Patents

Literature

36results about How to "Bearing area reduced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

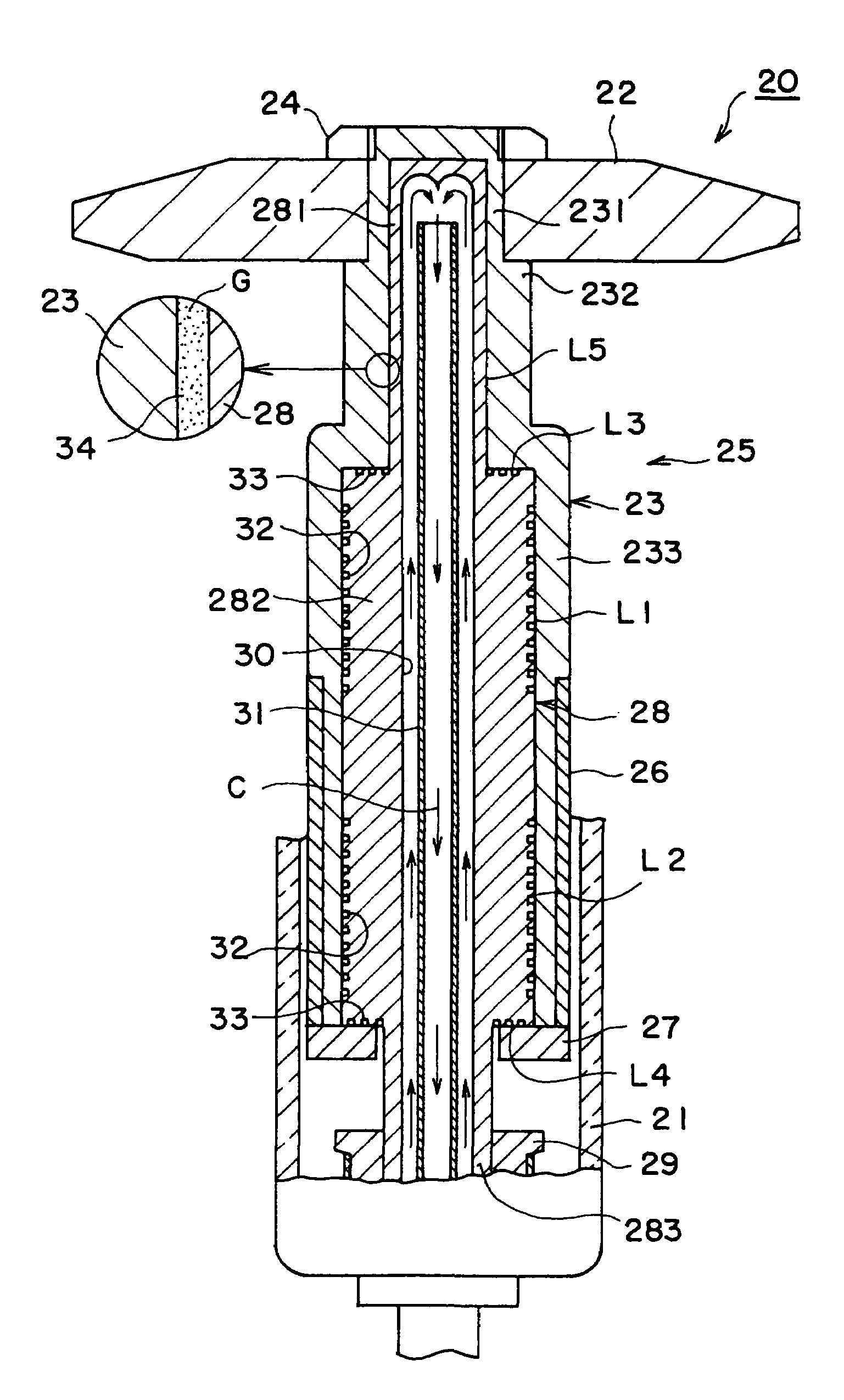

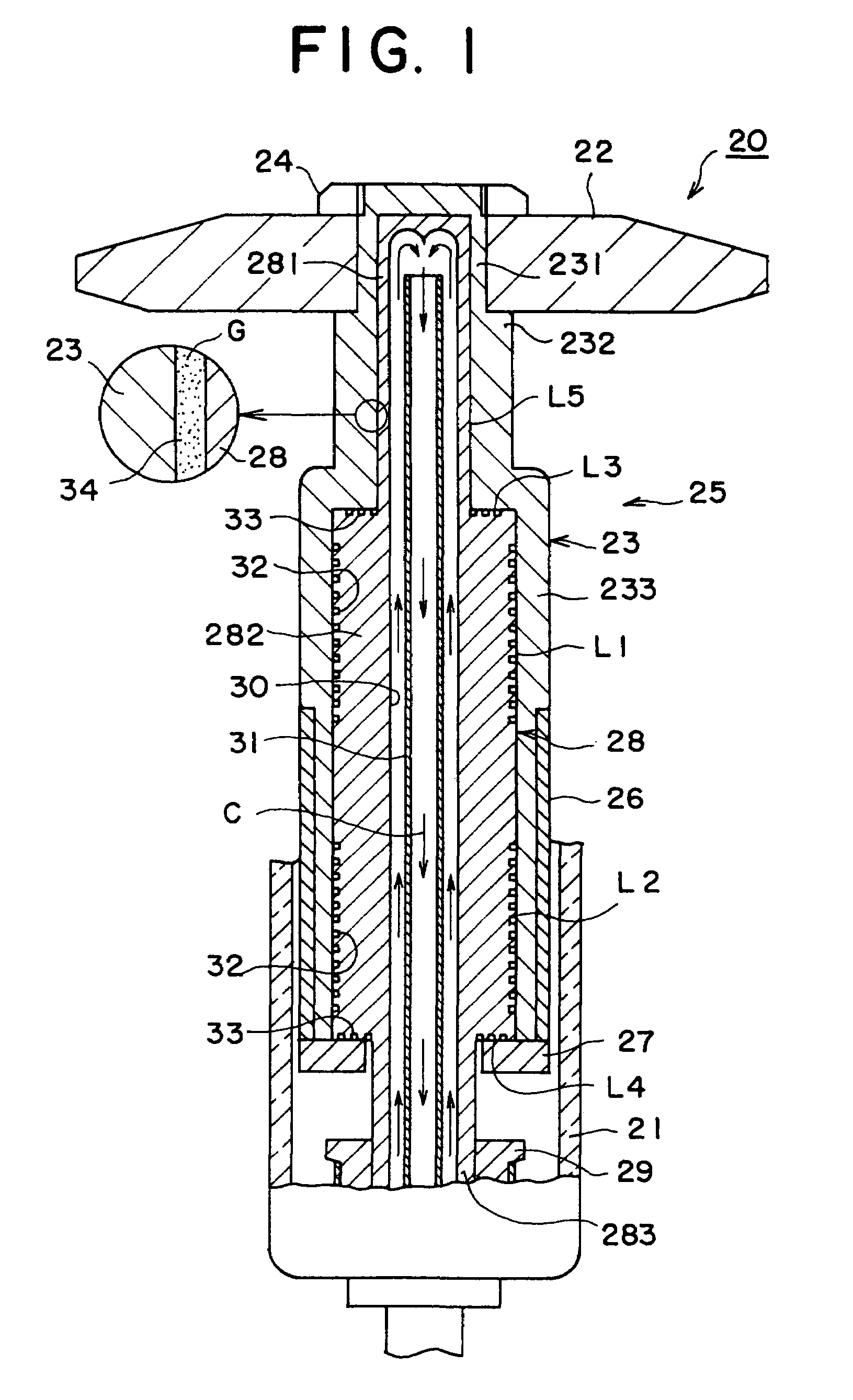

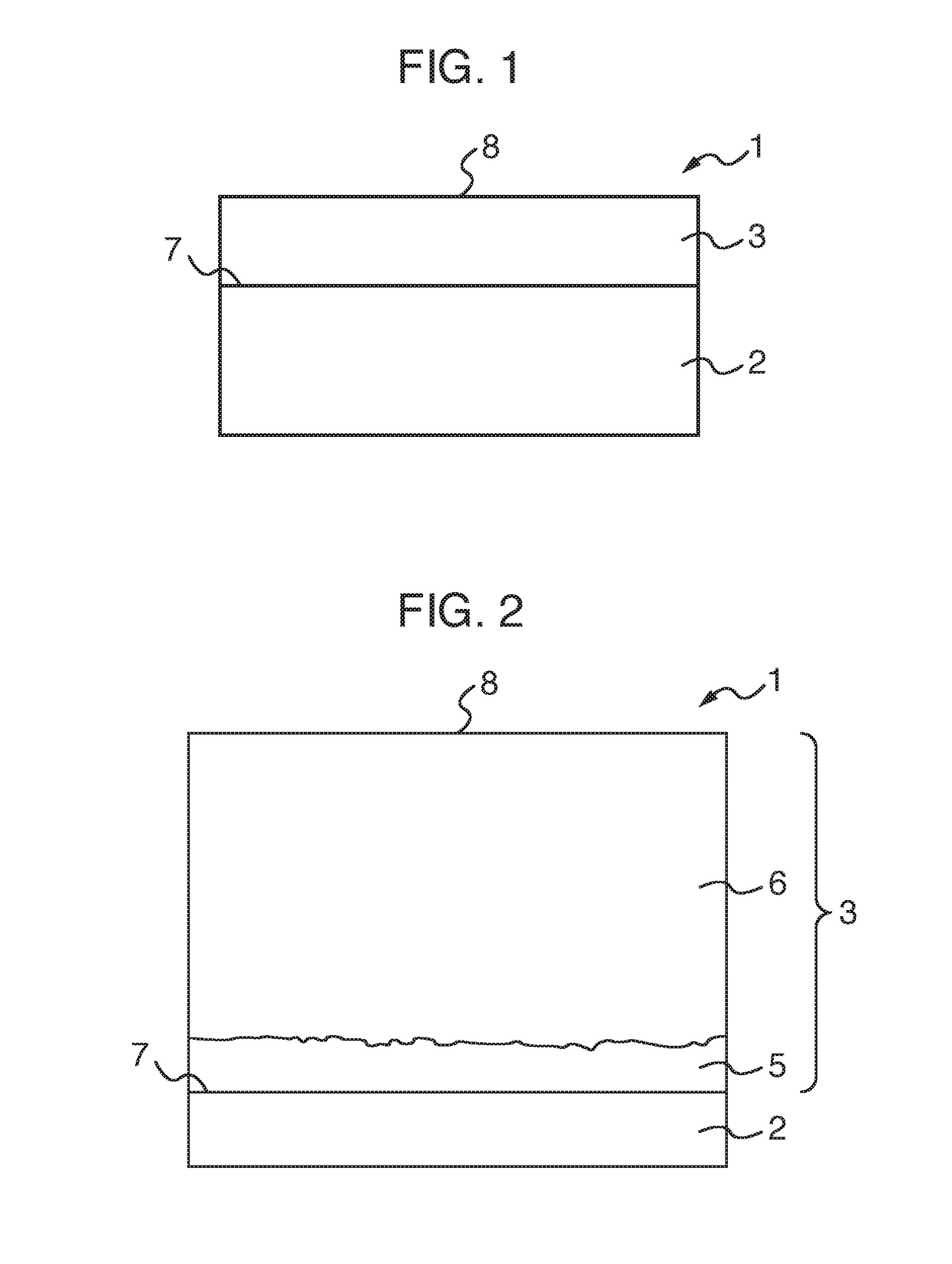

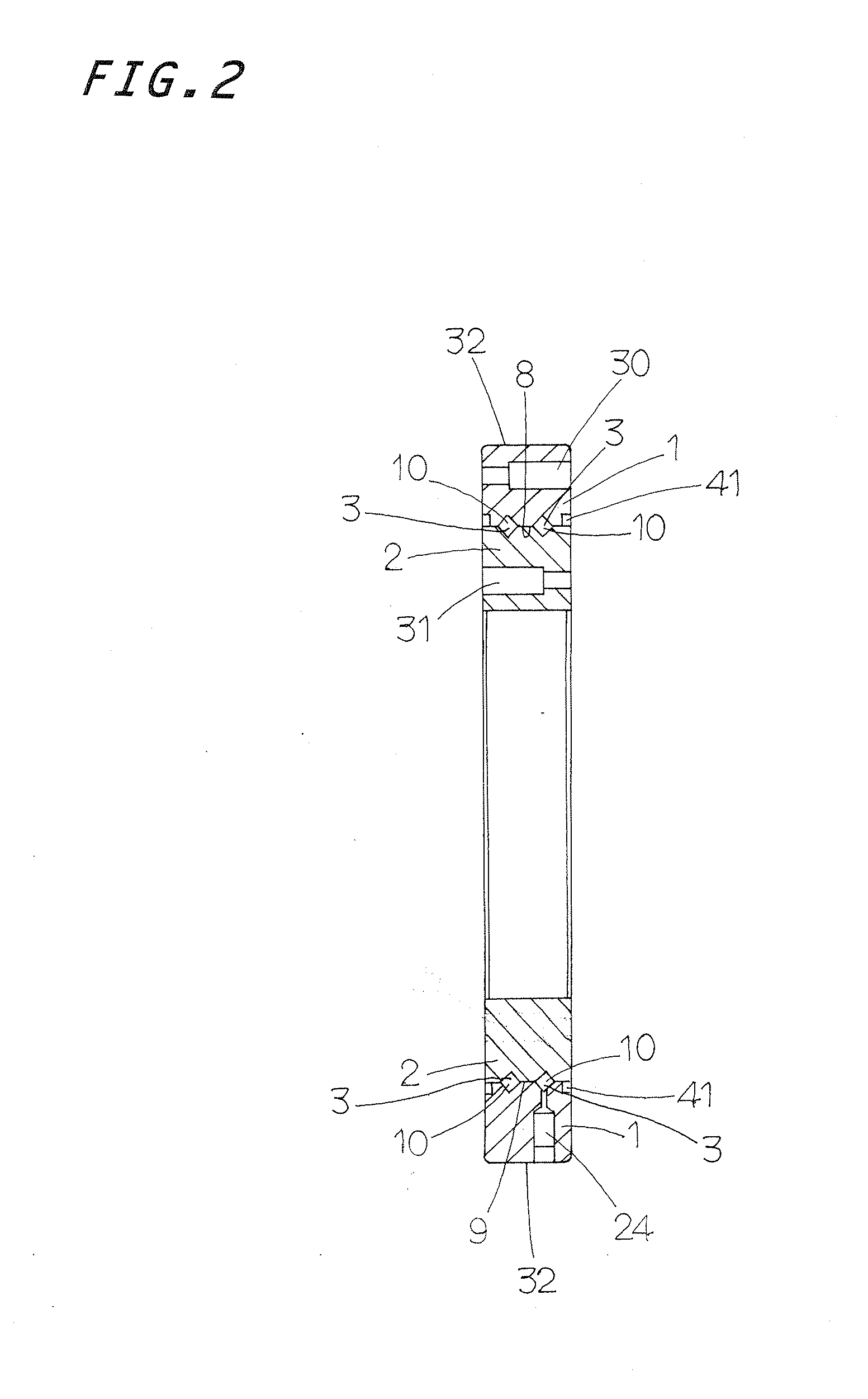

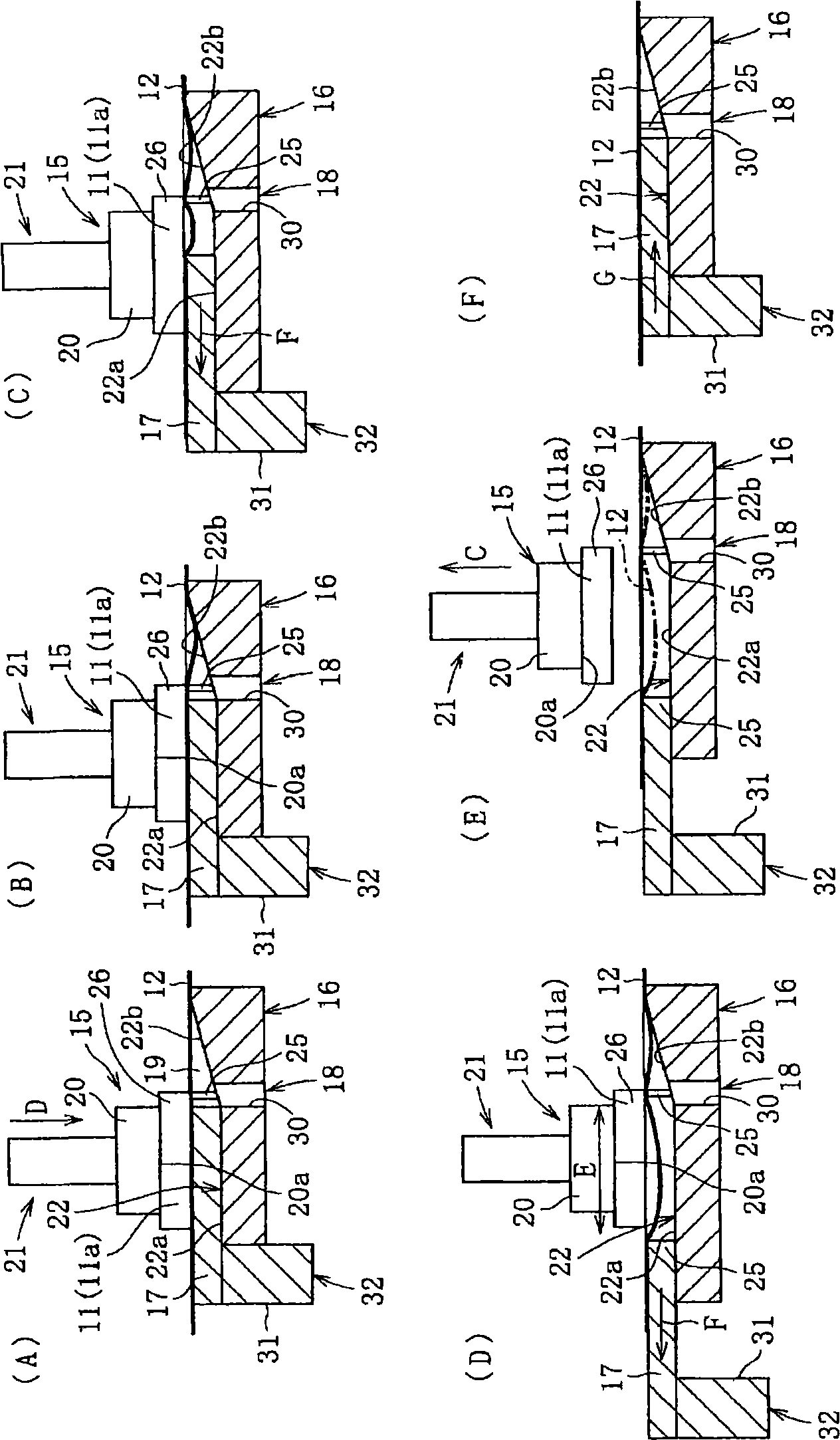

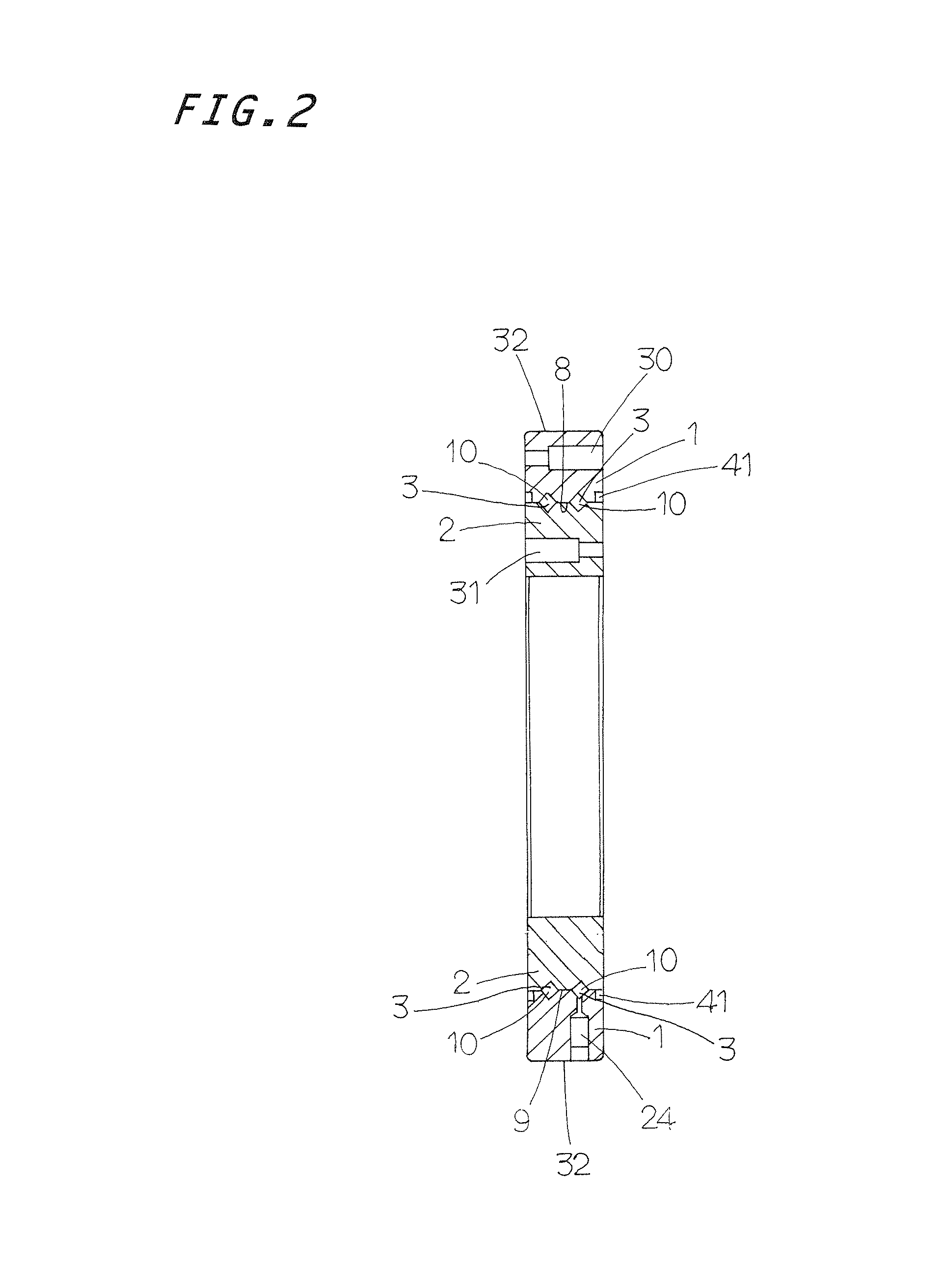

Rotary anode type X-ray tube

InactiveUS7127035B2Improve cooling efficiencyIncrease the effective contact areaX-ray tube electrodesSliding contact bearingsThermal radiationMechanical engineering

An anode target is roratably supported by a rotating mechanism having a rotary body and a staionary body. A fitted portion between the rotary body and the stationary body is formed of bearing areas having dynamic pressure type sliding bearings and a non-bearing area having a clearance between the rotary body and the stationary body larger than that in the bearing areas. The rotary body facing the non-bearing area is positioned where a time for heat transfer from the anode target is shorter than the rotary body facing the bearing areas. Thus, the characteristics of heat radiation from the anode target can be improved, and a stable bearing operation can be maintained.

Owner:TOSHIBA ELECTRON TUBE & DEVICES

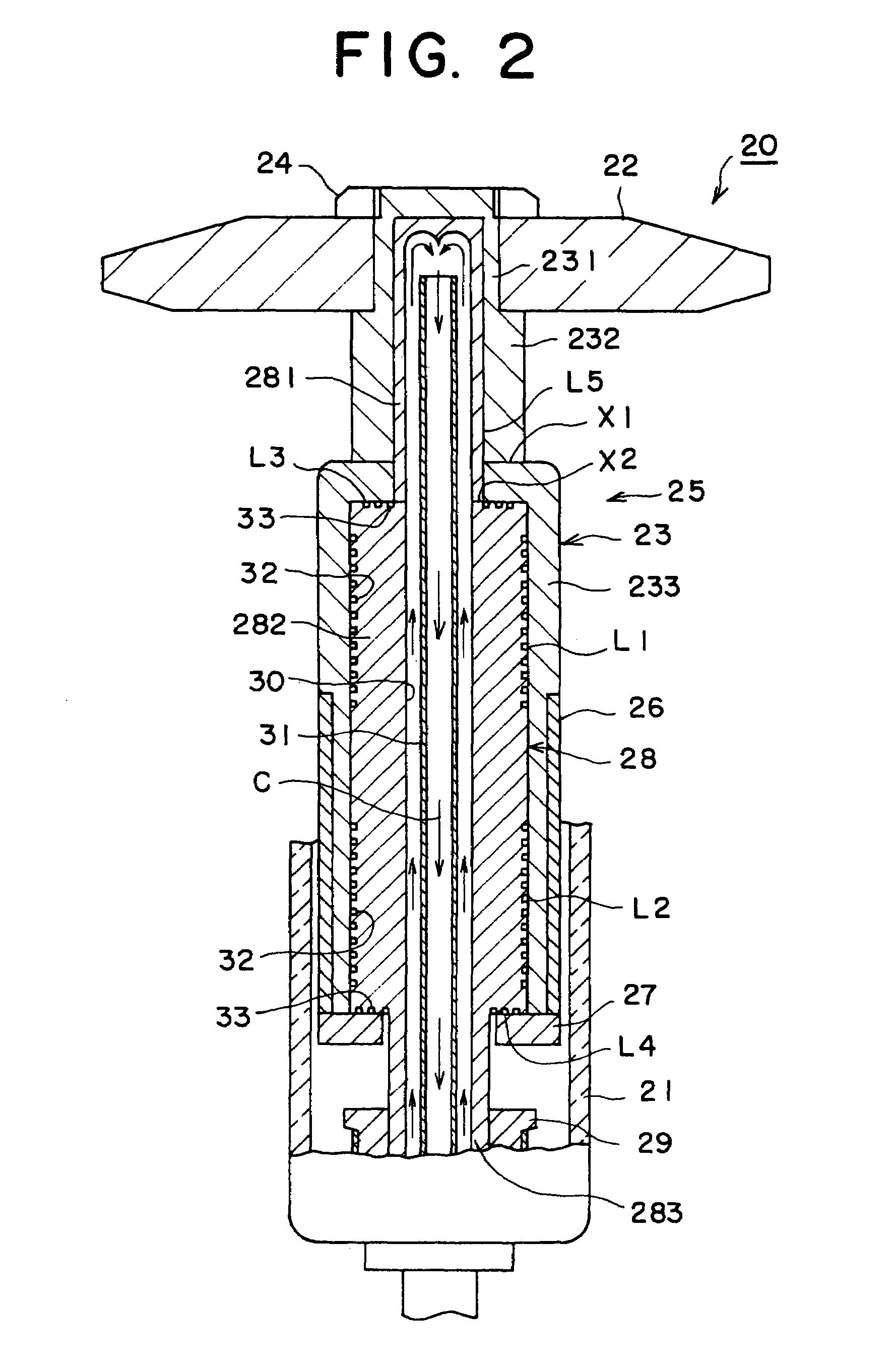

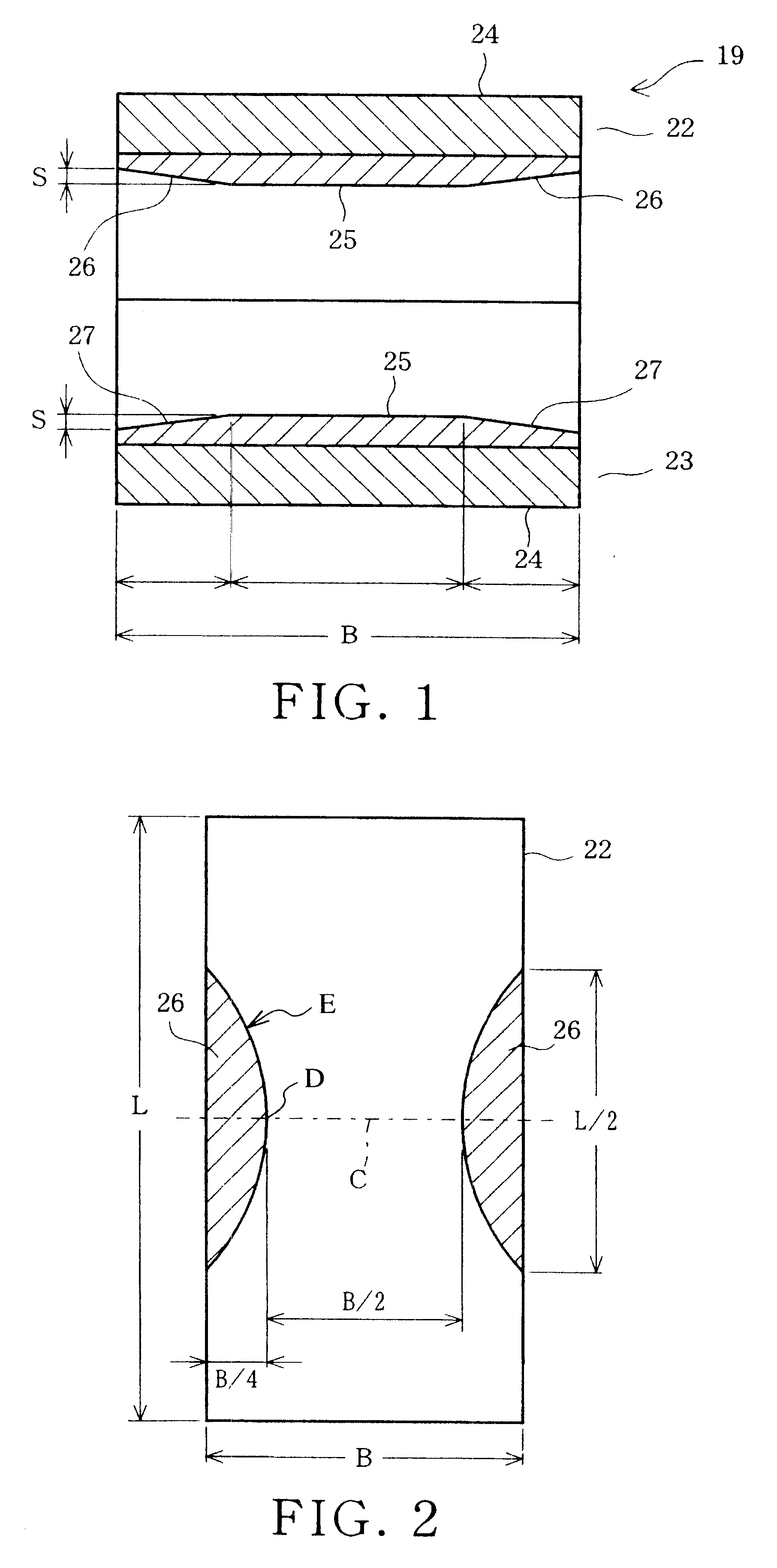

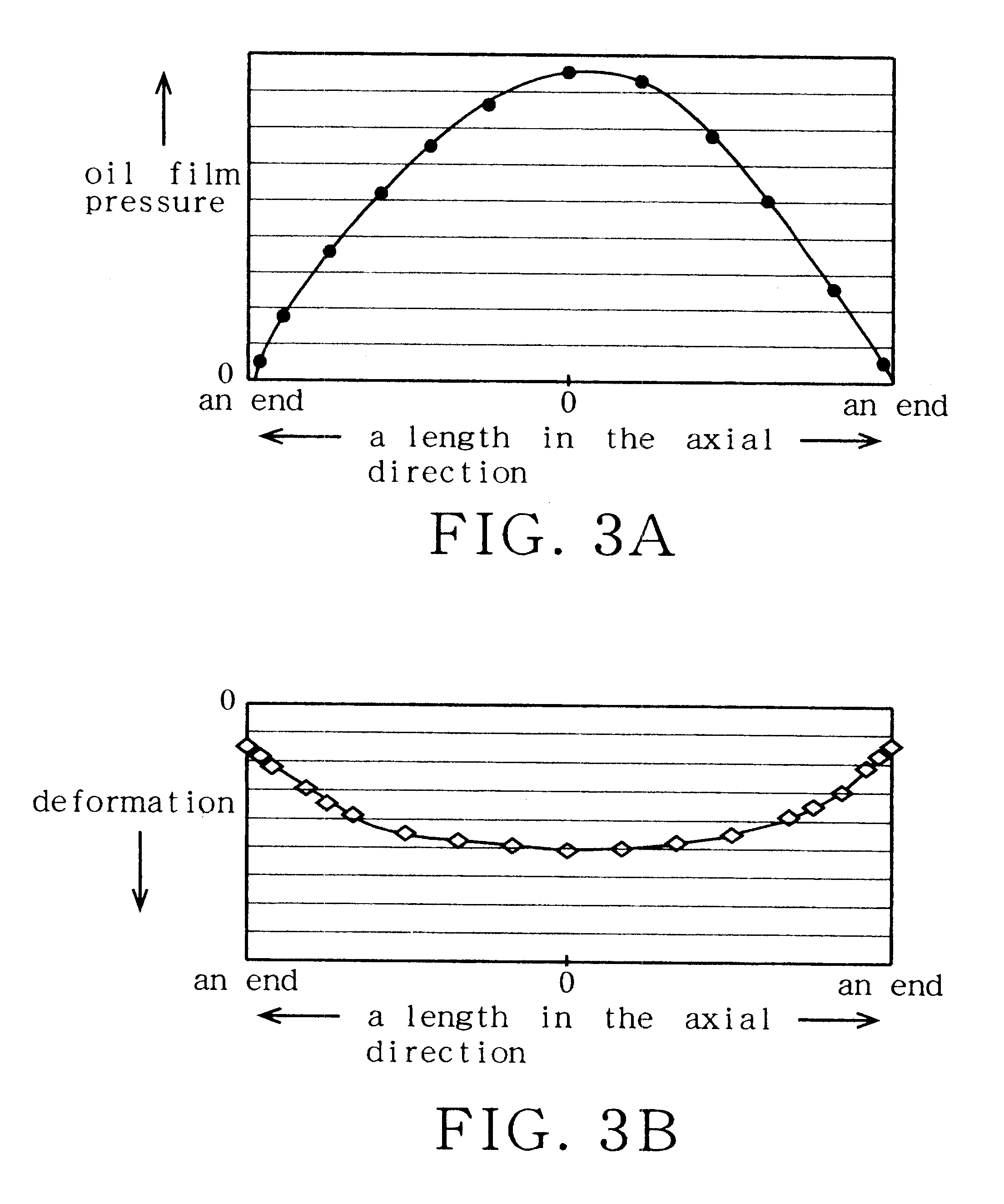

Plain bearing

InactiveUS6648513B2Reduce stiffnessLight weightConnecting rod bearingsRolling contact bearingsAlloyMechanical engineering

There is disclosed a plain bearing comprising: a back metal; and a bearing alloy layer bonded onto the back metal which bearing alloy layer is provided at a surface side thereof with a cylindrical bearing face extended in the direction of the axis of the plain bearing, the bearing alloy face being provided at each of axial terminal portions thereof with an inclination face inclined radially outwardly from a location defined between both of axially terminal ends of said bearing face toward said axially terminal ends thereof, the inclination face having an axial length varying along the circumference of the inclination face.

Owner:DAIDO METAL CO LTD

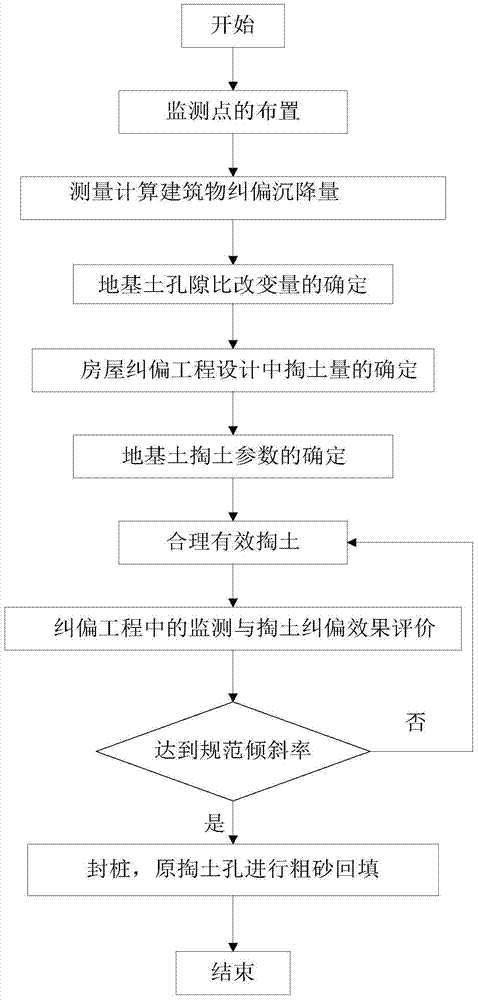

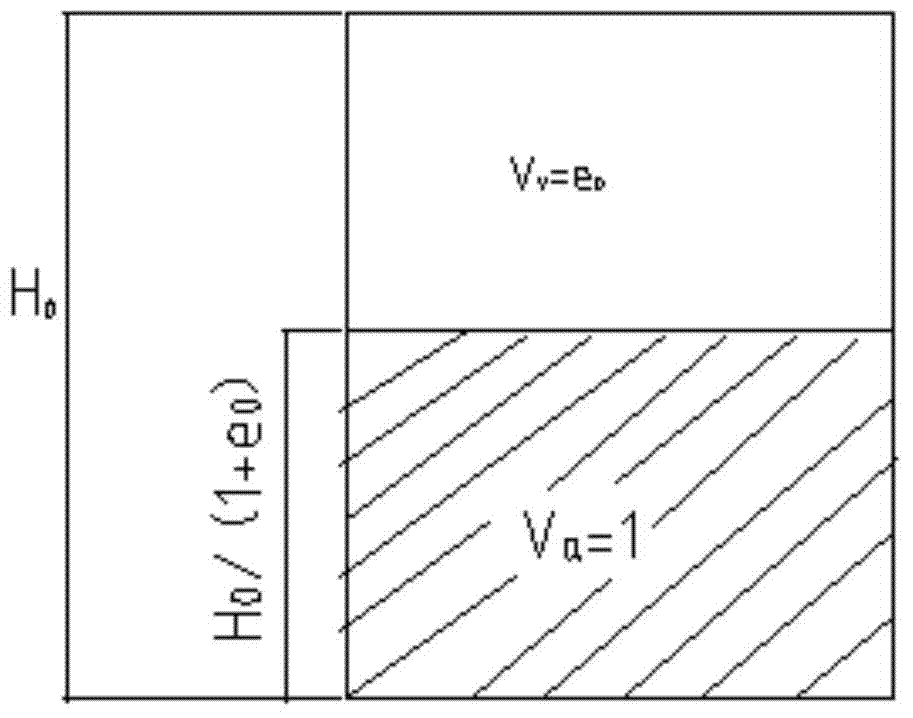

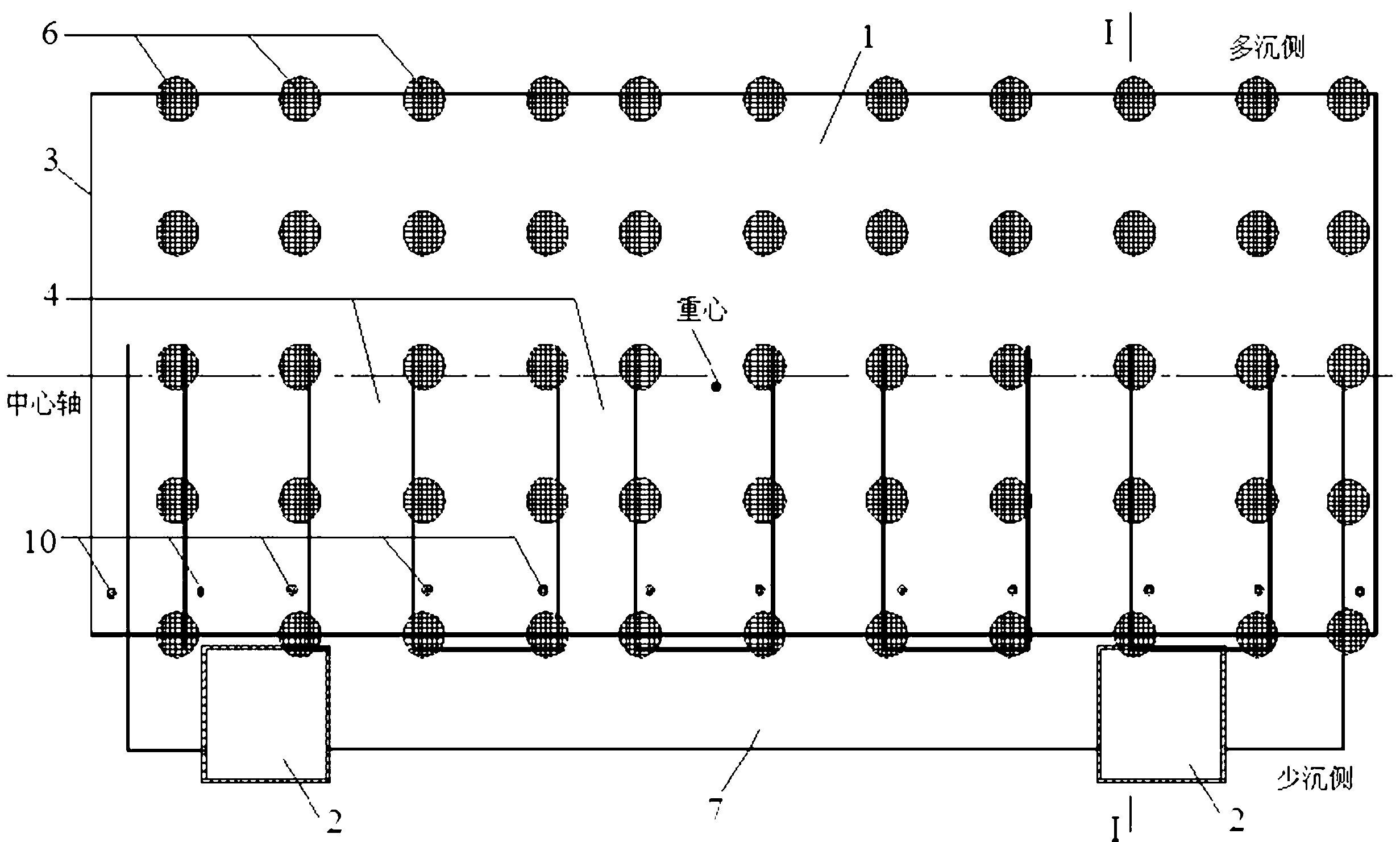

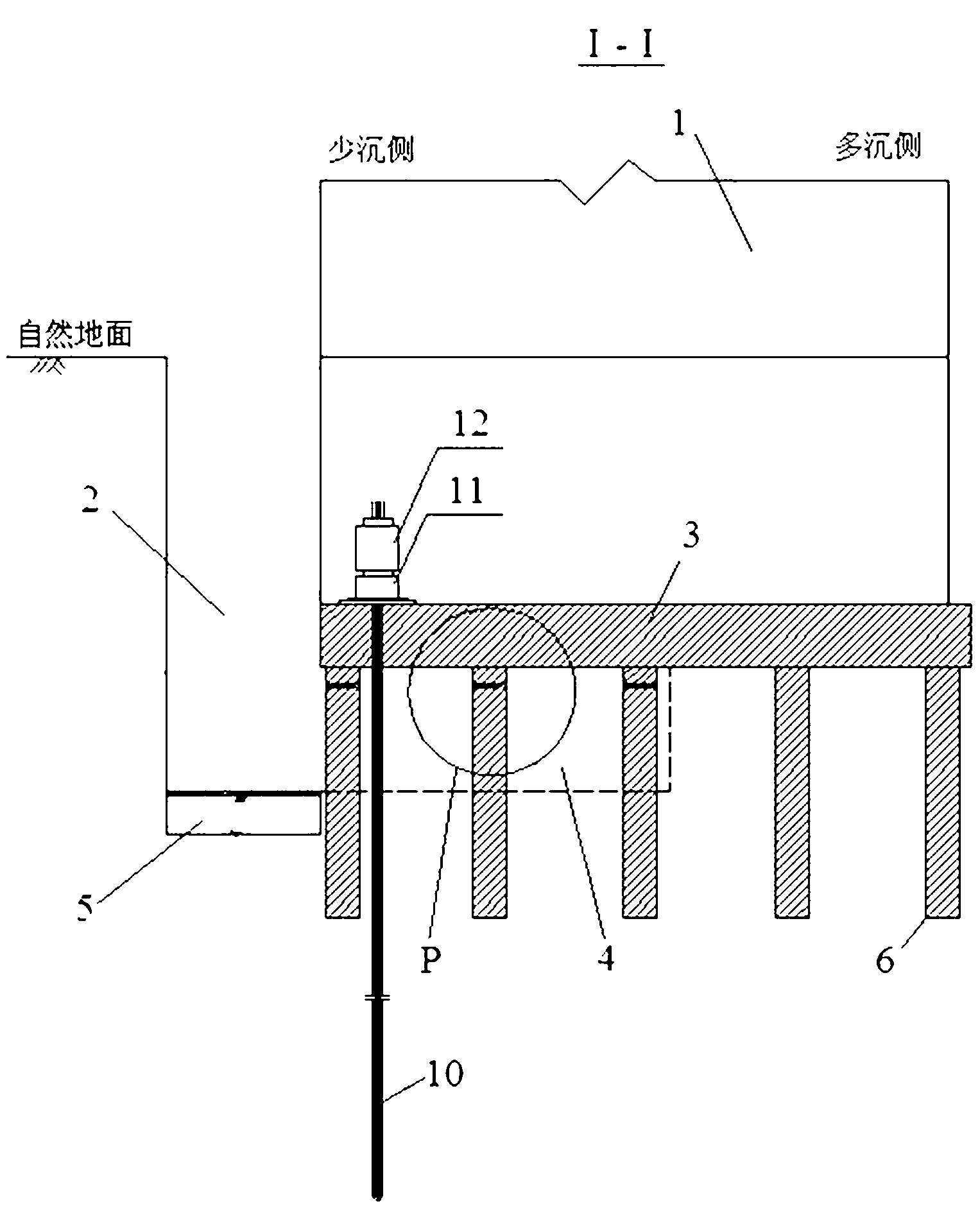

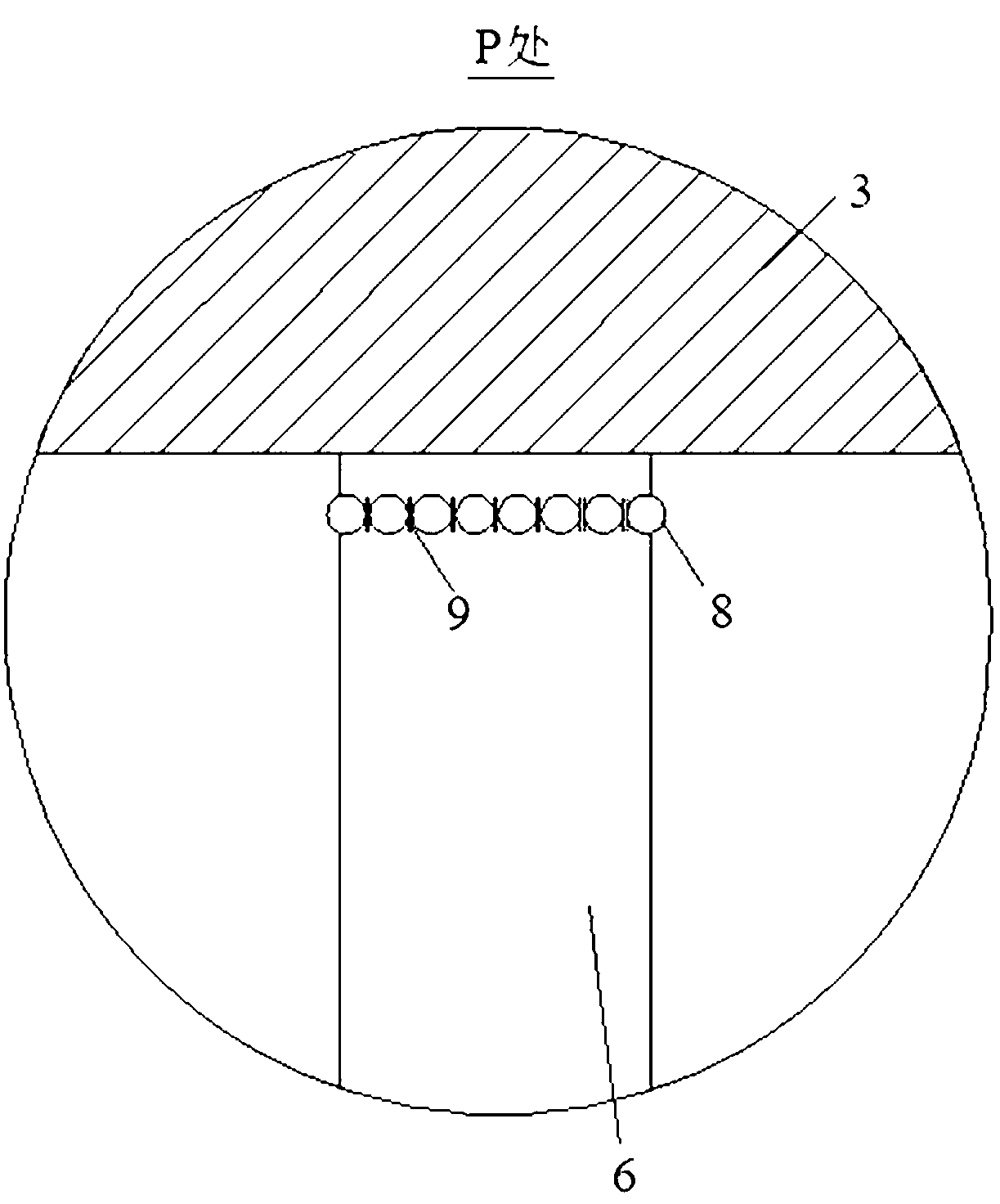

Drilling and soil taking deviation correcting and treating method for house foundation

InactiveCN104499515ADeformation modulus equalizationGood for lateral extrusionFoundation engineeringSoil science

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

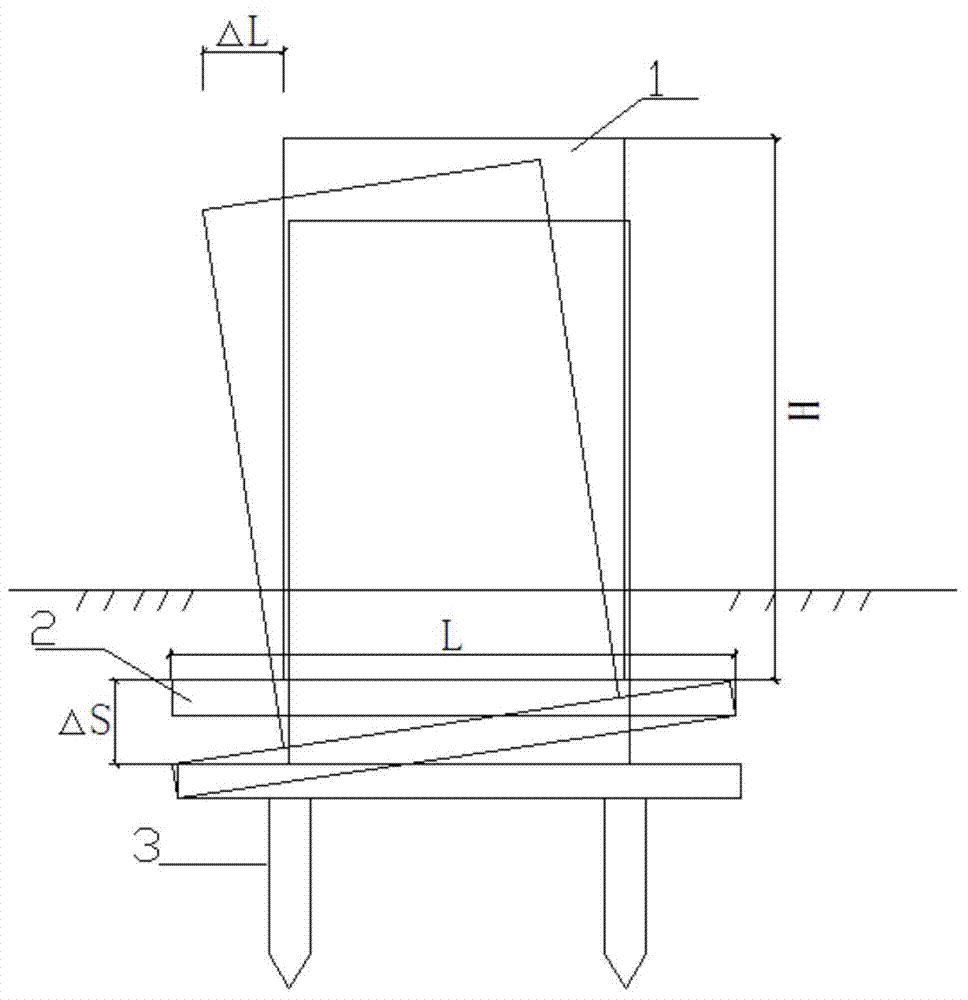

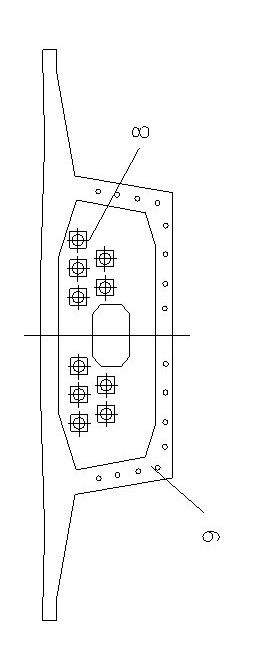

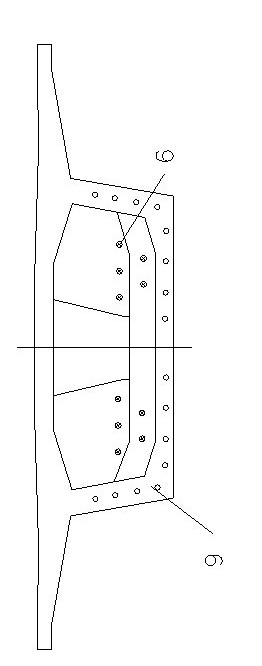

Rectifying method by drilling at intervals and pile cutting off

ActiveCN103321260ABearing area reducedAccelerated settlementFoundation engineeringStructural engineeringControllability

The invention provides a rectifying method by drilling at intervals and pile cutting off. The method includes excavating at least two constructing wells along the longitudinal direction of the light settlement side, communicating all the constructing wells, excavating a plurality of horizontal roadways, determining the pile cutting height of each concrete pile from the light settlement side to the heavy settlement side in a same row of concrete piles according to designed maximum rectifying amount by the principle of similar triangles, cutting off piles in batches, and arranging a pre-reserved stripe between two adjacent pile-cutting holes on one concrete pile; rectifying by the own weight of an inclined building and force of an anchor cable arranged at the light settlement side until a rectifying target is achieved; patching the pile-cutting hole, filling back the wells and the roadways, and finishing rectifying of the inclined building. By the aid of the method, blindness and sudden sinking effect of pile cutting off can be avoided effectively, rectifying risks are reduced, defects of poor controllability, difficulty in mastering pile cutting amount accurately and the like are overcome, controllability and security of rectifying are improved greatly, and the method can be applied in the fields of building rectifying and reinforcing.

Owner:NORTHWEST RES INST CO LTD OF C R E C

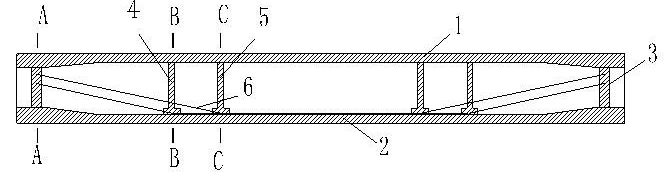

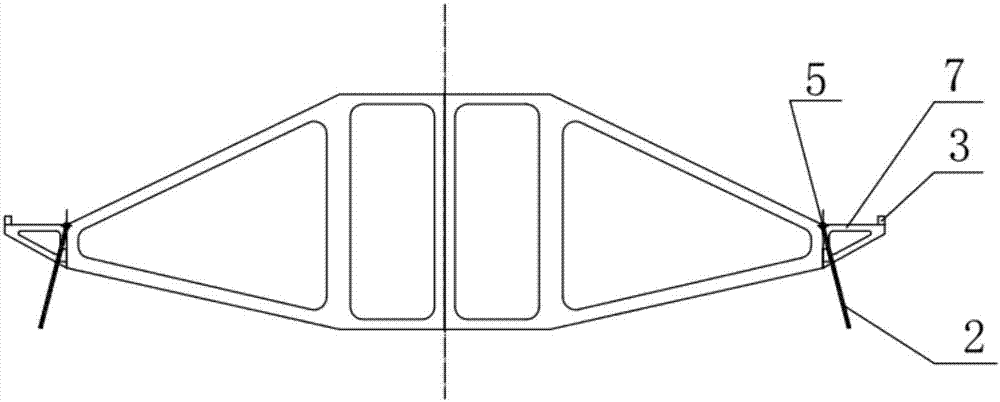

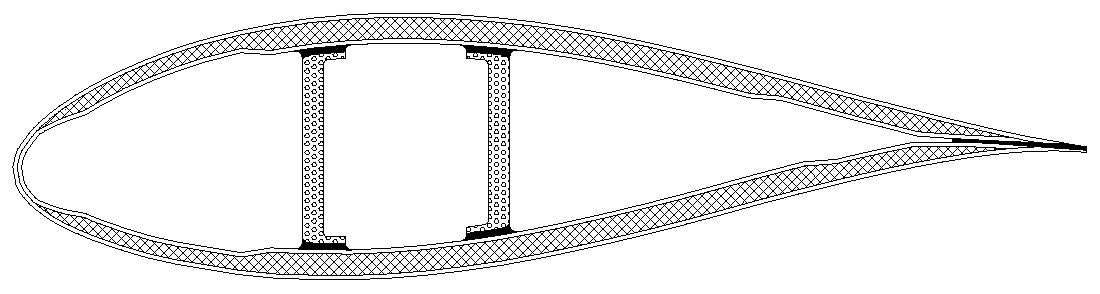

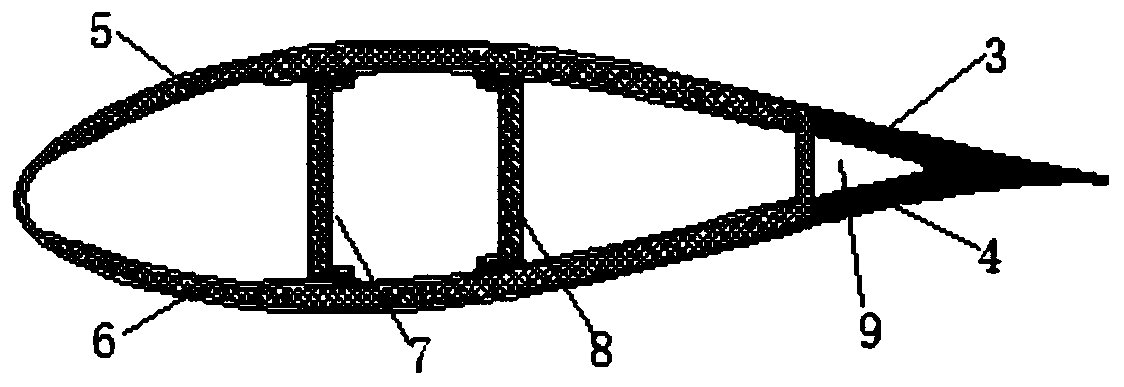

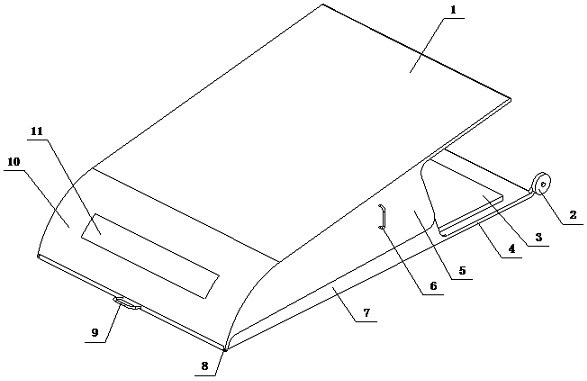

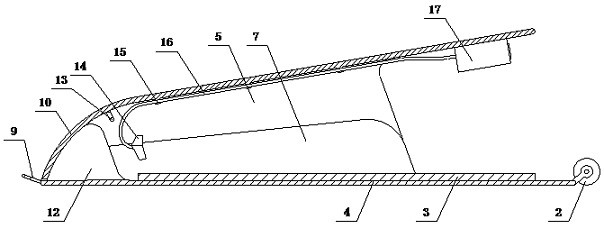

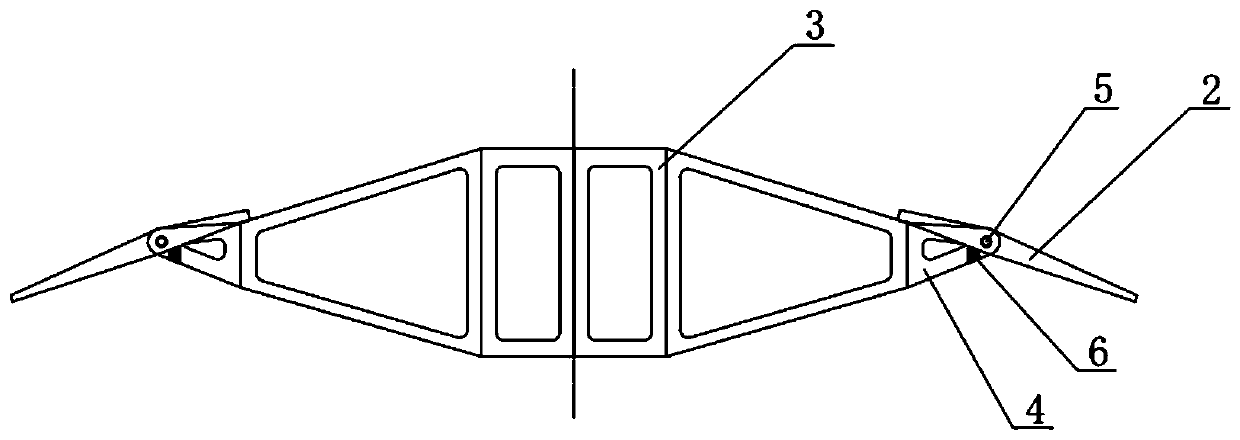

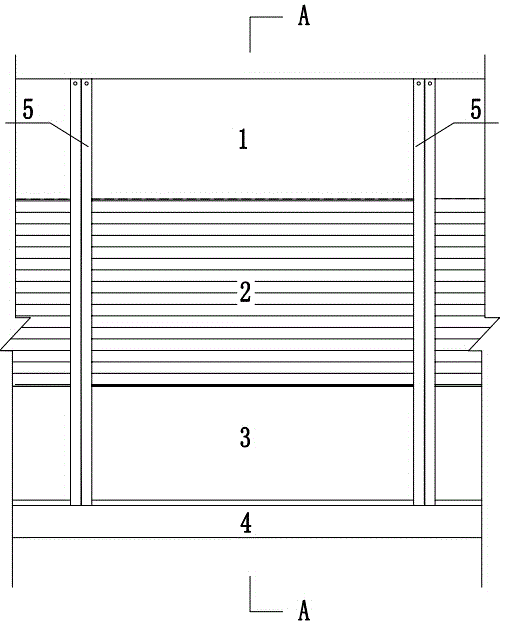

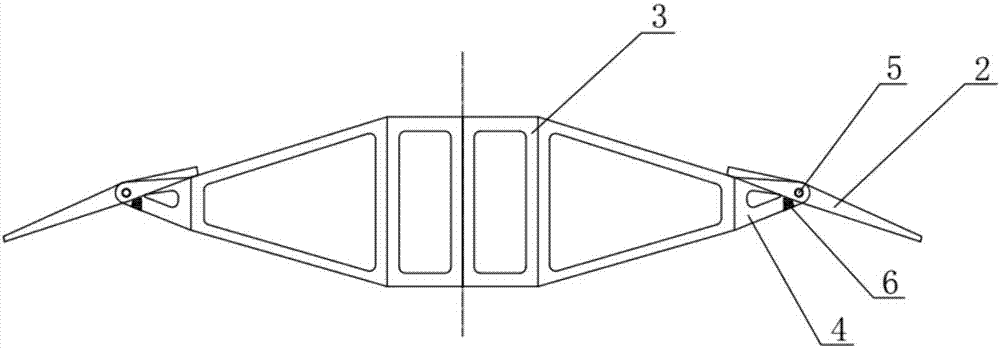

Partial external prestressed and fine-grain reinforcing steel bar fiber reinforced cementitious composite (FRCC) railway box girder

The invention discloses a partial external prestressed and fine-grain reinforcing steel bar fiber reinforced cementitious composite (FRCC) railway box girder. The partial external prestressed and fine-grain reinforcing steel bar FRCC railway box girder comprises a hollow beam frame body consisting of a top plate and a webplate, wherein the top plate and the webplate are made from an FRCC material; an anchoring toothed plate and an anchoring diaphragm plate are symmetrically arranged on the two sides of the center in the hollow beam frame body; an anchor is arranged on the anchoring toothed plate; a diverter is arranged on the anchoring diaphragm plate; an external prestressed rib is arranged between the anchoring toothed plate and the anchoring diaphragm plate; and one end of the external prestressed rib is fixed on the anchor, and the other end of the external prestressed rib is fixed in the diverter. At the same time, an external prestressed technique has the advantages that: the partial external prestressed and fine-grain reinforcing steel bar FRCC railway box girder is convenient to construct, detect and change; and the friction loss of the prestressed rib is low, and the like. The webplate of the box girder is shrunk; the strength of the materials used by the box girder is improved; and the FRCC is used for substituting the conventional C50-grade concrete, the bearing capacity of the girder body is not reduced but increased, so that the box girder has an extremely wide application prospect.

Owner:SOUTHEAST UNIV +1

Multipurpose nondestructive testing natural defect test block and manufacturing method

ActiveCN110553884AConvenient teachingEasy to trainMaterial analysis using wave/particle radiationPreparing sample for investigationShielded metal arc weldingSlag

The invention belongs to the field of nondestructive testing, and discloses a manufacturing method of a multipurpose nondestructive testing natural defect test block, which comprises the following steps: forming a groove on a base material with the thickness of more than 12mm, and carrying out backing welding by adopting argon tungsten-arc welding, wherein both the base material and a weld joint can be magnetized; filling the grooves of the base metal through shielded metal arc welding to complete weld joint filling; in the filling welding process, making an incomplete fusion defect, an incomplete penetration defect, an air hole defect, a slag inclusion defect and a tungsten inclusion defect in the weld joint; determining a designed crack area on the weld joint, coating ferrous sulfide powder on the designed crack area, and then performing shallow penetration and remelting on the weld joint in the designed crack area; polishing the remelting area of the weld joint, and polishing off unmelted ferrous sulfide; and performing cosmetic welding on the surface of the weld joint to obtain the multipurpose nondestructive testing natural defect test block. The manufacturing process is simple, the cost is low, cracks with various defects and that are close to the natural forms are formed, and the training and teaching requirements are met.

Owner:盐山双盛金属材料检测有限公司

Sliding member

ActiveUS20180258991A1High strengthBearing area reducedShaftsBearing componentsSurface coolingCopper alloy

Provided is a sliding material including a substrate; and a copper alloy layer bonded to the substrate. The copper alloy includes 2.0 to 15.0% by mass of tin. The copper alloy layer includes a sliding body part including a sliding surface, and a gradient region including a bond surface with the substrate. A tin concentration in the gradient region reduces from the sliding body part toward the bond surface. A method for producing the siding material is also provided. The method includes preparing the substrate having a first surface and a second surface opposite to the first surface; melting the copper alloy; casting the molten copper alloy on the first surface of the substrate; and solidifying the copper alloy unidirectionally by cooling the substrate from the second surface by a coolant.

Owner:DAIDO METAL CO LTD

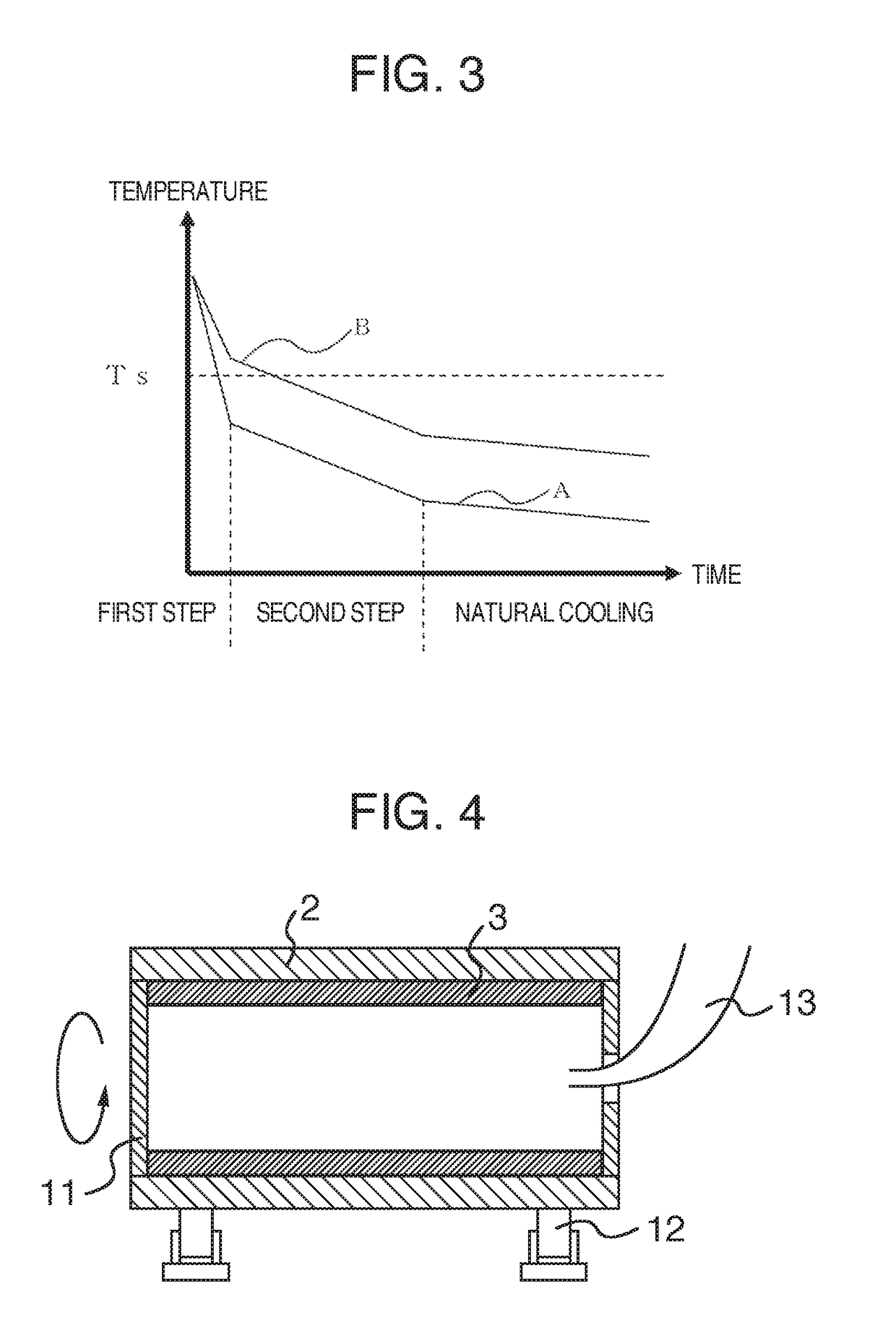

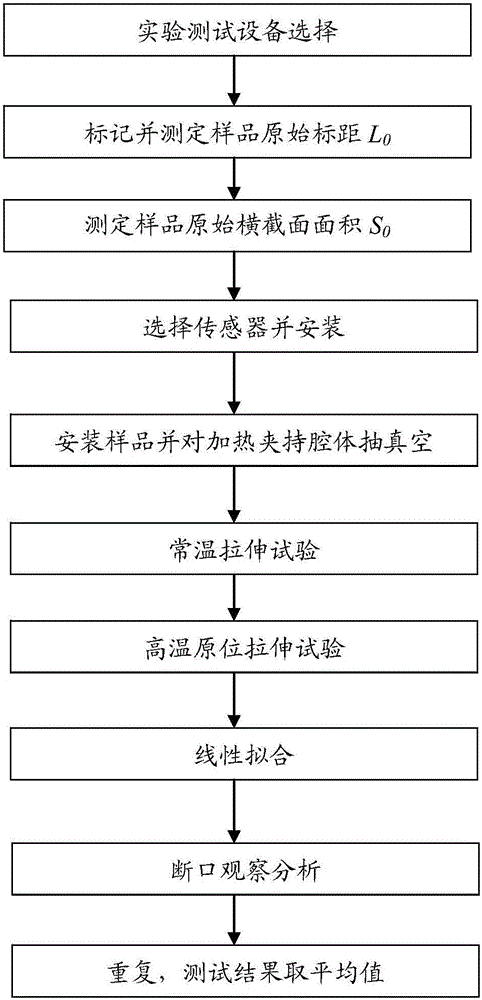

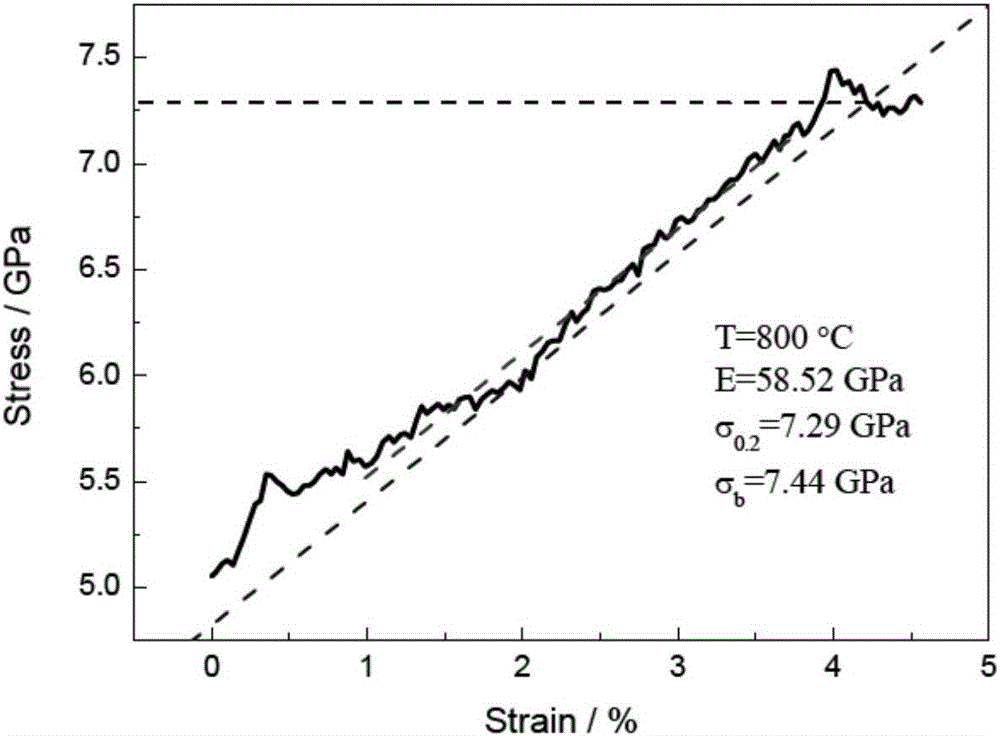

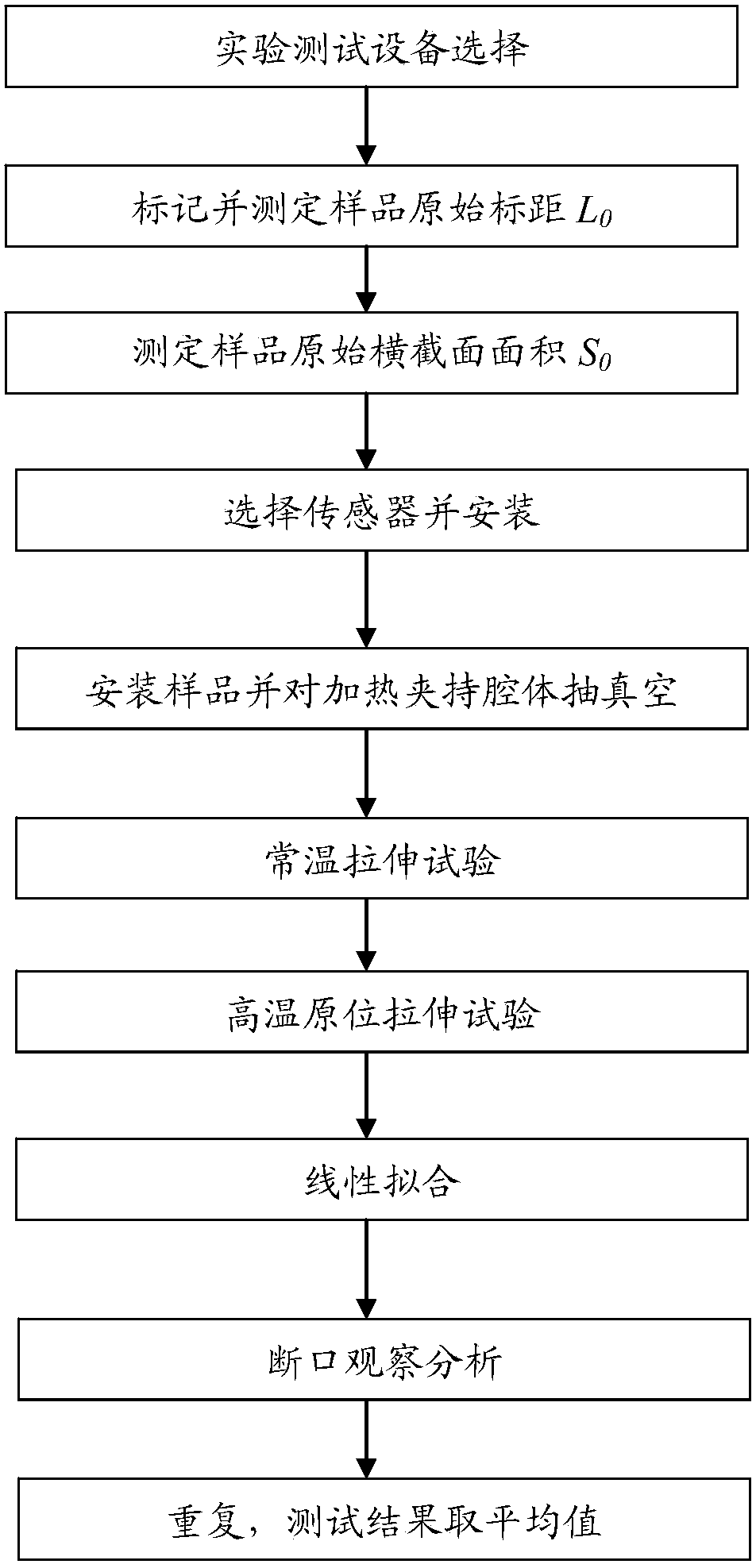

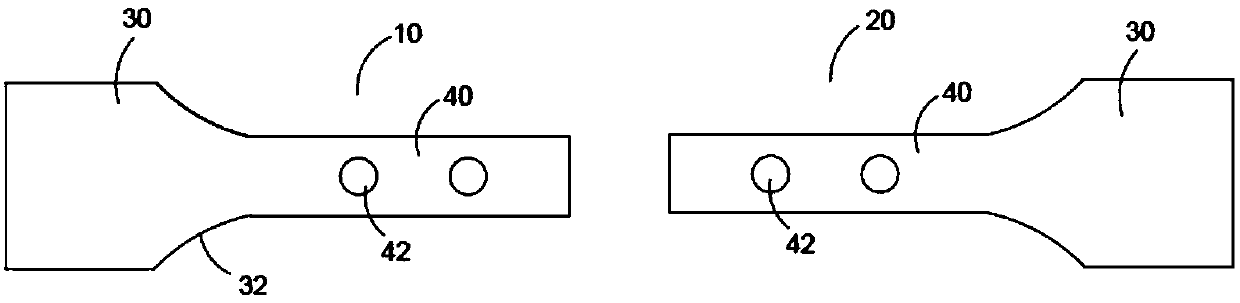

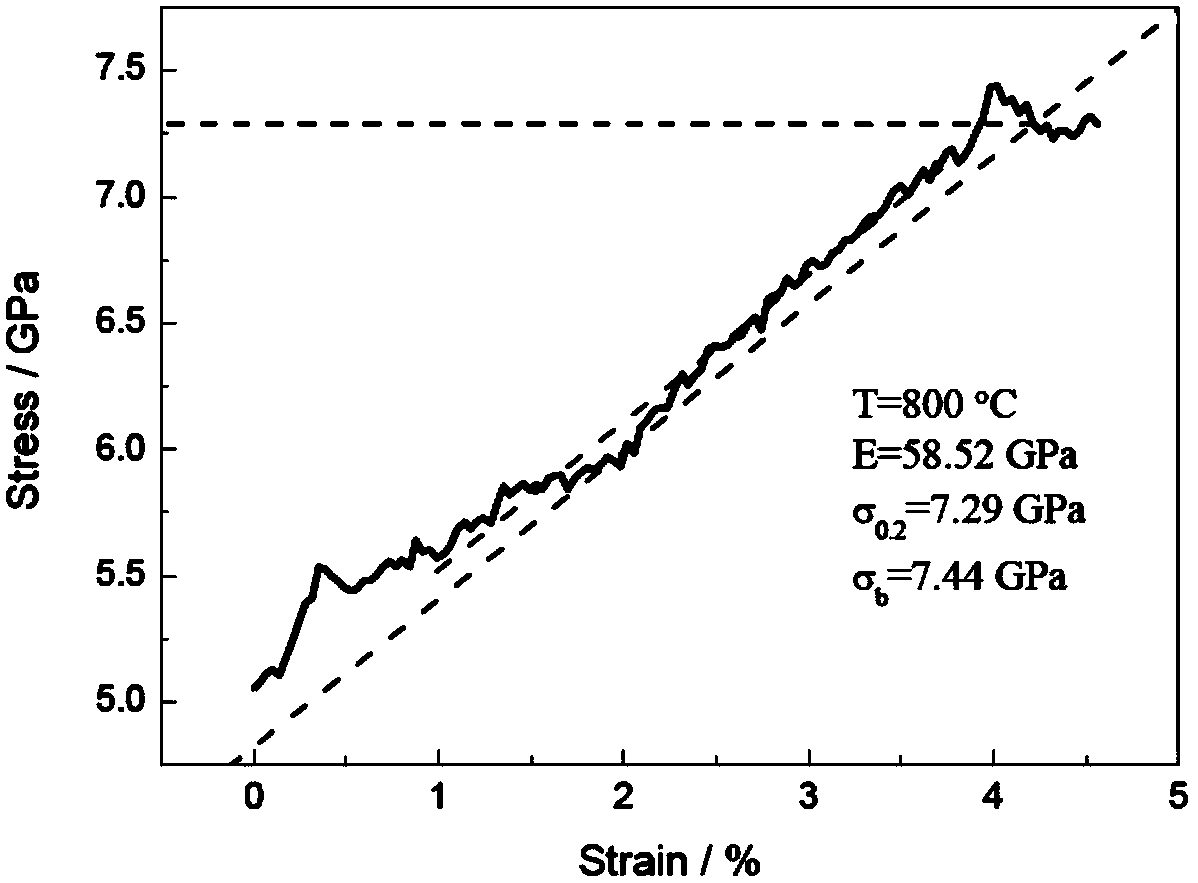

Method for testing mechanical properties of electronic gun heater assembly

ActiveCN105738224AAccurate measurement of mechanical tensile properties parametersSolve the testing problems of engineering requirementsMaterial strength using tensile/compressive forcesLinear relationshipEngineering

The invention relates to a method for testing mechanical properties of an electronic gun heater assembly, comprising the following steps: (1), taking at least two heater assemblies under detection; (2), marking an original scale distance on a heater of each heater assembly under detection, and determining original scale distances L0 and S0; (3), testing yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection in an actual vacuum environment at different temperatures; (4), establishing a change-with-temperature linear relationship of the yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection by linear fitting; (5), according to the linear relationship, calculating to obtain the yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection at the actual operation temperatures. The method enables chemical tensile performance parameters of a heater or a combination of a heater with a platinum sheet and / or a cathode head in a vacuum high-temperature operating environment to be accurately measured, and the testing problem of engineering needs is solved.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

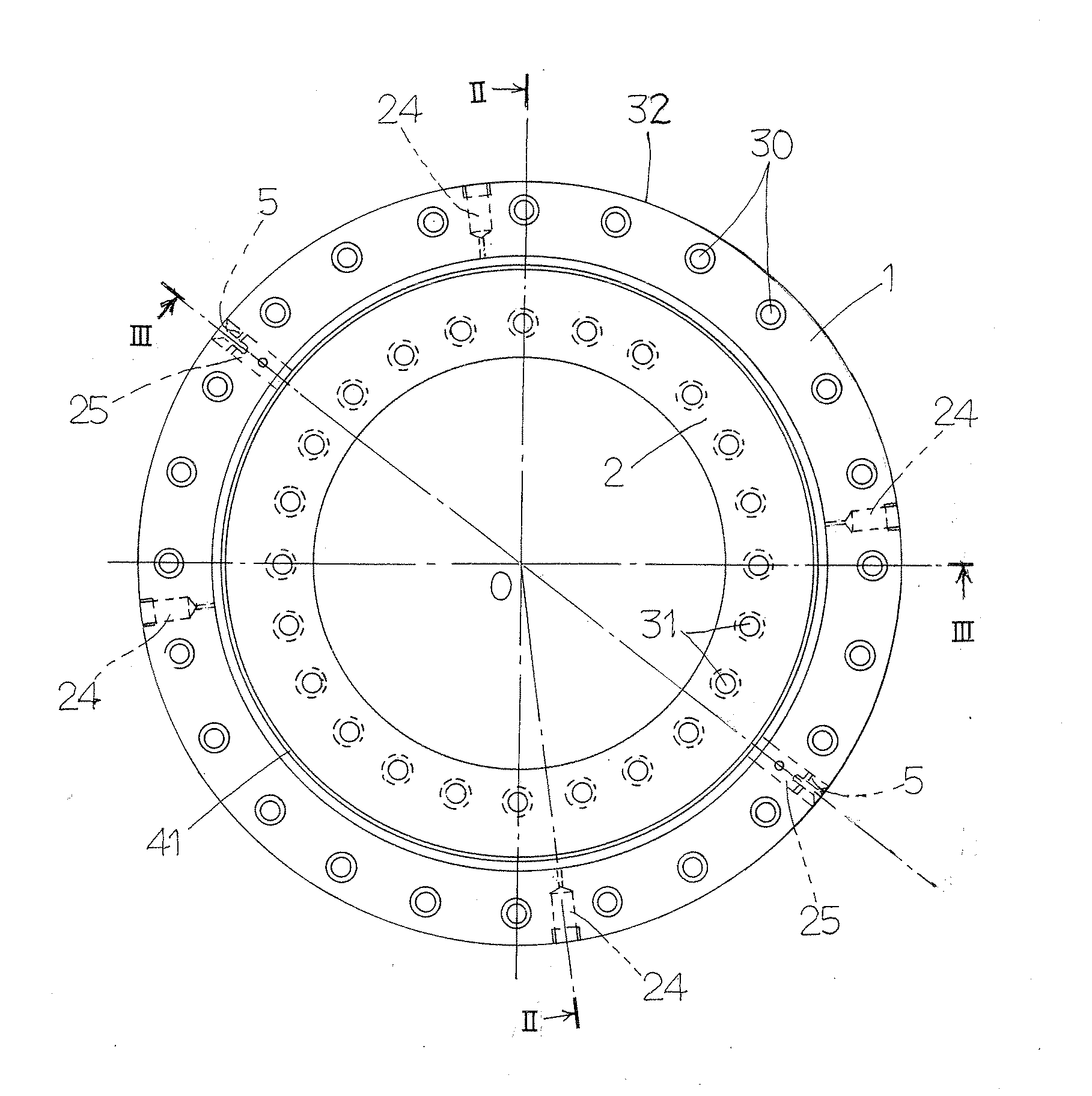

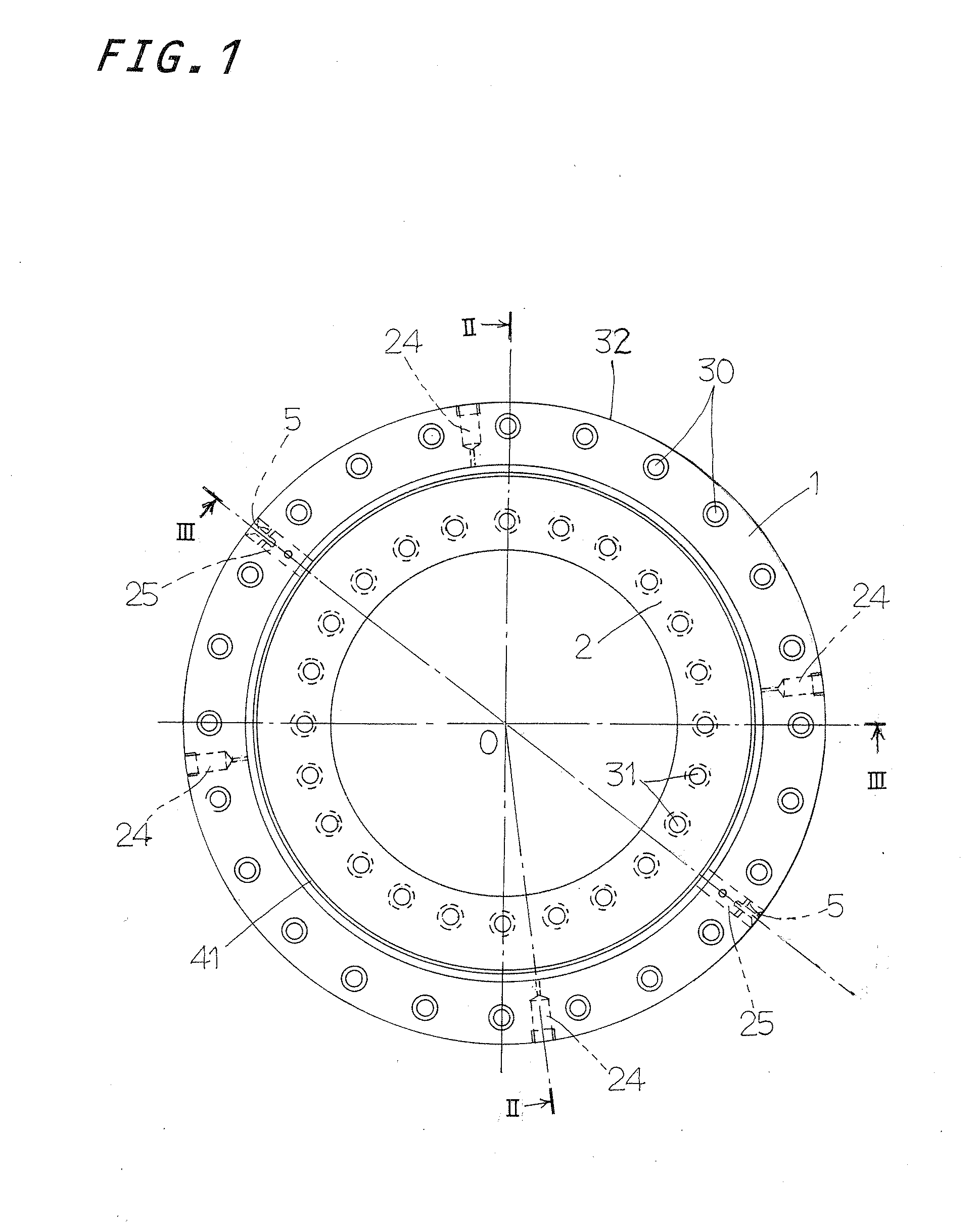

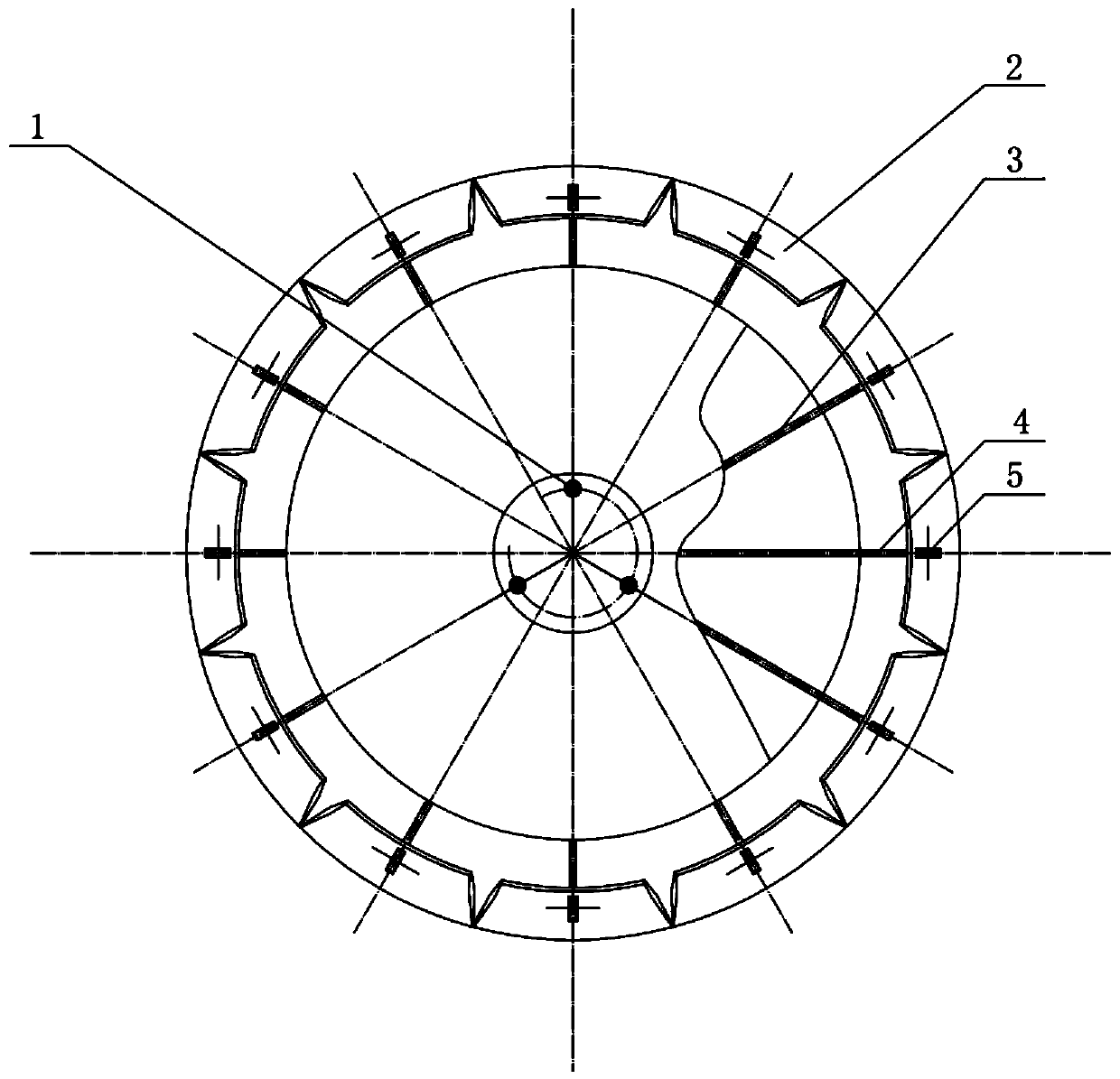

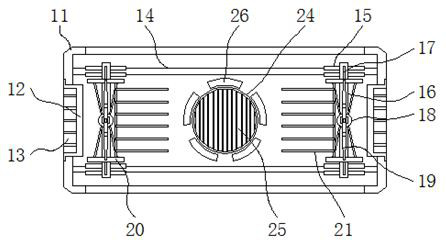

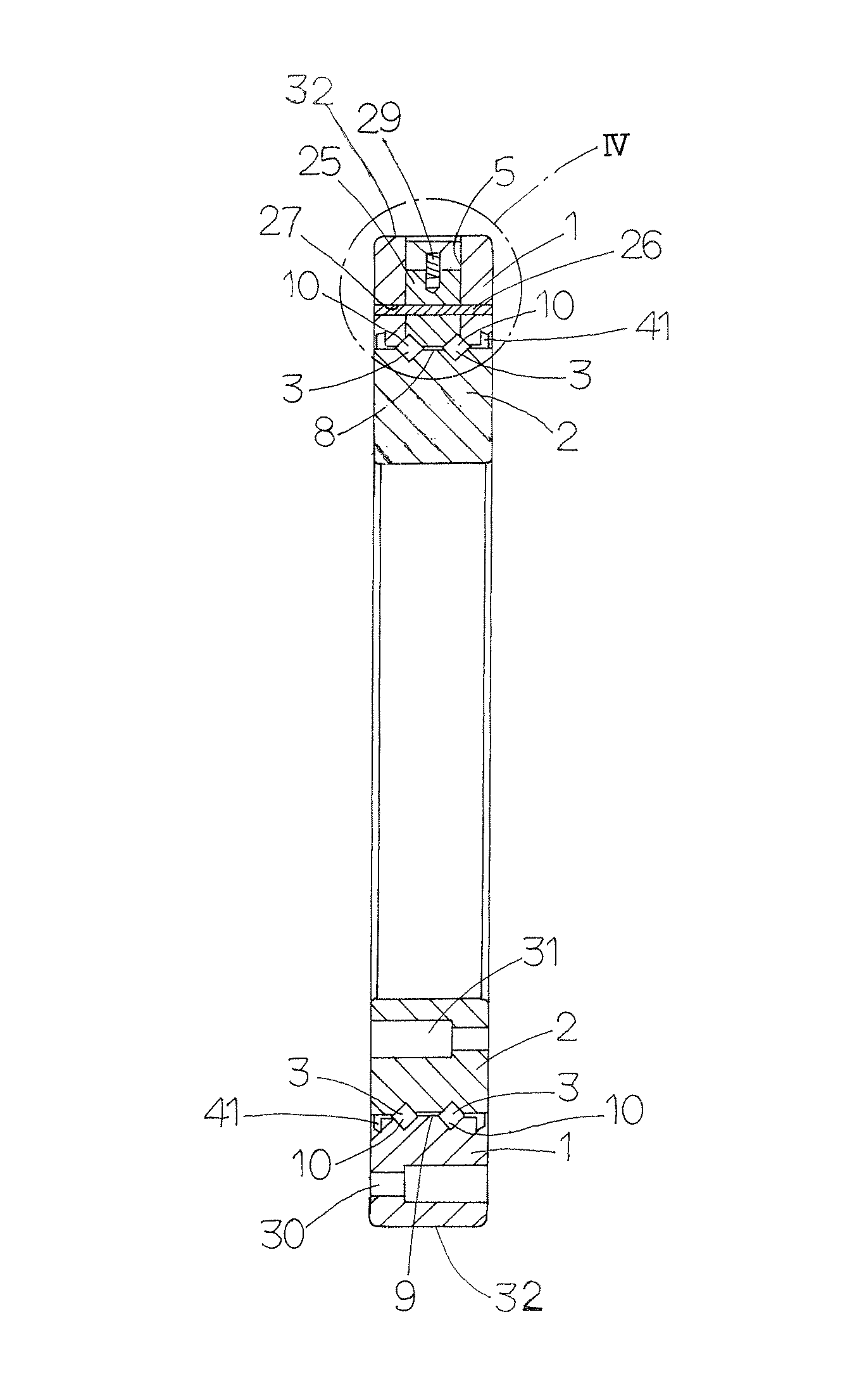

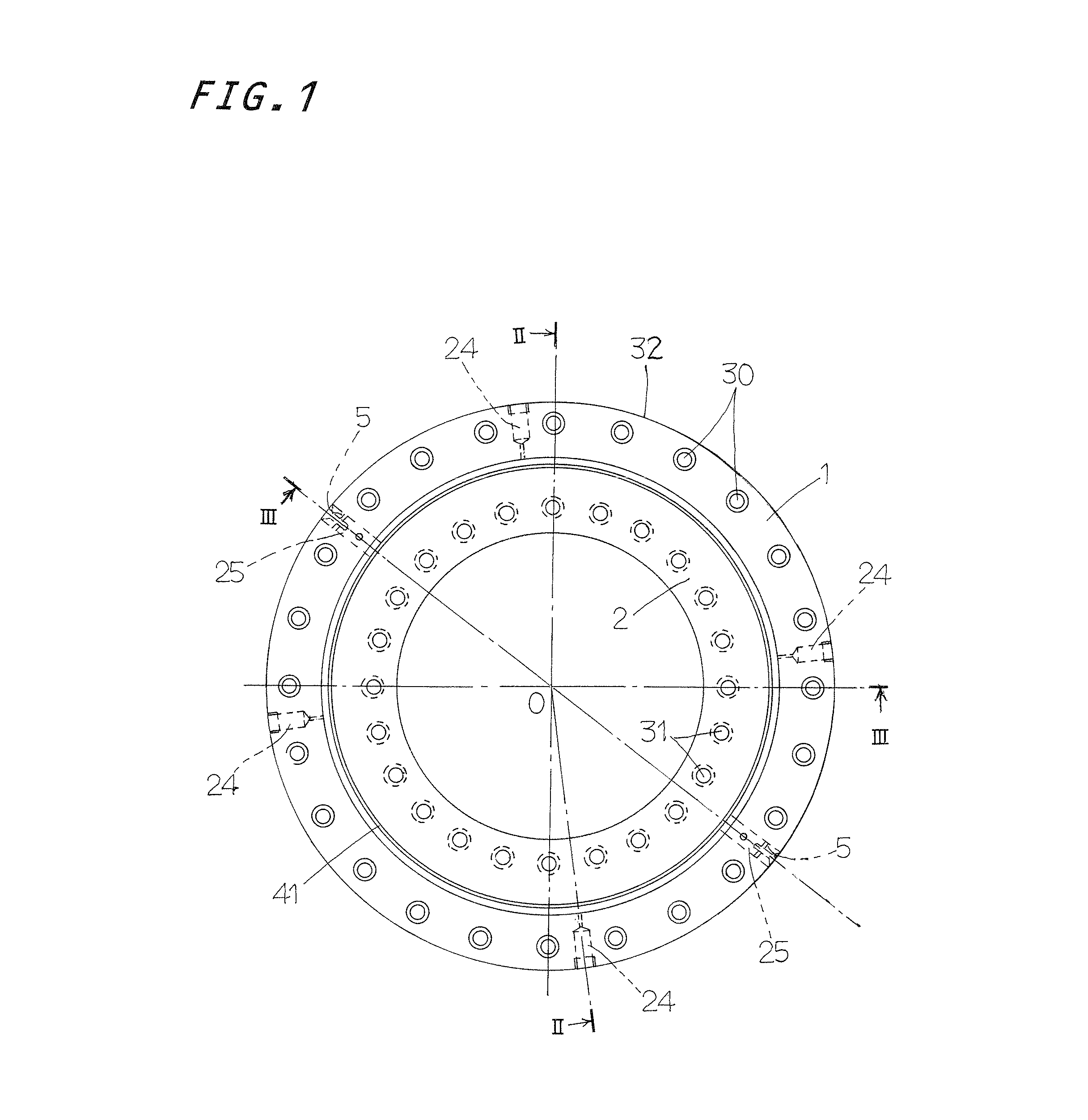

Turning bearing with rollers between outer ring and inner ring

ActiveUS20130202240A1Reduce frictional resistanceImprove load rateRoller bearingsShaftsLoad carryingEngineering

An effective contact length in race surfaces formed on grooved races cut in an outer ring and an inner ring is made as greater as permitted to improve the load-carrying capacity, and correspondingly guide parts born against axially opposite ends of a roller are made as less as possible in width to reduce frictional contact resistance applied to the axially opposite ends of the roller, thereby preventing a skew of the roller. An inside circular surface on the outer ring is staggered or different in level on opposite sides of a outside grooved race to make greater the race surface than an effective contact length of circular rolling surfaces of the rollers and correspondingly less the guide part in width than the race surface.

Owner:NIPPON THOMPSON

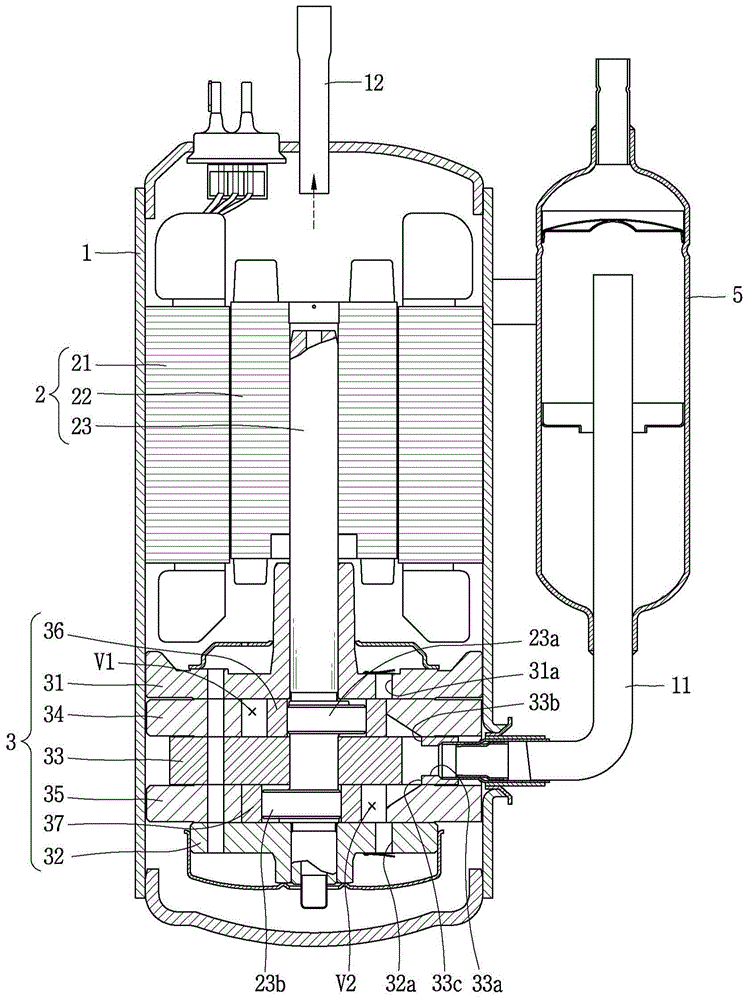

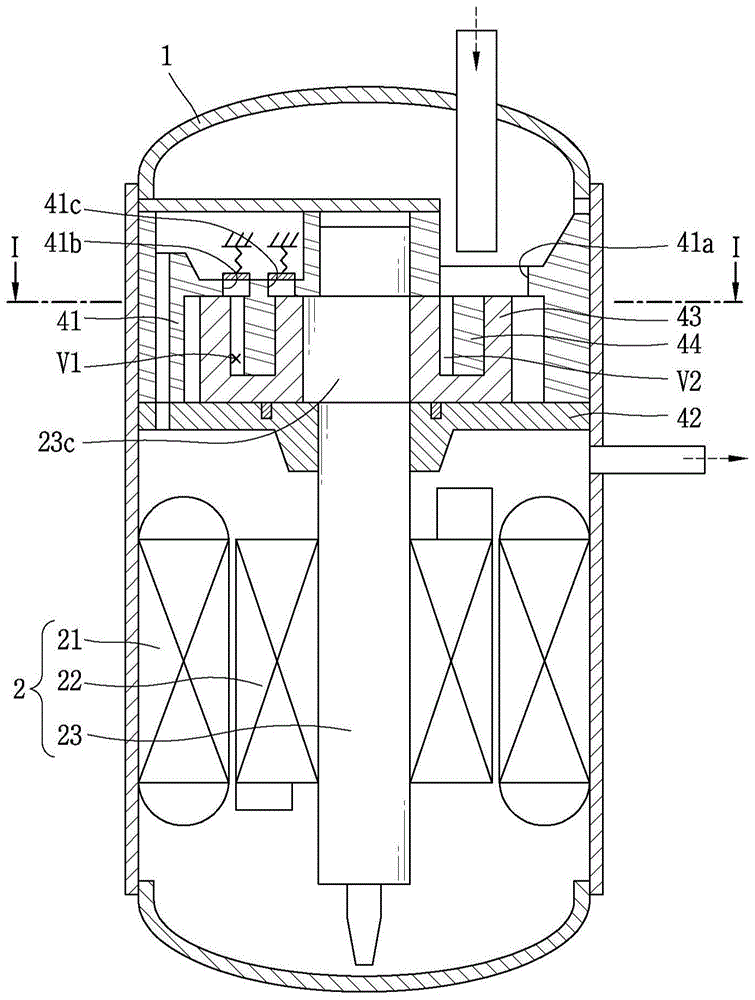

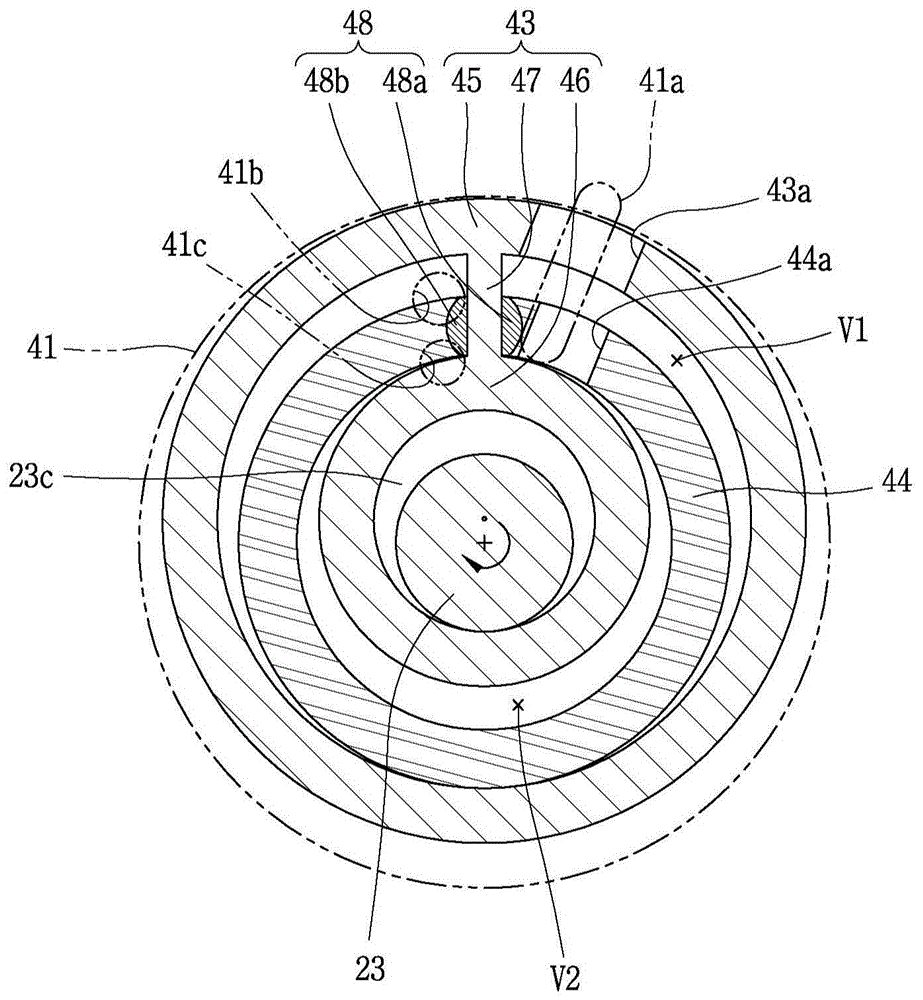

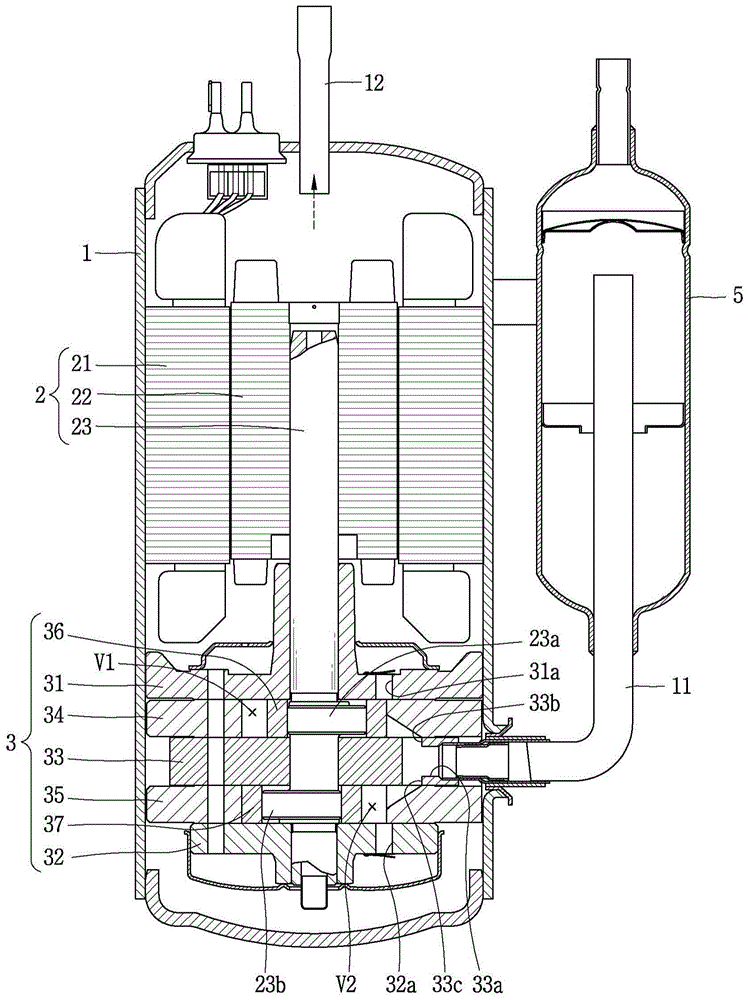

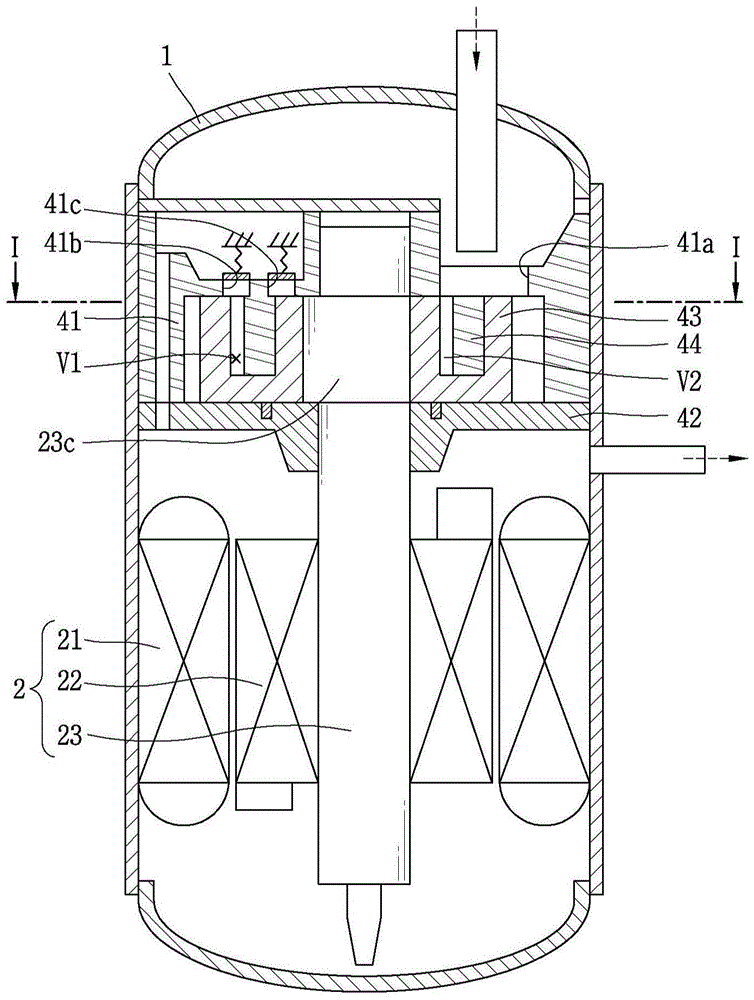

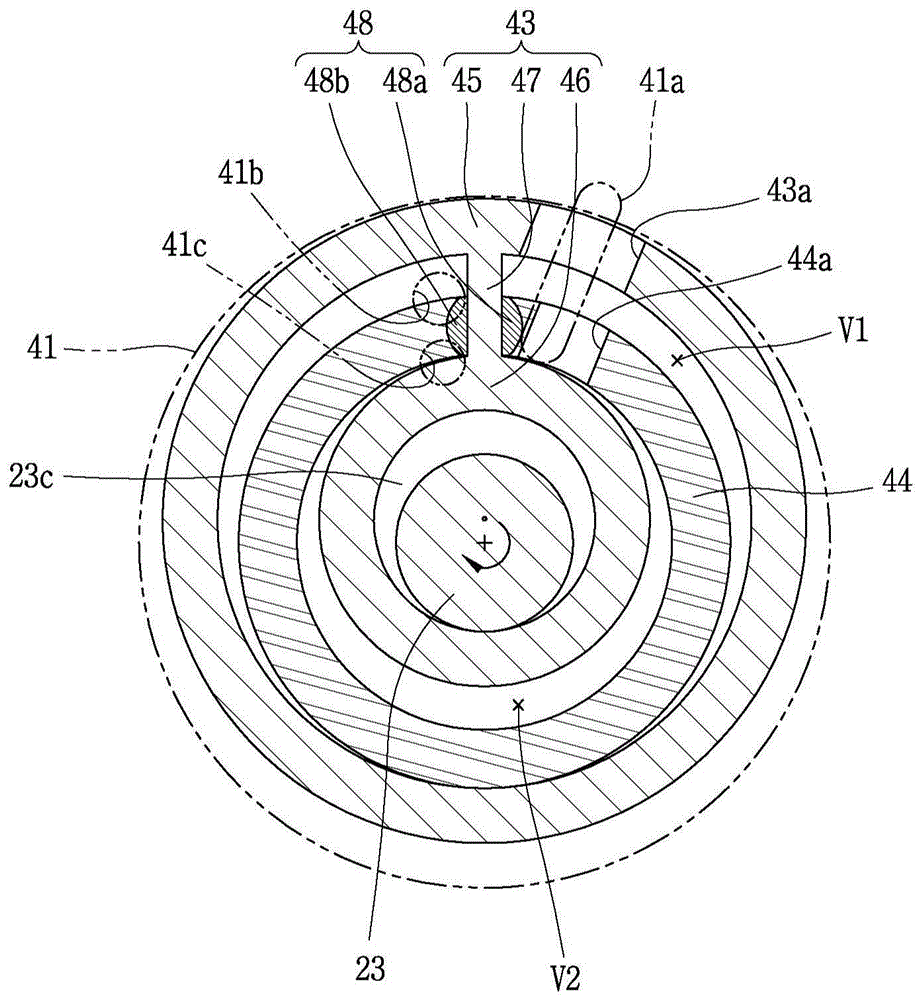

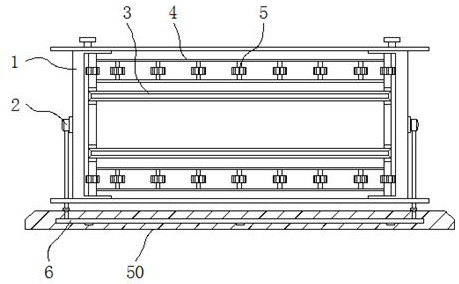

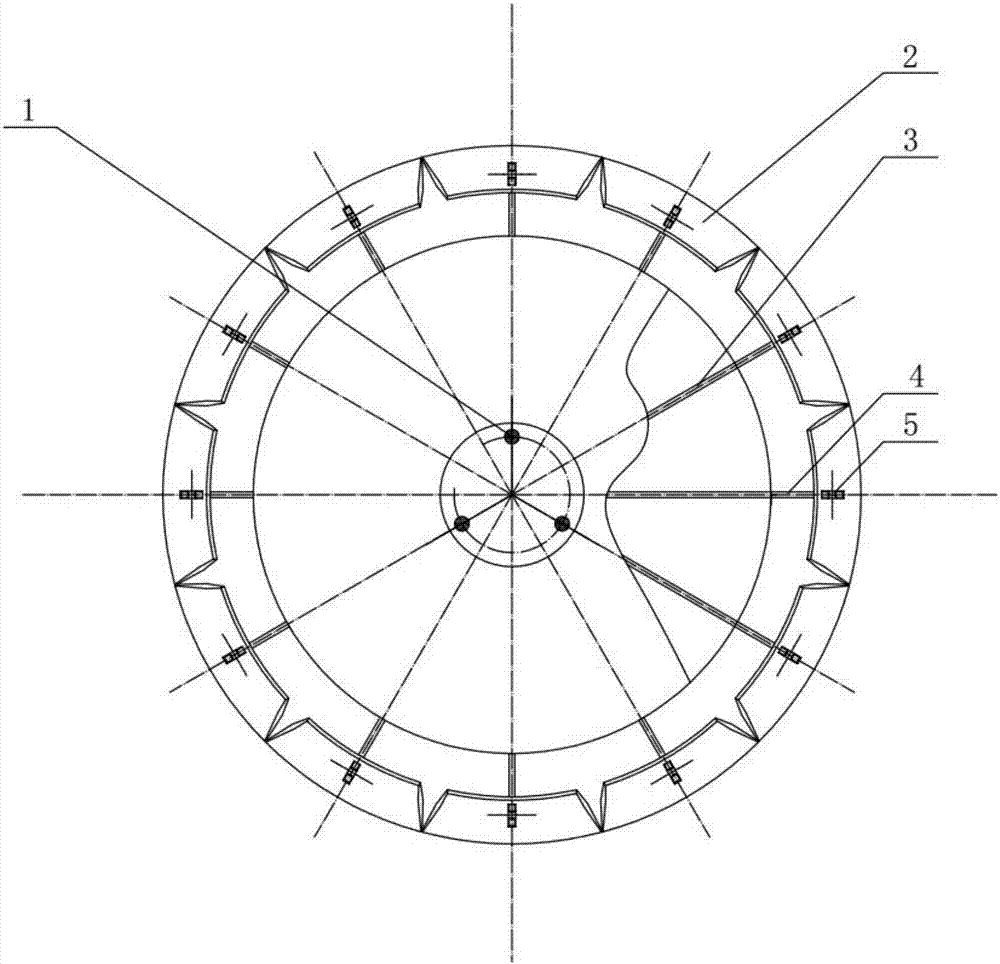

Compressor

ActiveCN103912497AReduce power lossReduce leakageRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsFriction lossEngineering

A compressor is provided, and may include a cylinder including an outer cylinder portion and an inner cylinder portion, and a vane portion which is connected between the outer cylinder portion and inner cylinder portion, and is fixed to a casing. A rolling piston may be slidably coupled to the vane portion to form an outer compression space and an inner compression space while making a turning movement between the outer cylinder portion and the inner cylinder portion. Through this, a weight of a rotating body may be reduced to obtain low power loss with respect to a same cooling power and a small bearing area, thereby reducing refrigerant leakage as well as easily changing a capacity of a cylinder in an expanded manner. Moreover, refrigerant may be discharged in opposite directions in each compression space, thereby reducing vibration noise of the compressor. In addition, a back pressure groove may be formed on an upper surface of a drive transmission portion of the rolling piston, thereby reducing a friction area between the rolling piston and the upper bearing, as well as reducing a friction loss between the rolling piston and the upper bearing due to oil filled into the back pressure groove.

Owner:LG ELECTRONICS INC

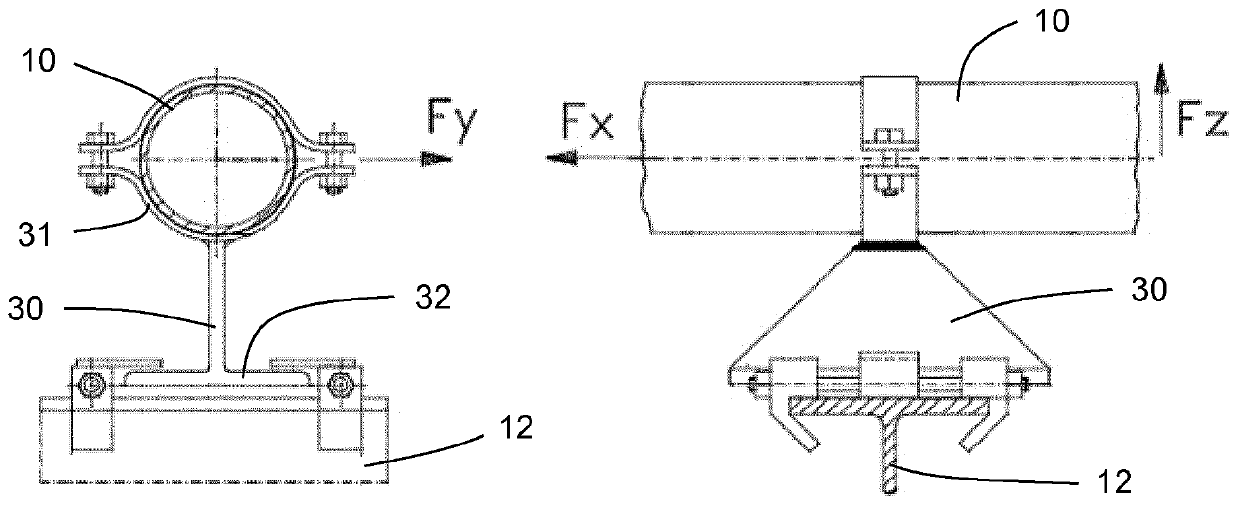

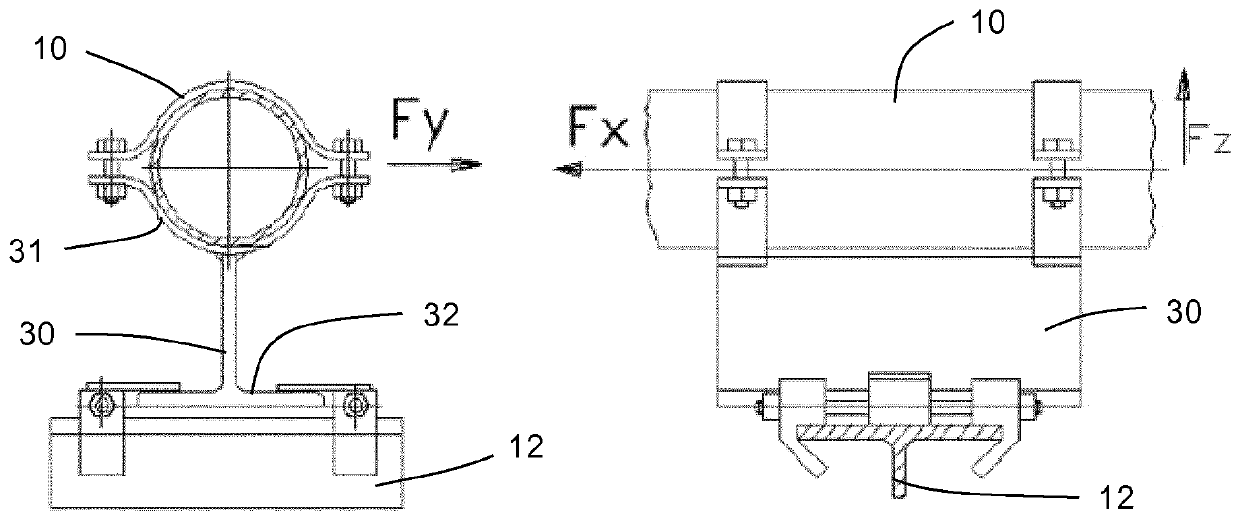

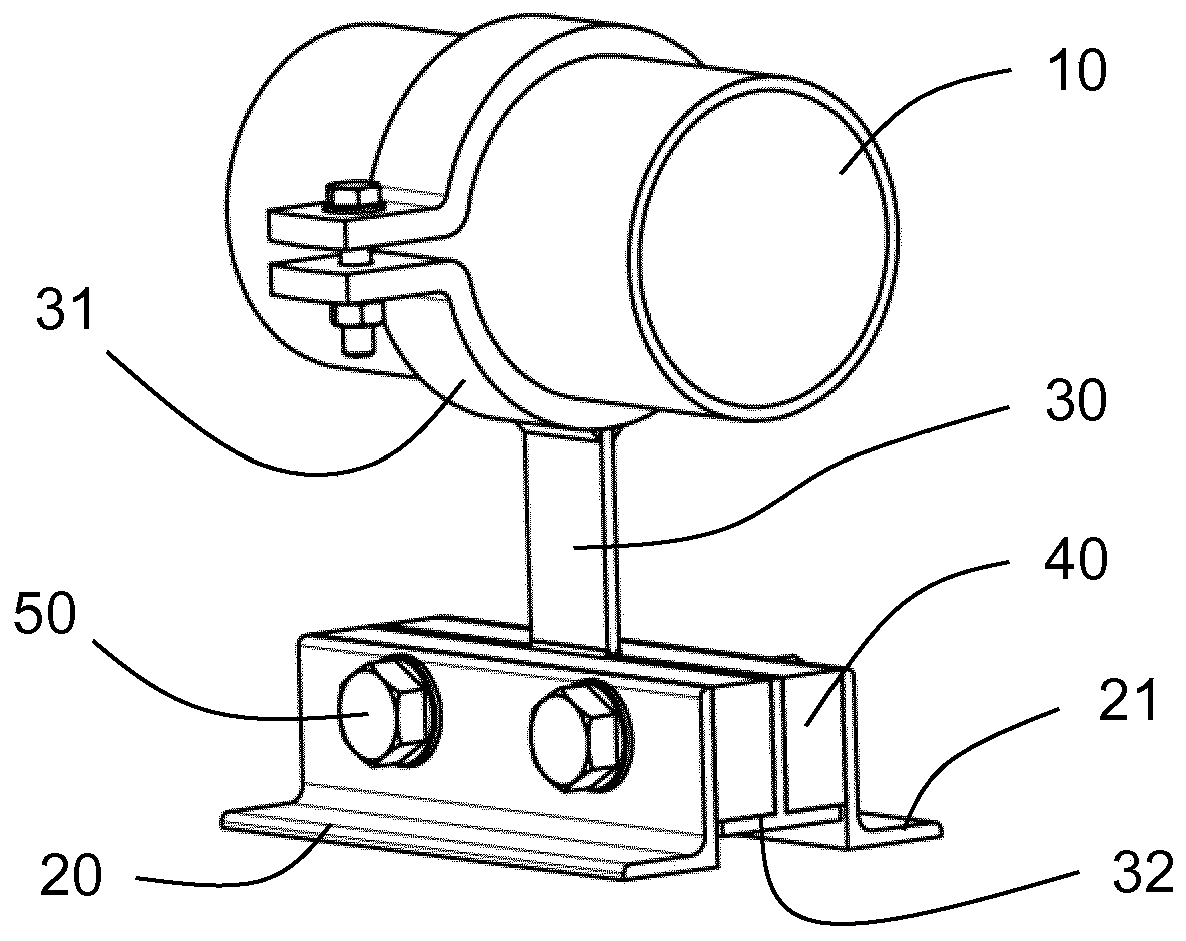

Thermally decoupled pipe bracket with high mechanical loading capacity

The invention relates to a pipe bracket for holding a pipe on a support comprising: two feet, which are arranged spaced from each other and can each be connected to the support; a carrying element with a web, a pipe holder at the upper end of the web and a foot part at the lower end of the web, wherein the foot part is arranged in the intermediate space between the feet; and at least one compression-resistant insulating element, which is arranged between the first foot and the foot part and between the second foot and the foot part of the carrying element, wherein feet, insulating elements andfoot part are frictionally connected together by at least one fastening.

Owner:BASF AG

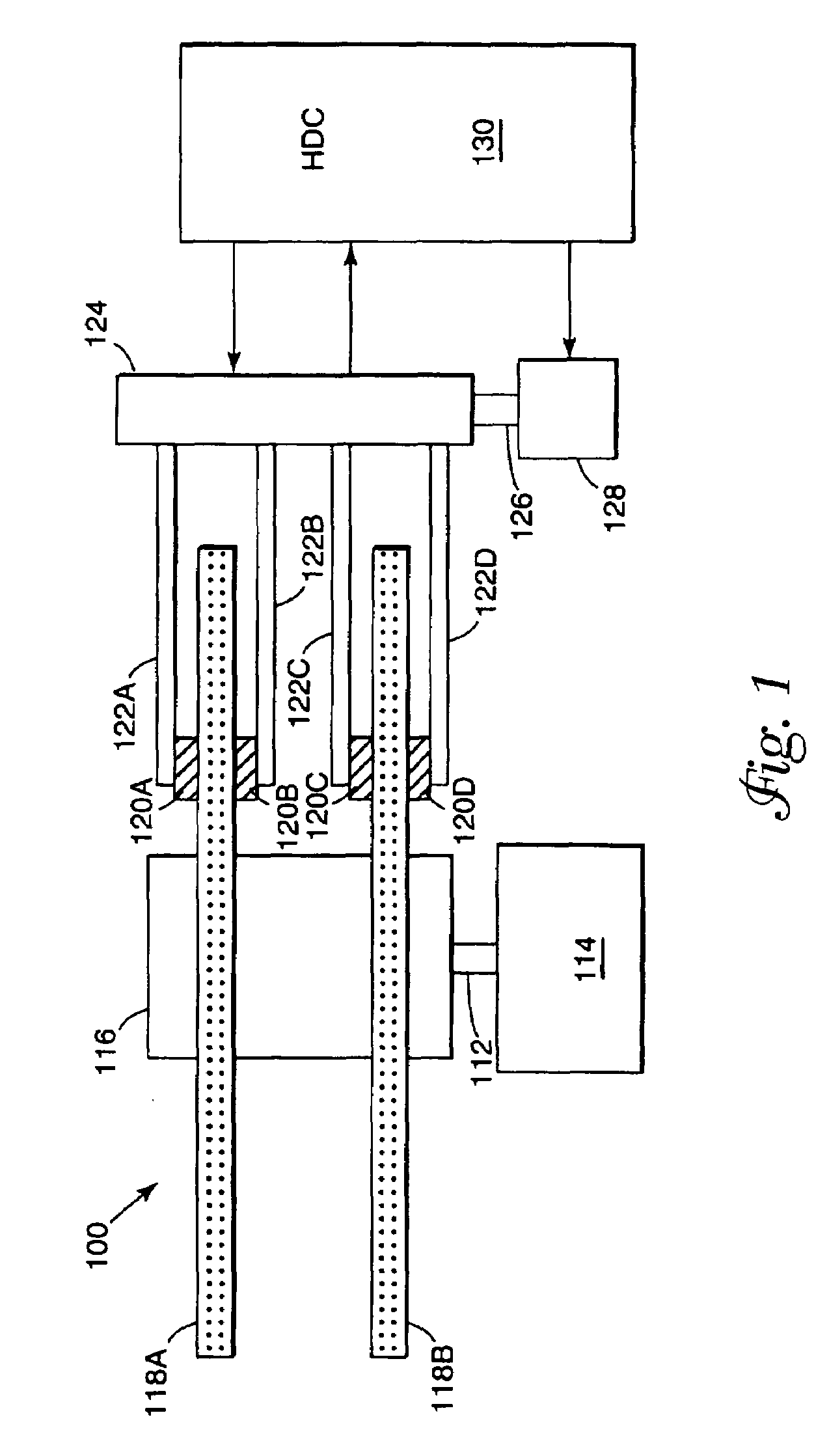

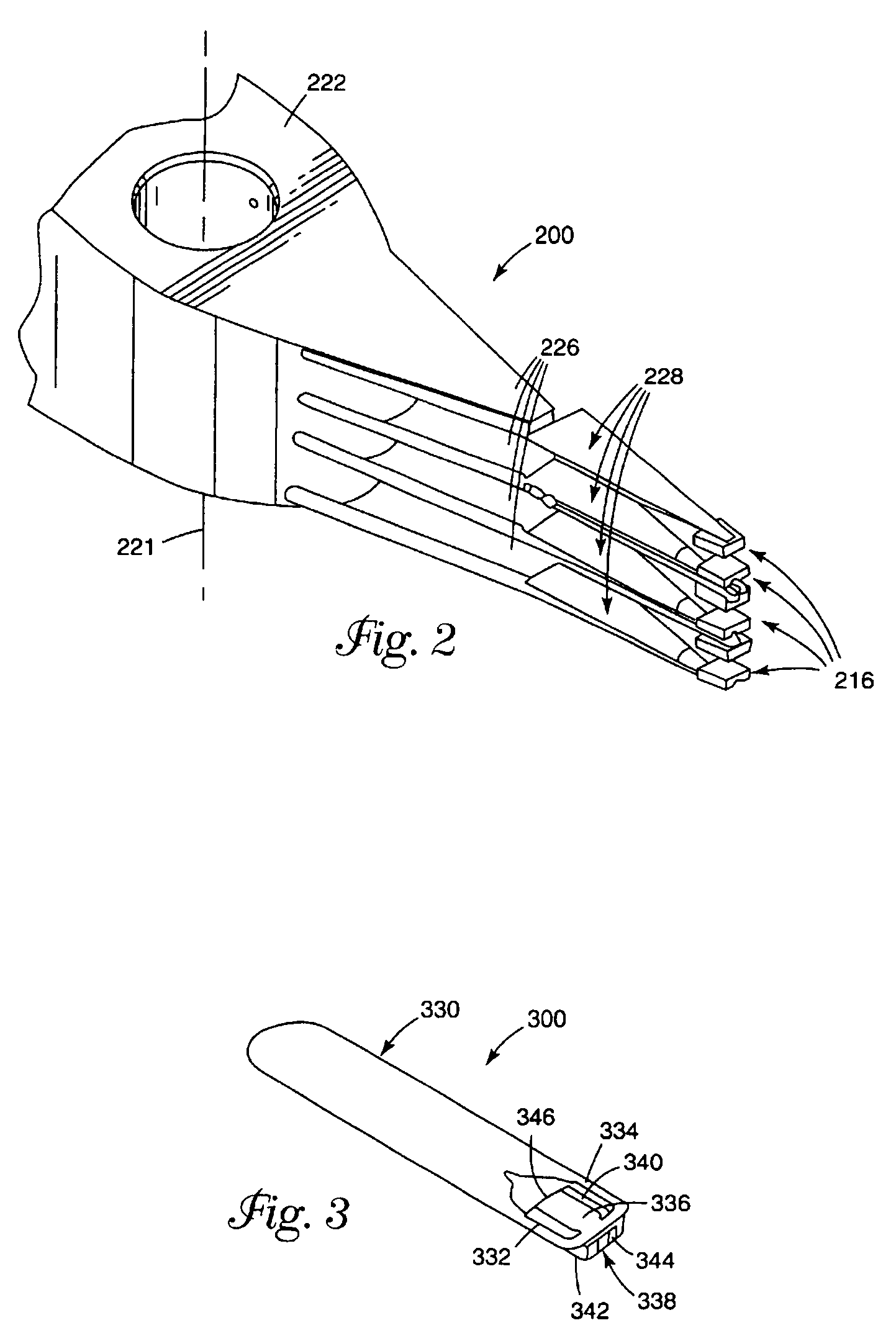

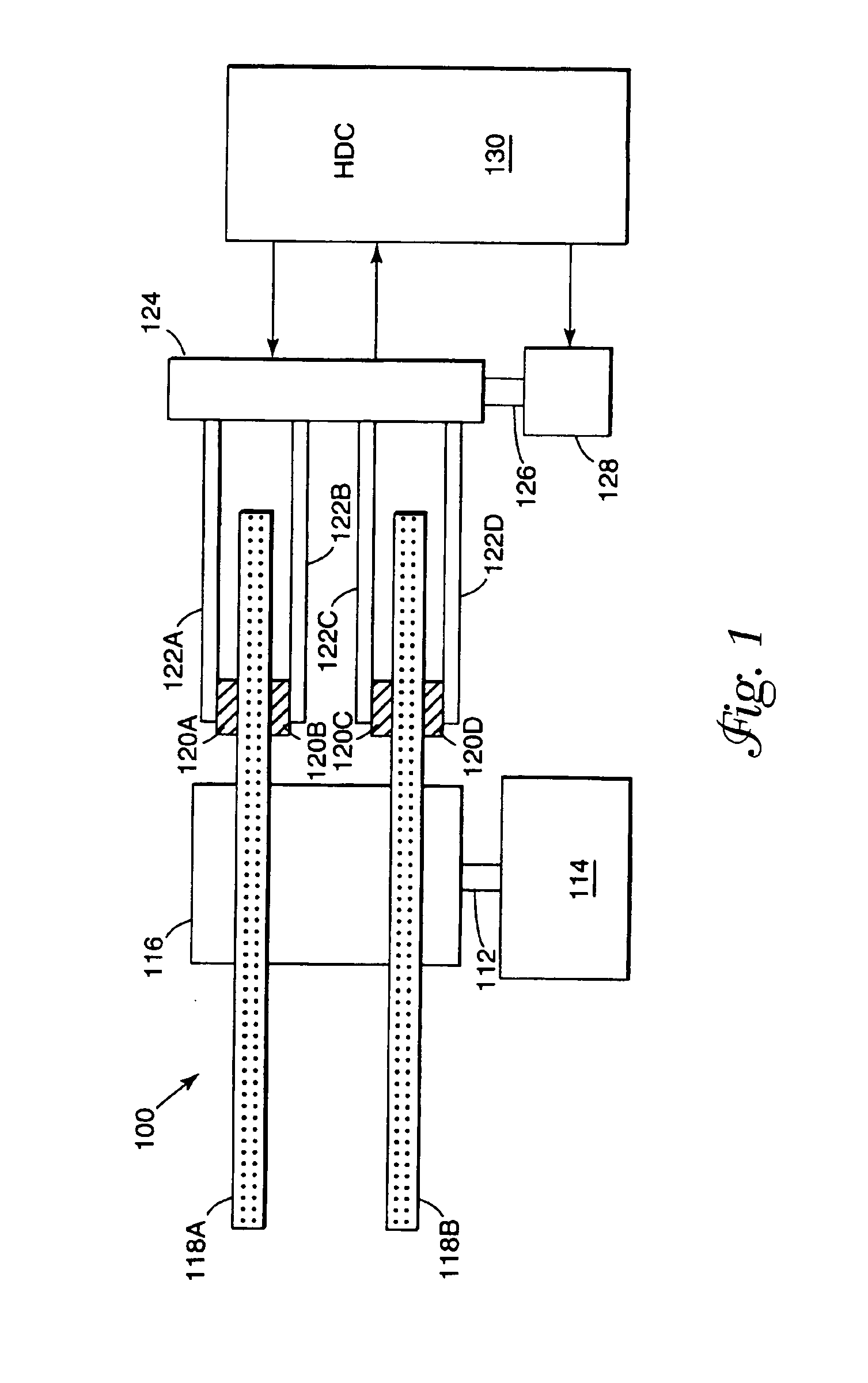

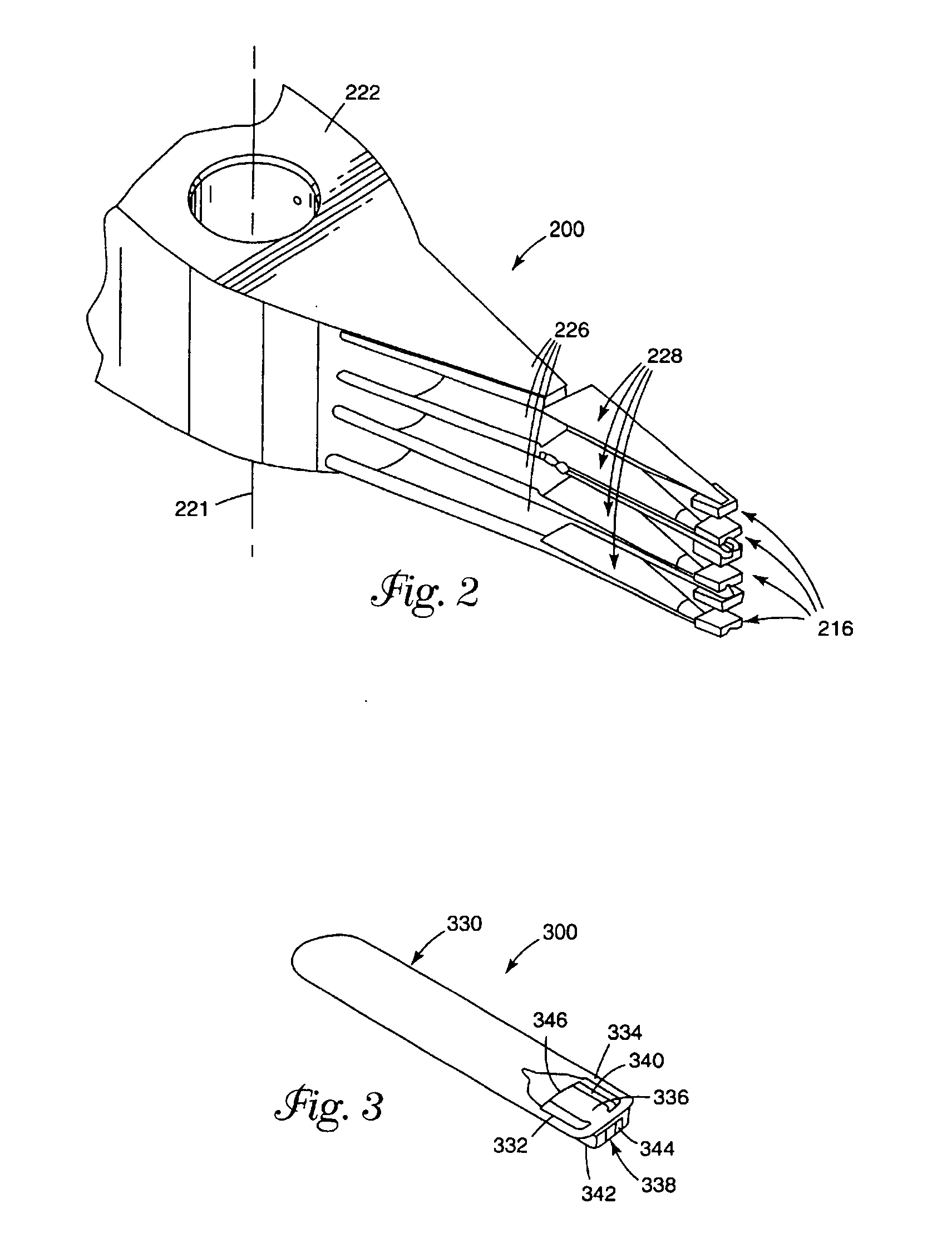

Method and apparatus for providing an air bearing pad having improved roll angle sigma

InactiveUS7251107B2Improved roll angle sigmaImprove roll stiffnessRecord information storageFluid-dynamic spacing of headsAir bearingEngineering

A method and apparatus for providing an air bearing pad having improved roll angle sigma is disclosed. Two Z-shaped air bearing pads are formed to provide two additional negative pockets for improving roll angle stiffness of the slider and for shrinking the air bearing area.

Owner:WESTERN DIGITAL TECH INC

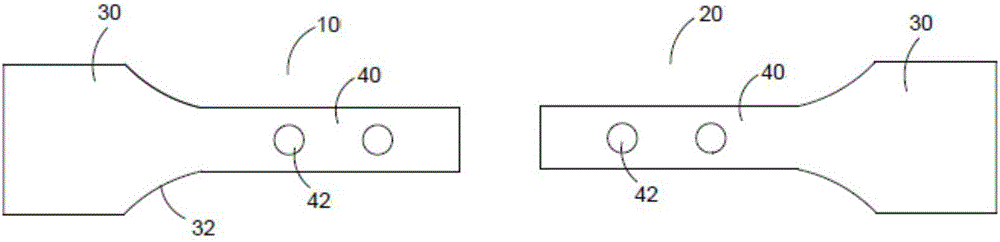

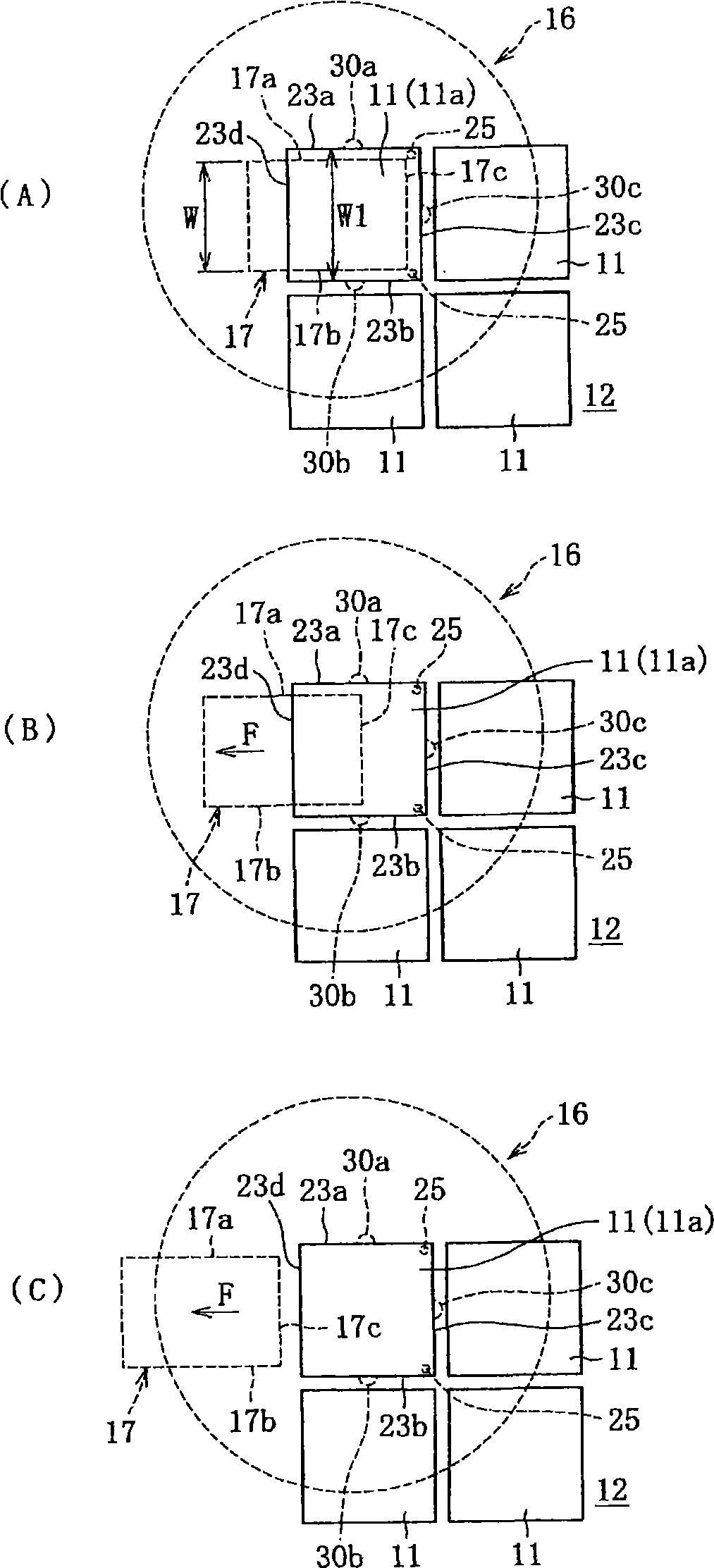

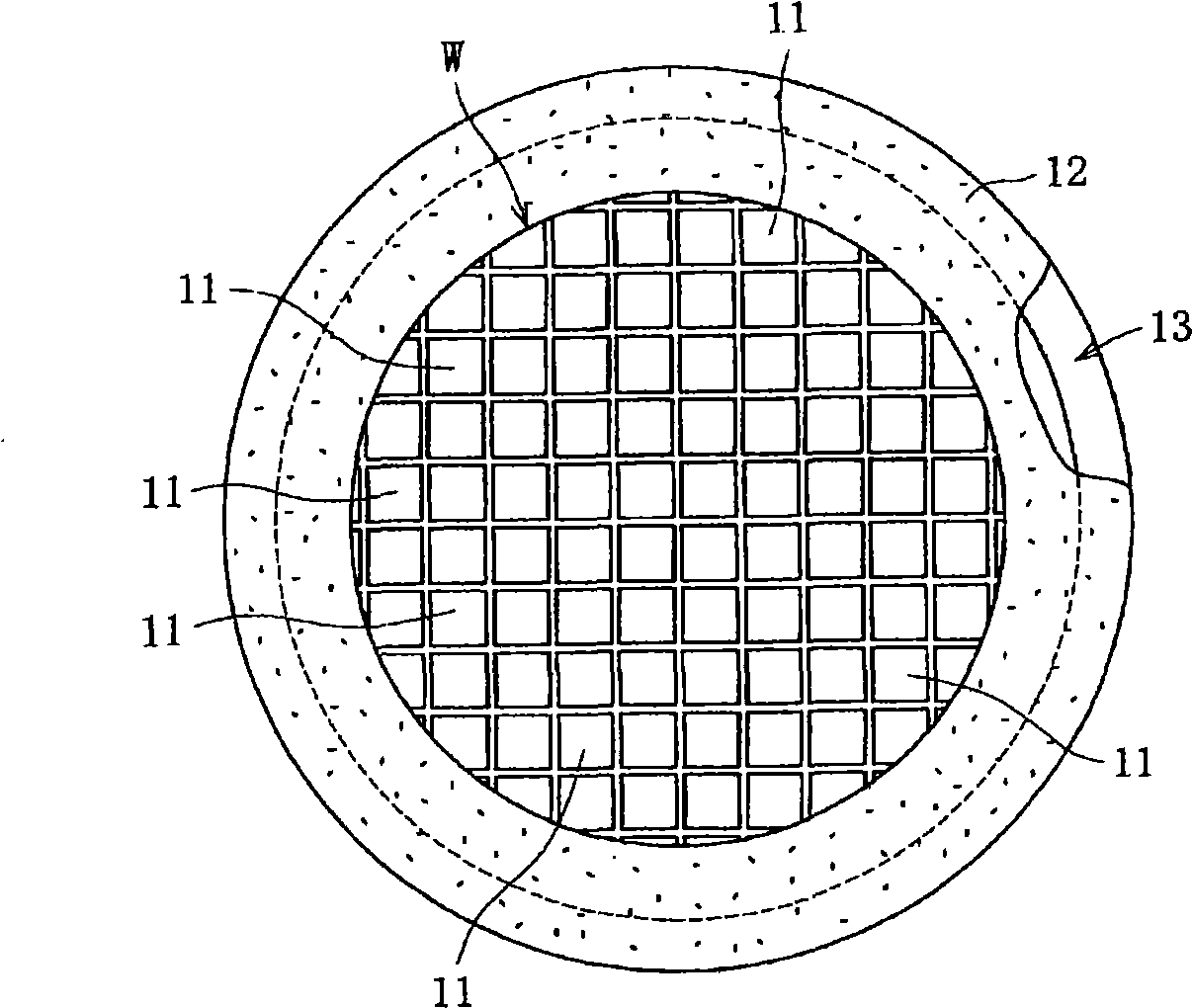

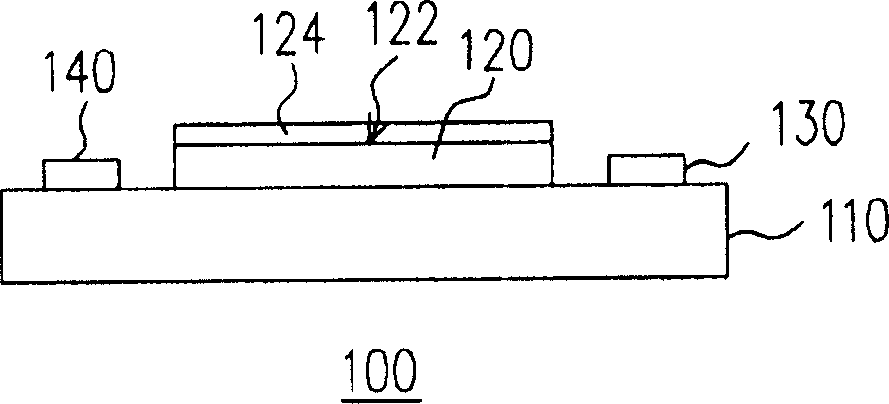

Pick-up method and pick-up device

ActiveCN101512746ABearing area reducedIncreased adsorption (suction) areaSemiconductor/solid-state device manufacturingElectrical componentsEngineeringBiomedical engineering

A method of pickup and pickup apparatus that lower the possibility of cracking of neighboring pellets and realize unfailing easy detaching and taking out of pellets to be detached. Multiple rectangular thin pellets (11) stuck onto pressure sensitive adhesive sheet (12) are sequentially detached from the pressure sensitive adhesive sheet (12) and taken out. While retaining each pellet (11) to be detached from above, suction from below is applied to the pressure sensitive adhesive sheet (12). Simultaneously with the air suction and pellet retention from above, while supporting the pressure sensitive adhesive sheet (12) from below by means of protrusions (25) for insertion in apertures (19), receiving part (17) is traveled in the horizontal direction to thereby realize detaching of the pellet (11).

Owner:CANON MACHINERY

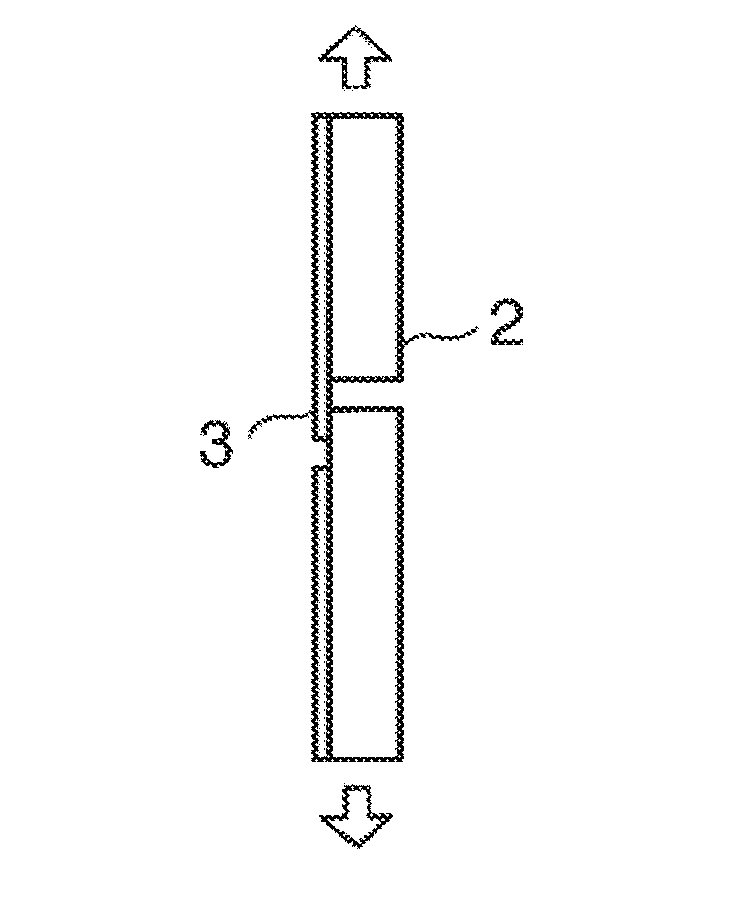

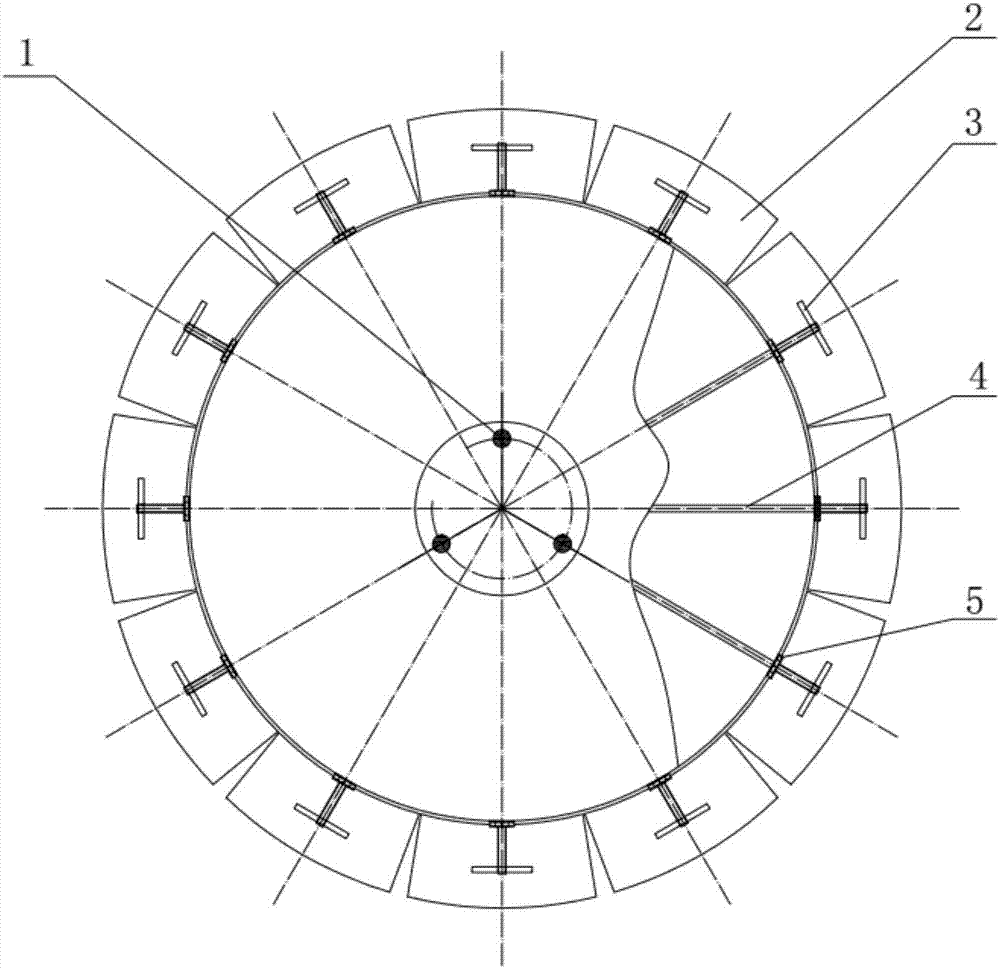

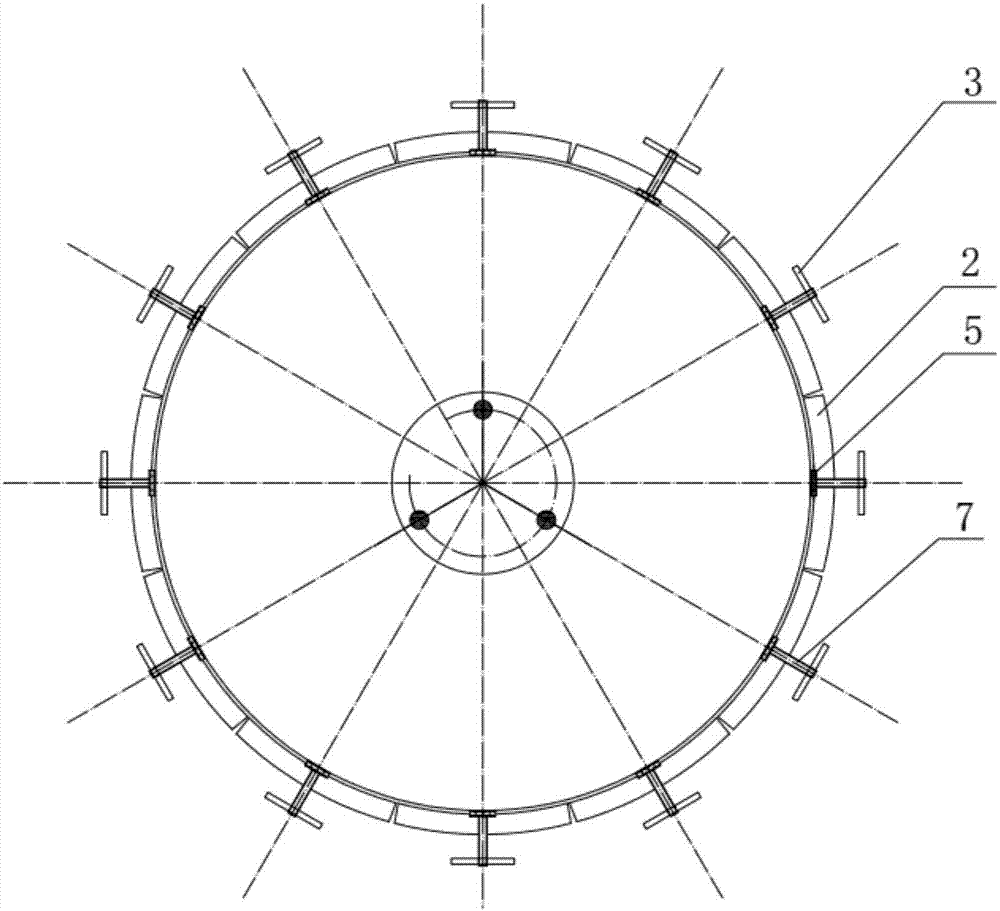

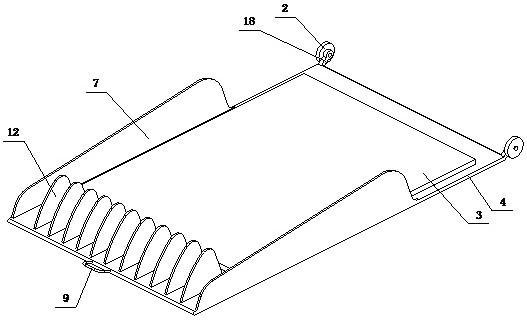

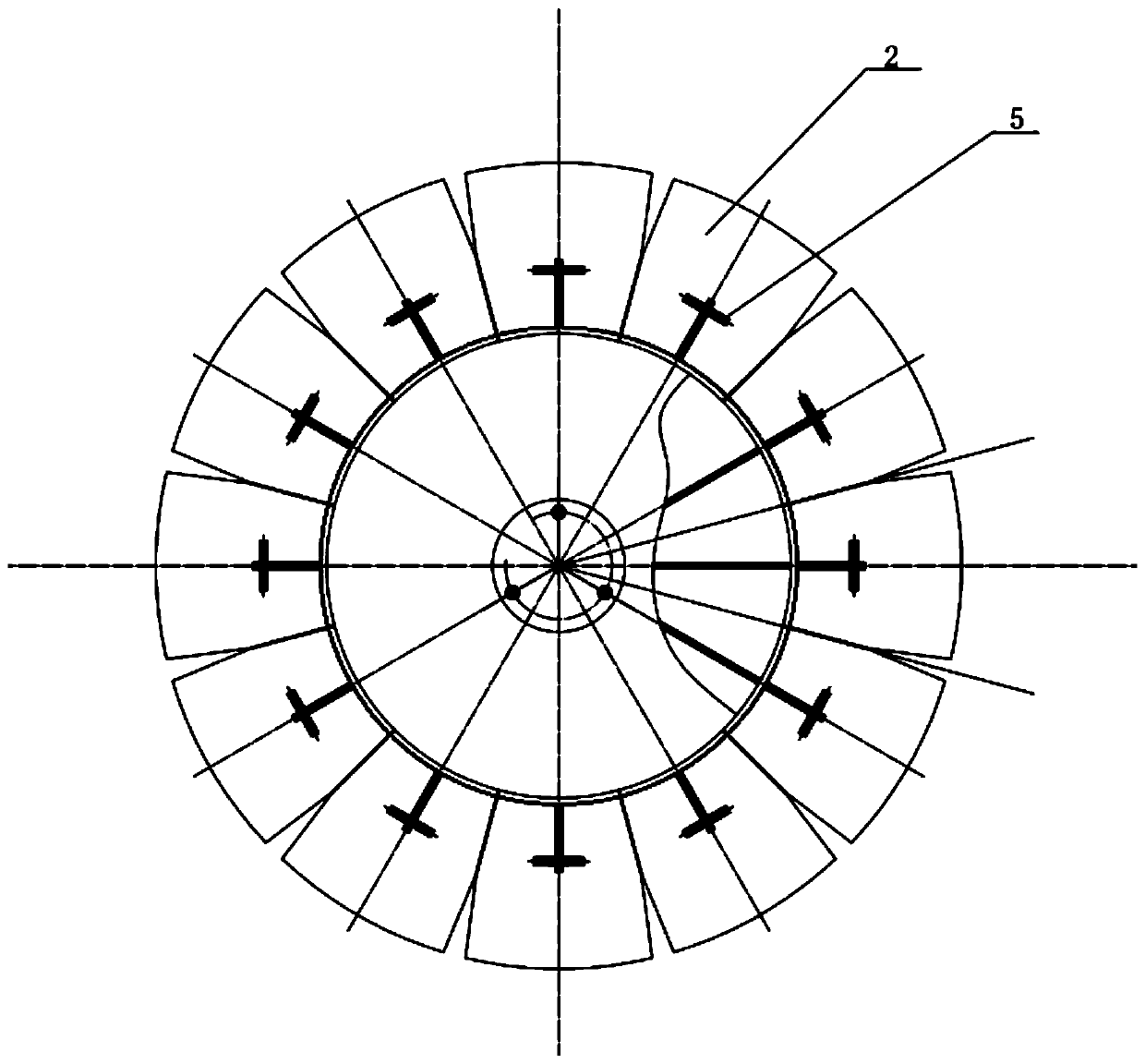

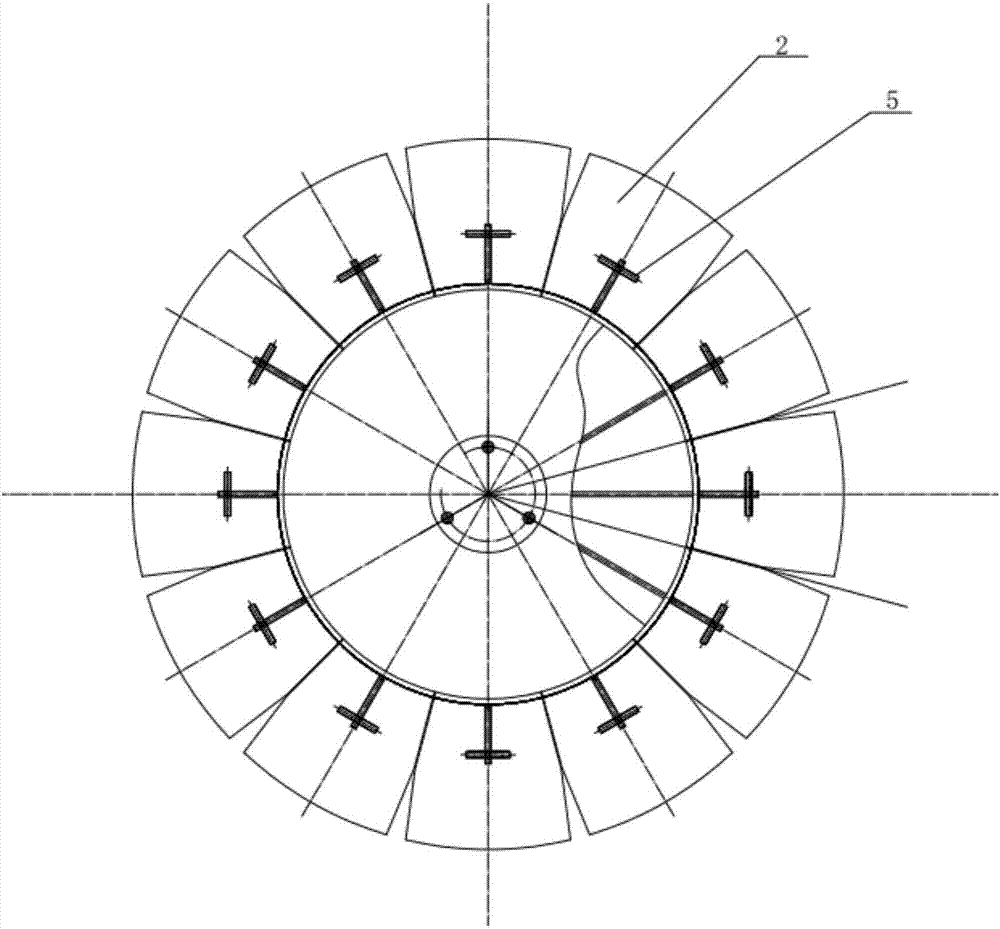

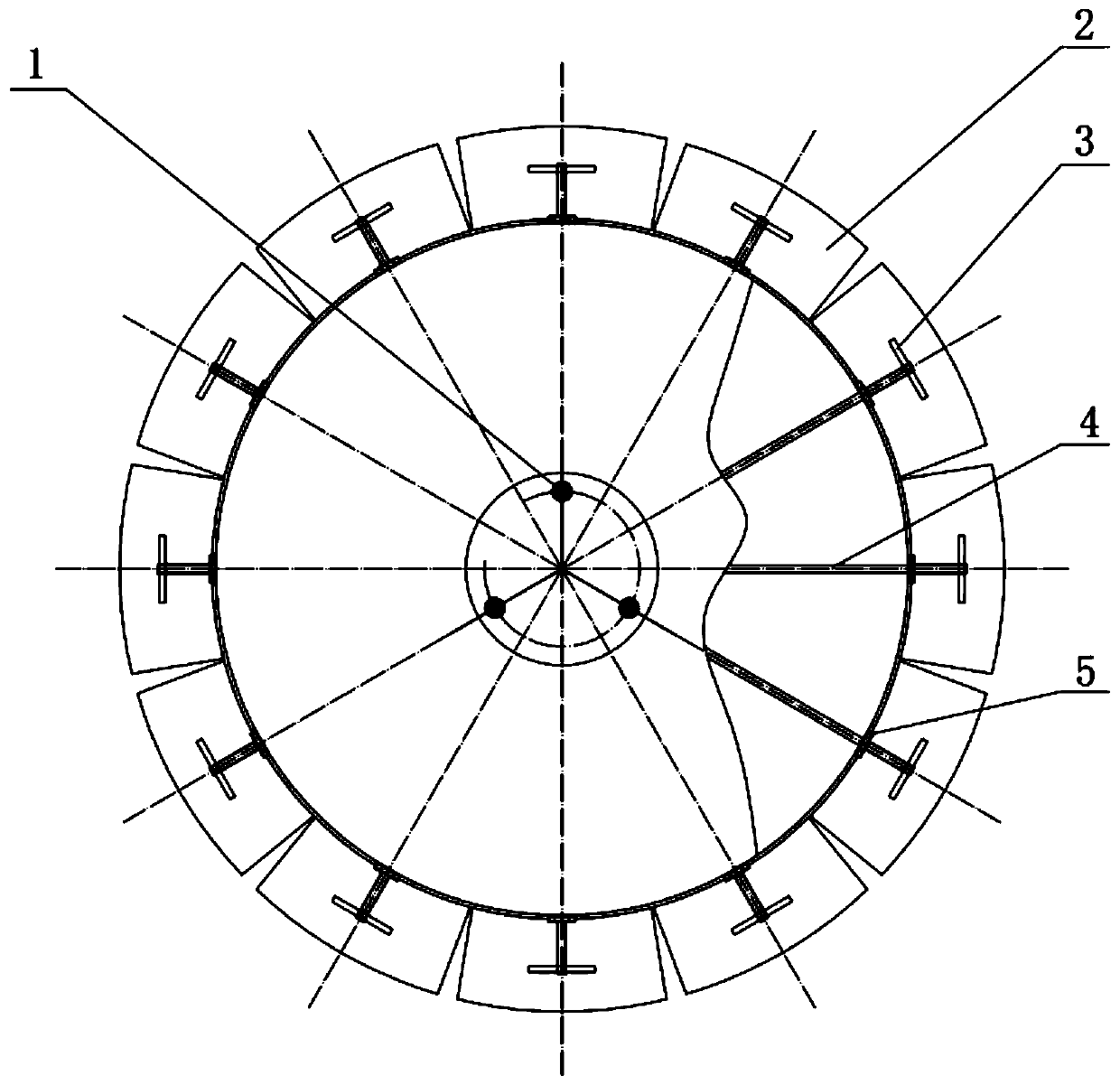

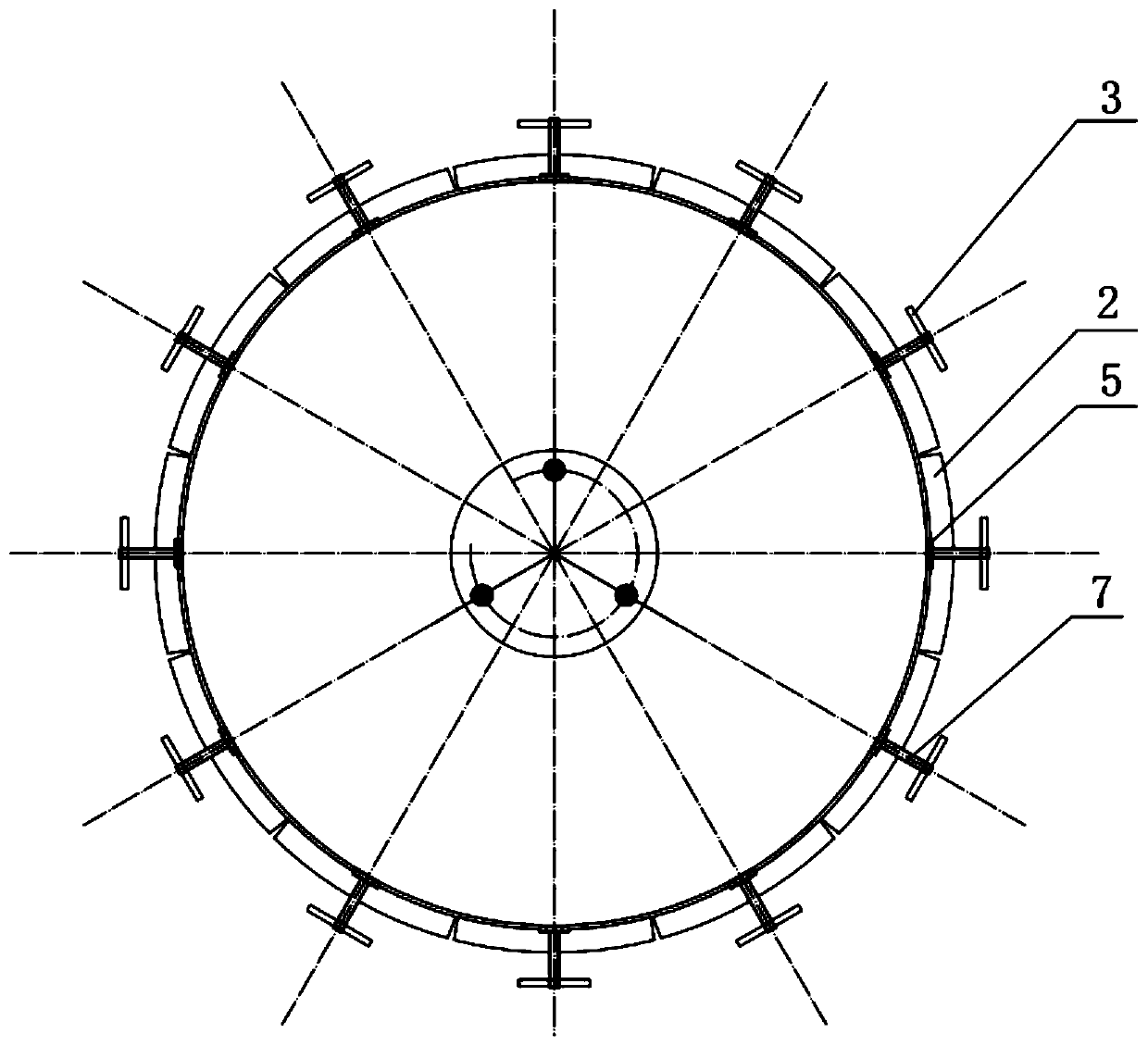

Platform pile shoe and drilling platform

ActiveCN107245993AIncrease the carrying areaExpansion (increase the bearing areaArtificial islandsUnderwater structuresStructural engineeringEngineering

The invention discloses a platform pile shoe and a drilling platform. The platform pile shoe comprises a pile shoe main body, and a plurality of turnover boards hinged with the pile shoe main body; the turnover boards surround the pile shoe main body; the turnover boards rotate outwards under soil body acting force during pile inserting, so that the bearing area of the platform pile shoe is enlarged; the turnover boards rotate inwards under the own gravity and the soil body gravity during pile pulling, so that the bearing area of the platform pile shoe is reduced; and the outer ends of the turnover boards are higher than the lowest point of the pile shoe main body when the pile inserting is completed, and are lower than the lowest point of the pile shoe main body when the pile inserting is not carried out. The platform pile shoe and the drilling platform can provide better bearing area, so that the platform stability is ensured; and the bearing area during the pile pulling is reduced, the pile pulling resistance is reduced, and thus the pile pulling is facilitated.

Owner:PETROCHINA CO LTD

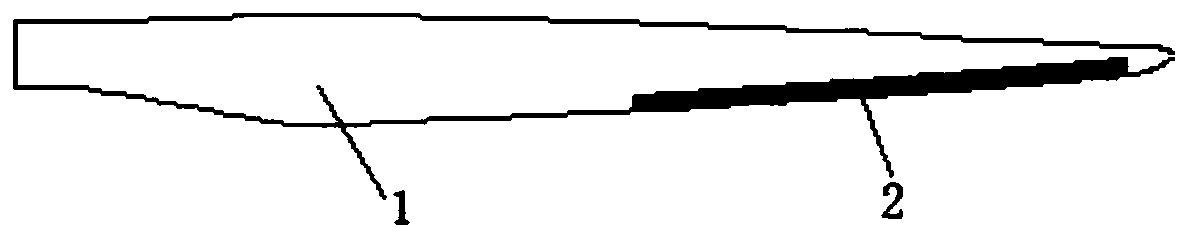

Wind turbine blade of wind turbine generator system

PendingCN111188728AEnsure safetyReduce load inputMachines/enginesEngine componentsTurbine bladeClassical mechanics

The invention relates to the technical field of wind power generation, and provides a wind turbine blade of a wind turbine generator system. The wind turbine blade is characterized in that a cavity isformed in a blade body, a supporting structure is arranged in the cavity; the blade body is provided with an elastic trailing edge, and the elastic trailing edge extends along the first side wall andthe second side wall of the blade body and is closed; and the cross section of the elastic trailing edge is a conical cross section, the elastic trailing edge comprises a first elastic wall and a second elastic wall, and the elastic trailing edge can be locally elastically deformed and integrally elastically deformed. The wind turbine blade has the beneficial effects that the elastic trailing edge is arranged in the blade body, and the polymer-based material with elastic elongation is introduced, so that the single material mode of the blade structure of the traditional fiber reinforced plastic is changed, the elastic trailing edge of the blade body can reduce the load input through elastic deformation, and the safety of the whole wind turbine generator system and all parts thereof is guaranteed from the source.

Owner:中国船级社质量认证有限公司

compressor

ActiveCN103912497BReduce power lossReduce leakageRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsFriction lossEngineering

Owner:LG ELECTRONICS INC

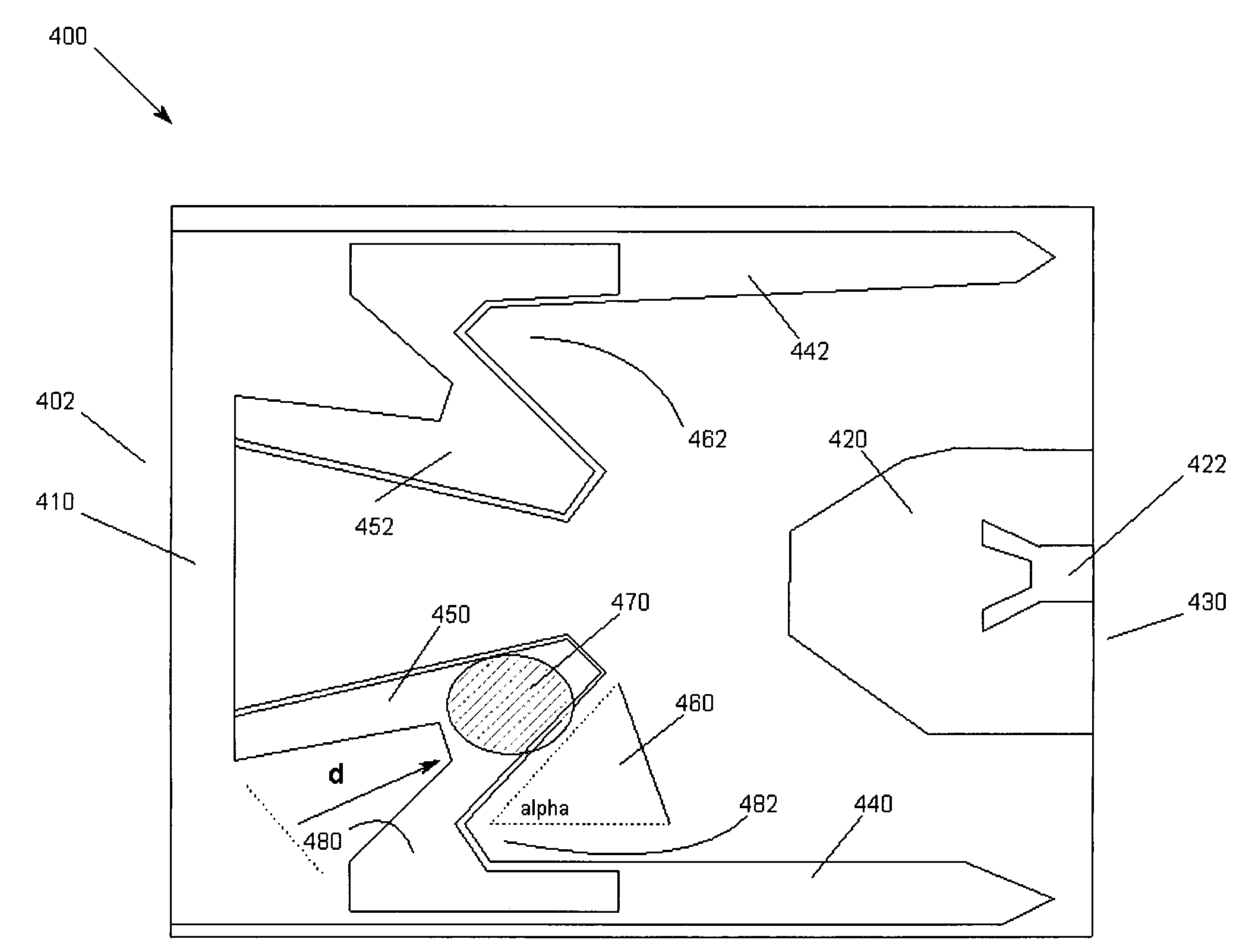

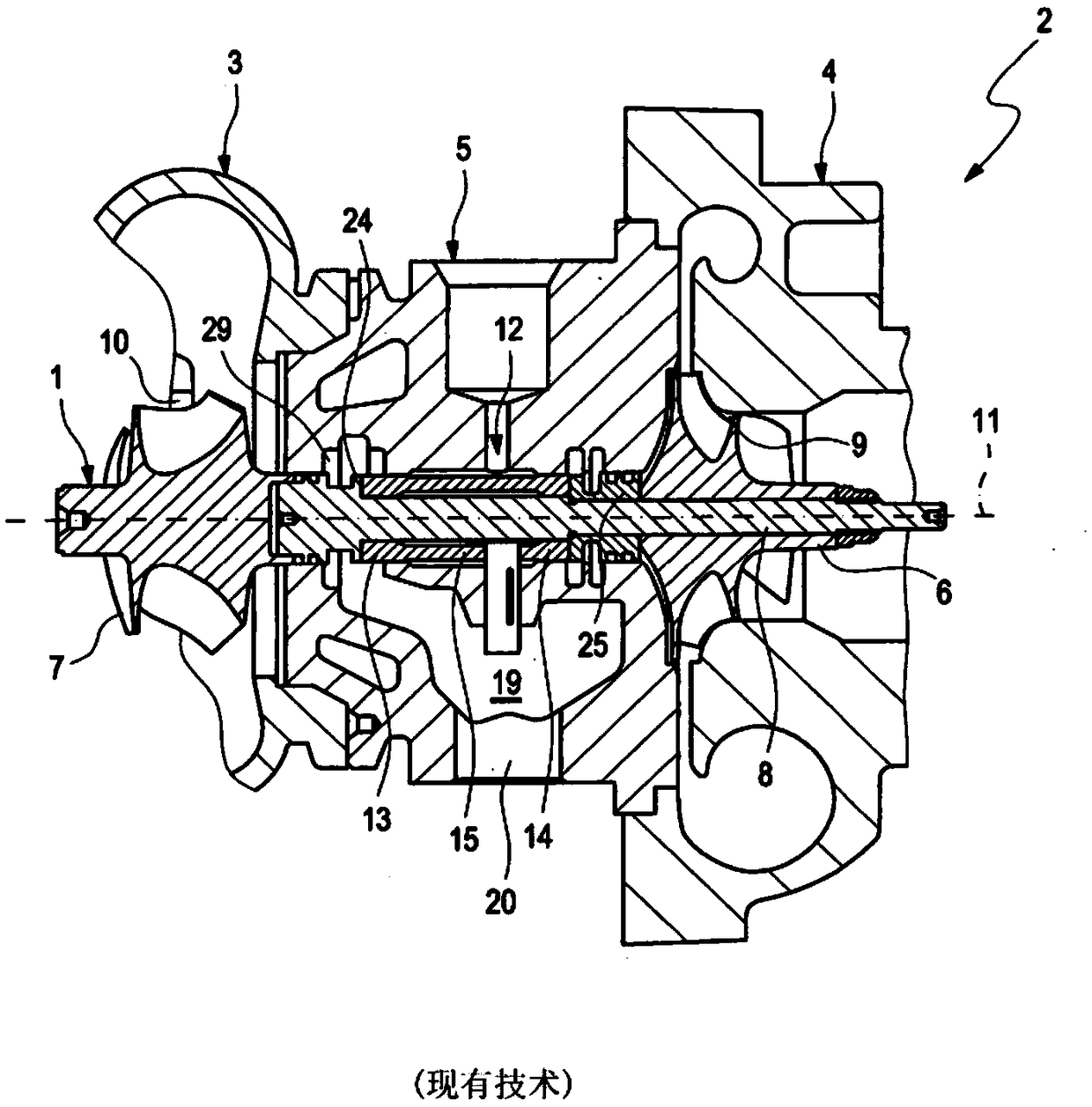

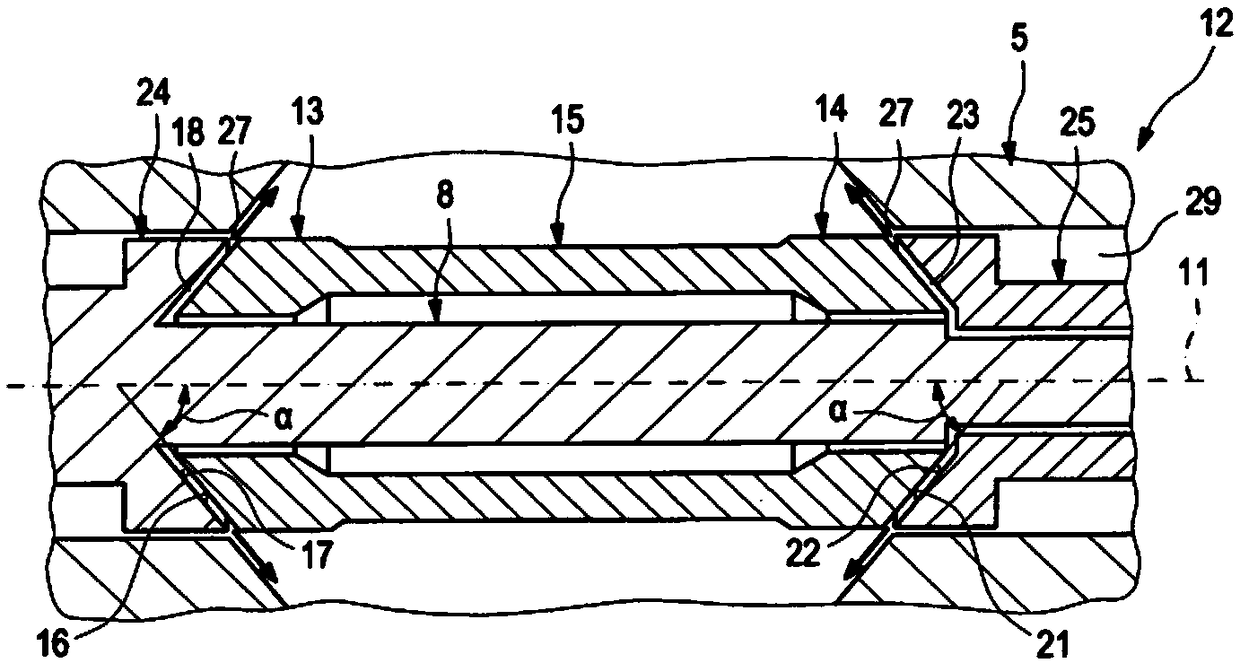

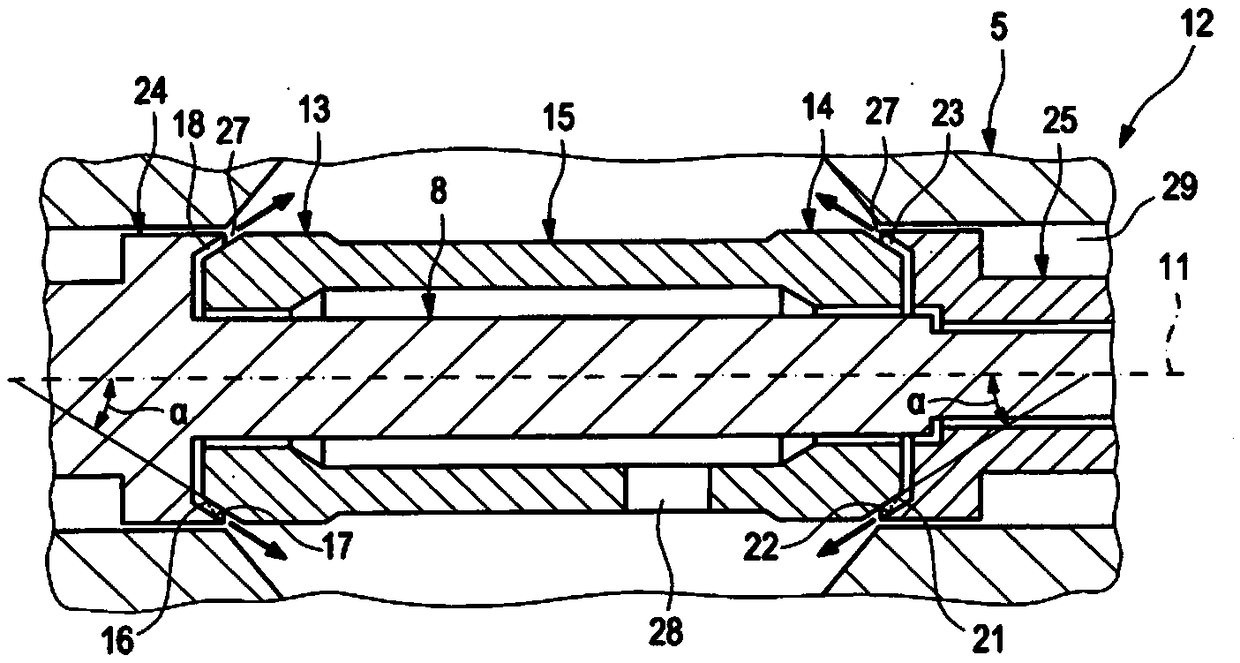

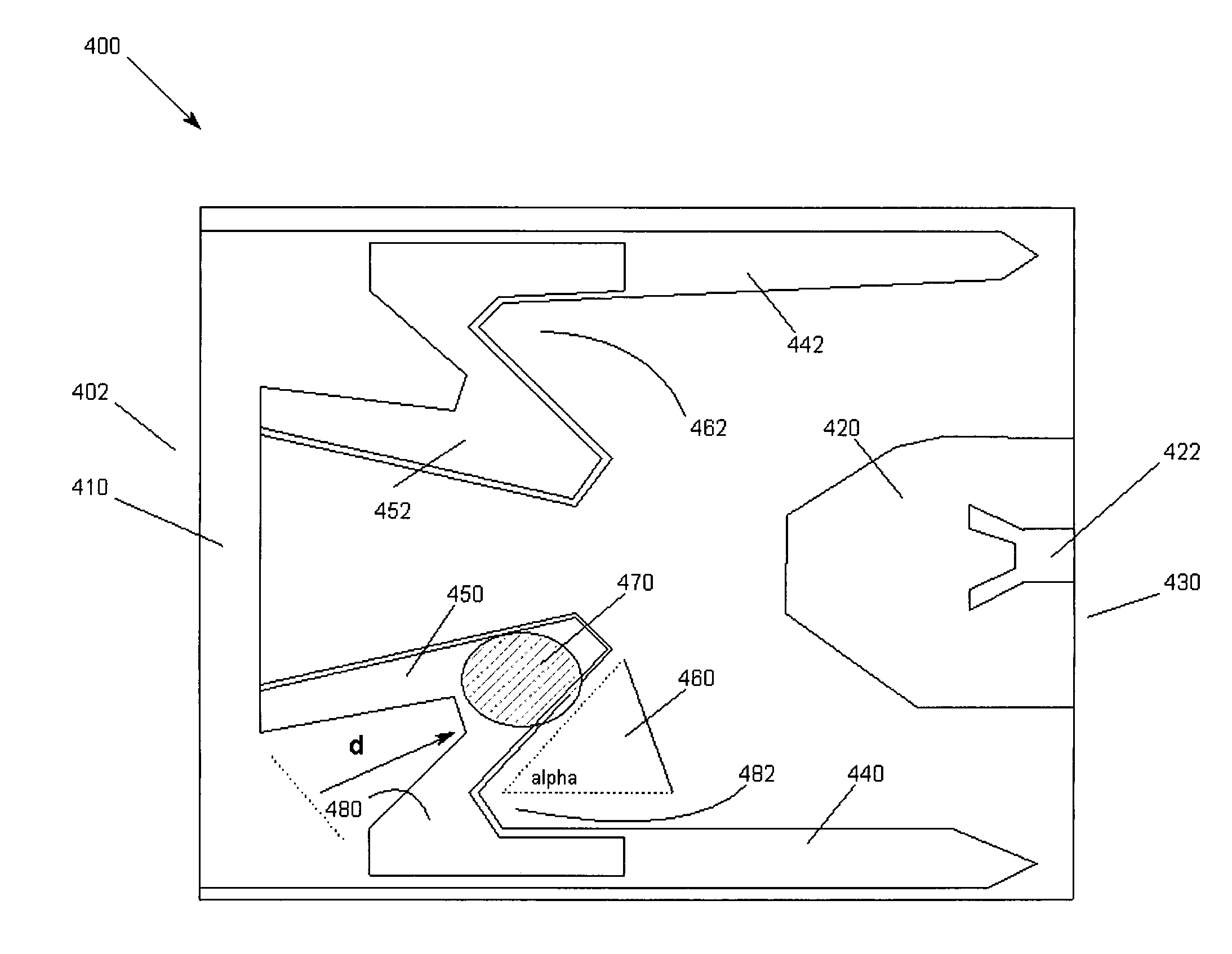

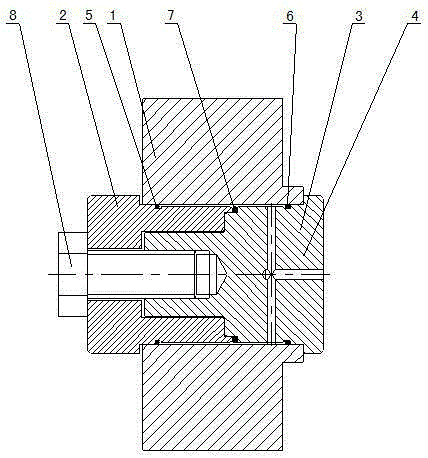

Bearing device for an exhaust gas turbocharger, and exhaust gas turbocharger

The invention relates to a bearing device for an exhaust gas turbocharger, having a first radial bearing (13) and a second radial bearing (14), wherein the radial bearings (13, 14) are configured forradially mounting a shaft (8) of the exhaust gas turbocharger (2) with a rotational axis (11), and wherein a first outflow gap (18) and a second outflow gap (23), respectively, are configured betweenthe first radial bearing (13) and a first supporting wall (17) of the exhaust gas turbocharger (2) for axially supporting the first radial bearing (13), which first supporting wall (17) extends radially and is configured so as to face a turbine wheel (7) of the exhaust gas turbocharger (2), and between the second radial bearing (14) and a second supporting wall (22) of the exhaust gas turbocharger(2) for axially supporting the second radial bearing (14), which second supporting wall (22) extends radially and is configured so as to face a compressor impeller (6) of the exhaust gas turbocharger(2). According to the invention, for axial and simultaneous radial bearing and / or for supporting the radial bearing, the first outflow gap (18) and / or the second outflow gap (23) are / is configured soas to be inclined or curved with respect to the rotational axis (11) at least partially with the configuration of an angle (alpha) which is greater than or less than 90 DEG.

Owner:IHI CHARGING SYST INT +1

Safety protection device for mine blasting

PendingCN112697001ABearing area reducedReduce impactBlastingArchitectural engineeringStructural engineering

Owner:张玉

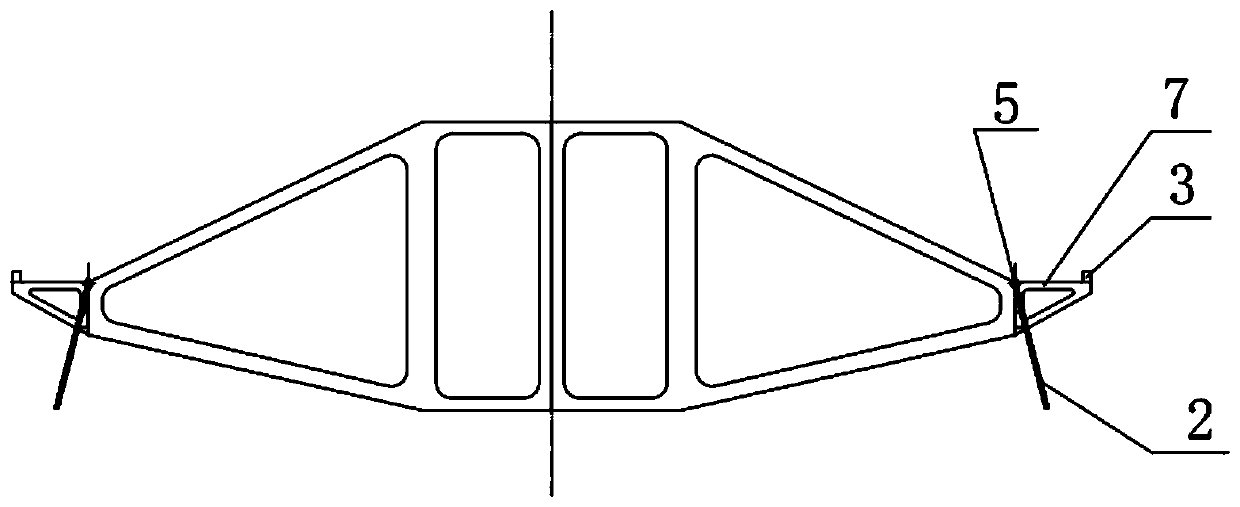

Jack-up platform spud shoes and drilling platform for high-capacity easy-extraction piles

ActiveCN107119679BIncrease the carrying areaImprove pile end bearing capacityArtificial islandsUnderwater structuresEngineeringBuoyancy function

The invention discloses a high-bearing capacity and easy-pile pulling self-elevating platform pile shoe and a drilling platform. The high-bearing capacity and easy-pile pulling self-elevating platform pile shoe comprises a pile shoe main body and a bearing unit hinged to the edge of the pile shoe main body, wherein the bearing unit surrounds the pile shoe main body; the bearing unit rotates outwards under acting force of a soil body during pile insertion, so that bearing area of the pile shoe is expanded; the bearing unit rotates inwards under gravity, buoyancy and adhesive force of the soil body during pile pulling, so that bearing area of the pile shoe is decreased; and the lowest point of the bearing unit is higher than the lowest point of the pile shoe main body after pile insertion. According to the high-bearing capacity and easy-pile pulling self-elevating platform pile shoe and the drilling platform, better bearing area can be provided, platform stability is guaranteed, bearing area of the pile shoe is decreased during pile pulling, pile pulling resistance is reduced, and pile pulling is facilitated.

Owner:PETROCHINA CO LTD

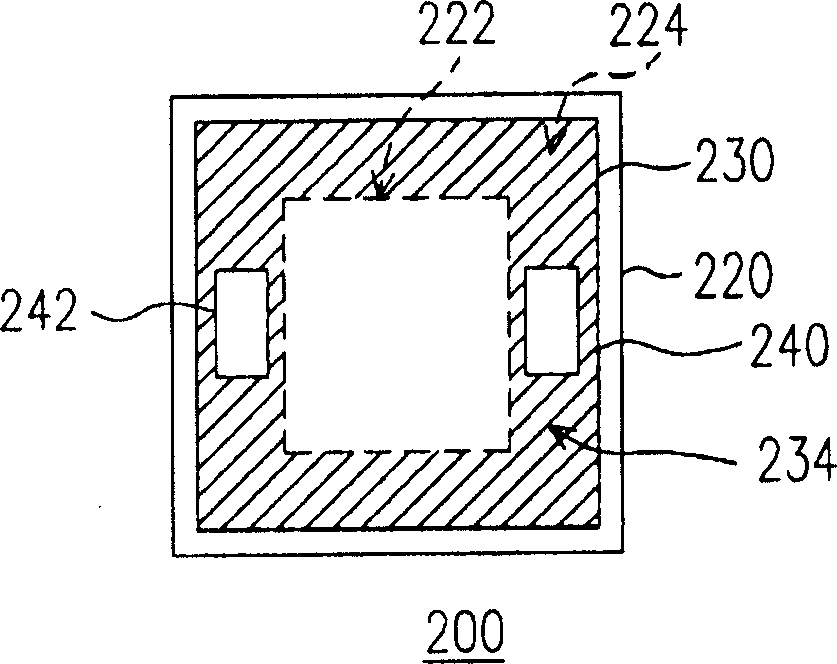

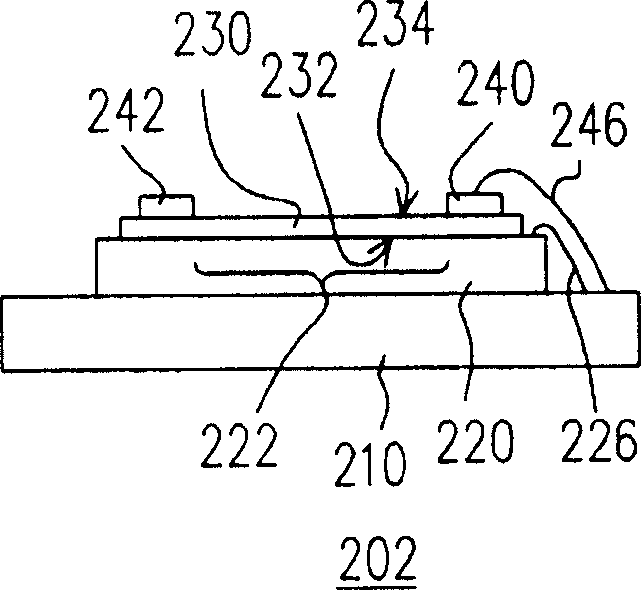

A packaging structure with a chip above a photosensitive element and electric packaging structure thereof

InactiveCN1670967ABearing area reducedHighly integratedSemiconductor/solid-state device detailsSolid-state devicesLight sensingSurface cover

A package structure of chip on light sensitive device containing a light sensitive device, a light transparent board and a chip, wherein the light sensitive device having a light sensing area and a non light sensing area, the light transparent board having a first surface and second surface and located on light sensitive device, the first surface covering on light sensing area and non light sensing area, the chip located the second surface and above the non light sensing area.

Owner:UNITED MICROELECTRONICS CORP

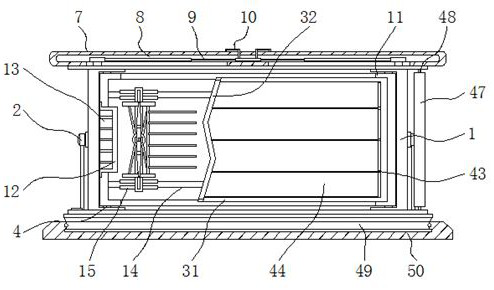

A multi-signal output video playback device with protective structure

ActiveCN108989722BBearing area reducedEasy to moveTelevision system detailsColor television detailsAir pumpStructural engineering

The invention discloses a multi-signal output video playing device with a protective structure, comprises a base plate and a force receiving plate, wherein the left and right side walls of the base plate are embedded with brackets, the front face of the base plate is fixed with clamping rails, a matching rack is arranged on the side of the clamping rails far away from the horizontal centerline ofthe base plate, insertion plates are fixed on the left and right sides of the surface of the force receiving plate, and the force receiving plate is located on the side of the base plate close to thevertical centerline of the top plate. The multi-signal output video playback device having a protective structure is provided with a plurality of substrates, forming a first carrier structure of the video playback apparatus, the carrier structure is completely used for supporting and fixing the video playing device, the upper and lower ends of the base plate are respectively clamped in the top plate and the base, and the base plate can obtain the displacement action power on the top plate, and the air pipe is externally connected with the air pump body, and the pneumatic telescopic rod is correspondingly expanded and contracted through the control of the air pressure, so as to drag the base plates on the left and right sides to move horizontally.

Owner:深圳市歌扬文化传播有限公司

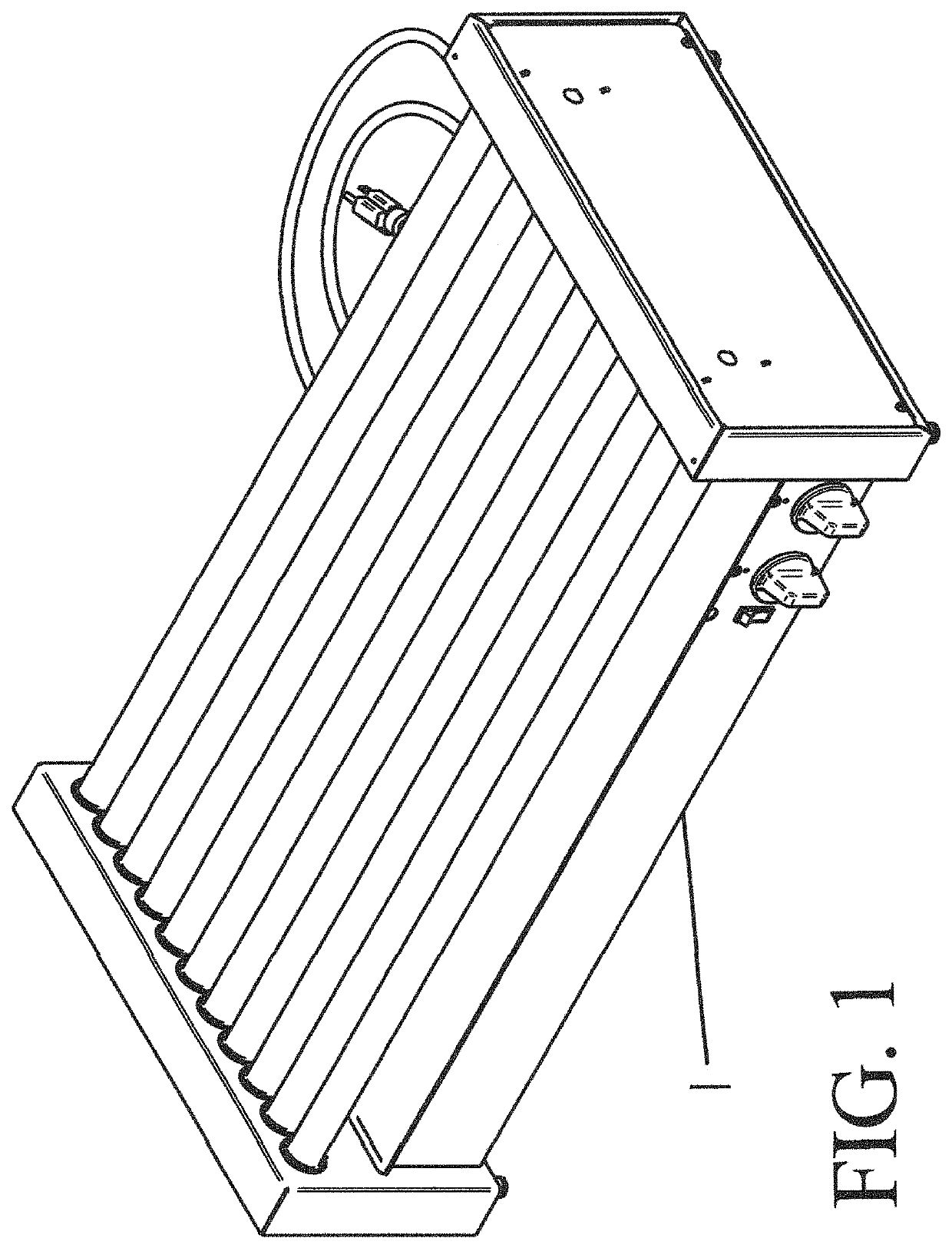

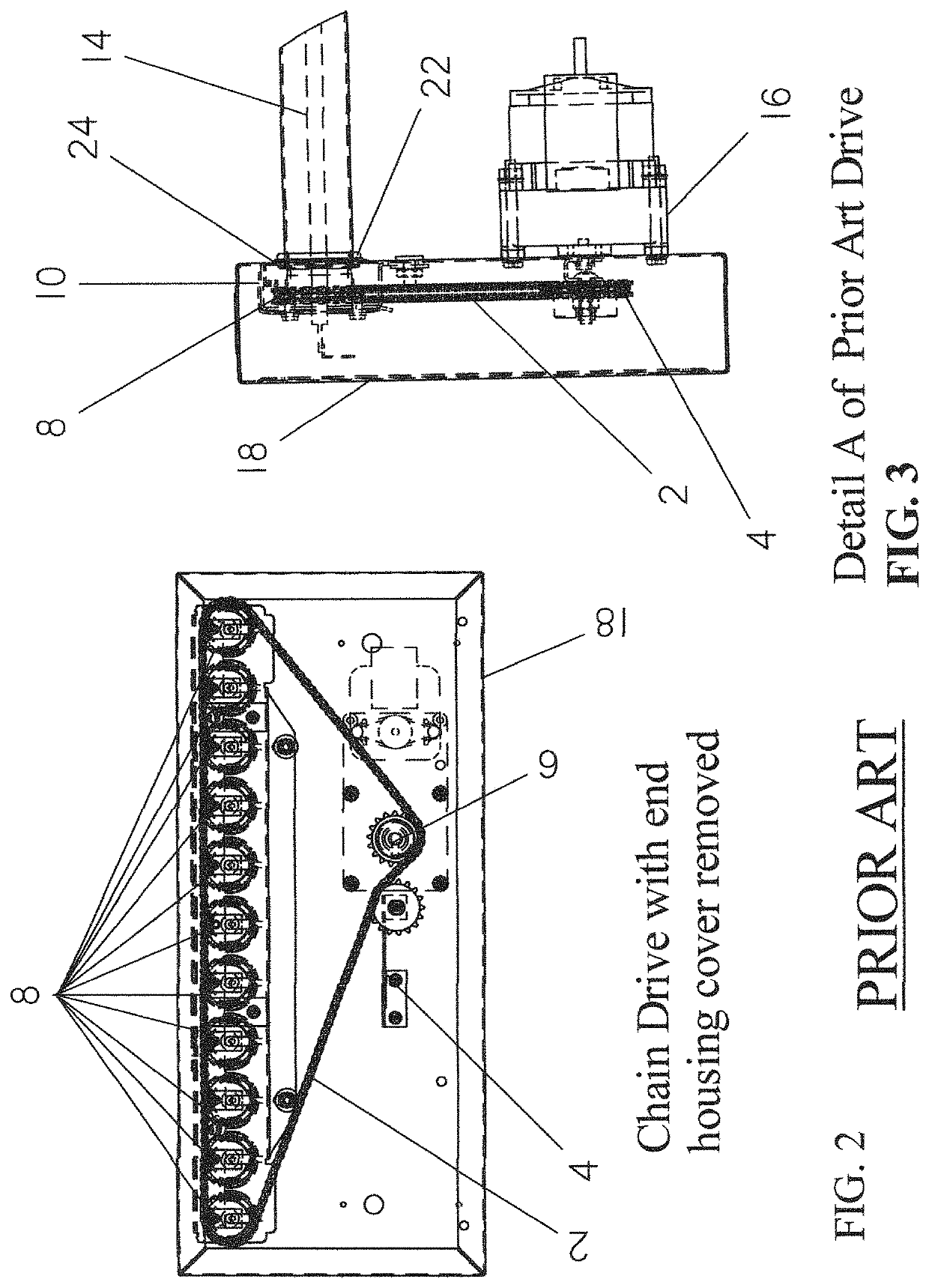

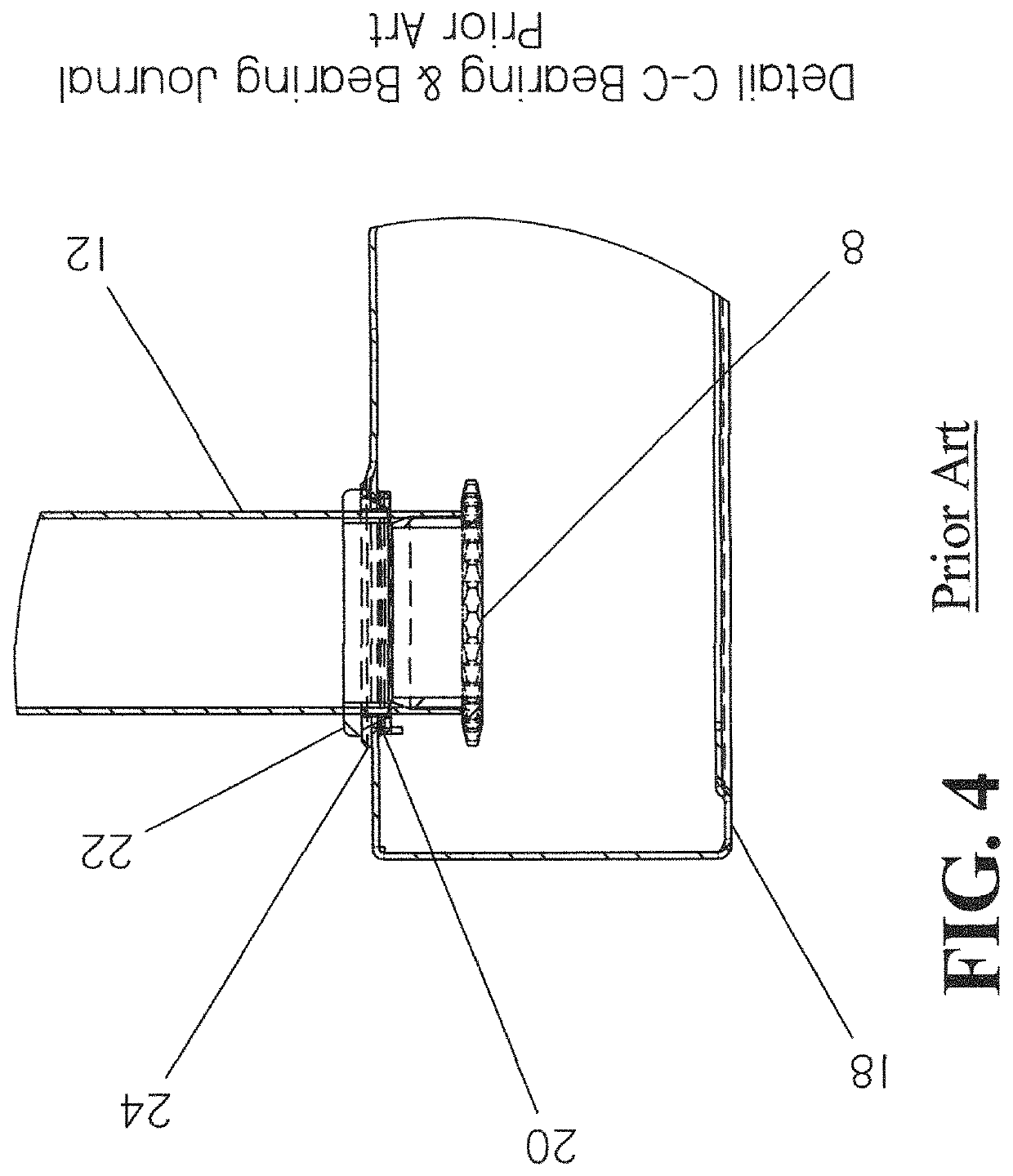

Extended life roller grill

Owner:HUMPHREY IND APPLIANCE DESIGN & CONSULTING LLC

Method and apparatus for providing an air bearing pad having improved roll angle sigma

InactiveUS20060023360A1Improved roll angle sigmaImprove roll stiffnessRecord information storageFluid-dynamic spacing of headsAir bearingEngineering

A method and apparatus for providing an air bearing pad having improved roll angle sigma is disclosed. Two Z-shaped air bearing pads are formed to provide two additional negative pockets for improving roll angle stiffness of the slider and for shrinking the air bearing area.

Owner:WESTERN DIGITAL TECH INC

A measuring head pressure test tool

InactiveCN102928299BEasy to manufactureEasy to useMaterial strength using tensile/compressive forcesStructural/machines measurementHigh pressure waterEngineering

Owner:SUZHOU MINZHE MACHINERY

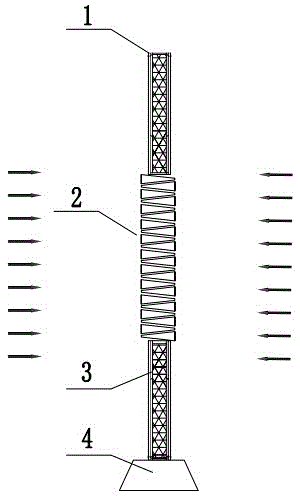

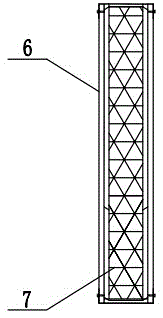

Adjustable automatic load shedding sound barrier

ActiveCN104612071BChange direction of propagationReduce adverse effectsNoise reduction constructionFatigue damageLoad Shedding

The invention discloses an adjustable automatic load-reduction sound barrier. The load-reduction sound barrier comprises an upper-layer plate, a middle-layer plate, a lower-layer plate, a base and stand columns. The adjustable automatic load-reduction sound barrier has the advantages that on the basis of theoretical analysis and numerical simulation calculation, noise mainly transmitted by a pantograph and a wheel rail can be straightly blocked and absorbed through a seamless structure of the upper-layer plate and the lower-layer plate; the spreading direction and spreading distance of sound waves can be effectively changed while the middle-layer plate can guarantee that train wind and natural wind pass freely, and the aim of lowering noise is achieved; mounting is convenient, and economical efficiency is achieved; the sound barrier is of an assembled structure, flow-process construction can be achieved, work efficiency can be improved, construction time can be shortened, and a large amount of manpower and cost can be saved; the cost is saved; the structure is durable; the negative influence of wind loads on the sound barrier is eliminated through the sound barrier, fatigue damage of loads of the train wind and the natural wind to the structure of the sound barrier is reduced, and therefore the aims of prolonging the maintenance period and service life of the structure of the barrier are achieved, and the use cost is greatly saved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Turning bearing with rollers between outer ring and inner ring

An effective contact length in race surfaces formed on grooved races cut in an outer ring and an inner ring is made as greater as permitted to improve the load-carrying capacity, and correspondingly guide parts born against axially opposite ends of a roller are made as less as possible in width to reduce frictional contact resistance applied to the axially opposite ends of the roller, thereby preventing a skew of the roller. An inside circular surface on the outer ring is staggered or different in level on opposite sides of a outside grooved race to make greater the race surface than an effective contact length of circular rolling surfaces of the rollers and correspondingly less the guide part in width than the race surface.

Owner:NIPPON THOMPSON

Measuring method for mechanical properties of electron gun thermal subassembly

ActiveCN105738224BIncrease stressLarge deformationMaterial strength using tensile/compressive forcesPlatinumWorking environment

The invention relates to a method for testing mechanical properties of an electronic gun heater assembly, comprising the following steps: (1), taking at least two heater assemblies under detection; (2), marking an original scale distance on a heater of each heater assembly under detection, and determining original scale distances L0 and S0; (3), testing yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection in an actual vacuum environment at different temperatures; (4), establishing a change-with-temperature linear relationship of the yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection by linear fitting; (5), according to the linear relationship, calculating to obtain the yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection at the actual operation temperatures. The method enables chemical tensile performance parameters of a heater or a combination of a heater with a platinum sheet and / or a cathode head in a vacuum high-temperature operating environment to be accurately measured, and the testing problem of engineering needs is solved.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

A kind of multi-purpose non-destructive testing natural defect test block and manufacturing method

ActiveCN110553884BImprove the detection effectBearing area reducedMaterial analysis using wave/particle radiationPreparing sample for investigationSlag (welding)Destructive testing

Owner:盐山双盛金属材料检测有限公司

High-bearing capacity and easy-pile pulling self-elevating platform pile shoe and drilling platform

ActiveCN107119679AIncrease the carrying areaImprove pile end bearing capacityArtificial islandsUnderwater structuresEngineeringBuoyancy function

The invention discloses a high-bearing capacity and easy-pile pulling self-elevating platform pile shoe and a drilling platform. The high-bearing capacity and easy-pile pulling self-elevating platform pile shoe comprises a pile shoe main body and a bearing unit hinged to the edge of the pile shoe main body, wherein the bearing unit surrounds the pile shoe main body; the bearing unit rotates outwards under acting force of a soil body during pile insertion, so that bearing area of the pile shoe is expanded; the bearing unit rotates inwards under gravity, buoyancy and adhesive force of the soil body during pile pulling, so that bearing area of the pile shoe is decreased; and the lowest point of the bearing unit is higher than the lowest point of the pile shoe main body after pile insertion. According to the high-bearing capacity and easy-pile pulling self-elevating platform pile shoe and the drilling platform, better bearing area can be provided, platform stability is guaranteed, bearing area of the pile shoe is decreased during pile pulling, pile pulling resistance is reduced, and pile pulling is facilitated.

Owner:PETROCHINA CO LTD

Platform Stakes and Drilling Platforms

ActiveCN107245993BIncrease the carrying areaExpansion (increase the bearing areaArtificial islandsUnderwater structuresStructural engineeringGeotechnical engineering

The invention discloses a platform pile shoe and a drilling platform. The platform pile shoe comprises a pile shoe main body, and a plurality of turnover boards hinged with the pile shoe main body; the turnover boards surround the pile shoe main body; the turnover boards rotate outwards under soil body acting force during pile inserting, so that the bearing area of the platform pile shoe is enlarged; the turnover boards rotate inwards under the own gravity and the soil body gravity during pile pulling, so that the bearing area of the platform pile shoe is reduced; and the outer ends of the turnover boards are higher than the lowest point of the pile shoe main body when the pile inserting is completed, and are lower than the lowest point of the pile shoe main body when the pile inserting is not carried out. The platform pile shoe and the drilling platform can provide better bearing area, so that the platform stability is ensured; and the bearing area during the pile pulling is reduced, the pile pulling resistance is reduced, and thus the pile pulling is facilitated.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com