Patents

Literature

38results about How to "Reduce load bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

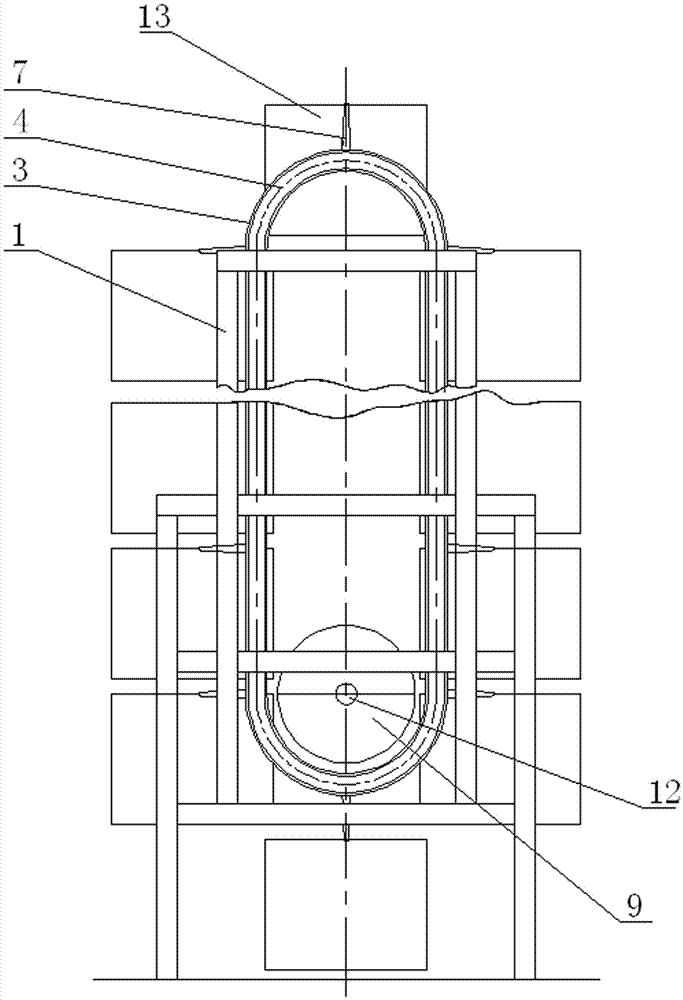

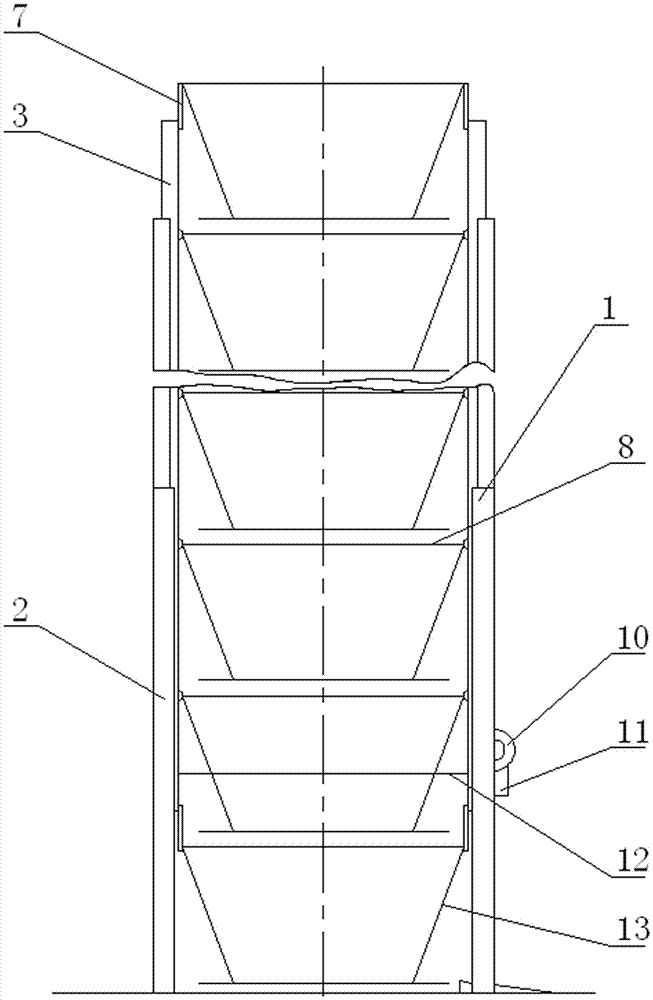

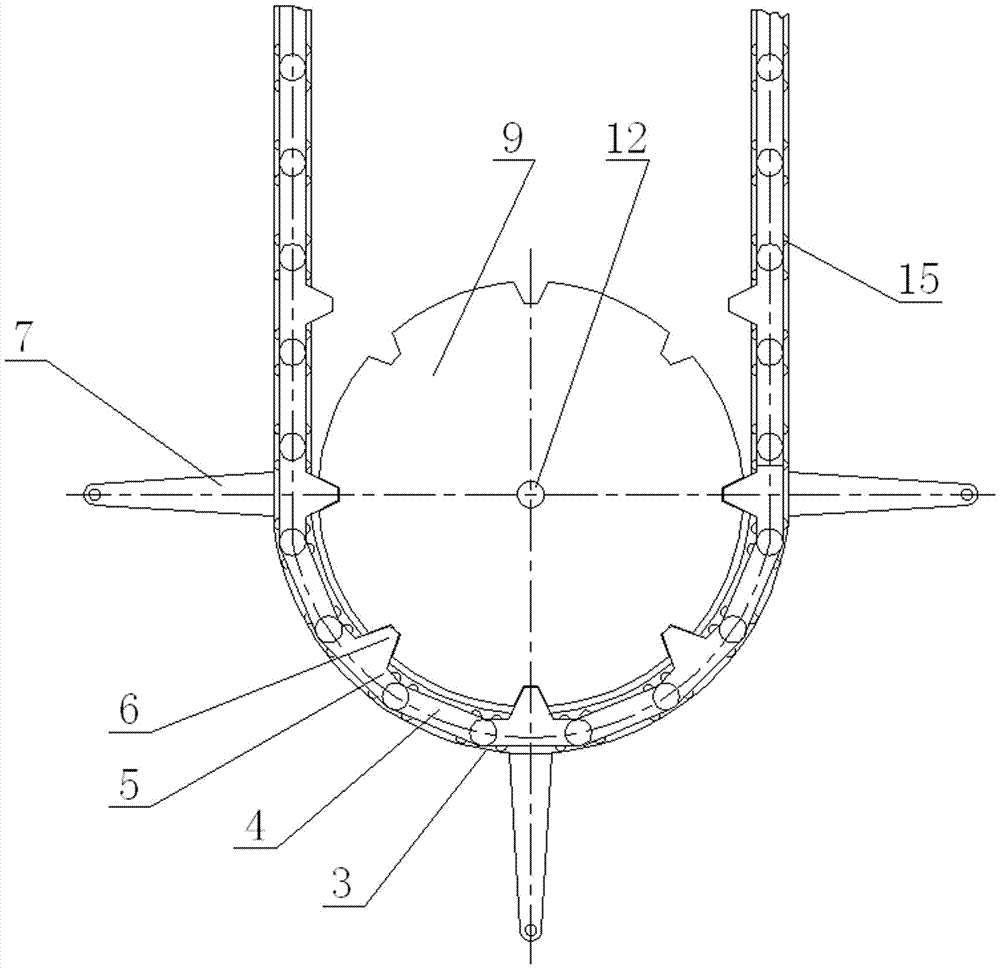

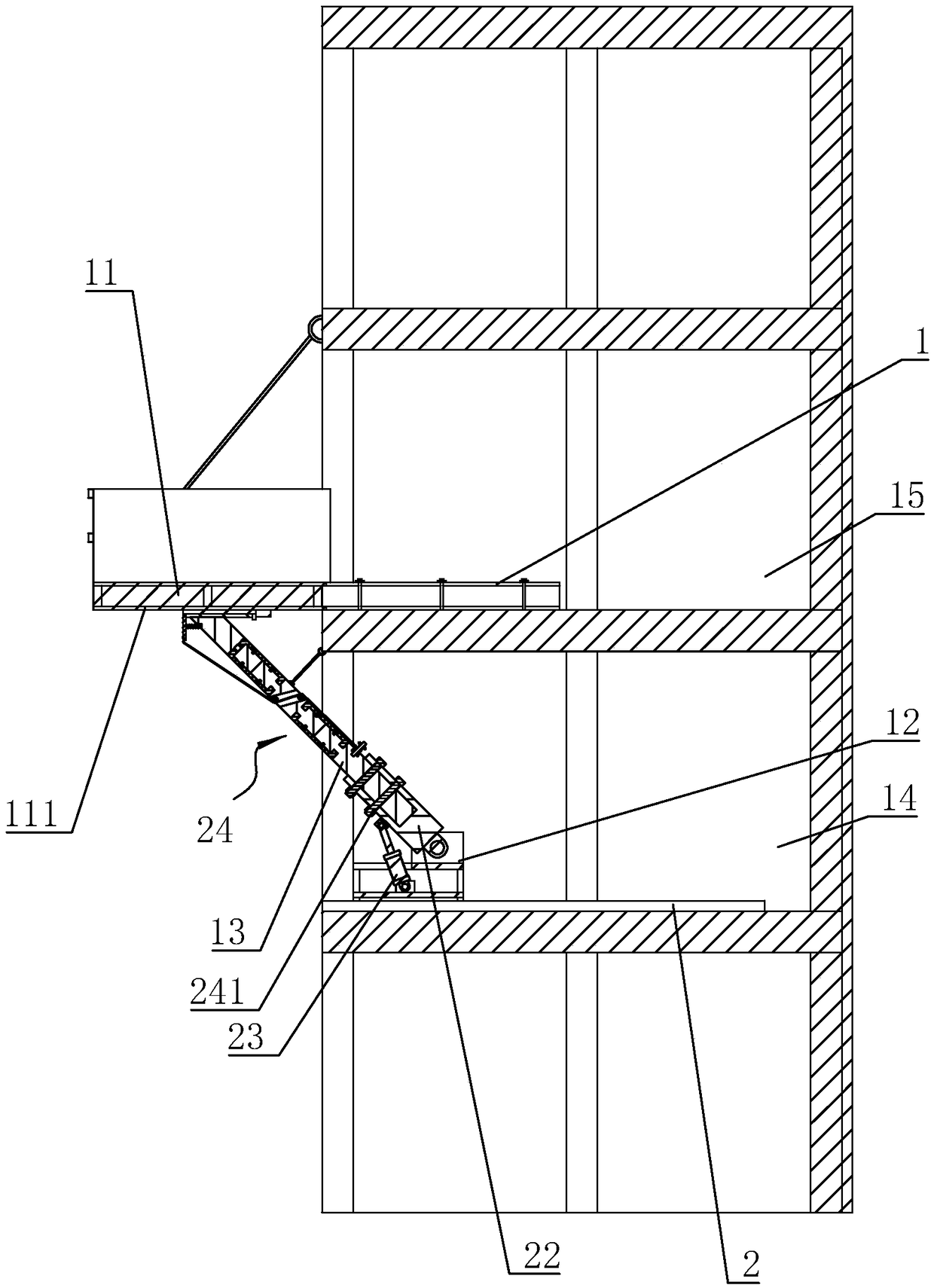

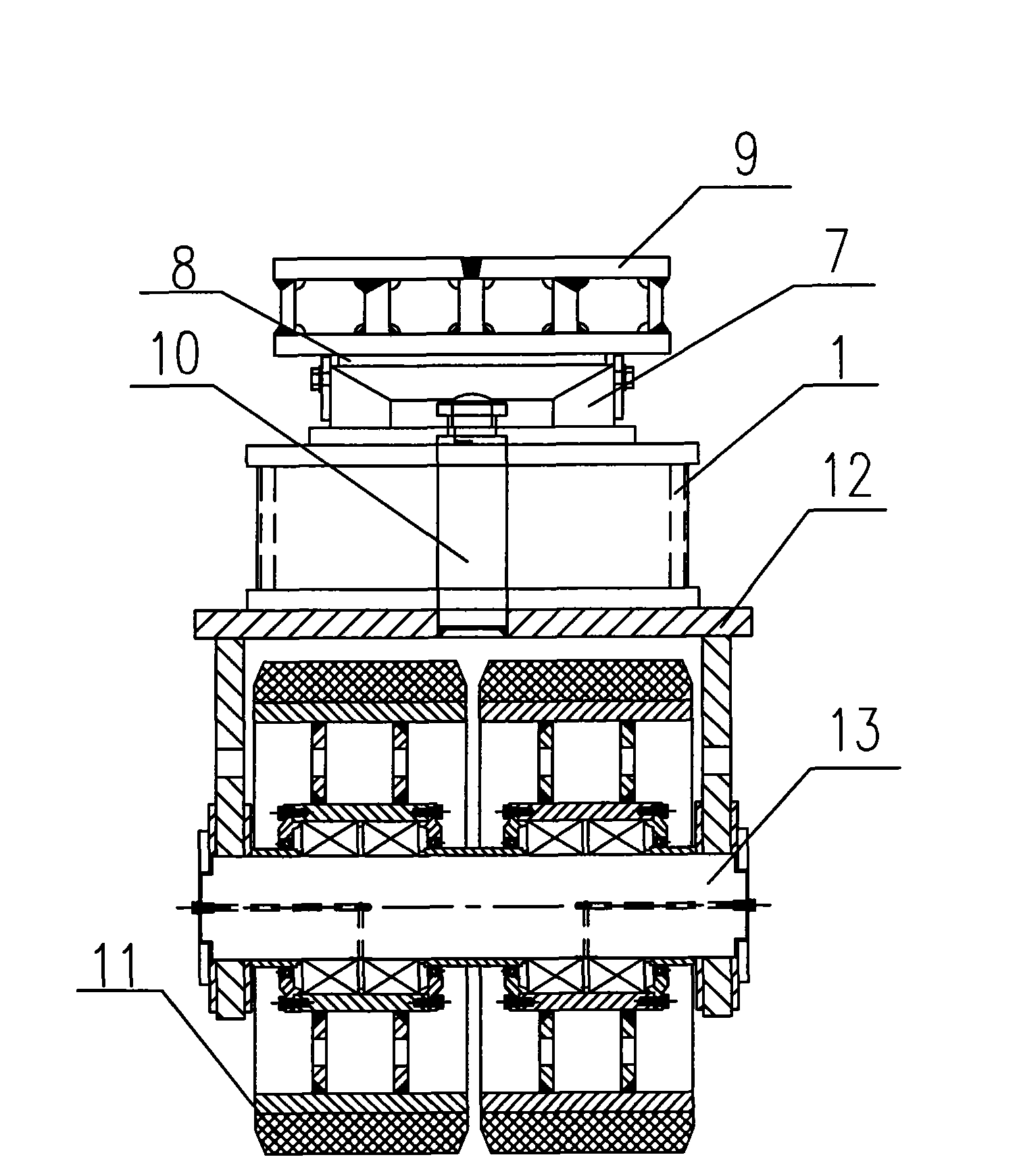

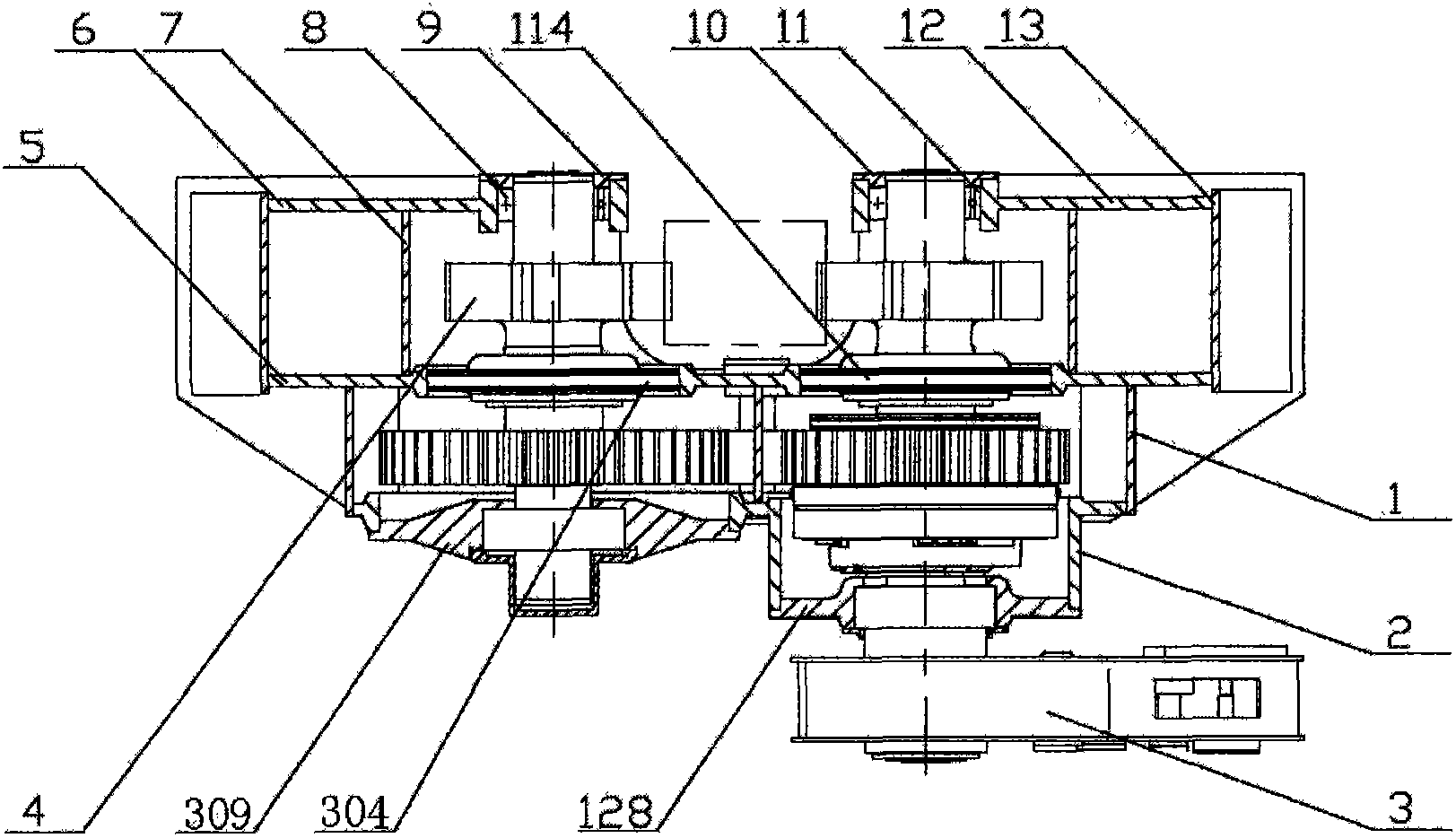

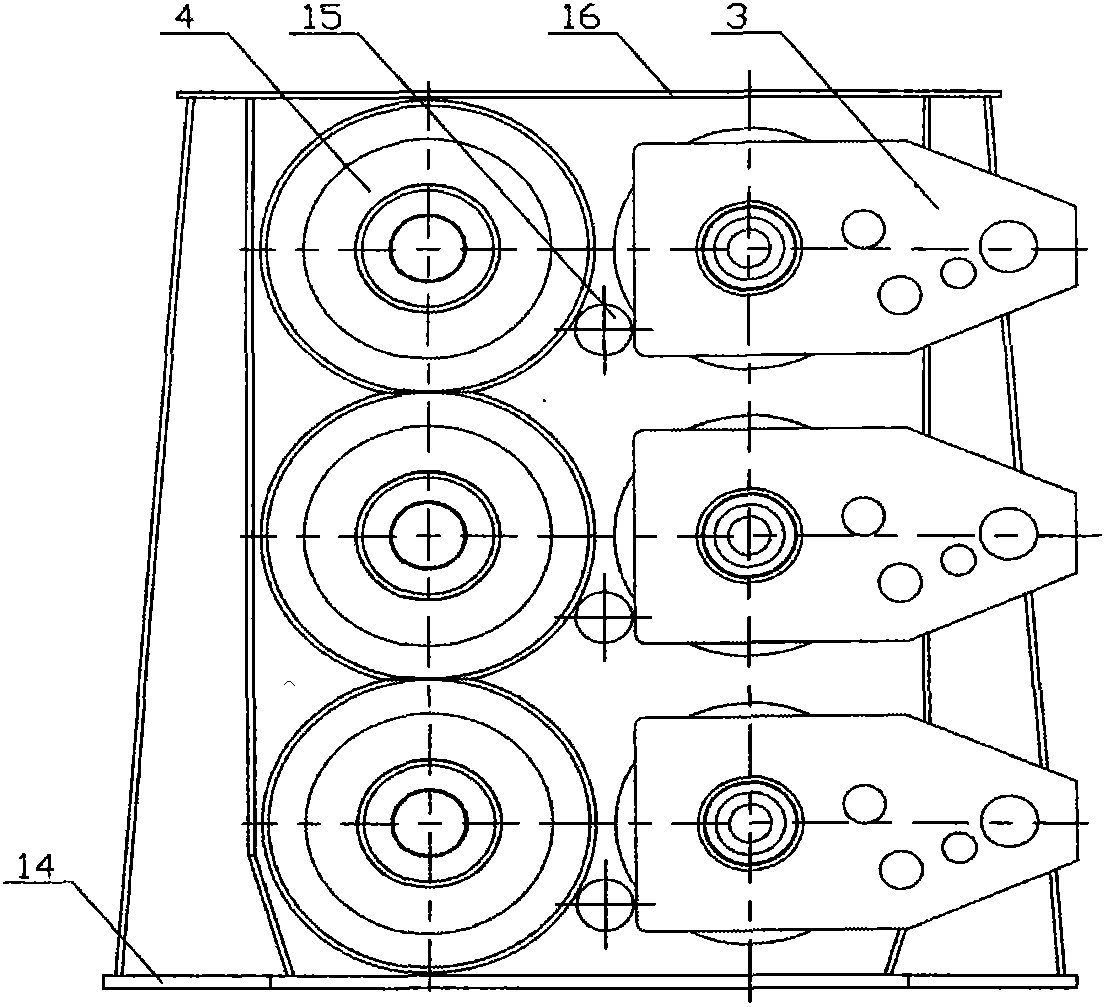

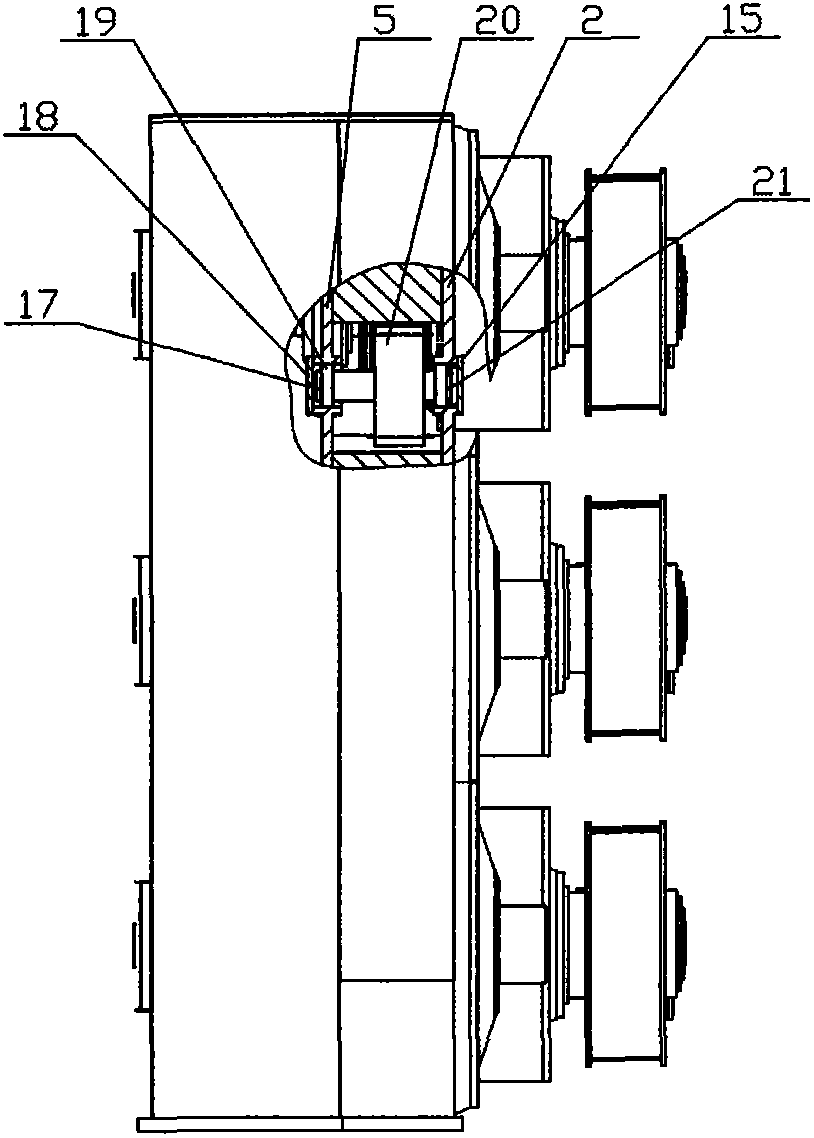

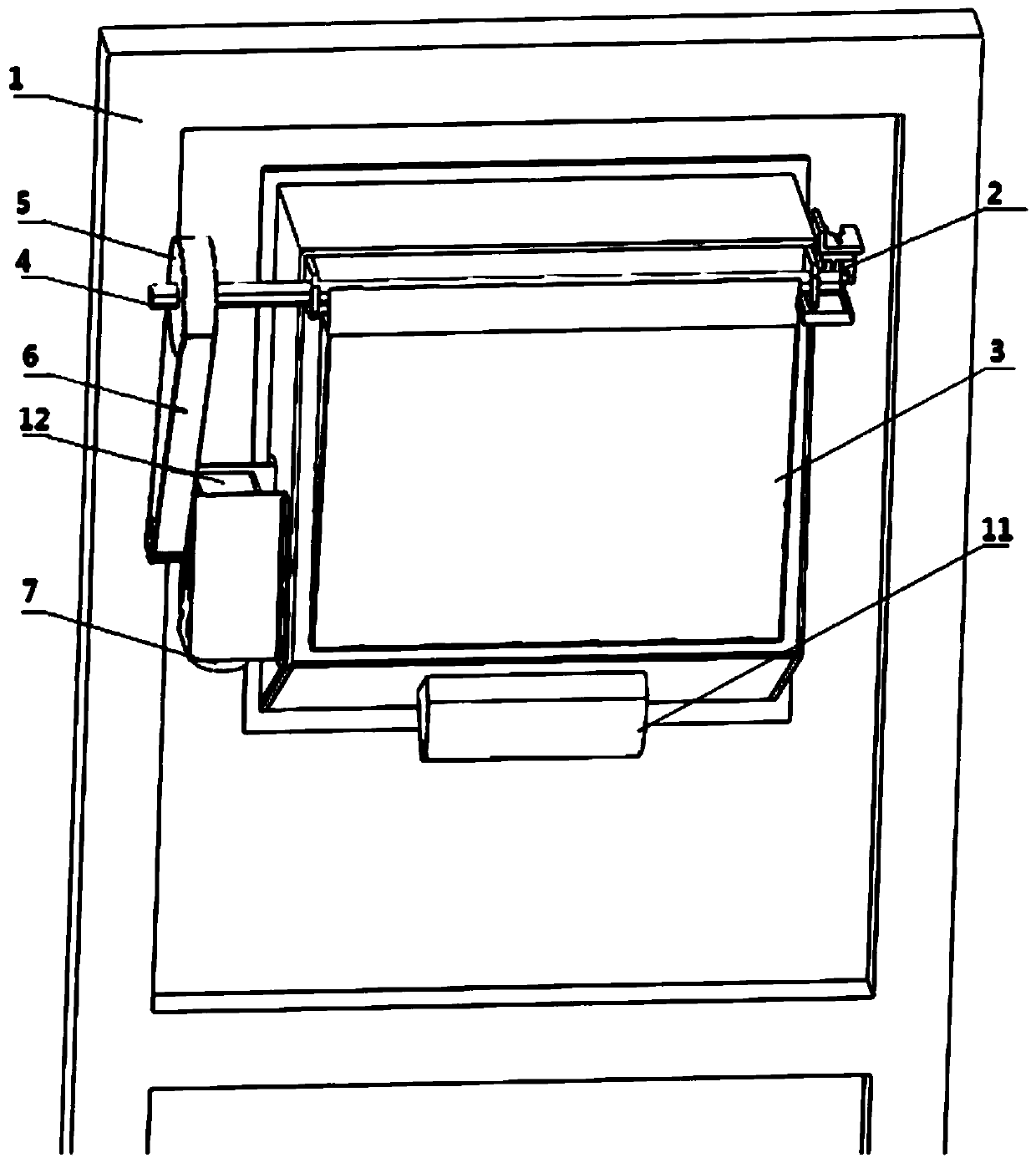

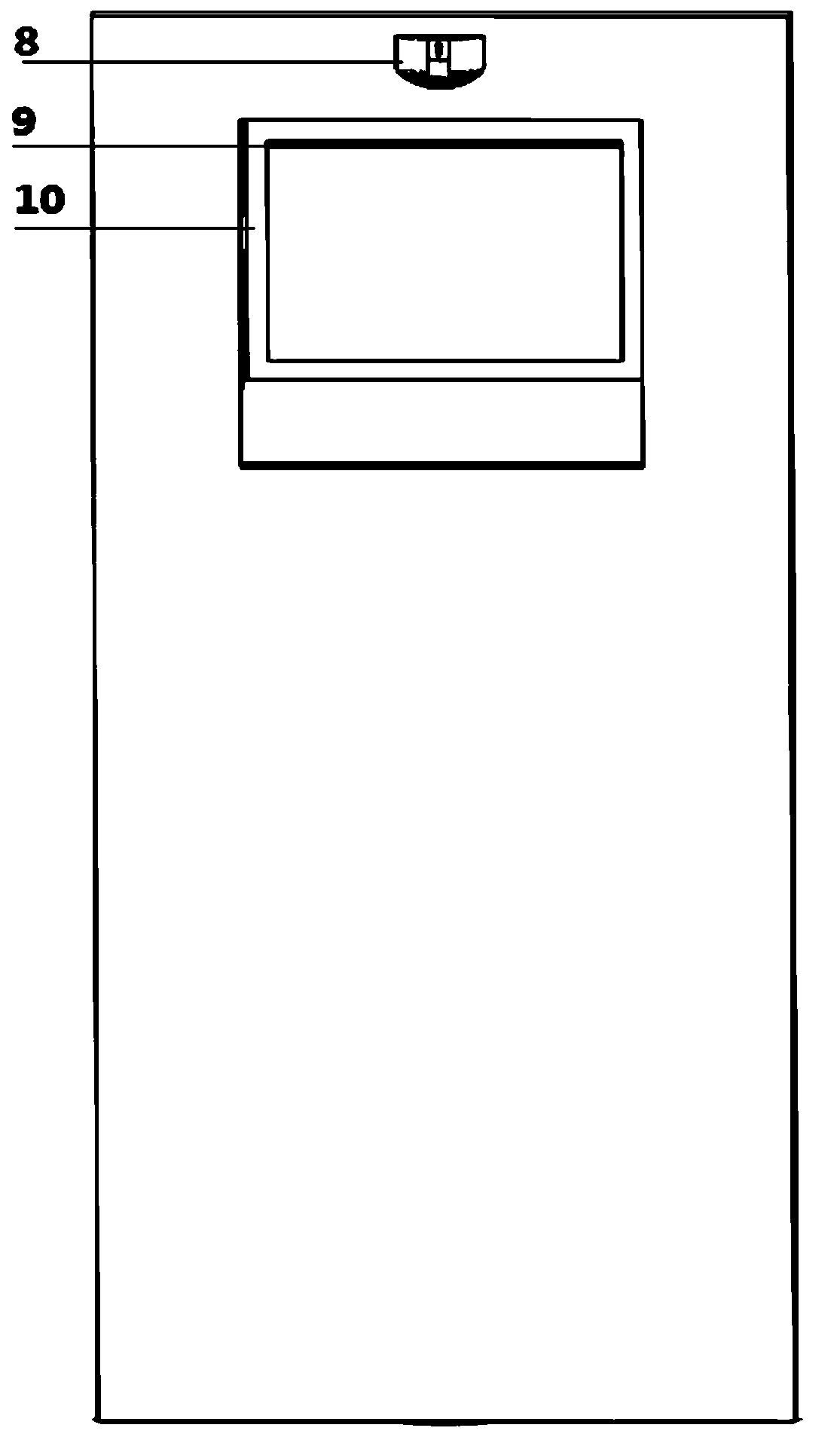

Rail-mounted vertical circulating three-dimensional garage

InactiveCN105442884AAchieve the purpose of accessing the carOutstanding FeaturesParkingsParking spaceEngineering

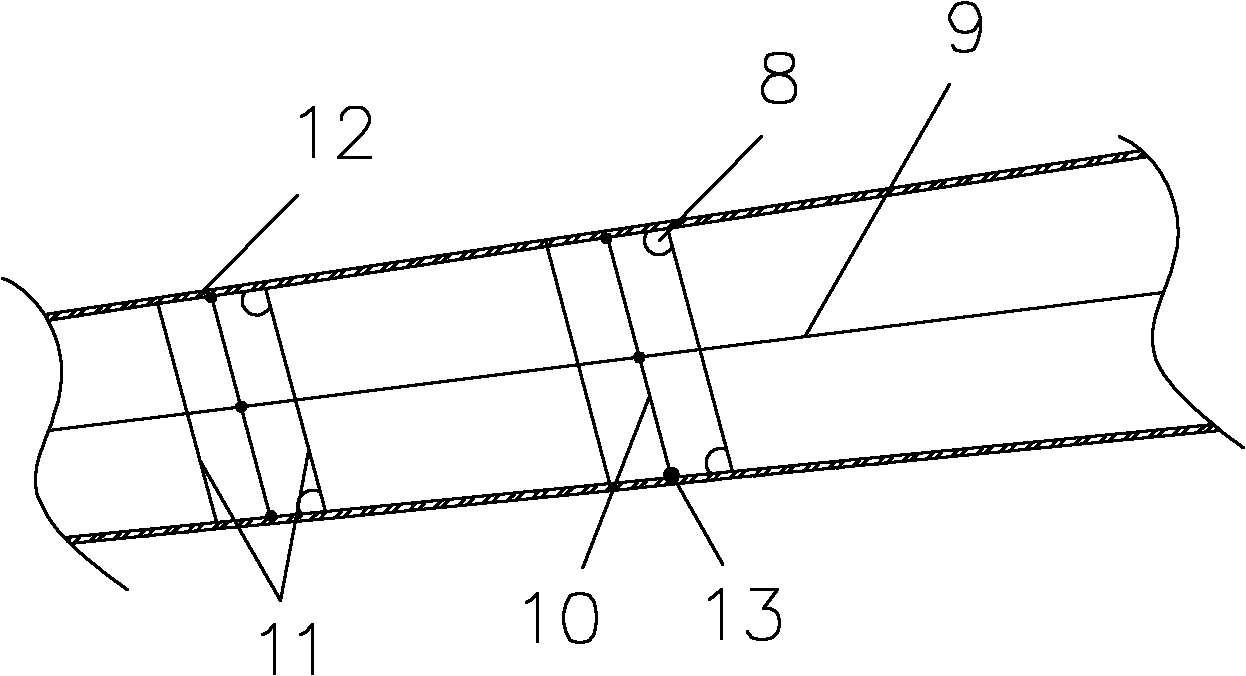

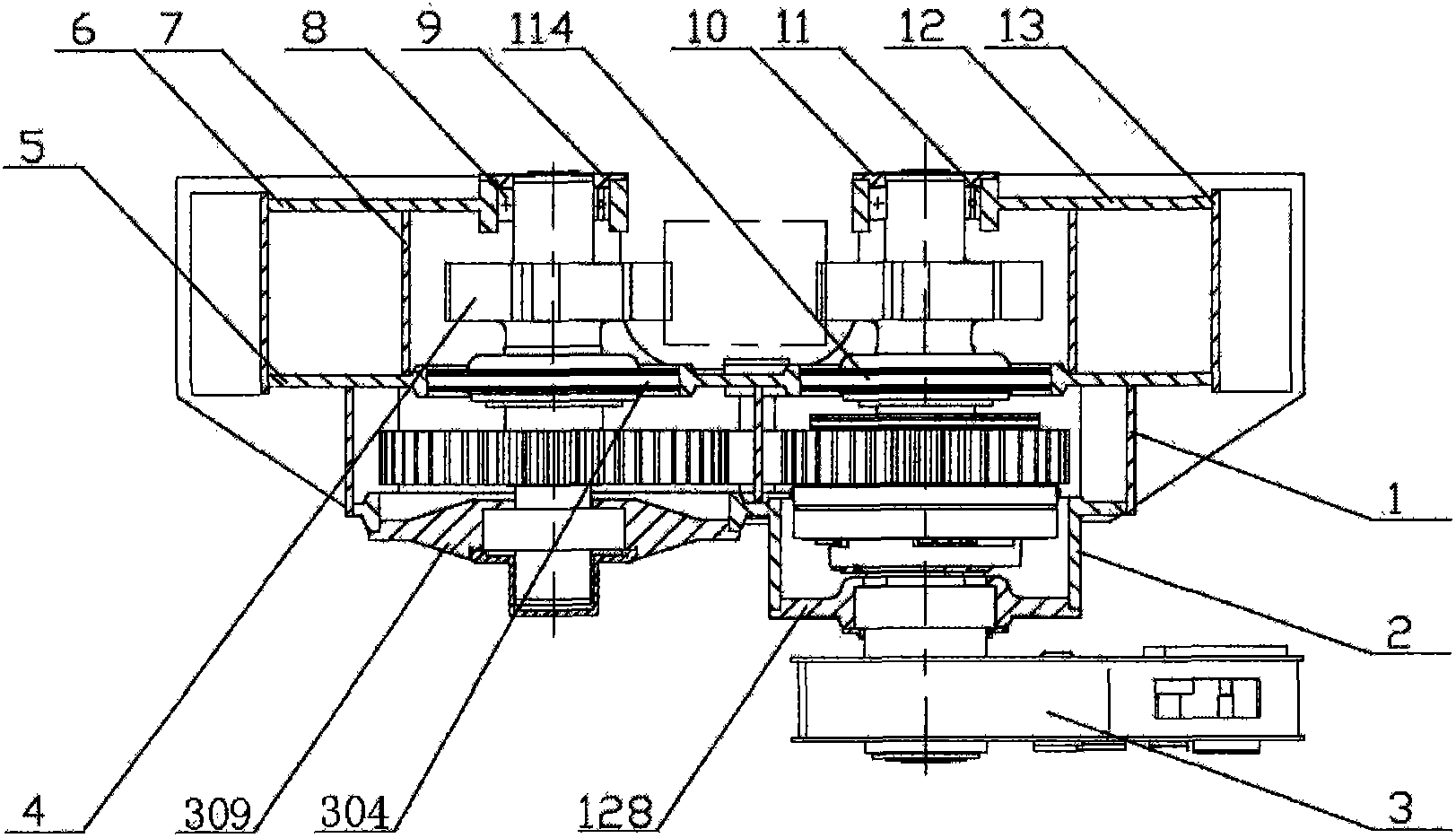

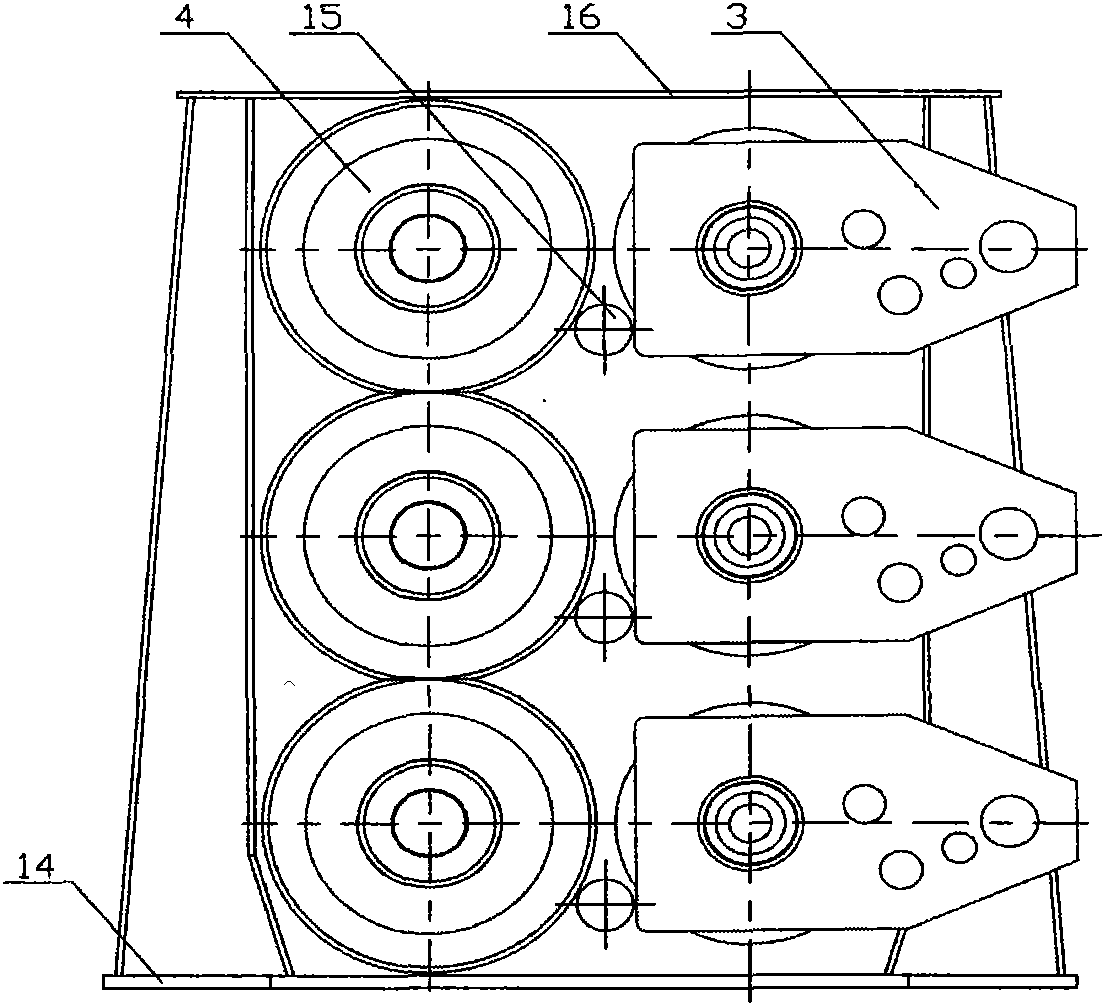

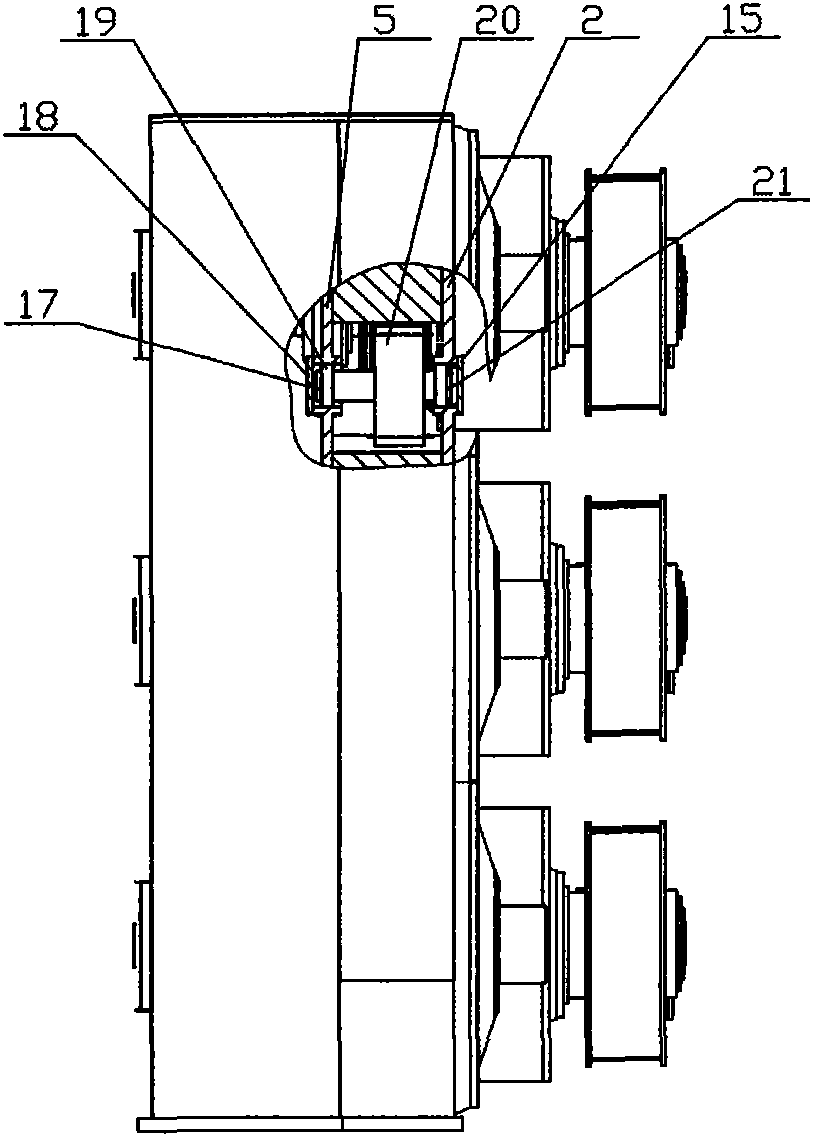

The invention discloses a rail-mounted vertical circulating three-dimensional garage which comprises a body frame, a basket parking unit and a drive chain wheel. The garage is characterized in that the body frame comprises a front frame and a rear frame, the front frame and the rear frame are each provided with a pair of symmetrical chain wheel track grooves in a fastened mode, an idler wheel trolley chain is installed in each chain track groove, the drive chain wheels are symmetrically installed below the front frame and the rear frame respectively and drive the idler wheel trolley chains respectively to move on the vertical face up and down in a circulating mode, the idler wheel trolley chains drive the basket parking unit to move up and down in a circulating mode, and all the components form the rail-mounted vertical circulating three-dimensional garage. The garage has the advantages of being simple and reasonable in structure, safe, reliable, easy to install, convenient to maintain, small in occupied area, large in parking number, and capable of achieving the purpose of increasing parking lots by improving structural strength of the frame and increasing the structural height.

Owner:何文年

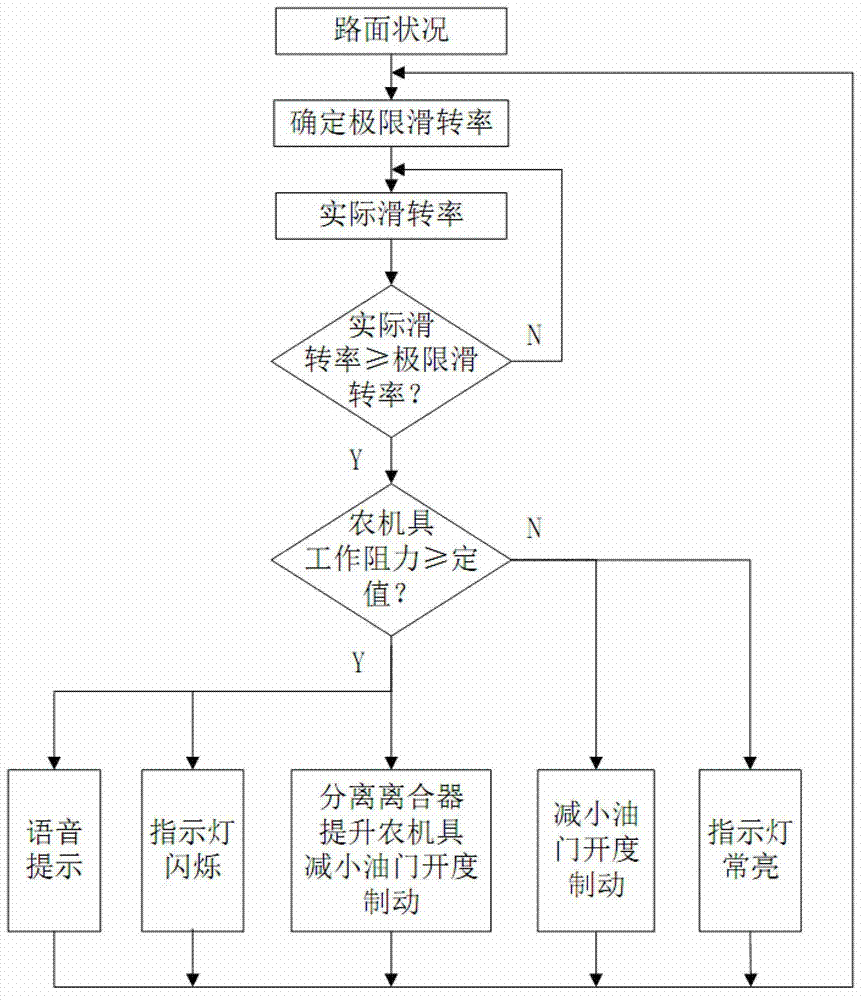

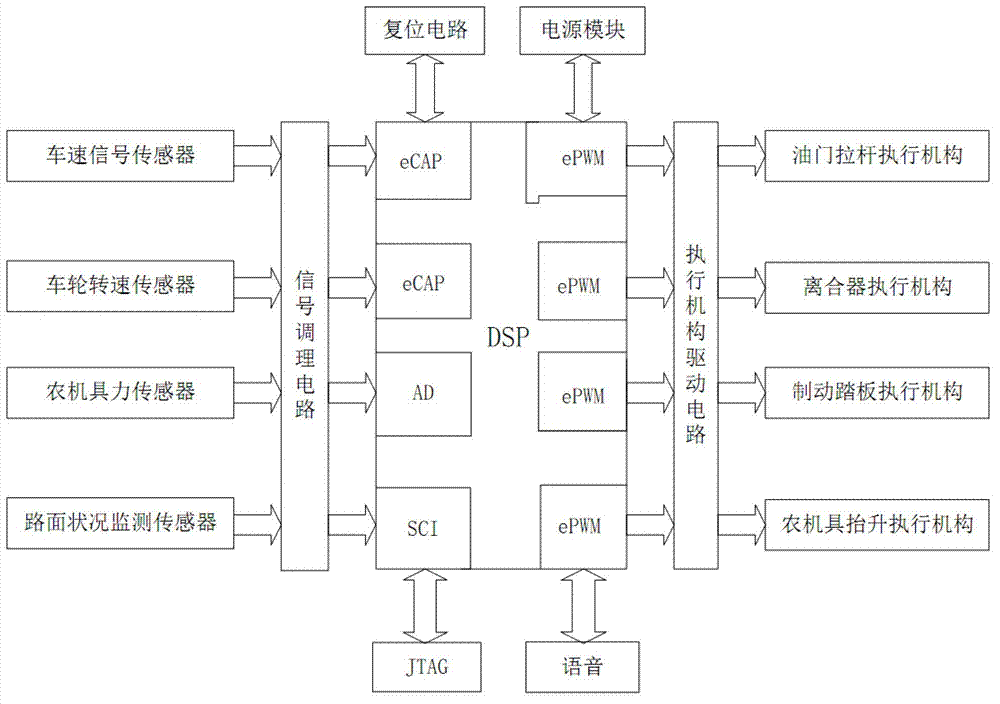

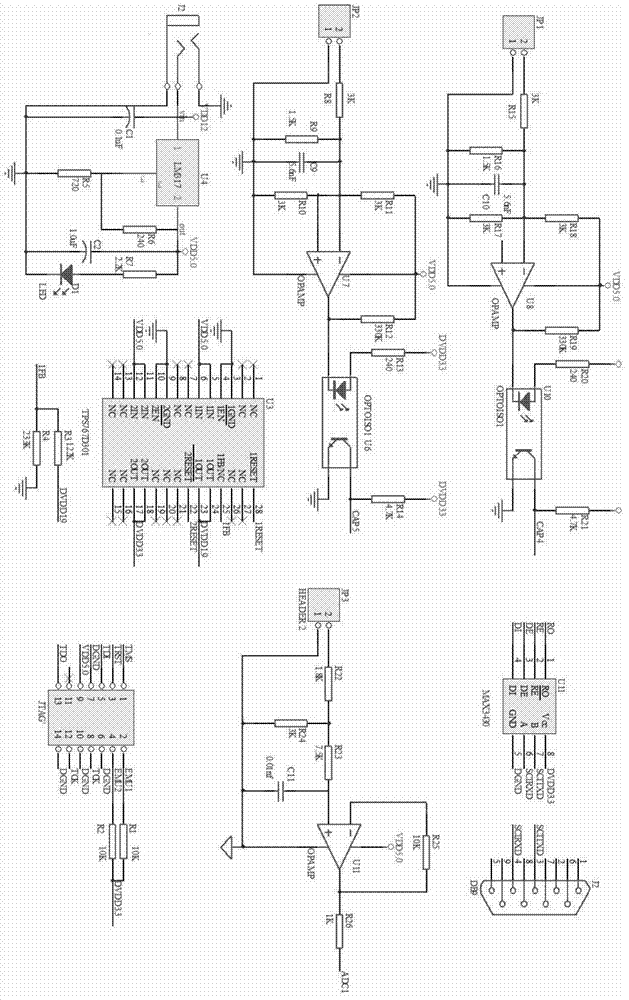

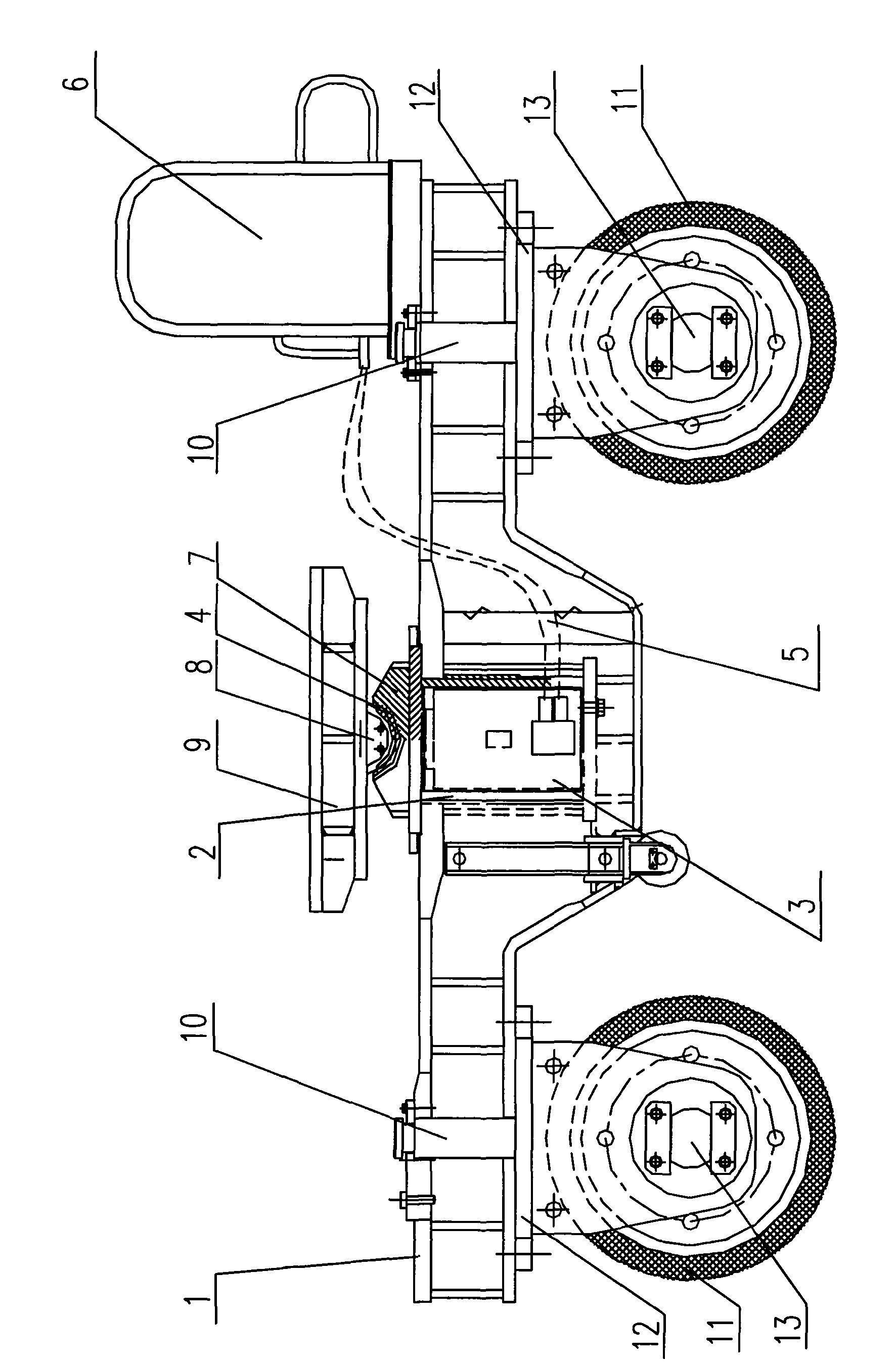

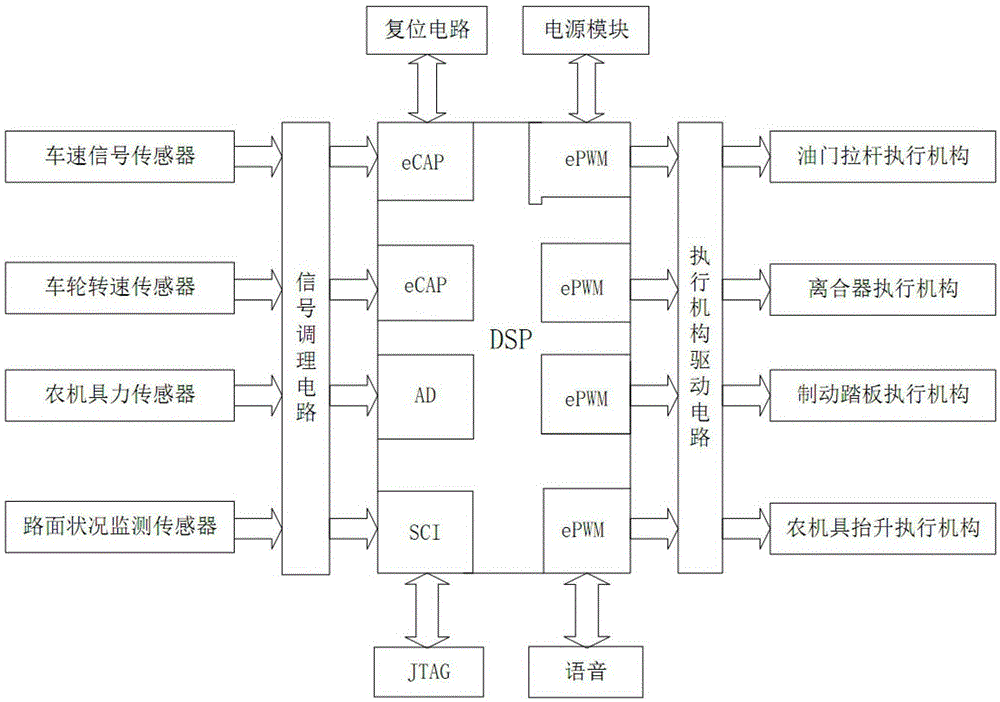

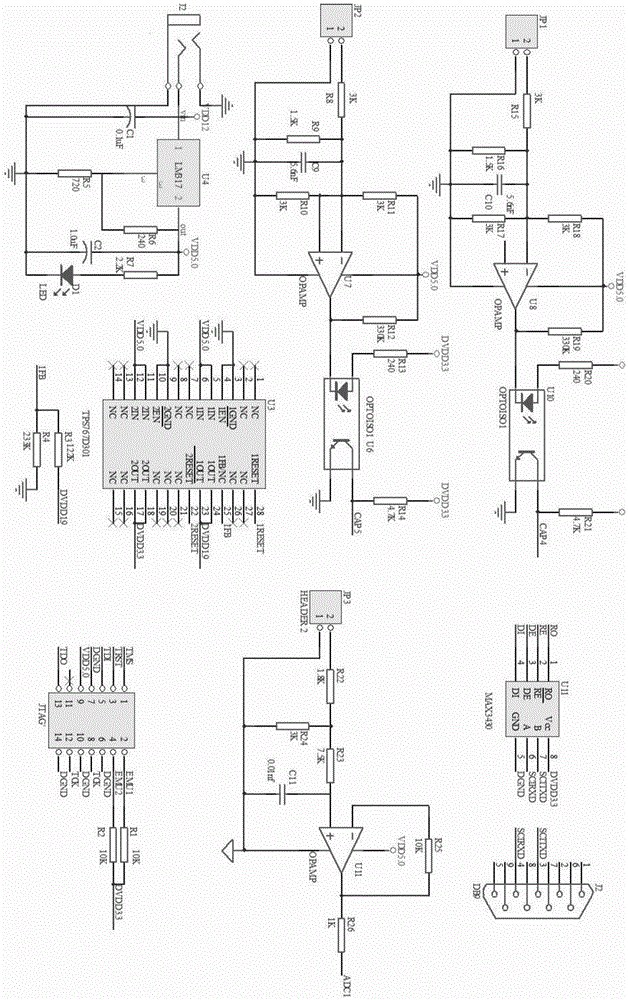

Tractor intelligent control method and intelligent control system

InactiveCN103158713AReduce fuel consumptionSmall slip rateInternal combustion piston enginesClutchIntelligent control system

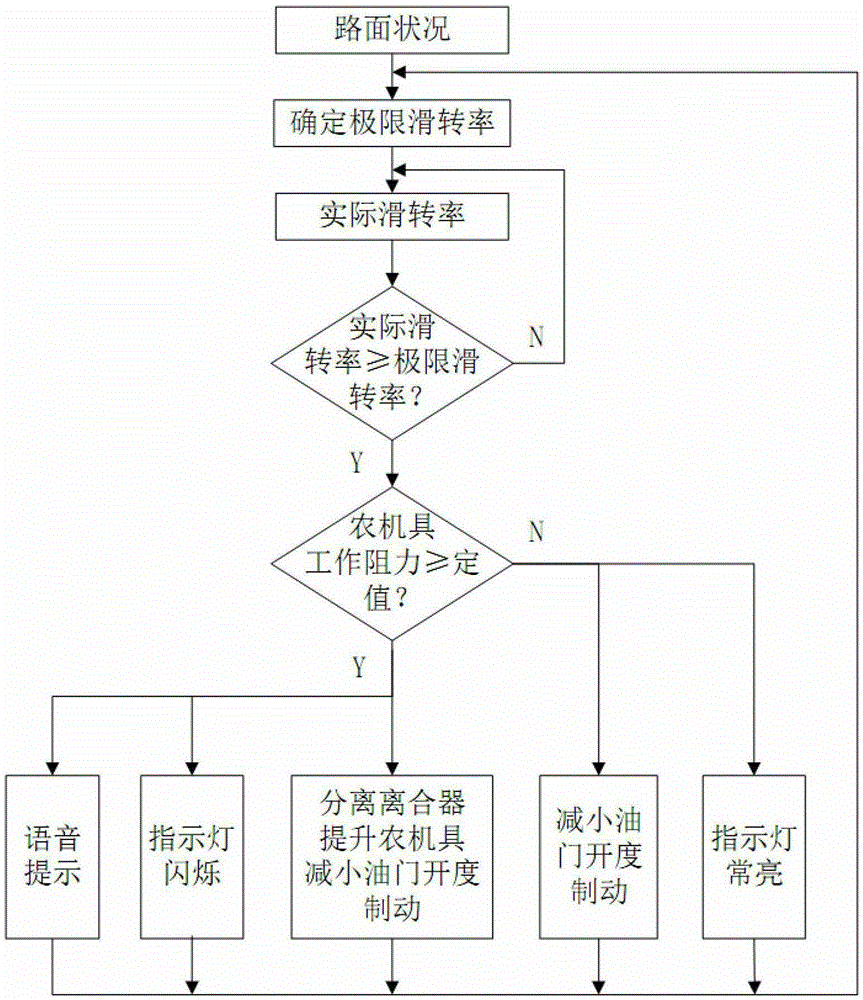

The invention relates to a tractor intelligent control method and an intelligent control system. A corresponding signal is collected by a sensor to obtain an existing operating state of a tractor, all parameters are calculated, analyzed and judged by a controller on the basis, and after information is processed, control signals are transmitted to a stepping motor and a high-speed electromagnetic valve so as to enable a main clutch, a PTO clutch, and a brake pedal executing mechanism, an engine throttle draw bar executing mechanism, a hydraulic hanging mechanism and the like to conduct motion to prevent a driving wheel of the tractor from excessive trackslip and overload of a transmission system, ensure good comfort, fuel economy and traction, and prolong service life of the transmission system and tires of the tractor.

Owner:HENAN UNIV OF SCI & TECH

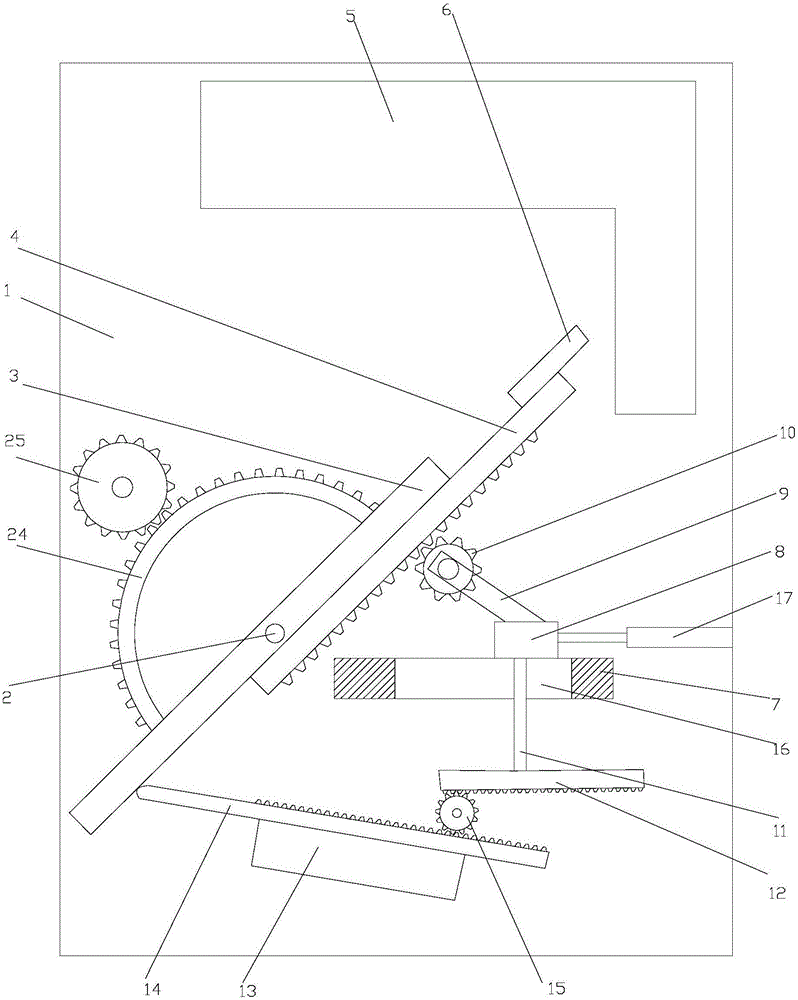

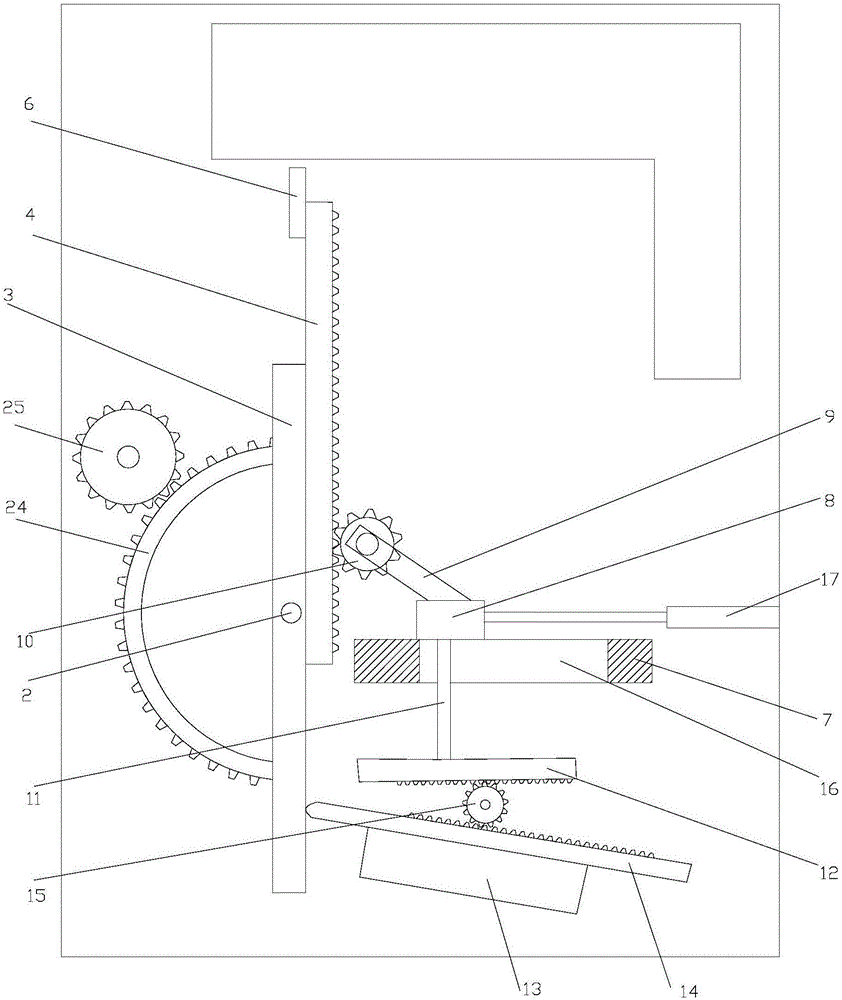

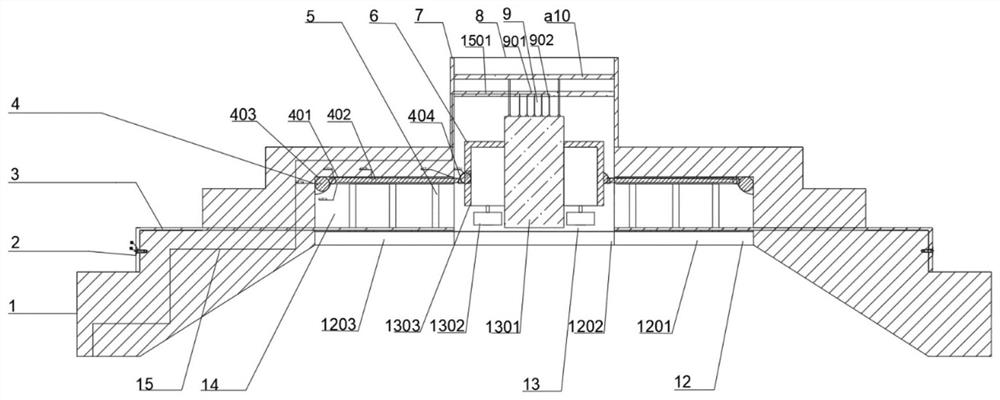

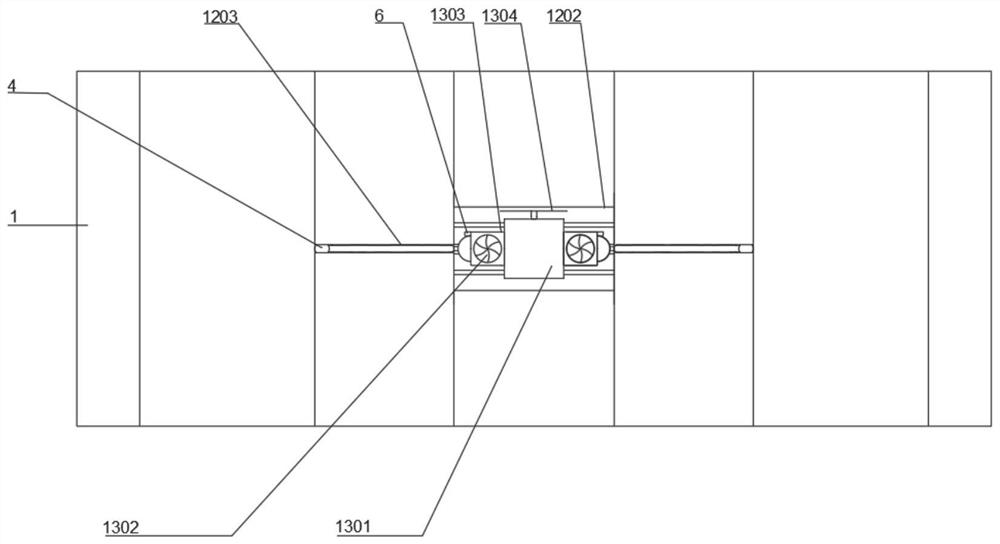

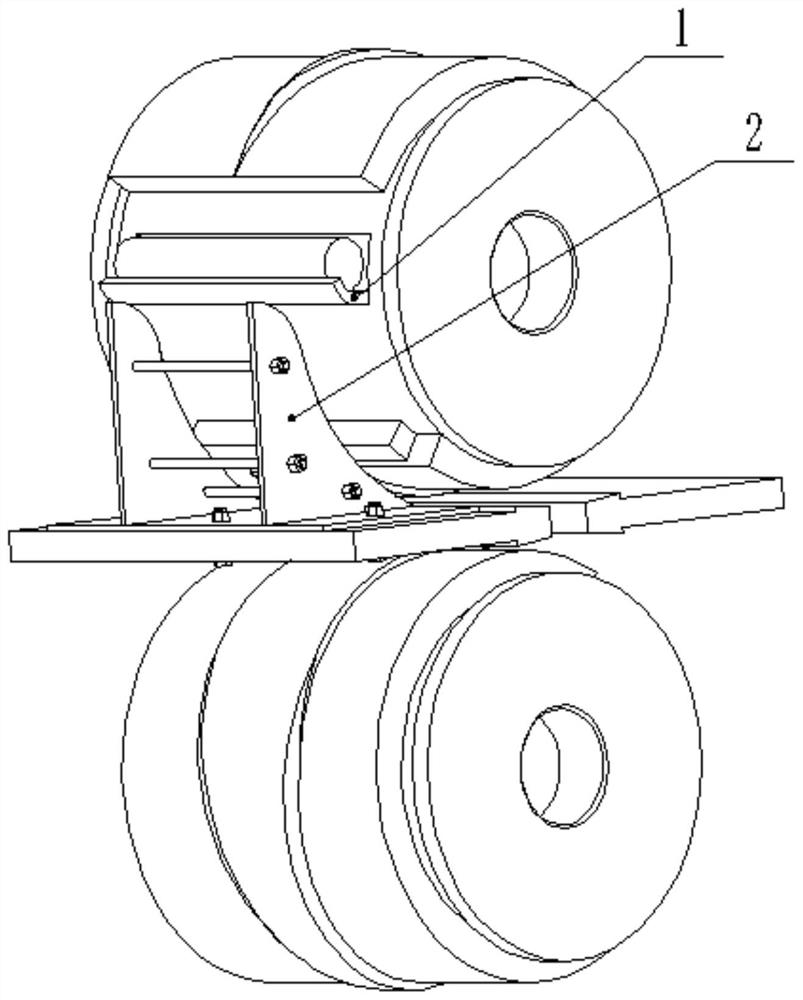

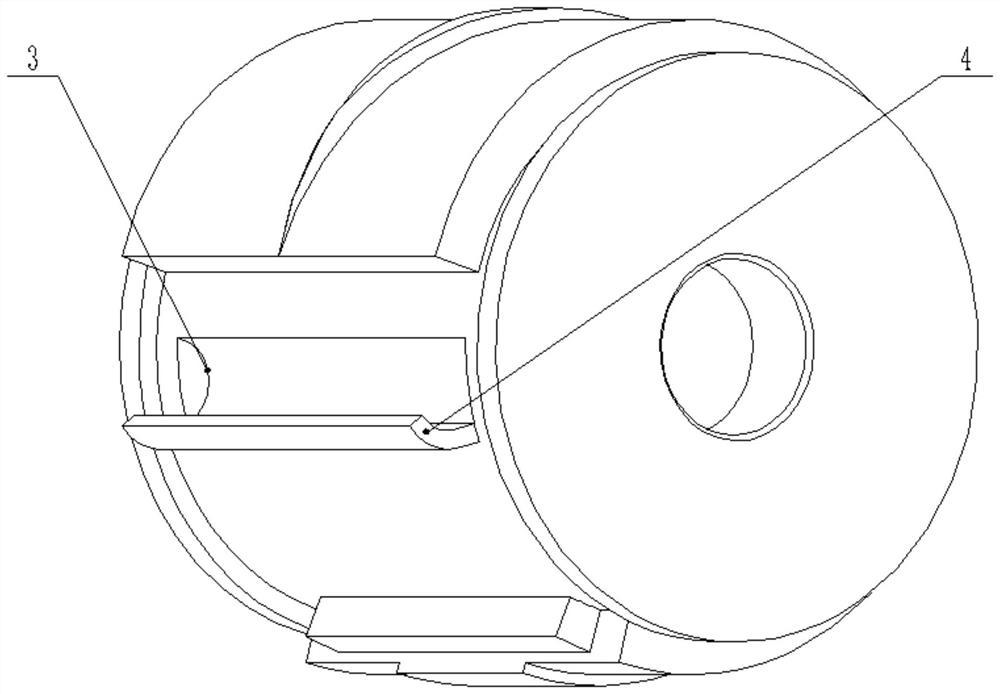

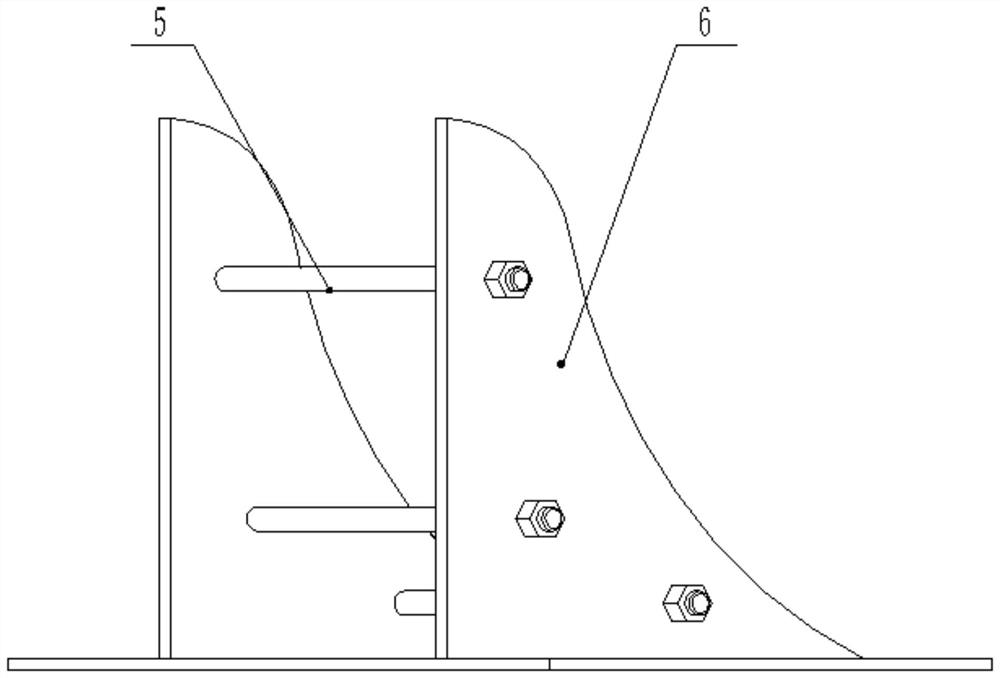

Mechanism for continuously punching workpieces

ActiveCN106238775AAvoid motion interferenceGuaranteed reliabilityFeeding apparatusBoring/drilling componentsEngineeringMechanical engineering

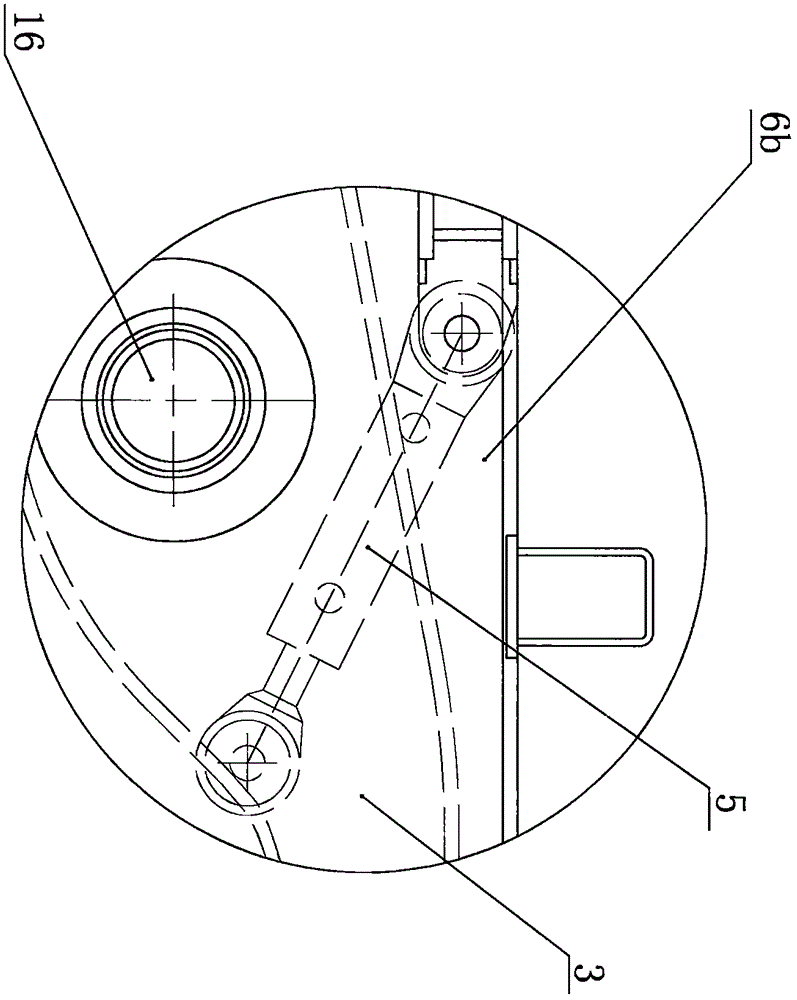

The invention discloses a mechanism for continuously punching workpieces. The mechanism comprises a base (1) which is rotatably connected with a guide rod (3) through a rotating shaft (2), the guide rod (3) is slidably connected with a first linear rack (4) through a dovetail groove, and a drilling machine (6) used for punching a workpiece (5) placed on the base (1) is arranged on the first linear rack (4); a platform (7) is arranged on the base (1) and slidably connected with a slider (8) through the dovetail groove, and a connecting rod (9) is obliquely arranged on the slider (8). The mechanism is higher in punching accuracy and capable of guaranteeing included angles among multiple holes when the holes are processed at the same time.

Owner:创客帮(山东)科技服务有限公司

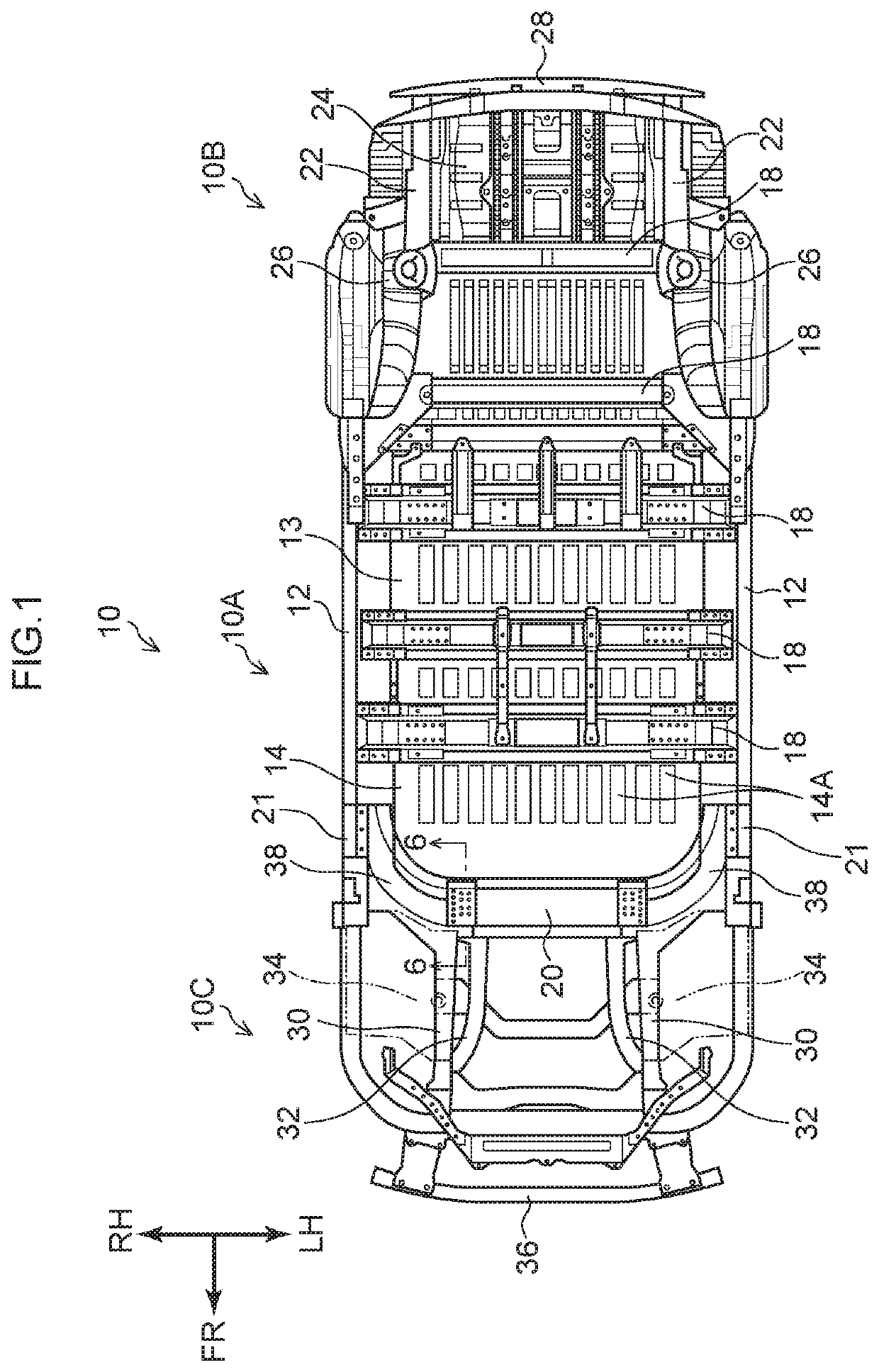

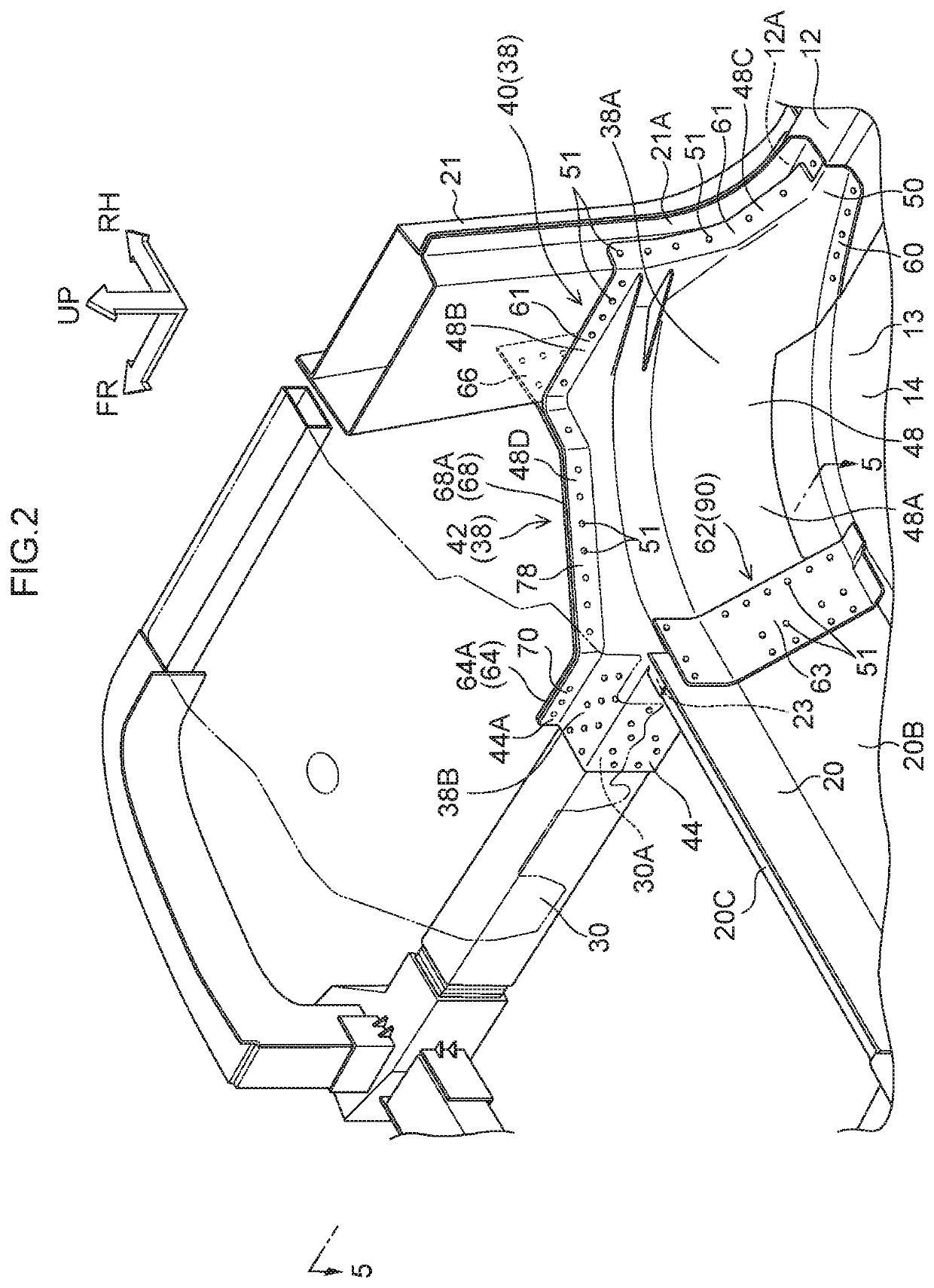

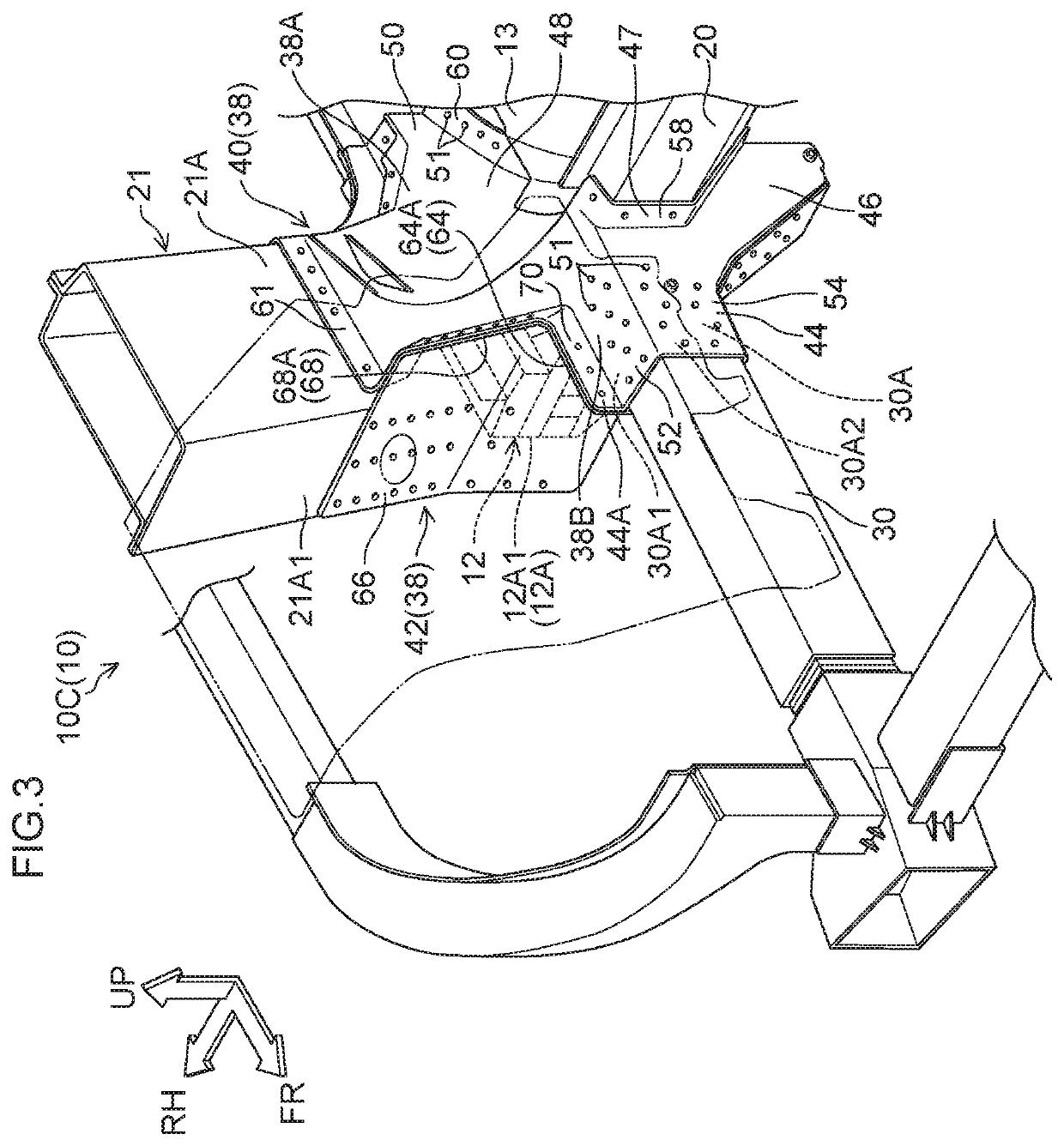

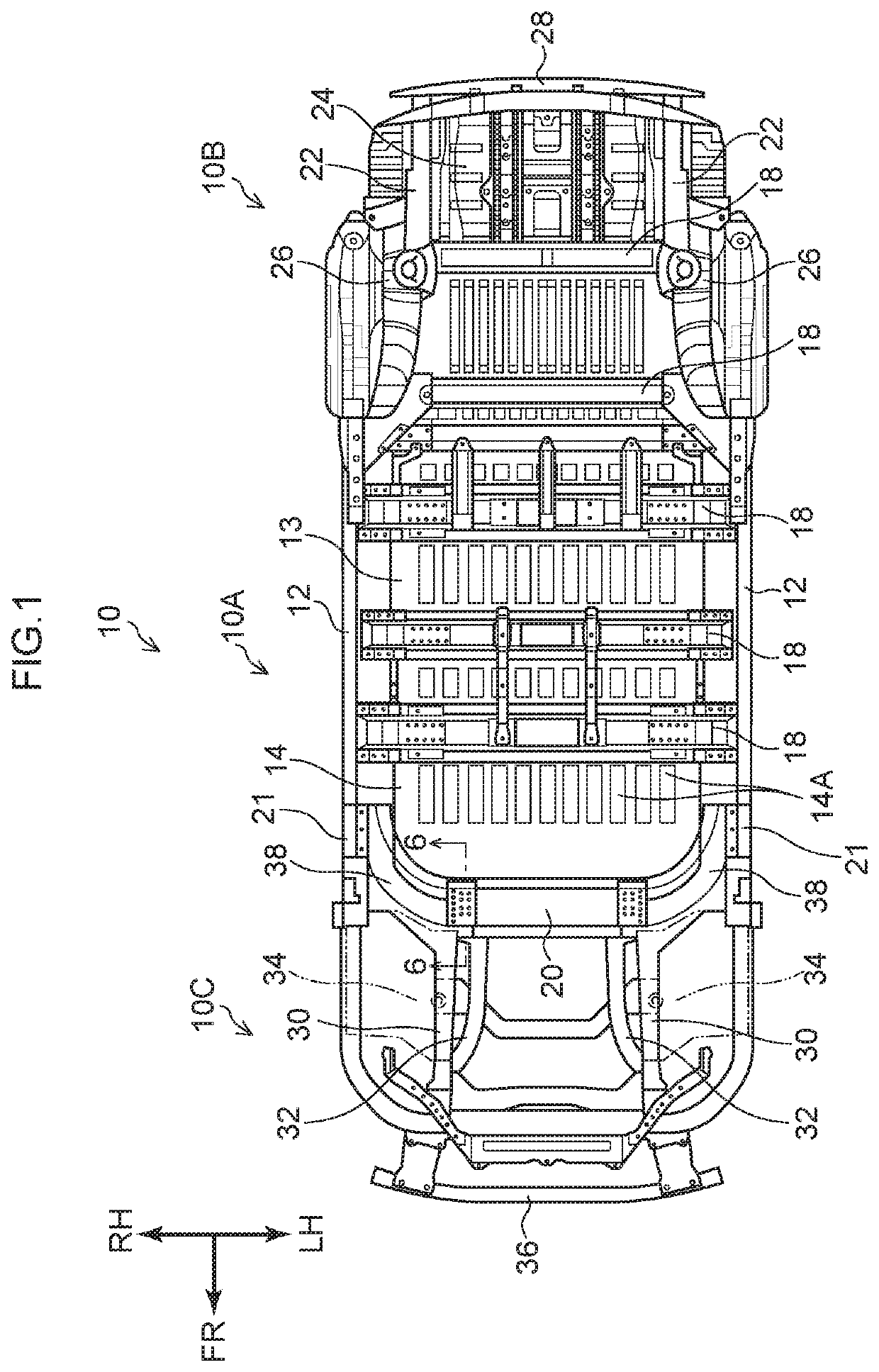

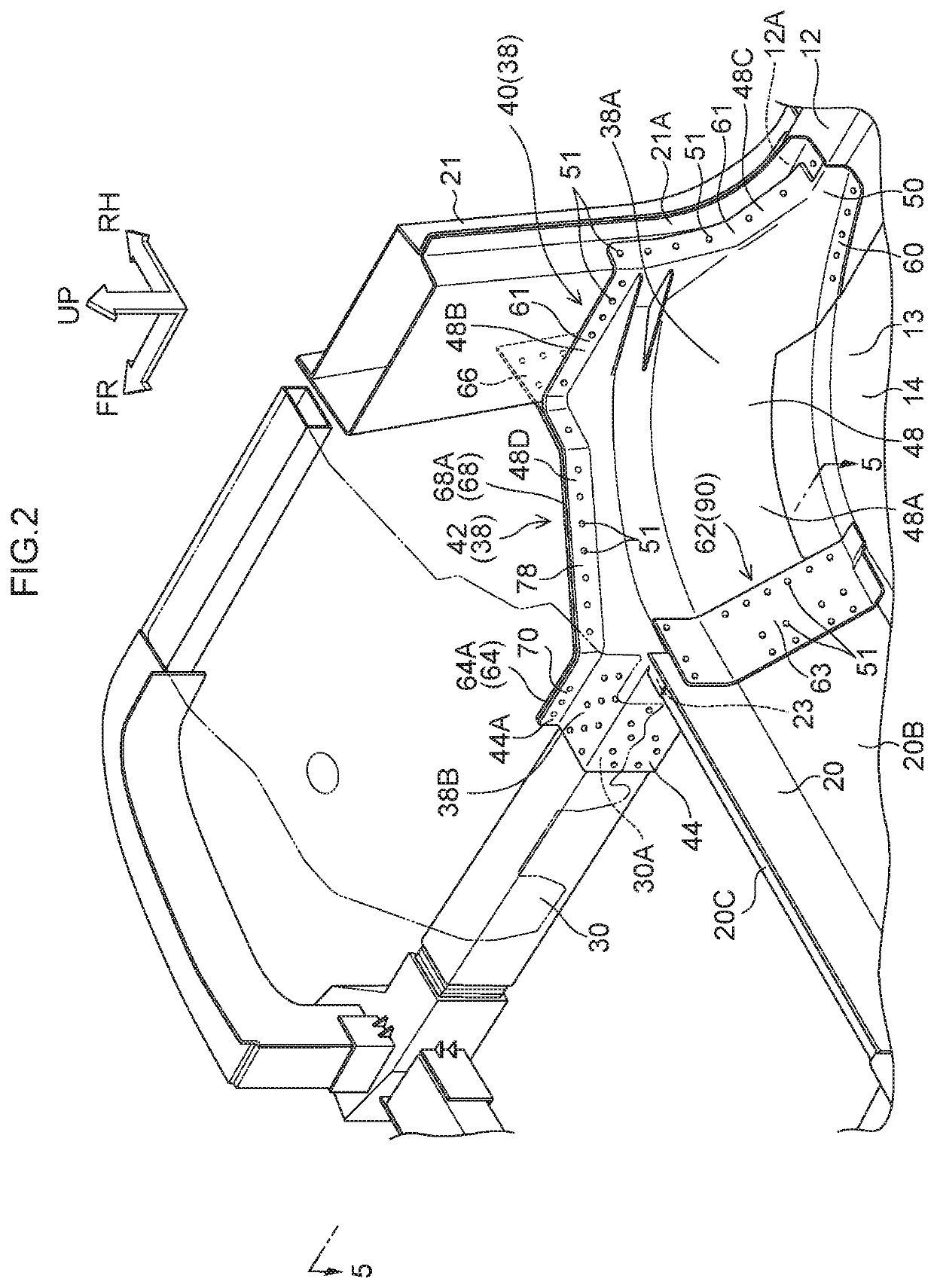

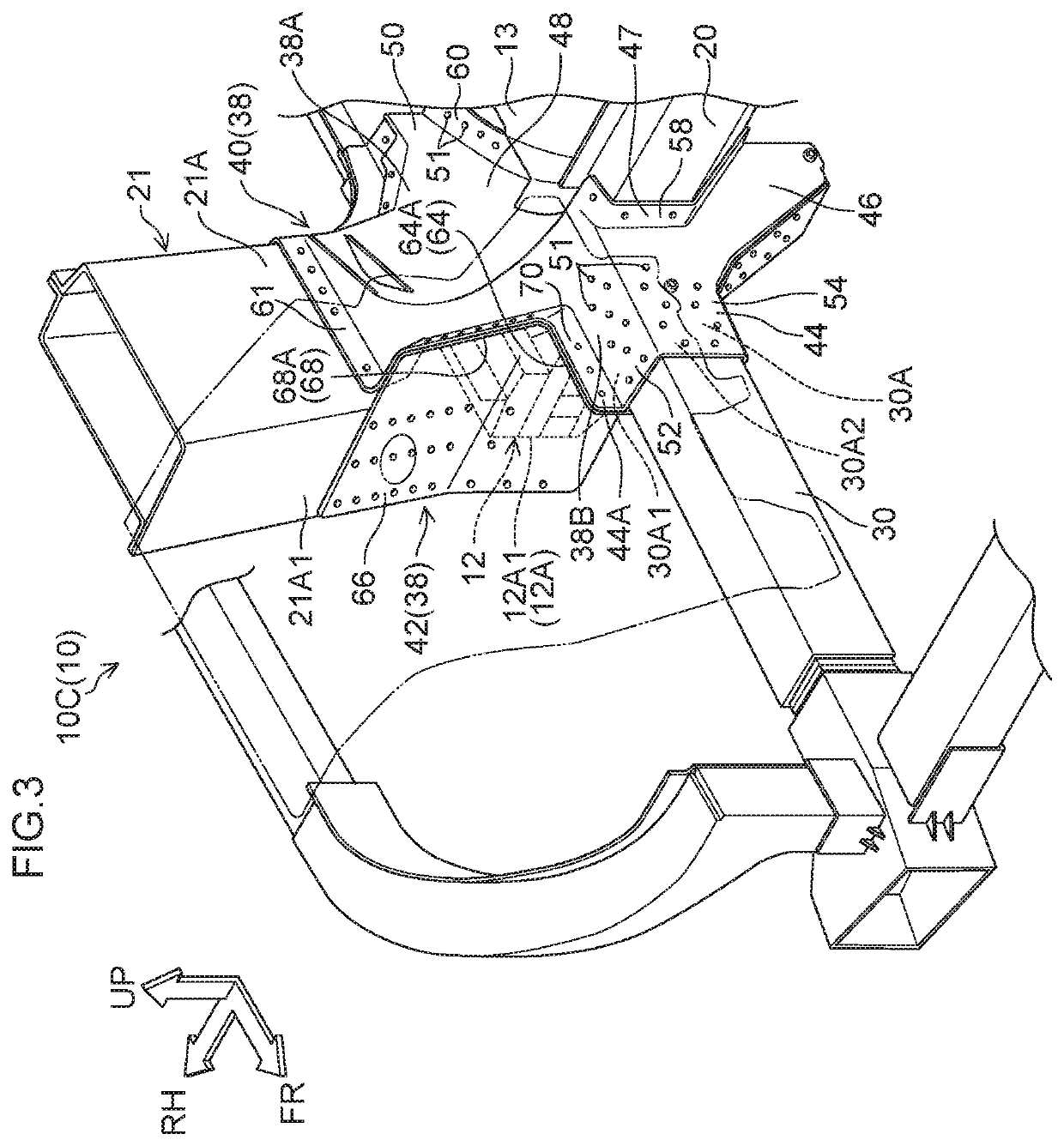

Vehicle front portion structure

ActiveUS20200047810A1Good effectIncrease flexibilityUnderstructuresSuperstructure subunitsClassical mechanicsStructural engineering

A reinforcing plate is provided between an inner central portion that structures a portion of a connecting member and a rear end portion of a dash cross-member. The reinforcing plate is a wrought member and is joined (at a join portion) to both the inner central portion and a rear wall portion of the dash cross-member via joining members. Because the wrought member has high tensile strength, when the reinforcing plate is provided at the join portion of the connecting member, a tensile load acting on the join portion may be borne by the reinforcing plate, and breakage of the connecting member may be suppressed. Therefore, an impact load transmitted from a front side member through the connecting member may be transmitted to the dash cross-member and rockers.

Owner:TOYOTA JIDOSHA KK

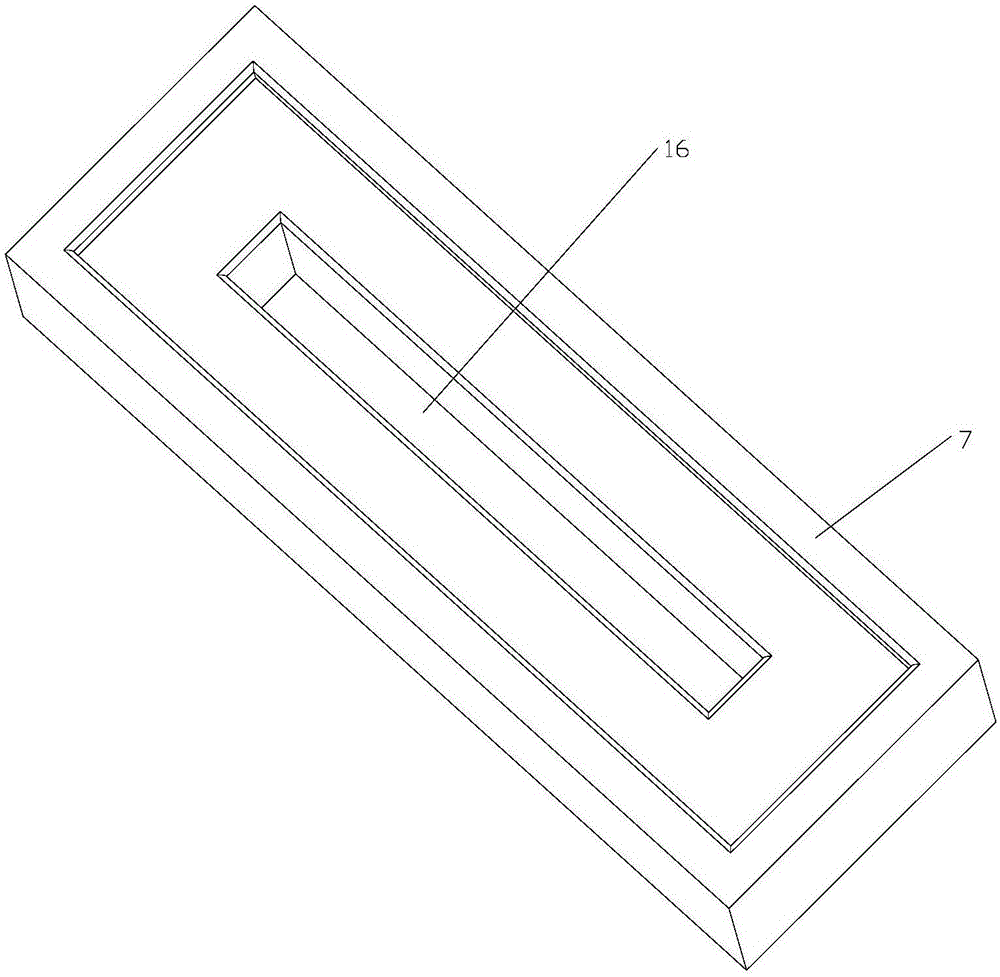

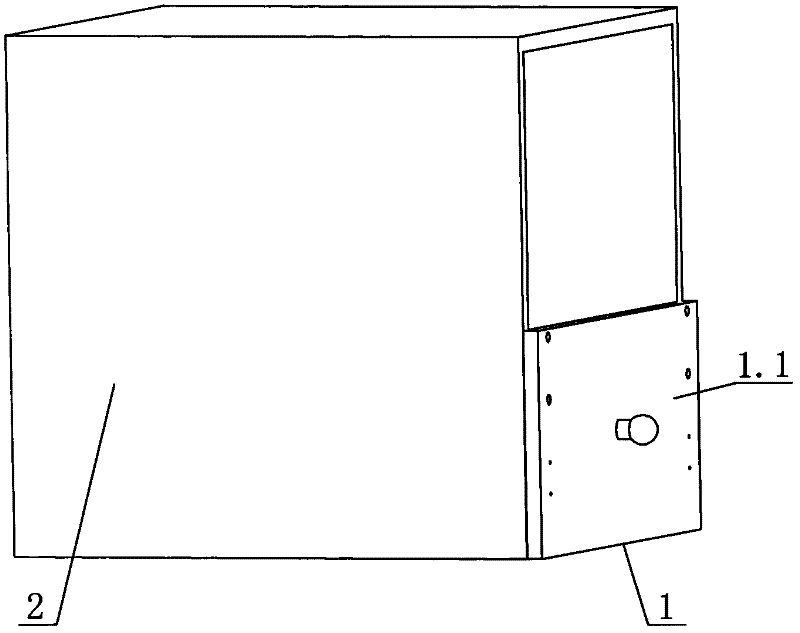

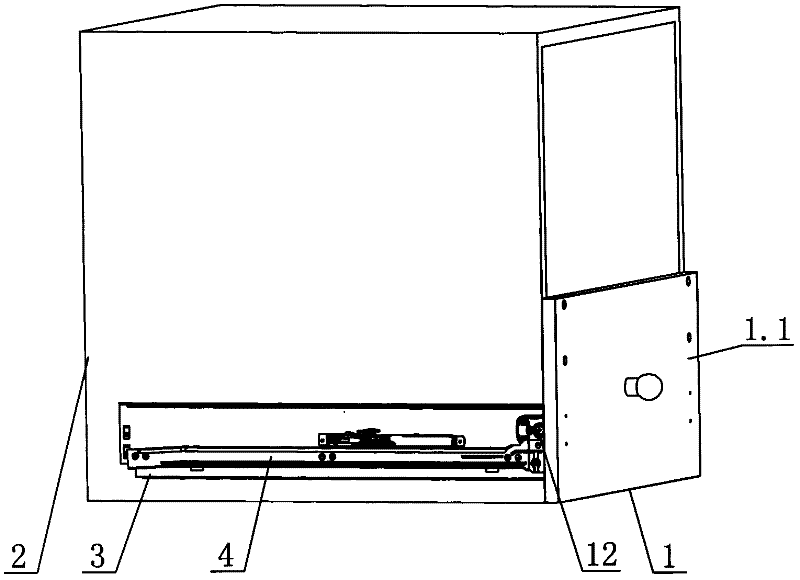

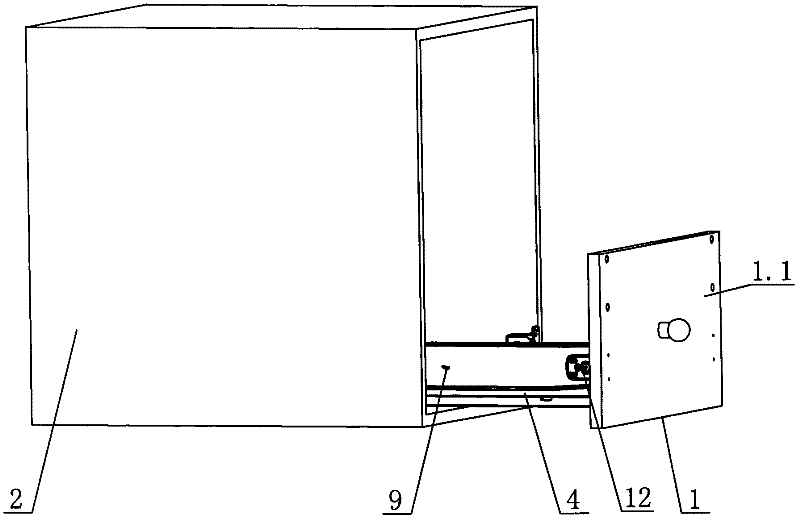

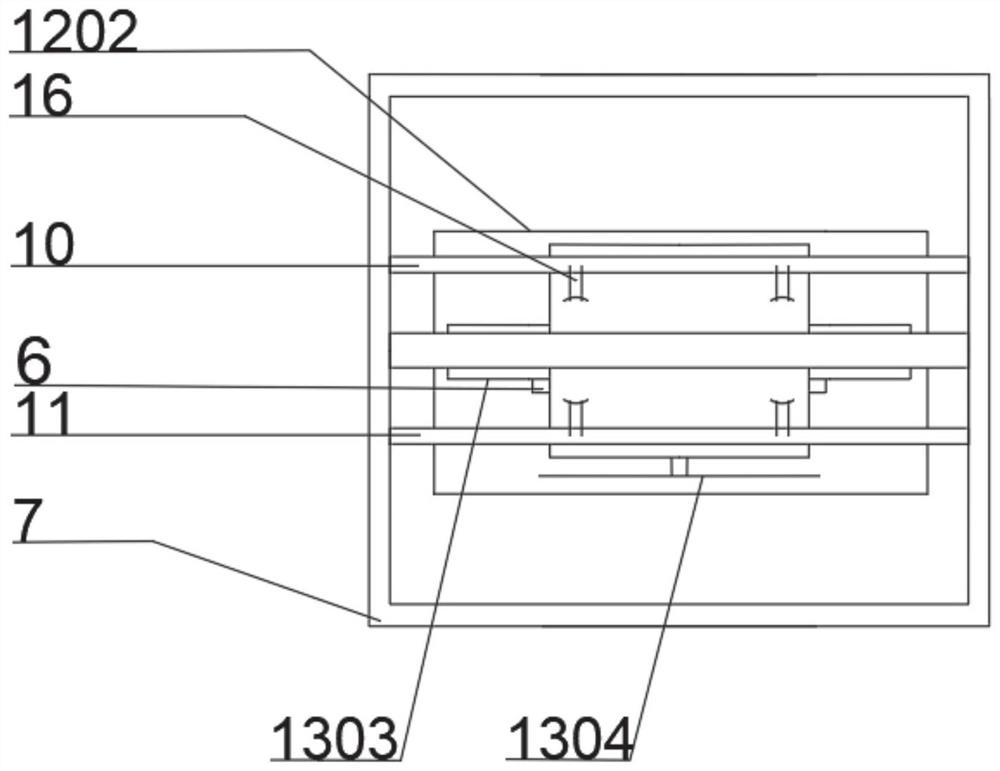

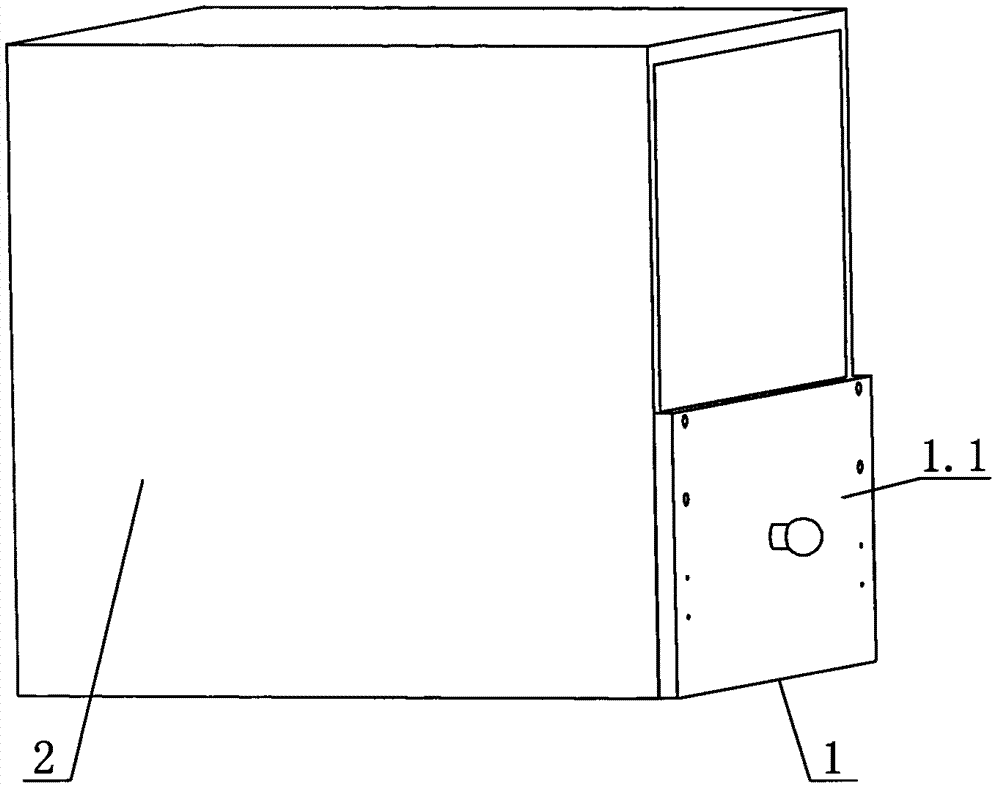

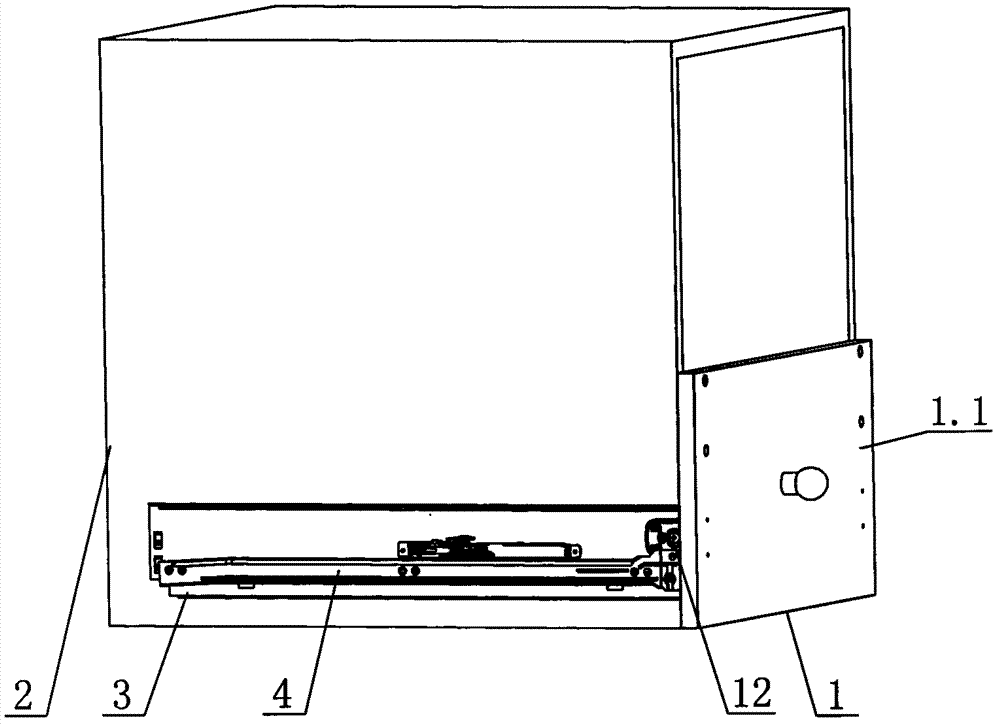

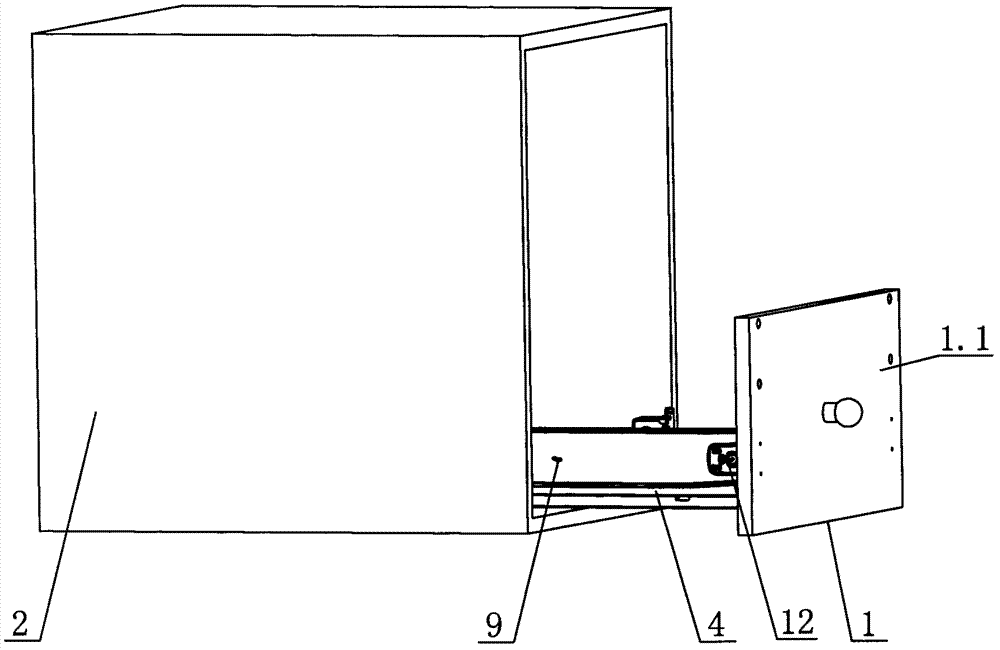

Drawer-sliding rail backstepping control device

The invention provides a drawer-sliding rail backstepping control device. The backstepping control device comprises a drawer main body and wheel type rolling sliding rails connected with a cabinet body; the wheel type rolling sliding rails include a fixed sliding rail arranged on the inner wall of the cabinet body, and a movable sliding rail arranged on the a drawer main body is arranged on the fixed sliding rail in a sliding way; the drawer main body is formed by assembling a front plate, metal side plates, a rear plate and a bottom plate together, the front plate is connected with the metalside plates through a detachable connecting base, the movable sliding plate is fixed at the middle parts of the metal side plates, a rebound part is arranged on the cabinet body or the fixed sliding rail or between the cabinet body and the fixed sliding rail, the metal side plates or / and the movable sliding plate are provided with shifting blocks for driving the rebound part to move. By the adoption of the invention, the problem that the installation of the rebound part occupies a large space in the prior art can be solved, the load borne by the rebound part is reduced, less installation process steps are implemented, installation time is reduced, and working efficiency is improved; and the backstepping control device has the characteristics of simple and reasonable structure, operation convenience, long service life and convenience for processing and production.

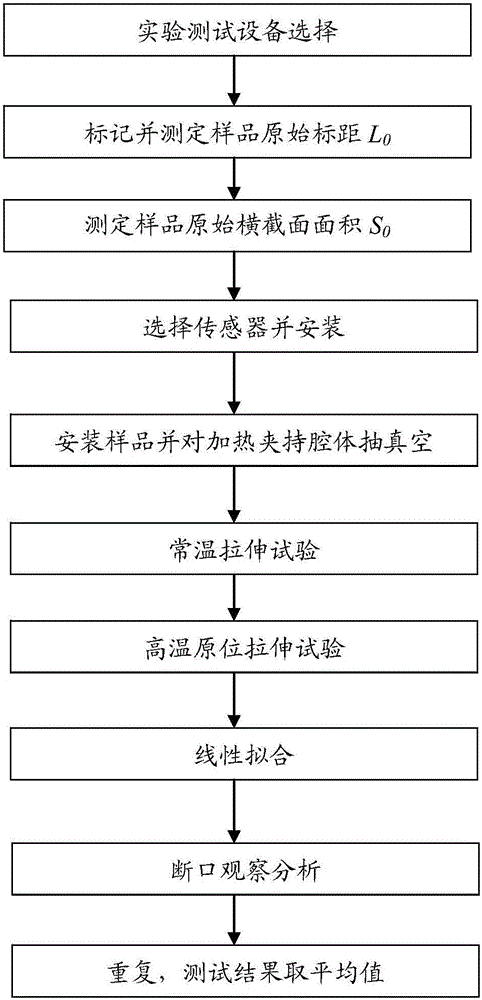

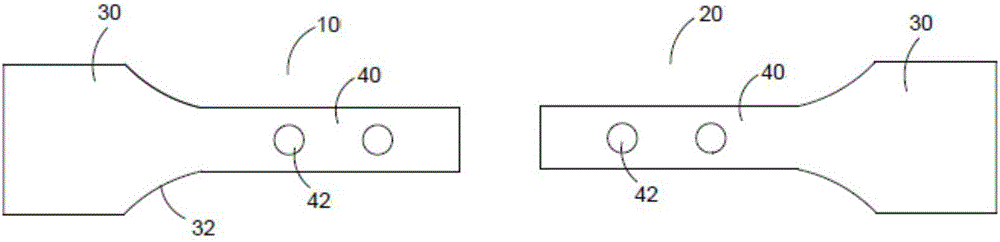

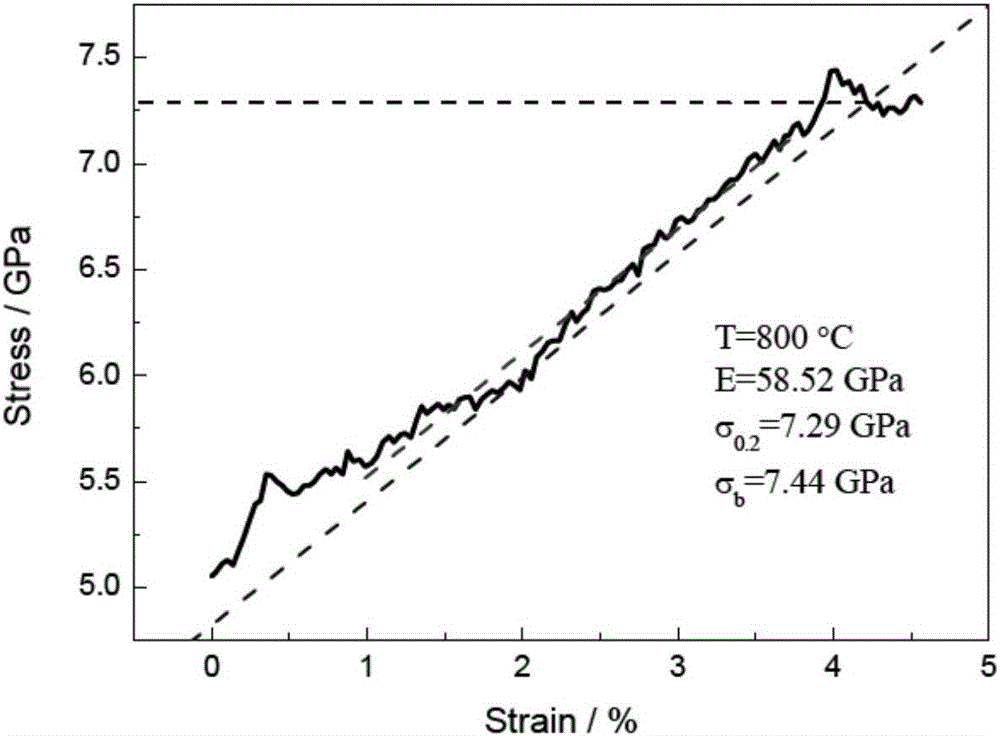

Method for testing mechanical properties of electronic gun heater assembly

ActiveCN105738224AAccurate measurement of mechanical tensile properties parametersSolve the testing problems of engineering requirementsMaterial strength using tensile/compressive forcesLinear relationshipEngineering

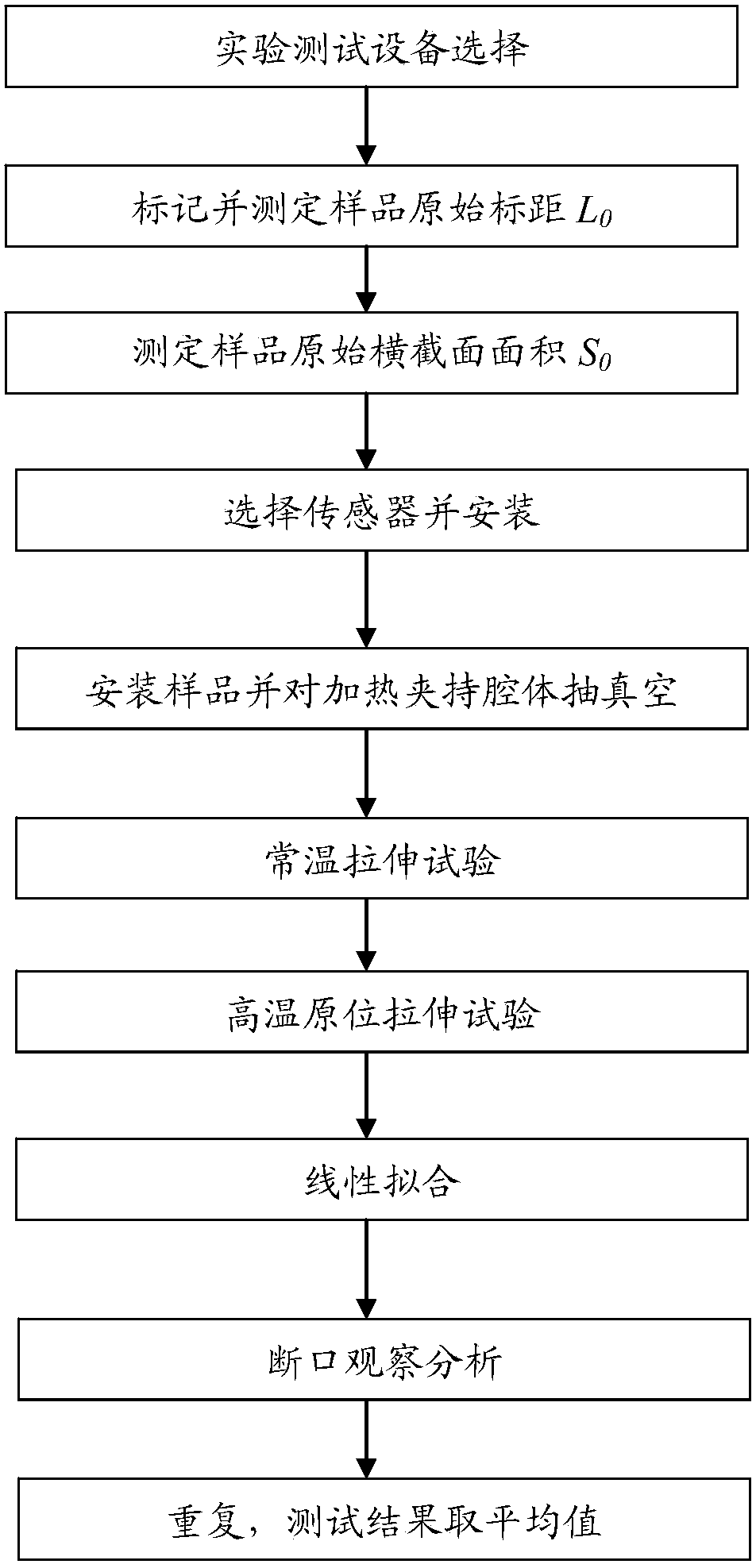

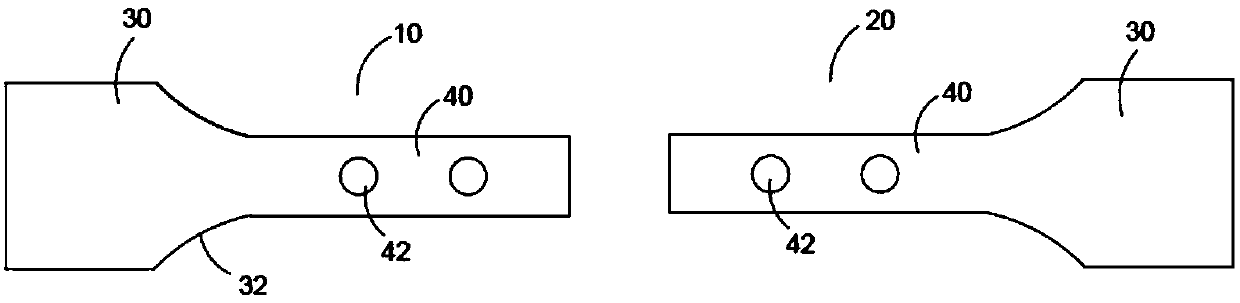

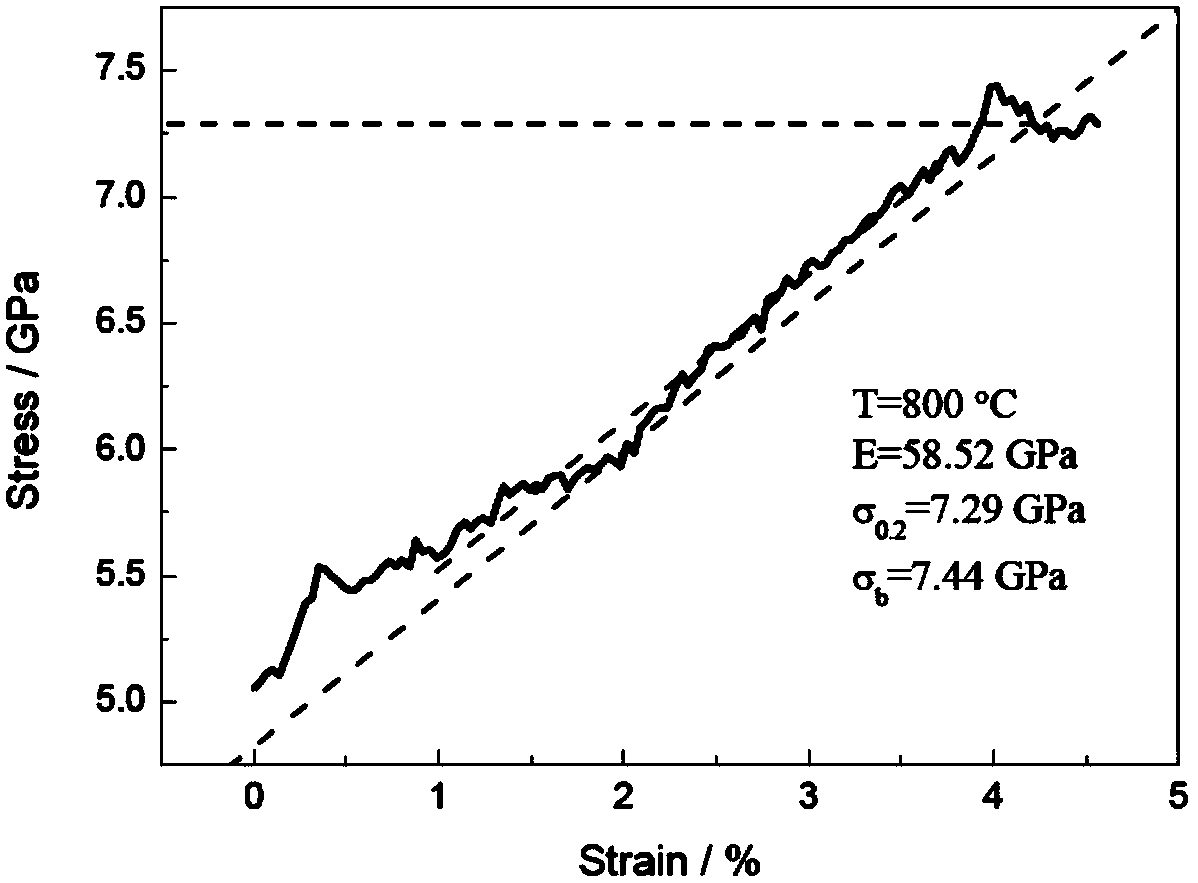

The invention relates to a method for testing mechanical properties of an electronic gun heater assembly, comprising the following steps: (1), taking at least two heater assemblies under detection; (2), marking an original scale distance on a heater of each heater assembly under detection, and determining original scale distances L0 and S0; (3), testing yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection in an actual vacuum environment at different temperatures; (4), establishing a change-with-temperature linear relationship of the yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection by linear fitting; (5), according to the linear relationship, calculating to obtain the yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection at the actual operation temperatures. The method enables chemical tensile performance parameters of a heater or a combination of a heater with a platinum sheet and / or a cathode head in a vacuum high-temperature operating environment to be accurately measured, and the testing problem of engineering needs is solved.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

Vehicle front portion structure

ActiveUS11027780B2Increase flexibilityEasy to joinUnderstructuresSuperstructure subunitsClassical mechanicsEngineering

A reinforcing plate is provided between an inner central portion that structures a portion of a connecting member and a rear end portion of a dash cross-member. The reinforcing plate is a wrought member and is joined (at a join portion) to both the inner central portion and a rear wall portion of the dash cross-member via joining members. Because the wrought member has high tensile strength, when the reinforcing plate is provided at the join portion of the connecting member, a tensile load acting on the join portion may be borne by the reinforcing plate, and breakage of the connecting member may be suppressed. Therefore, an impact load transmitted from a front side member through the connecting member may be transmitted to the dash cross-member and rockers.

Owner:TOYOTA JIDOSHA KK

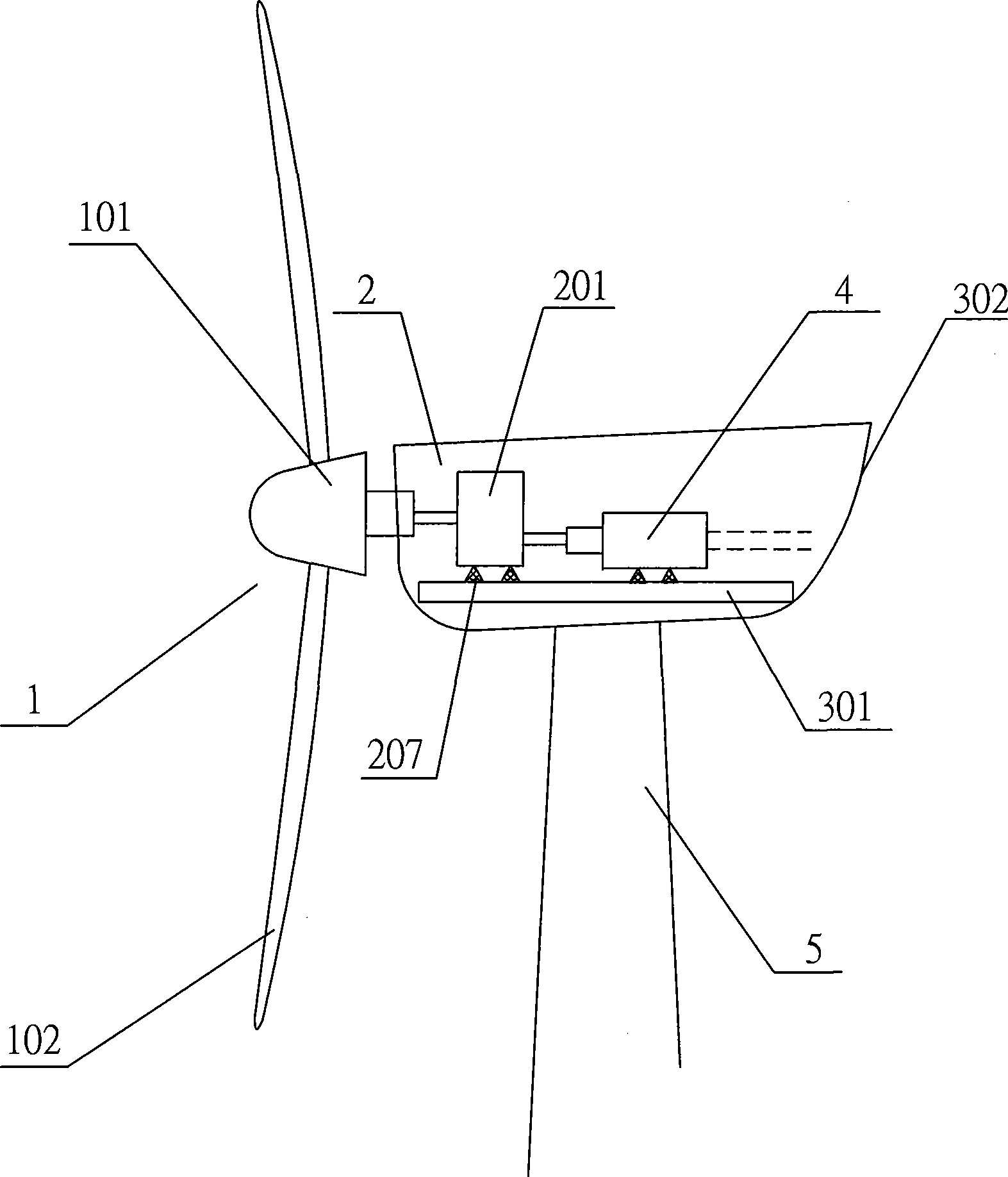

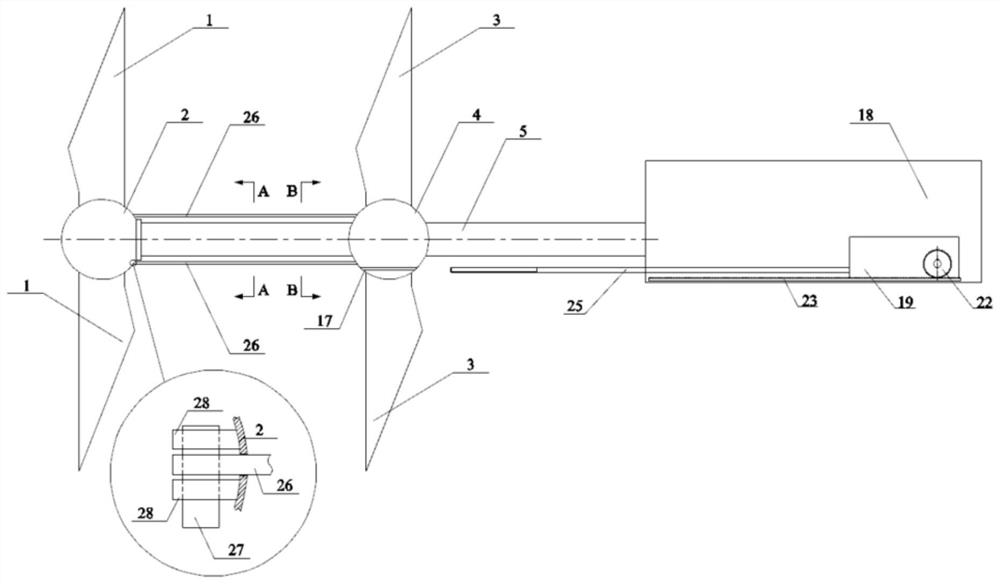

Wind generating set by using bamboo-based blade

InactiveCN101397976AImprove performanceLarge sweep areaMachines/enginesWind motor combinationsWind forceElectric generator

The invention discloses a wind generating set using bamboo blades, which comprises a wind wheel system, a drive system, a power generator and a pylon. An output end of the drive system is connected with the power generator and the drive system and the power generator are installed on the pylon. The wind wheel system comprises a wheel hub and blades which are fixed on the wheel hub. The revolving shaft of the wheel hub is connected with an input end of the drive system and the blades are made of bamboo composite materials. The invention provides a wind generating set applying bamboo blades, which improves the flexibility feature of the blade, prolongs the service life of the set, is environment-friendly and reduces cost.

Owner:ZHEJIANG WINDEY

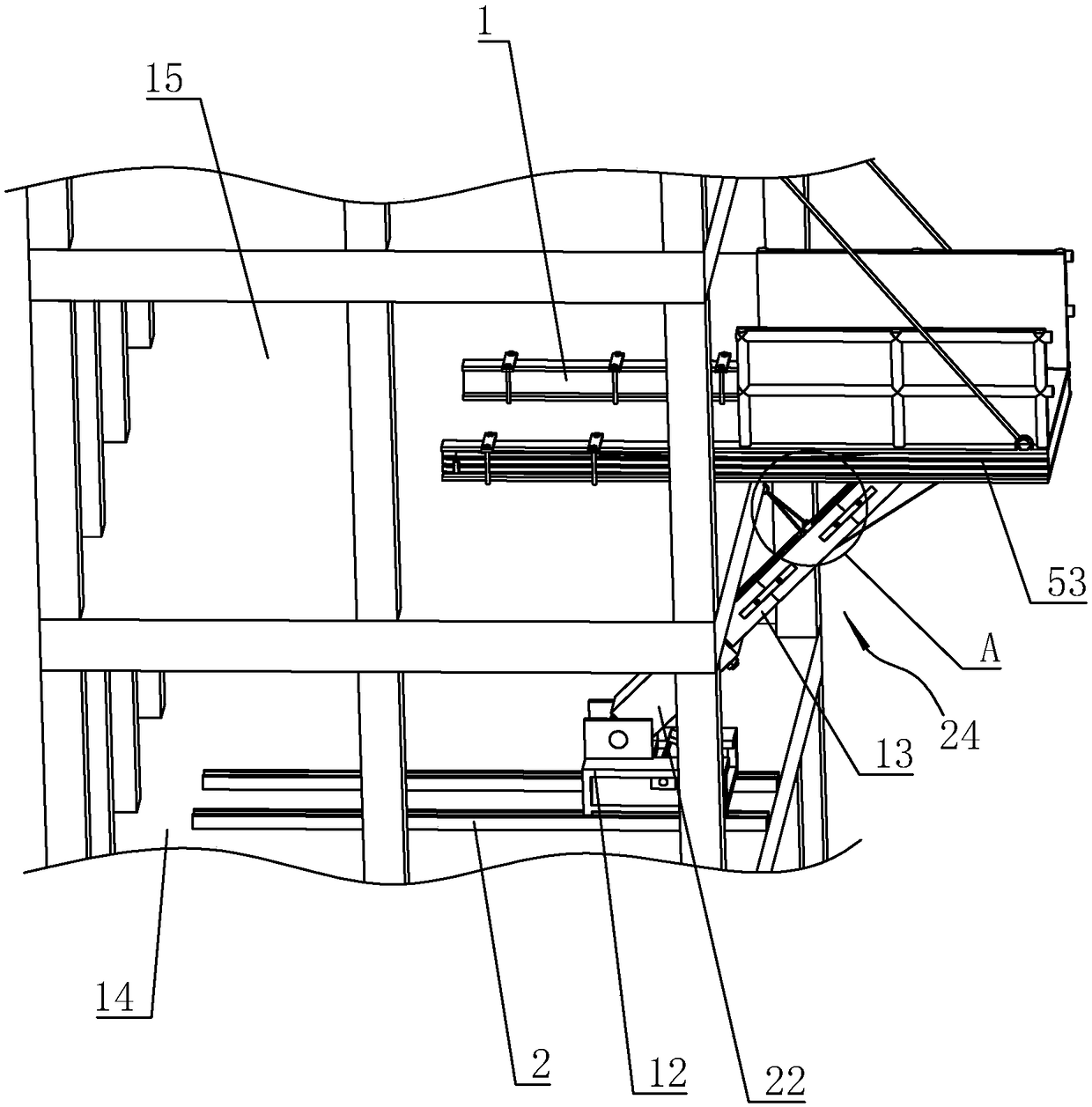

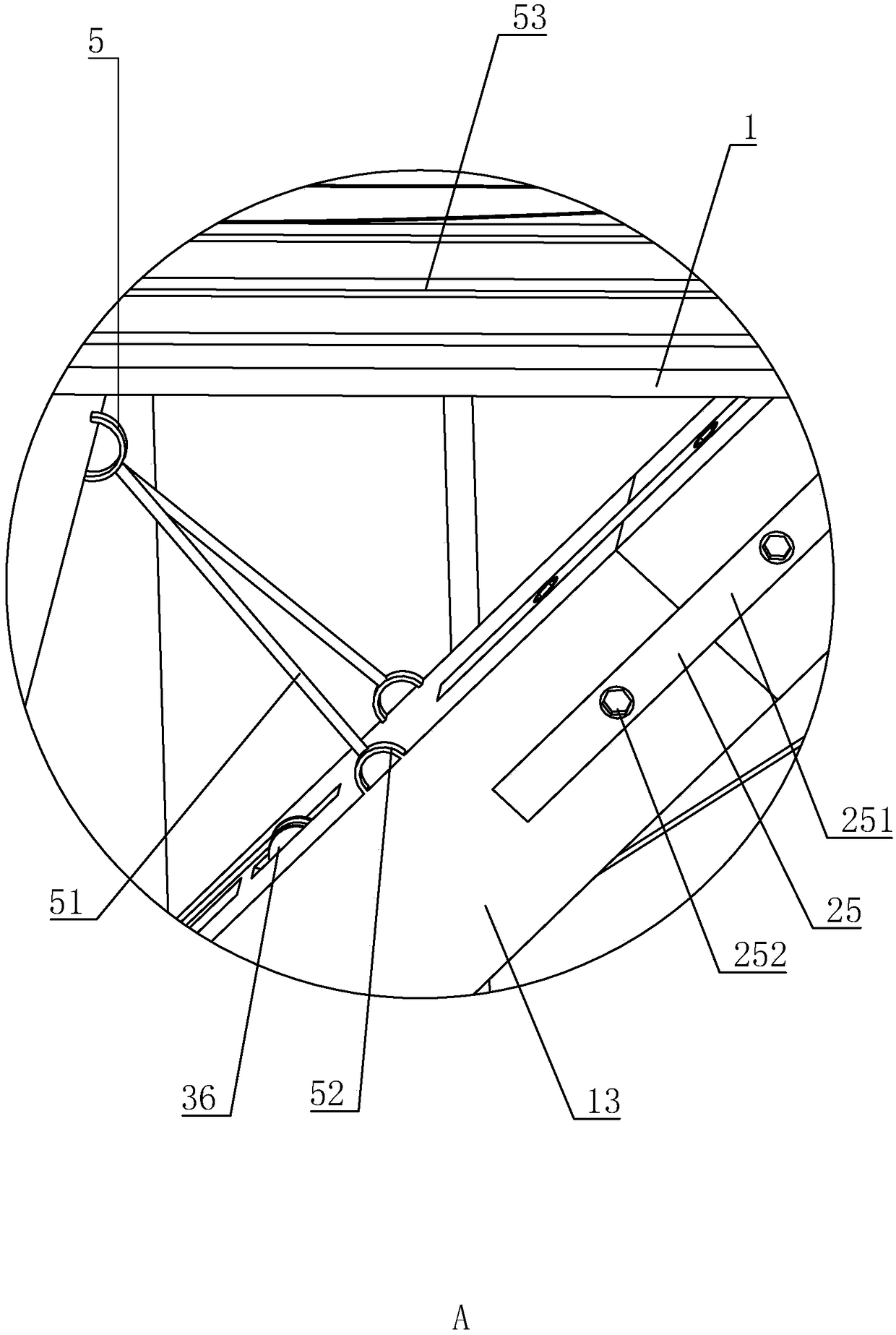

Reinforcing device of discharging platform

InactiveCN108868136AHigh strengthReduce load bearingBuilding material handlingHydraulic cylinderStructural engineering

The invention discloses a reinforcing device of a discharging platform, and applies to the field of architectural engineering equipment. In the technical scheme, the reinforcing device is characterized by comprising a main beam and a rectangular rack and further comprising a basic frame, multiple reinforcing rods, second floors and first floors, wherein the second floors and the first floors are sequentially distributed from top to bottom, the main beam is erected on one second floor, and a reinforcing plate is arranged on the bottom face of the rectangular rack; two parallel guide rails are laid on the ground of one first floor, the basic frame is in sliding connection with the guide rails, multiple fixing bases are pre-buried in the ground of the first floor and are in threaded connection with the basic frame through fixing bolts, a fixing barrel is rotatably connected to the basic frame, a hydraulic cylinder is rotatably connected inside the basic frame, a piston rod of the hydraulic cylinder is rotatably connected with the fixing barrel, and the multiple reinforcing rods are connected through connecting parts to form a bearing rod. The reinforcing device has the advantages thatthe bearing rod supports the rectangular rack to reduce the loads borne by a steel wire inhaul cable and the main beam when the discharging platform works, and accordingly influences on the personalsafety of an operator are reduced.

Owner:万越建设集团有限公司

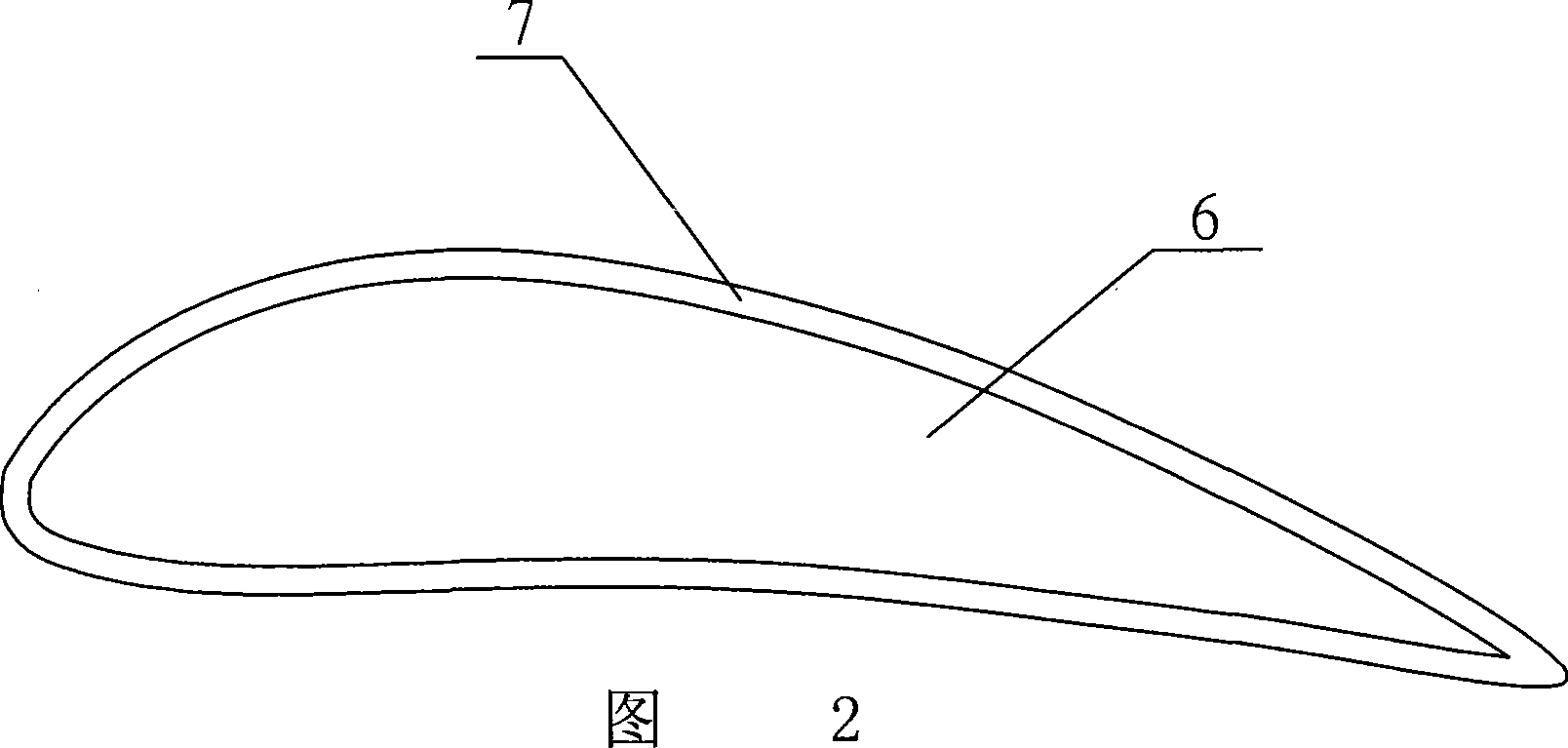

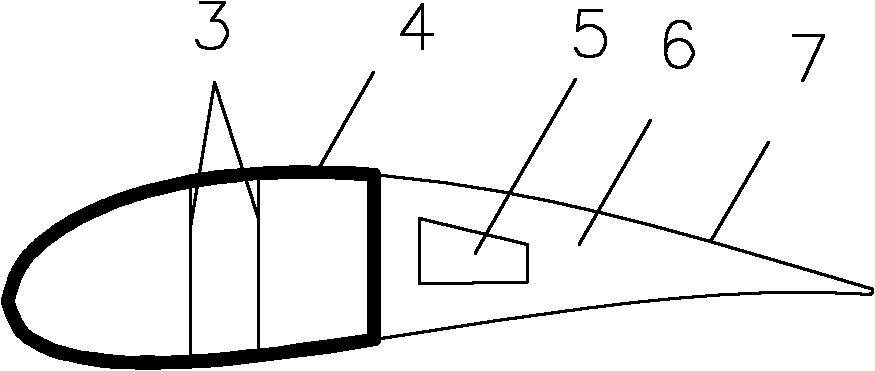

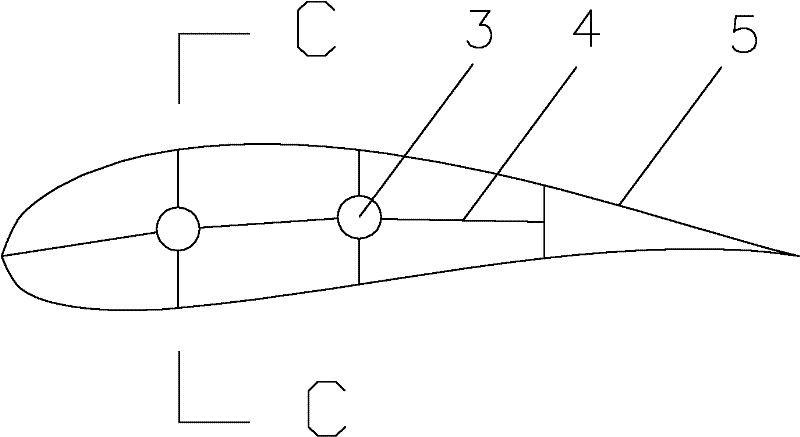

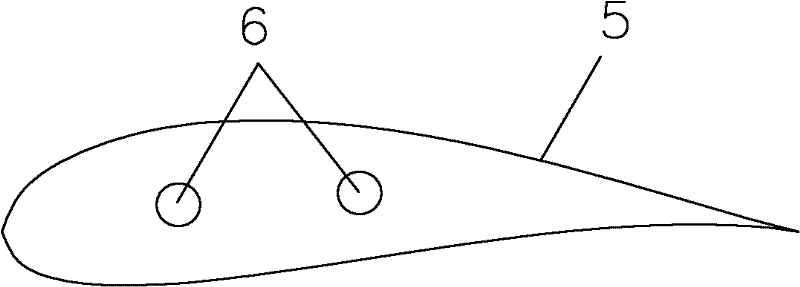

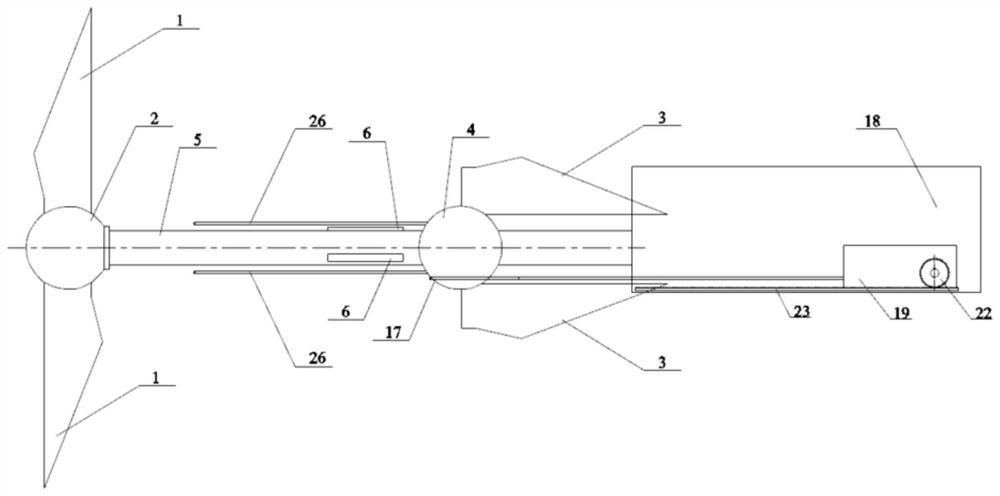

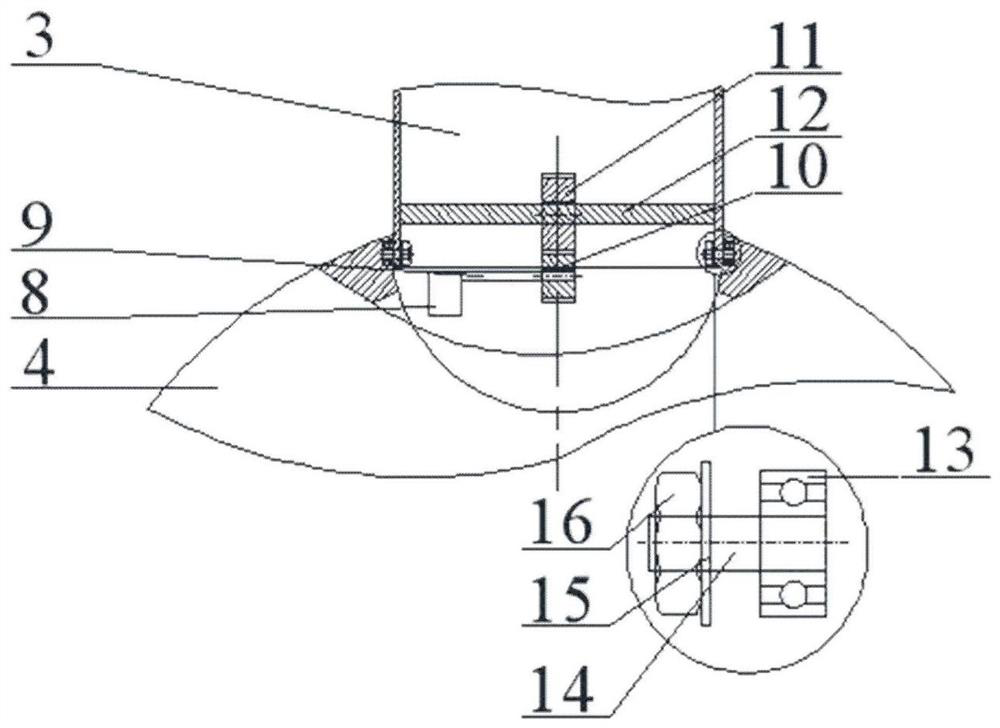

Blade structure for wind driven generator

InactiveCN101825070AReduce shockReduce load bearingWind motor controlMachines/enginesWind drivenWind force

The invention discloses a blade structure for a wind driven generator. The blade structure comprises air consumption holes, a baffle plate, a D-shaped steel longitudinal beam, an elastic hinge, a long steel wire, a short steel wire, a baffle plate with a hole, an air consumption hole cover plate and a hook, wherein positions with large windward areas on a blade in an axial direction are provided with a plurality of air consumption holes; one side of the air consumption hole cover plate is connected with the D-shaped steel longitudinal beam through the elastic hinge; the hook is arranged in the middle of the air consumption hole cover plate; the two ends of the short steel wire are connected with the hook in the middle of the air consumption hole cover plate respectively; and one end of the long steel wire is connected with the middle of the short steel wire, and the other end of the long steel wire is connected with a motor on a blade root of the blade. Energy capture of a wind wheel can be reduced so as to keep the rotating speed of the wind wheel below a rated value. Simultaneously, load borne by the blade and impact on the entire wind machine are reduced and the wind machine is prevented from being damaged.

Owner:XI AN JIAOTONG UNIV

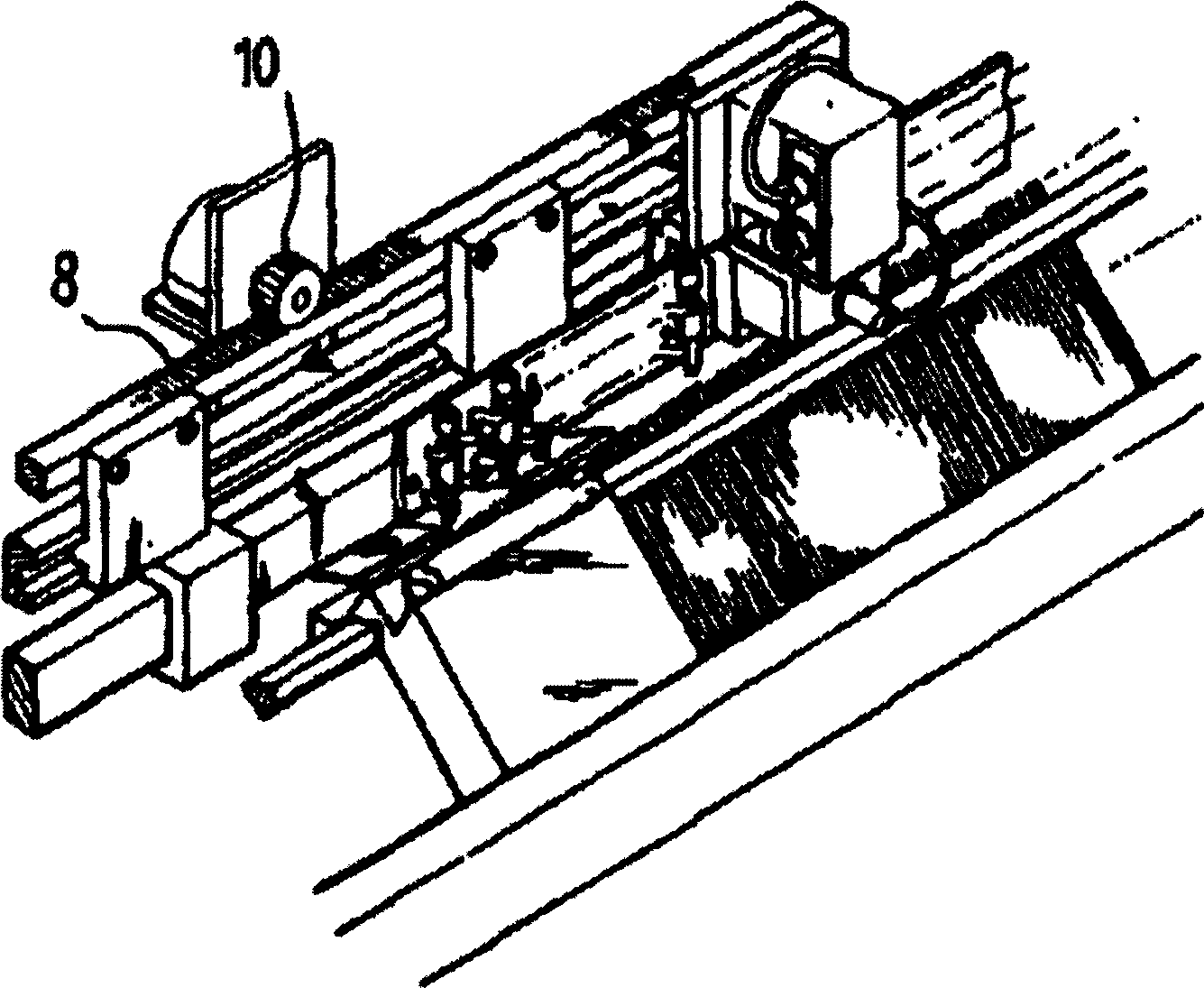

Automatic computer jacquard

InactiveCN1840757AMobile and stationaryExcellent position controlJacquardsTemperatue controlYarnEngineering

The invention relates to an automatic computer flat jacquard machine, which comprises: a yarn transmitter and a moving motor for moving said transmitter, wherein it comprises: two synchronous belt wheels connected to the upper and lower ends of the rotation axle of moving motor; a couple of synchronous belts at the moving direction of transmitter, while one end is connected to the synchronous belt wheels; the first idle wheel connected to another end of first synchronous belt wheel; the second idle wheel connected to another end of second synchronous belt, while its rotation axle is separated from the rotation axle of first idle wheel; and a yarn transmitter connected to the synchronous belts. The invention can independently adjust the tension of each synchronous belt.

Owner:吴洪柱

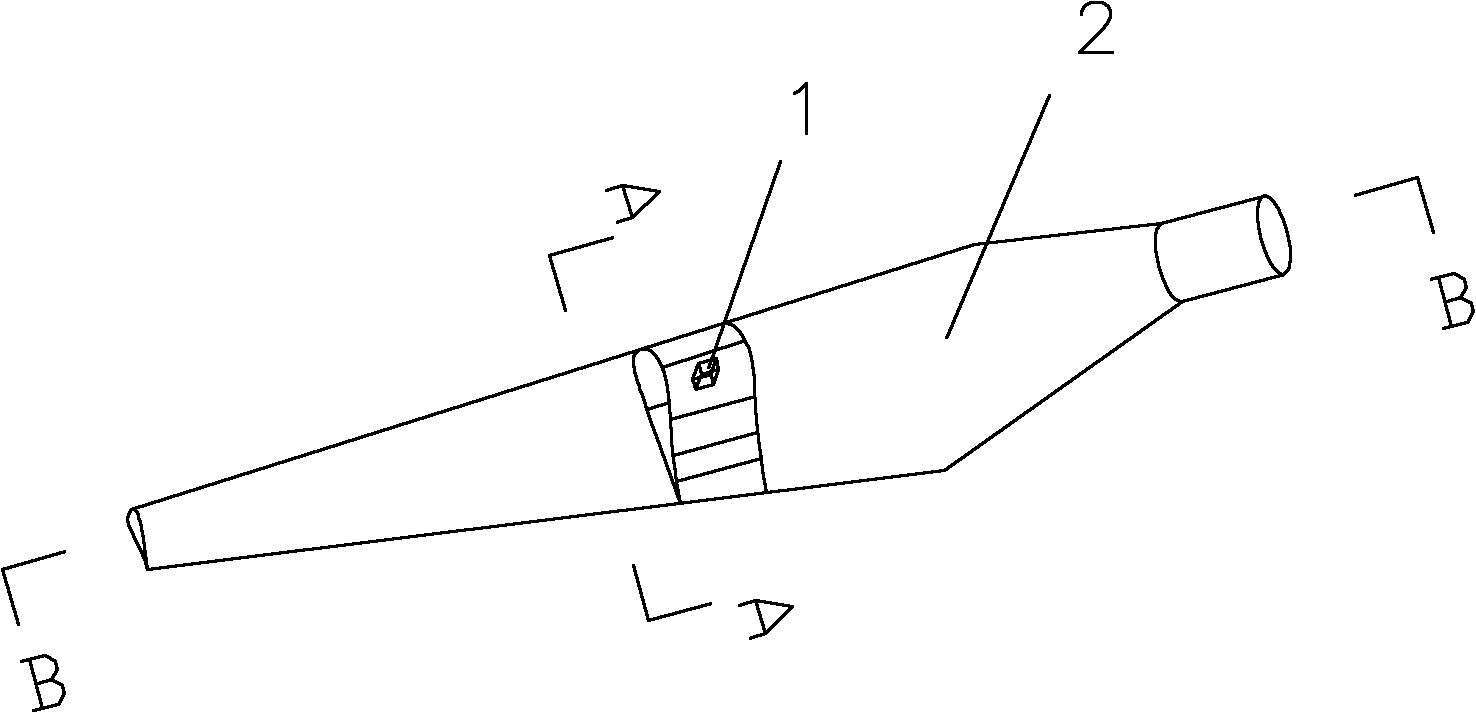

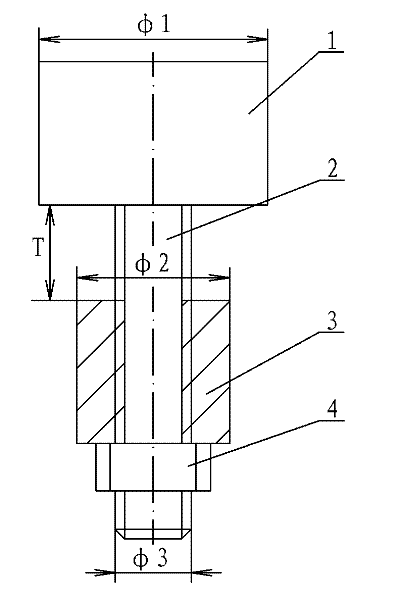

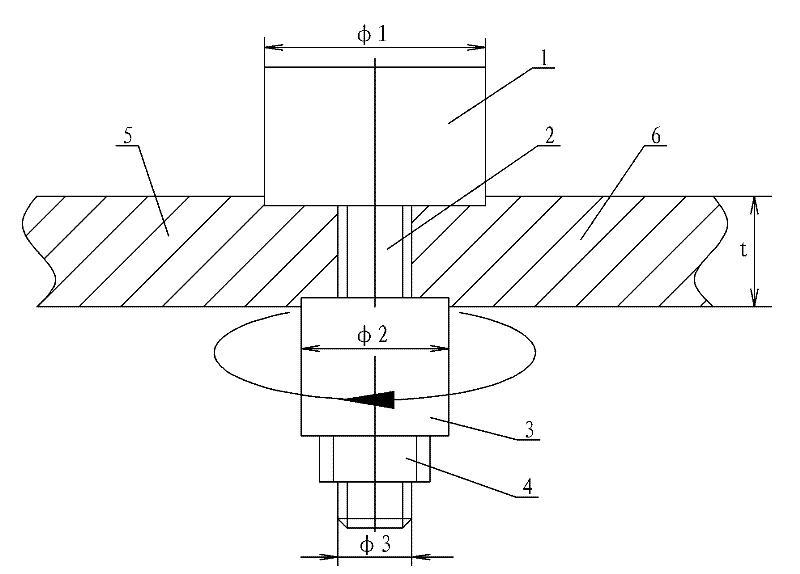

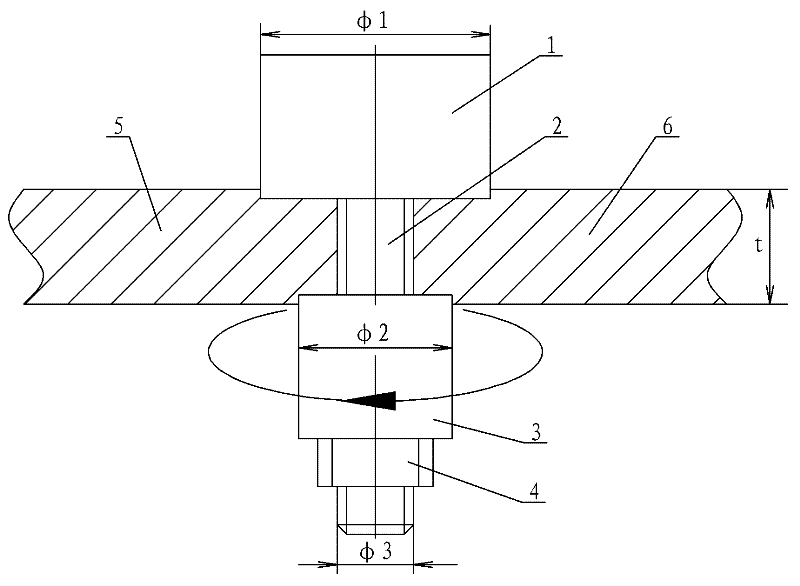

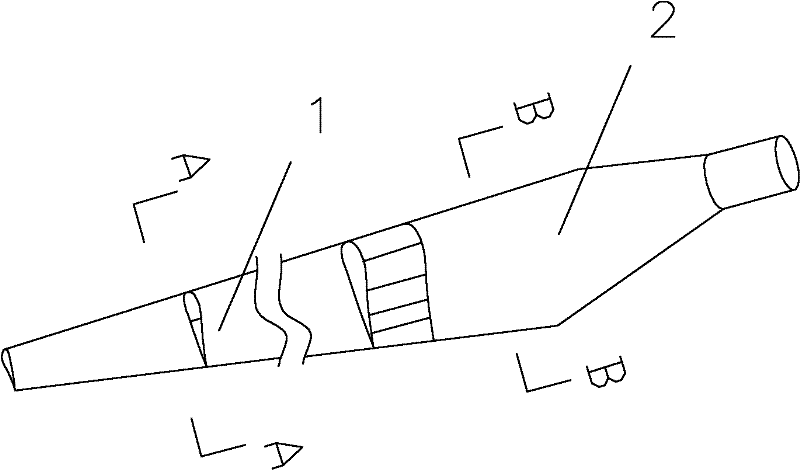

Self-supporting friction stir welding method with unequal diameters of upper and lower shaft shoulders and stirring head thereof

InactiveCN101947691BReduce load bearingReduce loadNon-electric welding apparatusFriction weldingEngineering

The invention relates to a self-supporting friction stir welding method with unequal diameters of upper and lower shaft shoulders and a stirring head thereof, and relates to the self-supporting friction stir welding method and the stirring head thereof. The invention aims to solve the problem that the diameters of the upper and lower shaft shoulders are equal and the problem that large heat inputof welding and bearing of a stirring pin influence the joint performance and even cause the rupture of the stirring pin in the conventional elf-supporting friction stir welding method. The method comprises the steps of: 1, determining the size of the stirring head; 2, determining the using length of the stirring pin; 3, fixing a first work piece to be welded and a second work piece to be welded; 4, positioning the stirring head; and 5, performing the stir friction welding on the first work piece to be welded and the second work piece to be welded. The stirring head and the stirring pin are vertical to the lower end face of the upper shaft shoulder; the stirring pin and the upper shaft shoulder are integrated into a whole; the outer surface of the stirring pin is provided with external threads; the lower shaft shoulder is in threaded connection with the stirring pin; a nut is arranged under the lower shaft shoulder; the nut is in threaded connection with stirring pin; and the diameter of the lower shaft shoulder is less than that of the upper shaft shoulder. The elf-supporting friction stir welding method with unequal diameters of upper and lower shaft shoulders and the stirring head thereof are used for stir friction welding.

Owner:HARBIN INST OF TECH

Unit forwarding rubber trolley of track crane

InactiveCN101648687AImprove operational efficiencyShorten the timeLifting devicesVehicle frameEngineering

The invention discloses a unit forwarding rubber trolley of a track crane, which comprises a balance beam, wherein an inner groove is arranged in the center of the balance beam, a jack and a cylinderare arranged in the inner groove; the cylinder is connected with a hydraulic tank arranged at the outer side of one end of the balance beam through a high-pressure oil pipe, a lower support seat is arranged at the upper end in the center of the balance beam, the bottom of the lower support seat is connected with the upper part of the jack, the lower support seat is connected with an upper supportseat arranged at the upper end of the lower support seat by a semicircular joint, a groove balance beam which is matched with the joint is arranged on the lower support seat, rotating shafts are arranged inside both two ends of the groove balance beam, two sides of the lower end of the rotating shafts are connected with a frame outside the balance beam, a central shaft is connected to the frame, and two rubber wheels are sleeved on the central shaft. The invention has the advantages of energy resource saving, compact structure, simple and convenient installation, flexible steering, convenientjacking, high operation efficiency, time saving, reduced cost and wide application range.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

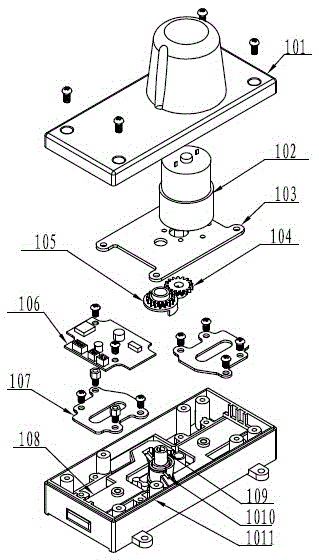

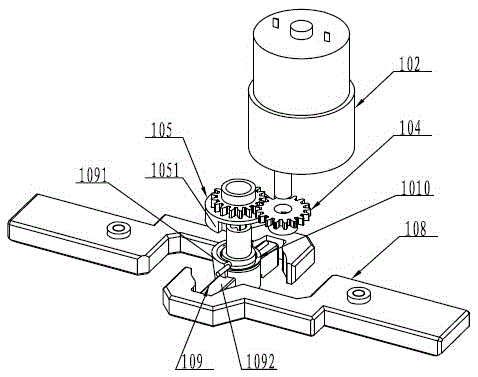

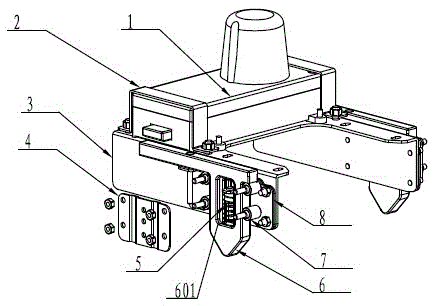

Double-lock-tongue electronic control lock and bicycle locking device comprising same

InactiveCN105625829ACompact structureReasonable designBicycle locksNon-mechanical controlsMicro motorBlocked Connection

The invention discloses a double-lock-tongue electronic control lock and a bicycle locking device comprising the same and belongs to the technical field of locksets. The double-lock-tongue electronic control lock comprises an upper cover and a lock box. A micro motor is fixedly arranged between the upper cover and the lock box. An output shaft of the micro motor is fixedly connected to a driving gear. The driving gear is engaged with a driven gear. A shifting fork is inserted into the lower portion of the driven gear in a matched mode. A shifting fork torsional spring is arranged between the shifting fork and the driven gear in a matched mode. The shifting fork torsional spring is in blocking-connection fit with a driven gear catch of the driven gear and a shifting fork catch of the shifting fork. Shifting slices on the two sides of the shifting fork are matched with one of lock tongues. The two lock tongues are symmetrically arranged with respect to the center of the shifting fork. The double-lock-tongue electronic control lock has the functions of buffering, shock absorption, machinery energy storing and the like; borne loads during instantly starting and suddenly stopping of the motor can be sufficiently reduced and relieved, the motor is protected effectively, operation is stable and reliable, and the service life is prolonged.

Owner:HANGZHOU JINTONG AUTO REPAIR CO LTD

Planet differential lifting device of wind power installation vessel

InactiveCN102442624AReduce load bearingSmall sizeLifting devicesGearing detailsElectricitySteering wheel

The invention provides a planet differential lifting device of a wind power installation vessel, consisting of a lifting frame and three groups of transmission units; and each group of transmission units comprises a main transmission component, a medium steering wheel and an auxiliary transmission component. A planet transmission component of the lifting device takes an output solar wheel axle ofa reduction box component as input, and takes a planet frame and a main transmission component main gear of the main transmission component as double-output. The medium steering wheel is synchronously engaged with the main transmission component main gear of the main transmission component and an auxiliary transmission component main gear of the auxiliary transmission component, thus the medium steering wheel belongs to a bridge for transmitting power from the main transmission component to the auxiliary transmission component. Output gears, which have the same size and specification and are completely synchronous, are respectively engaged with racks which are inlaid into pile legs, thus the lifting of the wind power installation vessel can be realized. The invention has the advantages that the size and the weight of the lifting device can be reduced, the operation stability can be increased, and the safety performance of the wind power installation vessel can be improved.

Owner:深圳市欧佩亚海洋工程有限公司

A tractor intelligent control method and intelligent control system

InactiveCN103158713BReduce fuel consumptionImprove traction performanceInternal combustion piston enginesDrive wheelControl signal

The invention relates to a tractor intelligent control method and an intelligent control system. A corresponding signal is collected by a sensor to obtain an existing operating state of a tractor, all parameters are calculated, analyzed and judged by a controller on the basis, and after information is processed, control signals are transmitted to a stepping motor and a high-speed electromagnetic valve so as to enable a main clutch, a PTO clutch, and a brake pedal executing mechanism, an engine throttle draw bar executing mechanism, a hydraulic hanging mechanism and the like to conduct motion to prevent a driving wheel of the tractor from excessive trackslip and overload of a transmission system, ensure good comfort, fuel economy and traction, and prolong service life of the transmission system and tires of the tractor.

Owner:HENAN UNIV OF SCI & TECH

Bridge suspension type turbine hydroelectric generation base station

ActiveCN113622287AReduce intensityHigh strengthWater-power plantsHydro energy generationStream flowMarine engineering

The invention relates to the technical field of hydroelectric generation, in particular to a bridge suspension type turbine hydroelectric generation base station which comprises a load-bearing bridge, a power generation element lifting device, a flow monitoring device, a power generation element, an underwater fixing device, a power generation element protection shell and an electric energy collecting device. The load-bearing bridge is built on both sides of a river, the power generation element protection shell is welded to the center of a bridge deck, the underwater fixing device is installed in a bridge deck cavity and connected with the waterproof closed shell welded to the center of the bridge deck, the power generation element lifting device is fixed to the upper portion in the protection shell, and the generators are protected in the waterproof closed shell and fixed to the two sides of the load-bearing bridge. The load-bearing structure is connected with the lifting system through a rope, and the flow monitoring devices are fixed to the two sides of the generator protection shell. The power generation system is convenient to maintain and capable of fully utilizing the river water head to generate power, and has the advantages of being wide in application range, convenient to maintain, capable of guaranteeing strength, low in cost, high in power generation efficiency and environmentally friendly.

Owner:XI AN JIAOTONG UNIV

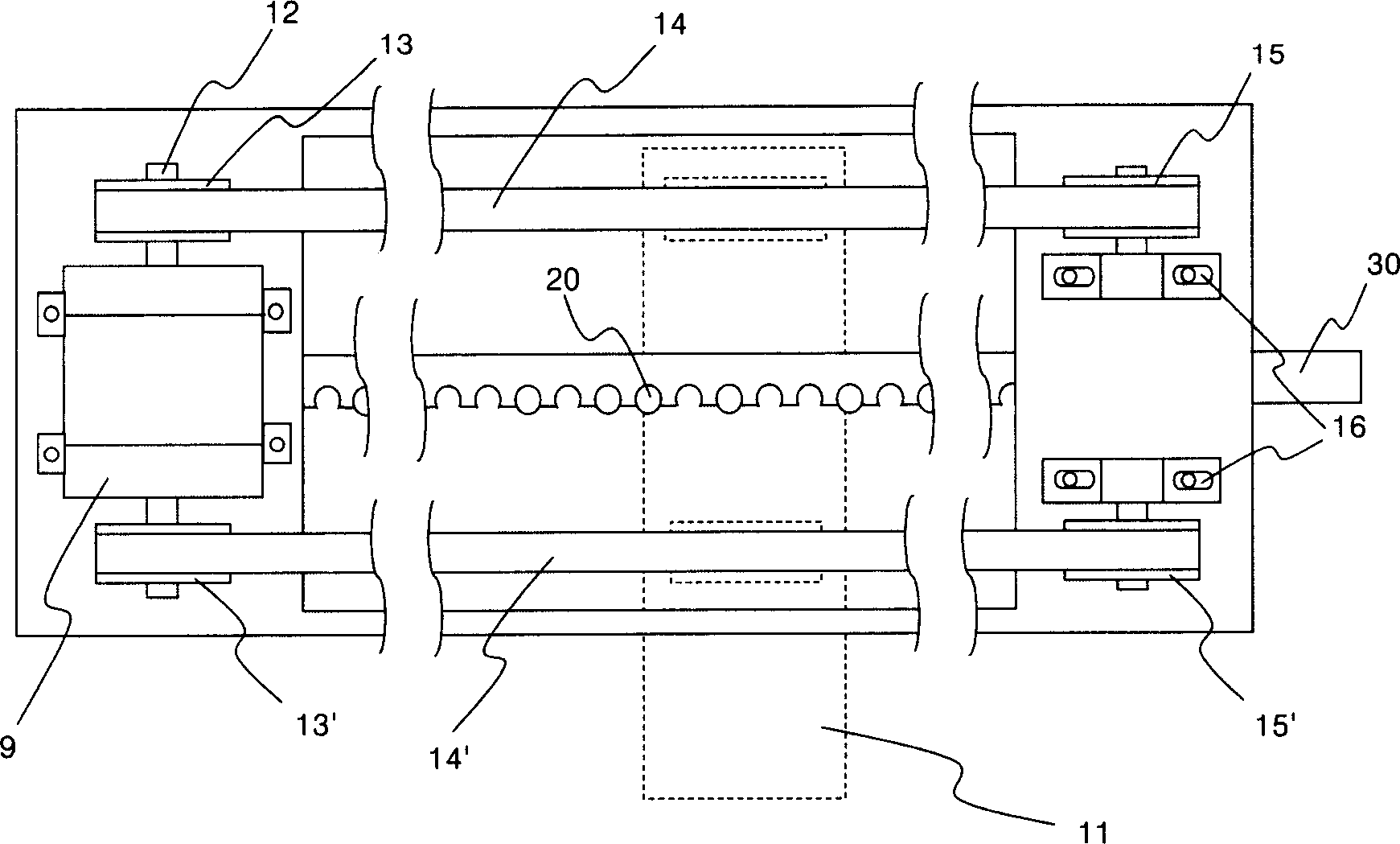

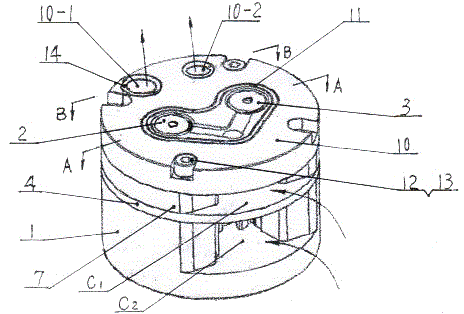

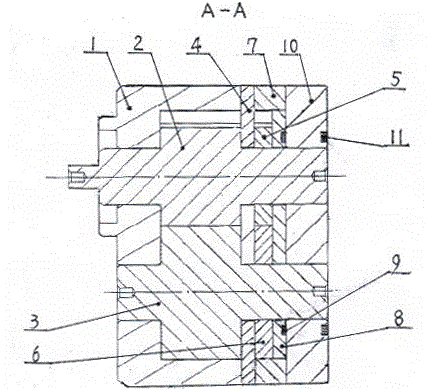

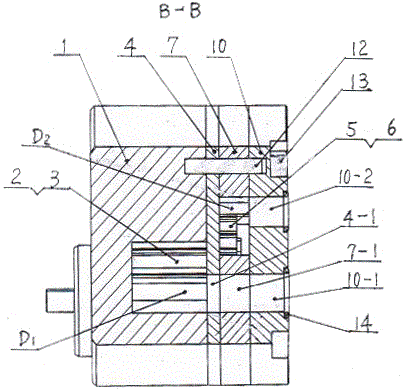

Circumferential feeding device for cross wedge rolling

ActiveCN111185550BReduce widthEasy to placeMetal-working feeding devicesMetal rollingEngineeringStructural engineering

Owner:UNIV OF SCI & TECH BEIJING

Blade stretching structure for wind driven generator

InactiveCN101825068BReduced energy captureReduce load bearingWind motor controlMachines/enginesWind drivenWinding machine

The invention discloses a blade stretching structure for a wind driven generator. The blade structure is a stretching structure; a port of a first blade section, connected with a second blade section, is provided with a cross section with four sections of foldable blades; the four sections of foldable blades are connected with a steel longitudinal beam through elastic hinges; simultaneously, contact surfaces among the four sections of foldable blades and contact surfaces between the four sections of foldable blades and the second blade section are slope-shaped; the steel longitudinal beam is arranged inside the first blade section and two screw rod holes are formed inside the first blade section; and one end of a screw rod is connected with the screw rod holes inside the first blade section, and the other end of the screw rod is connected with the tail end of the second blade section, namely, a motor on a blade root, through a gear. Energy capture of a wind wheel can be reduced so as to keep power output close to a rated value. Simultaneously, load borne by the blade and impact on the entire wind machine are reduced and the wind machine is prevented from being damaged due to stall. The structure can automatically adjust the windward area of the blade so as to enlarge economical wind speed range of the wind driven generator and make full use of wind energy.

Owner:XI AN JIAOTONG UNIV

Drawer-sliding rail backstepping control device

The invention provides a drawer-sliding rail backstepping control device. The backstepping control device comprises a drawer main body and wheel type rolling sliding rails connected with a cabinet body; the wheel type rolling sliding rails include a fixed sliding rail arranged on the inner wall of the cabinet body, and a movable sliding rail arranged on the a drawer main body is arranged on the fixed sliding rail in a sliding way; the drawer main body is formed by assembling a front plate, metal side plates, a rear plate and a bottom plate together, the front plate is connected with the metalside plates through a detachable connecting base, the movable sliding plate is fixed at the middle parts of the metal side plates, a rebound part is arranged on the cabinet body or the fixed sliding rail or between the cabinet body and the fixed sliding rail, the metal side plates or / and the movable sliding plate are provided with shifting blocks for driving the rebound part to move. By the adoption of the invention, the problem that the installation of the rebound part occupies a large space in the prior art can be solved, the load borne by the rebound part is reduced, less installation process steps are implemented, installation time is reduced, and working efficiency is improved; and the backstepping control device has the characteristics of simple and reasonable structure, operation convenience, long service life and convenience for processing and production.

Owner:伍志勇

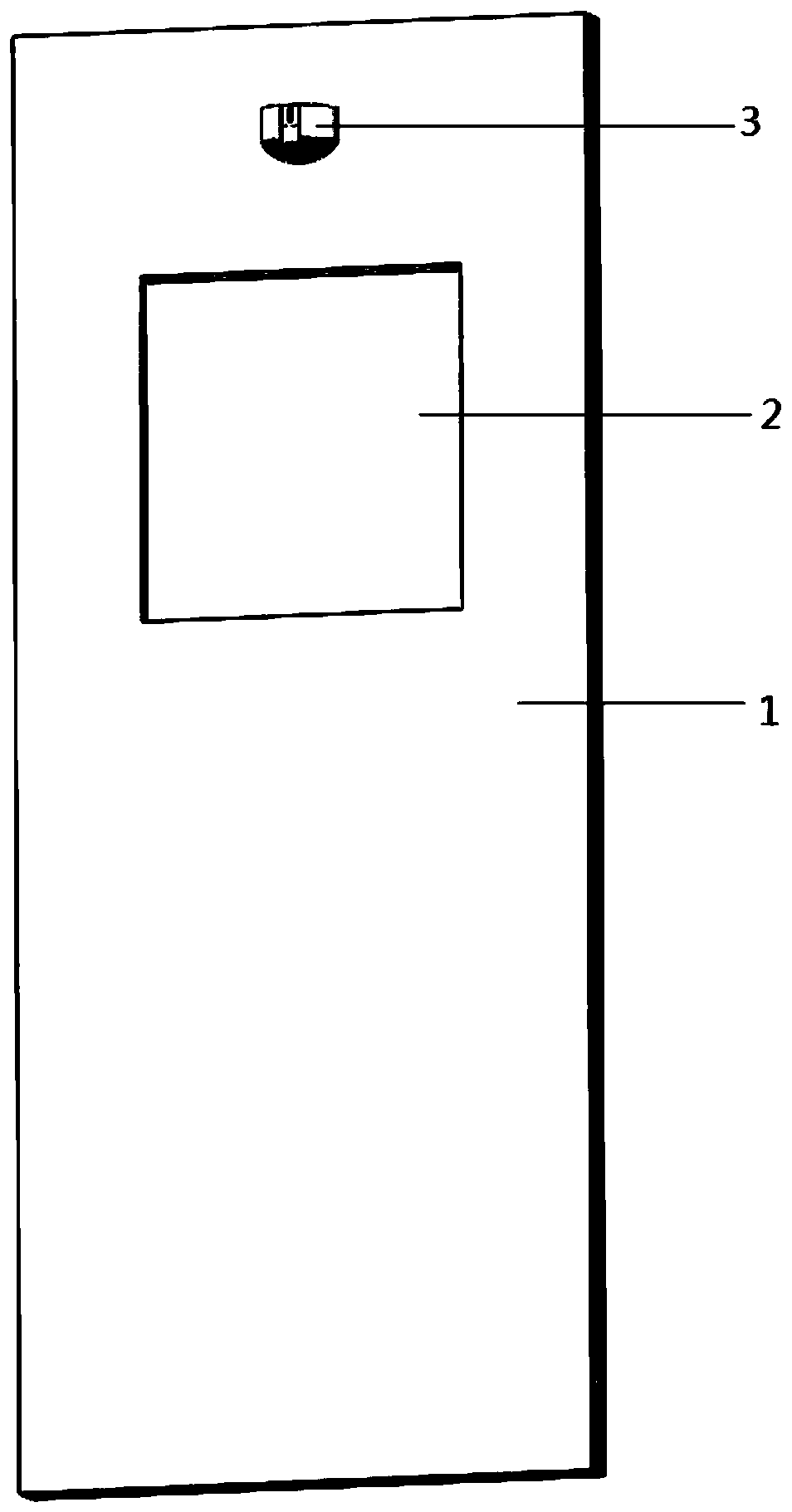

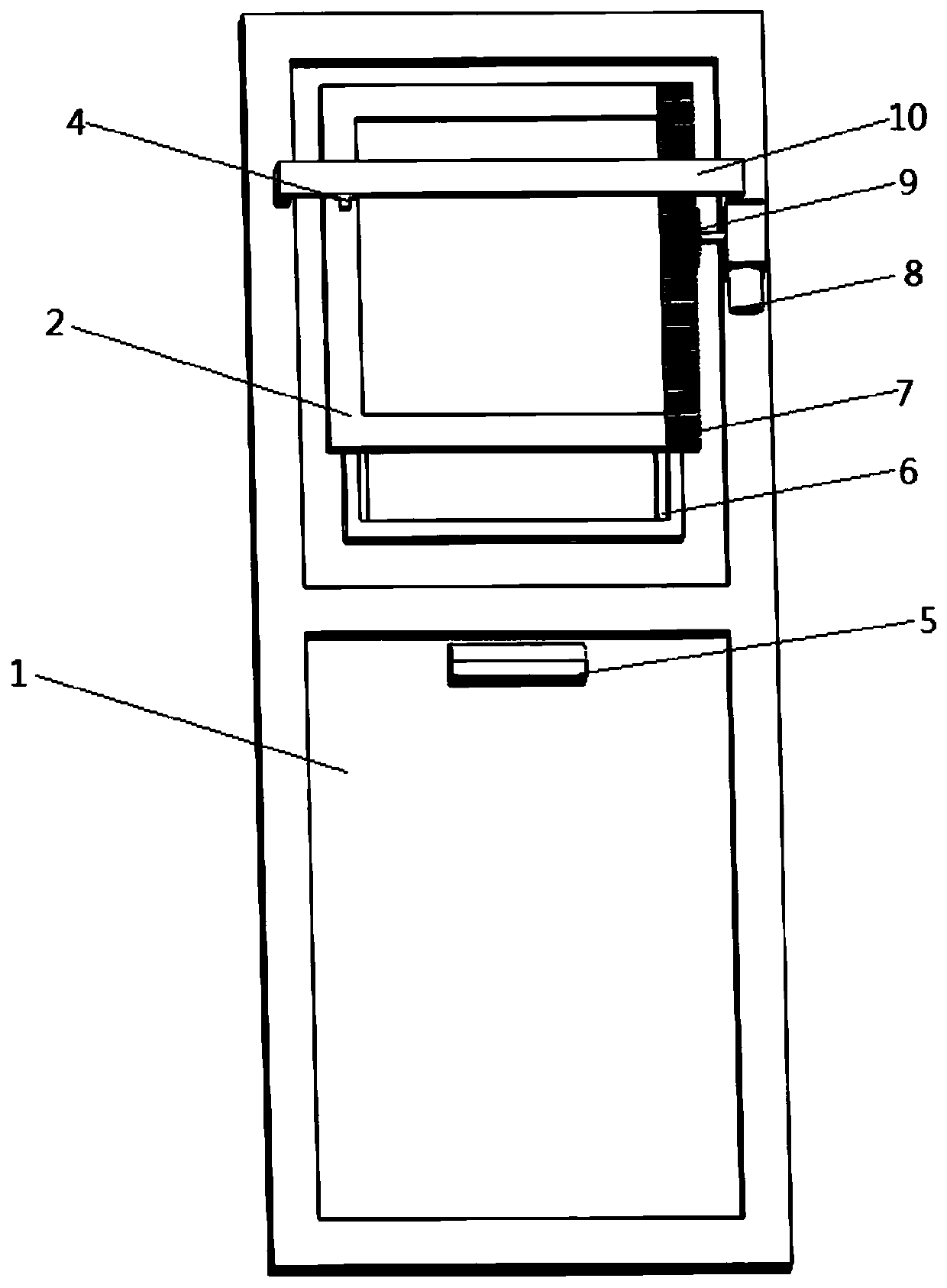

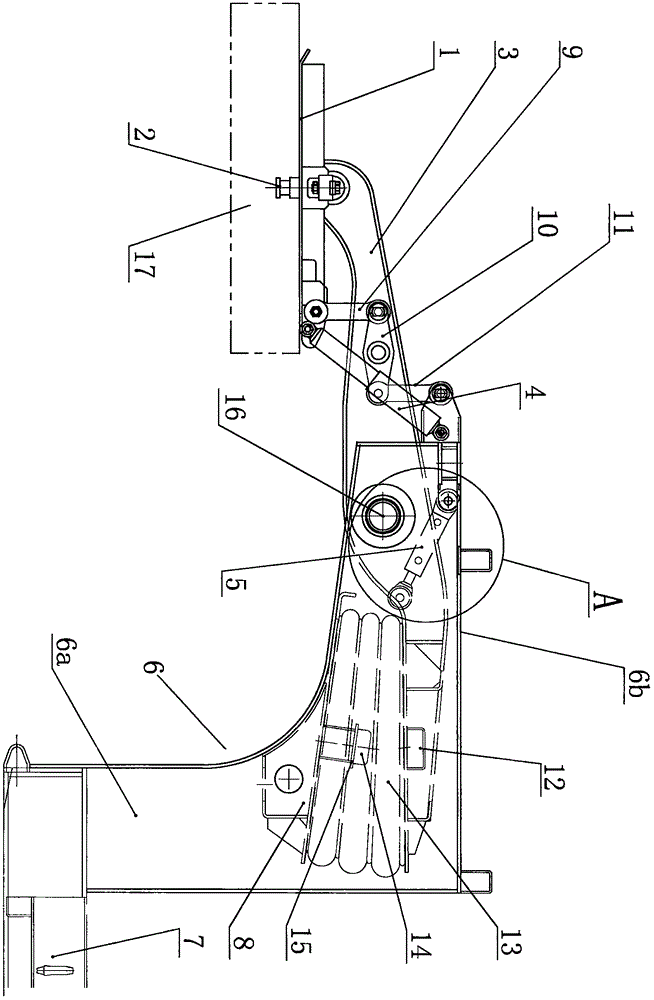

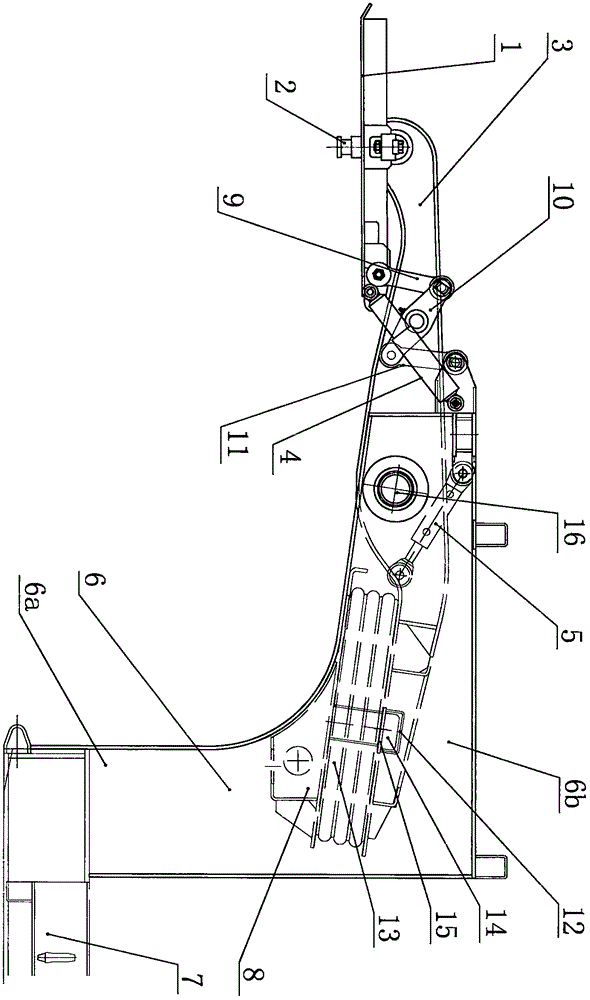

Intelligent garbage door

InactiveCN111422533AReduce load bearingExtended service lifeRefuse receptaclesInductorElectrical and Electronics engineering

The invention discloses an intelligent garbage door which comprises a door body, a brushless motor, a rack, a gear, an infrared inductor, a stroke switch and a detection device, wherein the infrared inductor is mounted at the upper end of a front input port of the door body, a cover plate of the input port is translational up and down, a detector is mounted at the lower end of a back putting portof the door body, the brushless motor is mounted on the right side of the back putting port of the door body, and the brushless motor is connected to the cover plate by means of interaction of the gear and the rack. In order to prevent the cover plate from swinging front and back and control the translational distance of the cover plate, a limiting bracket is mounted on the door body, and the stroke switch is mounted on the limiting bracket. By matching the devices, daily household garbage is put conveniently to a great extent in a daily household garbage putting process. The intelligent garbage door further has convenient, rapid and clean and sanitary functions, and can meet the demand of people putting garbage on the garbage door.

Owner:DONGHUA UNIV

Planet differential lifting device of wind power installation vessel

InactiveCN102442624BReduce load bearingSmall sizeLifting devicesGearing detailsElectricitySteering wheel

The invention provides a planet differential lifting device of a wind power installation vessel, consisting of a lifting frame and three groups of transmission units; and each group of transmission units comprises a main transmission component, a medium steering wheel and an auxiliary transmission component. A planet transmission component of the lifting device takes an output solar wheel axle ofa reduction box component as input, and takes a planet frame and a main transmission component main gear of the main transmission component as double-output. The medium steering wheel is synchronously engaged with the main transmission component main gear of the main transmission component and an auxiliary transmission component main gear of the auxiliary transmission component, thus the medium steering wheel belongs to a bridge for transmitting power from the main transmission component to the auxiliary transmission component. Output gears, which have the same size and specification and are completely synchronous, are respectively engaged with racks which are inlaid into pile legs, thus the lifting of the wind power installation vessel can be realized. The invention has the advantages that the size and the weight of the lifting device can be reduced, the operation stability can be increased, and the safety performance of the wind power installation vessel can be improved.

Owner:深圳市欧佩亚海洋工程有限公司

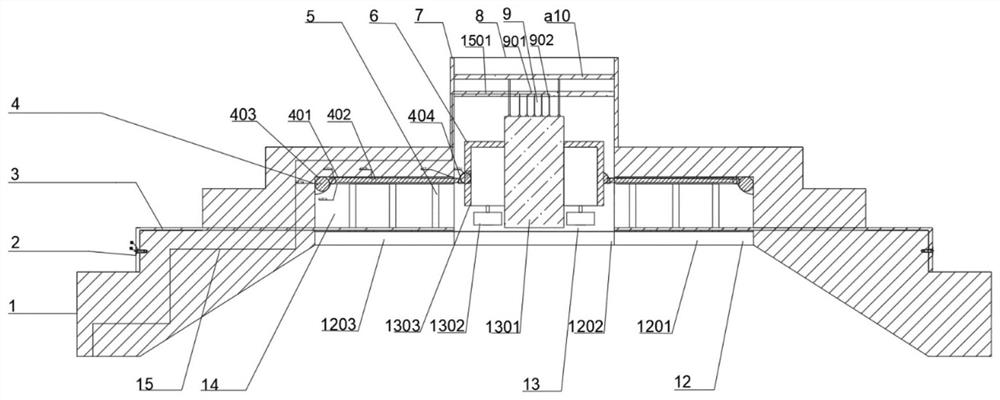

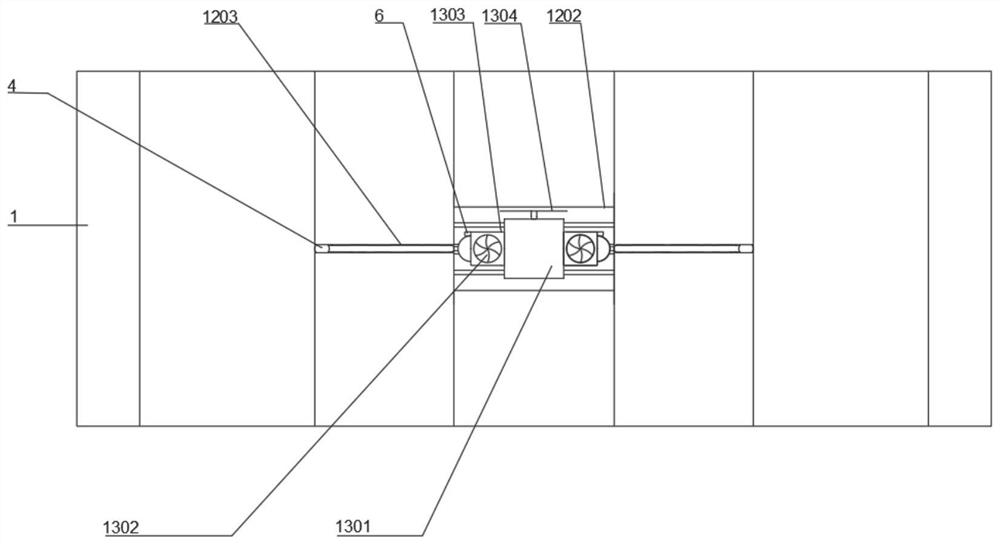

Wind wheel with adjustable blade number and working method thereof

PendingCN112283017AIncreased solidityIncrease power generation capacityWind motor controlEngine fuctionsGear wheelControl engineering

The invention discloses a wind wheel with the adjustable blade number and a working method thereof. The wind wheel mainly comprises fixed blades, a fixed hub, adjustable blades, an adjustable hub, a main shaft, a control device, a supporting rod, a hub axial fixing rod, a hydraulic locking pin shaft and pin holes, wherein the fixed blades are fixed outside the fixed hub, and the fixed hub is fixedon the end surface of the main shaft; the adjustable blades are connected with the adjustable hub through bolt connecting structures, and a first motor is used for driving a driving gear and a drivengear to rotate and driving the adjustable blades to rotate around a screw; the adjustable hub is connected with the main shaft through a spline structure; the hub axial fixing rod is connected with the hydraulic locking pin shaft and the pin holes, so that the axial fixation of the adjustable hub is realized; and the control device drives a gear to rotate through a second motor, the movement of the control device in the horizontal direction is realized, and the third motor drives the supporting rod to rotate and is used for being connected with the hub supporting hole. The number of the blades of the wind wheel can be adjusted according to the change of the external wind speed of a wind turbine generator, and the power generation capacity of the wind turbine generator is maximized.

Owner:XIAN THERMAL POWER RES INST CO LTD

A bridge-suspended turbine hydropower base station

ActiveCN113622287BReduce intensityHigh strengthWater-power plantsHydro energy generationStream flowMarine engineering

Owner:XI AN JIAOTONG UNIV

Storage battery frame structure for commercial vehicle

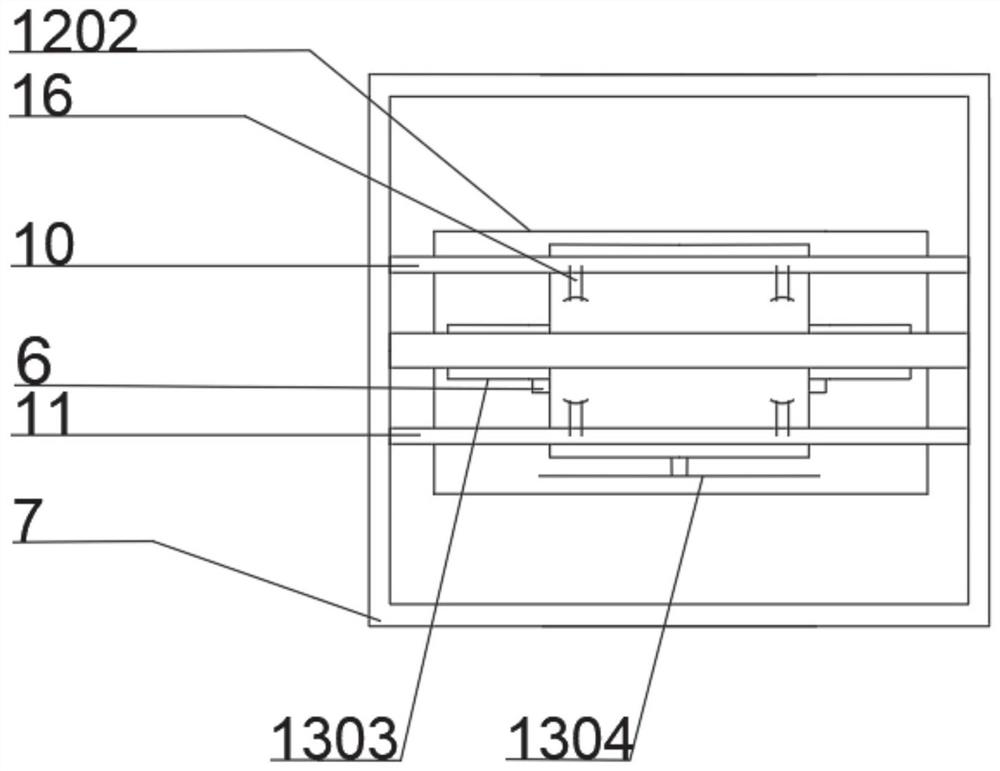

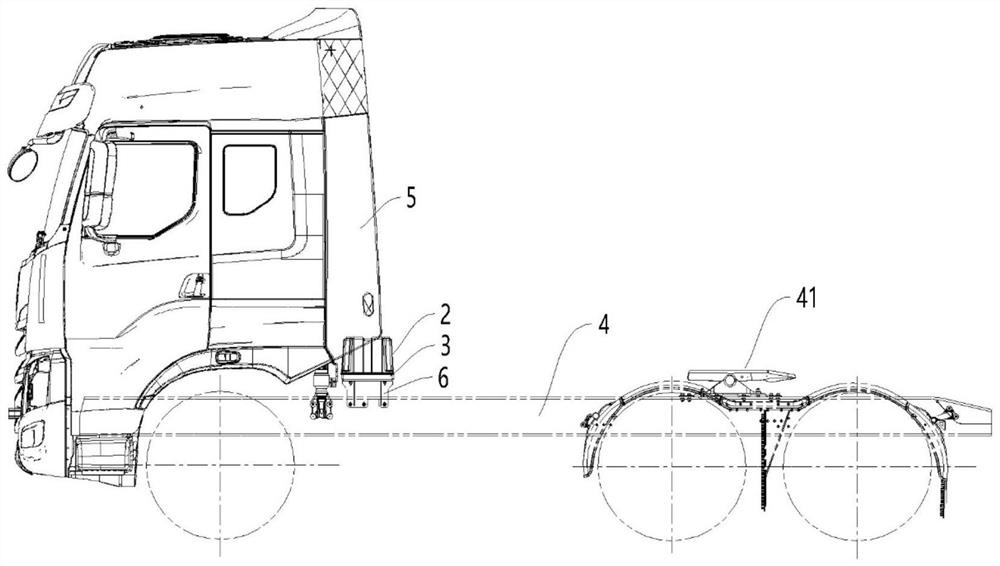

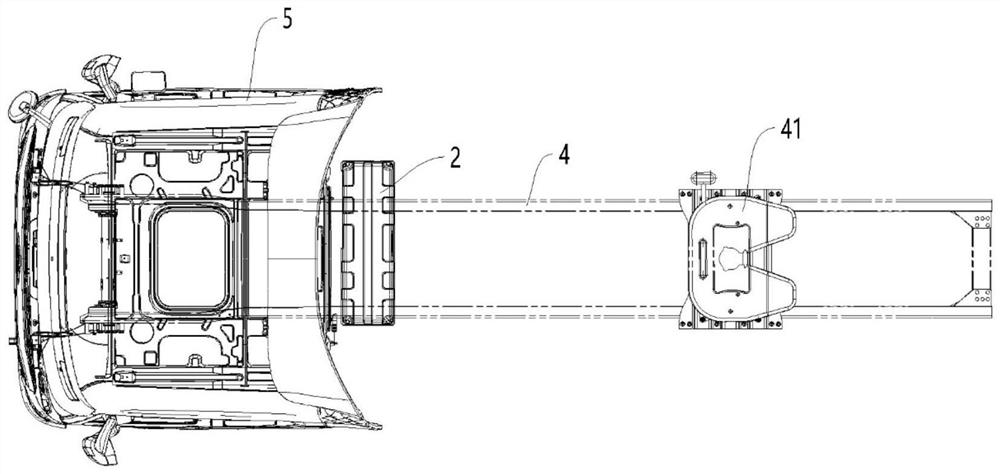

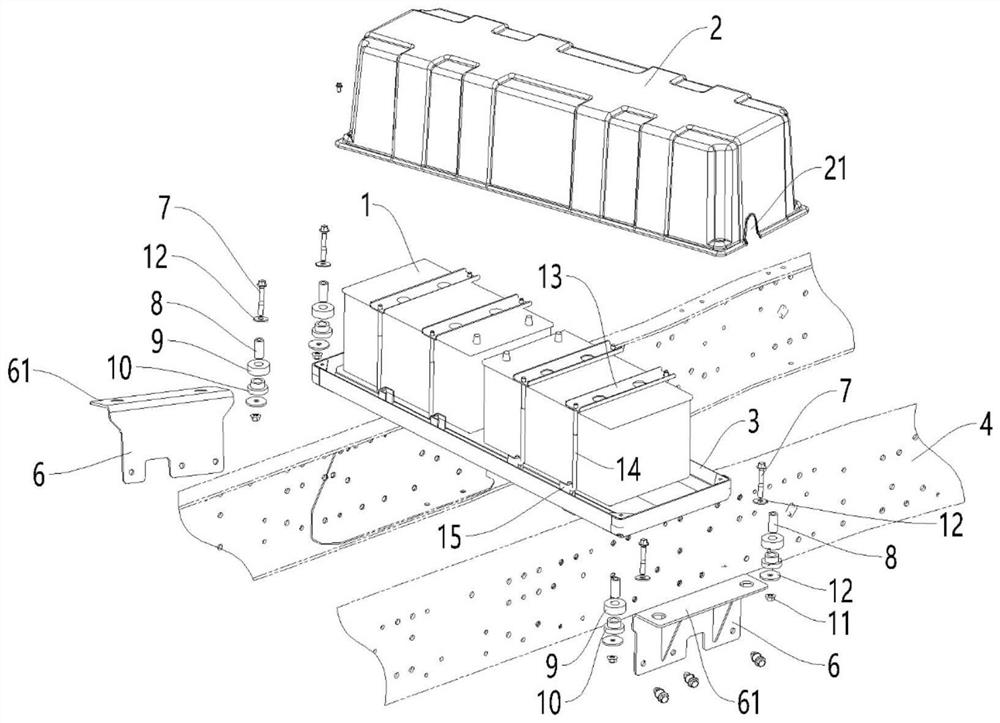

PendingCN114771444AHigh structural reliabilitySimple installation structureUnderstructuresCell lids/coversVehicle frameCommercial vehicle

The invention relates to the technical field of vehicle structures, and discloses a commercial vehicle storage battery frame structure which comprises a base, a storage battery fixedly arranged on the base and a cover cap covering the storage battery, the cover cap is fixedly connected with the base, the base is arranged at the position of the rear wall of a cab of a vehicle frame, and the bottom of the base is fixedly connected with a transition support. The base is fixedly arranged on a frame longitudinal beam at the rear wall of a cab through a transition support, and the base extends and is fixed in the width direction of a vehicle. The base is arranged at the position of the cab rear wall, the arrangement space of the cab rear wall is fully utilized, and the storage battery frame is located on the upper side of the frame and does not occupy the arrangement space of the oil tank, so that the volume of the oil tank is increased; the cab rear wall is located in the middle of the whole vehicle, vibration is small, the load borne by the storage battery is reduced, and the structural reliability of the storage battery frame is improved; the base is fixedly arranged on the frame longitudinal beam through the transition support to form a simply supported beam structure, the installation structure of the storage battery frame is simplified, and light weight of the storage battery frame structure is achieved.

Owner:DONGFENG LIUZHOU MOTOR

Intelligent garbage door

The invention provides an intelligent garbage door. The intelligent garbage door comprises a door body, a travel switch, a cover plate, a shaft, a gear, a belt, a motor, a garbage releasing opening, an infrared sensor, a sealing strip and a detector. The infrared sensor is installed at the upper end of a front opening of the door body, the opening is of an concave type, the motor is installed on the reverse side of the door body, the motor is connected with the cover plate through the gear, the belt, a belt wheel and a bearing, and the travel switch is installed at the right end of the cover plate. Through the cooperation of the devices, releasing of daily life garbage is facilitated to a great extent. Long time waiting for garbage releasing is avoided, the safety of releasing personnel isfurther ensured, and the personnel safety of the garbage releasing personnel cannot be affected.

Owner:DONGHUA UNIV

Height-adjustable air bag type gooseneck

InactiveCN106005065AReduce load bearingHeight adjustableTractor-trailer combinationsLeveling mechanismButt joint

The invention discloses a height-adjustable air bag type gooseneck and belongs to the technical field of semitrailers. The height-adjustable air bag type gooseneck comprises an L-shaped base and a butt-joint platform. The L-shaped base is composed of a supporting section and an extending section. An overturning shaft and an overturning seat are arranged on the extending section. The upper end of the butt-joint platform is hinged to the front end of the overturning seat. The overturning seat is further provided with a leveling mechanism used for adjusting the levelness of the butt-joint platform. The leveling mechanism comprises a first connecting rod, a lever and a second connecting rod, wherein the lever is rotatably mounted on the overturning seat and rotates with the middle of the lever as a rotating point; the front end of the lever is hinged to the upper end of the second connecting rod, and the lower end of the second connecting rod is hinged to the rear edge of the butt-joint platform; and the rear end of the lever is hinged to the lower end of the first connecting rod, and the upper end of the first connecting rod is hinged to the extending section. A bracket is fixed to the L-shaped base and provided with an air bag, and the rear end of the overturning seat presses the air bag. When the air bag is in a full state, the rear end of the overturning seat is jacked by the air bag, and meanwhile the front end of the overturning seat drives the butt-joint platform to be butted with a traction saddle.

Owner:别宜春

Measuring method for mechanical properties of electron gun thermal subassembly

ActiveCN105738224BIncrease stressLarge deformationMaterial strength using tensile/compressive forcesPlatinumWorking environment

The invention relates to a method for testing mechanical properties of an electronic gun heater assembly, comprising the following steps: (1), taking at least two heater assemblies under detection; (2), marking an original scale distance on a heater of each heater assembly under detection, and determining original scale distances L0 and S0; (3), testing yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection in an actual vacuum environment at different temperatures; (4), establishing a change-with-temperature linear relationship of the yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection by linear fitting; (5), according to the linear relationship, calculating to obtain the yield strength Sigma0.2 and tensile strength Sigmab of the heater assemblies under detection at the actual operation temperatures. The method enables chemical tensile performance parameters of a heater or a combination of a heater with a platinum sheet and / or a cathode head in a vacuum high-temperature operating environment to be accurately measured, and the testing problem of engineering needs is solved.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

Oil conveying device of vehicle automatic transmission

InactiveCN104913038ACompact structureImprove efficiencyGear lubrication/coolingTransmission elementsEngineeringMechanical engineering

The invention belongs to automobile parts and particularly relates to an oil conveying device of a vehicle automatic transmission. Positioning between a first shell (1), a separating plate (4), a second shell (7) and an upper end cover (10) is achieved through two opposite positioning sleeves (12), two bolts (13) penetrate through center holes of the positioning sleeves (12) to be connected with the first shell (1) in a threaded mode, the fastening connection among the first shell (1), the separating plate (4), the second shell (7) and the upper end cover (10) in the axial direction is achieved through the two bolts (13), a first driving gear (2) and a first driven gear (3) are installed in the inner cavity of the first shell (1), the other axial side of the first driving gear (2) penetrates through the separating plate (4) to be in interference connection with a second driving gear (5) in a penetrating mode, and the other axial side of the first driven gear (3) penetrates through the separating plate (4) to be in interference connection with a second driven gear (6) in a penetrating mode. The oil conveying device of the vehicle automatic transmission is provided with two oil absorbing cavities and two oil discharging cavities, the oil discharging cavities are independent respectively, and the oil conveying device of the vehicle automatic transmission has the advantages of being compact in structure and high in efficiency.

Owner:FUXIN DARE AUTOMOTIVE PARTS

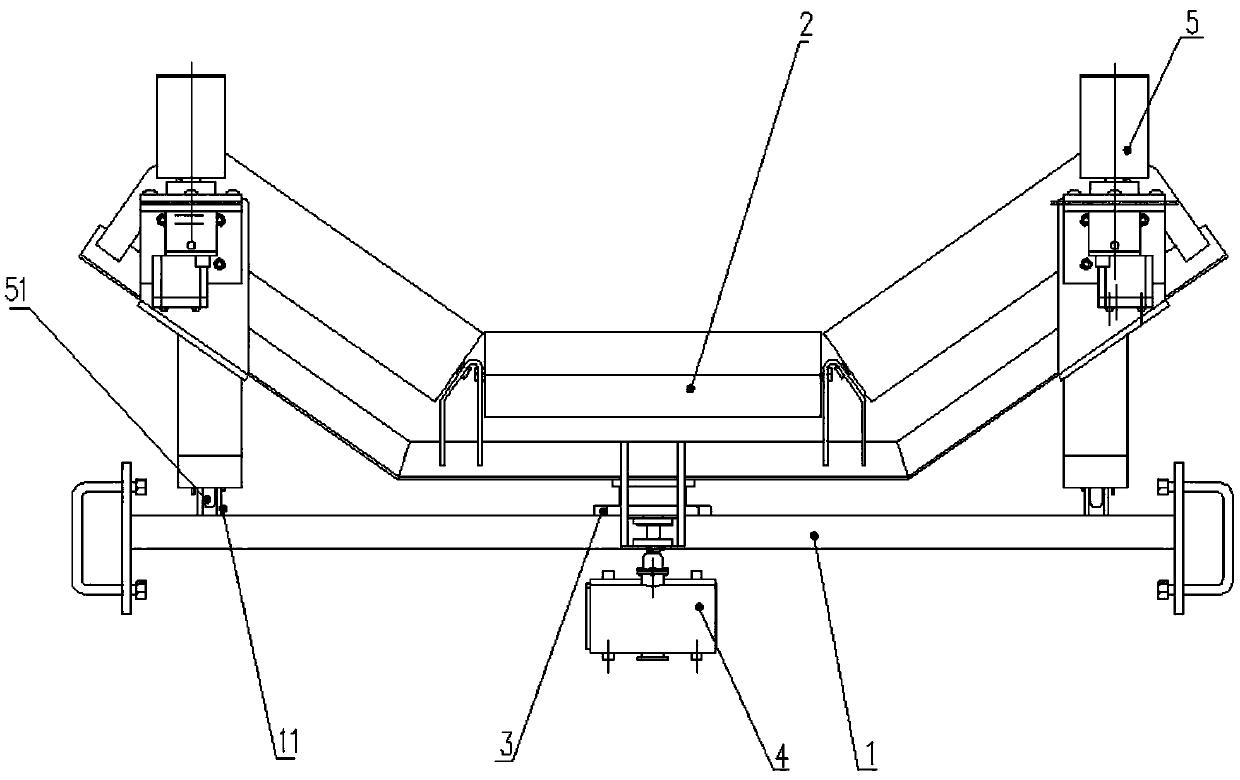

Stable deviation adjusting method of conveyor

The invention discloses a stable deviation adjusting method of a conveyor. The method comprises the following steps that an angle sensor detects a deflection angle in real time and transmit the deflection angle to a controller; the controller controls a stepping type rotary motor to rotate when the controller judges that a belt is deviated, and a driving shaft of the stepping type rotary motor drives a supporting seat, the belt and a supporting roller to rotate reversely; in the rotating process, limiting rotating rollers limit the belt from the two sides, rolling elements move along arc-shaped guide rails during rotating, so that the deviation correcting process is smoother; when the deflection angle detected by the angle sensor is zero, the offset belt and the supporting rollers are corrected to the correct position; and the controller controls the stepping type rotary motor to stop rotating. According to the method, the limiting rotating rollers limit the belt from the two sides; the rolling elements can move along the arc-shaped guide rails, so that the deviation correcting process is smoother; and the rolling elements at the bottom end of the limiting rotating rollers can playa role in supporting, the strength is increased, so that inclination of the supporting rollers during rotation is avoided, and the bearing load of the supporting seat is reduced.

Owner:江苏英洲智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com