Thin ceramic rock plate and preparation method thereof

A ceramic and thin technology, applied in the field of thin ceramic slate and its preparation, can solve the problems of low green strength, poor toughness of finished products, deformation of thin plates, etc., to achieve uniform particle size, reduce power consumption, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with embodiment:

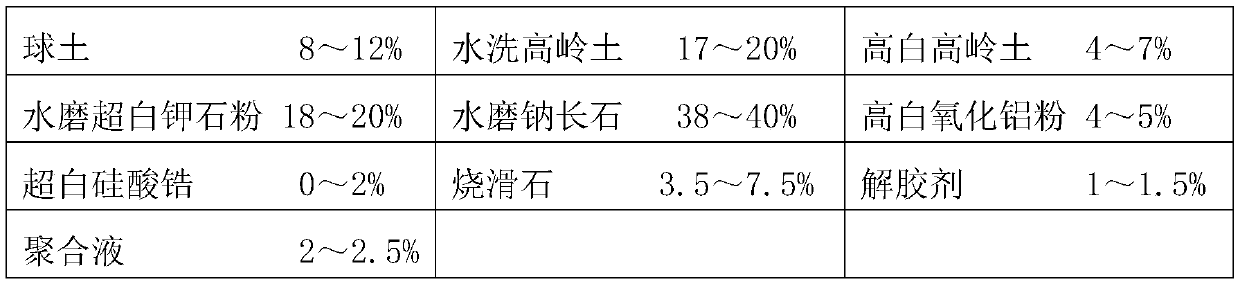

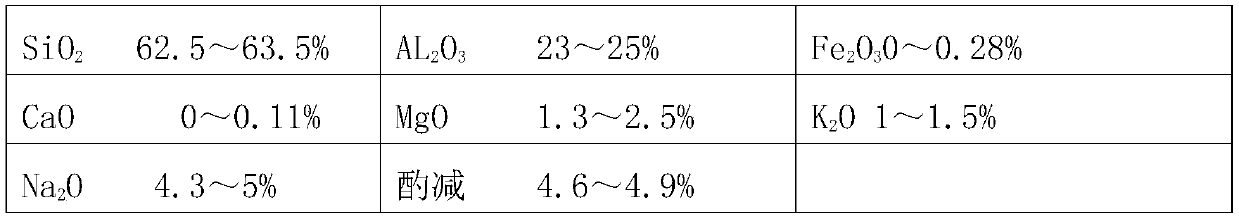

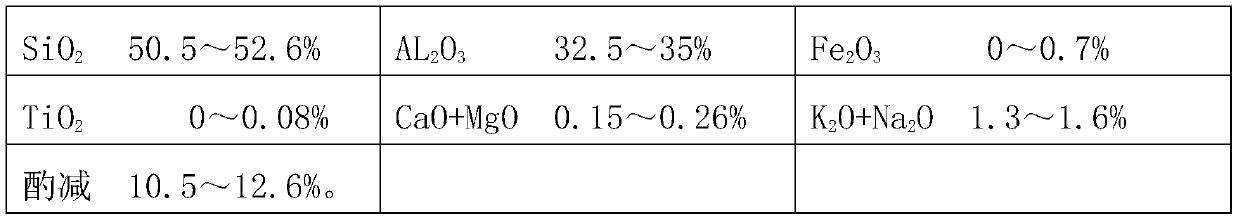

[0056] The thin ceramic rock slab, the thin ceramic rock slab blank consists of the following weight percentages:

[0057]

[0058] Among them: the aluminum content of spherical clay is 39%, the iron content is 0.1%, the aluminum content of washed kaolin is 41%, and the iron content is 0.05%; the specific surface area of high white kaolin is 28m 2 / g, particle size distribution D9019.2μm, whiteness 85°, LAB value: L: 94.8, A: 1.1, B: 5.6; water-milled ultra-white potassium stone powder iron content 0.1%, water-milled albite iron content 0.08%; The aluminum content of high-white alumina powder is 99.33%, the iron content is 0.03%, and the particle size distribution is D9010.8μm; the debonding agent is a mixture of sodium tripolyphosphate, sodium hexametaphosphate, sodium humate, and sodium polyacrylate; The polymerization liquid is a mixed liquid of modified lignin, po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com