Ceramic rock plate and preparation method thereof

A technology of ceramics and slabs, applied in the field of ceramic slabs and its preparation, can solve the problems of low body strength, high product brittleness, poor plasticity, etc., achieve uniform particle size, good plasticity, and reduce power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with embodiment:

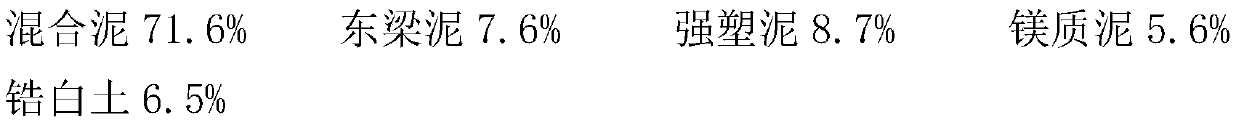

[0056] The ceramic rock slab body consists of the following weight percentages:

[0057]

[0058] In the present embodiment, the mud is further composed of the following weight percentages:

[0059]

[0060] Among them: the plasticity index Ip>16 of super plastic clay.

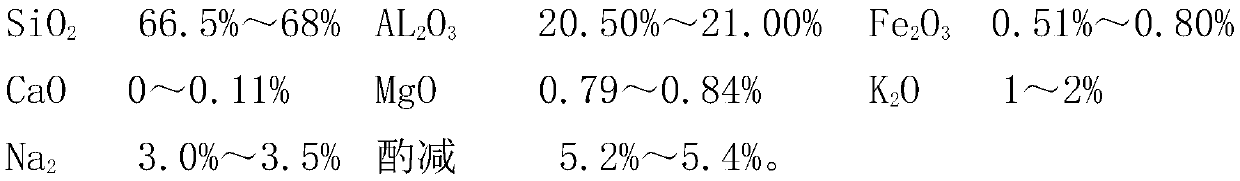

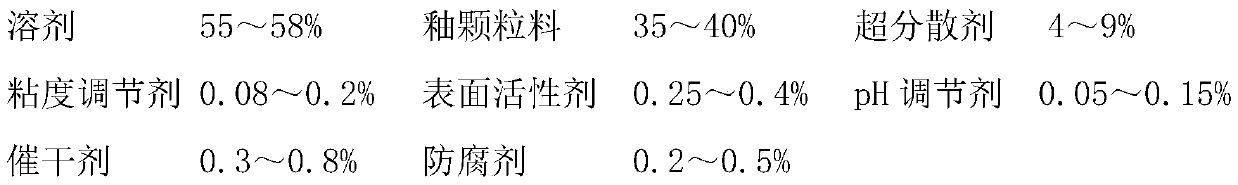

[0061] In the present embodiment, the water abrasive further consists of the following weight percentages:

[0062]

[0063] Wherein: the water-washed potassium-sodium stone particles are obtained after the potassium-sodium feldspar is subjected to ball milling, water washing, and iron removal processes, and the potassium-sodium feldspar is a feldspar mixture composed of K, Na, and Ca alkali metal compounds; the mortar The recovered material is water mill tailings with a fineness of 200 mesh.

[0064] In this embodiment, the additives include a reinforcing agent and a debonding agent; the reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com