Multi-layer porous polyimide film and preparation method of porous polyimide film

A technology of polyimide film and multi-layer structure, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of low service life, low film strength, poor reliability, etc., and achieve resistance Small, holistic, and easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

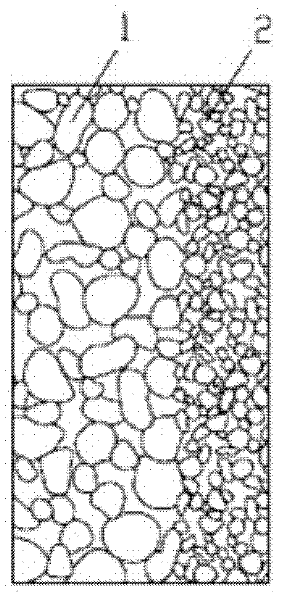

[0034] This example is a double-layer structure porous polyimide film, such as figure 1 Shown consists of one layer of macroporous polyimide layer 1 and one layer of small hole polyimide layer 2 .

[0035] The pores contained in the macroporous polyimide layer 1 have an average pore diameter of 3 microns and a thickness of 50 microns, and the pores contained in the small-porous polyimide layer 2 have an average pore diameter of 0.10 microns and a thickness of 3 microns.

Embodiment 2

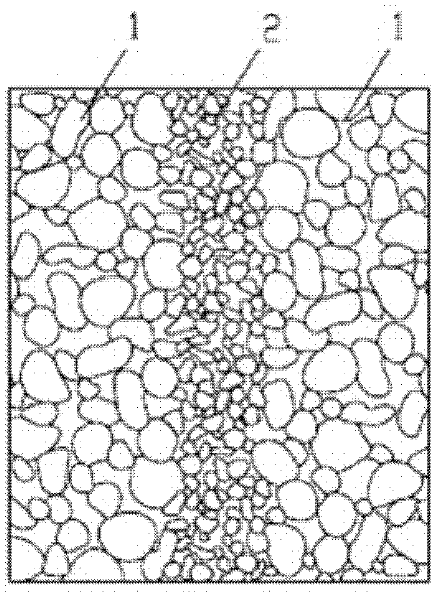

[0037] This example is a three-layer structure porous polyimide film, such as figure 2 As shown, it consists of two layers of macroporous polyimide layer 1 sandwiching a layer of small hole polyimide layer 2.

[0038] The macroporous polyimide layer 1 of two outer layers wherein is identical, and the average pore diameter of the hole contained in it is 5 microns, and the thickness is 30 microns, and the average pore diameter of the hole contained in the small-porous polyimide layer 2 is 0.01 micron, The thickness is 1 micron.

Embodiment 3

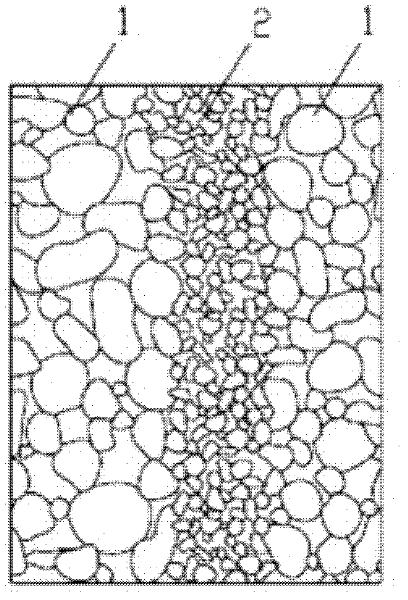

[0040] This example is a three-layer structure porous polyimide film, such as image 3 As shown, it consists of two layers of macroporous polyimide layer 1 sandwiching a layer of small hole polyimide layer 2.

[0041] The macroporous polyimide layer 1 of two outer layers wherein is different, and the average aperture diameter of wherein one layer contains is 4 microns, and thickness is 30 microns, and the average aperture diameter that another layer contains is 0.5 microns, and thickness is 20 microns. micron, the pores contained in the small-porous polyimide layer 2 have an average pore diameter of 0.05 micron and a thickness of 2 micron.

[0042] Example 1 of the Manufacturing Method of Multilayer Porous Polyimide Film

[0043] This example is the manufacturing method of the above-mentioned multilayer structure porous polyimide film embodiment 1

[0044] Specific steps are as follows:

[0045] I. Preparation

[0046] Weigh two spare parts,

[0047] The first is:

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com