Wind wheel with adjustable blade number and working method thereof

An adjustable blade technology, applied in the field of wind turbines, can solve the problems of blades exceeding the design value, blade lifting, blade sweeping towers, etc., to maximize the power generation capacity, stabilize the operation, and improve the power generation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

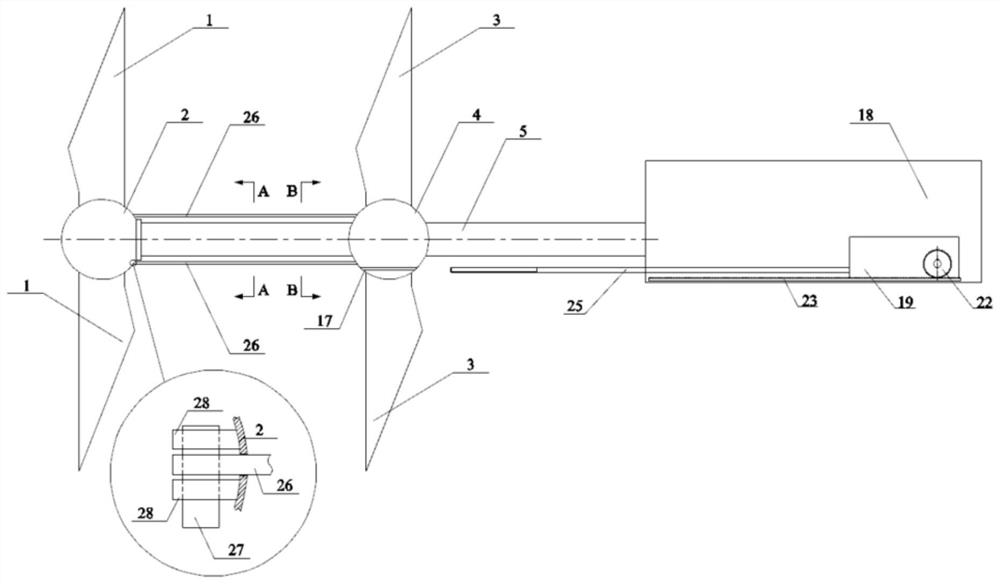

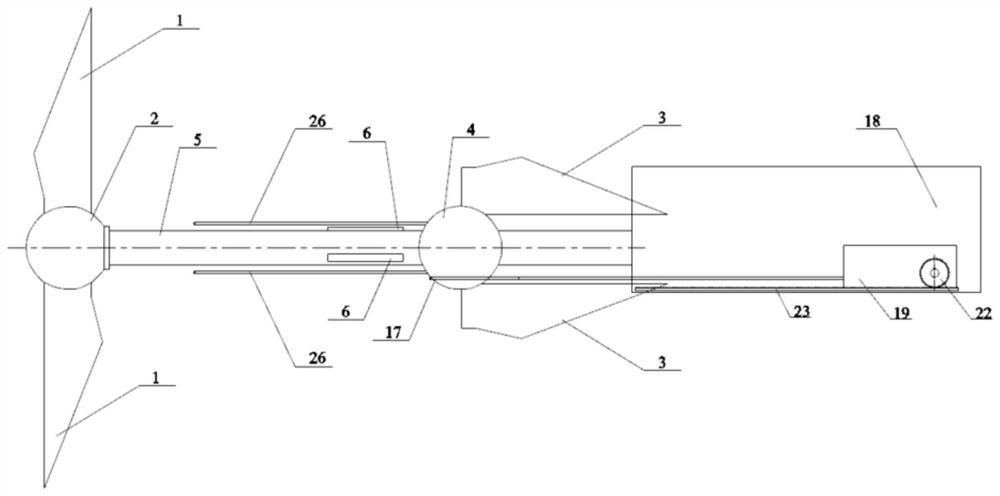

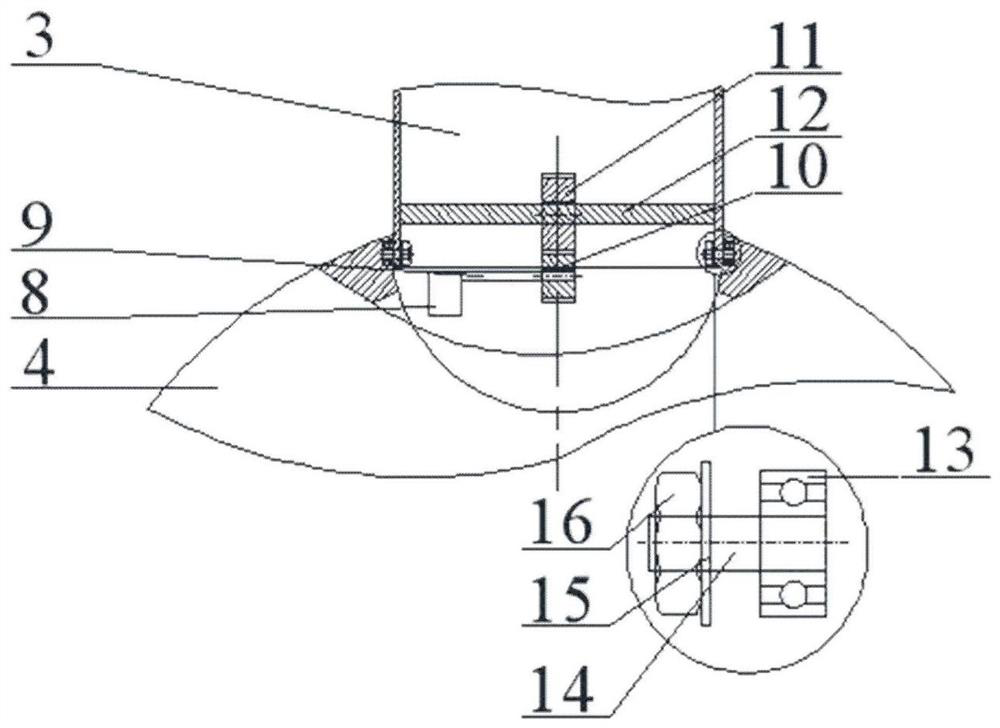

[0026] Such as figure 1 , figure 2 , Figure 4 and Figure 6As shown, a wind wheel with an adjustable number of blades in the present invention includes a main shaft 5, a fixed hub 2 fixed on one end of the main shaft 5, and a fixed blade 1 fixed on the fixed hub 2, and is characterized in that: it also includes a spline The connection structure is arranged on the adjustable hub 4 on the main shaft 5 and the adjustable blades 3 are arranged on the adjustable hub 4 through the bolt connection structure, the nacelle 18 is arranged at the other end of the main shaft 5, and the control panel placed on the inner platform of the nacelle 18 Device 19; one end of the adjustable hub axial fixing rod 26 is fixed on the adjustable hub 4, when the six blades are working, the other end of the adjustable hub axial fixing rod 26 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com