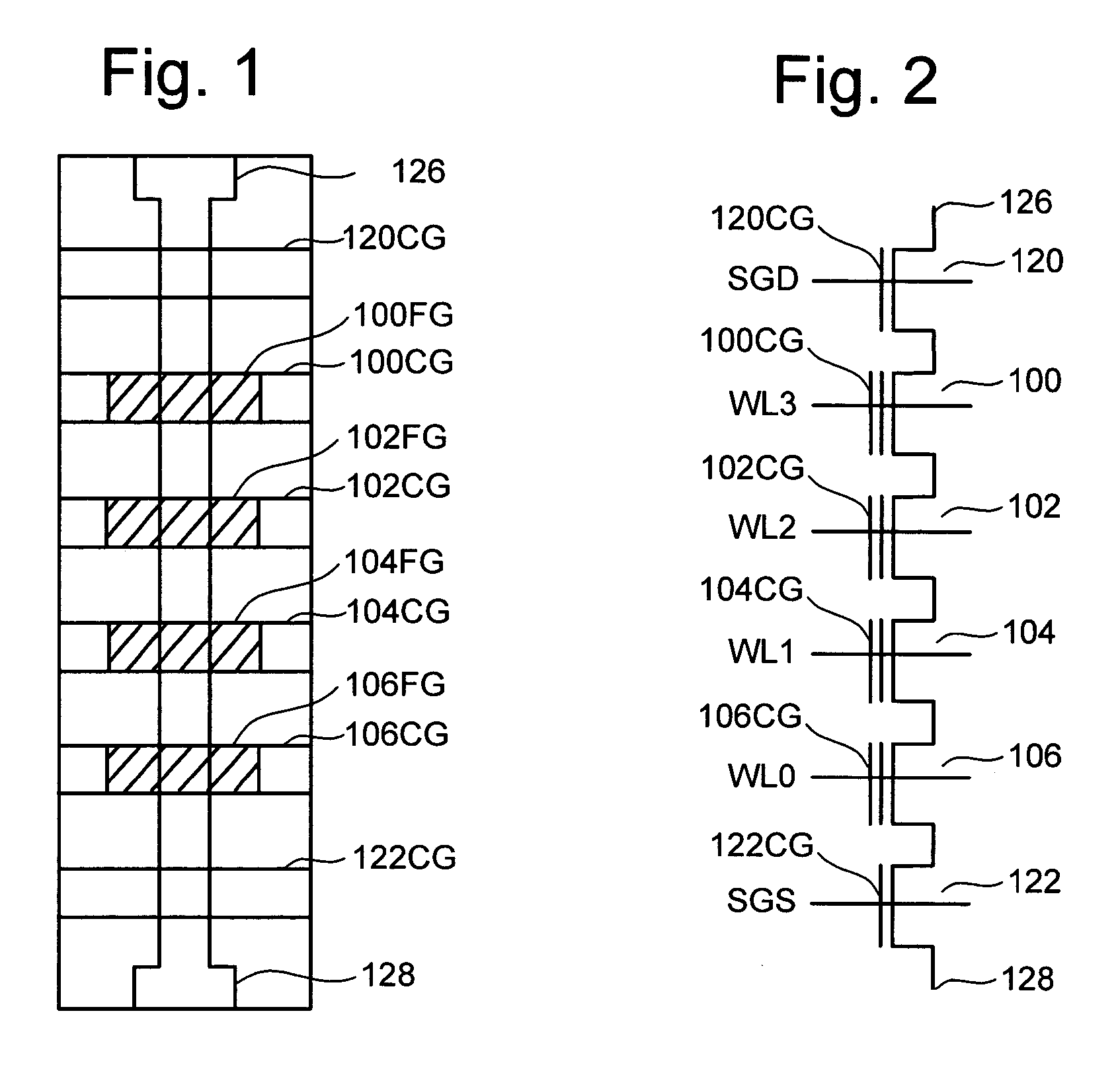

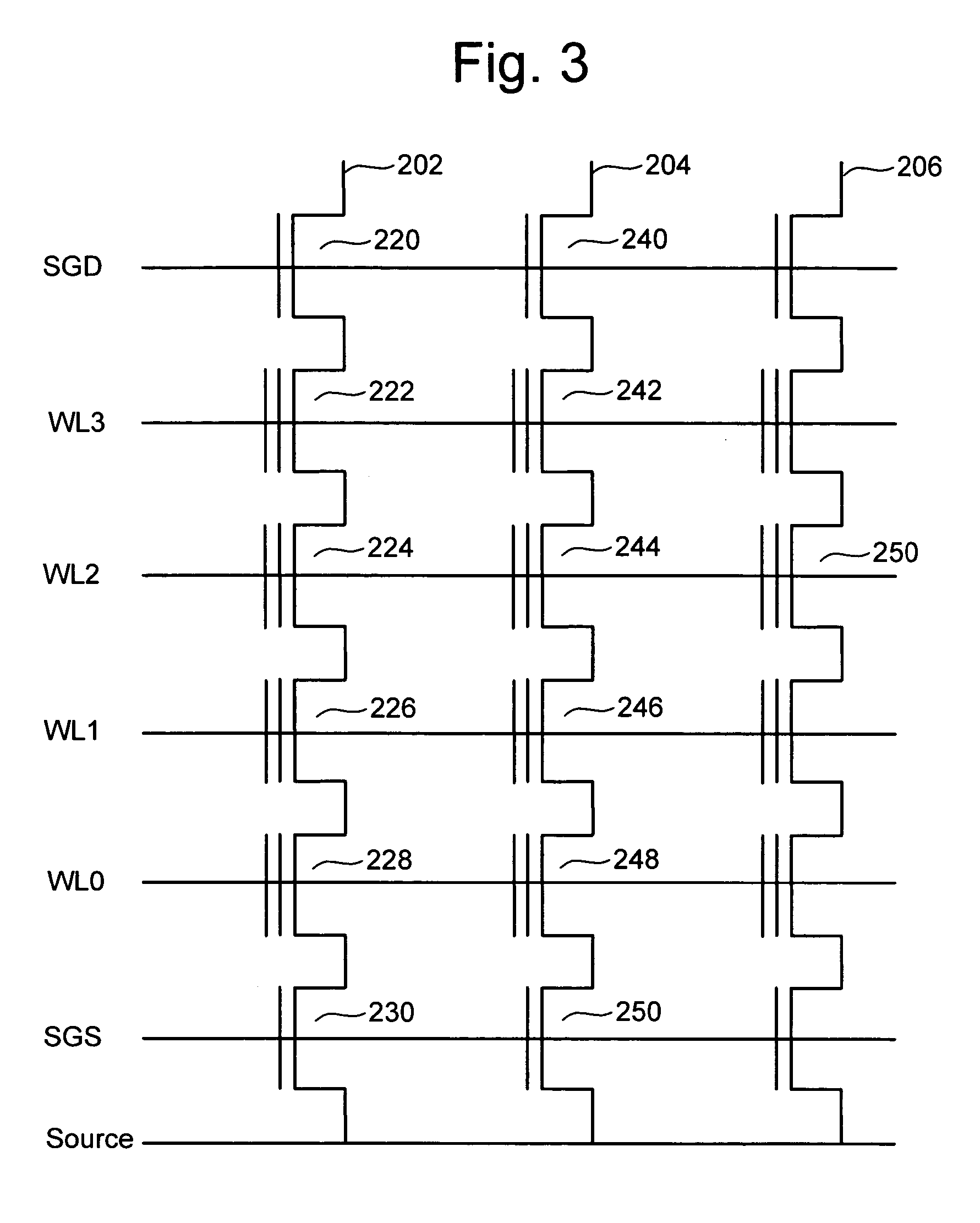

Non-volatile memory with asymmetrical doping profile

InactiveUS20070015332A1Maintain good propertiesImprove leakageSolid-state devicesRead-only memoriesEngineeringDoping profile

Stacked gate structures for a NAND string are created on a substrate. Source implantations are performed at a first implantation angle to areas between the stacked gate structures. Drain implantations are performed at a second implantation angle to areas between the stacked gate structures. The drain implantations create lower doped regions of a first conductivity type in the substrate on drain sides of the stacked gate structures. The source implantations create higher doped regions of the first conductivity type in the substrate on source sides of the stacked gate structures.

Owner:WODEN TECH INC

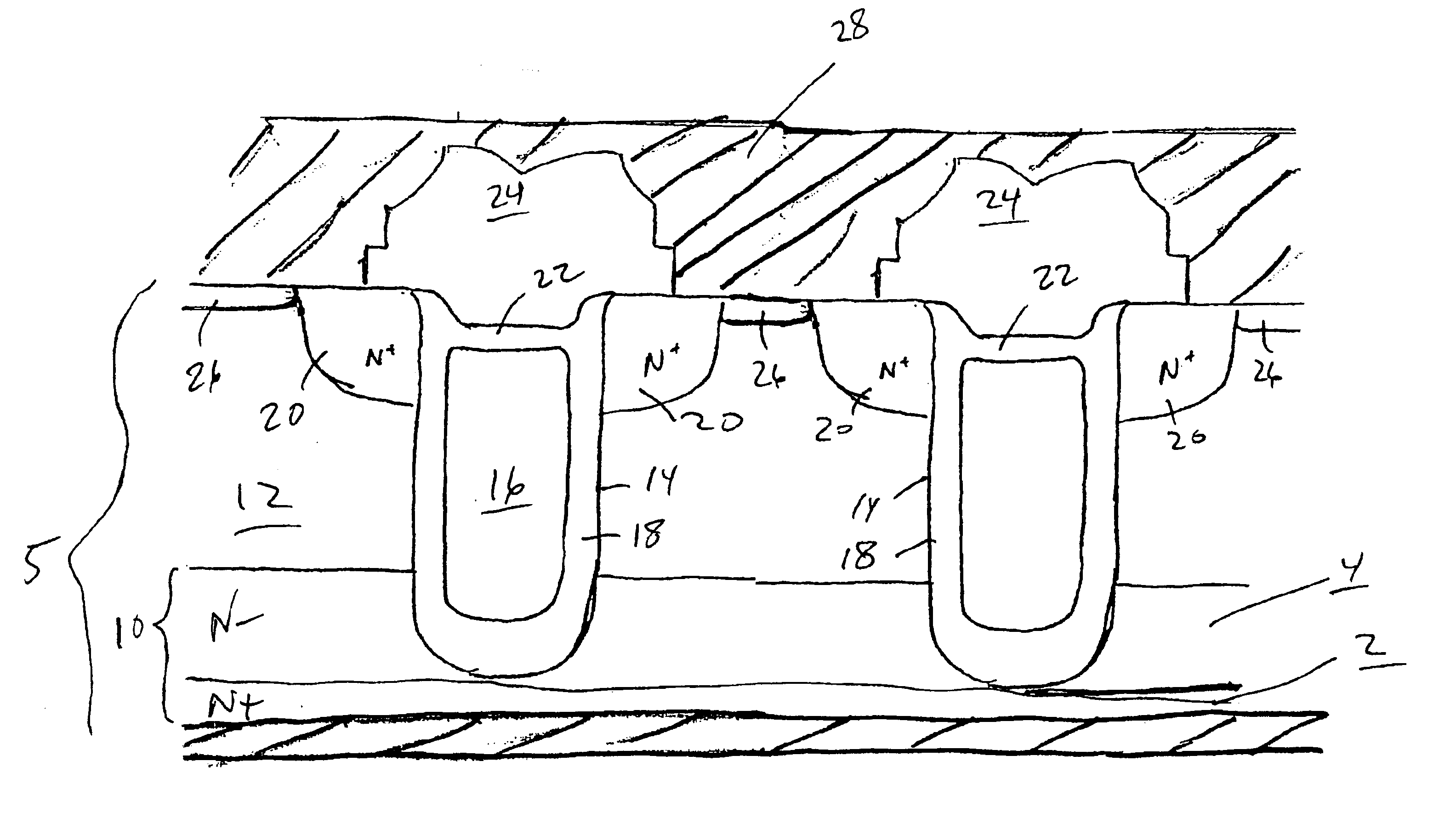

Method for manufacturing a semiconductor device with a trench termination

ActiveUS6921699B2High current capabilityEfficient power supplySemiconductor/solid-state device manufacturingSemiconductor devicesOxideSemiconductor

A process for manufacturing a semiconductor device of the trench variety with reduced feature sizes and improved characteristics which process includes forming a termination structure having a field oxide disposed in a recess below the surface of the semiconductor die in which the active elements of the device are formed, and forming source regions after the major thermal steps have been performed.

Owner:INFINEON TECH AMERICAS

Hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil

ActiveCN104611037AEffectively play an active roleBroaden sources of raw materialsTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenNitrogen

The present invention discloses a hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil. According to the method, poor-quality heavy distillate oil and hydrogen gas enter a first-stage reaction zone to carry out a hydrorefining reaction, the reaction effluent is separated, the obtained liquid enters a second-stage reaction zone to carry out a hydrorefining reaction, the second-stage reaction effluent enters a third-stage reaction zone to carry out a hydrocracking reaction, the hydrocracking effluent is separated, and at least part of the tail oil and new hydrogen are mixed and then are subjected to an isomerizing dewaxing and finishing reaction to obtain various lubricating oil base oils. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the lubricating oil base oil raw material source is broadened; and the hydrorefining temperature is substantially reduced so as to increase the operation period of the device and process the poor-quality raw material, or increase the processing capacity of the device in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

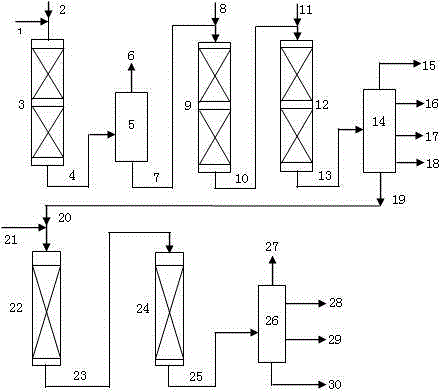

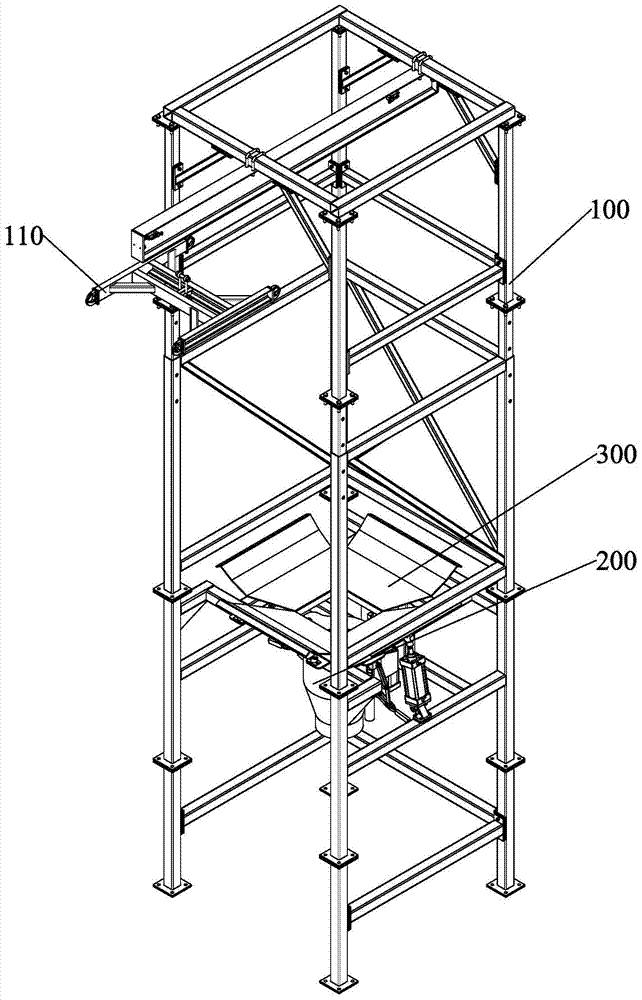

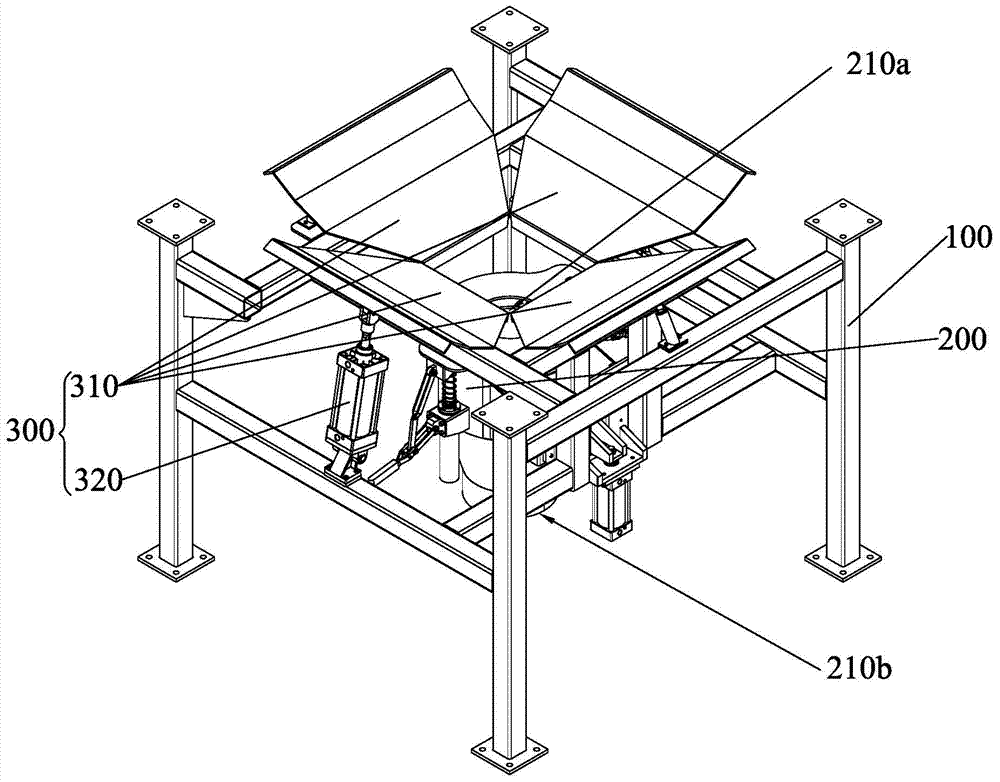

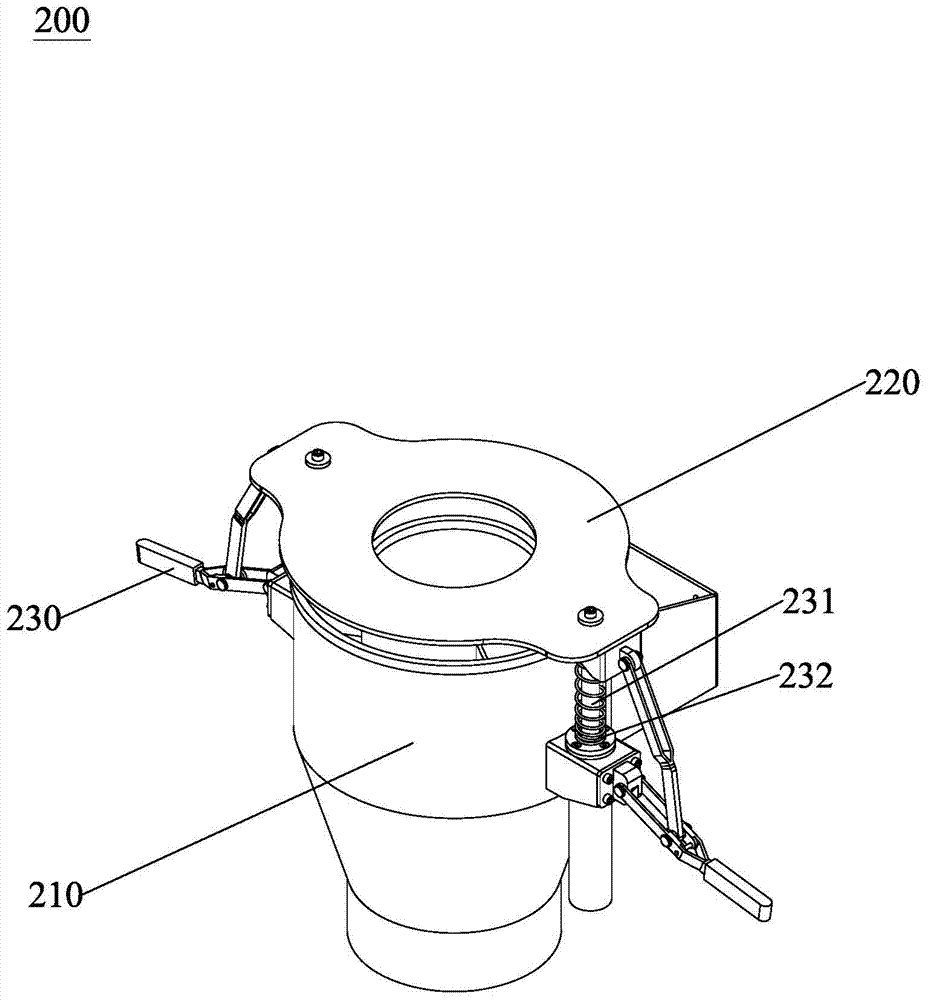

Ton bag unloading mechanism

ActiveCN104326274AConvenient direct unloadingReduce lossesFlexible bulk container emptying systemsBottle emptyingMechanical engineeringTon

The invention discloses a ton bag unloading mechanism. The ton bag unloading mechanism comprises a carrying device and an unloading device, wherein the carrying device is used for bearing ton bags and putting the ton bags above the unloading device; the unloading device comprises a vertically arranged unloading cylinder; the unloading cylinder comprises an outer cylinder and an inner cylinder arranged on the inner side of the outer cylinder in a clearance way; the upper end of the unloading cylinder is provided with a feeding hole of the unloading device; the lower end of the unloading cylinder is provided with a discharge hole of the unloading device; the feeding hole is right opposite to a bag opening of each ton bag. According to the ton bag unloading mechanism, the unloading cylinder is of a double-layer structure with the outer cylinder and the inner cylinder, inner bag openings are positioned in the inner cylinder, outer bag openings are positioned between the inner cylinder and the outer cylinder, and channels for materials in the ton bags with the outside are reduced, so that dust diffusion is reduced and the working environment is effectively improved; meanwhile, dust is settled and recycled, so that the material loss is reduced.

Owner:ONGOAL MATERIAL AUTOMATION EQUIP

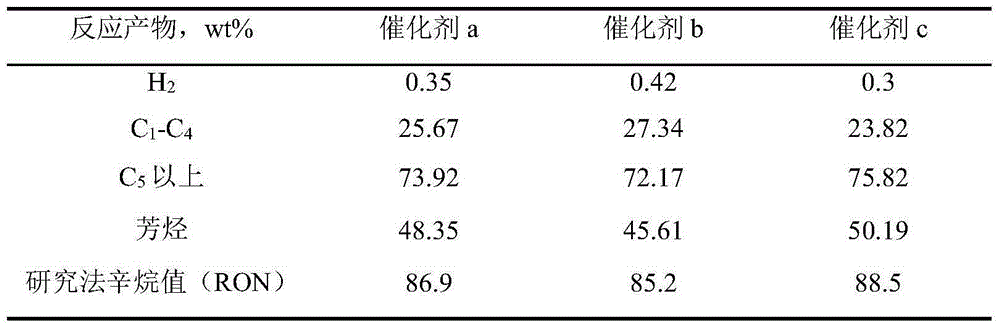

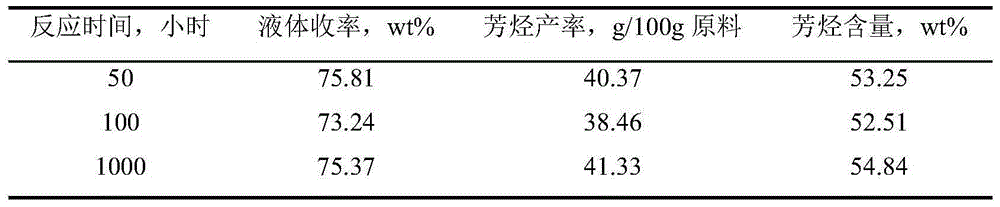

Catalyst for straight-run naphtha aromatization and preparation method thereof

InactiveCN106552663ARegular skeleton structureFast responseMolecular sieve catalystsHigher alkanesNaphtha

The invention discloses a catalyst for straight-run naphtha aromatization and a preparation method thereof. The catalyst for straight-run naphtha aromatization is prepared by modifying a nano ZSM-5 molecular sieve, preparing a carrier and preparing the catalyst. The catalyst is suitable for treating raw materials with high alkane content. And the catalyst has high catalytic activity and high arene selectivity. So the catalyst can be applied to more mild process conditions and can be applied to production of high-octane gasoline blending components and chemical raw materials like benzene, toluene, xylene, etc.

Owner:PETROCHINA CO LTD

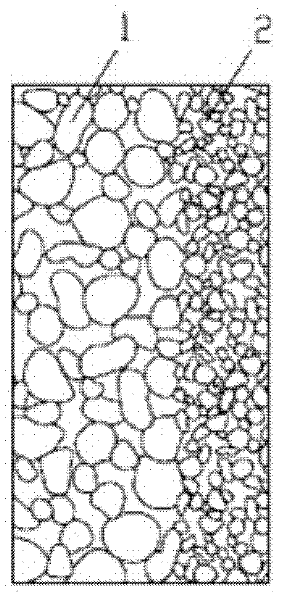

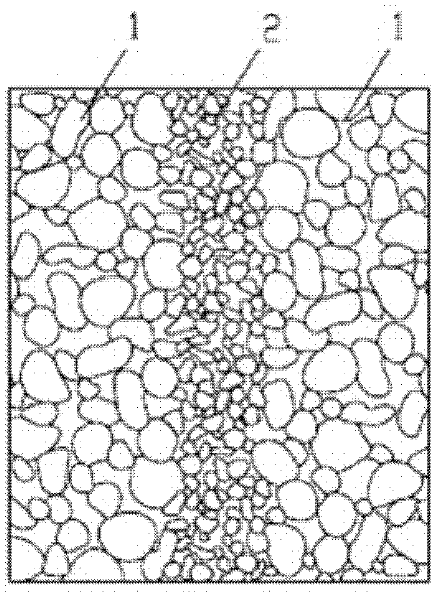

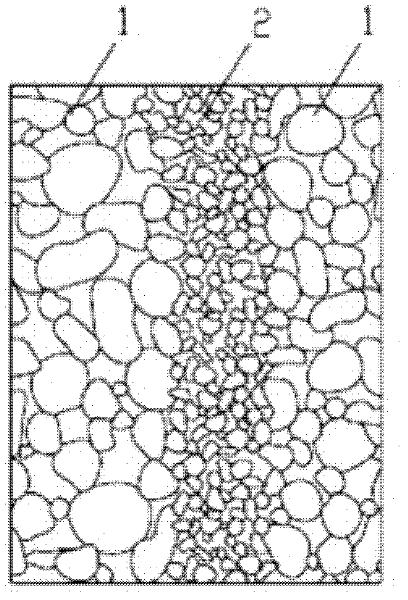

Multi-layer porous polyimide film and preparation method of porous polyimide film

ActiveCN102582138AImprove integrityReduce resistanceSynthetic resin layered productsGranularityPolyamide

The invention provides a multi-layer porous polyimide film and a preparation method of the porous polyimide film. The film comprises a large-hole layer and a small-hole layer or is formed in the way that one small-hole layer is sandwiched between two large-hole layers, wherein the large-hole layer is 0.15-6 microns in hole diameter and 5-100 microns in thickness, and the small-hole layer is 0.01-0.15 microns in hole diameter and 1-5 microns in thickness. The preparation method of the film comprises the following steps of: synthesizing two or three kinds of composite polyamide resin solution, by using dianhydride, diamine and two or three kinds of pore-forming materials with different granularities; carrying out composite salivating to form a two / three-layer film, carrying out two-way stretch and imidization, pickling the film for removing the pore-forming materials, thus obtaining the multi-layer porous polyimide film. The molar ratio of dianhydride to diamine is 1:1, and the mass of the pore-forming materials is 0.25-2 times that of dianhydride and diamine. Various media can conveniently pass through the large-hole layer of the film and the strength of the film is ensured; the small-hole layer can be thinned to 1 micron and the transmittance is good. According to the method, the porosity and hole diameter of all layers in the film can be easily controlled, and the method is suitable for preparing porous film products.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Method for fabricating semiconductor device

ActiveUS20080020525A1Channel shortInhibit swellingSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricDevice material

A method for fabrication a memory having a memory area and a periphery area is provided. The method includes forming a gate insulating layer over a substrate in the periphery area. Thereafter, a first conductive layer is formed in the memory area, followed by forming a buried diffusion region in the substrate adjacent to the sides of the first conductive layer. An inter-gate dielectric layer is then formed over the first conductive layer followed by forming a second conductive layer over the inter-gate dielectric layer. A transistor gate is subsequently formed over the gate insulating layer in the periphery area.

Owner:MACRONIX INT CO LTD +1

Partial external prestressed and fine-grain reinforcing steel bar fiber reinforced cementitious composite (FRCC) railway box girder

The invention discloses a partial external prestressed and fine-grain reinforcing steel bar fiber reinforced cementitious composite (FRCC) railway box girder. The partial external prestressed and fine-grain reinforcing steel bar FRCC railway box girder comprises a hollow beam frame body consisting of a top plate and a webplate, wherein the top plate and the webplate are made from an FRCC material; an anchoring toothed plate and an anchoring diaphragm plate are symmetrically arranged on the two sides of the center in the hollow beam frame body; an anchor is arranged on the anchoring toothed plate; a diverter is arranged on the anchoring diaphragm plate; an external prestressed rib is arranged between the anchoring toothed plate and the anchoring diaphragm plate; and one end of the external prestressed rib is fixed on the anchor, and the other end of the external prestressed rib is fixed in the diverter. At the same time, an external prestressed technique has the advantages that: the partial external prestressed and fine-grain reinforcing steel bar FRCC railway box girder is convenient to construct, detect and change; and the friction loss of the prestressed rib is low, and the like. The webplate of the box girder is shrunk; the strength of the materials used by the box girder is improved; and the FRCC is used for substituting the conventional C50-grade concrete, the bearing capacity of the girder body is not reduced but increased, so that the box girder has an extremely wide application prospect.

Owner:SOUTHEAST UNIV +1

Method for fabricating non-volatile memory

InactiveUS20080064158A1Expansion of the buried diffusion region is preventedChannel shortSolid-state devicesSemiconductor/solid-state device manufacturingTrappingVolatile memory

A method for fabrication a memory having a memory area and a peripheral area includes forming a first gate insulating layer with a first thickness over a substrate of a first region in the peripheral area and a second insulating layer with a second thickness over the substrate of the memory region. Thereafter, a buried diffusion region is formed in the substrate of the memory area. A charge trapping layer and a third insulating layer are formed over the substrate. A gate insulating layer is formed in the second region in the peripheral area, wherein the first thickness is greater than a second thickness after removing the charge trapping layer and third insulating layer on the first and second region in the peripheral area. A conductive layer is formed over the substrate of the memory area and the peripheral area substantially after the gate insulating layer is formed.

Owner:MACRONIX INT CO LTD

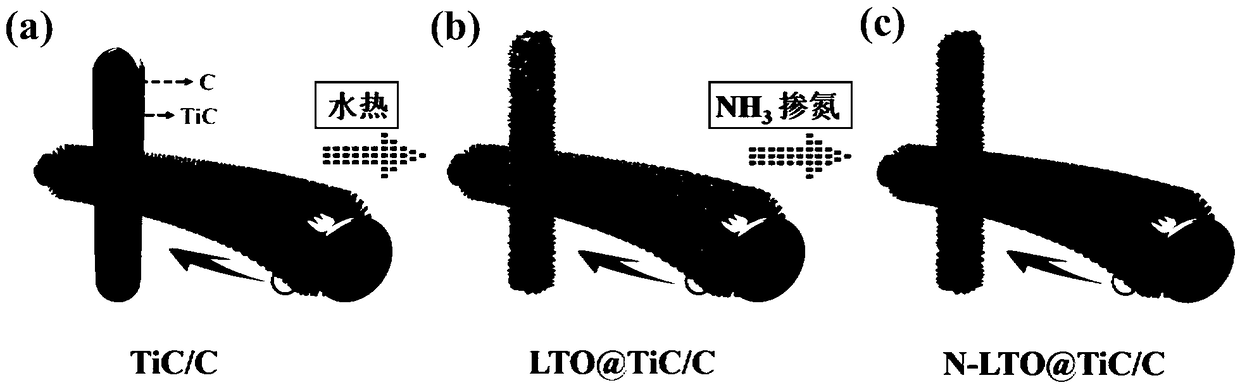

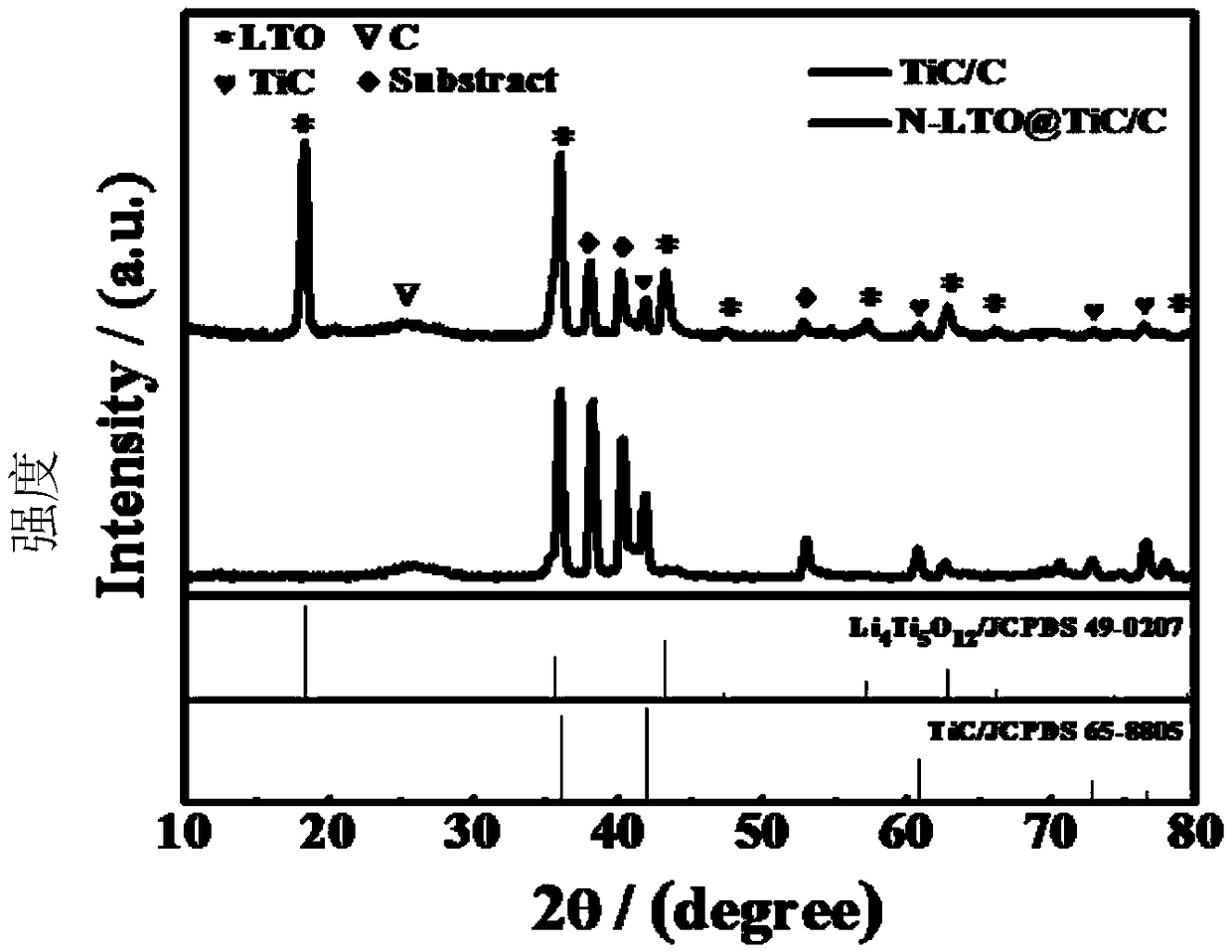

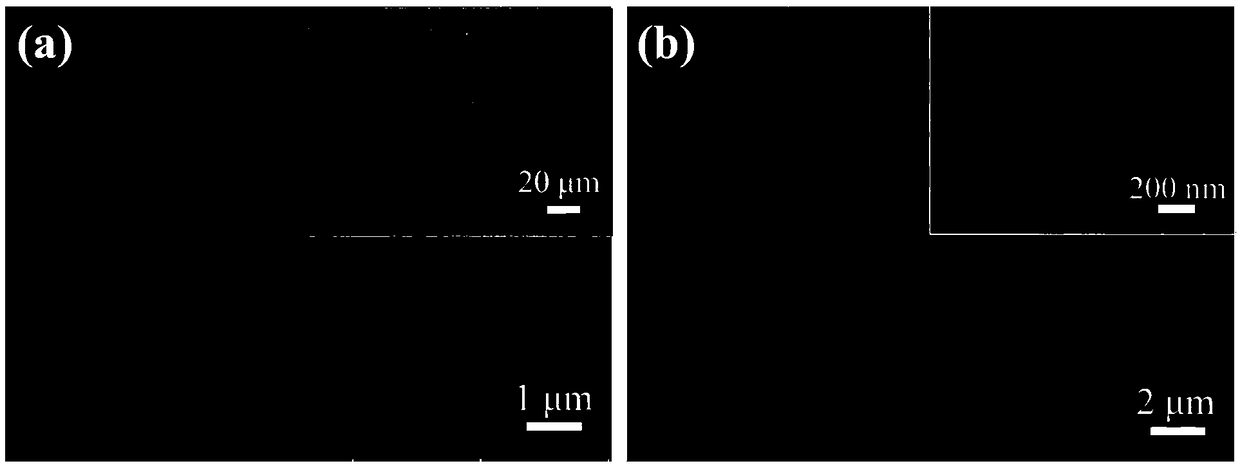

Titanium carbide/carbon core-shell nanowire array load nitrogen-doped lithium titanate composite material, preparation method and application thereof

ActiveCN108649189ALarge specific surface areaImprove conductivityMaterial nanotechnologyCell electrodesTitanium carbideLithium electrode

The invention discloses a titanium carbide / carbon core-shell nanowire array load nitrogen-doped lithium titanate composite material, a preparation method and application thereof. The method comprisesthe following steps: using an atomic layer deposition technology to grow aluminum oxide on a titanium mesh; using a chemical vapor deposition technology to grow a titanium carbide / carbon core-shell nanowire core-shell array (TiC / C) on the titanium mesh; then putting the titanium carbide / carbon core-shell nanowire array composite material in a solution to carry out a hydrothermal reaction, and thencarrying out washing, drying and calcinations to obtain LTO@TiC / C; and finally using an ammonia gas nitrating technology to nitrate the LTO@TiC / C composite array to obtain N-LTO@TiC / C. The constructed composite material, as a negative electrode material for lithium ion batteries, has excellent high rate capability and super long cycle life.

Owner:ZHEJIANG UNIV

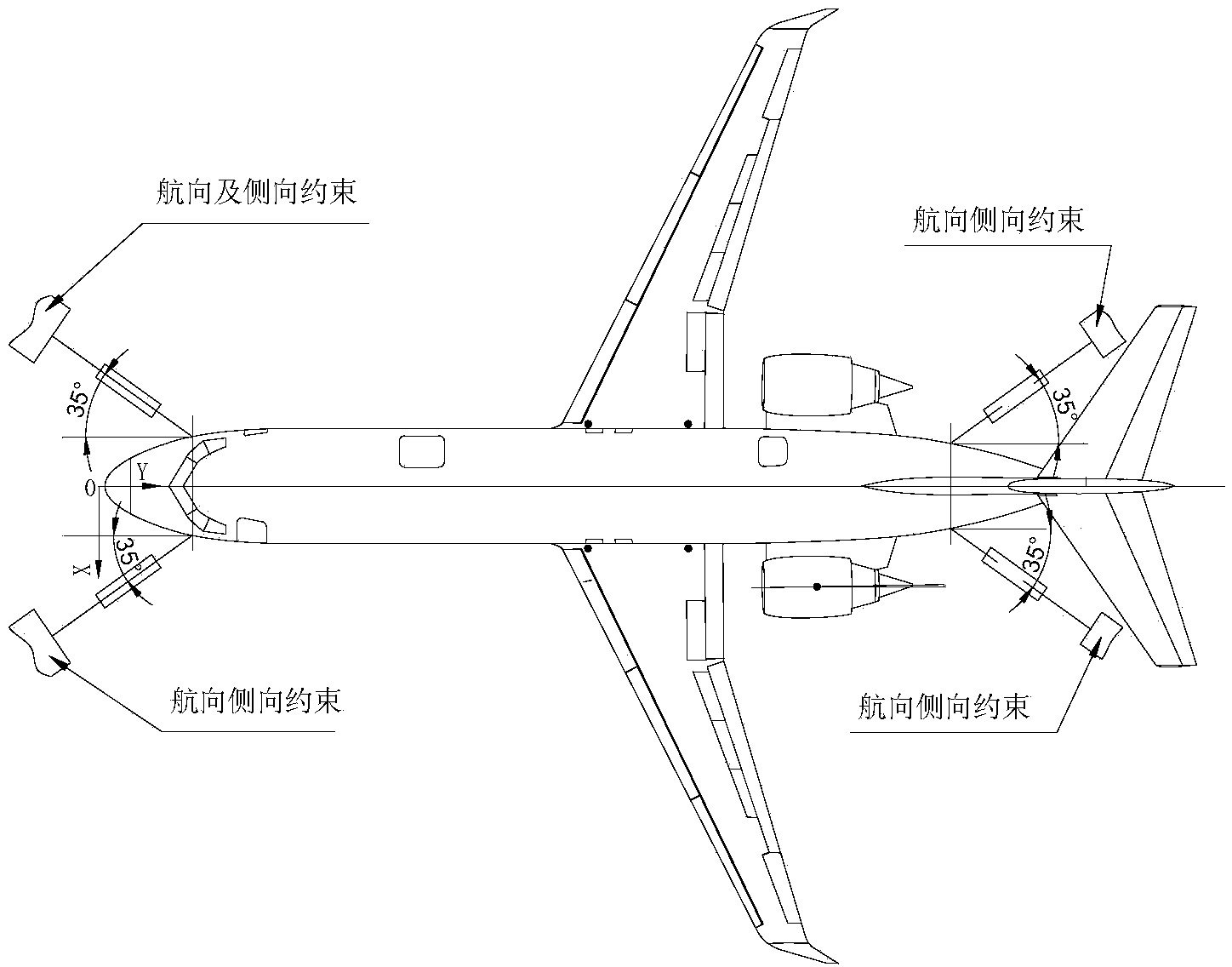

Included angle constraining method for full-scale fatigue test

ActiveCN103625653AAvoid squeezingReduce distanceAircraft components testingFixation pointShortest distance

The invention belongs to an aircraft testing constraining technology and particularly relates to an included angle constraining method for a full-scale fatigue test. According to the included angle constraining method for the full-scale fatigue test, four inclined constraints are symmetrically arranged on 1 to 2 strong frame sites of a forebody and a rear fuselage of an aircraft; and the angle of each inclined constraint relative to the heading is 35 degrees. According to the invention, the heading, the lateral displacement and the yaw moment are effectively constrained; an adhesive tape in a load direction is avoided being squeezed; and moreover, the distance from each constraint point and a fixed point is short and in a conventional method, a fuselage needs to be bypassed, but the short-distance setting of the constrain points can avoid influence of the weight of connecting pieces on a constraint load. In addition, the included angle constraining method is simple in installation, is convenient to operate and control, is passage-saving, is low in cost and has high practical application value.

Owner:CHINA AIRPLANT STRENGTH RES INST

Rubber tree wind-preventing wind-resisting planting method

InactiveCN103988754AReduce wind speedImprove wind resistanceForestryHorticultureFertilizerHigh yielding

The invention discloses a rubber tree wind-preventing wind-resisting planting method and relates to the technical field of planting. The rubber tree wind-preventing wind-resisting planting method comprises the steps that (A), rubber trees are planted, wherein the good-quality rubber tree varieties which are resistant to wind and high in yield are selected to be planted at the plant line spacing of 3 m*7 m; (B), interplanting tree varieties are selected and planted, wherein good-quality wind-resisting tree varieties such as michelia macclurei, mytilaria laosensis, tea-oil trees and mahoganies are inteplanted between the lines of the rubber trees, the row spacing is 3 m, the interplanting trees are crossed to be shaped like a Chinese character 'pin', and the interplanting trees and the rubber trees are planted in a triangular shape; (C), woodland work management measures are adopted, wherein the management of the rubber trees are executed by reference to rubber tree cultivation technical regulations, the local environmental climate and rubber garden production and management relevant regulations; wind-preventing wind-resisting tree interplanting meets the general requirements of pruning and shaping, rouging and after-replacement, additional fertilizer application and the like. According to the rubber tree wind-preventing wind-resisting planting method, the whole wind-resisting ability of the rubber garden can be effectively improved, more effective tapping rubber trees are reserved, the ecological benefits of the rubber garden are improved, and the whole production benefits of the rubber are improved.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

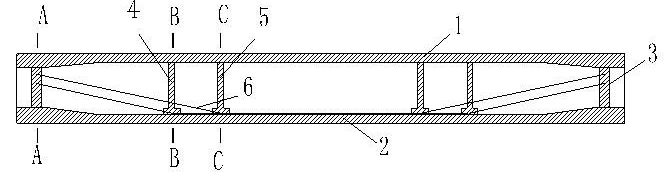

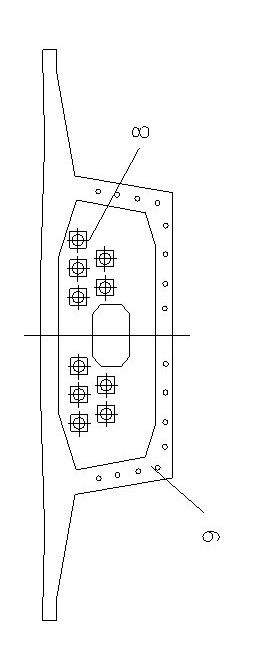

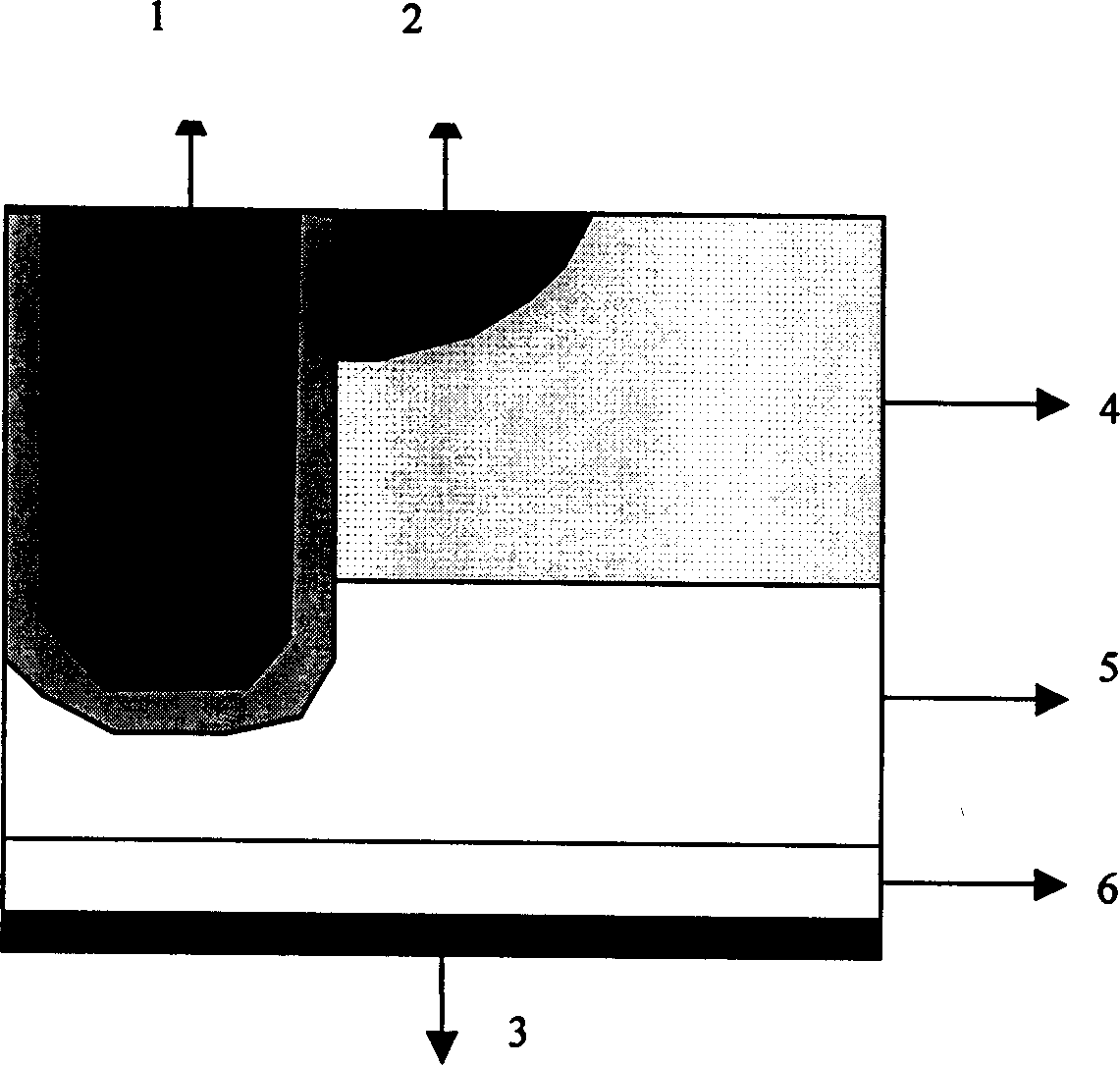

Vertical high-power field-effect transistor unit structure

InactiveCN1450657ASmall unit areaHigh pressureSemiconductor/solid-state device manufacturingSemiconductor devicesUnit structureSilicon chip

This invention relates to a vertical N channel MOS high-power field-effect transistor structure applying etching channel method on N silicon epitaxial chip to make grating oxygen layer of the fieldistor and W grating electrode in the channel of the silicon epitaxial film, W grating and silicon chip are vertical on the surface, when the fieldistor in working condition, the current flows from the drain of the silicon chip bottom through an inversion channel zone to get to the source vertical to silicon chip surface.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

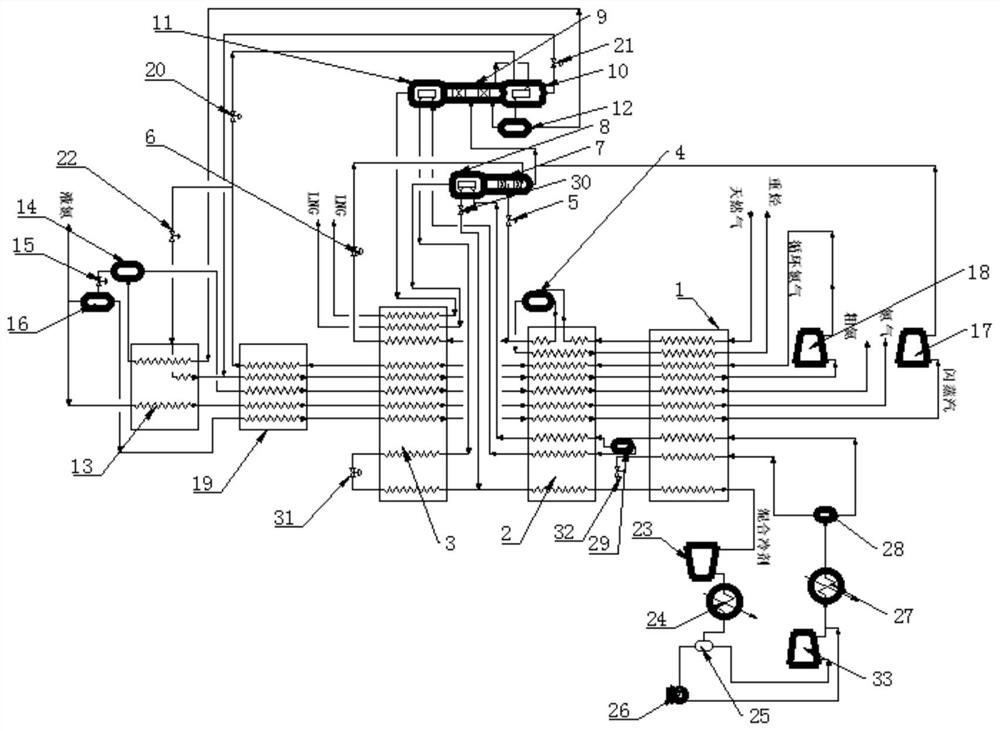

High-nitrogen-content and high-helium-content natural gas liquefaction and crude helium and nitrogen extraction system

PendingCN112066642AImprove extraction efficiencyEmission reductionSolidificationLiquefactionNitrogen gasControl valves

The invention discloses a high-nitrogen-content and high-helium-content natural gas liquefaction and crude helium and nitrogen extraction system and belongs to the technical field of extraction systems. The high-nitrogen-content and high-helium-content natural gas liquefaction and crude helium and nitrogen extraction system comprises a crude helium condenser. The crude helium condenser respectively communicates with a second liquid nitrogen throttle valve, a liquid nitrogen subcooler, a crude helium separator and a demethanizer condensation separator. The crude helium separator respectively communicates with a liquid nitrogen subcooler and a first liquid nitrogen throttle valve, the other end of the first liquid nitrogen throttle valve communicates with a flash steam separator, the flash steam separator communicates with the liquid nitrogen subcooler, and the liquid nitrogen subcooler communicates with a liquid nitrogen evaporation pressure control valve. The other end of the liquid nitrogen evaporation pressure control valve communicates with a demethanizer condenser. Natural gas is little diffused, the helium extraction efficiency is high, meanwhile, nitrogen in the natural gas is extracted to produce liquid nitrogen and nitrogen products, and the economic benefits are good.

Owner:四川空分集团工程有限公司

Method for producing propene for C4 and more olefin catalytic cracking

InactiveCN1274645CIncreased diffusion resistanceSize diffusion resistanceChemical recyclingHydrocarbon by hydrocarbon crackingMolecular sievePeriod problem

The invention relates to a kind of method for manufacturing propylene by catalytic cracking alkene of no less than tetra carbon, which mainly solves the short catalyst regeneration period problem and the stability problems uninvolved in previous technique. The invention uses minor crystalline grain and molecular sieve with high silicon-aluminium ratio as the catalyst for catalytic cracking with alkene that no less than tetra carbon to manufacture propylene. According to the technique scheme that described above, the invention can solve the problems mentioned above excellently, and can be used in industrial production of manufacturing propylene by catalytic cracking with alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

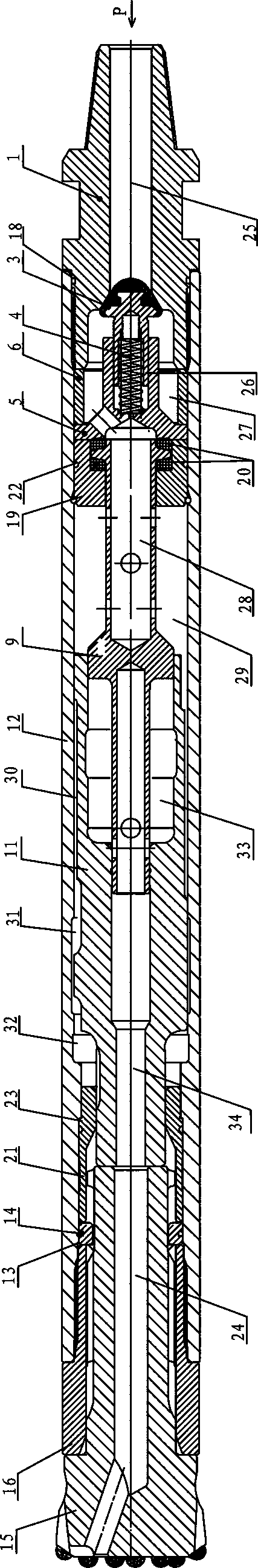

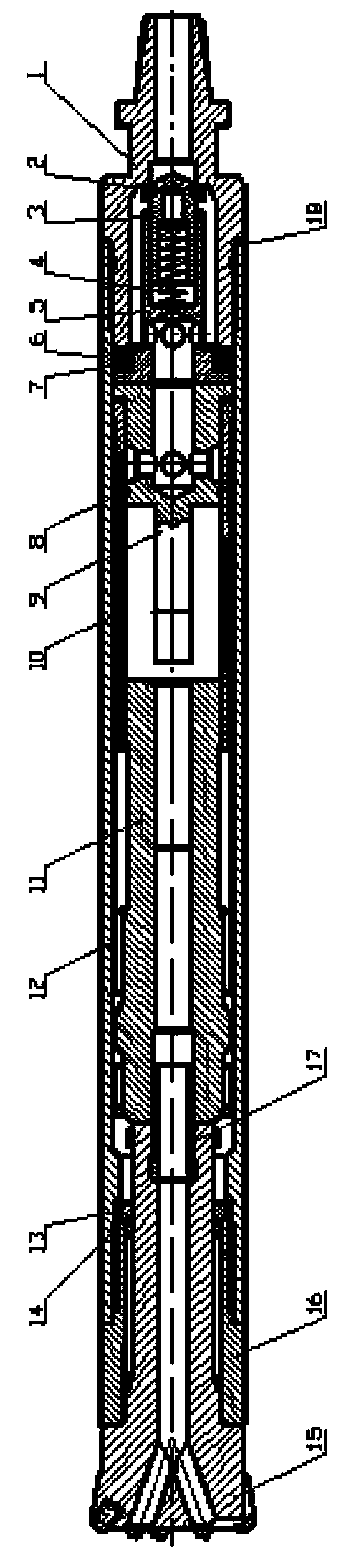

Efficient down-hole hammer

InactiveCN103375131AReliable connectionGuaranteed stability and efficiencyBorehole drivesPistonDrill bit

An efficient down-hole hammer comprises a back joint, a check valve, an air distribution rod, a piston, a cylinder, a clamping ring, a drill head and a front joint. The check valve is a one-way valve and comprises a valve seat, a spring and a steel washer. The slotted piston is provide with a hole, a positioning sleeve is arranged at the back end of a valve end cover, and the air distribution rod, a positive vibration-proof rubber ring and a negative vibration-proof rubber ring are clamped in the positioning sleeve together. The efficient down-hole hammer is not provided with an inner cylinder structure, the air distribution mode is greatly innovated, a vibration-proof fine tuning device arranged between the back joint and the air distribution rod can effectively absorb counterforce of piston motion, the air distribution rod can be subjected to automatic fine tuning so as to keep the assembling verticality, the adaptive drill head is not provided with a tail pipe, and therefore high pressure air leakage is reduced, work efficiency is improved and production cost is reduced. In addition, the piston has a reliable service life.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

Method for preparing porous carbon material from allyl wastes and application

ActiveCN108557819ALow ashImprove wettabilityCarbon compoundsHybrid capacitor electrodesPorous carbonHeating temperature

The invention discloses a method for preparing a porous carbon material from allyl wastes and application. The preparation method comprises the following steps: S1, heating and carbonizing the allyl wastes in an inert atmosphere, wherein the carbonizing temperature is 400-800 DEG C, and the carbonizing time is 80-150 min; S2, carrying out acid pickling on the product prepared in step S1, and washing the product until the product is neutral; S3, dipping the product prepared in step S2 in a chemical activating agent; and S4, heating and activating the product prepared in step S3, wherein the heating temperature is 700-900 DEG C, and the time is 60-140 min; and carrying out acid pickling, washing and drying to obtain an allyl waste porous carbon electrode material. The method is high in professional applicability, a design process is simple, and industrialization is easy to realize. While the porous carbon material is prepared, the allyl wastes are utilized at high quality, and an obtained porous carbon super-capacitor is excellent in performance.

Owner:SHANDONG UNIV

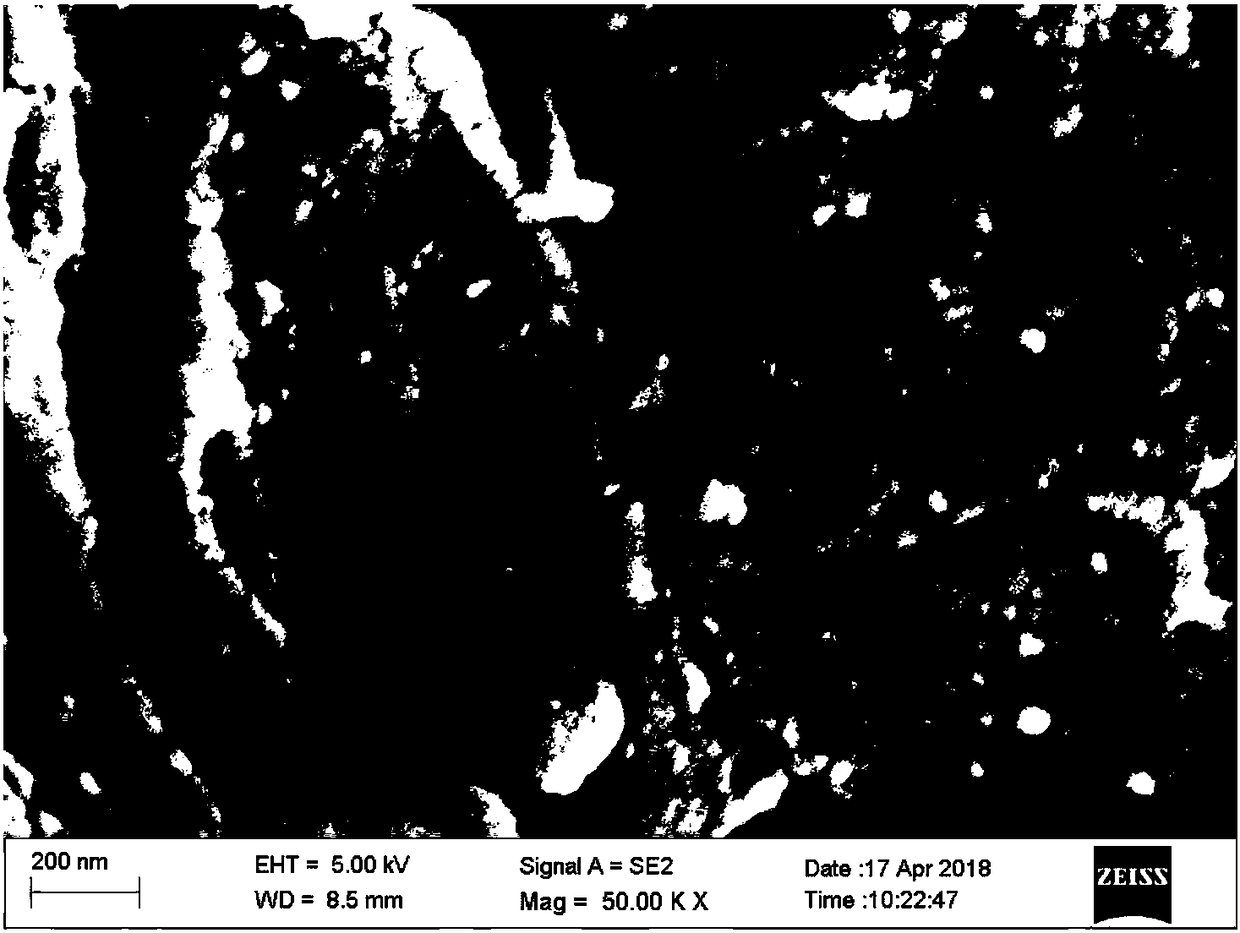

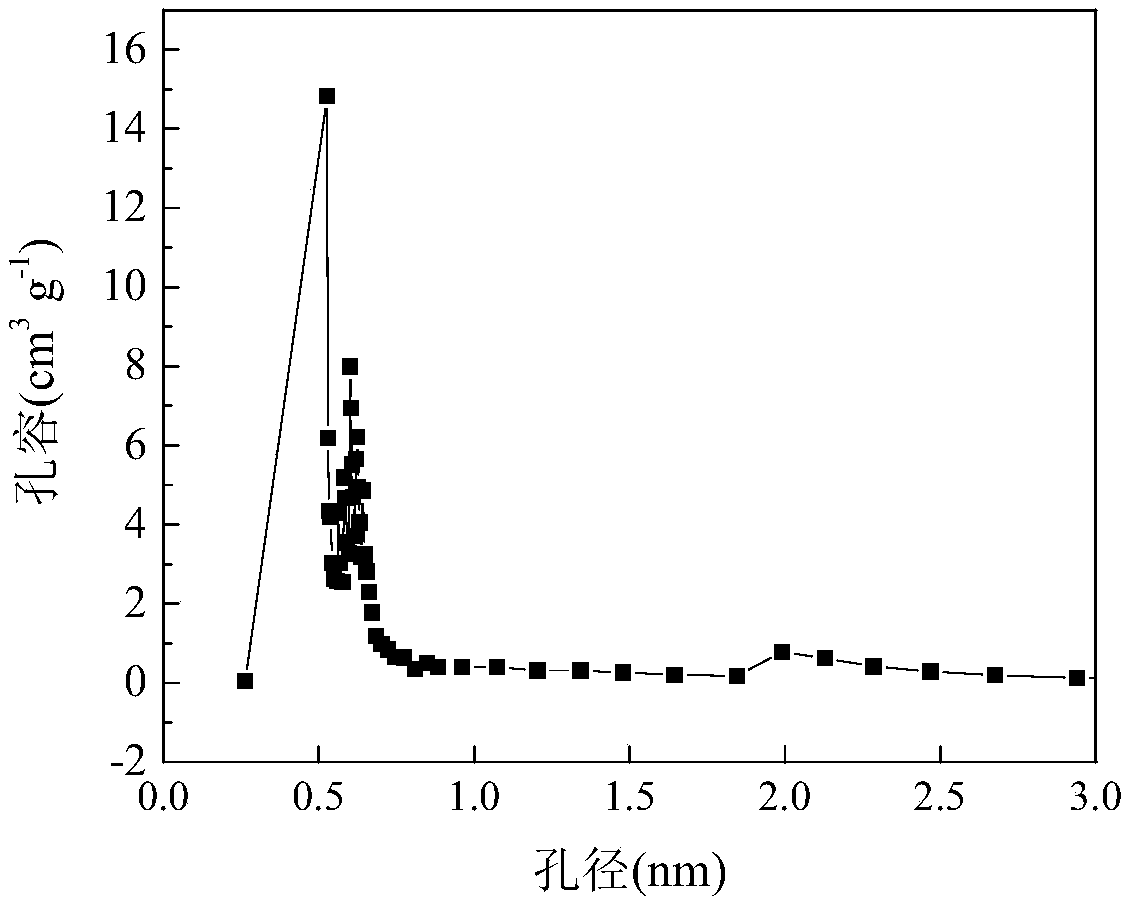

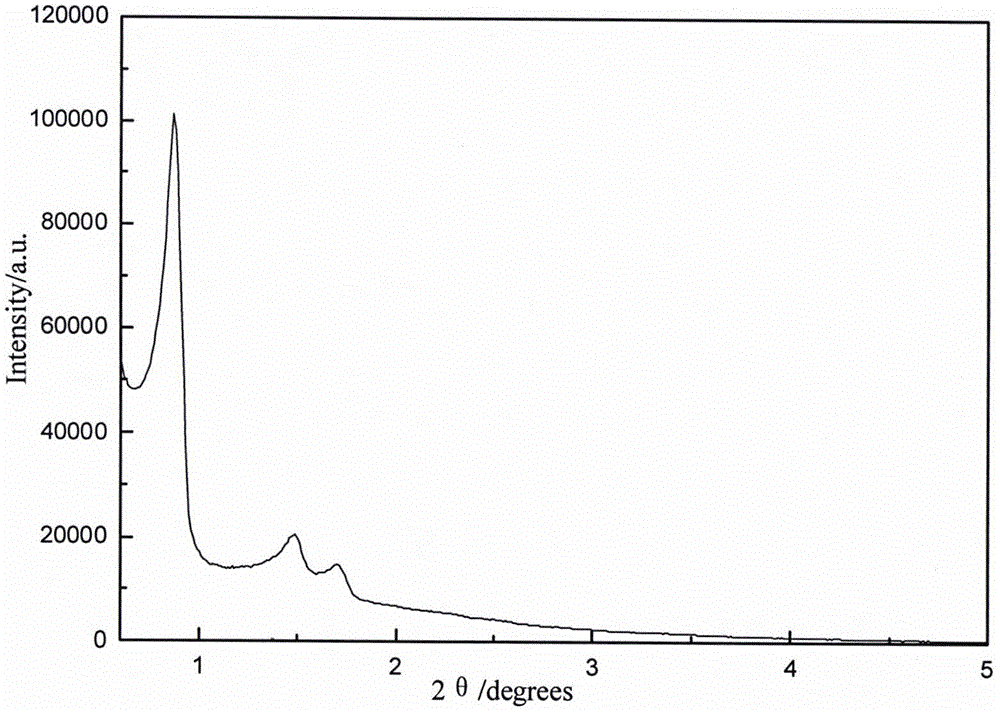

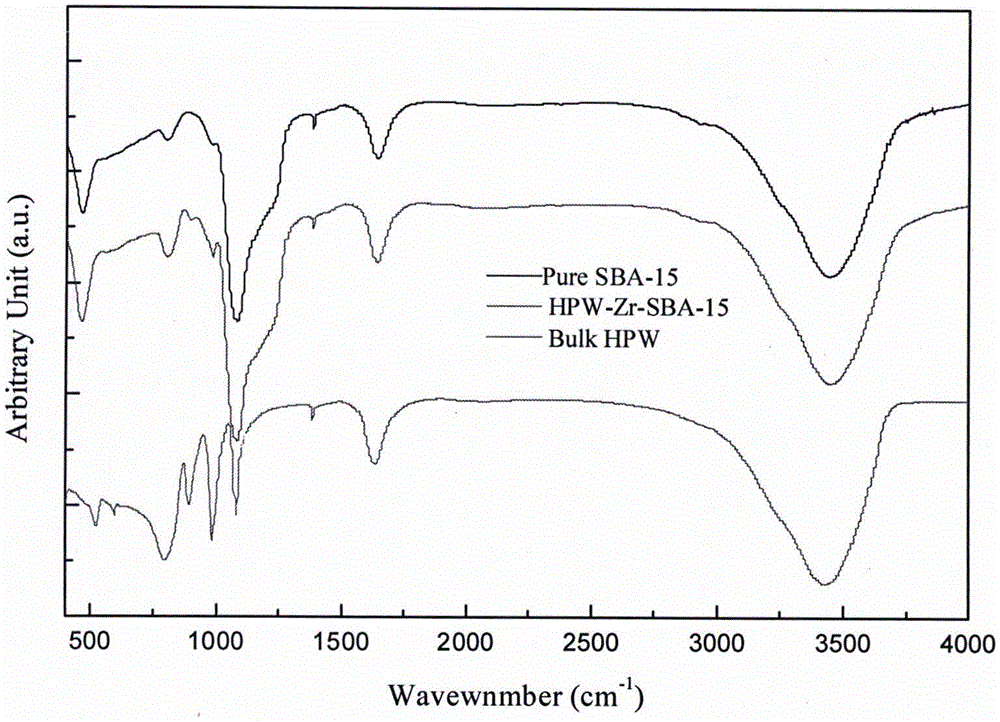

Method for synthesizing bisphenol-F with catalysis of phosphotungstic acid modified short channel HPW-Zr/SBA-15 catalyst

InactiveCN105566069AChannel shortShort reaction timeOrganic chemistryMolecular sieve catalystsPolyethylene oxideZirconium oxychloride

The invention discloses a method for synthesizing bisphenol-F with the catalysis of phosphotungstic acid modified short channel HPW-Zr / SBA-15 catalyst. According to the method, the bisphenol-F is catalytically synthesized by taking the phosphotungstic acid modified short channel HPW-Zr / SBA-15 as a catalyst and taking phenol and formaldehyde as raw materials. The adopted catalyst is synthesized through a one step method by taking polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) as a template, taking tetraethylortho silicate as a silicon source, taking phosphotungstic acid as a catalyst active component, and taking zirconium oxychloride as a modifying agent, and is simple in preparation process, short in channel, favourable to improve the mass transfer and reaction efficiency, high in reaction activity, short in reaction time, high in catalytic efficiency, easy to separate, reusable, green and environment-friendly; any organic solvent is not required to be added in the reaction process.

Owner:XIANGTAN UNIV

Non-volatile memory with asymmetrical doping profile

InactiveUS7294882B2Maintain good propertiesImprove leakageTransistorSolid-state devicesDoping profileNon-volatile memory

Stacked gate structures for a NAND string are created on a substrate. Source implantations are performed at a first implantation angle to areas between the stacked gate structures. Drain implantations are performed at a second implantation angle to areas between the stacked gate structures. The drain implantations create lower doped regions of a first conductivity type in the substrate on drain sides of the stacked gate structures. The source implantations create higher doped regions of the first conductivity type in the substrate on source sides of the stacked gate structures.

Owner:WODEN TECH INC

Aromatization modifying catalyst for catalytic gasoline and preocess

InactiveCN1290977CHigh yieldReduce carbon depositionRefining to change hydrocarbon structural skeletonLanthanideRare earth

Owner:CHINA PETROLEUM & CHEM CORP +1

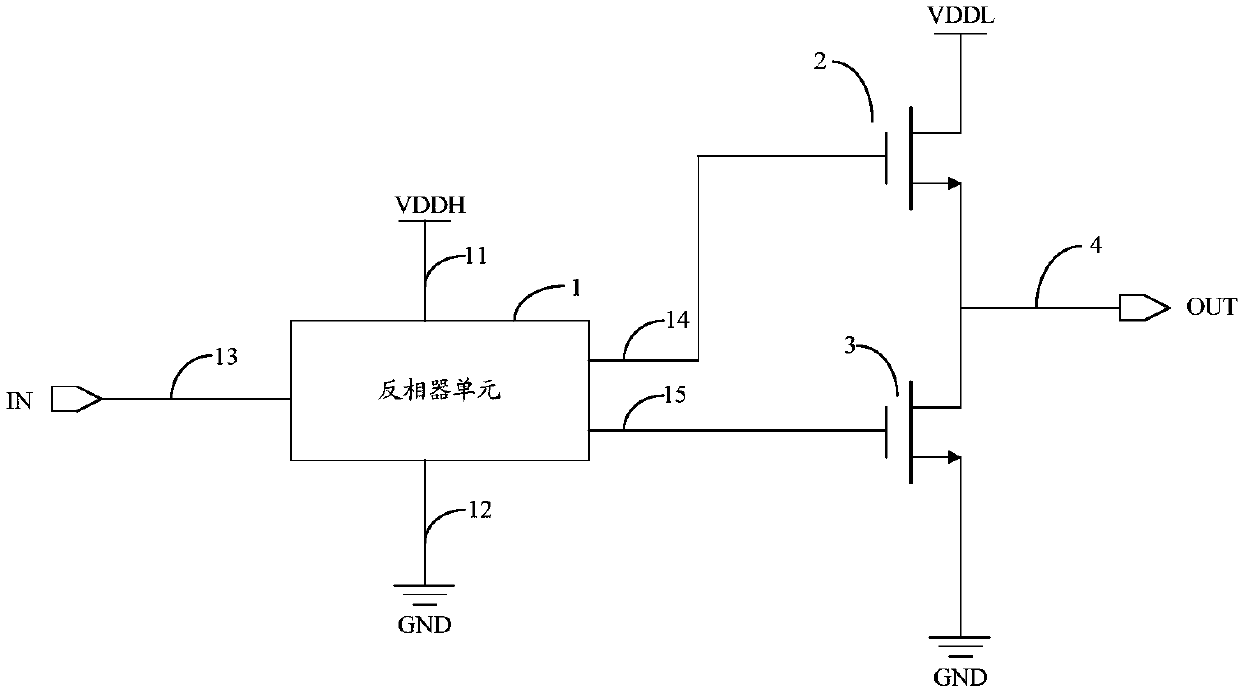

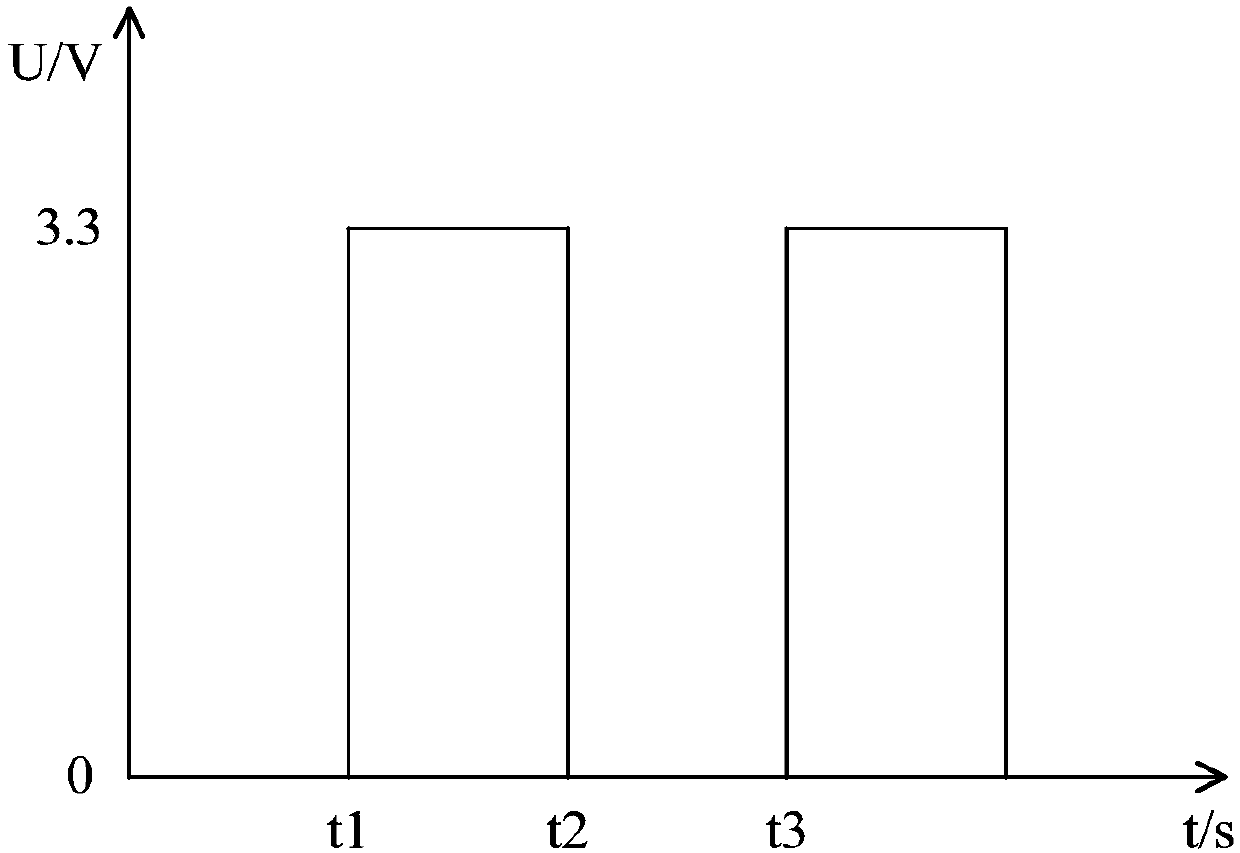

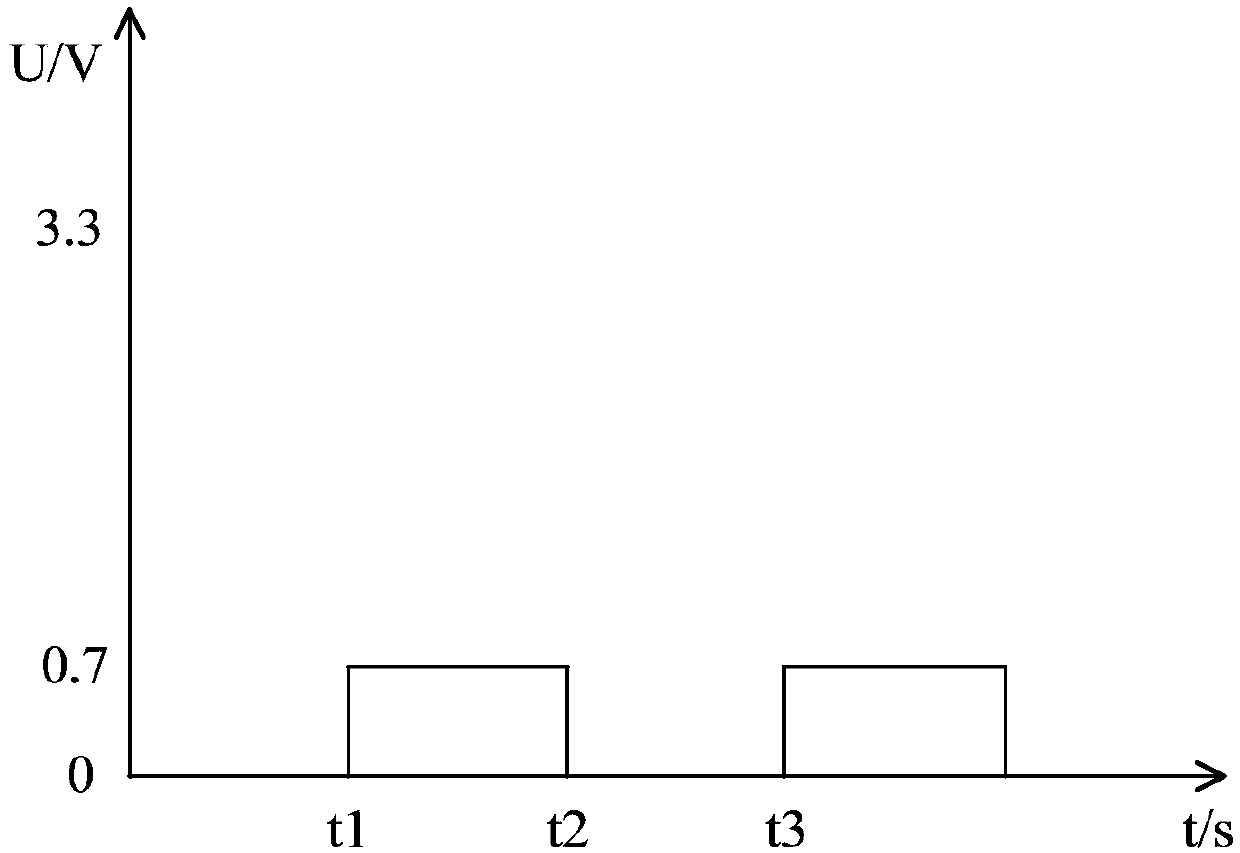

Level conversion circuit, integrated circuit chip and electronic device

ActiveCN108055033AGuaranteed to workTurn fasterLogic circuits coupling/interface using field-effect transistorsThreshold voltageIntegrated circuit

The invention provides a level conversion circuit, an integrated circuit chip and an electronic device. The level conversion circuit comprises an inverter unit, a first NMOS transistor and a second NMOS transistor, the inverter unit comprises a power input end used for receiving a first voltage; a signal input end used for receiving a pulse signal having a logic high level equal to the first voltage; an inverted output end; the drain of the first NMOS transistor is for receiving a second voltage, and the gate is connected with an in-phase output end; the gate of the second NMOS transistor is connected with the inverted output end, and the source is grounded; and a voltage difference between the first voltage and the logic low level in the pulse signal is greater than a threshold voltage ofthe PMOS transistor in the inverter unit, and the difference between the first voltage and the second voltage is greater than the threshold voltage of the first NMOS transistor. Compared with the prior art, no matter how low the second voltage is, the MOS transistors in the level conversion circuit provided by the invention can be rapidly turned on, and the circuit can work normally and effectively.

Owner:上海顺久电子科技有限公司

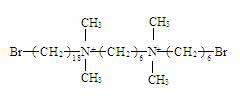

Method for preparing MFI catalyst carrying transition elements and MFI catalyst application

InactiveCN102380412AAvoid inactivationHigh activityMolecular sieve catalystsDispersed particle separationNucleationSodium silicate

Disclosed are a method for preparing an MFI catalyst carrying transition elements and MFI catalyst application. Cationic gemini surfactant- dibromide-1-(dimethyl hexyl ammonium)-6-(dimethyl octodecyl ammonium) hexane is used as structure directing agent of the MFI catalyst, sodium silicate is used as a silicon source and is subjected to low-temperature hot crystallization under self-generated pressure in a rotationally dynamic manner, and after directional polycondensation, rearrangement, nucleation and growth of inorganic atom Si-Al-Na-O on a two-dimensional plane, and single-structure-cell nano-layer MFI catalytic materials which are in mesoporous and microporous structure with the thickness ranging from 2 nanometers to 5 nanometers only are synthetized. Activity center point number of the MFI catalyst is increased evidently by utilizing two-dimensional single-structure-cell nano MFI carrying transition elements of Fe and Mo, the thickness of the catalyst crystal is reduced effectively, diffusion path is shortened, and molecular diffusion is speeded up. In addition, according to the result of a test of utilizing the selective catalytic reduction (SCR) process to remove tail gas of automobiles, NOx removal rate reaches 99.5%.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com