Method for testing mechanical properties of electronic gun heater assembly

A test method and electron gun technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as research failures, and achieve the effect of solving testing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

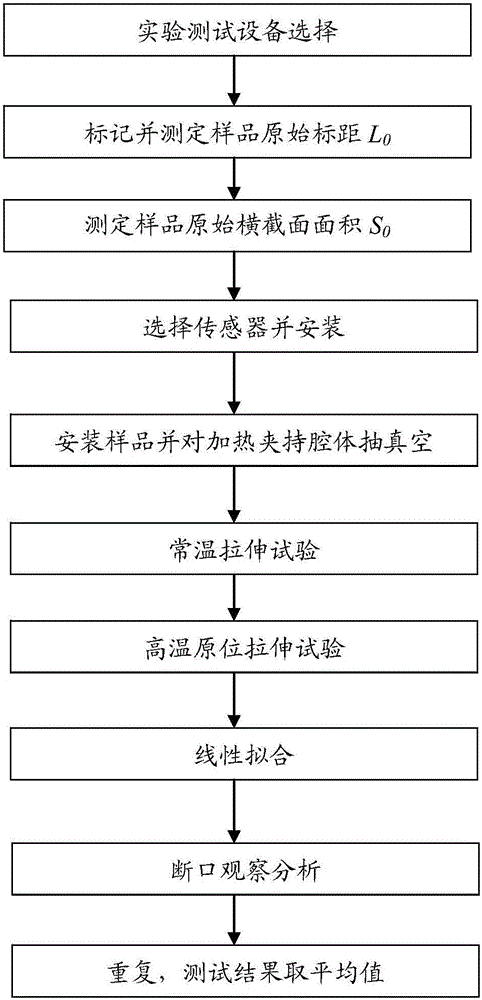

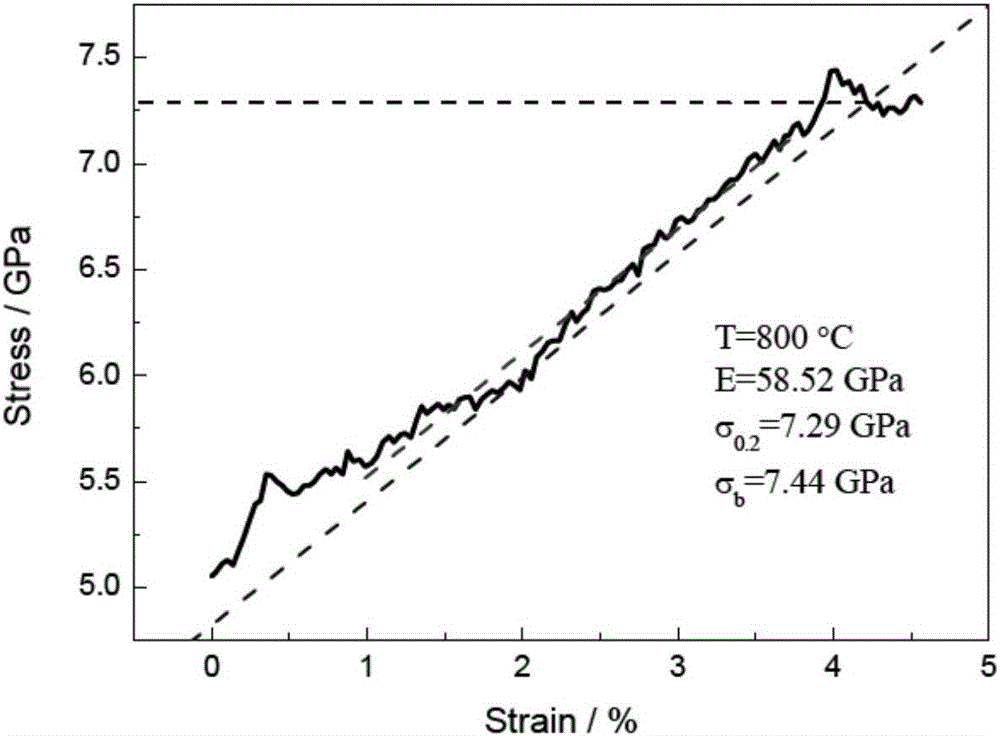

[0047] This embodiment is a method for testing the mechanical properties of an electron gun thermal subassembly. The thermal subassembly to be tested is a thermal subassembly. The test flow chart is shown in figure 1 ,Specific steps are as follows:

[0048] (1) Selected experimental testing equipment: SEM-SERVO produced by Shimadzu Corporation of Japan was selected for experimental testing. This equipment can provide the vacuum and high temperature environment required for the operation of the electron gun thermal subassembly, and can be observed in situ by SEM;

[0049] (2) Mark the original gauge length L of the sample 0 : Use a marking machine to mark the original length of the gauge length section with a thin circumferential line on the hot plate as the original gauge length L 0 ;

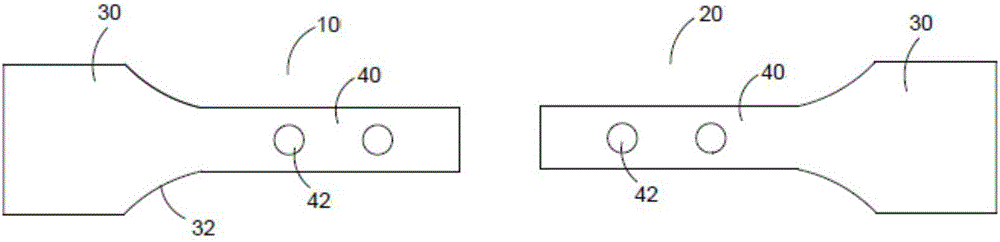

[0050] (3) For the original cross-sectional area S of the sample 0 Determination: Since the diameter of the thermon is very small, put it under the SEM electron microscope and measure it wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc angle | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com