Partial external prestressed and fine-grain reinforcing steel bar fiber reinforced cementitious composite (FRCC) railway box girder

A technology of in vitro prestressed, fine-grained steel bars, used in bridges, bridge materials, bridge construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

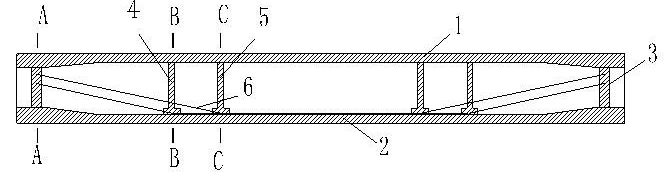

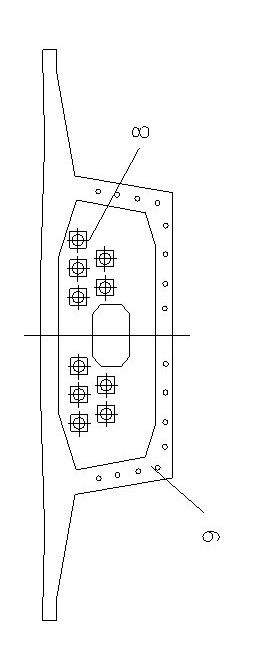

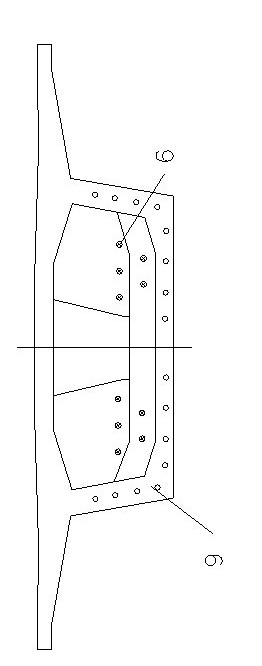

[0018] Below in conjunction with accompanying drawing, the present invention is described in detail, as figure 1 As shown, part of the external prestressed and fine-grained steel FRCC railway box girder of the present invention includes a hollow beam frame composed of a top plate 1 and a web 2, wherein the top plate 1 and the web 2 are made of FRCC materials, and the center of the hollow beam frame is An anchor tooth plate 3 and two anchor diaphragms are arranged symmetrically on both sides, and 10 external prestressed tendons 6 are anchored on the anchor tooth plate 3 through anchors 8, and the other ends of four of them are fixed on the first anchor diaphragm 4, the other 6 are fixed on the second anchor diaphragm 5 with the external prestressed tendons 6, and the external prestressed tendons 6 are turned by the diverter 7, see figure 2 , 3 and 4, of which 9 are prestressed tendons in the body.

[0019] The structural diagram of steering gear 7 is shown in Figure 5 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com