Patents

Literature

66results about How to "High solidity" patented technology

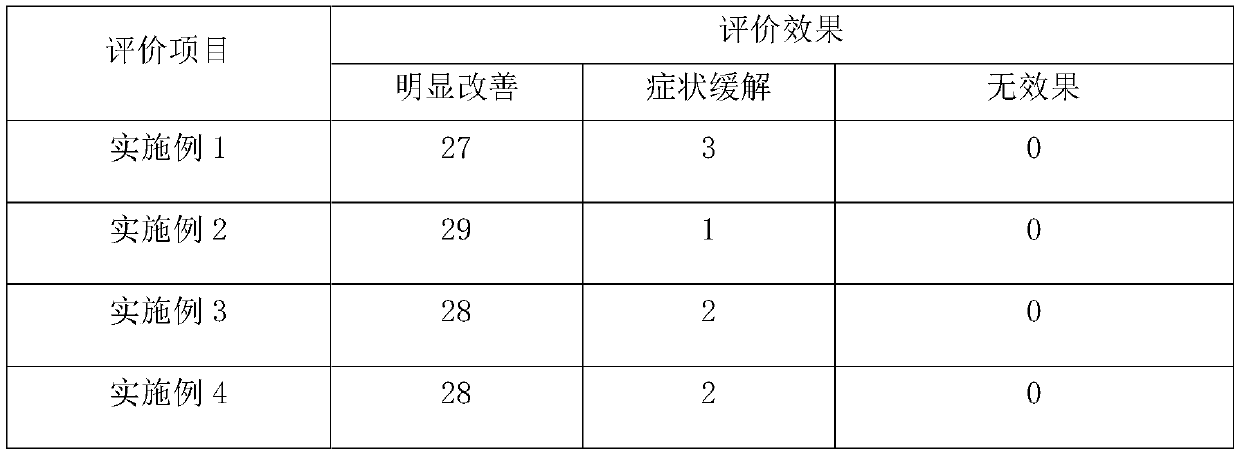

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

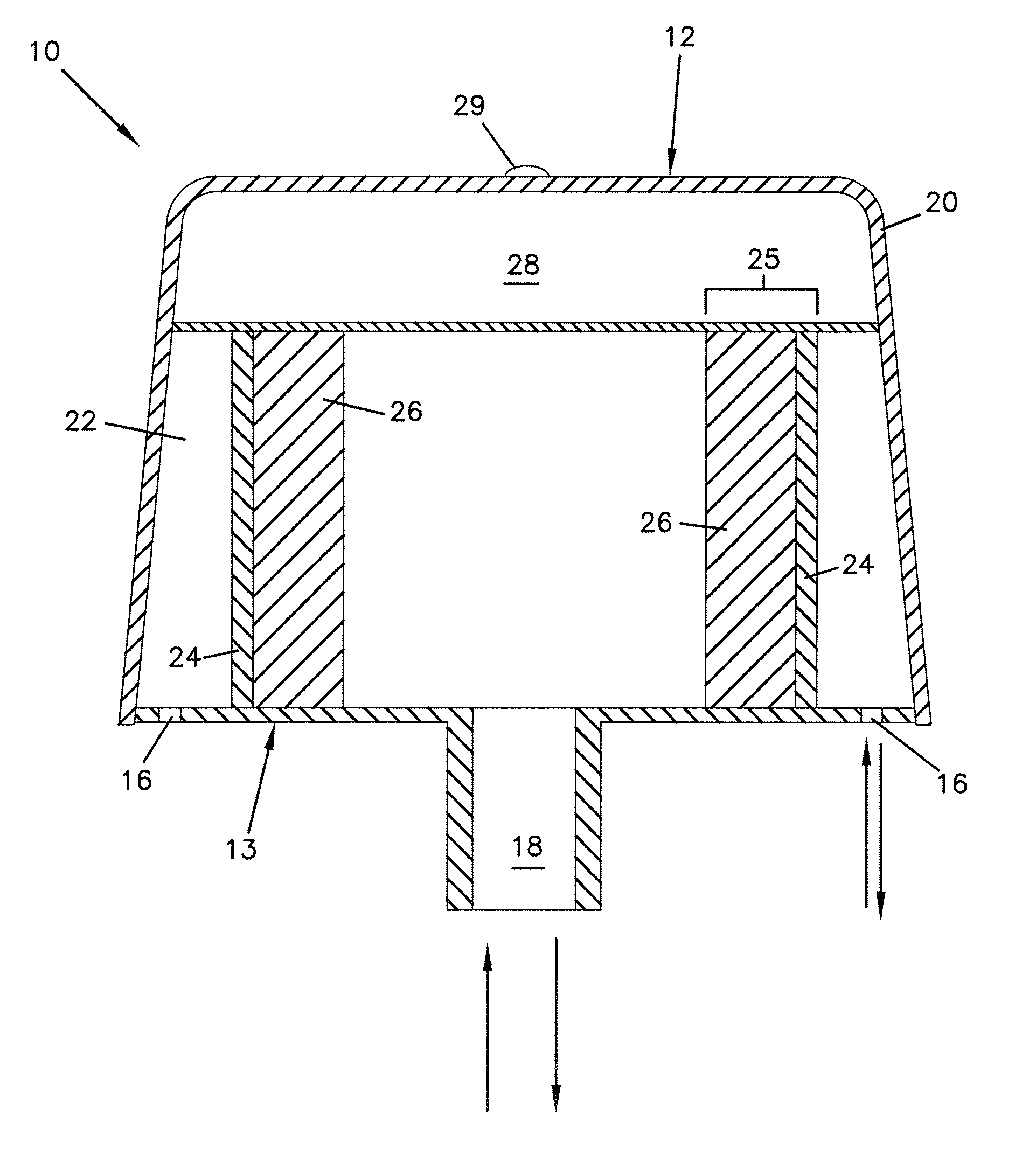

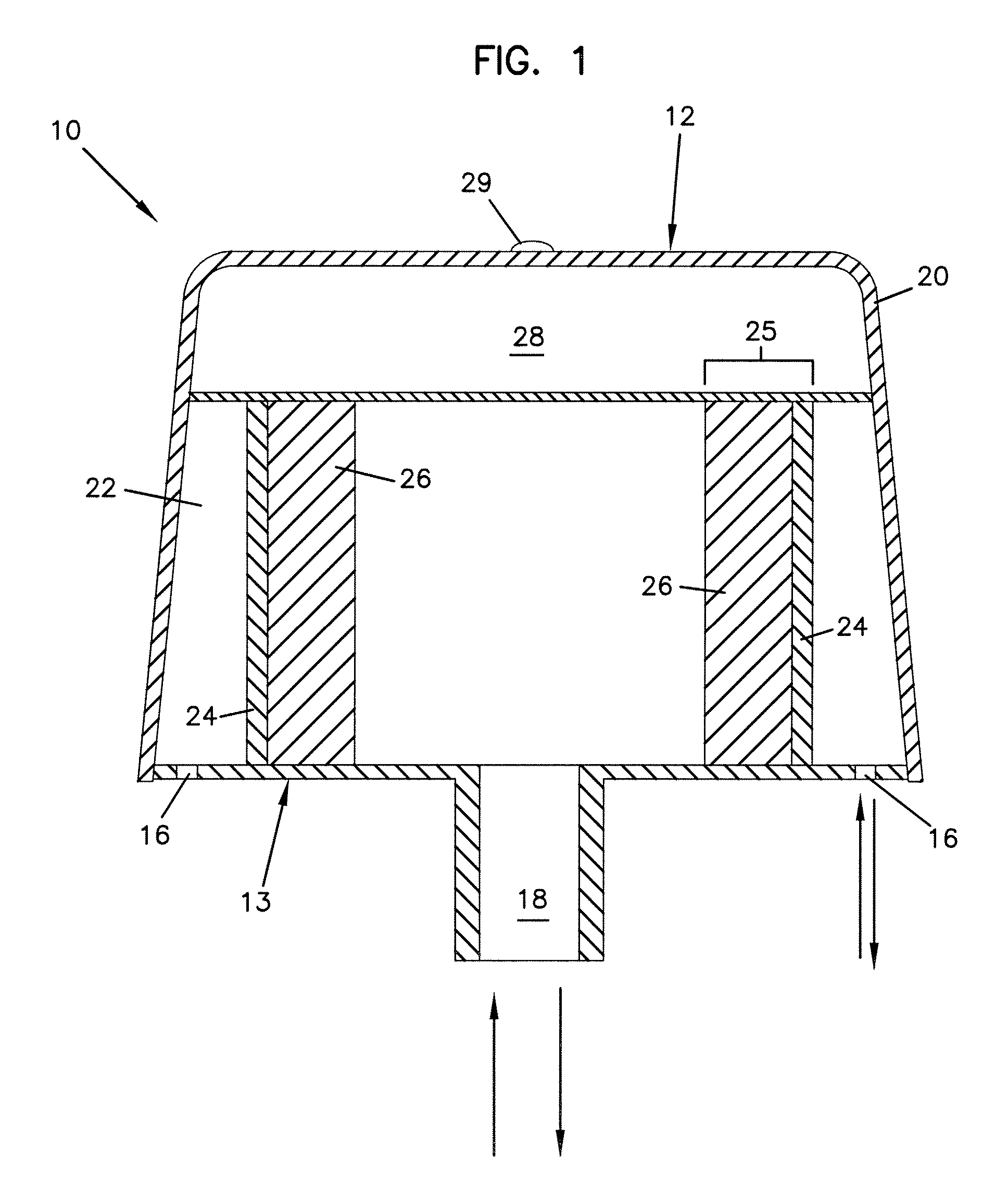

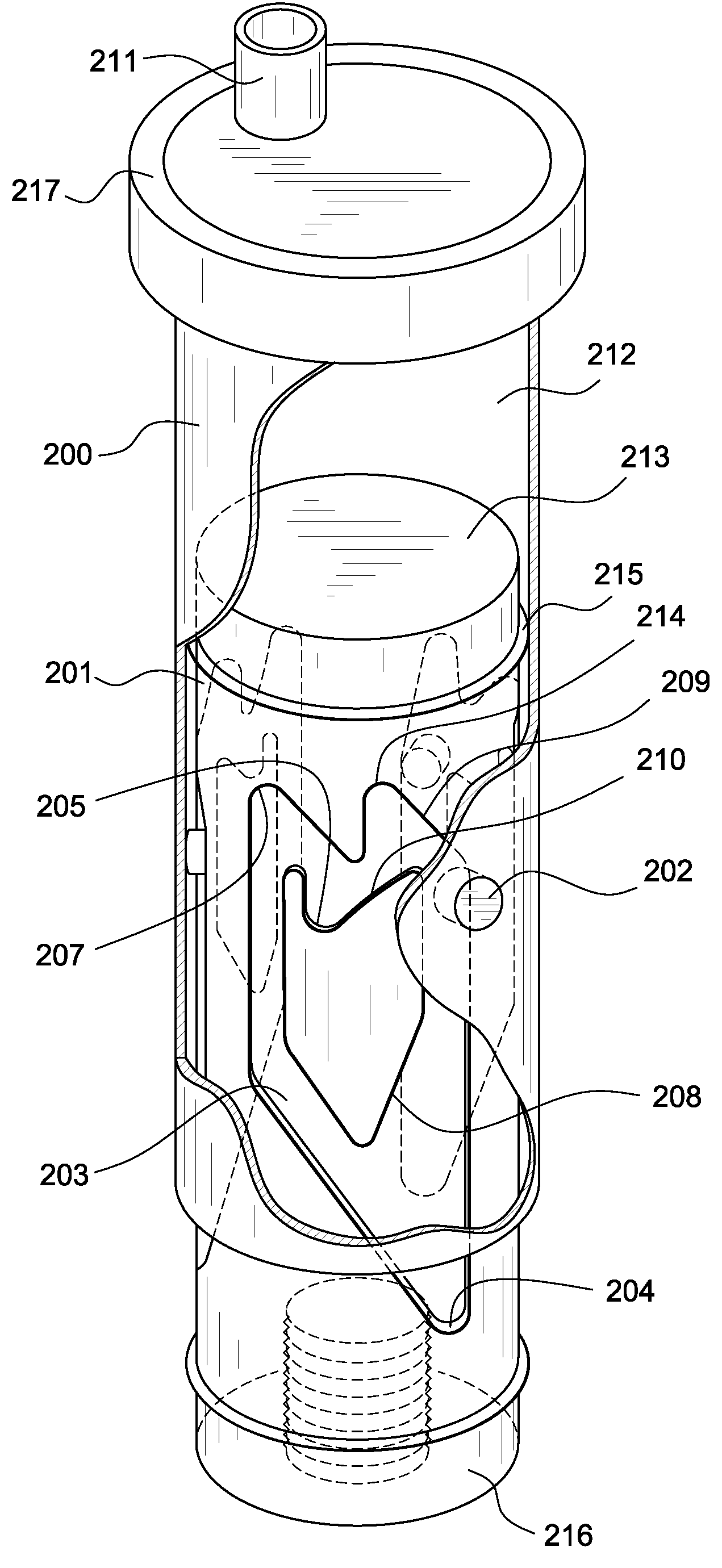

Filter medium and breather filter structure

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

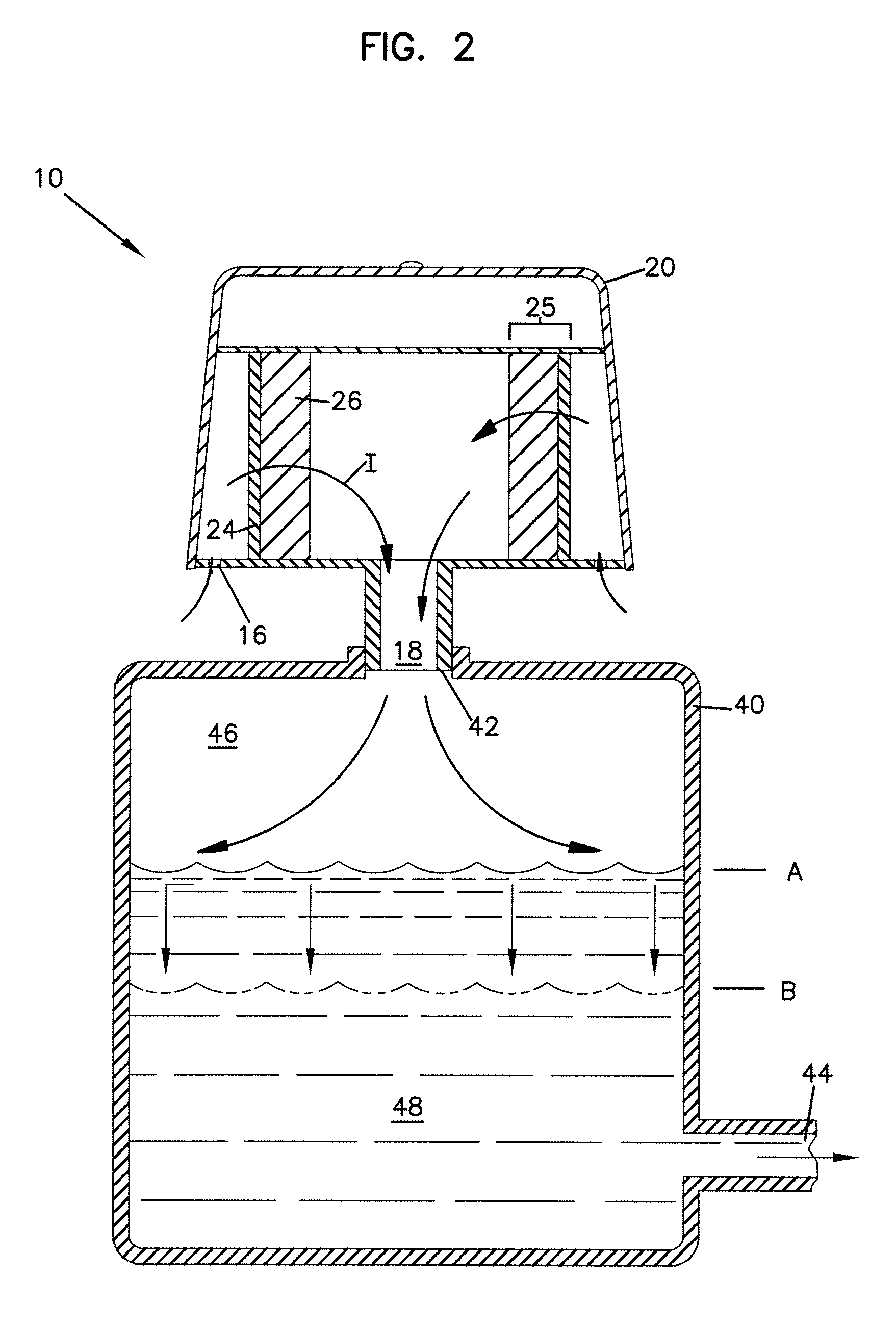

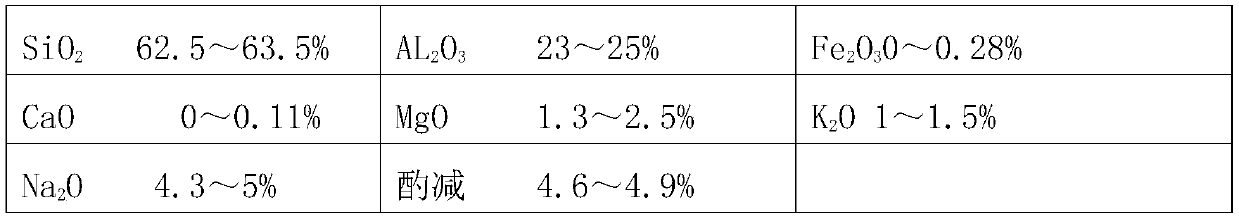

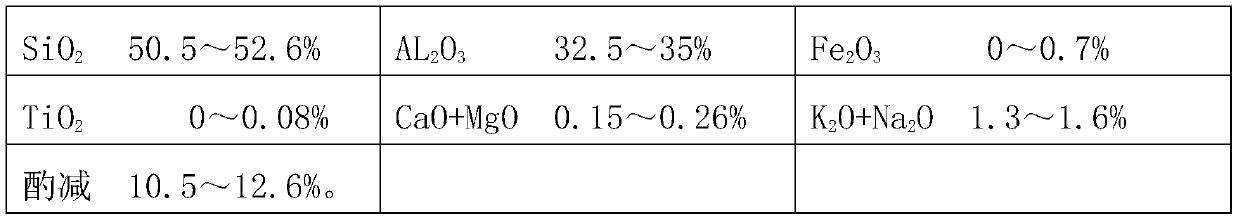

Thin ceramic rock plate and preparation method thereof

The invention relates to a preparation method of a thin ceramic rock plate. A thin ceramic rock plate blank is composed of the following components in percentage by weight: 8-12% of ball clay; 17-20%of washed kaolin; 4-7% of high-whiteness kaolin; 18-20% of water-milled ultra-white potash stone powder; 38 to 40% of water milled albite; 4-5% of high-whiteness aluminum oxide powder; 0-2% of ultra-white zirconium silicate; 3.5%-7.5% of calcined talc; 1 to 1.5% of a dispergator; and 2-2.5% of a polymerization liquid. The preparation method of the thin ceramic rock plate comprises the following steps: preparing a green body, processing a blank, spray-drying to prepare powder, dry-pressing to form, brushing the green body to remove ash, printing ground coat on a roller, decorating patterns, decorating a pattern protective layer, firing, polishing and edging.

Owner:JIANGXI HEMEI CERAMICS +3

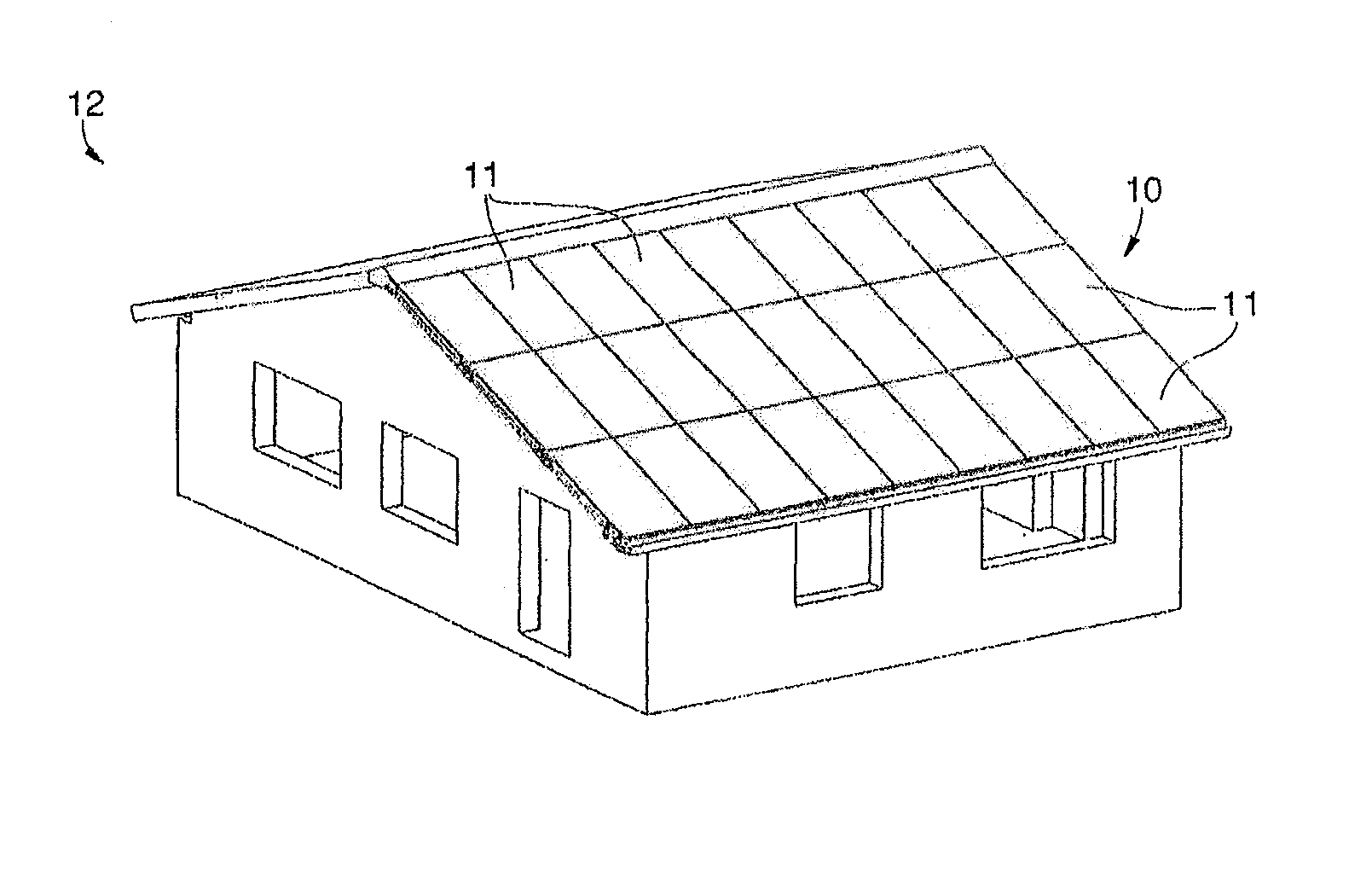

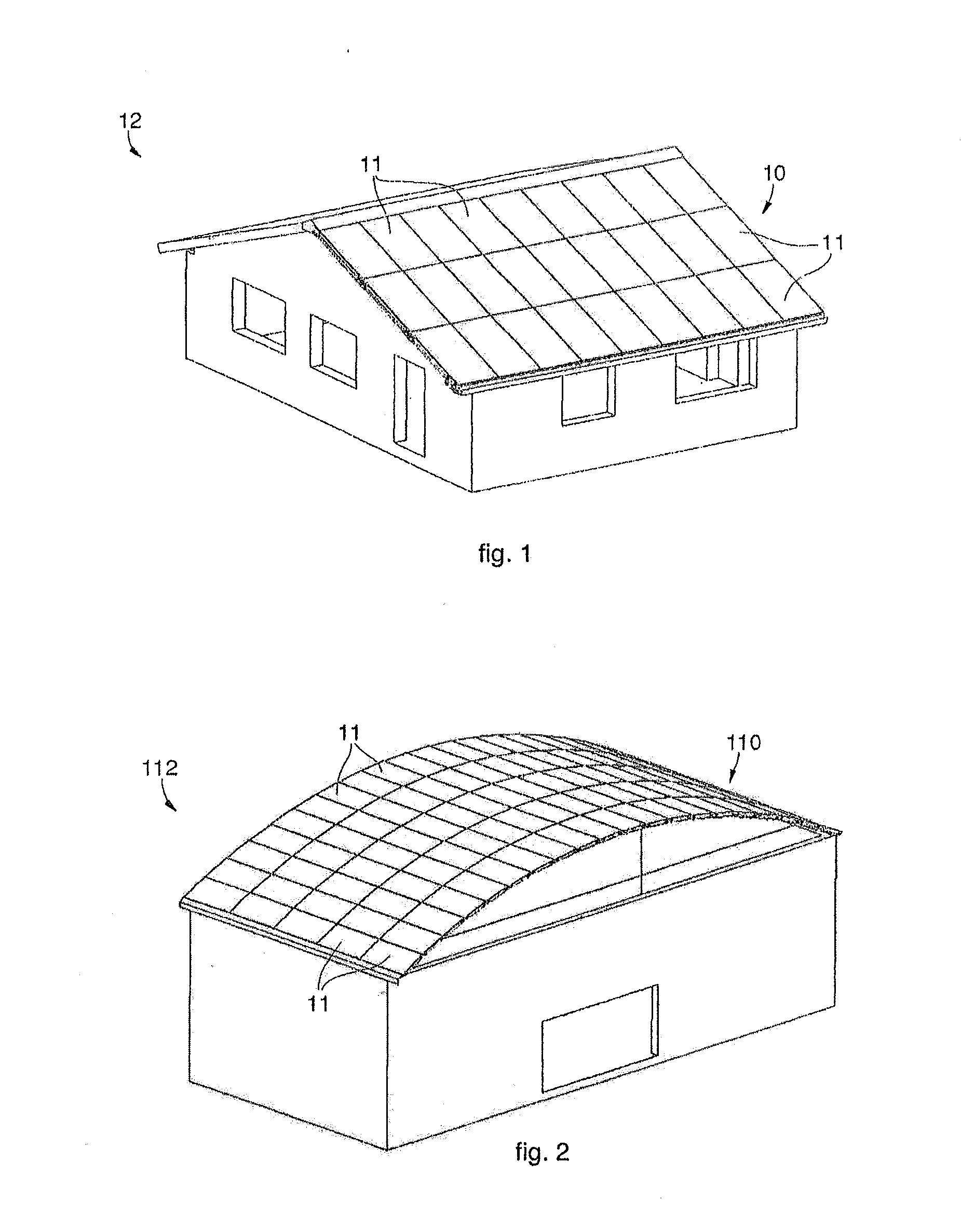

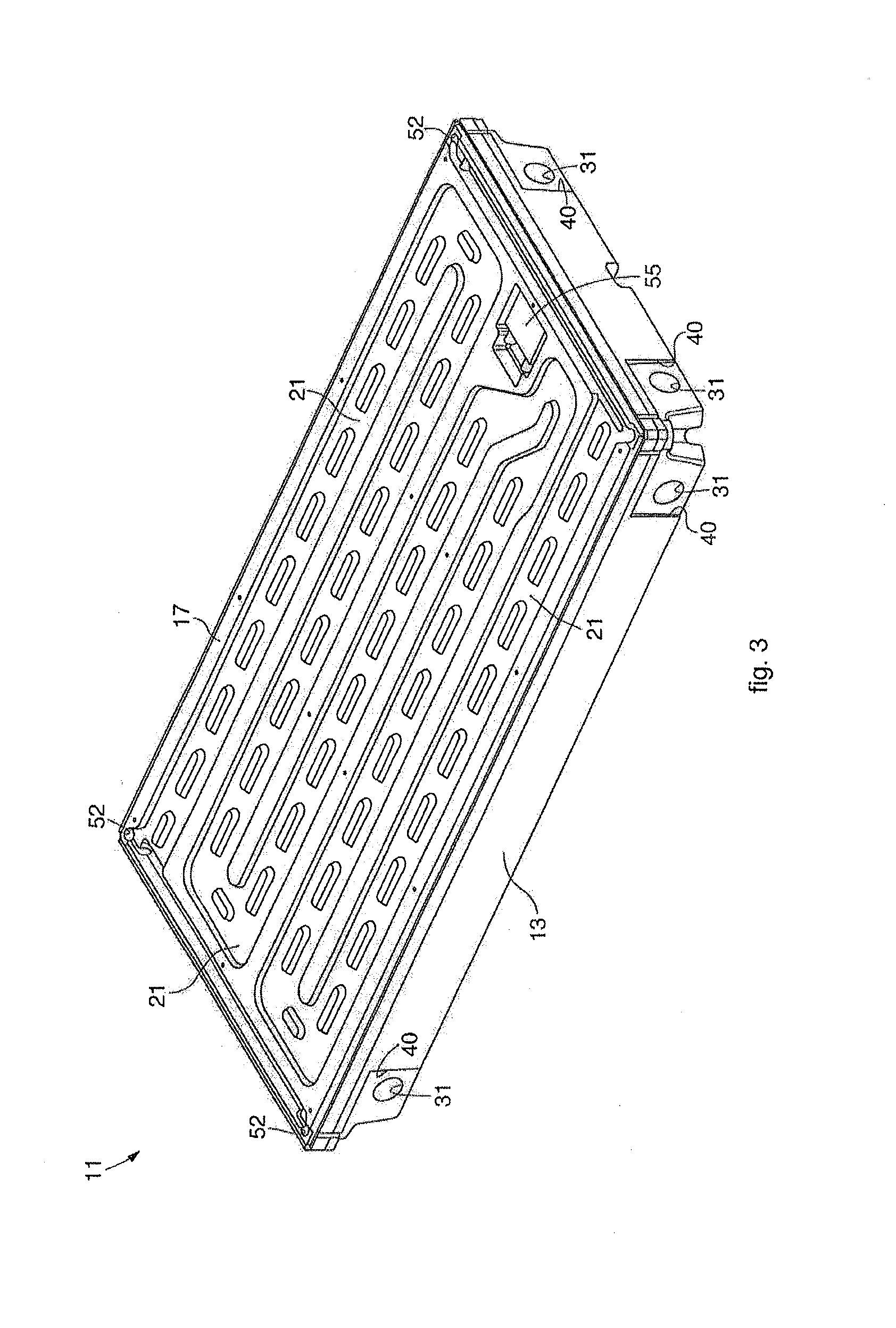

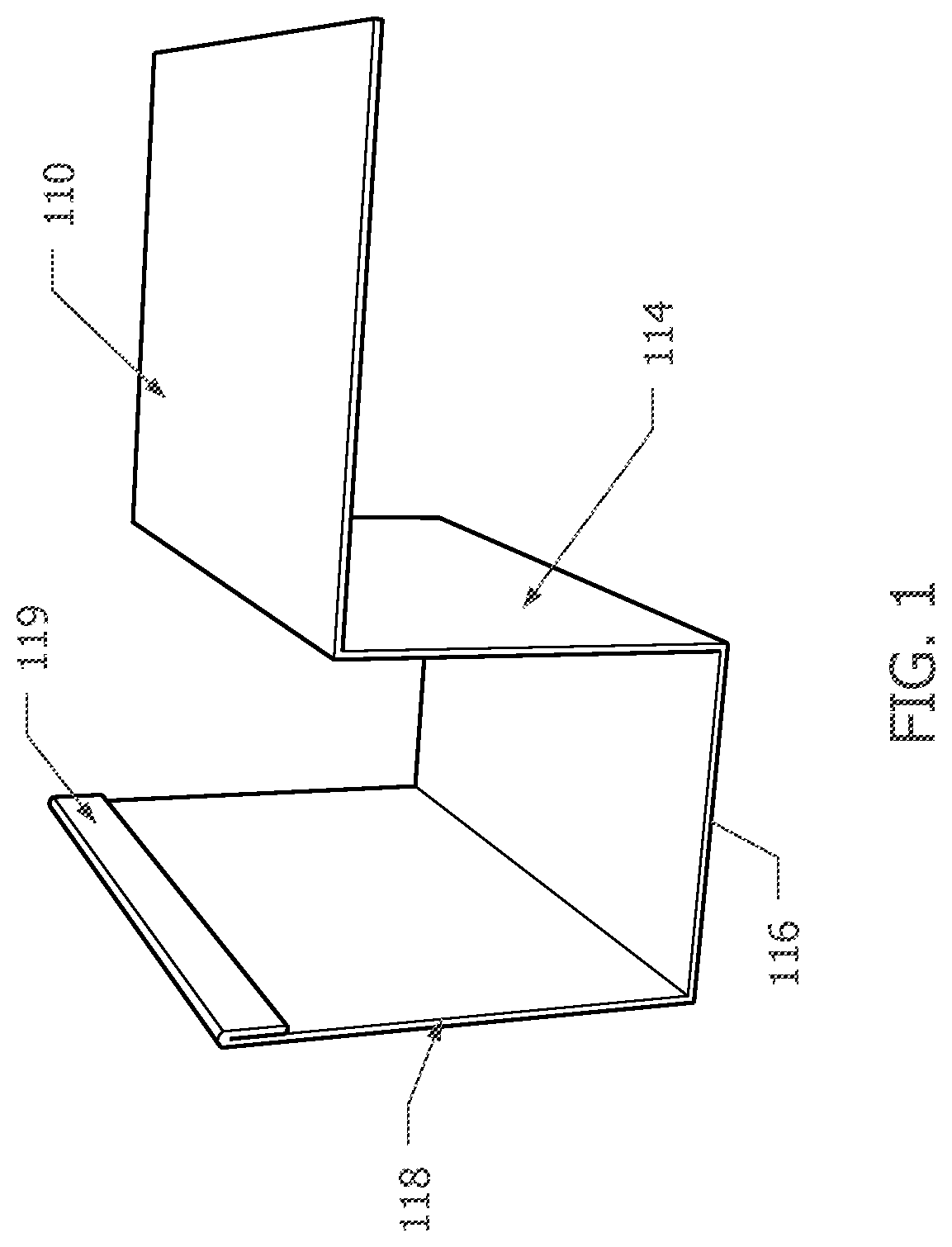

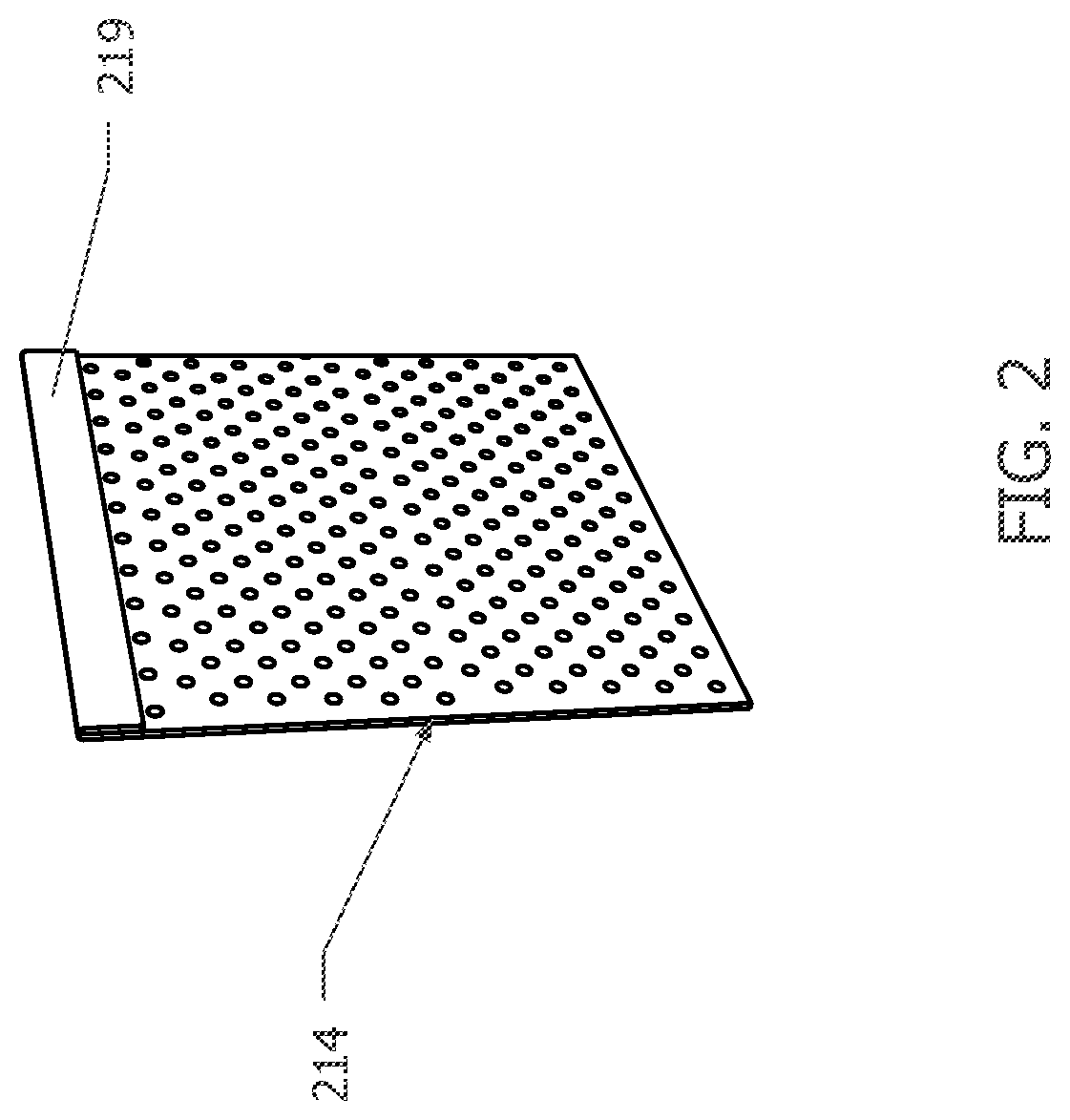

Modular Structure, Modular Panel To Make Said Modular Structure And Corresponding Method To Make Said Modular Structure

InactiveUS20130333310A1Easy to assembleEasy to dismantlePhotovoltaic supportsSolar heating energyEngineeringMechanical engineering

Owner:MAS

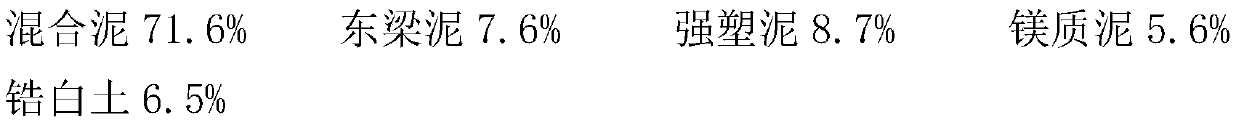

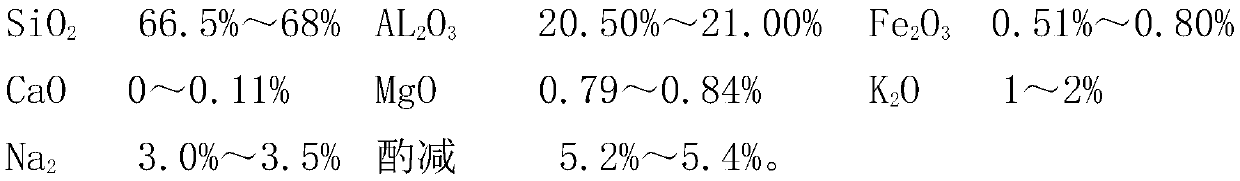

Ceramic rock plate and preparation method thereof

ActiveCN111470848AImprove plasticityGood molding effectCeramic materials productionClaywaresGlazeSpray dried

The invention relates to a ceramic rock plate and a preparation method thereof. A ceramic rock plate blank is composed of the following components in percentage by weight: 35-46.1% of mud; 50 to 60 percent of a water abrasive; 1-7% of a green body toughening material; 0.5 to 3 percent of a reclaimed material; and 0.1-0.8% of an additive. The preparation method comprises the following steps: preparing a green body, processing the green body, performing spray drying to prepare powder, performing dry pressing to form the green body (with a plane or concave-convex effect), drying, polishing the green body, blowing ash, spraying water, spraying white ink, spraying engobe, decorating patterns, decorating isolation glaze, decorating a transparent glaze layer, firing, polishing and edging.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +3

Water-based environment-friendly porcelain glaze-like plastic coating and preparation method thereof

The invention discloses water-based environment-friendly porcelain glaze-like plastic coating and a preparation method thereof. The water-based environment-friendly porcelain glaze-like plastic coating adopts a formula comprising the following materials by mass: 20 to 40 percent of a water-based acrylic emulsion, 10 to 20 percent of water-based silica sol, 35 to 50 percent of water-based inorganic silicon dioxide nanodispersion, 0.1 to 0.3 percent of a wetting dispersant, 1 to 5 percent of silane, 0.1 to 0.5 percent of an amine neutralizing agent, 5 to 10 percent of lead-free pigment, 0.5 to 2.5 percent of a film-forming additive, and 5 to 25 percent of deionized water. The water-based environment-friendly porcelain glaze-like plastic coating can be coated on the surfaces of various materials in the form of porcelain glaze, and can be applied on the surfaces of the materials of various shapes through roller-applied coating, shower coating, spraying, blade coating, brush coating, dip coating and the like; moreover, the formed porcelain glaze coating is unique and free from hydrolysis, and cannot be melted at a certain temperature, so that a base material can be effectively protected from corrosion, abrasion, scraping, acid-alkali, impact, inflaming and fire.

Owner:吕标

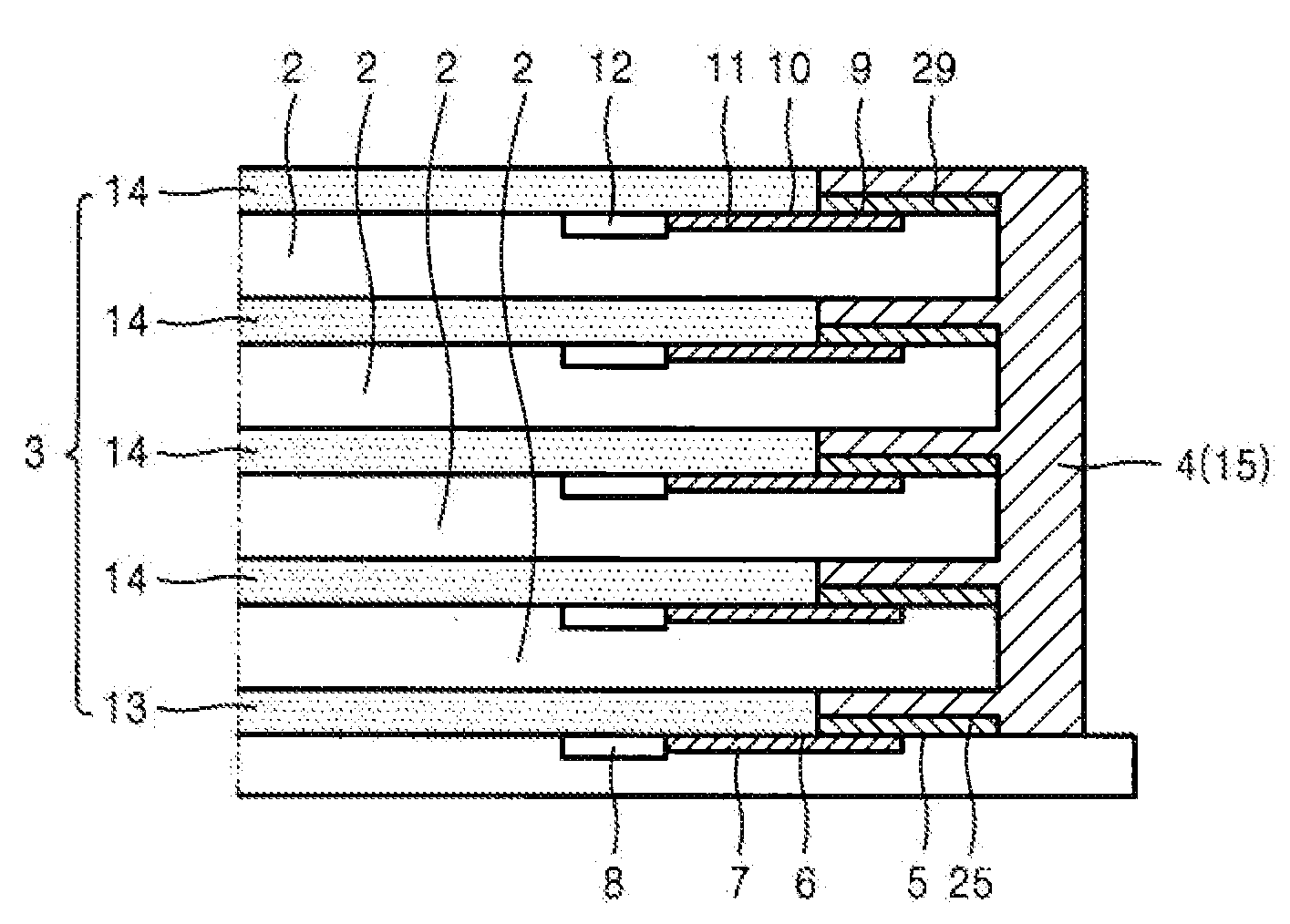

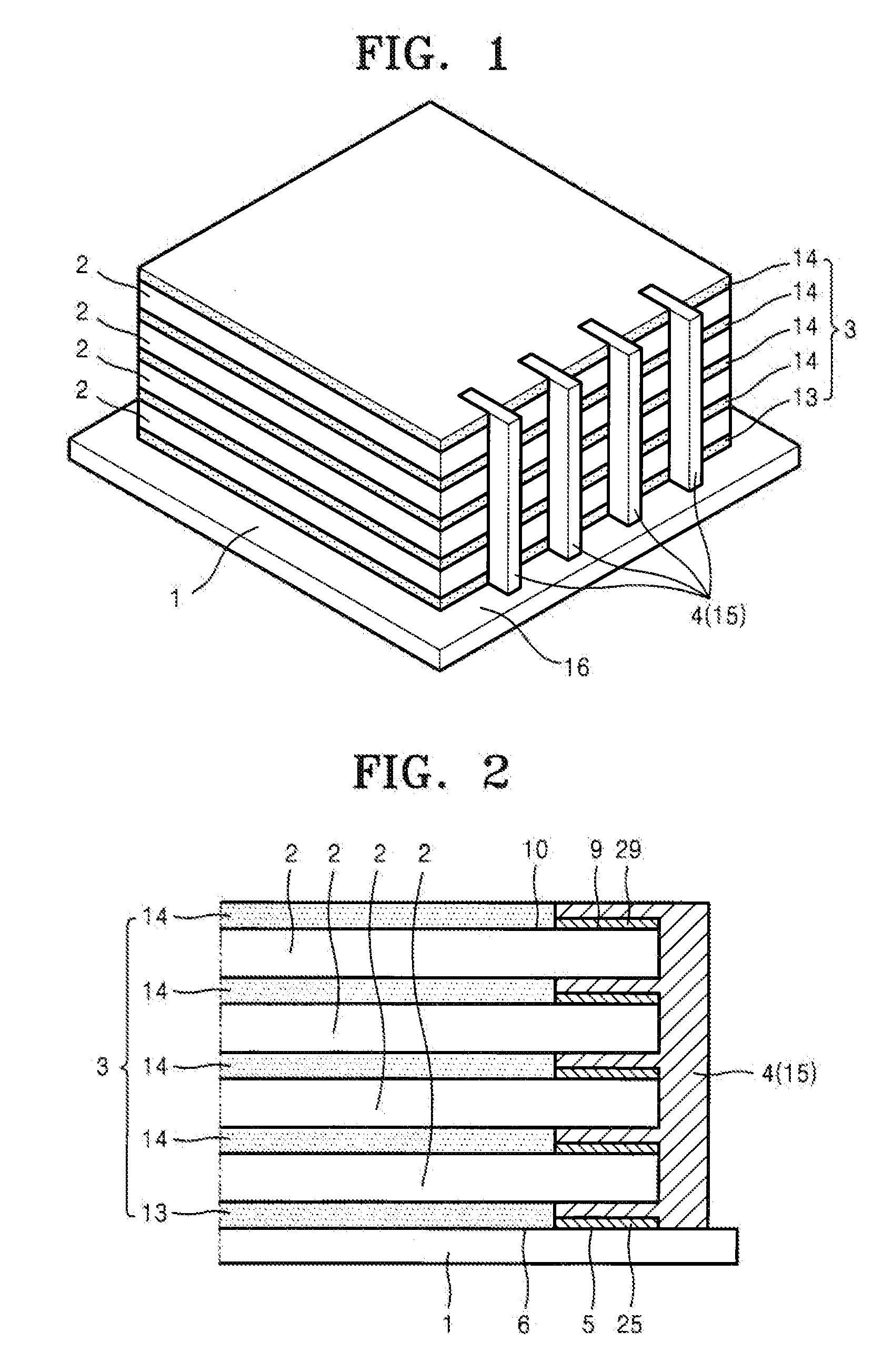

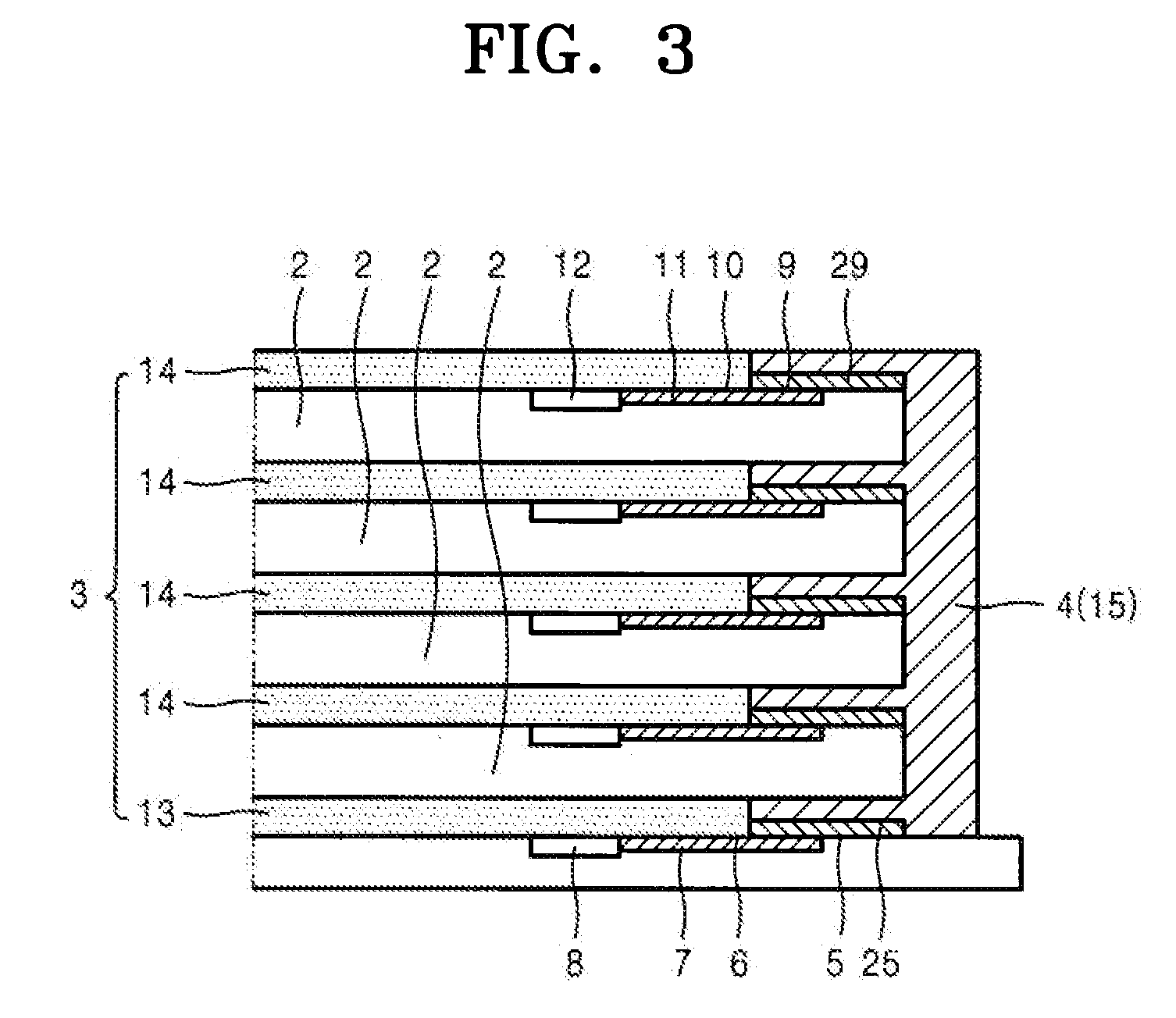

Stack-type semiconductor package

InactiveUS20090085224A1Reduce in quantityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesProduction rateManufacturing technology

Provided is a stack-type semiconductor package including a base chip having a circuit formed on one of its surfaces, at least one stack chip having a circuit stacked on the base chip, an adhesive interposed between the base chip and the stack chip, and signal transmission members formed along a lateral surface of the stack chip. The fabrication process of this stack-type semiconductor package may be simplified and the number of process operations may be lessened, thereby reducing the production time and cost. Also, a state of electrical contact of a terminal with a signal transmission member may be solidified, thereby improving the reliability of the stack-type semiconductor package. Furthermore, new post-type signal transmission members are adopted instead of wires or electrodes so that the structural stability and productivity of the stack-type semiconductor package may be markedly enhanced.

Owner:SAMSUNG ELECTRONICS CO LTD

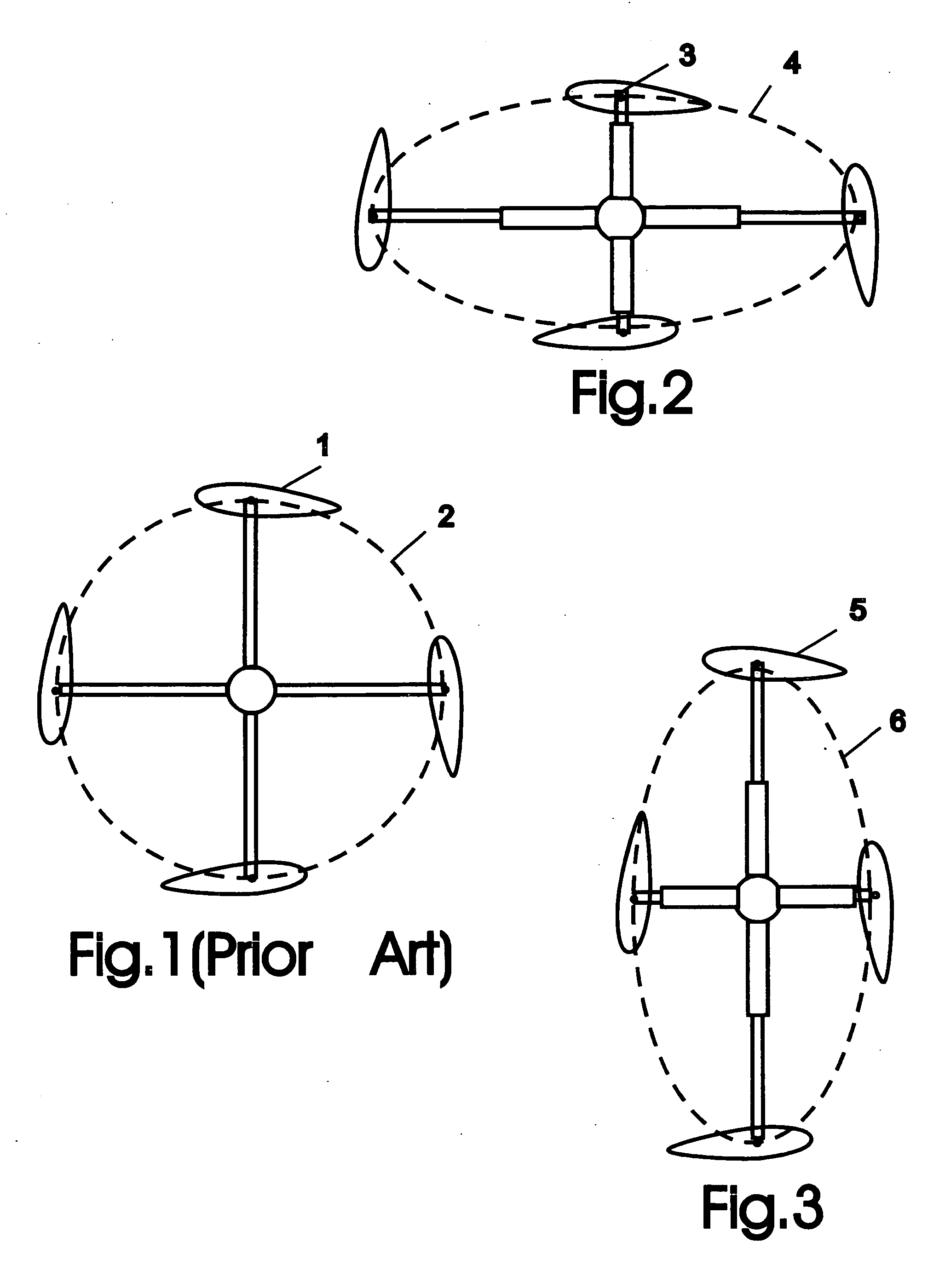

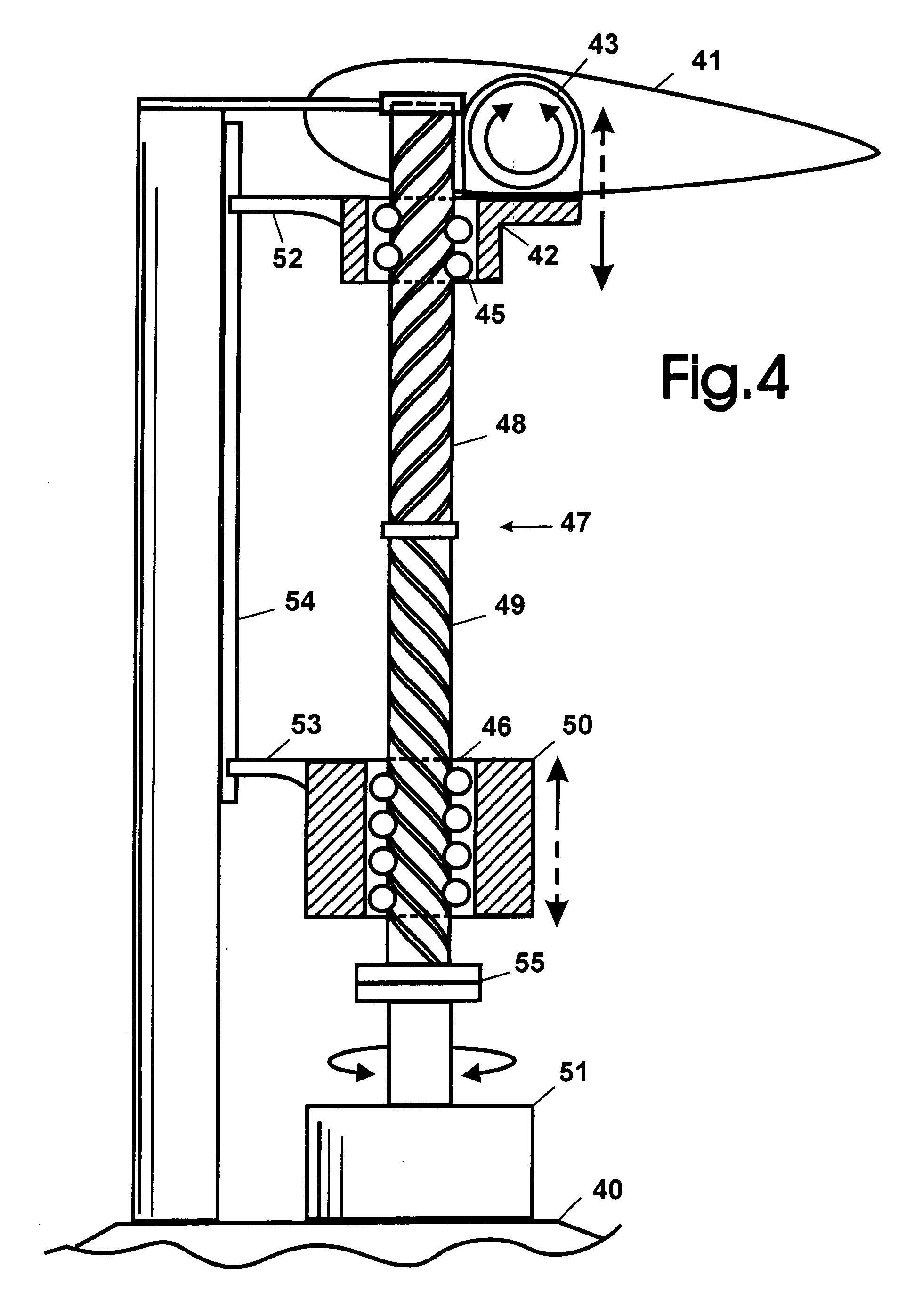

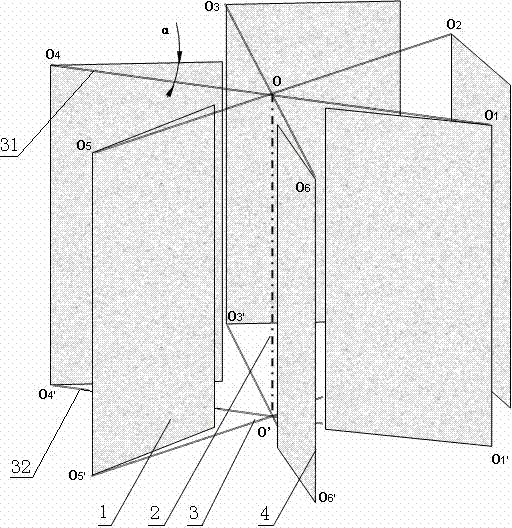

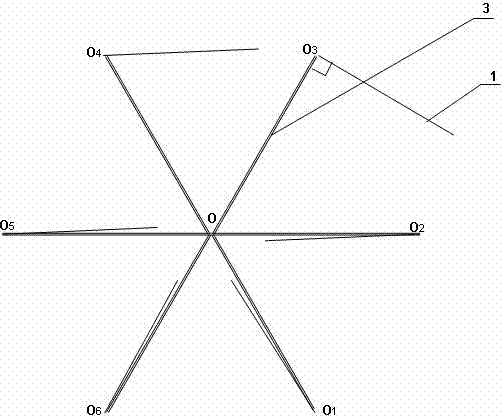

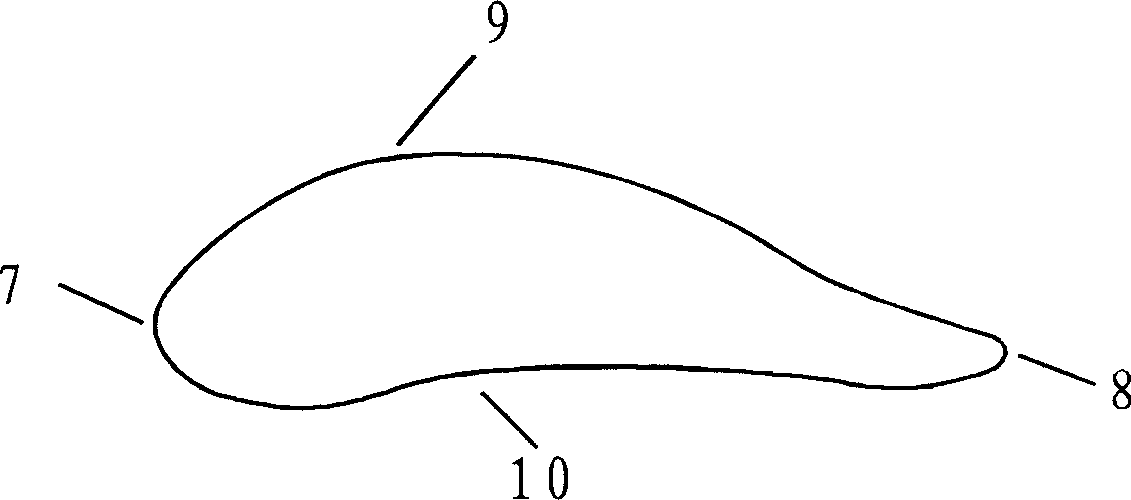

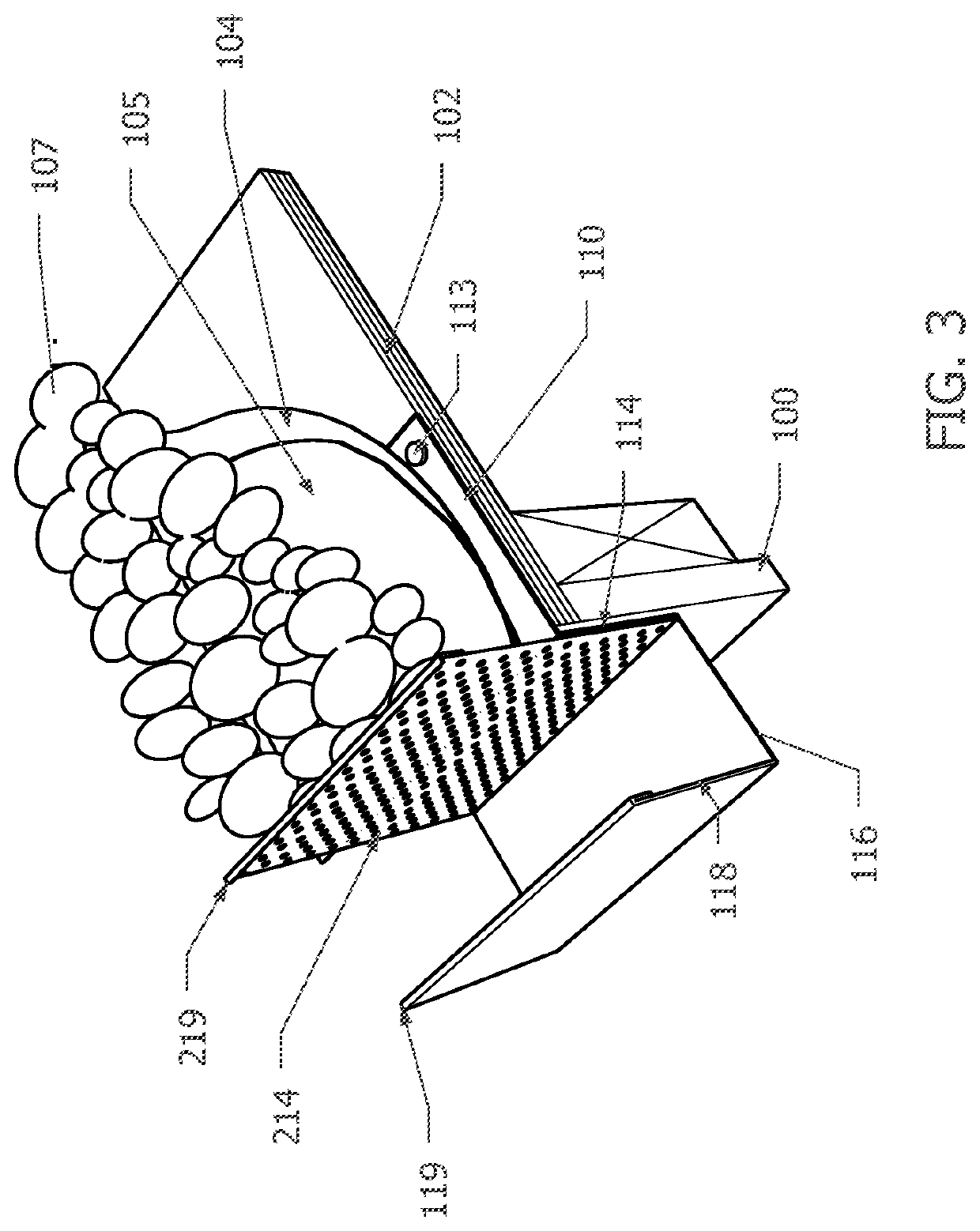

Cycloidal rotor with non-circular blade orbit

ActiveUS20090226314A1Improve efficiencyPowerfulPropellersRotary propellersFlight vehicleCircular orbit

A cycloidal rotor system having airfoil blades travelling along a generally non-circular, elongated and, in most embodiments, dynamically variable orbit. Such non-circular orbit provides a greater period in each revolution and an optimized relative wind along the trajectory for each blade to efficiently maximise lift when orbits are elongated horizontally, or thrust / propulsion when orbits are vertically elongated. Most embodiments, in addition to having the computer system controlled actuators to dynamically vary the blade trajectory and the angle of attack, can also have the computer system controlled actuators for dynamically varying the spatial orientation of the blades; enabling their slanting motion upward / downward and / or backsweep / forwardsweep positioning to produce and precisely control a variety of aerodynamic effects suited for providing optimum performance for various operating regimes, counter wind gusts and enable the craft to move sideways. Thus a rotor is provided, which when used in a VTOL rotorcraft, will require lower engine power to match or exceed the operating performance of VTOL rotorcrafts equipped with prior art cycloidal rotors, this rotor also offers increased efficiency and decreased required power when used for generating the propulsive force for various vehicles or used as a fan.

Owner:OPTIVECTOR LTD

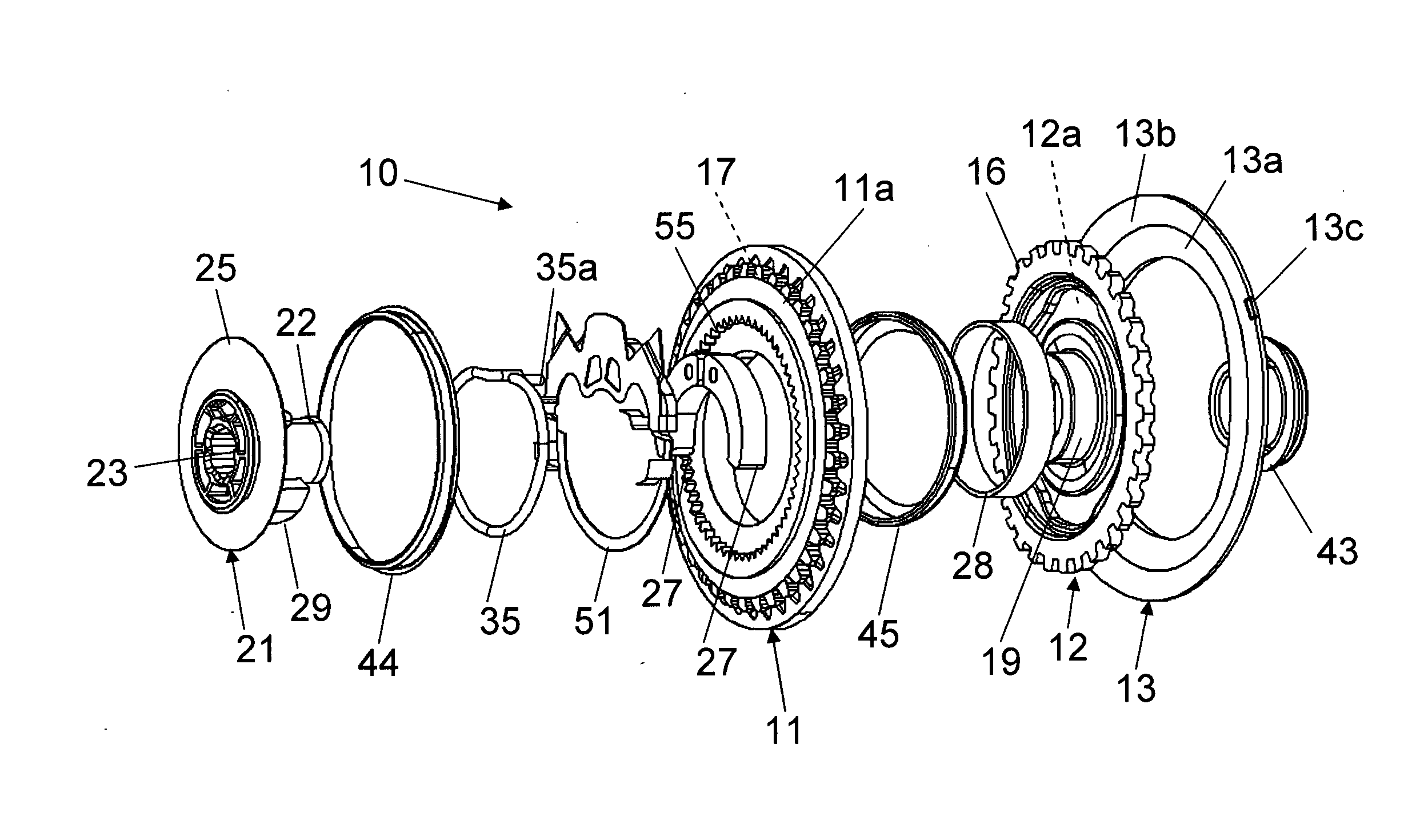

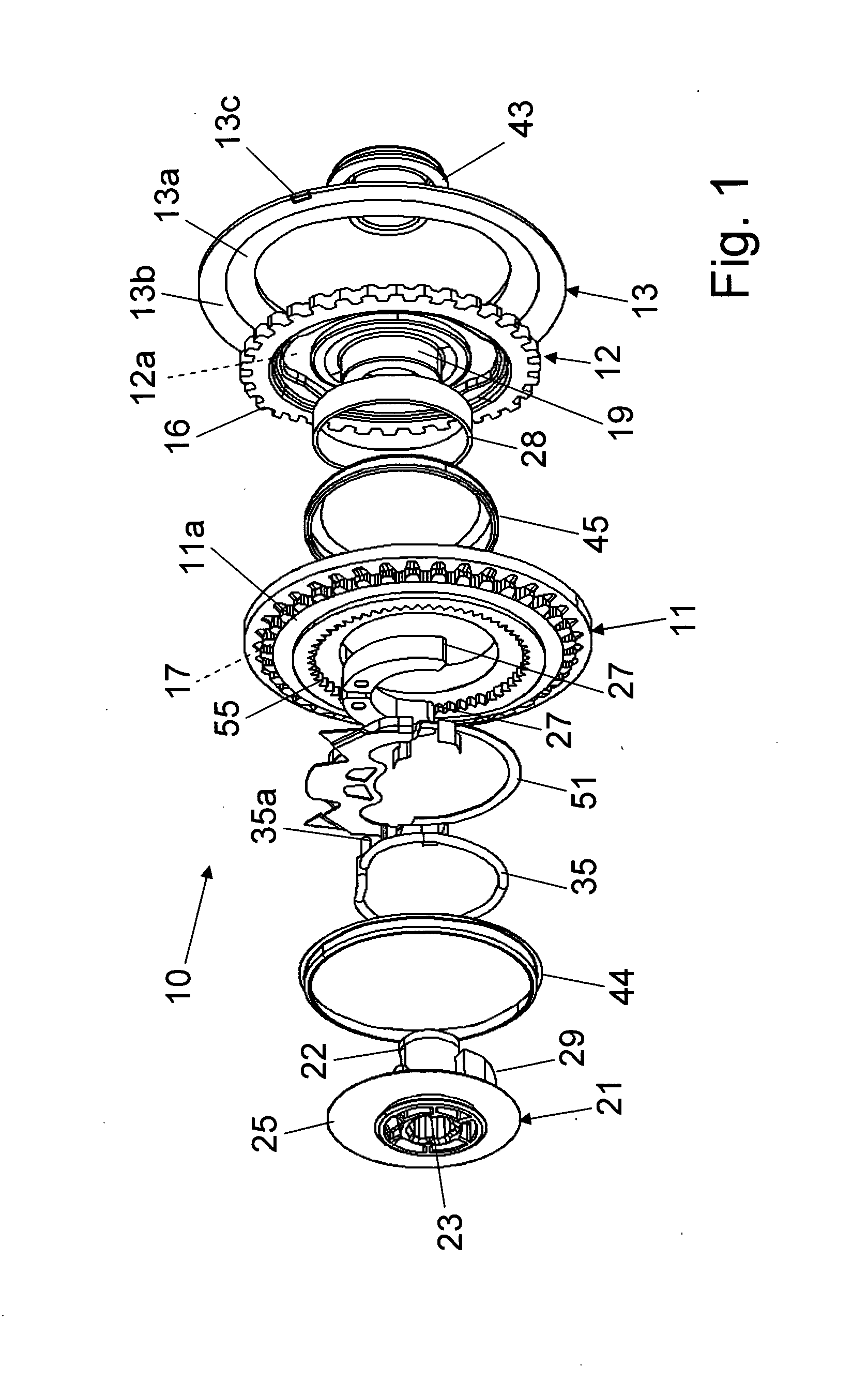

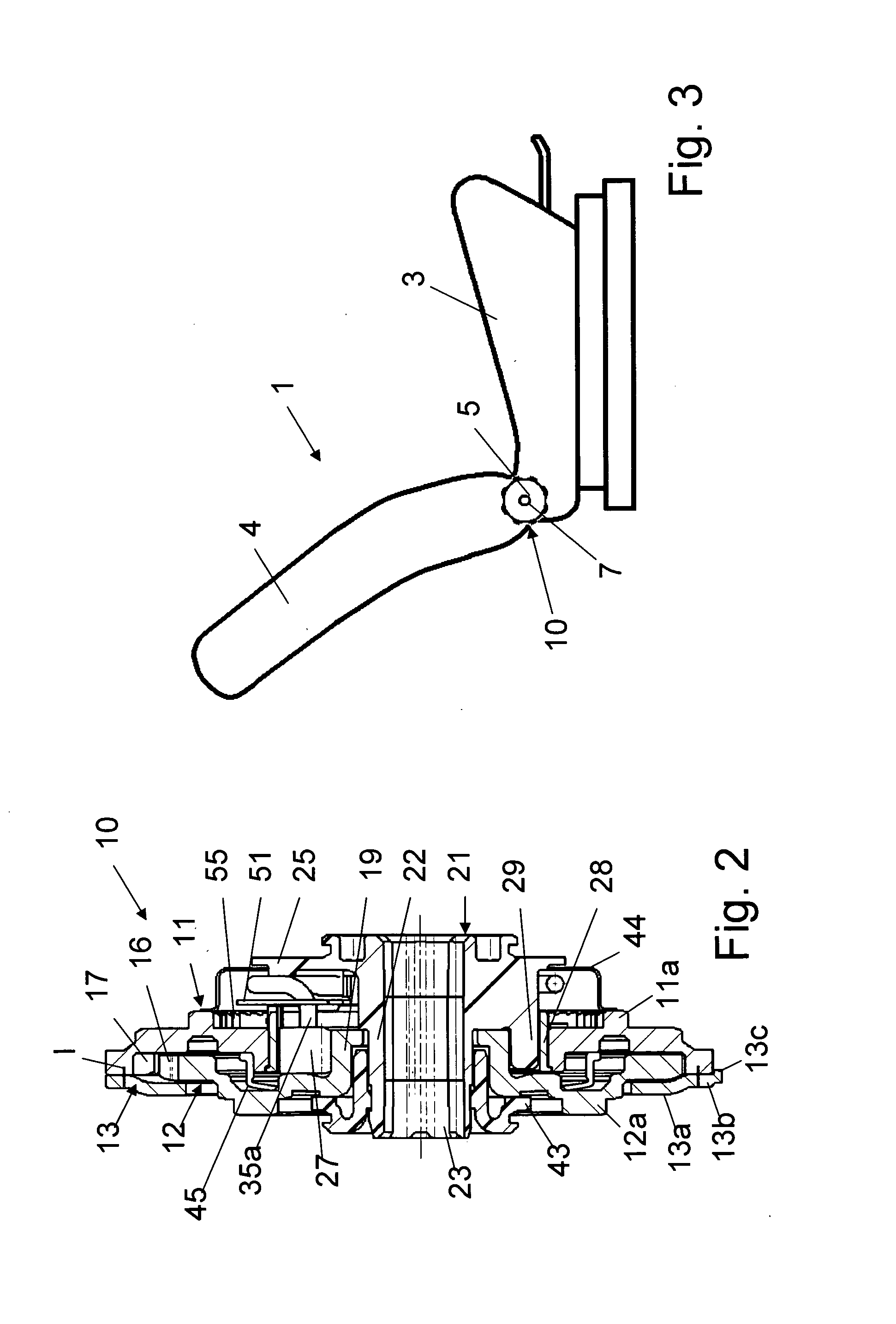

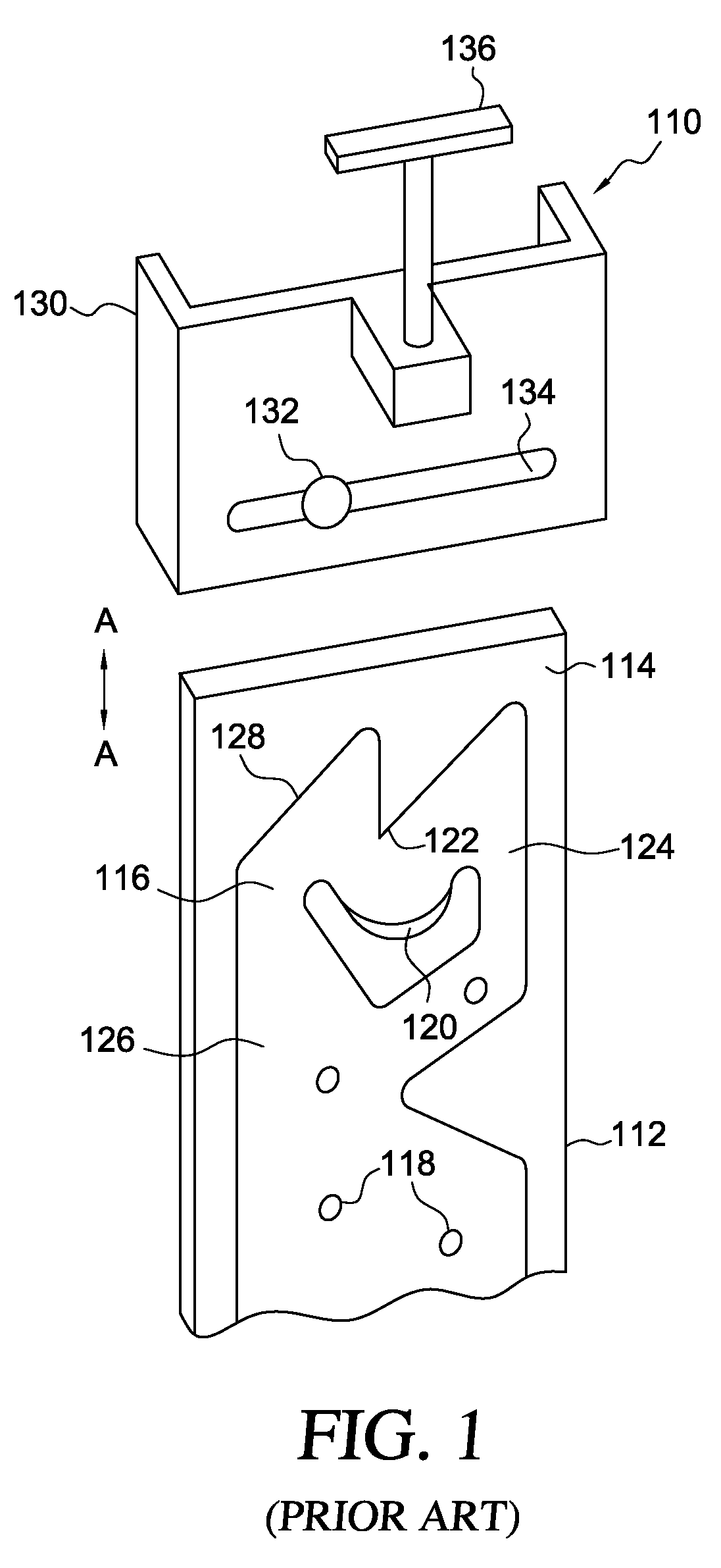

Fitting for a vehicle seat

Owner:KEIPER GMBH & CO KG

Mineral culture material capable of blocking-up adsorption of heavy metal by mushroom

InactiveCN101417902AReduce heavy metal contentImprove the level of quality and safetyHorticultureFertilizer mixturesShiitake mushroomsMaterials science

The invention discloses a mineral culture material which can prevent champignon from absorbing heavy metal and consists of clinoptilolite power with the weight percentage of 50 to 89 percent, limestone powder or gypsum powder with the weight percentage of 9 to 42 percent and magnesium sulfate with the weight percentage of 2 to 8 percent. The invention reduces the content of heavy metal in the cultivated champignon to 10 to 50 percent, which is beneficial for improving the quality and safety of champignon and greatly reducing the heavy metal overweighting rate in champignon. The invention avoids adding sugar, increases the fixation property, ventilation property, water retention property and the function of adjusting the pH value, reduces the occasions of mushroom-stick rotten and damage by disease and insect at high-temperature over-summer period, prolongs the fruiting period, raising the conversion rate of culture material, raises the champignon-stick yield by 3 to 5 percent and increases the yield quantity of champignon by 5 to 8 percent. The invention can provide calcium, magnesium and a plurality of mineral trace elements necessary for champignon growth, has the function of evenly providing nitrogen and regulating nutrient delivery speed, reduces the occurring of deformed champignon and head-damped champignons and raises the high-quality champignon proportion by 8 to 15 percent.

Owner:丽水市食用菌研究开发有限公司

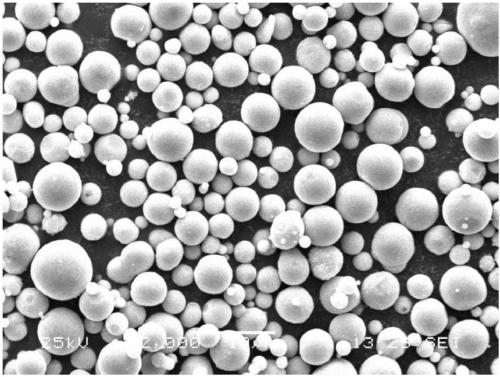

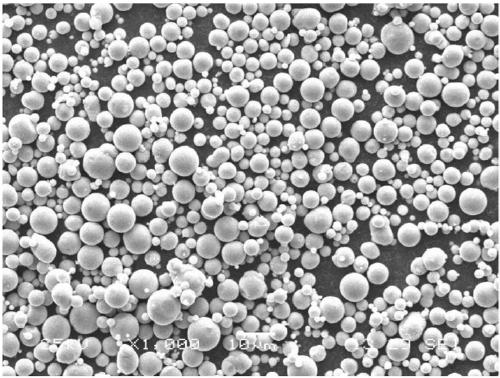

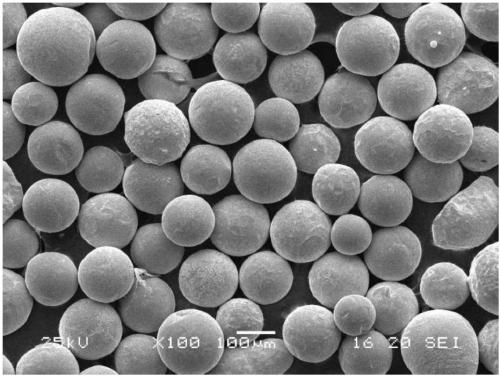

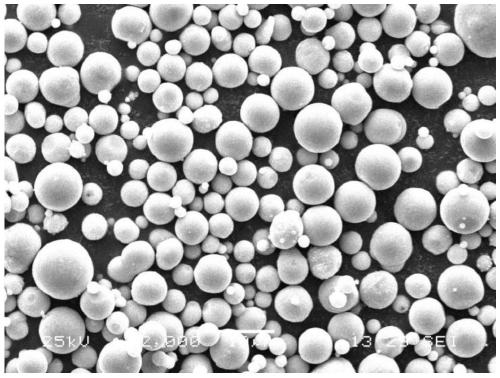

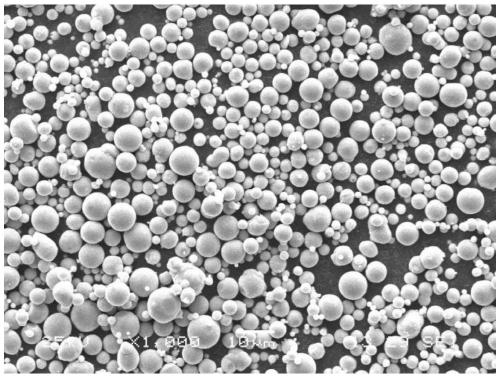

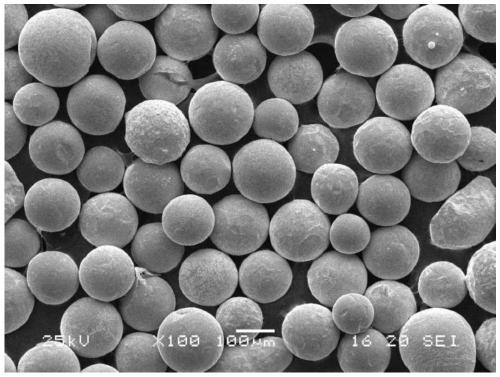

High-compact WC-WB-Co spherical powder hard-face material and preparation method thereof

ActiveCN109266939AGood corrosion resistanceImprove corrosion resistanceTransportation and packagingMetal-working apparatusCorrosionMaterial system

The invention relates to a high-compact WC-WB-Co spherical powder hard-face material and a preparation method thereof. The high-compact WC-WB-Co spherical powder hard-face material is prepared from, by mass, 50-75% of WC powder, 15-38% of WB powder, 8-12% of Co powder, and 1.0-4.0% of PEG binders. The high-compact WC-WB-Co spherical powder hard-face material has the advantages that WB is introduced into the design of a material system, and due to the fact that WB can react with metal-phase Co to obtain ternary-phase CoWB during powder sintering and CoWB has higher microhardness and better corrosion resistance performance than WC, wear resistance and corrosion resistance of the material can be improved greatly by adding of WB, the microhardness HV0.3 of the coating is increased to be and even higher than 1900, the corrosion resistance performance of the material is increased by at least twice; besides, by the high-temperature spherical production process, powder is heated and molten quickly, molten powder particles can solidify into spheres within a short time under action of surface tensions, so that degree of sphericity and the solid degree of single powder can be increased greatly, the apparent density of the finished powder product is equal to and even higher than 7.5 g / cm<3>, the powder flow velocity is lower than 10s / 50g, and the coating porosity is lower than 0.5%.

Owner:株洲江钨博大硬面材料有限公司

Solid cosmetic composition and uses thereof

InactiveUS20010006653A1Reduced stabilityHigh solidityCosmetic preparationsHair removalFiberKappa-Carrageenan

The present invention relates to a solid composition for topical application, which is free of fillers, containing, in an aqueous phase, less than 20% of the total weight of the composition of a hydrophilic gelling system comprising the combination of at least 2% by weight of kappa-carrageenan, relative to the total weight of the composition, and at least one hydrocolloid chosen from xanthan gum and cellulose derivatives which are soluble in hot water. The solid composition obtained is, in the absence of oil, transparent or translucent and can be applied directly to a support. This composition is generally in the form of tubes, pencils or bars and can constitute solid products to care for and / or treat the skin, the scalp, the hair or mucous membranes, to make up the skin and / or keratin fibres such as the eyelashes and the hair, and to style and / or shape keratin fibres, and in particular the hair.

Owner:LOREAL SA

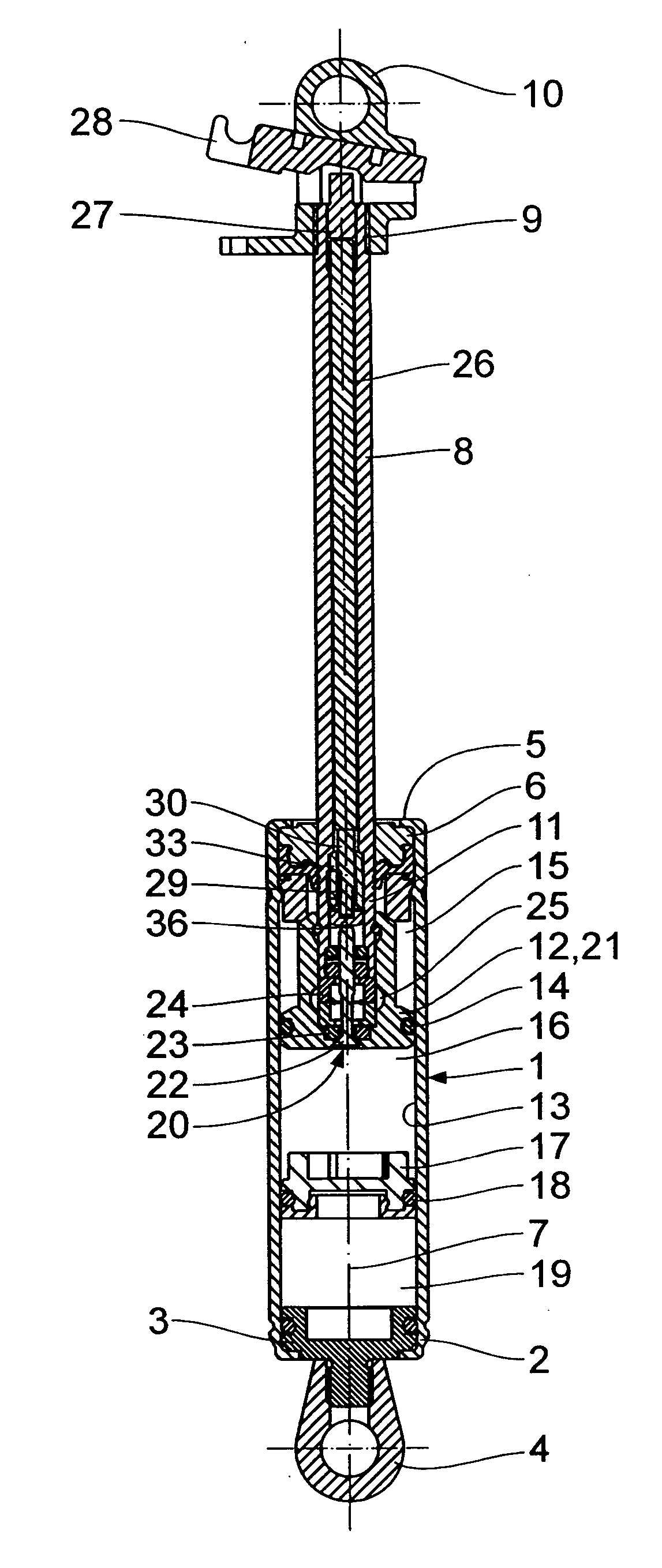

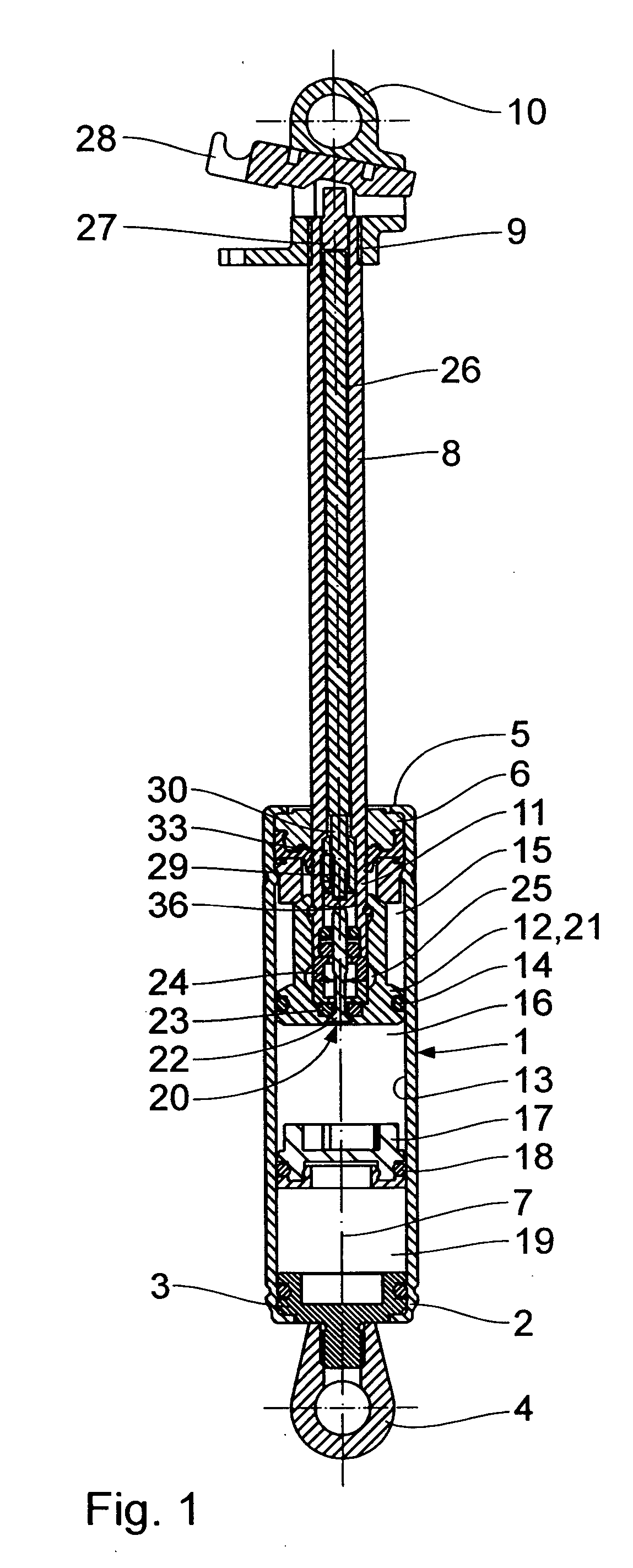

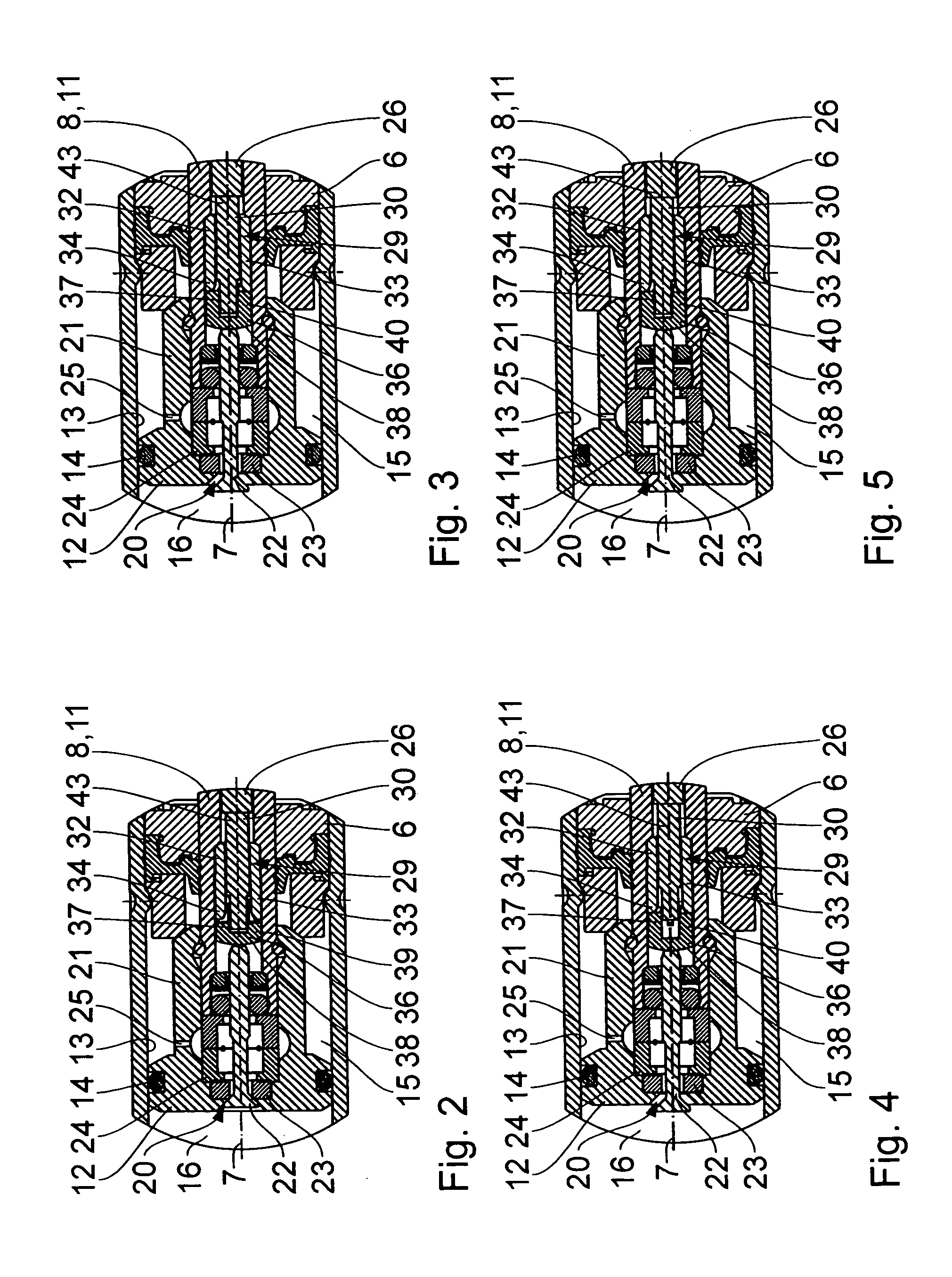

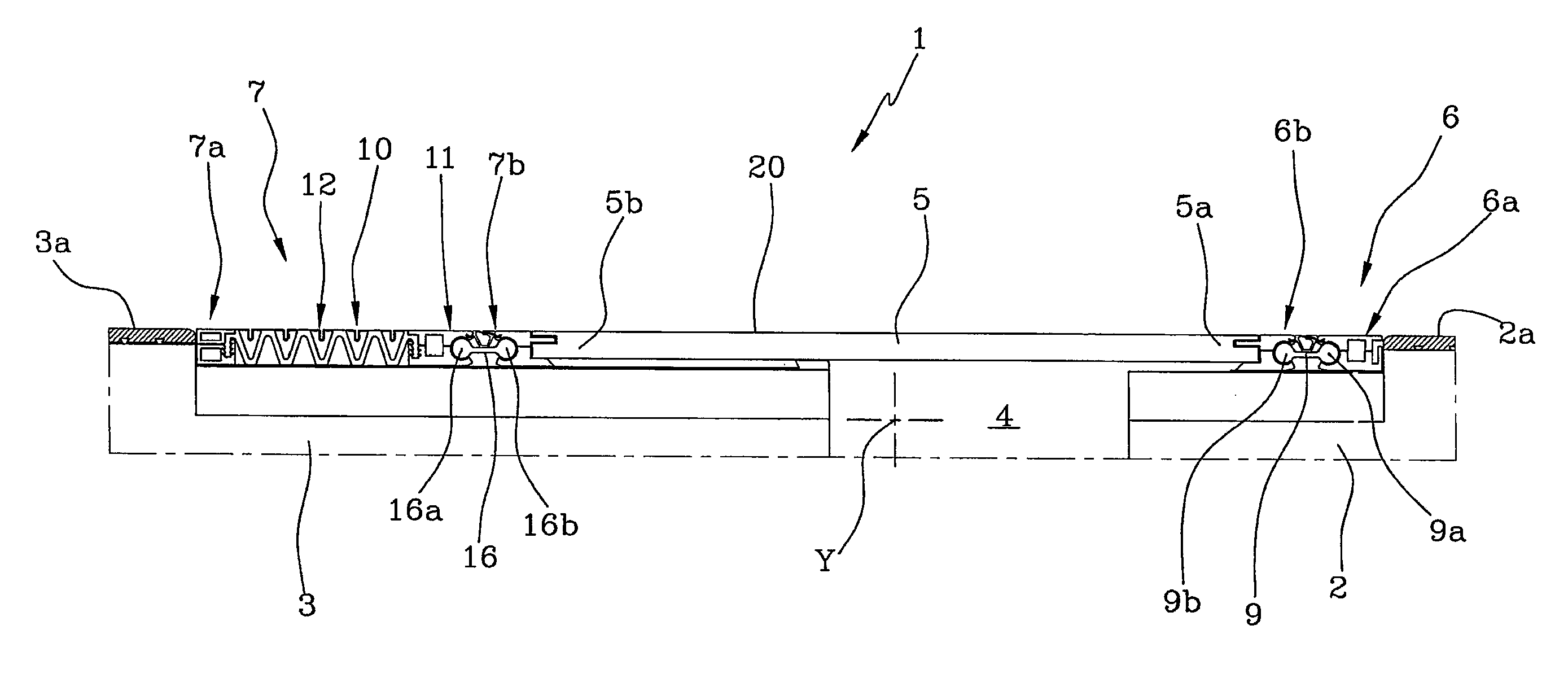

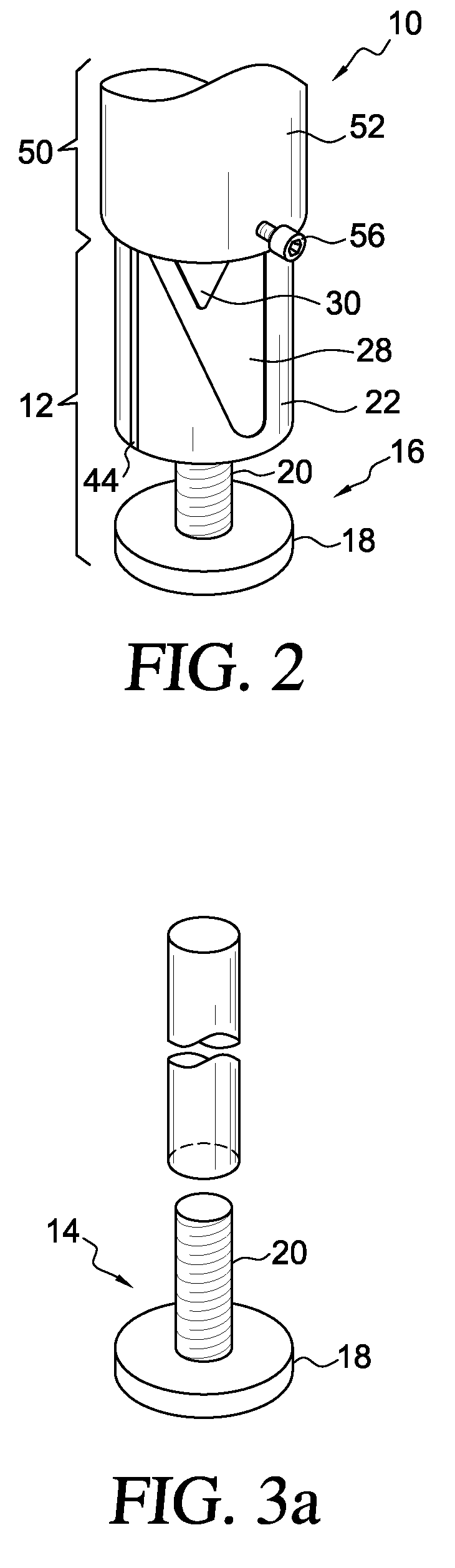

Adjustable-length compression spring

InactiveUS20050103586A1Improve sturdinessSufficient liftLiquid springsAdjustable chairsEngineeringStructural engineering

An adjustable-length compression spring comprises a casing filled with pressure fluid. A piston rod is sealingly extended through a guide and seal unit which closes the casing, a piston, which is sealingly guided therein, being joined to the piston rod. The piston divides the casing into two sectional casing chambers, which are filled with pressure fluid. For connection to each other of the sectional casing chambers, provision is made for a valve operated by a valve pin. The casing includes a locking mechanism which comprises a first and a second locking element, the first of which being in pushing connection with a first operating element and the second with the valve pin. They cooperate in the way of a retractable-ballpoint-pen mechanism so that, in a first position of locking, the valve pin takes a position of release with free connection between the sectional casing chambers and, in a second position of locking, it takes a position of blocking with any connection between the sectional casing chambers being shut off. This type of integrated locking mechanism can be made solid, nevertheless needing little space.

Owner:SUSPA

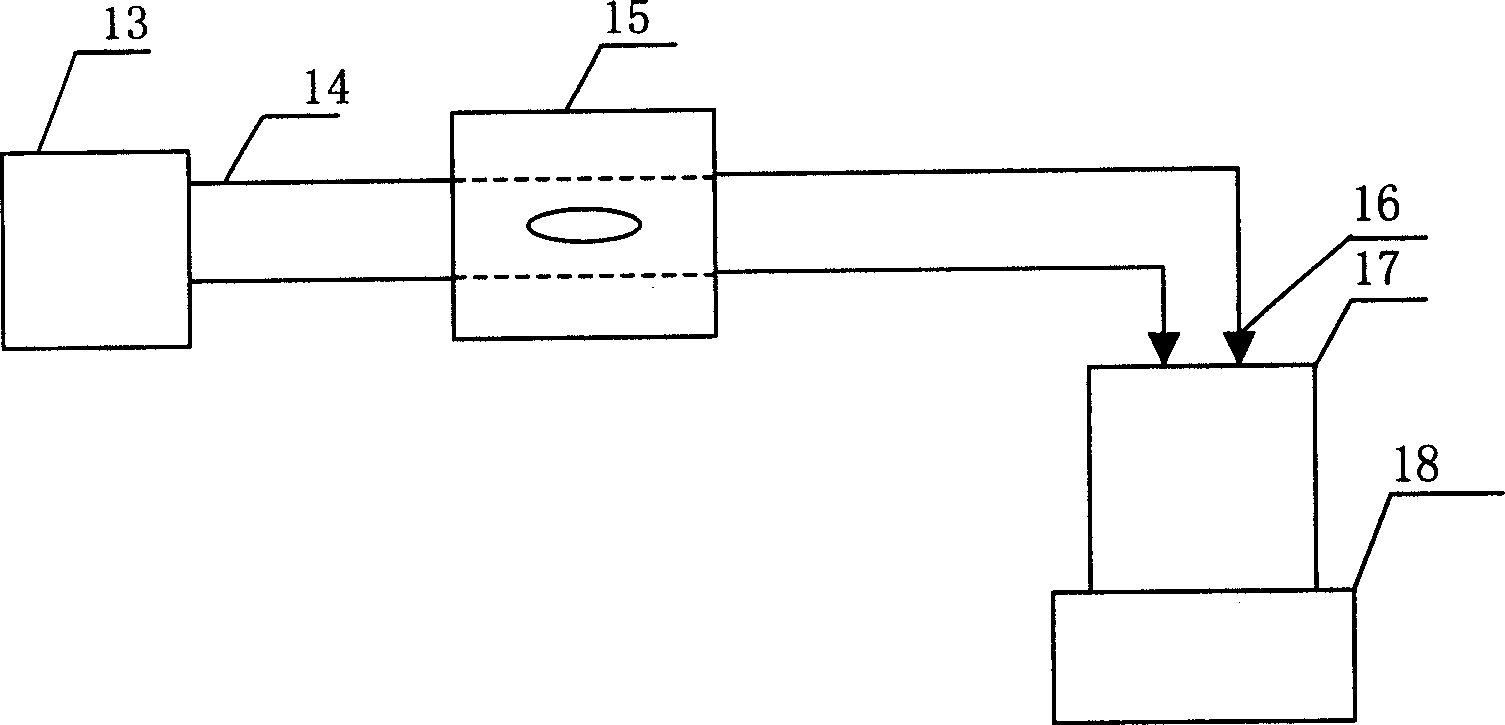

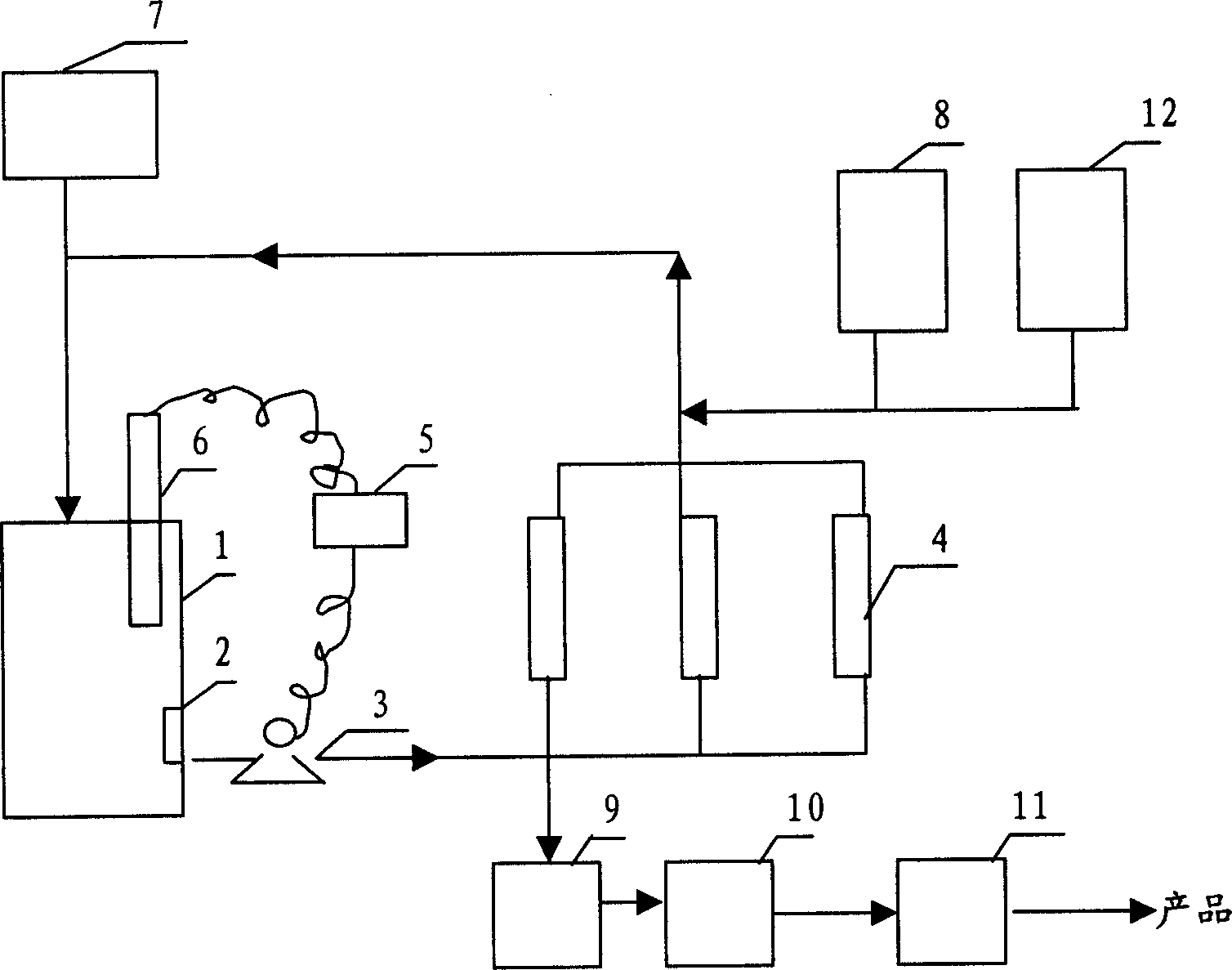

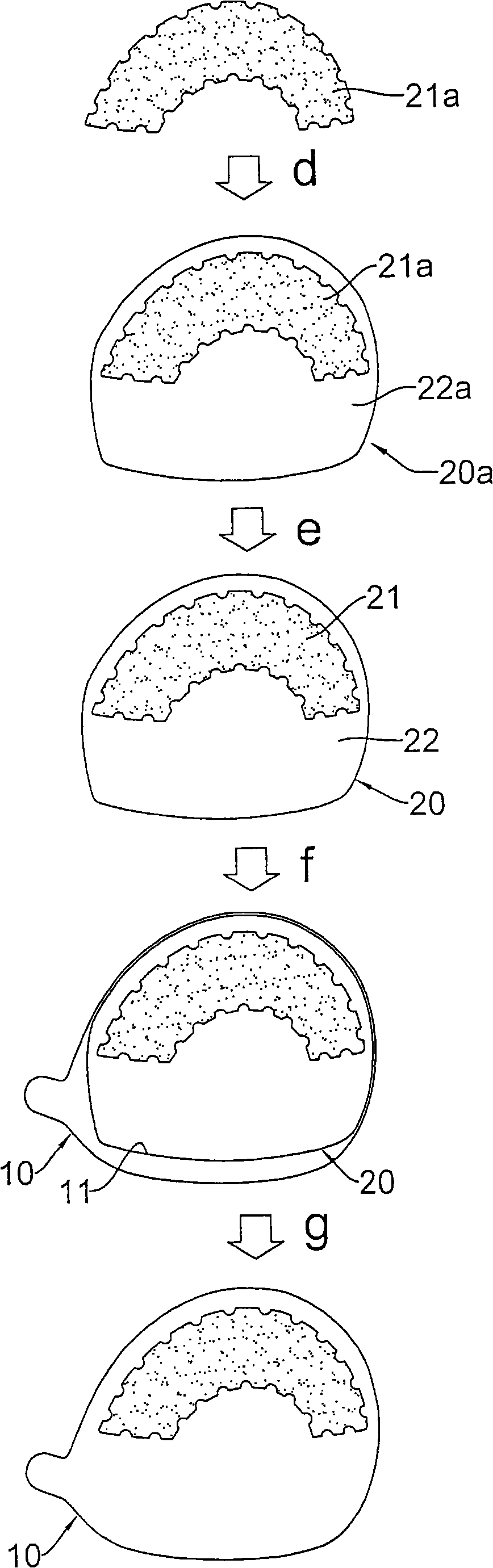

Lactobacillus fixed cell in-situ separating-fermenting lactic-acid production process

InactiveCN1528909AImprove product qualityHigh mechanical strengthOn/in organic carrierFermentationYeastAutomatic control

The invention refers to a process for using yeasting method to produce lactic acid. Takes out the mixed liquid of embedding agent and fungus suspending liquid to solidify the cells, the embedding agent is made up of fungus suspending liquid: 2% kala glue liquid: 8-12% polyvinyl alcohol and 2-4 sodium alginate with proportion 1:1:3-5, combines with using pH controller to control the acid rate pH value = 5.0-6.2 automatically, when the pH gauge displays the pH value is 5.0 in the yeasting liquid, the pH control system switches on the power automatically, the circular pump begin to work, when the pH value reaches 6.5, the relay cuts off the power, the circular pump stops, the yeasting is going on, it realizes in situ separation yeast lactic acid generating.

Owner:TIANJIN GUARD T & D

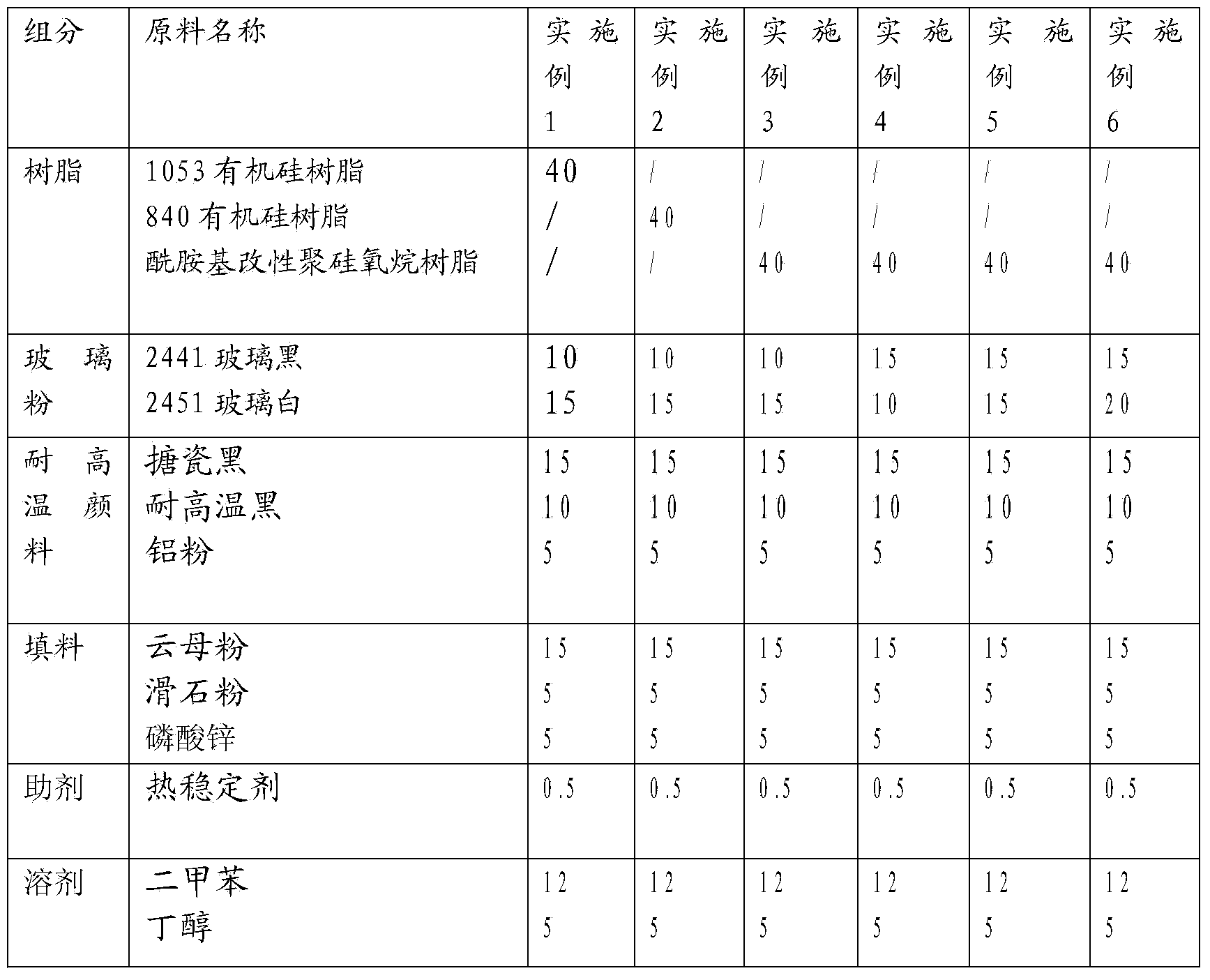

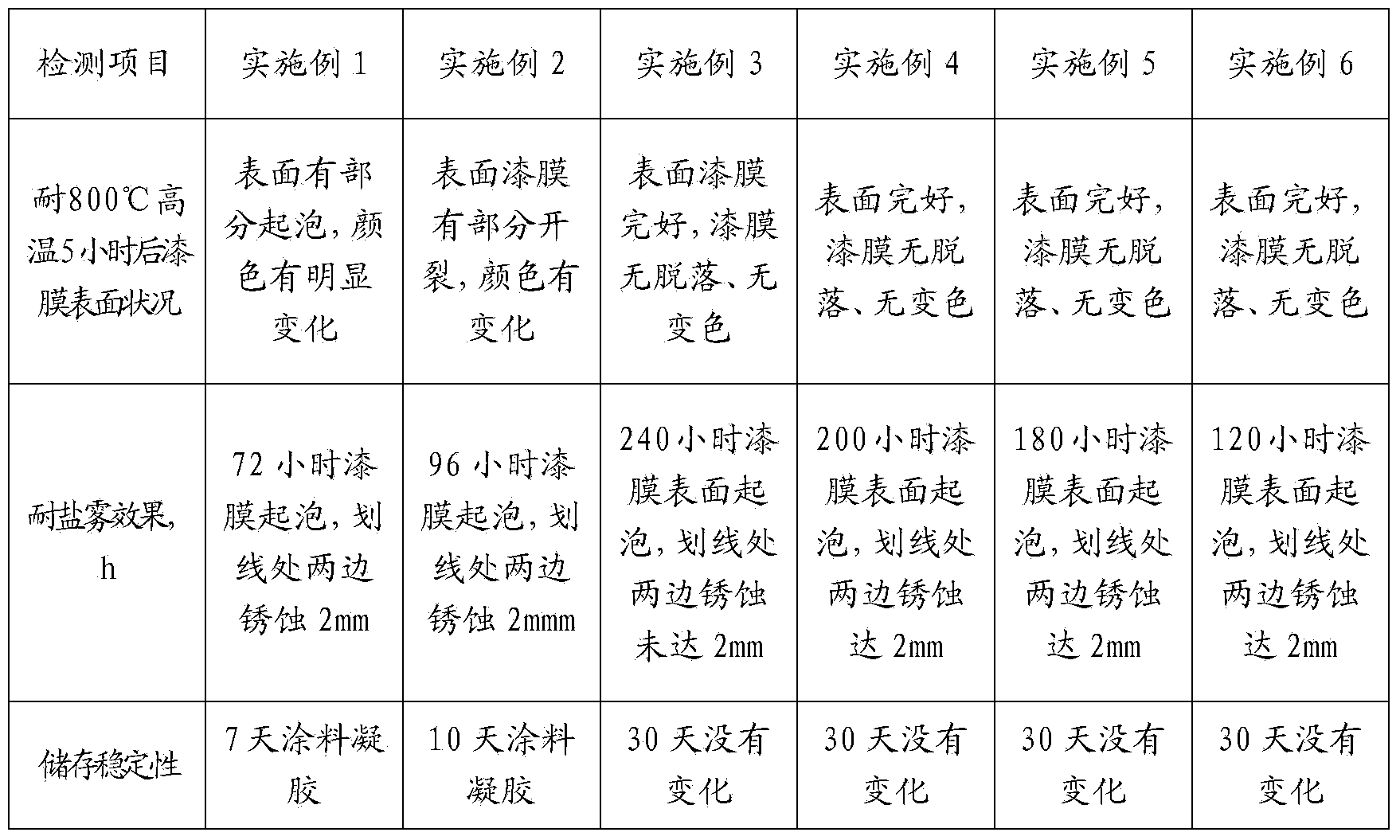

Superhigh-temperature-resisting and anti-corrosion coating as well as preparation method thereof

ActiveCN103525298ASolve the compactness problemGuaranteed durabilityAnti-corrosive paintsDouble bondSilicone resin

The invention relates to a preparation method of a superhigh-temperature-resisting and anti-corrosion coating. An amide group is introduced by a silane coupling agent containing double bonds and then the silane coupling agent is copolymerized with silicone resin containing methoxyl active groups to prepare modified organic silicon resin containing amide groups, and the modified organic silicon resin has extremely strong compatibility with alkaline pigments and consequently no longer react with alkaline glass powder filler, so that the coating has excellent storage stability; besides, the coating can resist high temperature of 800 DEG C and has strong anti-corrosion capability.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

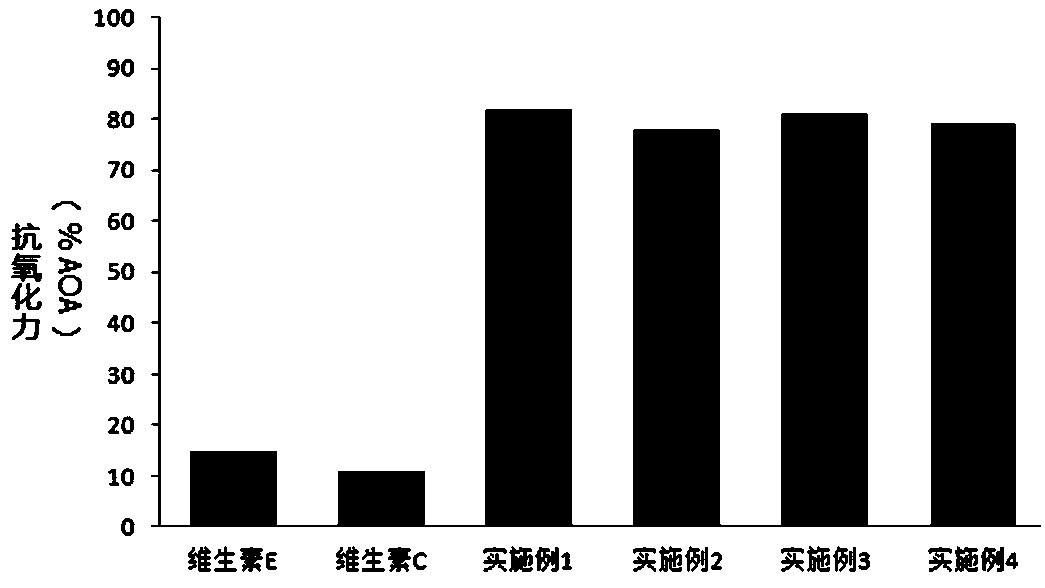

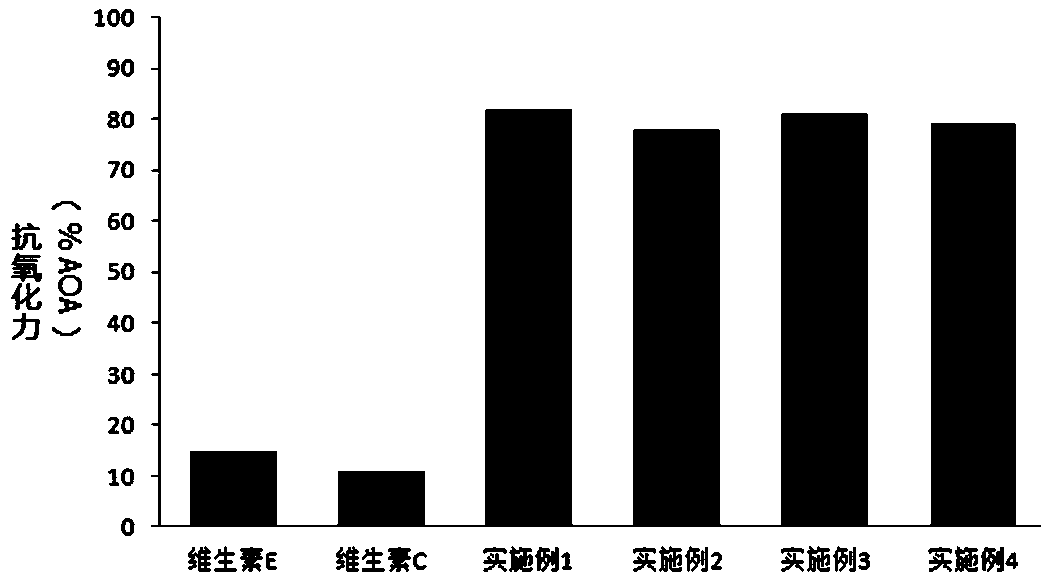

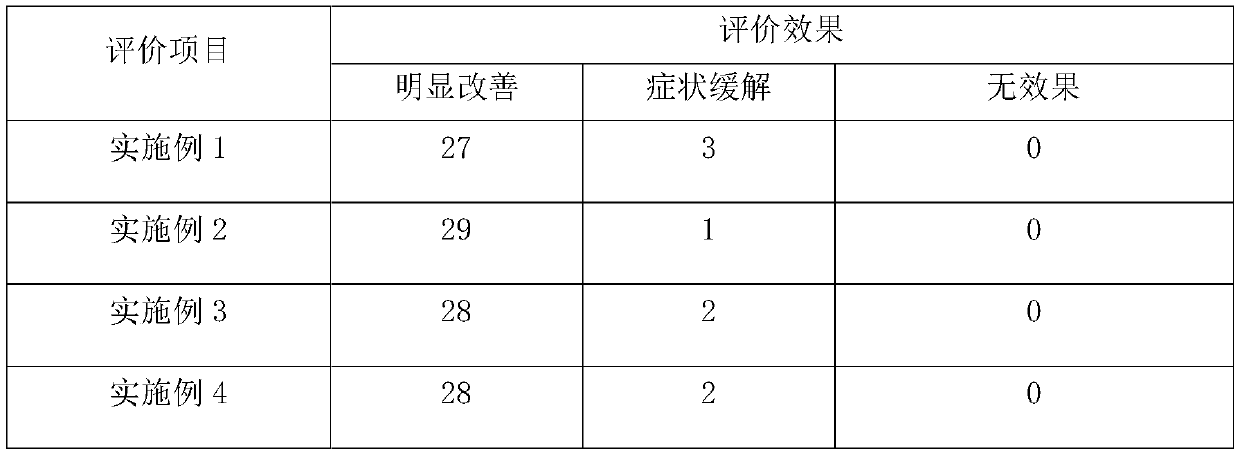

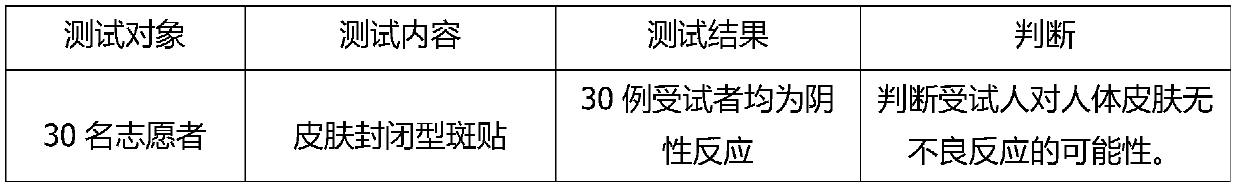

Polypeptide essence with multi-directional brightening effect and preparation technology thereof

InactiveCN110384653APromotes collagen synthesisInhibit the danger of glycationCosmetic preparationsToilet preparationsLicorice root extractPanax notoginseng root extract

The invention discloses a polypeptide essence with a multi-directional brightening effect and preparation technology thereof. The polypeptide essence with the multi-directional brightening effect comprises the following components of aloe vera extract, carnosine,pseudoalteromonasfermented productextract,a compound ofdendrobium stem extract, radix sophorae extract,Ningxia wolfberry fruit extract, and purple coneflower extract, a compound of reed extract, licorice root extract, angelica root extract, salvia miltiorrhiza root extract, dogwoodfruit extract, and boxthorn rootextract, a compound ofpseudo-ginseng root extract, astragalus membranaceusrootextract, and fructus ligustrilucidi extract,terminalia ferdinandianafruit extract; dihydrooatylo-anthranilic acid, humectant,and skin conditioning agents. According to the polypeptide essence with themulti-directional brightening effect and the preparation technology thereof, the dull yellow problem of skin is improved from multiple directions, meanwhile production water is replaced with the aloe extract, and a cold matching method is adopted to maximize efficiencyand integrity of active ingredients of the extracts.

Owner:奢脉国际化妆品(北京)有限公司

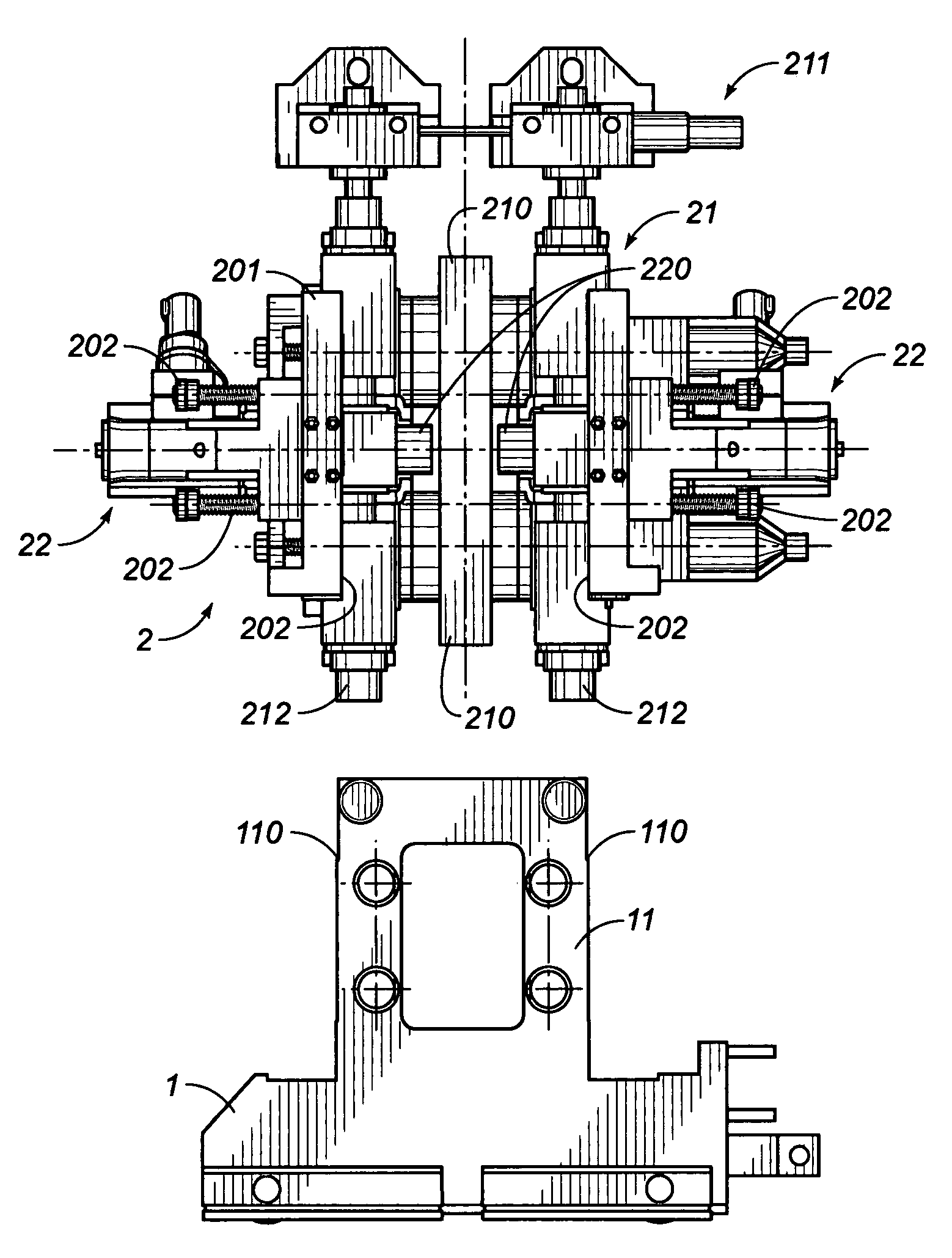

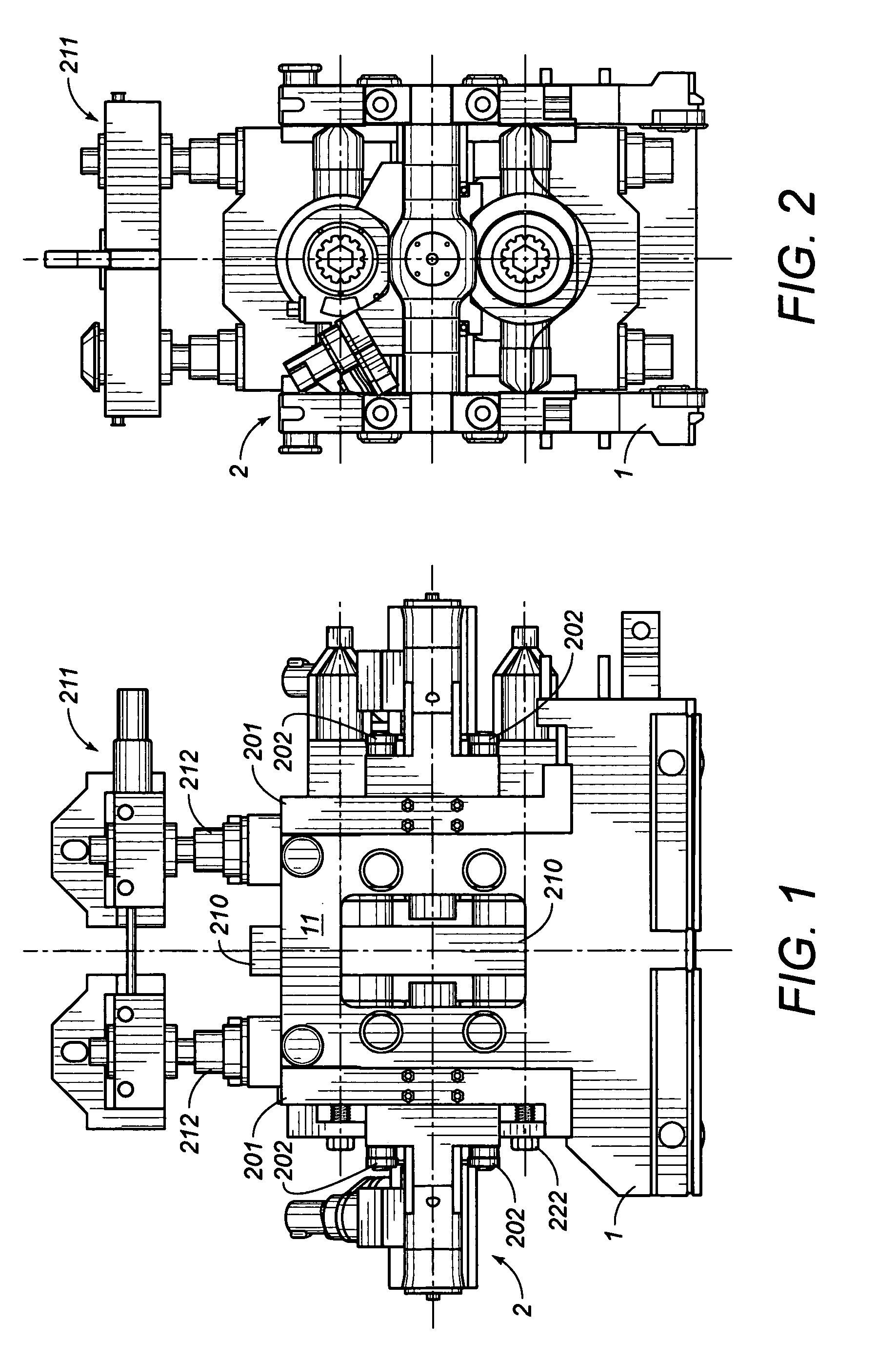

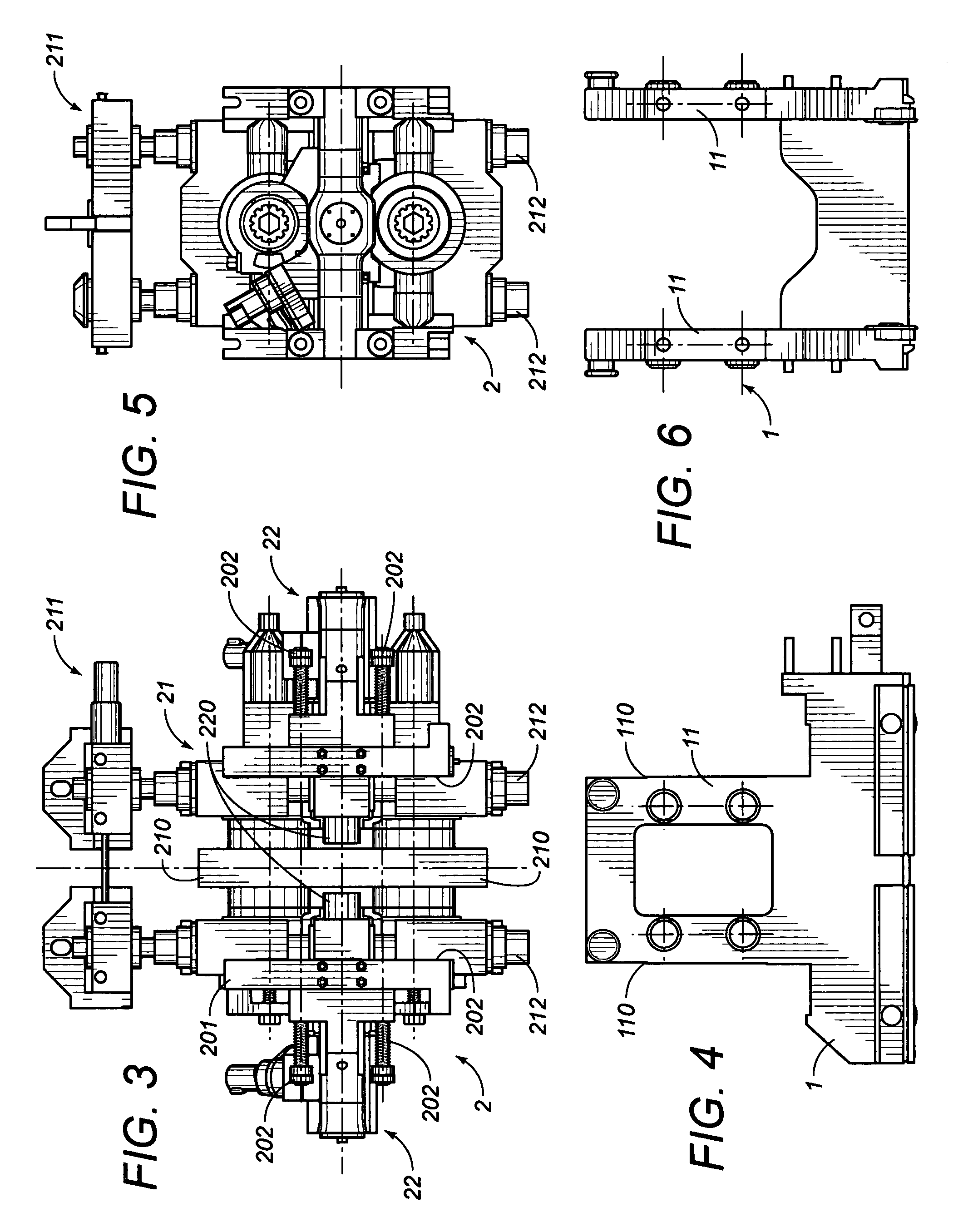

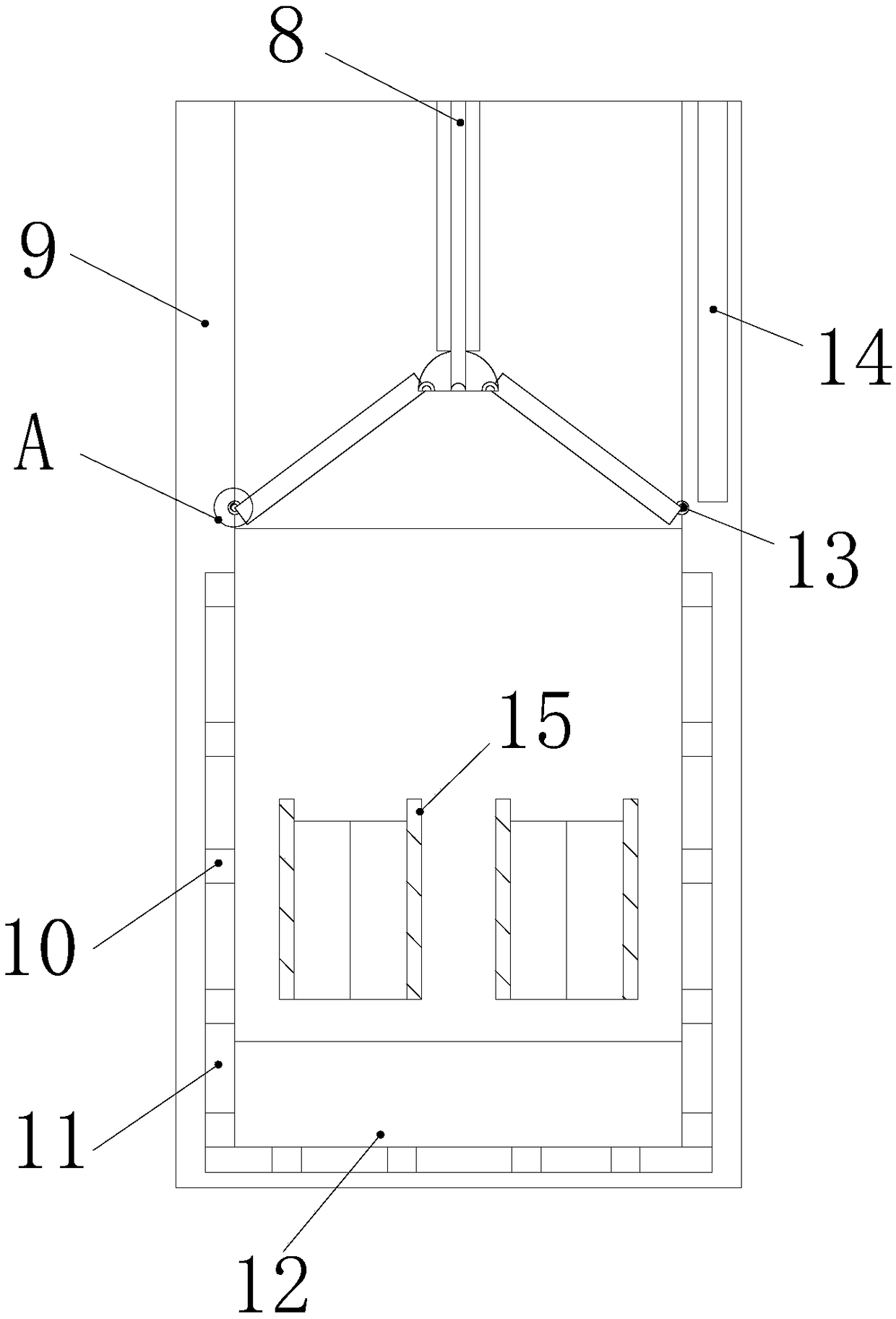

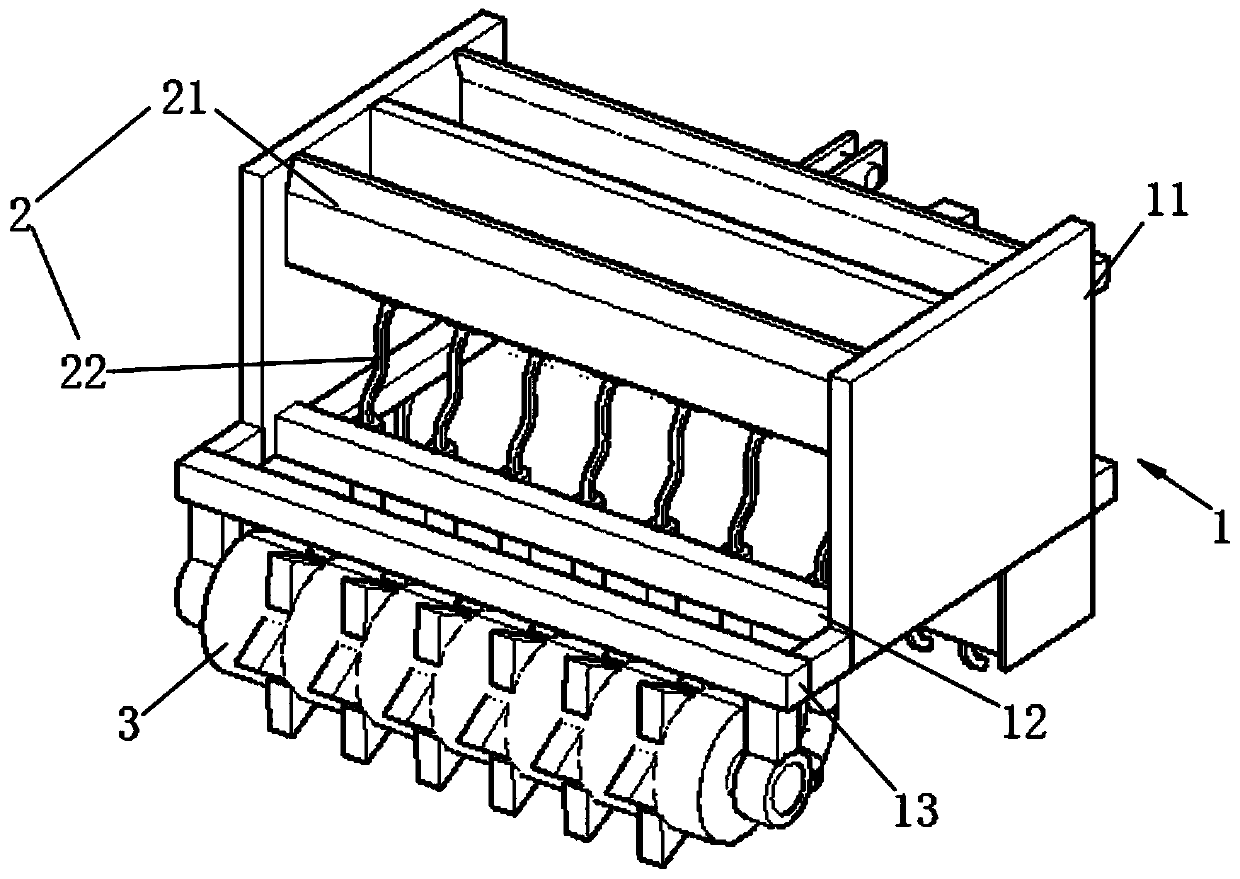

Disassemblable rolling mill stand

InactiveUS6904781B1Simple structureHigh strengthMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

Disassemblable rolling mill stand, of the type involving a bedplate structure with a substantially “U”-shaped embedding structure (1), within which the rolling mill assembly is embedded and fixed (2), with at least one couple of horizontal rolling cylinders (210–310), by fixing means (202-10 / 12), of said substantially “U”-shaped embedding structure, which extends upwards at least up to the upper horizontal cylinder axis of said couple of horizontal rolling cylinders (210–310) and makes up vertical sliding jointed guide elements (11–110) with corresponding opposite vertical counter-guides (201) in the rolling mill assembly (2).

Owner:SIMAC

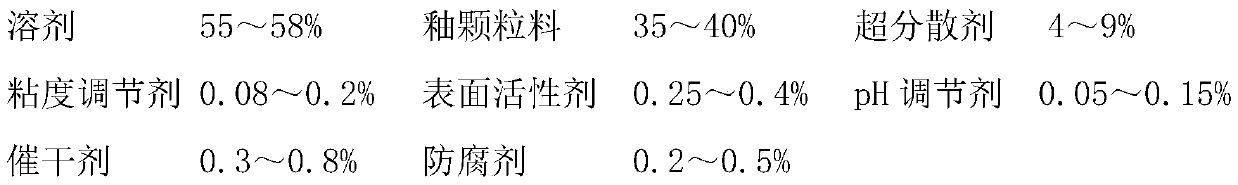

Waterborne wood enamel seal primer and preparation method thereof

InactiveCN107502109ANo cumulative effectHigh solidityFireproof paintsAntifouling/underwater paintsEmulsionUltraviolet absorption

The embodiment of the invention discloses a waterborne wood enamel seal primer and a preparation method thereof. The waterborne wood enamel seal primer is prepared from the following components in percentage by mass: 30 to 50 percent of waterborne nanometer enamel seal emulsion, 5 to 8 percent of waterborne nanometer flame-retardant dispersion slurry, 0.5 to 1 percent of waterborne nanometer silver dispersion slurry, 10 to 20 percent of waterborne polyurethane emulsion, 1 to 3 percent of a waterborne wetting dispersant, 5 to 10 percent of a lead-free filler, 1 to 3 percent of a penetrant, 0.5 to 1 percent of a solubilizing stabilizer, 0.3 to 0.5 percent of an ultraviolet absorption stabilizer, 0.2 to 0.5 percent of a mildew preventive, 0.5 to 2 percent of an anti-fouling agent, 1 to 3 percent of an amine neutralizer, 2 to 5 percent of an antifreezing agent, 0.5 to 2.5 percent of a coalescing agent and 10 to 25 percent of deionized water. The waterborne wood enamel seal primer has excellent properties such as water resistance, early compression resistance, reinforcement expansion resistance and sanding property; the burning of wood products can be effectively prevented and reduced; and the waterborne wood enamel seal primer has active mildew-resisting and antibacterial properties.

Owner:珠海市盟友化工有限公司

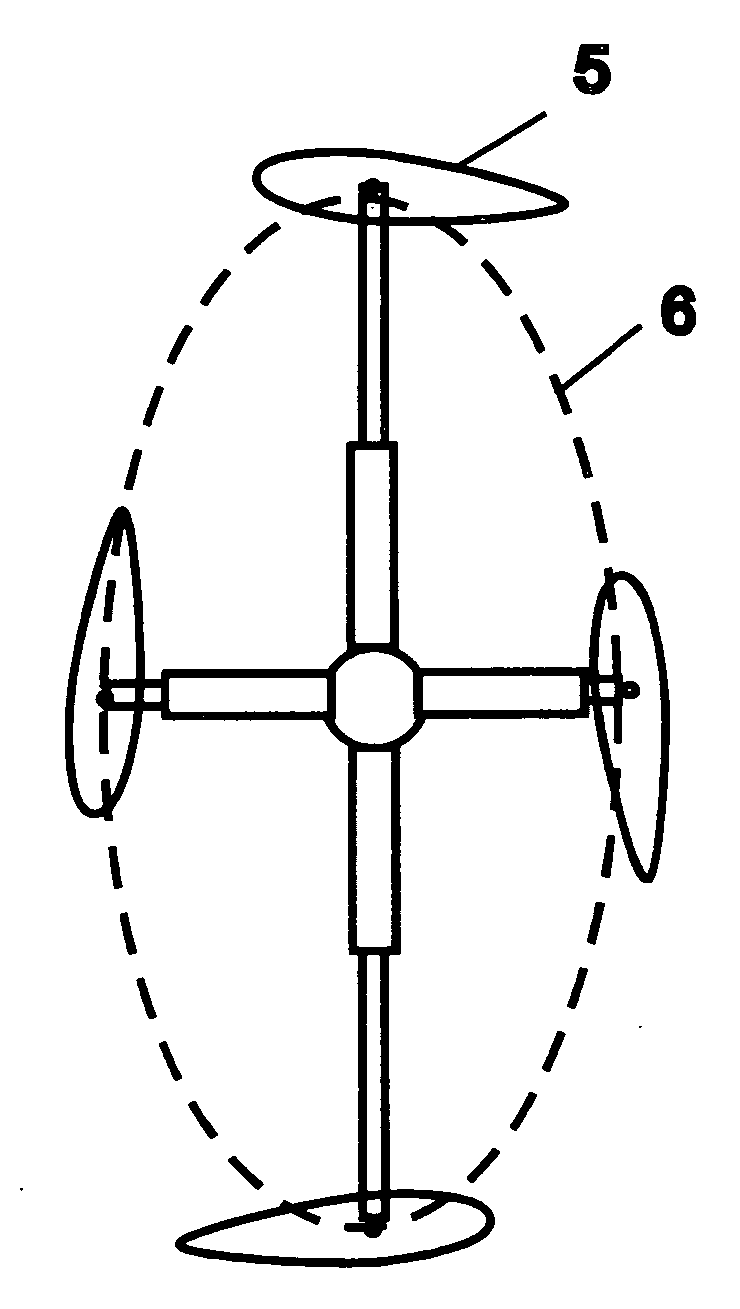

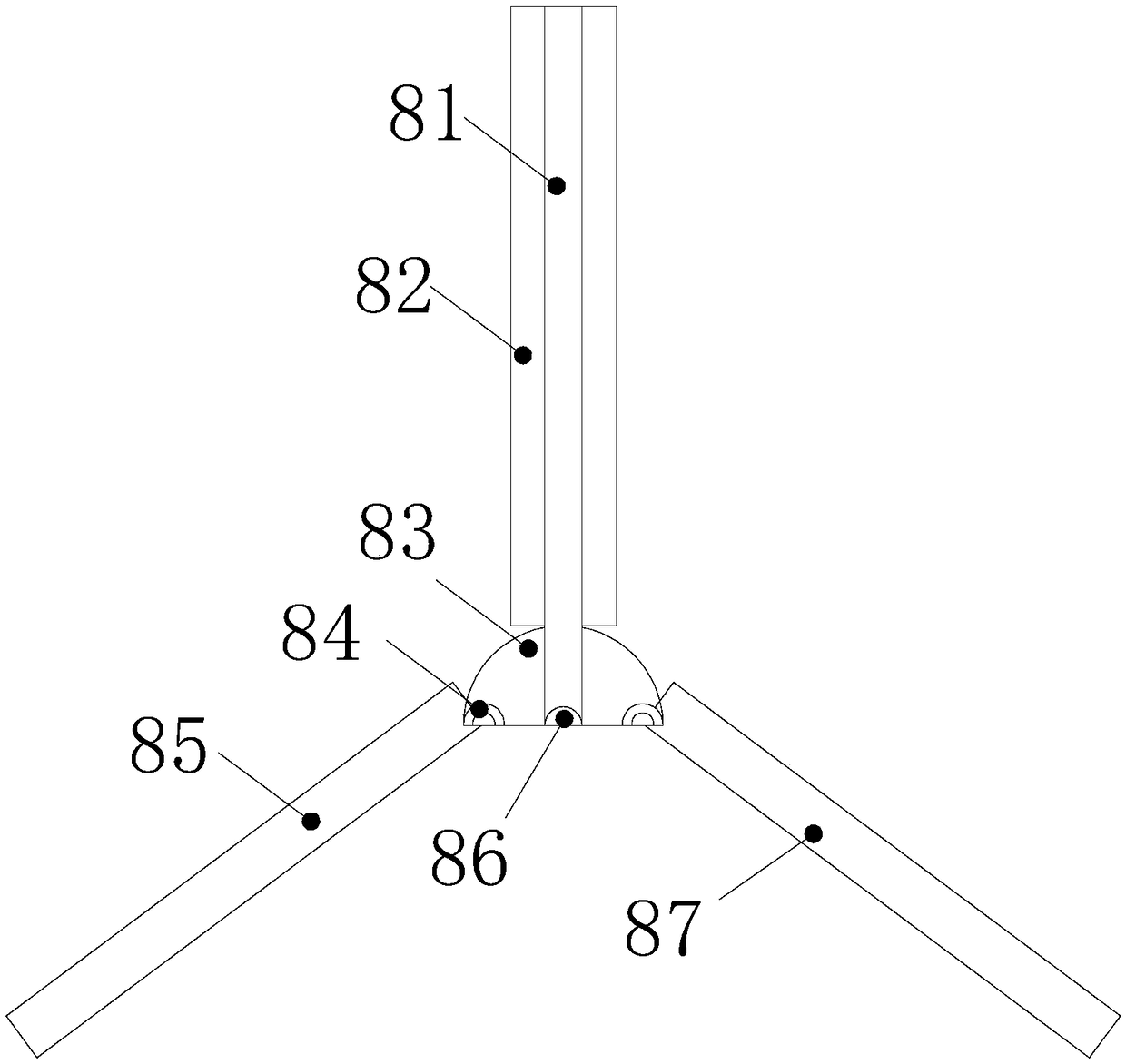

Setover-type vertical-shaft wind machine capable of limiting rotating of blades

InactiveCN102926926AImprove wind wheel solidityImprove wind energy utilization factorRenewable energy generationMachines/enginesWind forceGenerating capacity

The invention discloses a setover-type vertical-shaft wind machine capable of limiting rotating of blades, which comprises a tower frame and a wind wheel, wherein the wind wheel comprises a main shaft, lightweight blades, blade shaft brackets and blade shafts; the main shaft is mounted on the tower frame vertically, and can rotate freely; the blade shaft brackets are uniformly fixed on the main shaft radially; the blade shafts are vertically mounted at the both ends of the blade shaft brackets respectively; and the lightweight blades are fixedly mounted on the blade shafts, so that the lightweight blades can revolve relative to the blade shaft brackets, and the angle of revolution is 0-90 degrees. According to the wind machine, the solidity of the wind wheel is high; the wind blocking areas of the lightweight blades are increased; the solidity of the wind wheel is improved; the utilization factor of the wind energy is large; the rotating torque is increased; and power generating capacity is high. The wind wheel is small in starting wind speed; breeze power generating capacity is strong; the starting wind speed is low; when the resistance and the friction of a power generator are ignored, the starting wind speed is lower than 1m / s; the wind machine is suitable for wide regions; and the operating time proportion is high.

Owner:CHONGQING UNIV OF TECH

Aseismic joint

InactiveUS20080229682A1Simple and cheap constructionHigh solidityCouplings for rigid shaftsBridge structural detailsEngineeringMechanical engineering

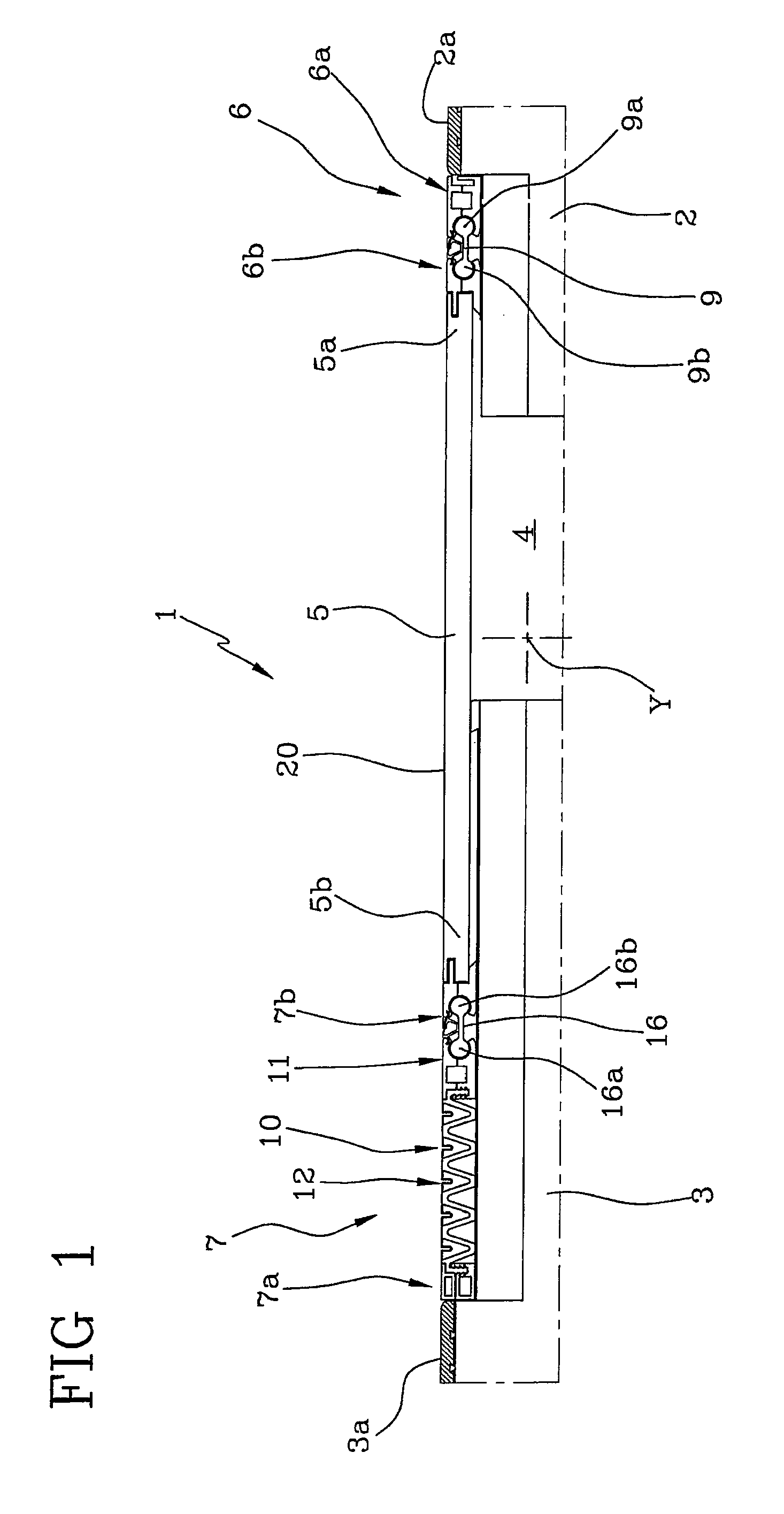

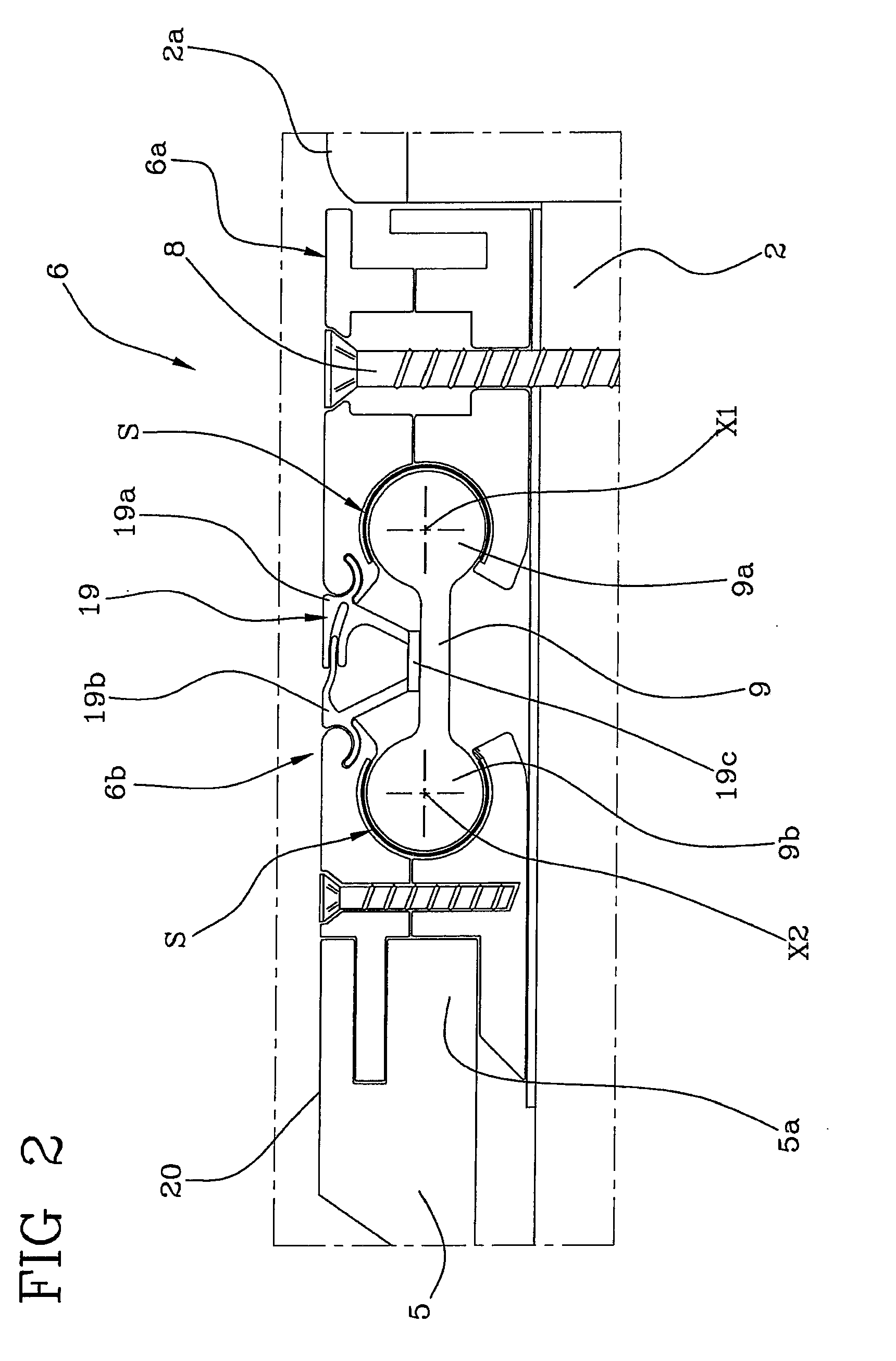

A seismic joint, for covering a gap (4) defined between a first (2) and a second (3) structural element, comprises: a first anchoring portion (6a) to be steadily associated with the first structural element (2); a first interconnecting portion (6b) rotatably connected to the first anchoring portion (6a); a covering element (5) having a first end (5a) rotatably in engagement with the interconnecting element (6b) and a second end (5b) able to be engaged in a slidably supported relationship on the second structural element (3).

Owner:KIVATEC

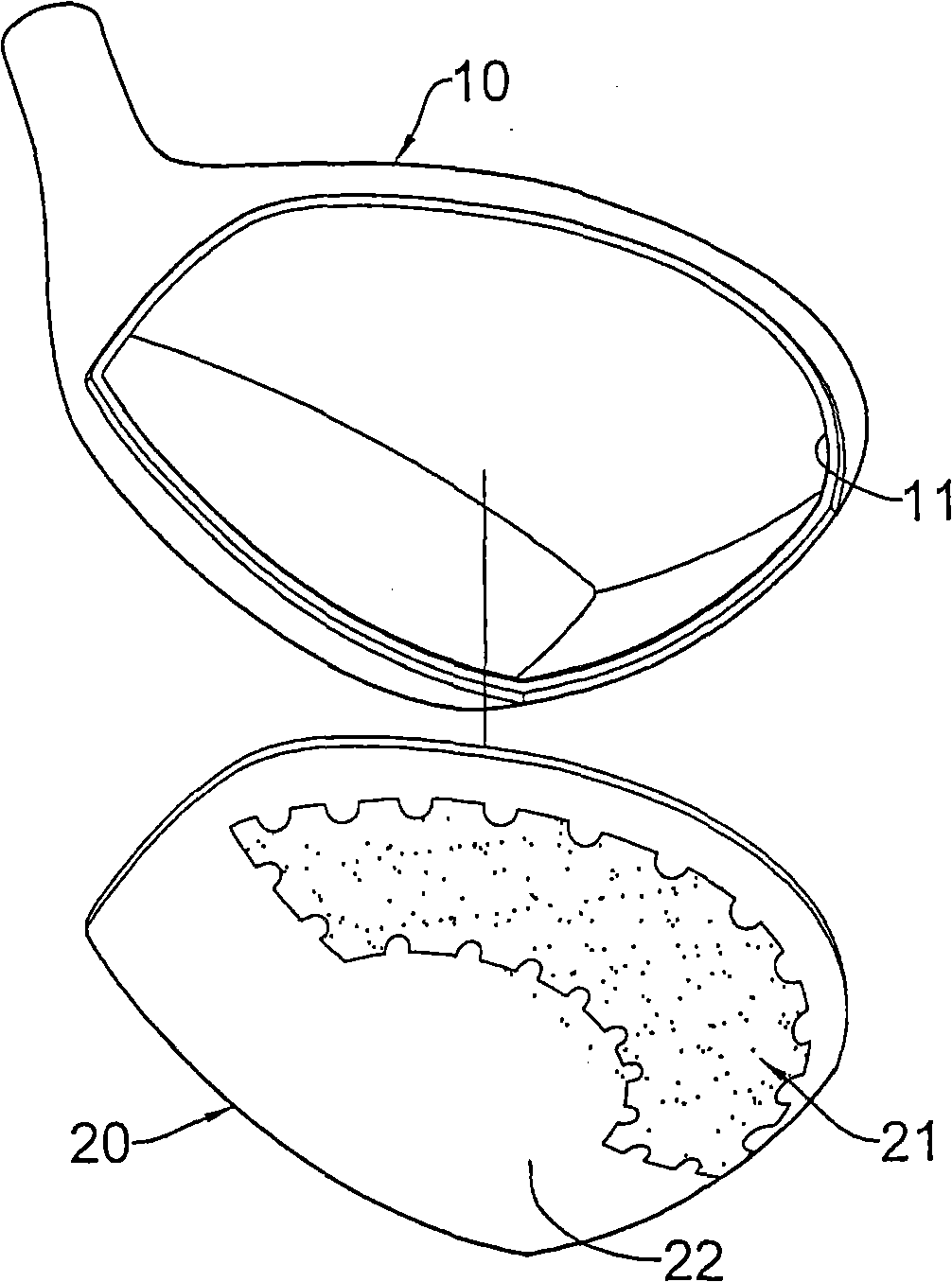

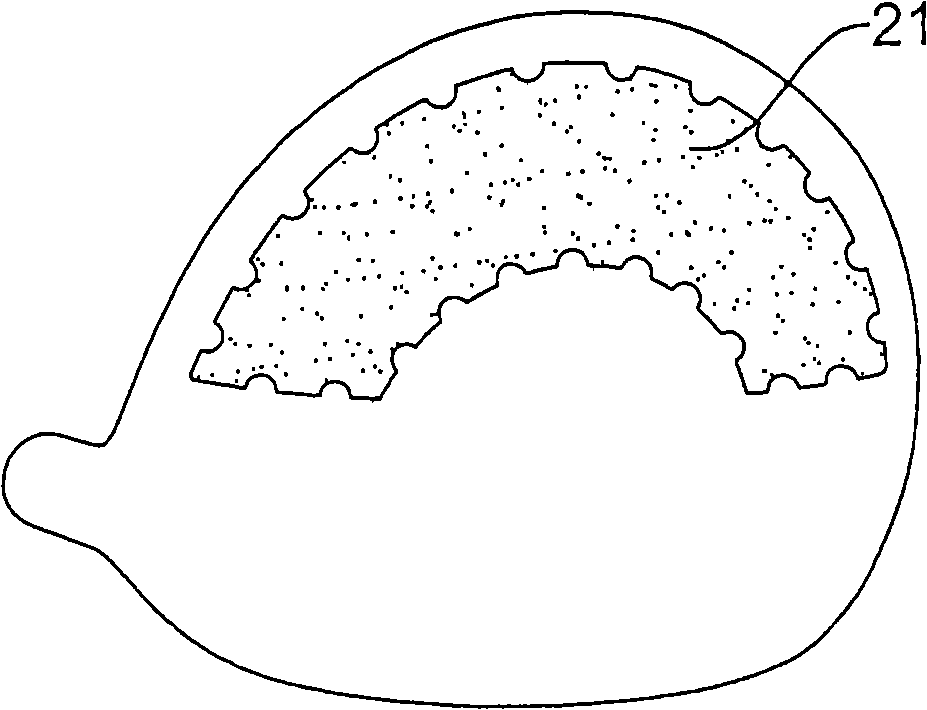

Golf head easy to weld counterweight device and production method thereof

InactiveCN101357263AIncrease natural colorReduce manufacturing costGolf clubsRacket sportsResonanceGravity center

The invention discloses a golf head which is easily welded with a counterweight device and a manufacturing method thereof. The golf head comprises a golf head body, the bottom of which is provided with a welding port and a dual-gravity counterweight plate body which is welded to the welding port. The dual-gravity counterweight plate body comprises a high-gravity alloy part and a metal part which is arranged at the periphery of the high-gravity alloy part and is made from the same metal material as the golf head body. The dual-gravity counterweight plate body is welded to the welding port of the golf head body, and the welding port is ground to form the golf head, the bottom of which is provide with the high-gravity alloy part. The gravity and weight are averagely distributed on the area of the bottom of the golf head under the condition that the thickness of the golf head is not changed, so the effect of lower center of gravity and better counterweight can be achieved, silvery resonance is produced when the golf is played by the arm, and thus greatly improving stability and solidity of playing the golf.

Owner:SUPER WAY TECH

A preparation method of high-density wc-wb-co spherical powder hard surface material

ActiveCN109266939BIncreased microhardnessImprove corrosion resistanceTransportation and packagingMetal-working apparatusPhysical chemistryWear resistance

A high-density WC-WB-Co spherical powder hard surface material of the present invention and its preparation method, its formula ratio is calculated by mass percentage: WC powder 50%-75%; WB powder 15%-38%; Co powder 8% %‑12%; PEG binder 1.0%‑4.0%. Beneficial effects: WB is introduced into the material system design, because WB will react with metal phase Co to form ternary phase CoWB during the powder sintering process, and CoWB has higher microhardness and better corrosion resistance than WC, Therefore, the addition of WB can significantly improve the wear resistance and corrosion resistance of the material, increase the microhardness HV0. The powder is rapidly heated and melted, and the melted powder particles are solidified into a spherical shape in a very short time under the action of surface tension, which can greatly improve the sphericity and solidity of a single powder, and make the bulk density of the final powder product reach 7.5g / cm3 or more , The powder flow rate is less than 10s / 50g, and the porosity of the coating is less than 0.5%.

Owner:株洲江钨博大硬面材料有限公司

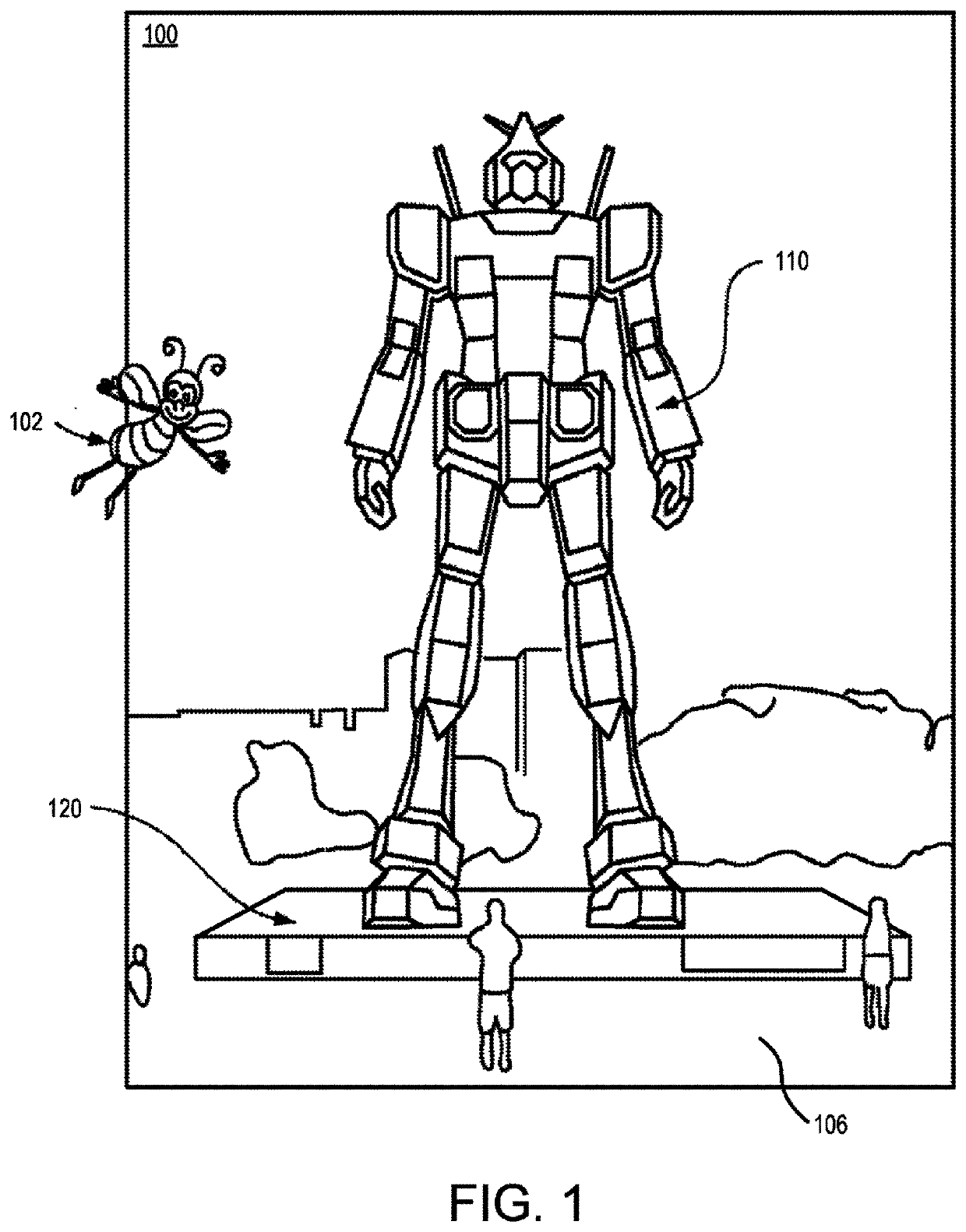

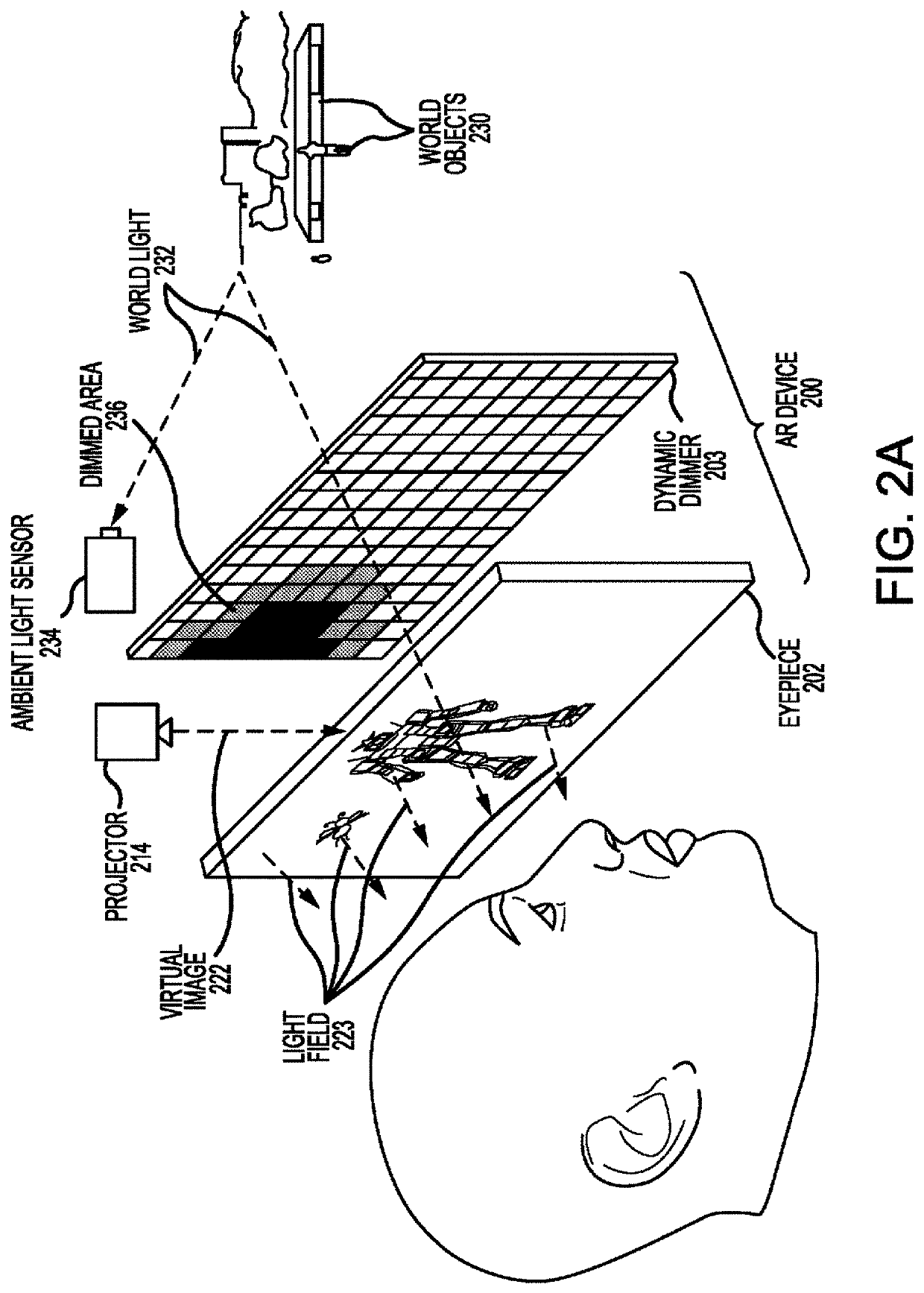

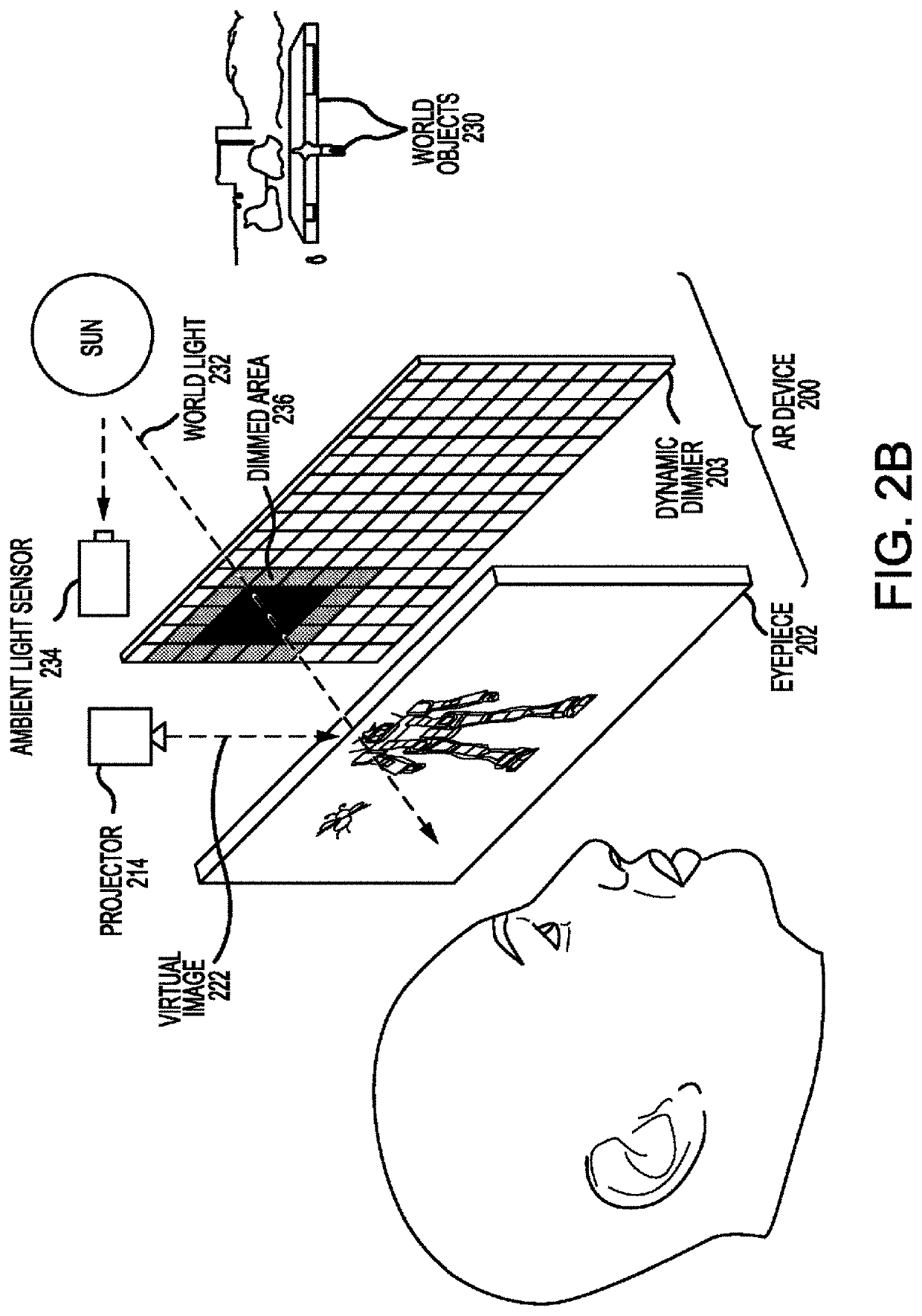

Ghost Image Mitigation in See-Through Displays With Pixel Arrays

ActiveUS20210048676A1Mitigate vergence accommodation conflictExtend battery lifeNon-optical adjunctsNon-linear opticsEyepieceSee-through display

A head-mounted apparatus include an eyepiece that include a variable dimming assembly and a frame mounting the eyepiece so that a user side of the eyepiece faces a towards a user and a world side of the eyepiece opposite the first side faces away from the user. The dynamic dimming assembly selectively modulates an intensity of light transmitted parallel to an optical axis from the world side to the user side during operation. The dynamic dimming assembly includes a variable birefringence cell having multiple pixels each having an independently variable birefringence, a first linear polarizer arranged on the user side of the variable birefringence cell, the first linear polarizer being configured to transmit light propagating parallel to the optical axis linearly polarized along a pass axis of the first linear polarizer orthogonal to the optical axis, a quarter wave plate arranged between the variable birefringence cell and the first linear polarizer, a fast axis of the quarter wave plate being arranged relative to the pass axis of the first linear polarizer to transform linearly polarized light transmitted by the first linear polarizer into circularly polarized light, and a second linear polarizer on the world side of the variable birefringence cell.

Owner:MAGIC LEAP

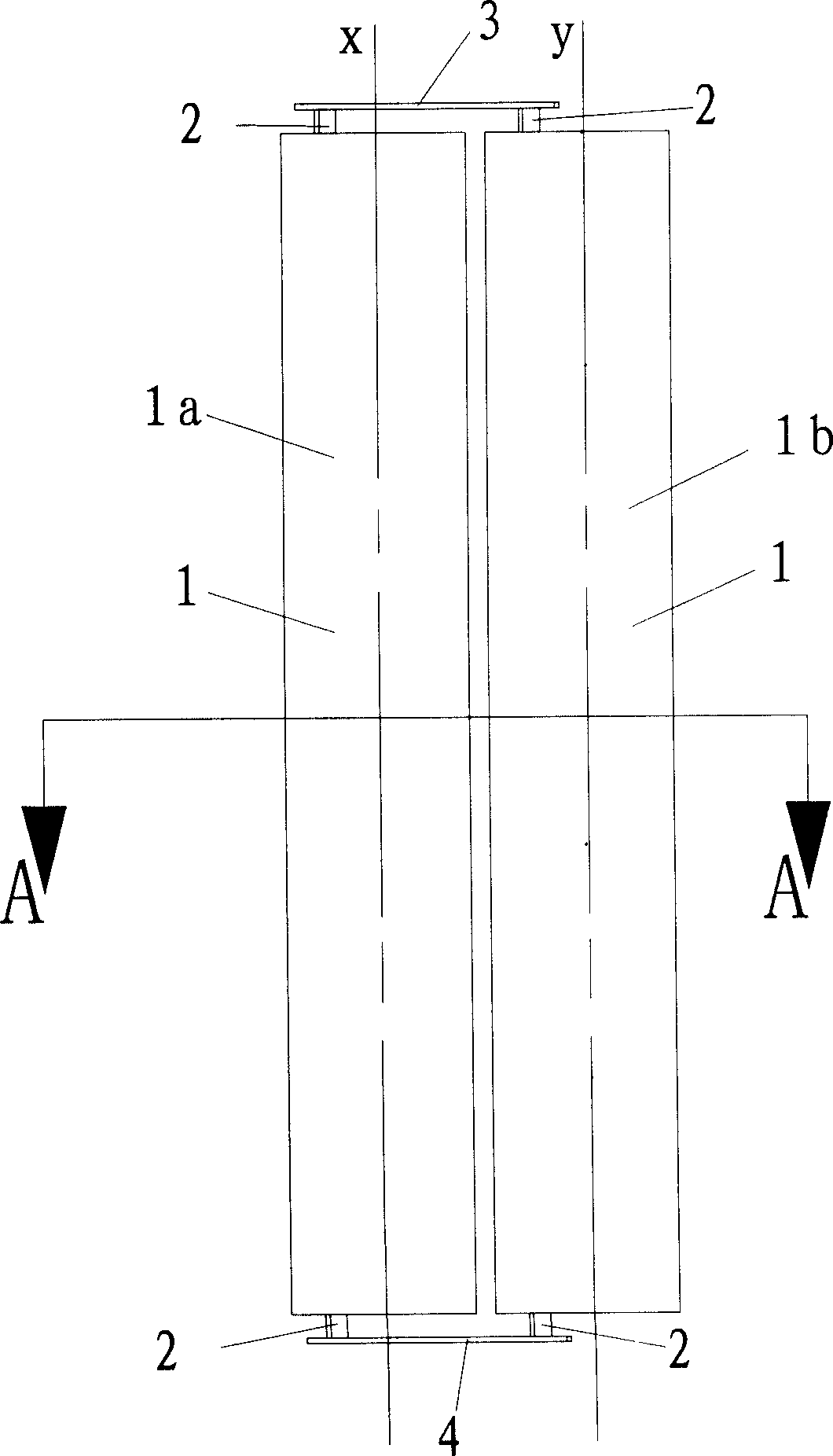

Impeller of power device utilizing wind energy

The invention discloses a blade of wind-energy dynamic device, which comprises at least two blades. The abdominal region of one blade of adjacent blades faces the back of the others and the heads of adjacent blades are at one direction. One end of blade connects the upper beam through the shaft and the other end connects the lower beam through the shaft. At least two blades and upper and lower beam constitute a blade unit. The invention can increase or enlarge elevating force of blade, which improves the wind-power utility efficiency.

Owner:FLY RENEWABLE ENERGY TECH

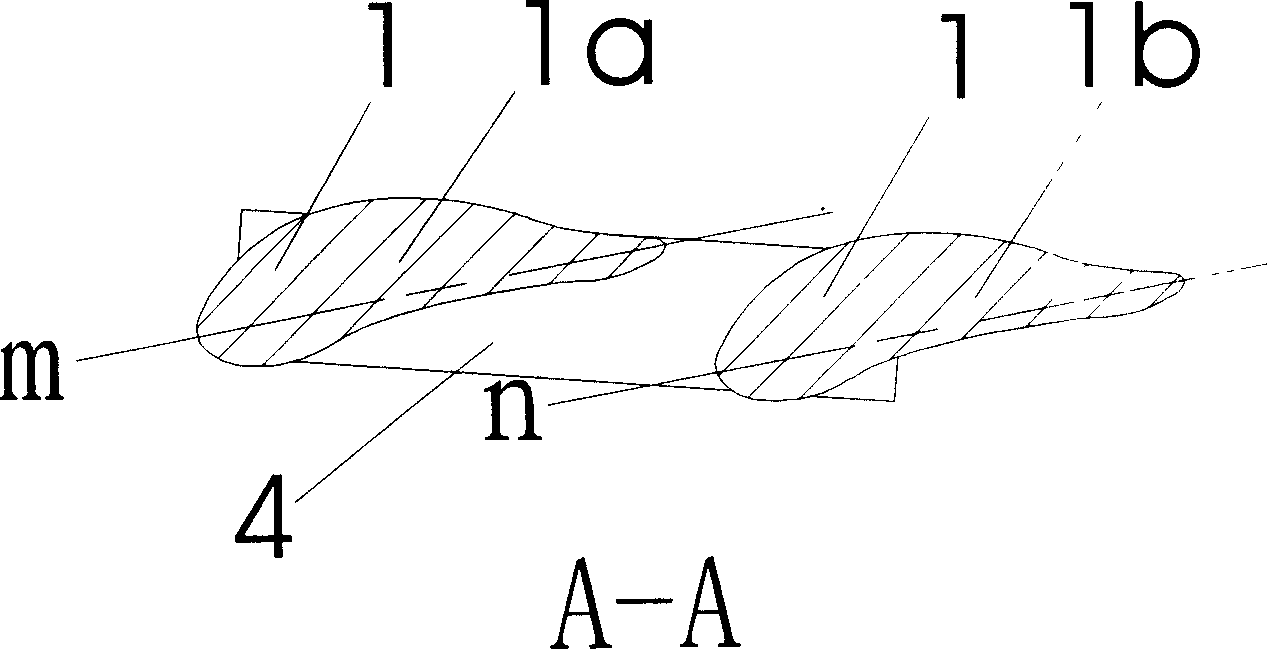

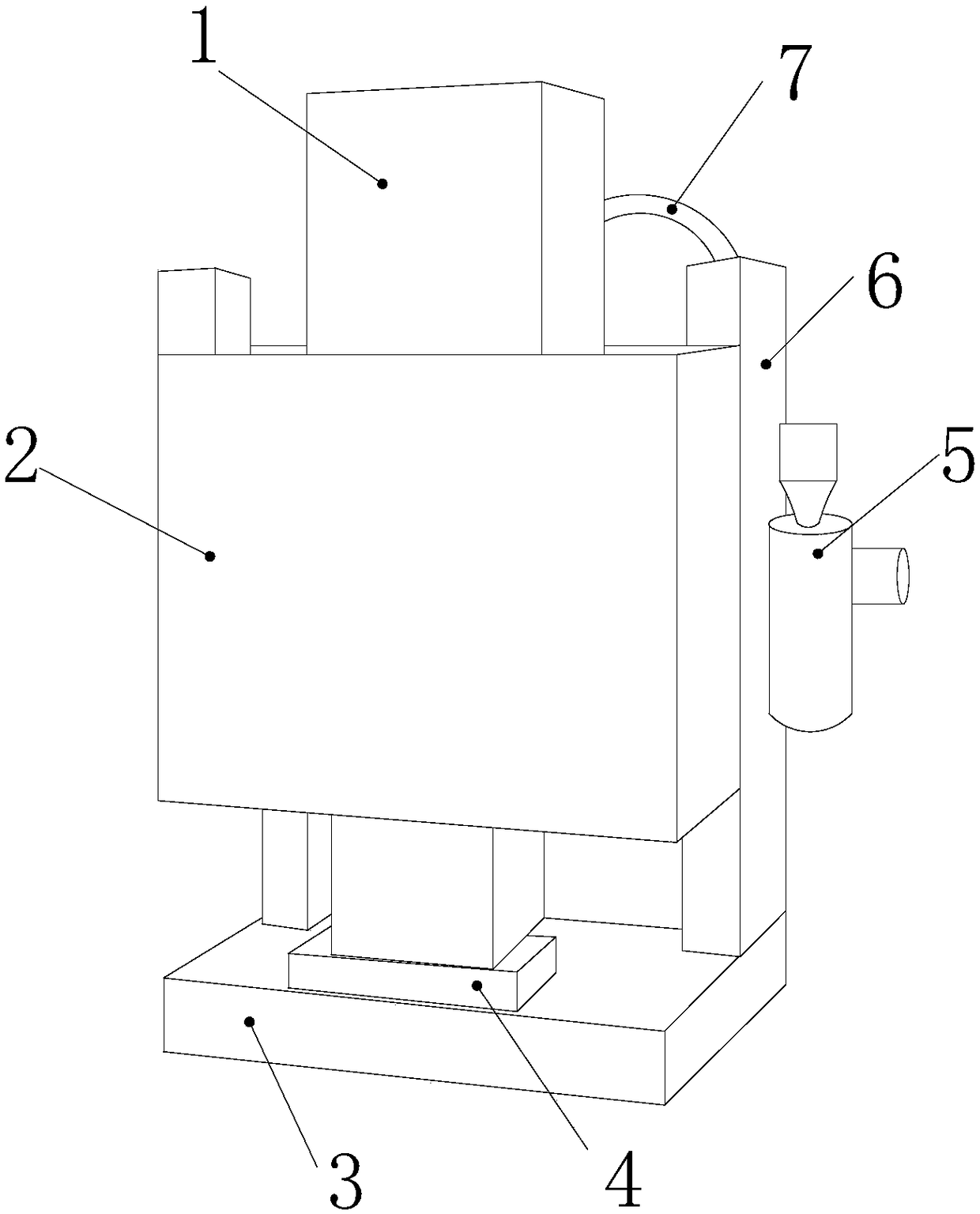

Injection moulding water conservancy equipment achieving negative pressure suction and tiling pressurization

ActiveCN108890854AWill not open in both directionsReduce wearFeeding arrangmentsAuxillary shaping apparatusFixed frameEngineering

The invention discloses an injection moulding water conservancy equipment achieving negative pressure suction and tiling pressurization. The injection moulding water conservancy equipment structurallycomprises a formwork, a fixed frame, a lower steel plate, a bearing plate, a negative pressure pump, a welding column, an air guide pipe, a three-fork pressurizing structure, an interlayer plate, anair suction opening, an adhering net, an inner formwork, a clamping mechanism, an air guide column and a one-way valve. According to the injection moulding water conservancy equipment, after injectionis carried out on the equipment, pressure is increased, a connecting handle is pressed through a compacting column, a first compacting plate and a second compacting plate are expanded downwards to beattached to the top of a cement layer till the first compacting plate and the second compacting plate are kept horizontal, and the first compacting plate and the second clamping plate are clamped byan inner roller and cannot be bent towards the inner side through the resisting function of a clenching sheet, a surrounding spring and a pressing block; cement is pressed through pressure exerted again, and the compaction degree of the cement is increased; after pressing is carried out, the negative pressure pump is started, air in the interlayer plate is sucked away, air attached to a pluralityof air suction opening ends on the adhering net is sucked, the air suction opening is communicated with the cement end, bubbles and air in the cement are sucked away, and clearances between the cementbecome small.

Owner:合肥蓝川生态科技有限公司

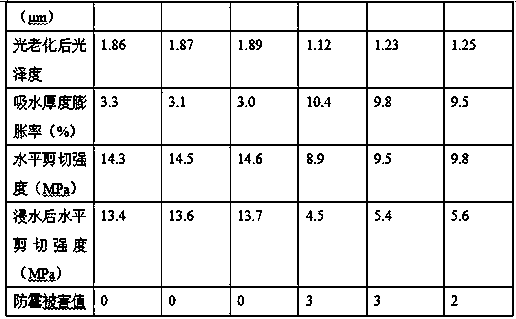

Preparation method of long-acting weather-proof type recombinant bamboo

ActiveCN109986674AImprove light aging resistanceImproved anti-mold and anti-corrosion effectWood treatment detailsCane mechanical workingPotassium permanganateCorrosion

The invention discloses a preparation method of long-acting weather-proof type recombinant bamboos, and belongs to the technical field of furniture material preparation. According to the preparation method of the long-acting weather-proof type recombinant bamboos, pretreated bamboo skin fiber bundles are firstly soaked by using absolute ethanol, hydroxylation modifying is conducted on the pretreated bamboo skin fiber bundles to obtain polyhydroxy bamboo skin fiber bundles, then the pretreated fiber bundles are oxidized by using a potassium permanganate solution, thus gydroxyl groups on the surface of the fiber bundles are oxidized to carboxyl groups, the oxidized fiber bundles, zinc nitrate, iron nitrate and tetrabutyltitanate are mixed to react, nano-titanium oxide and zinc oxide have ultraviolet shielding properties, the light aging resistance and the mildew and corrosion resistance of the recombinant bamboos are improved, metal oxide particles are formed by in-situ chelation and arenot prone to being scratched and lost, the recombinant bamboos can be protected for a long time, the modified bamboo fiber bundles are used as raw materials to conduct in-situ condensation sizing with phenolic material emodin and furfural, a thermosetting furfural resin adhesive and the modified bamboo fiber bundles are obtained to be cross-linked and mixed, because the formaldehyde content of furfural resin is lowered, and the recombinant bamboos are made without formaldehyde.

Owner:福建省九竹工贸有限公司

Position adjustment mechanism

Owner:HALSTEAD ROGER GEOFFREY

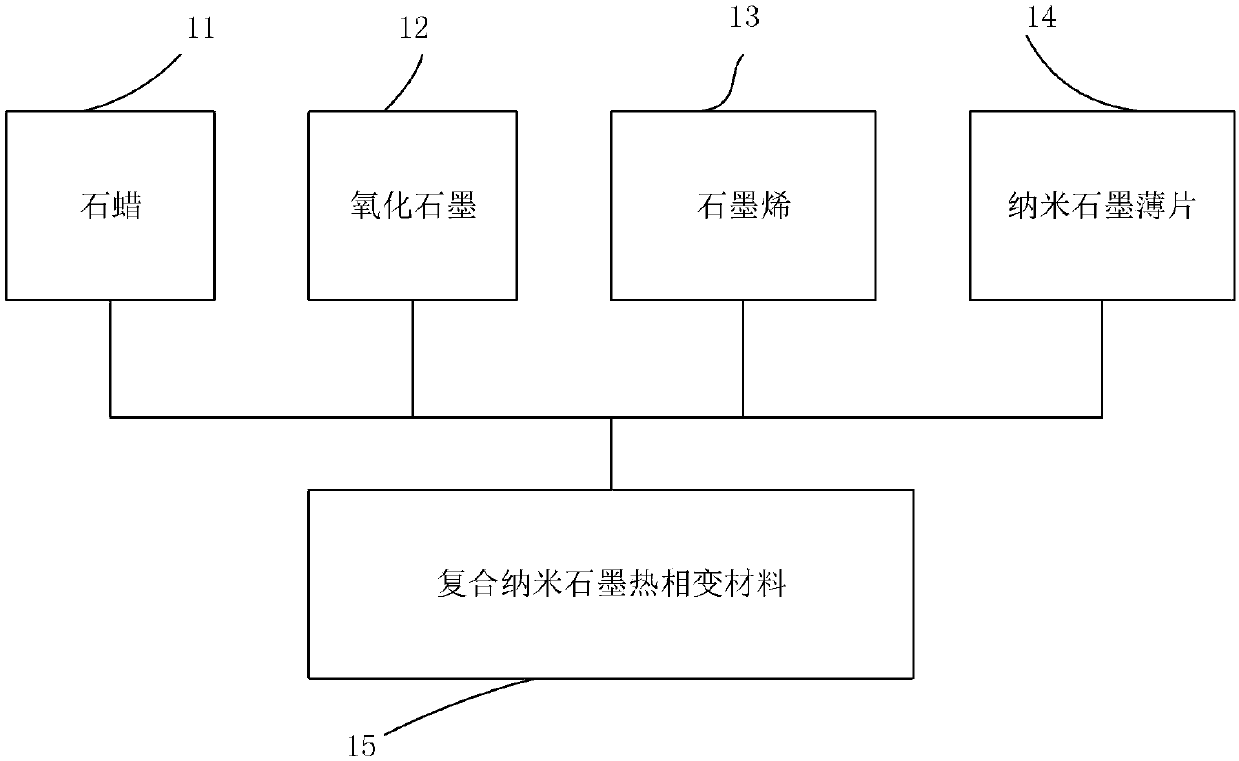

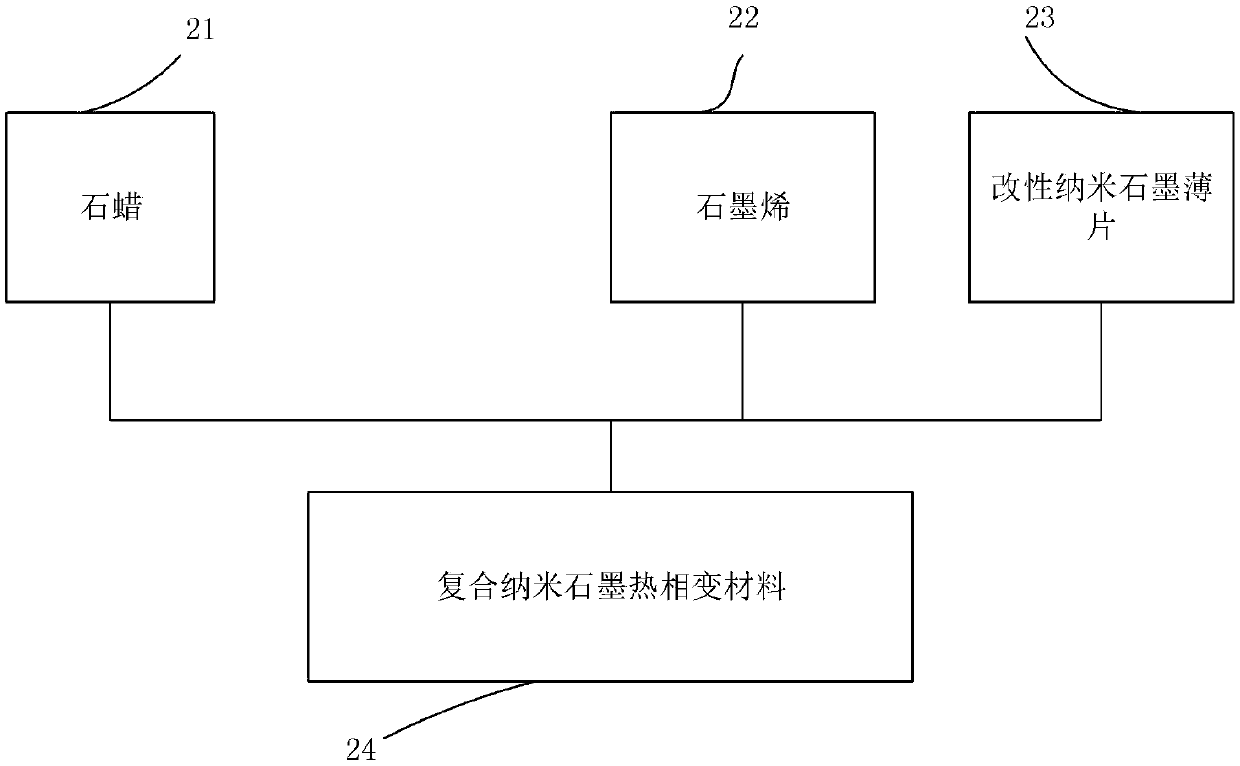

Graphene preparation method

InactiveCN109835887AImprove thermal conductivityHigh solidityGrapheneHeat-exchange elementsGraphite oxideHydrochloric acid

The invention discloses a graphene preparation method, which comprises: adding 5 g of natural graphite powder to a mixed solution of sulfuric acid and nitric acid, uniformly stirring, and slowly adding 55 g of potassium chlorate; stirring the mixed solution for 96 h at a room temperature, repeatedly adding a 5% hydrochloric acid solution, carrying out centrifugation until no sulfate ion exists inthe solution, diluting with a large amount of deionized water, and carrying out centrifugation until the pH value of the filtrate is neutral; filtering the neutral solution with filtering paper havinga pore size of 0.5 [mu]m, baking for 24 h at a temperature of 80 DEG C, taking out, and grinding by an agate mortar to obtain graphite oxide powder; and placing the prepared graphite oxide in a tubular high-temperature furnace, vacuumizing for 5 min, introducing argon gas for 30 min to prevent the influence of external air on the process, heating to a temperature of 1100 DEG C at a heating rate of 60 DEG C / min, maintaining the temperature for 1 h, continuously introducing argon gas at a flow rate of 100 sccm during the heating, introducing hydrogen gas at a flow rate of 20 sccm to increase the reduction effect, and thermally stripping the oxidizable graphite to obtain graphene.

Owner:太仓斯迪克新材料科技有限公司

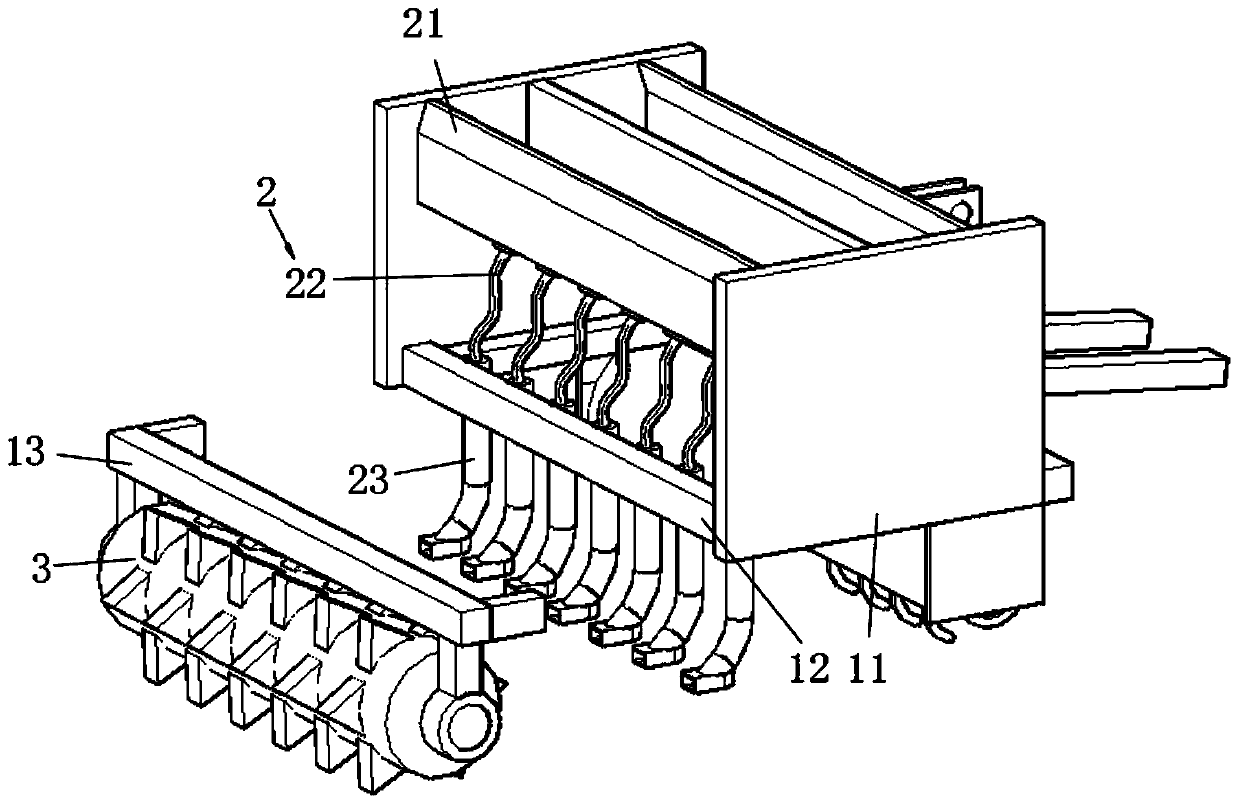

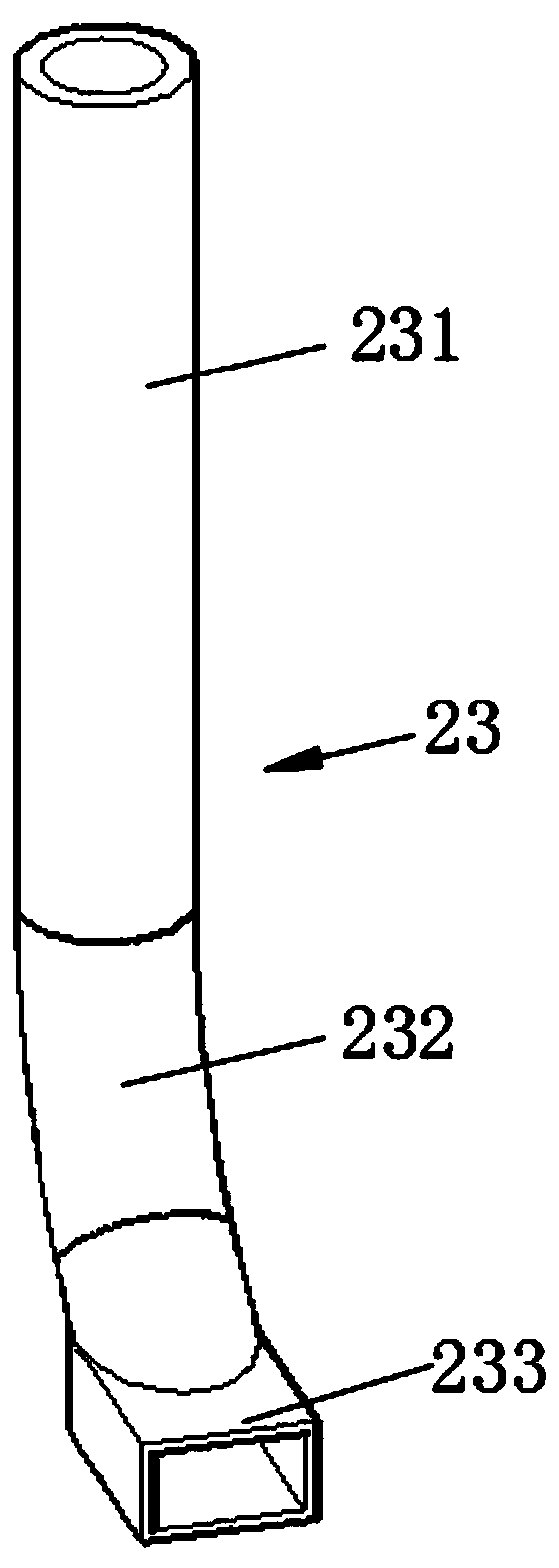

Seeding device and seeding pipe

InactiveCN110583171AGuaranteed cleanlinessLabor savingHollow article cleaningSeed depositing seeder partsAgricultural engineering

The invention discloses a seeding device and a seeding pipe. The seeding device comprises a rack and a seeding assembly, wherein the seeding assembly is fixedly connected to the rack; the seeding assembly comprises a seeding tank, a connecting pipe and the seeding pipe; the seeding tank is fixed to the top of the rack; the seeding pipe is connected to the bottom of the seeding tank through the connecting pipe. The seeding pipe comprises a first pipe section, a second pipe section and a seeding box with an opening facing the rear side of the seeding direction. The first pipe section is connected to the bottom of the seeding assembly; the top of the second pipe section is fixedly communicated with the bottom of the first pipe section; the bottom of the second pipe section is inclined towardsthe rear side of the seeding direction, and the bottom of the second pipe section is communicated with the seeding box. The two side walls of the seeding box are straight, and the distance between the two side walls is equal to the diameter of the second pipe section. The seeding pipe is contaminated by less soil and fewer weeds, and the seeding pipe is convenient to clean.

Owner:ANHUI DENGSHI MACHINERY MFG +1

Edge Flashing For Flat Roof With Functional Surface Material

ActiveUS20200325686A1High solidityIncreased longevityRoof coveringStructural engineeringMechanical engineering

Owner:ANTHONY ELI

Polypeptide essence with multi-directional brightening effect and preparation technology thereof

InactiveCN110575430AIncrease vitalityIncrease brightnessCosmetic preparationsToilet preparationsBiotechnologyBenzoic acid

The invention discloses a polypeptide essence with the multi-directional brightening effect and a preparation technology thereof. The polypeptide essenceis prepared from the following components ofthecompound of aloe vera extract, carnosine, fermented product extract of pseudoalteromonas, stem extract of dendrobium stem, radix sophorae extract, Ningxia wolfberry fruit extract, and purple coneflowerextract, the compound of reed extract, licorice root extract, angelica root extract, salvia miltiorrhizaroot extract, cornus officinalisfruit extract, andboxthorn rootextract, the compound ofpseudo-ginsengroot extract, astragalus membranaceus root extract, and ligustrumx vicaryiextract,terminalia ferdinandianafruit extract,dihydrooatyl anthranilic acid,moisturizer,and skin conditioner. Accordingto the polypeptide essence,the problem of dark yellow skin is improved from multiple aspects, simultaneously the aloe extract is used for replacing production water, preparation is conducted by a cold preparingmethod, andefficacy and integrity of the active ingredients of the extracts are exerted to the greatest extent.

Owner:奢脉国际化妆品(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com