Thermally decoupled pipe bracket with high mechanical loading capacity

A technology for retaining parts and pipes, which is applied in the direction of pipe protection, protection of pipes by heat insulation, pipe supports, etc., to achieve the effect of reducing the supporting area and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

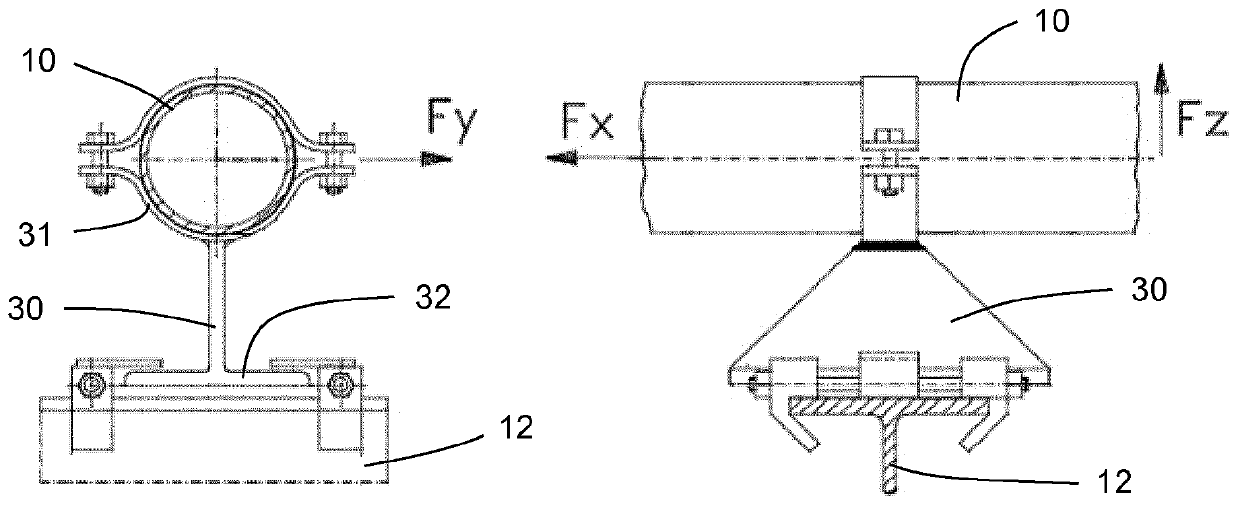

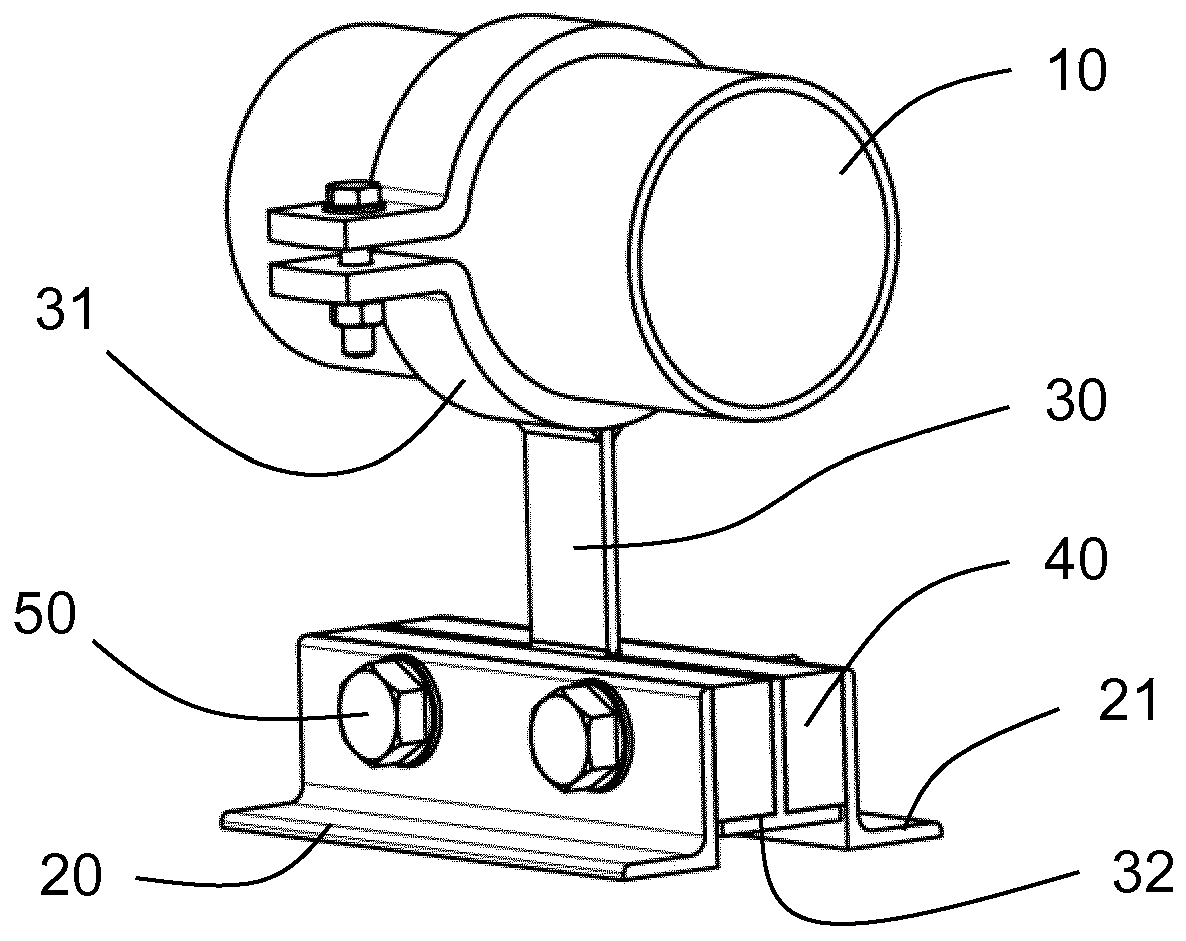

[0083] Example 1: Single Bracket Pipe Holder

[0084] According to the present invention and according to image 3 and 4 The single-bracket pipe holder of the illustrated embodiment is compared with respect to its thermal performance with the standard holder according to FIG. 1 known from the prior art. Furthermore, the single-bracket pipe holder according to the invention is combined with the corresponding pipe holder according to Fig. 2 of the first and unexamined publication DE 10 2014 109 599 A1 according to the teaching of this publication - hereinafter referred to as "Insulation Holder" - for comparison.

[0085] In the description of the pipe holder, for all parts hereinafter, the term "length" is used for the extent of said pipe holder in the axial pipe direction and the term "width" for the radial extent perpendicular to this length, And the term "height" is used for the extent of the duct 10 in a direction perpendicular to the direction of the support means 12 ....

example 2

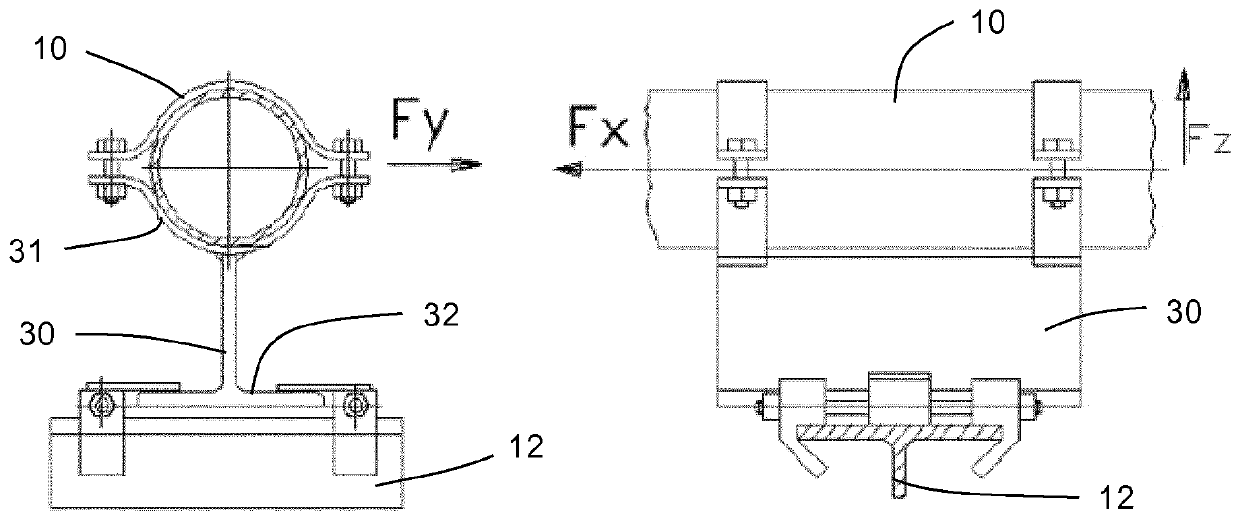

[0092] Example 2: Dual Bracket Pipe Retainer

[0093] In yet another series of tests, the Figure 5 and 6 The double-bracket pipe holder according to the invention of the illustrated embodiment is compared with the corresponding double-bracket standard holder according to FIG. 2 . Furthermore, combining the double bracket pipe holder according to the invention with the teaching according to the first and unexamined publication DE 10 2014 109 599 A1 according to the image 3 Corresponding pipe holders - hereinafter referred to as "insulation holders" - for comparison.

[0094] Standard holders are made of steel with a material thickness of 10mm. The leg portion 32 has a length of 250 mm and a width of 100 mm. The web 30 is designed as a rectangle with a height of 150 mm and a length of 250 mm. Pipe brackets as pipe brackets are respectively attached on both ends of the web in the axial direction. For the different nominal widths of the pipe holders tested, the pipe brac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com