Pick-up method and pick-up device

A pickup device, horizontal technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of chip 1 position shift, falling off, etc., to achieve the effect of easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

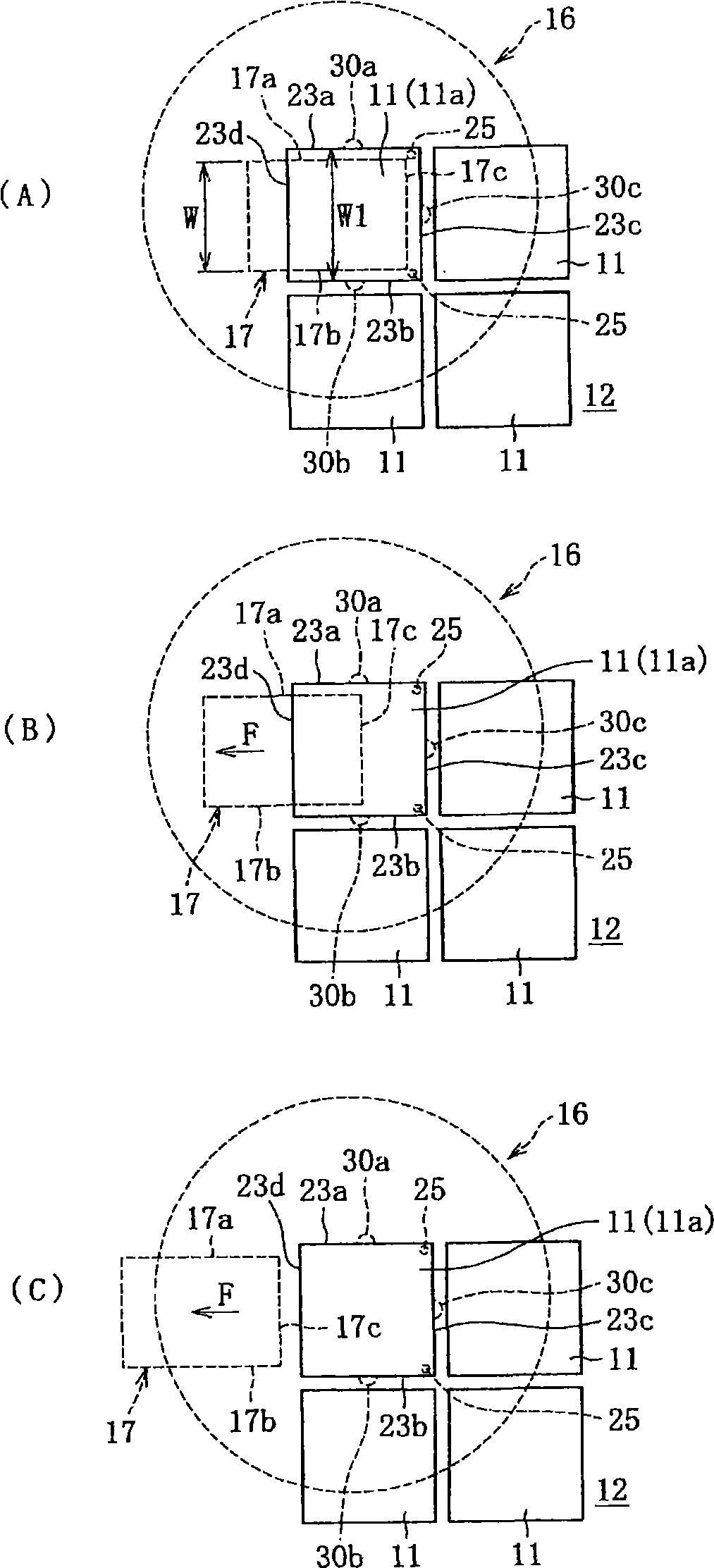

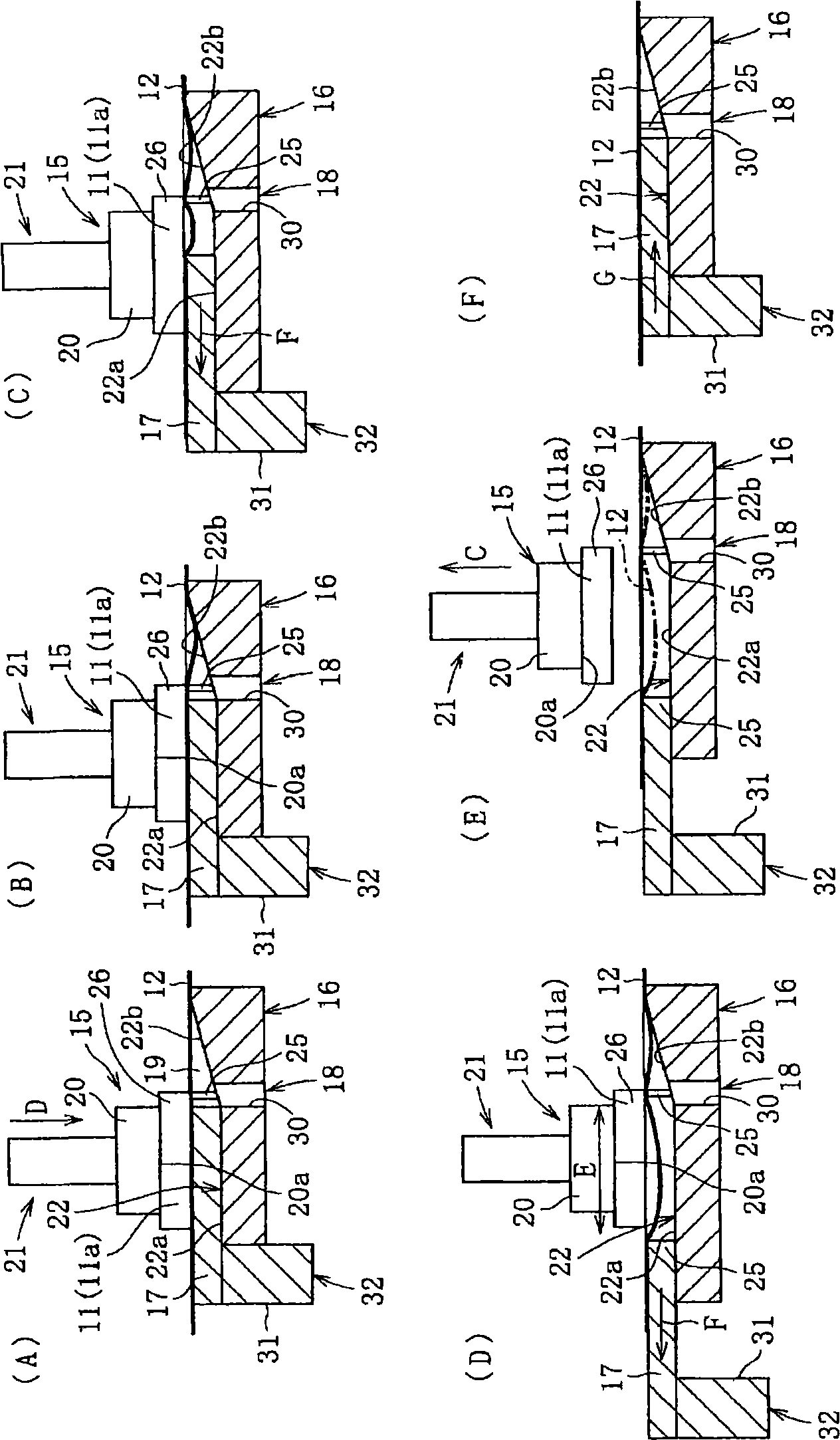

[0037] Below, based on Figure 1 to Figure 7 , to describe the embodiment of the present invention.

[0038] figure 2 The pick-up device of the present invention is shown in . This pick-up device is a device that sequentially peels and takes out a plurality of rectangular thin-walled chip devices (semiconductor chips) 11 attached to the adhesive sheet 12 from the adhesive sheet 12 .

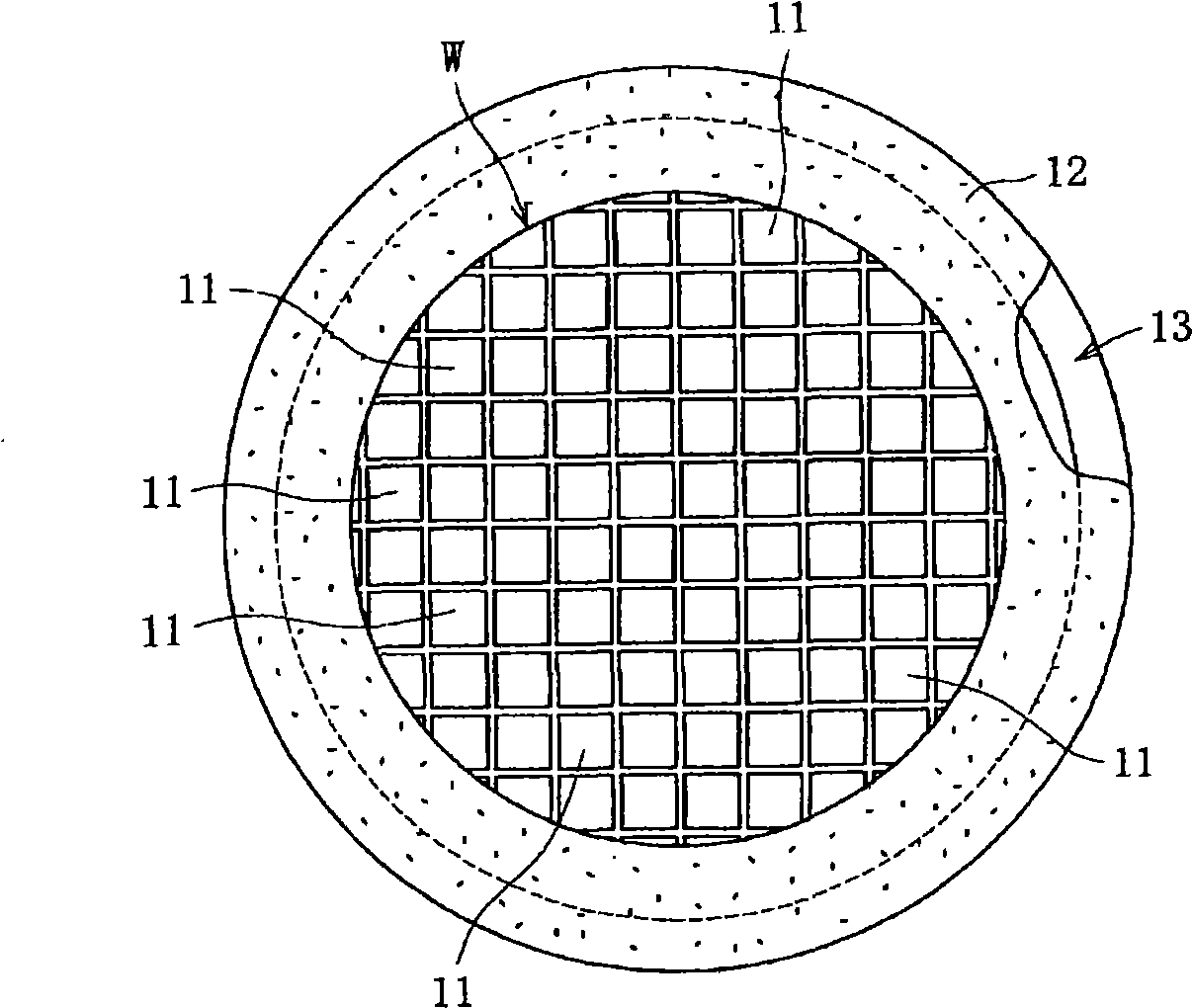

[0039] Chip device 11 is passed with wafer W (referring to image 3 ) is a raw material, and the raw material is cut into a rectangular shape to become a final product. Therefore, the chip device 11 includes square or strip-shaped chip devices and the like. That is, if image 3 As shown, the wafer W is circular as a whole, and is divided into individual chip devices 11 by dicing, and the chip devices 11 are attached to an adhesive plate 12 . In addition, a frame 13 made of a ring is attached to the outer peripheral side of the adhesive sheet 12 . That is, the frame 13 and the adhesive sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com