Patents

Literature

253results about How to "Easy to dismantle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

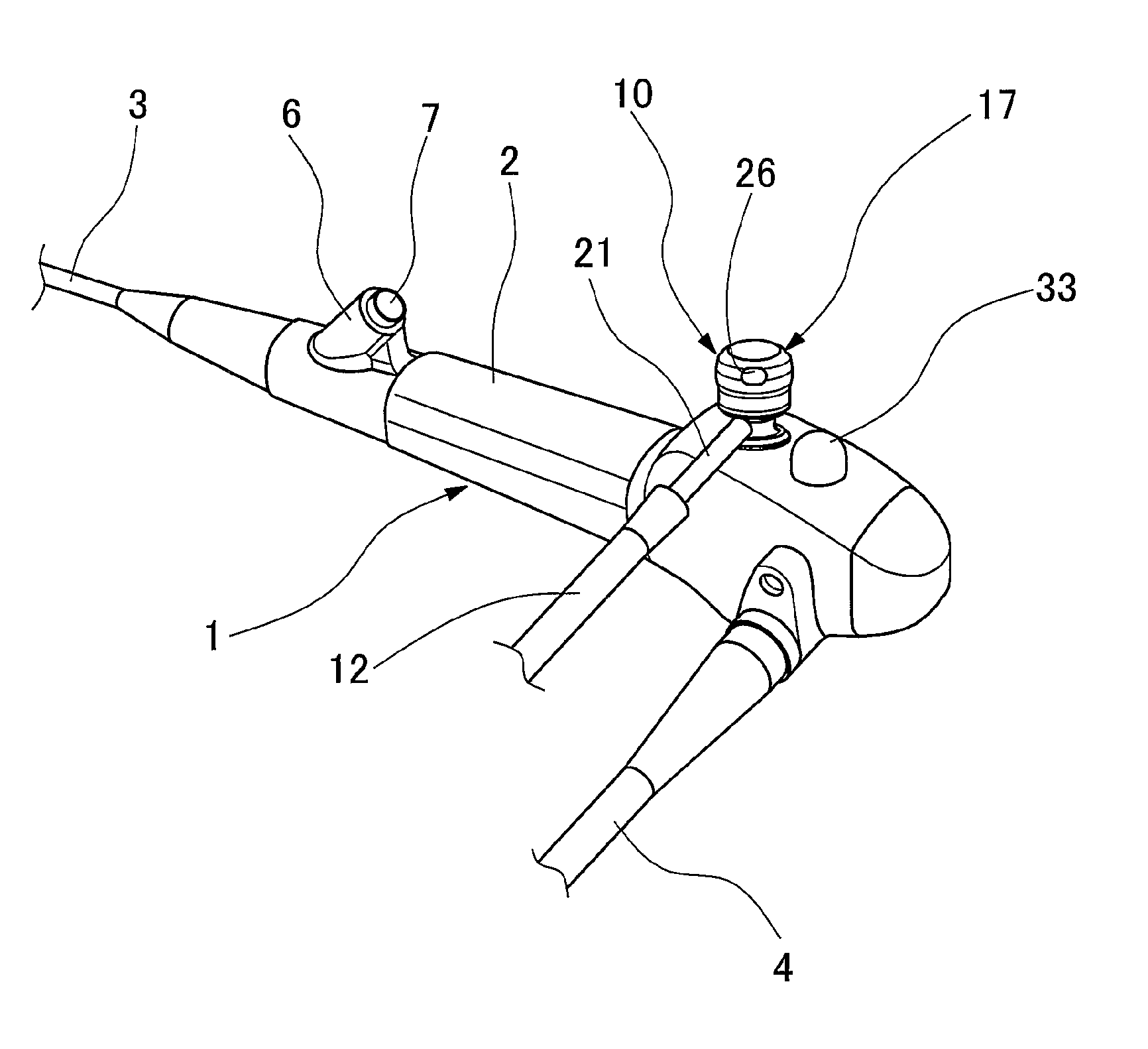

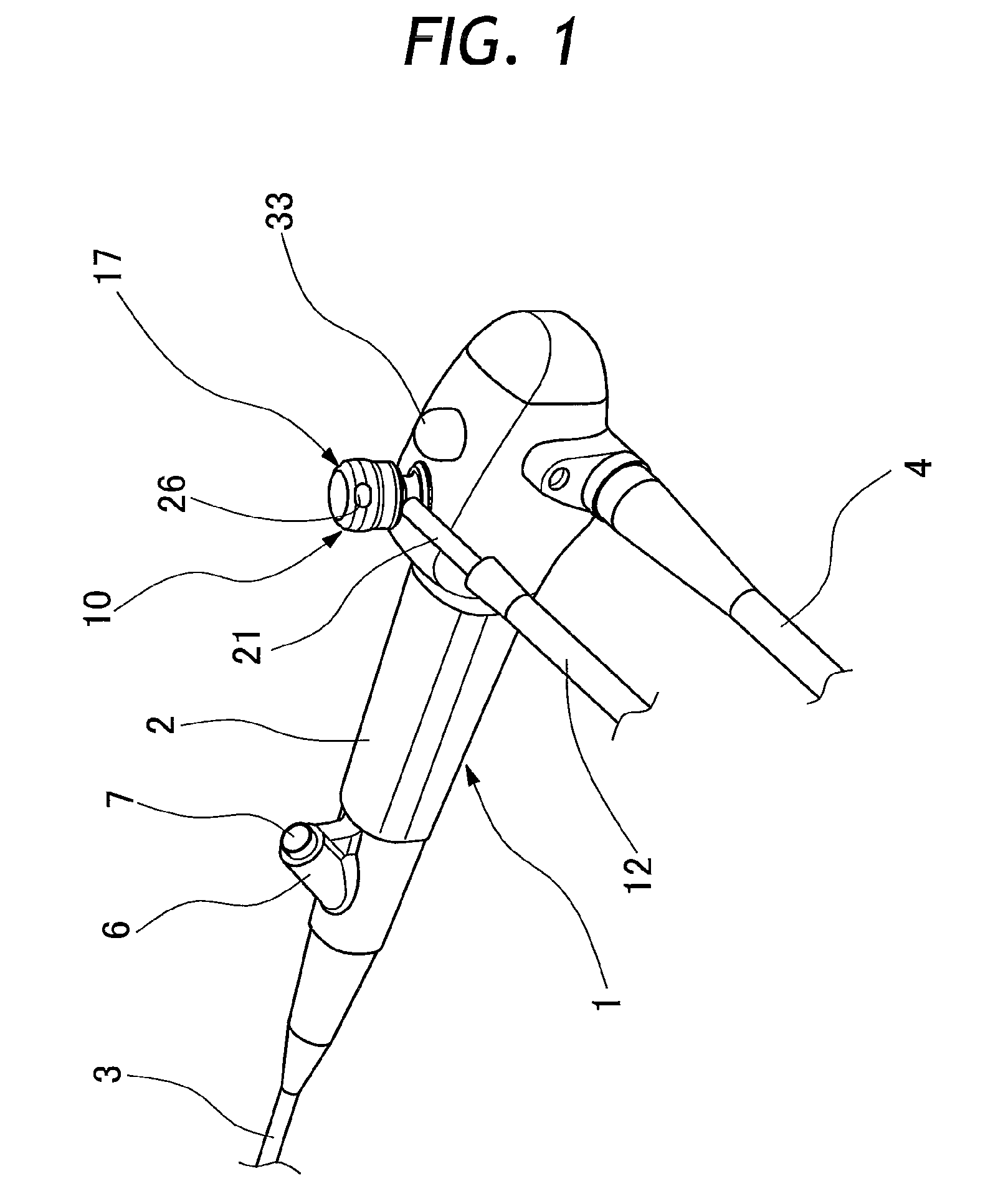

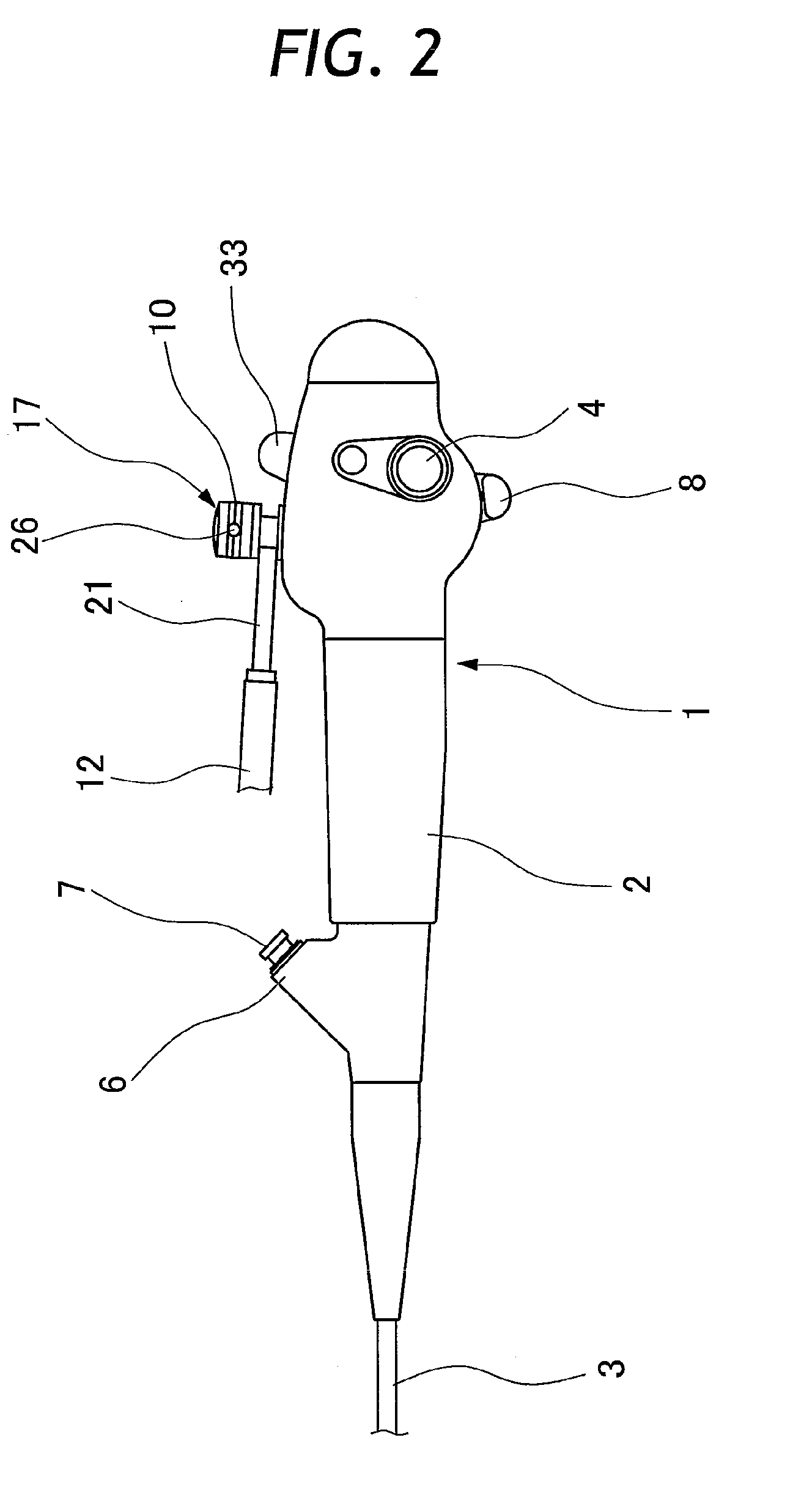

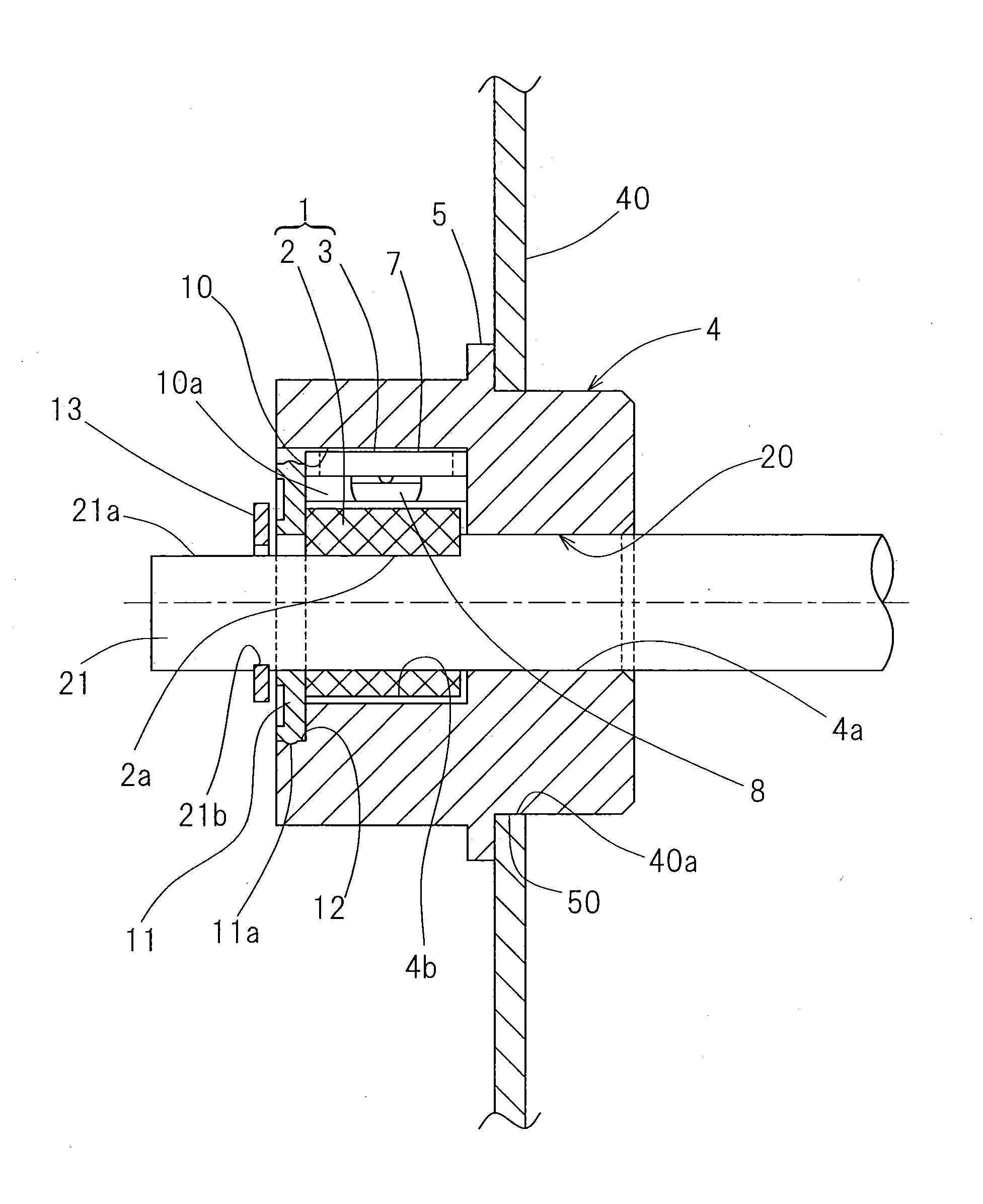

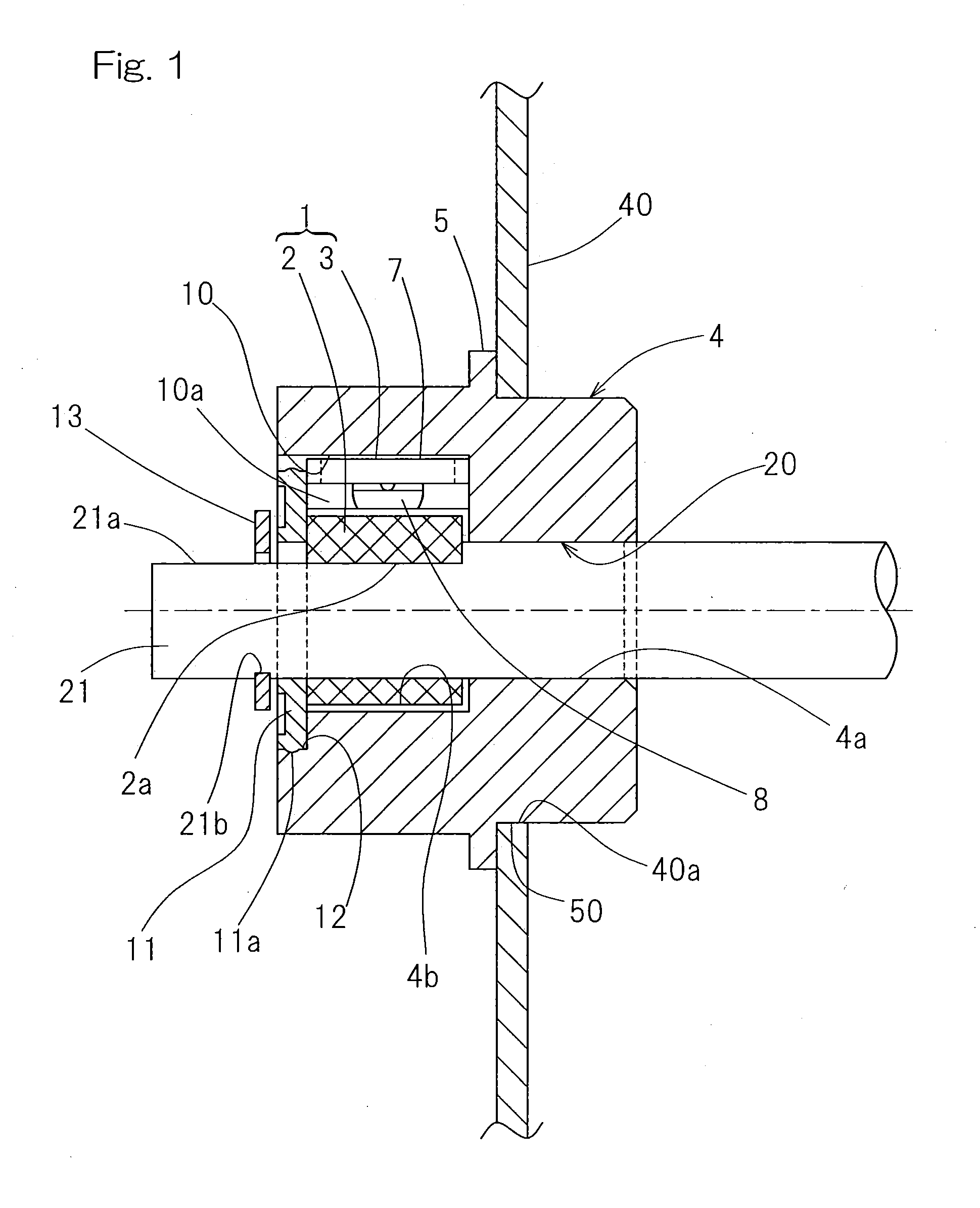

Endoscopic aspiration device

An endoscopic aspiration device is mounted on a manipulating head of an endoscope, from which an elongated insertion rod member is extended forward, the endoscopic aspiration device being composed of a valve casing which is mounted on the manipulation head in communication with an aspiration passage running through the insertion rod member, and a valve assembly unit including a valve member, a valve guide member and a connector member attached to the valve guide member to communicate same with a proximal aspiration passage on the side of a suction source. The valve member is put in a sliding displacement along the valve guide member to bring the aspiration passage into and out of communication with the proximal aspiration passage on the side of a suction source. The valve guide member is coupled with the valve casing through a coupling mechanism which permits to turn the valve assembly unit on and relative to the manipulating head. The coupling mechanism is arranged to perform a function of coupling and uncoupling the valve guide unit with and from the valve casing, and a function of locking the valve guide member in the valve casing to prevent spontaneous dislodgement from the latter.

Owner:FUJIFILM CORP

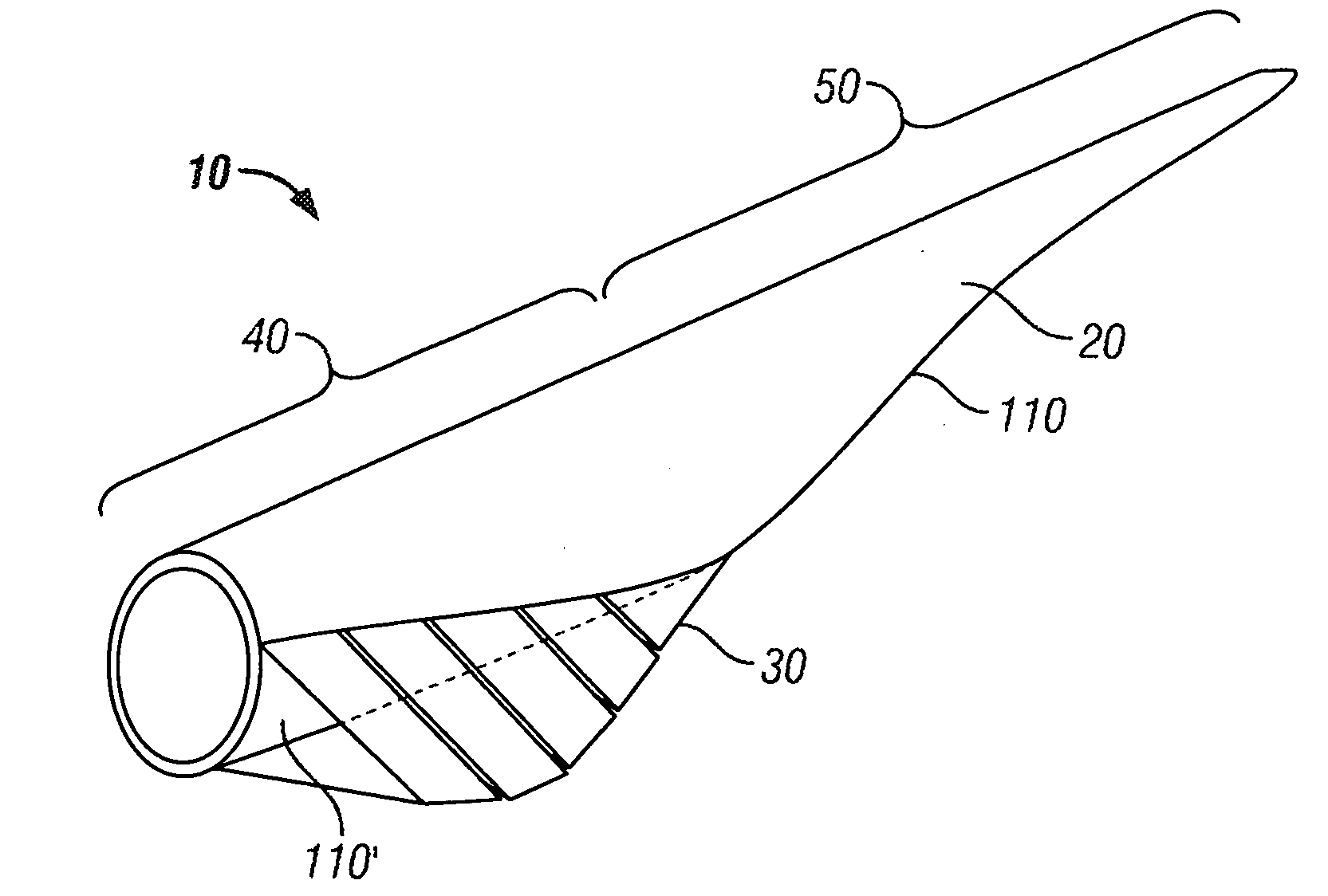

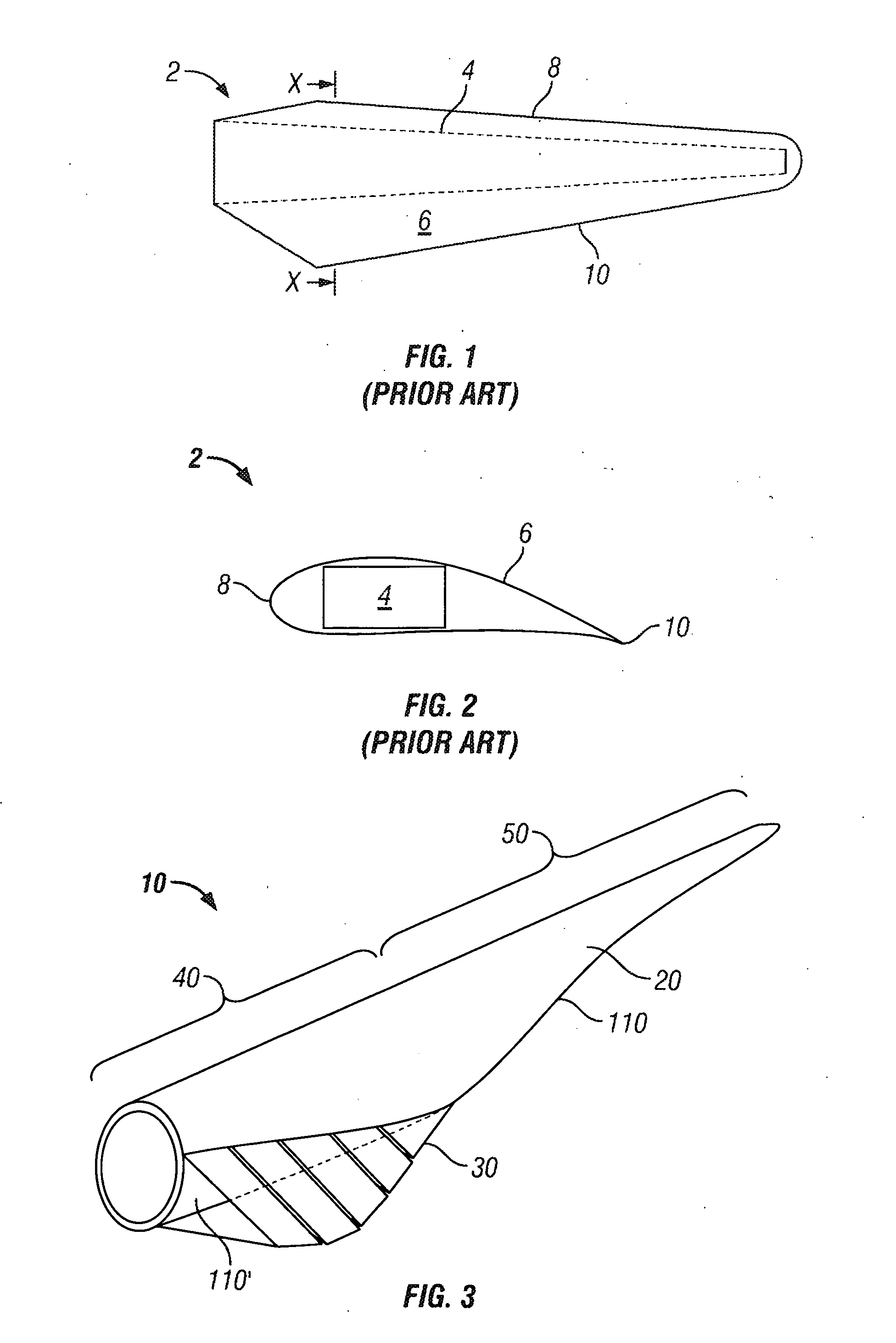

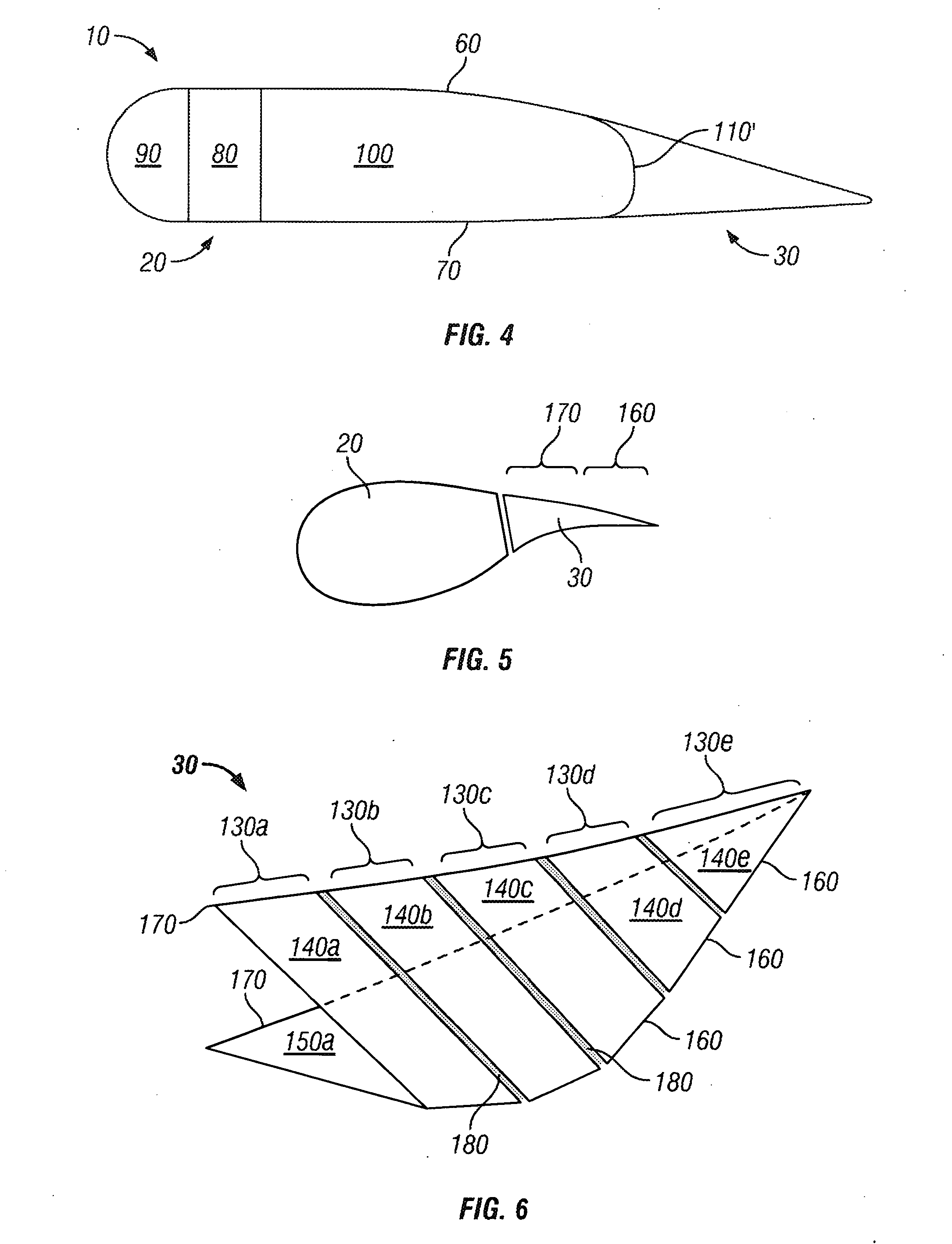

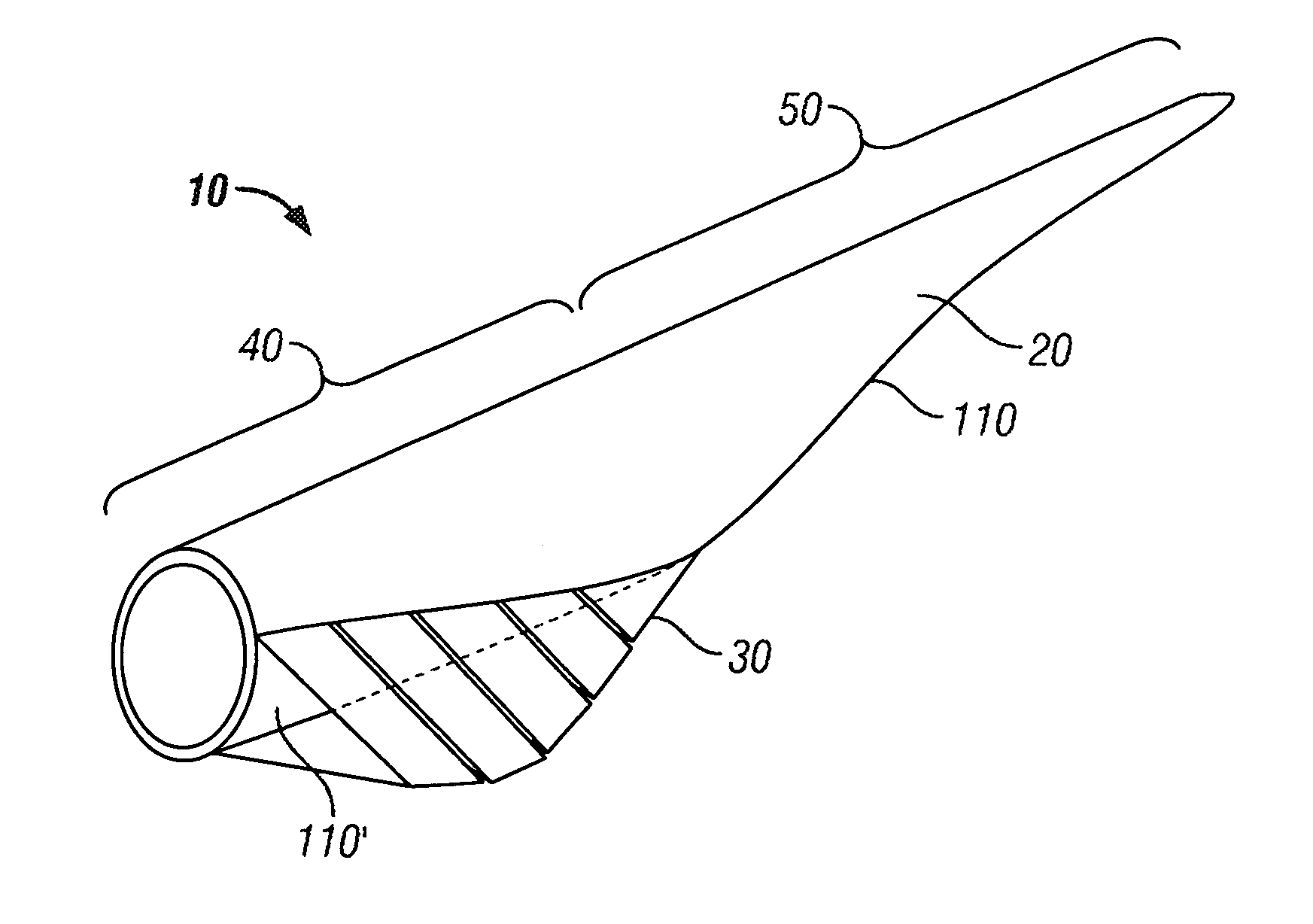

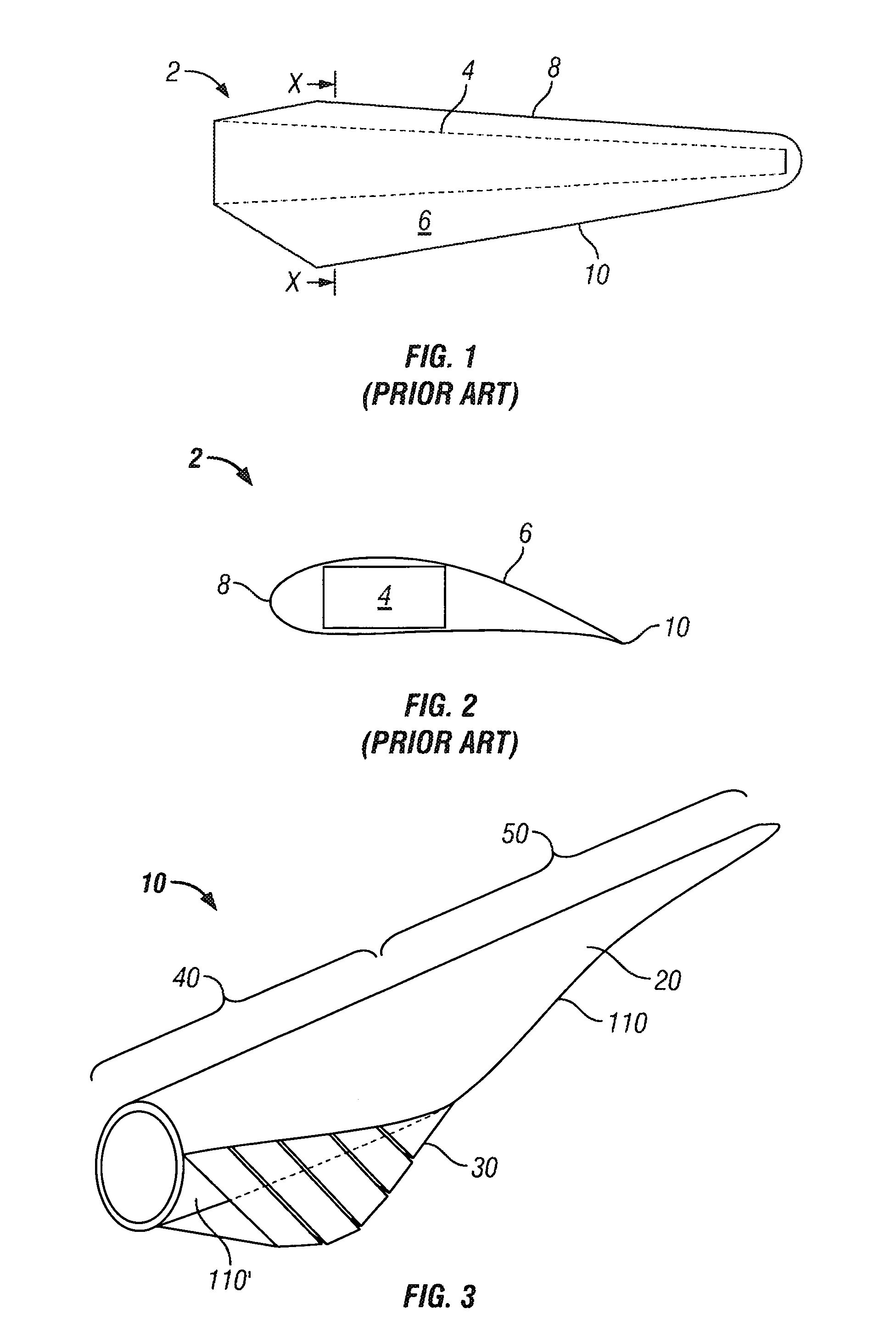

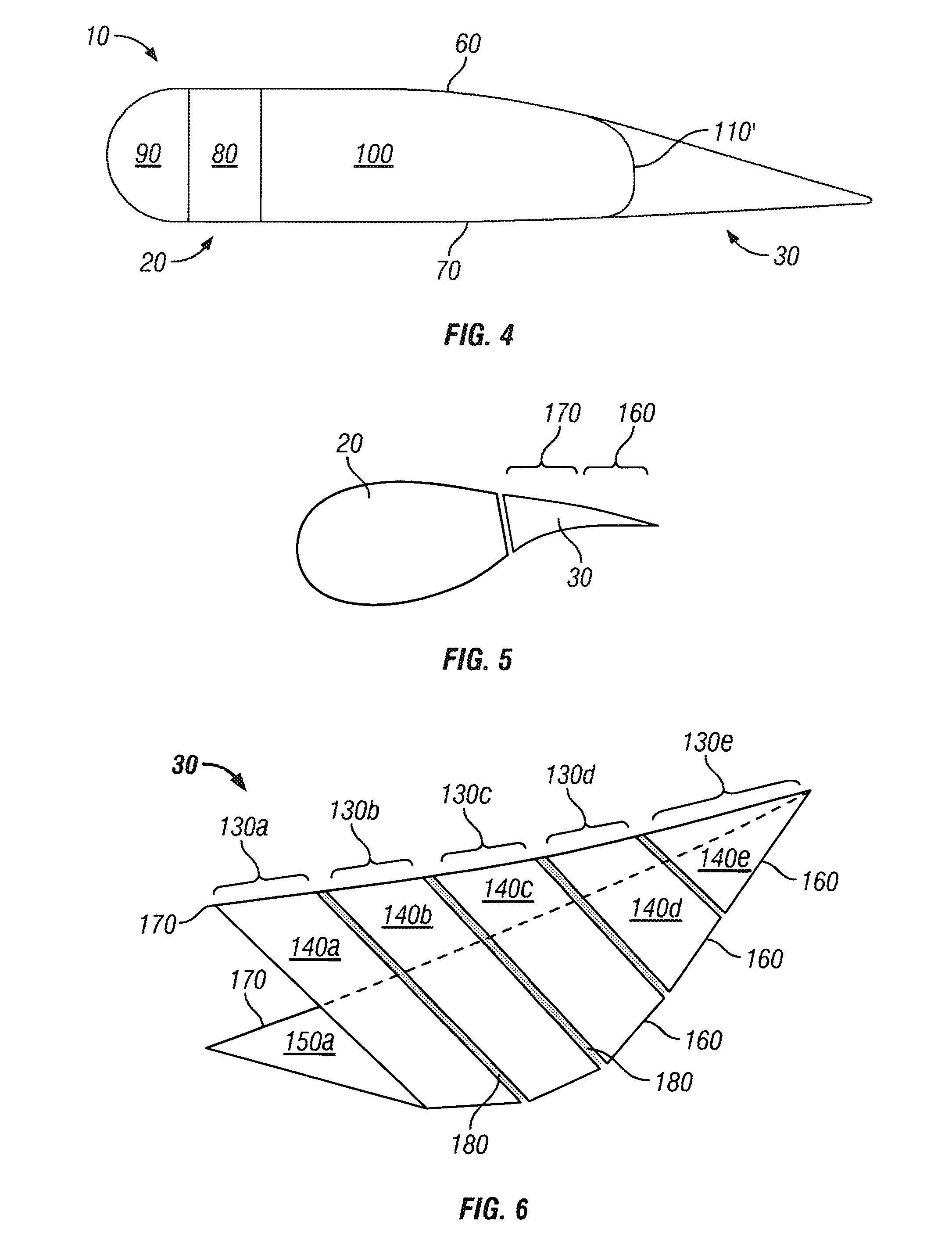

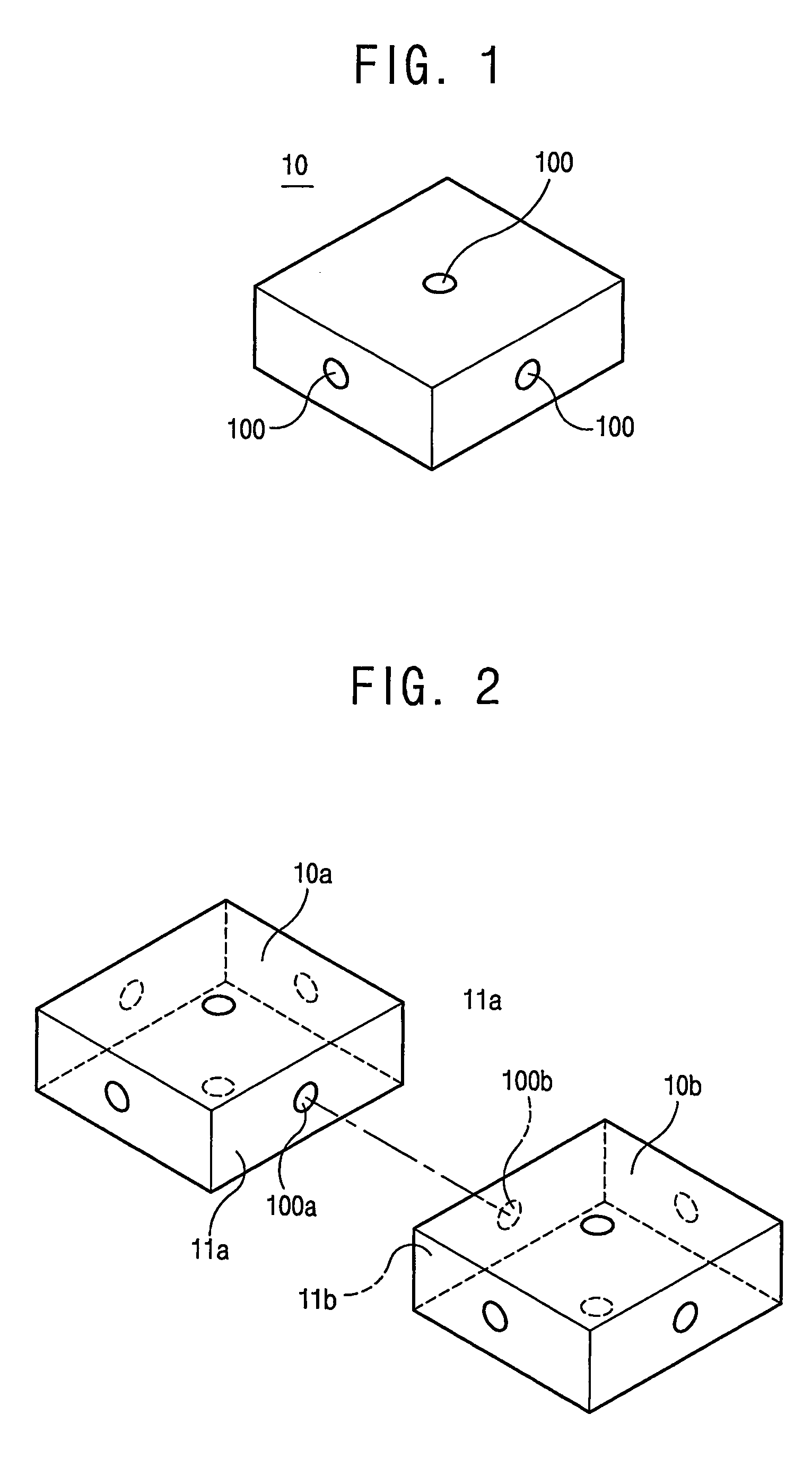

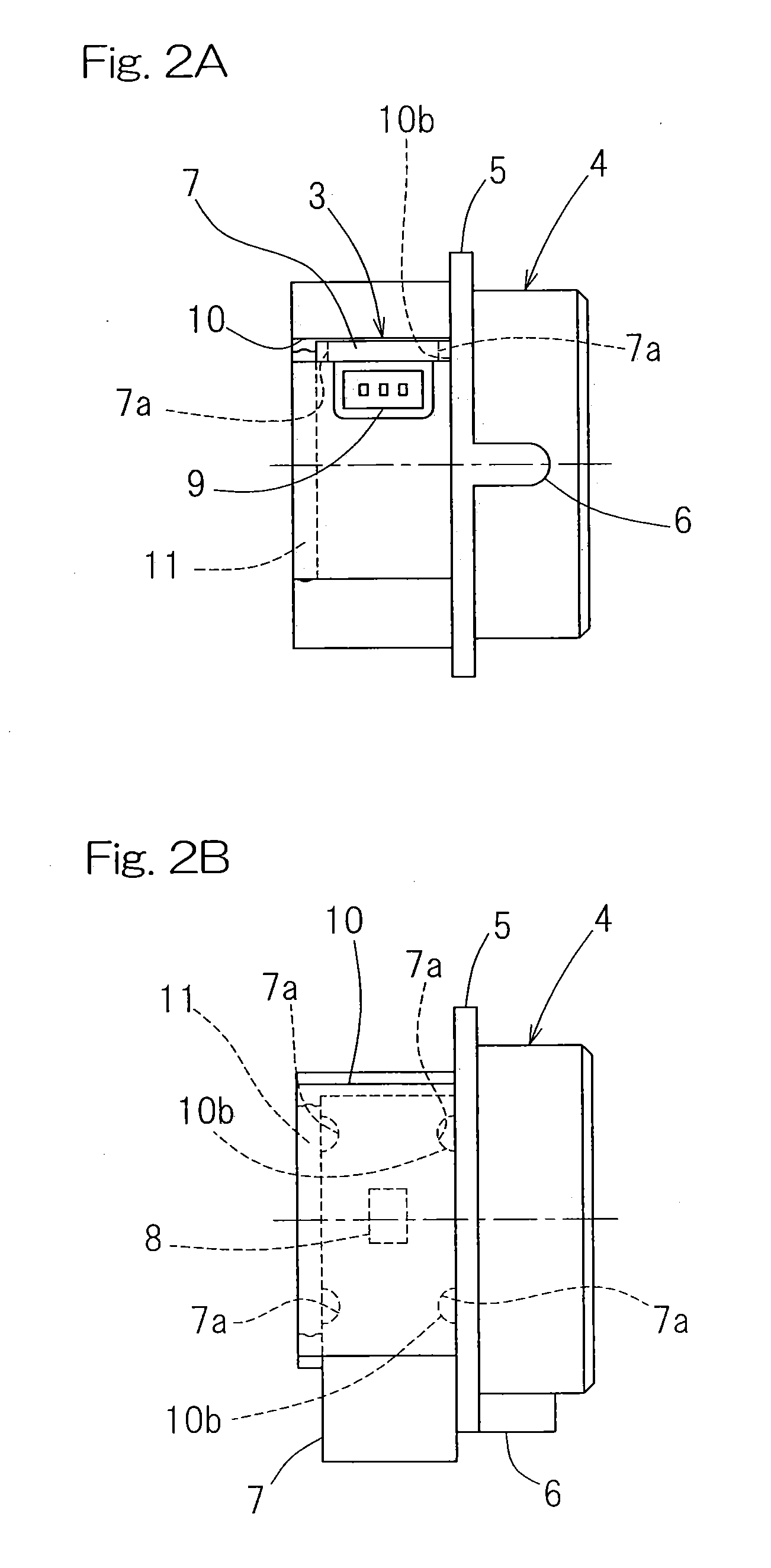

Segmented Rotor Blade Extension Portion

ActiveUS20100028161A1Optimize structural configurationEasy to dismantlePropellersEngine manufactureEngineeringMechanical engineering

A wind turbine rotor blade extension portion having a plurality of segments, located adjacent one another in a span-wise sense. An interface between adjacent segments is configured to minimise disruption to fluid passing thereover and to inhibit transmission of longitudinal loads between segments. Each segment has a first surface and a second surface. The first surface is spaced from the second surface at a proximal region of the extension portion and the first surface is connected to the second surface at a distal region of the extension portion to thereby generate a fair surface for a rotor blade to which the extension portion is connected, in use.

Owner:VESTAS WIND SYST AS

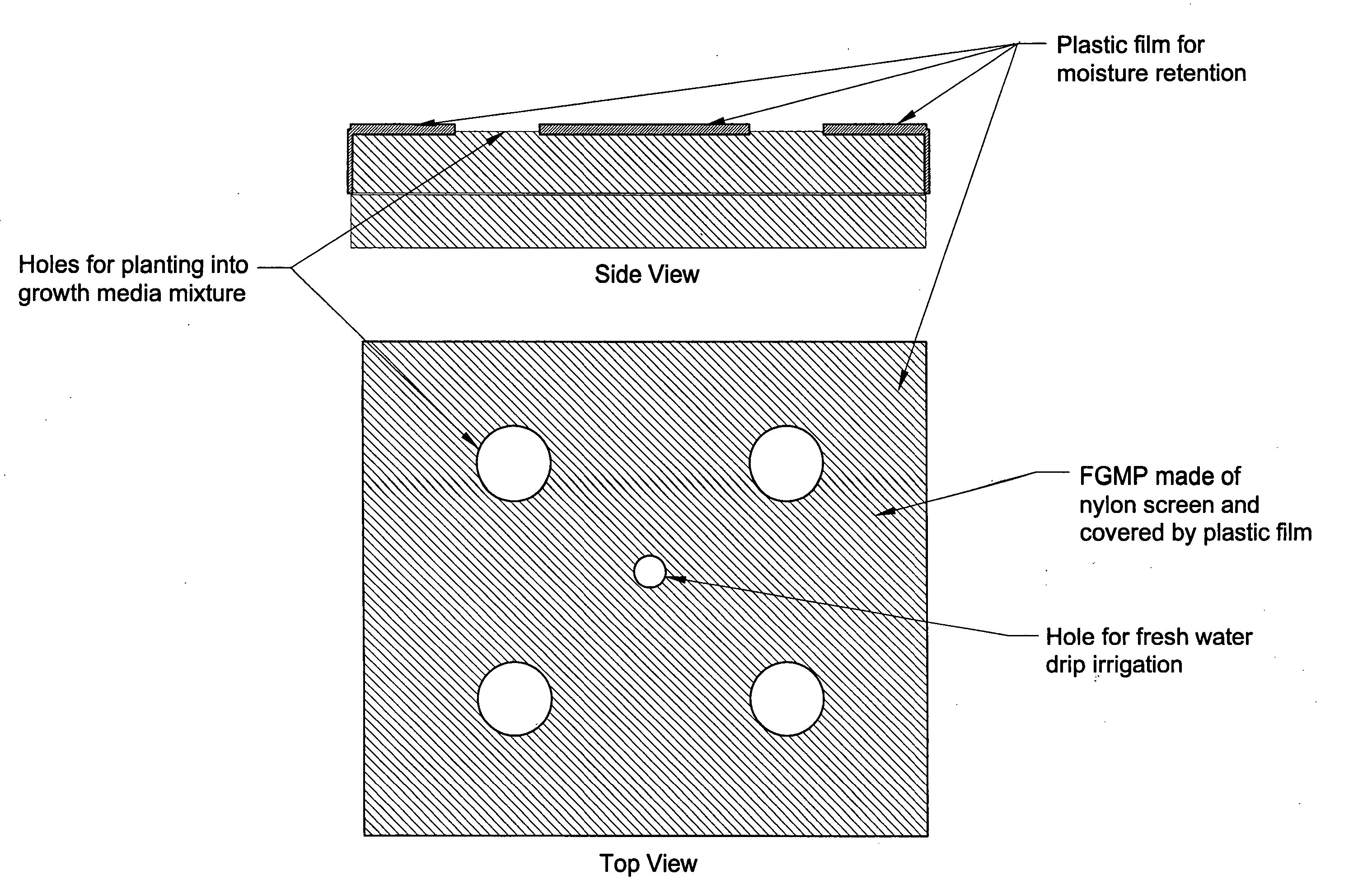

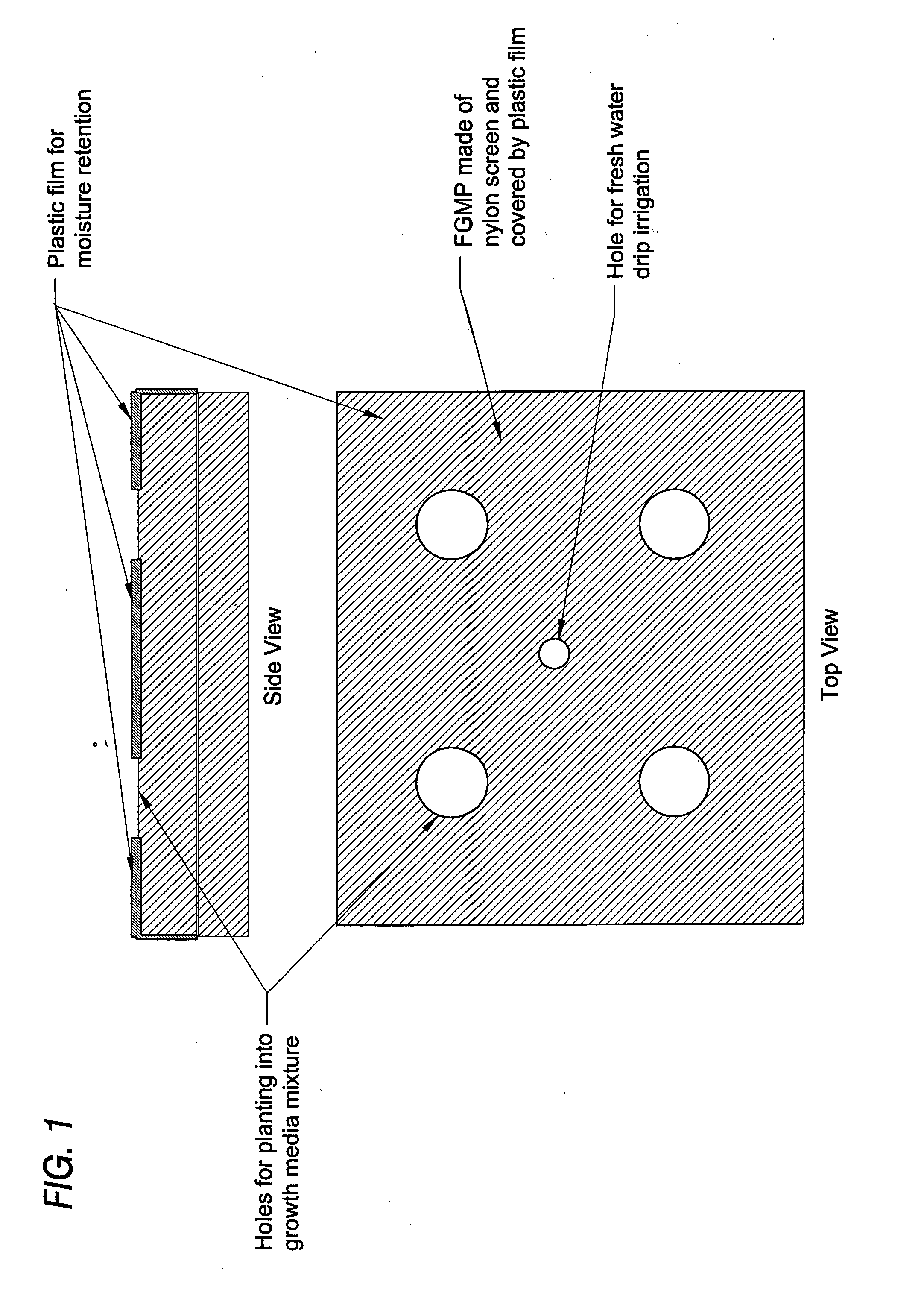

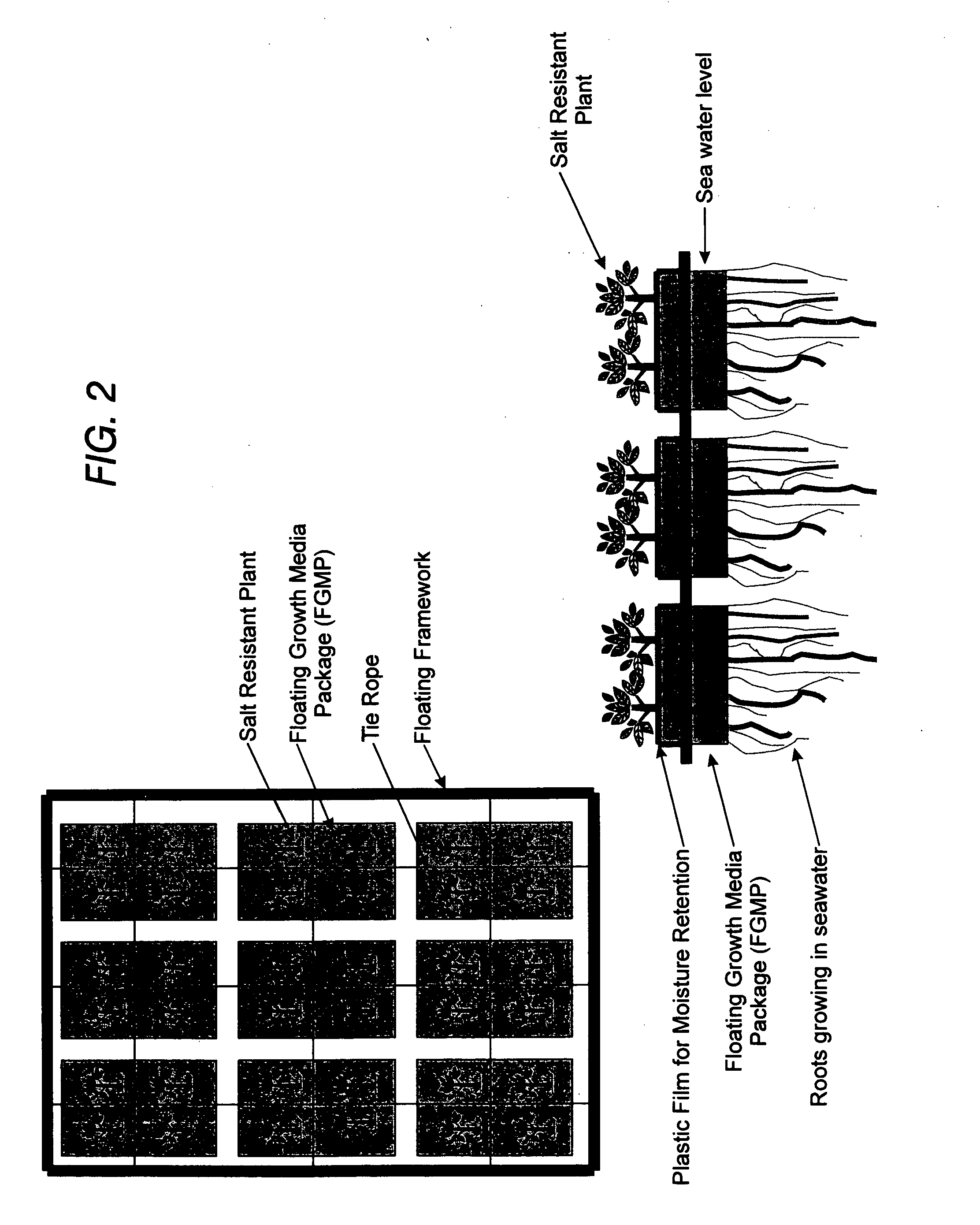

Floating plant cultivation platform and method for growing terrestrial plants in saline water of various salinities for multiple purposes

InactiveUS20050044788A1Efficient managementMinimal requirementSeed and root treatmentClimate change adaptationShootCell culture media

The cultivation of terrestrial plants in brackish water or seawater is carried out with this invention. A light-weight, floating growth medium package (FGMP) or, alternatively, a sheet of suitable material is used to support the growth of terrestrial plants floating on water bodies of various salinity, including 100% seawater in marine environments. The FGMP units can be linked together and confined in a floating, rigid or flexible framework to form a floating seawater cultivation platform (FSCP). Using the method, plants were able to grow and thrive on the FSCP floating on 100% seawater in a sustainable manner. Halophytic akulikuli (Sesuvium portulacastrum L.) can regenerate its shoot and root in seawater. Thus, the discovery will enable us to practice marine agriculture, or agriculture on the sea. The FSCP can be used for wide range of purposes, from environmental protection to landscaping to crop production.

Owner:UNIV OF HAWAII

Segmented rotor blade extension portion

ActiveUS8317479B2Optimize structural configurationEasy to dismantlePropellersEngine manufactureEngineeringMechanical engineering

A wind turbine rotor blade extension portion having a plurality of segments, located adjacent one another in a span-wise sense. An interface between adjacent segments is configured to minimize disruption to fluid passing thereover and to inhibit transmission of longitudinal loads between segments. Each segment has a first surface and a second surface. The first surface is spaced from the second surface at a proximal region of the extension portion and the first surface is connected to the second surface at a distal region of the extension portion to thereby generate a fair surface for a rotor blade to which the extension portion is connected, in use.

Owner:VESTAS WIND SYST AS

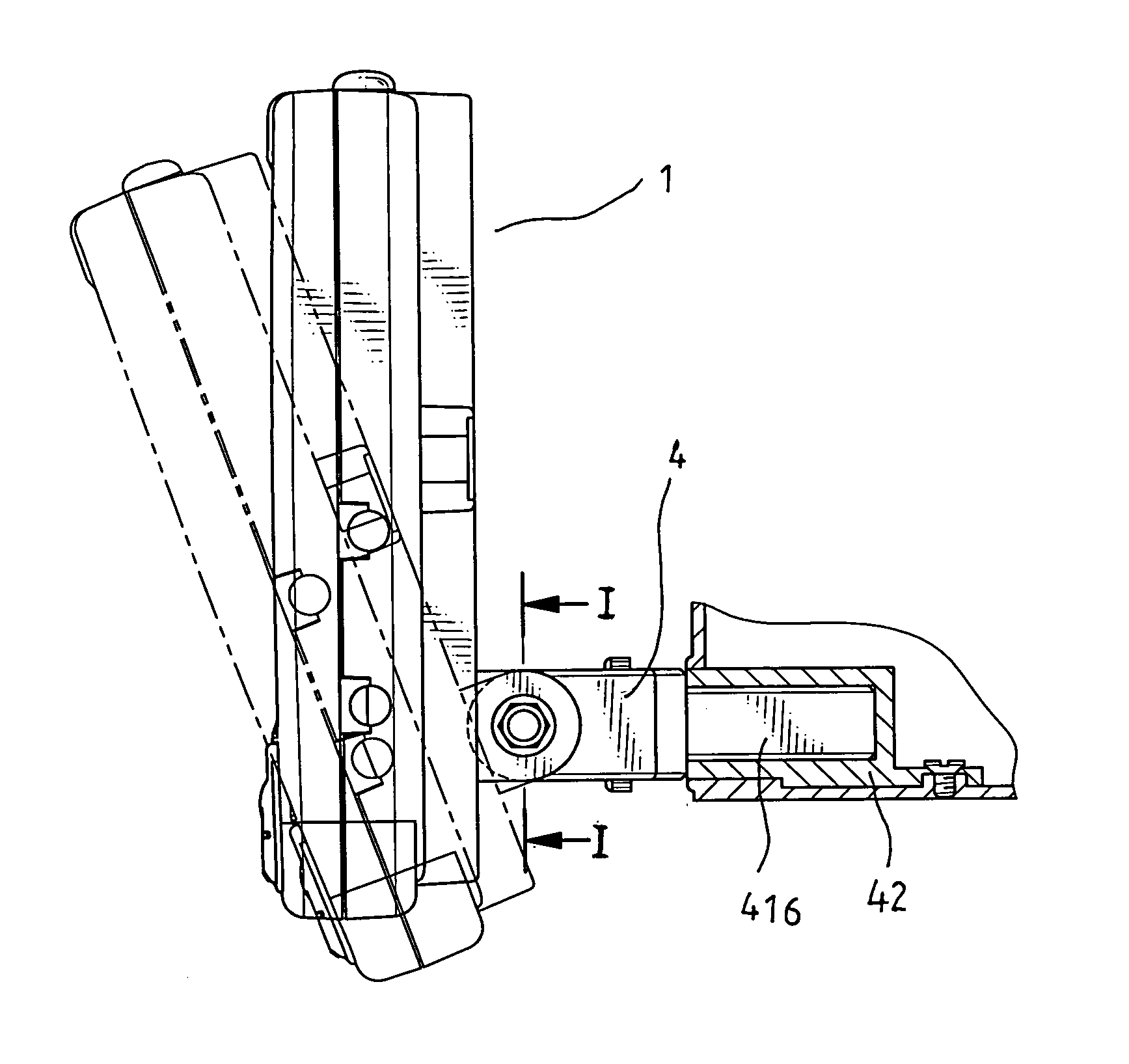

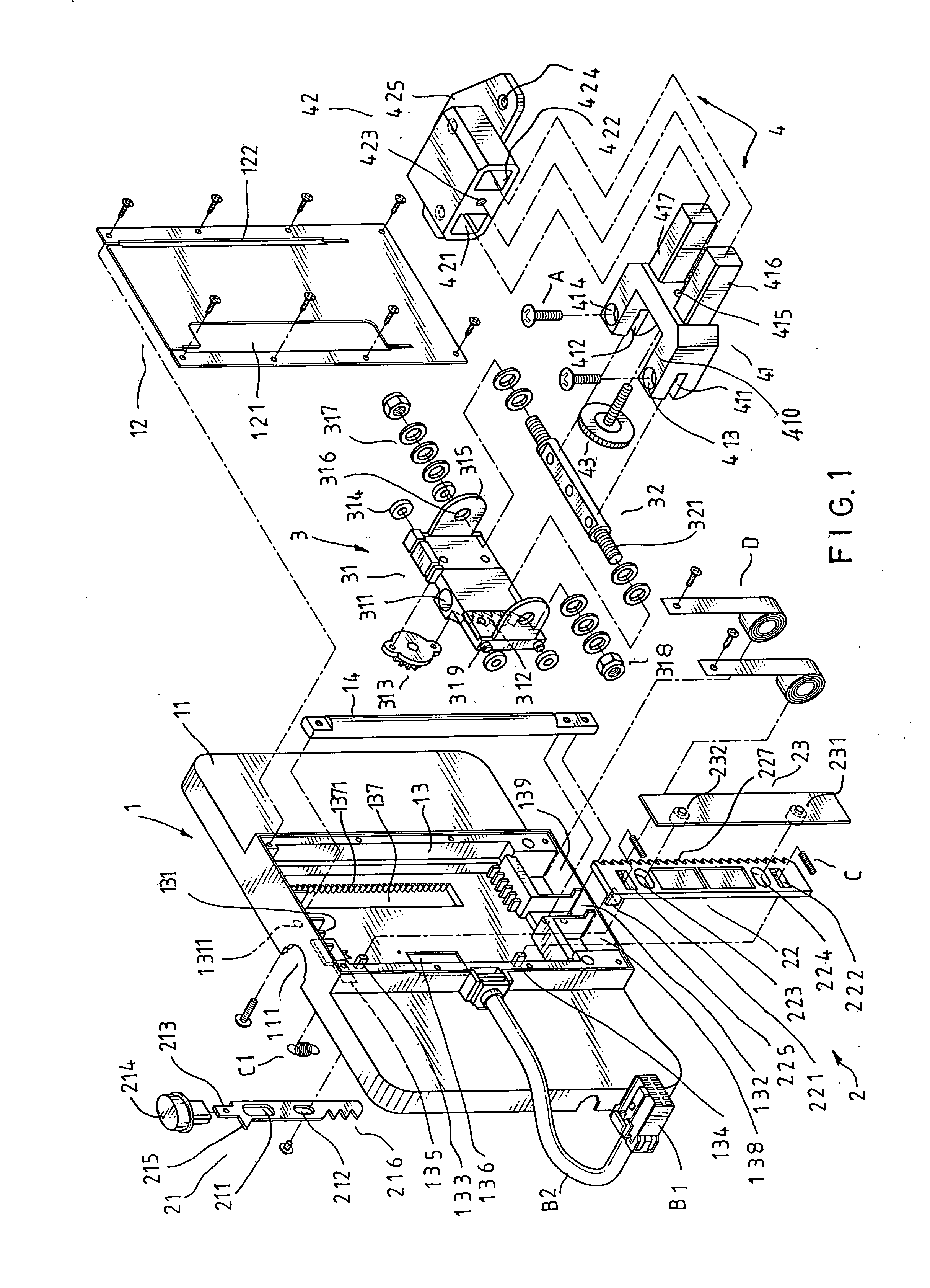

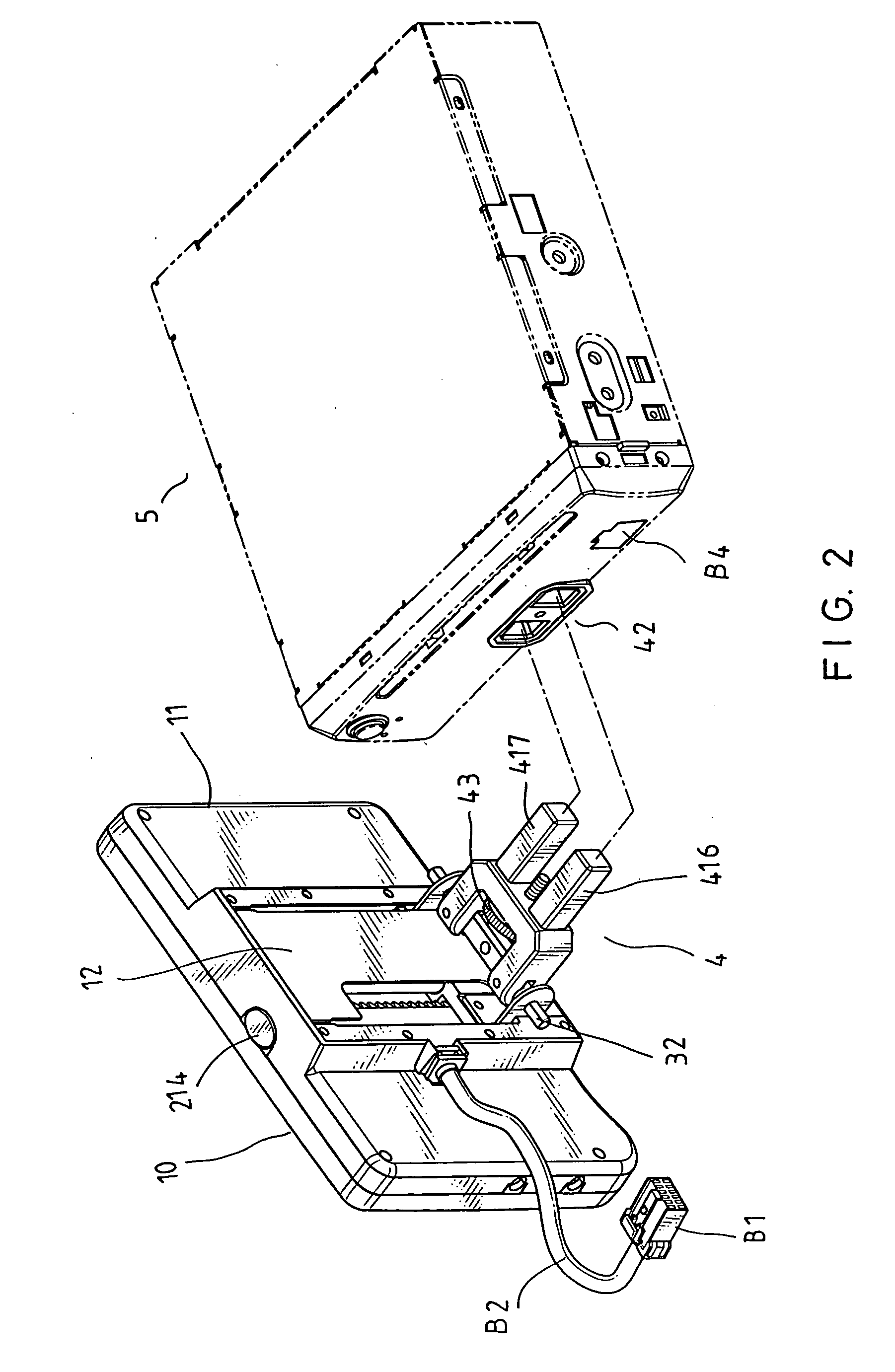

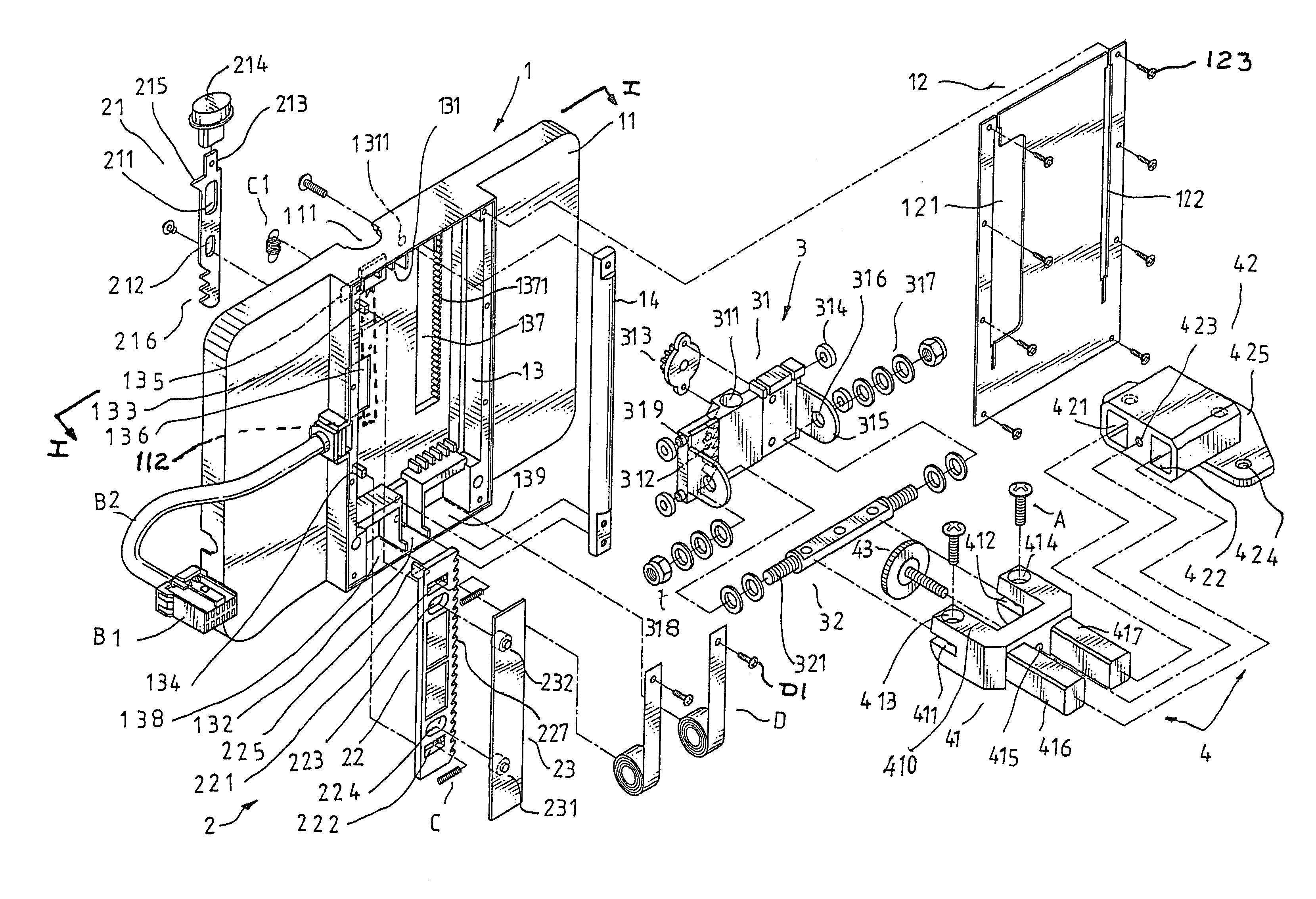

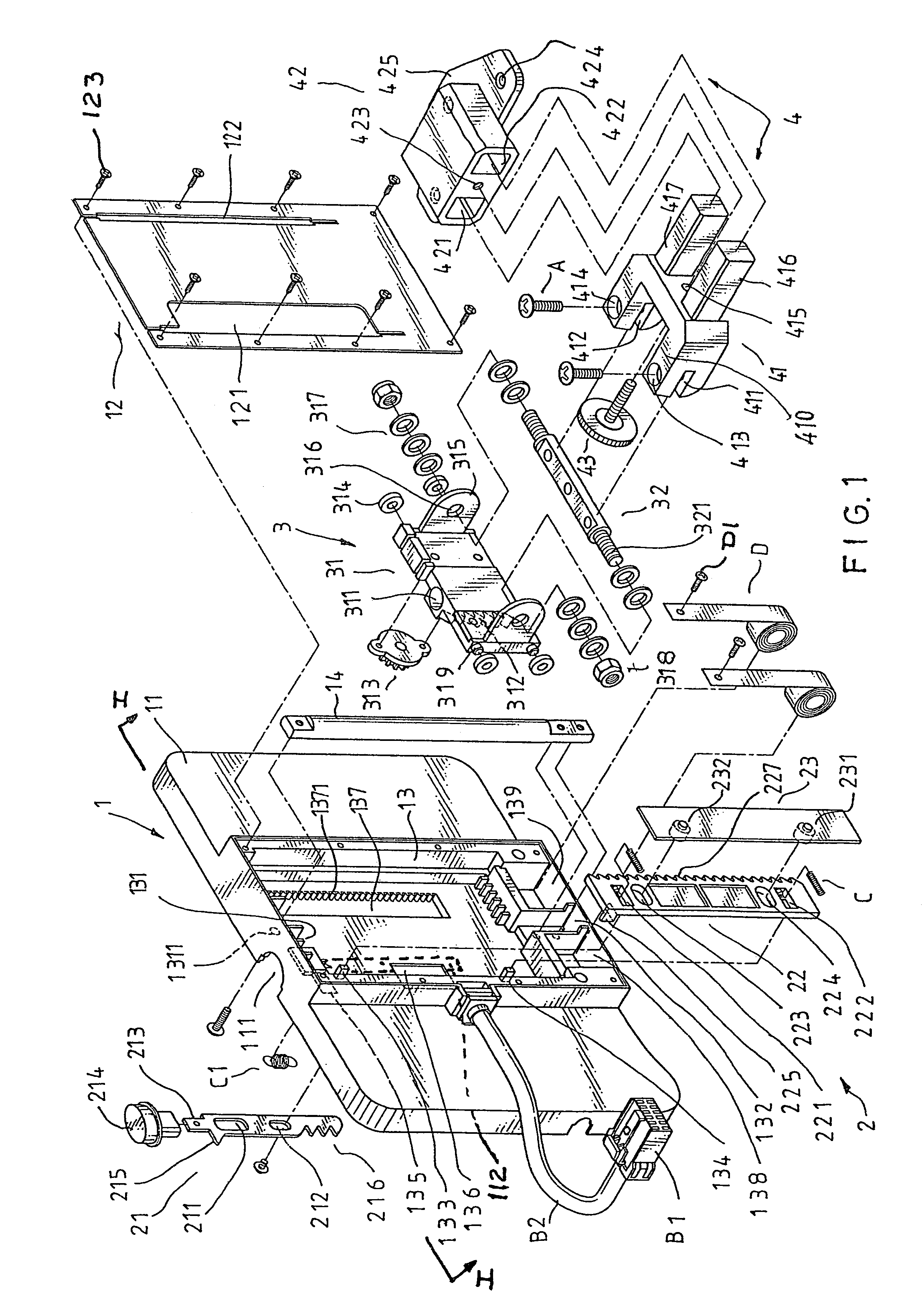

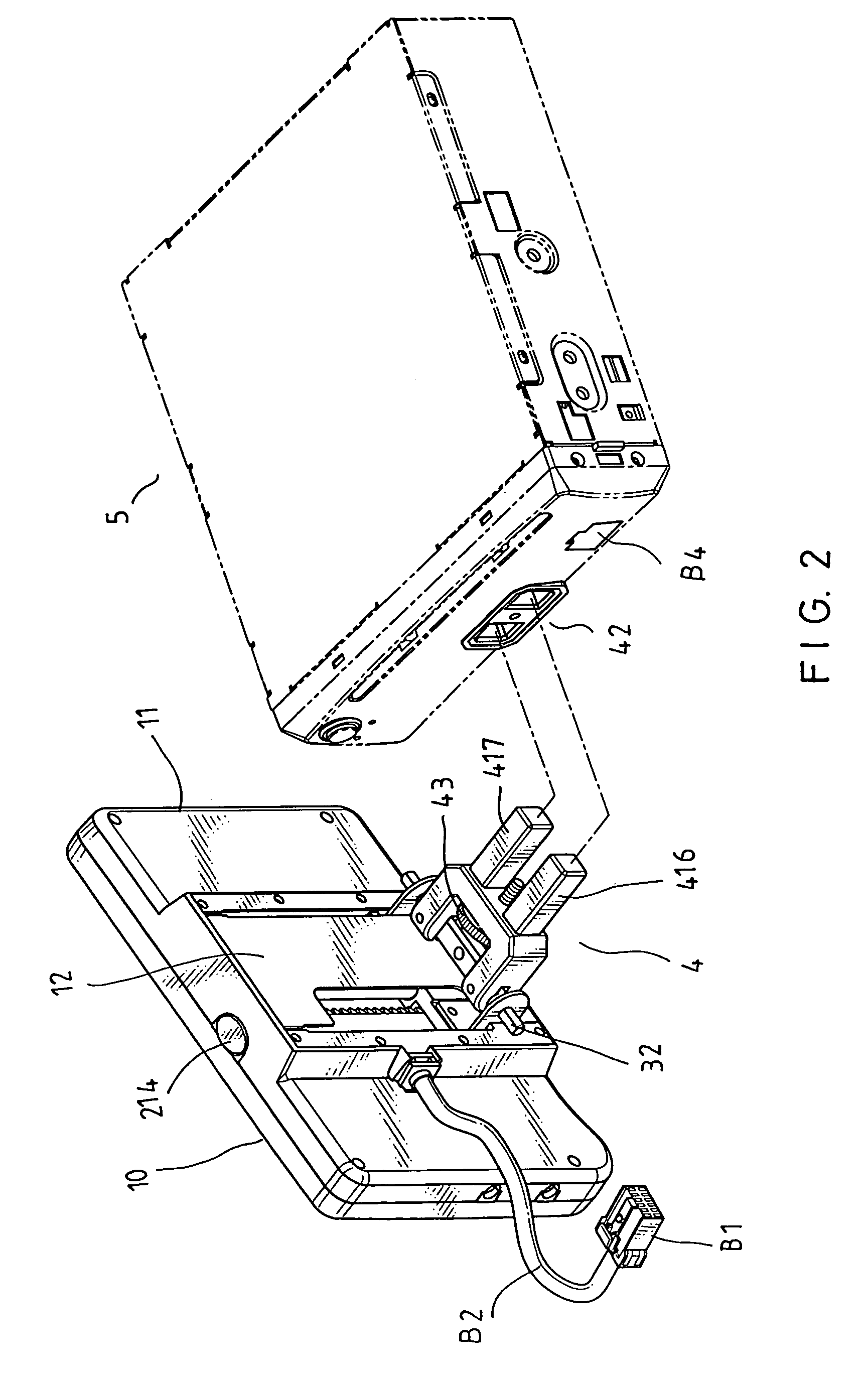

Structure for an adjustable support of monitor

InactiveUS20050035252A1Easy to dismantleEasy to assembleDigital data processing detailsCouplings for rigid shaftsFixed positionEngineering

A structure for an adjustable support of monitor comprises a main body disposing a monitor at the front and a positioning apparatus in the inside for controlling the monitor down or up; and a connecting means, at the front of the connecting means pivoting with the main body and the rear of the connecting means coupling to an assembly means for fastening the monitor with the car, and the positioning apparatus comprises a positioning member for fastening a position of the monitor; and a stop member for releasing the positioning member to make the positioning member to move.

Owner:E LEAD ELECTRONICS

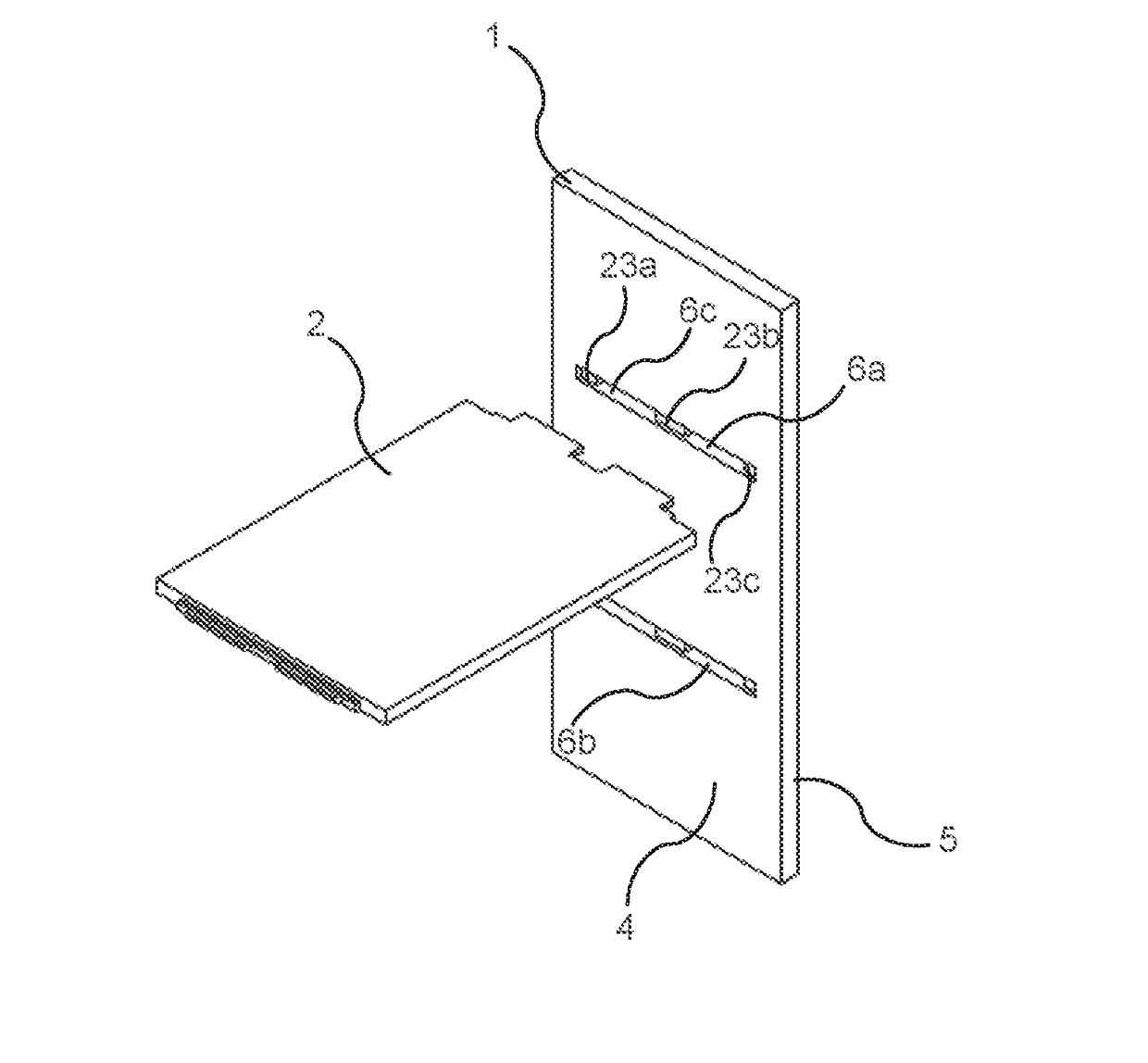

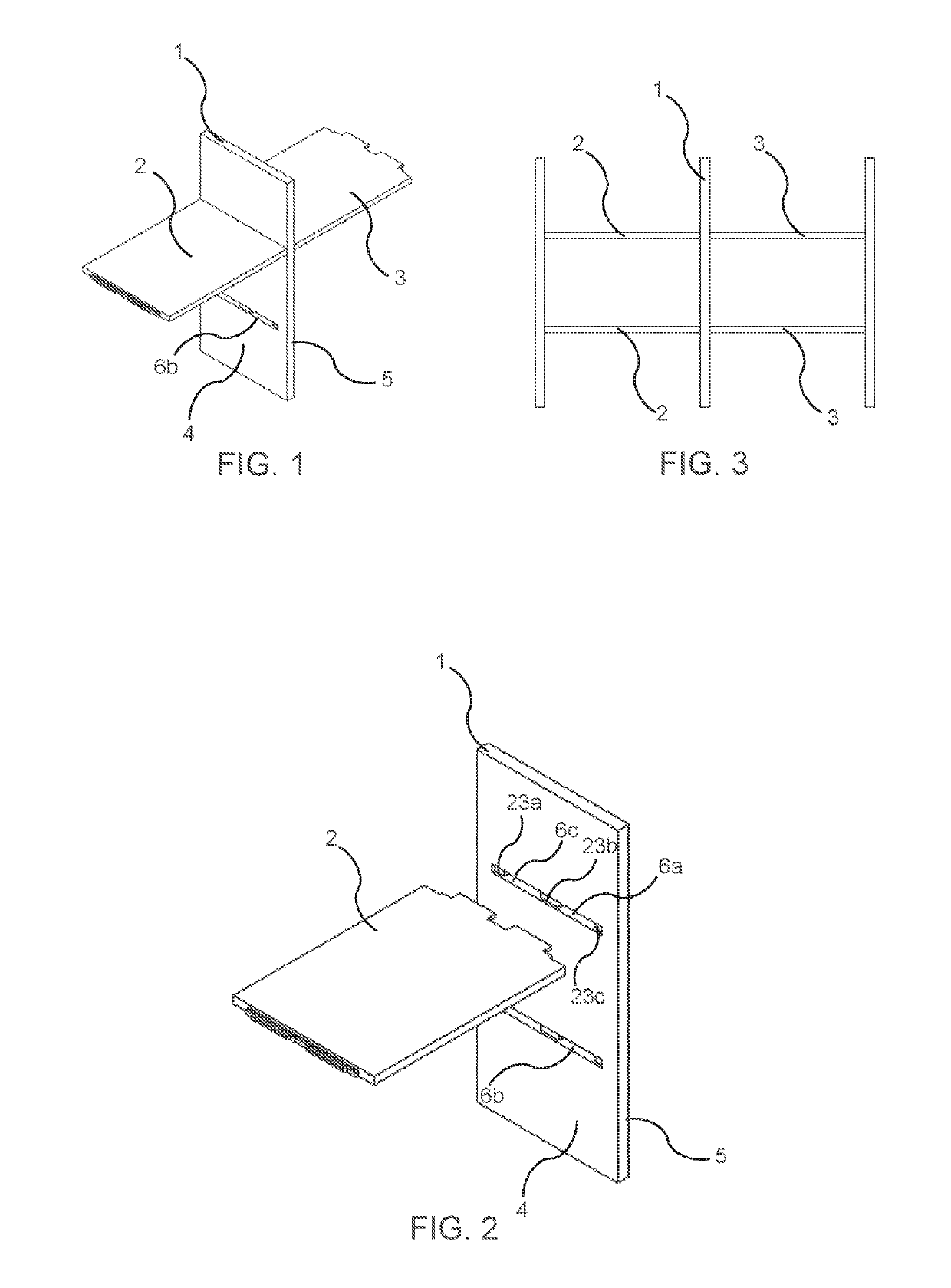

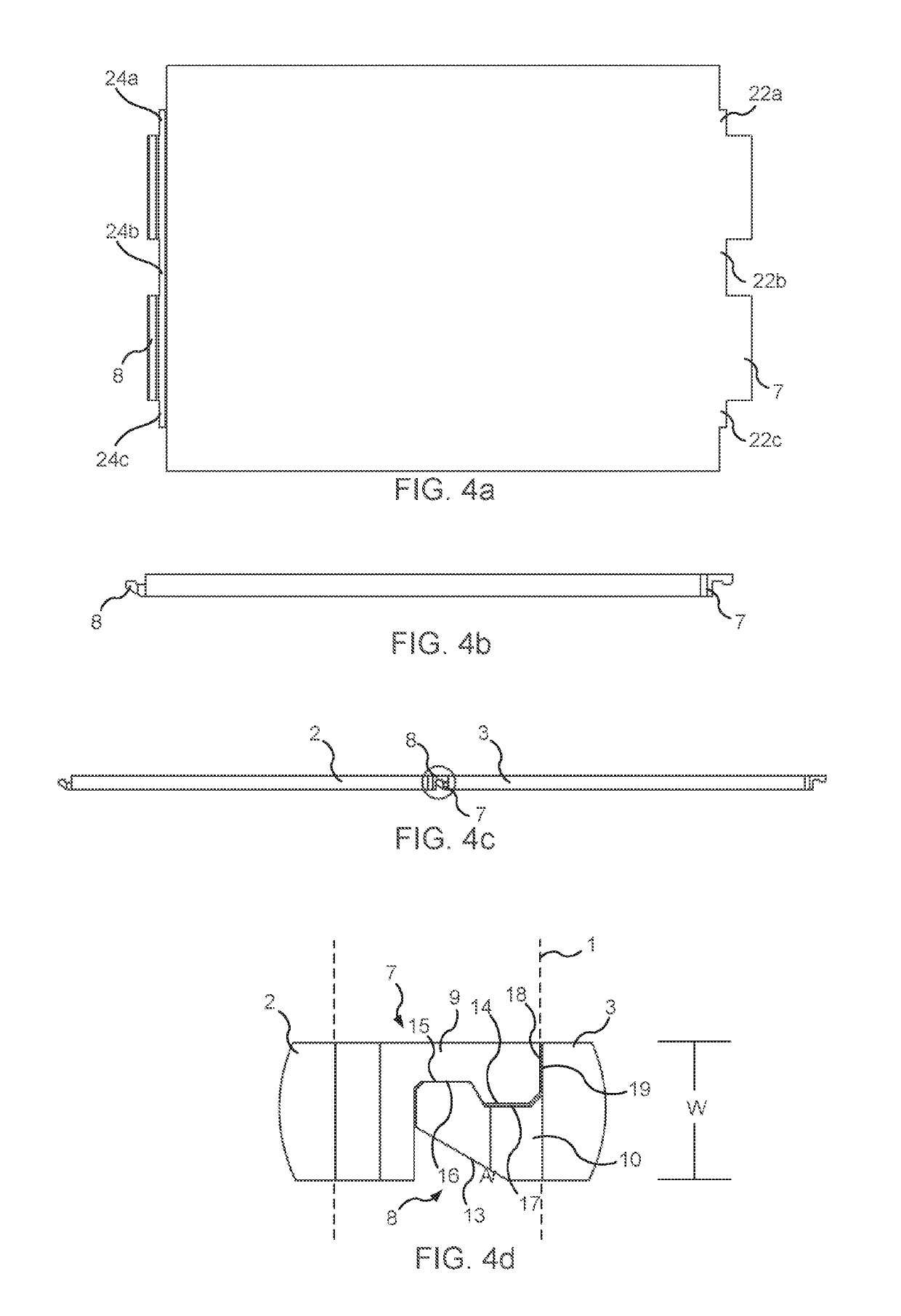

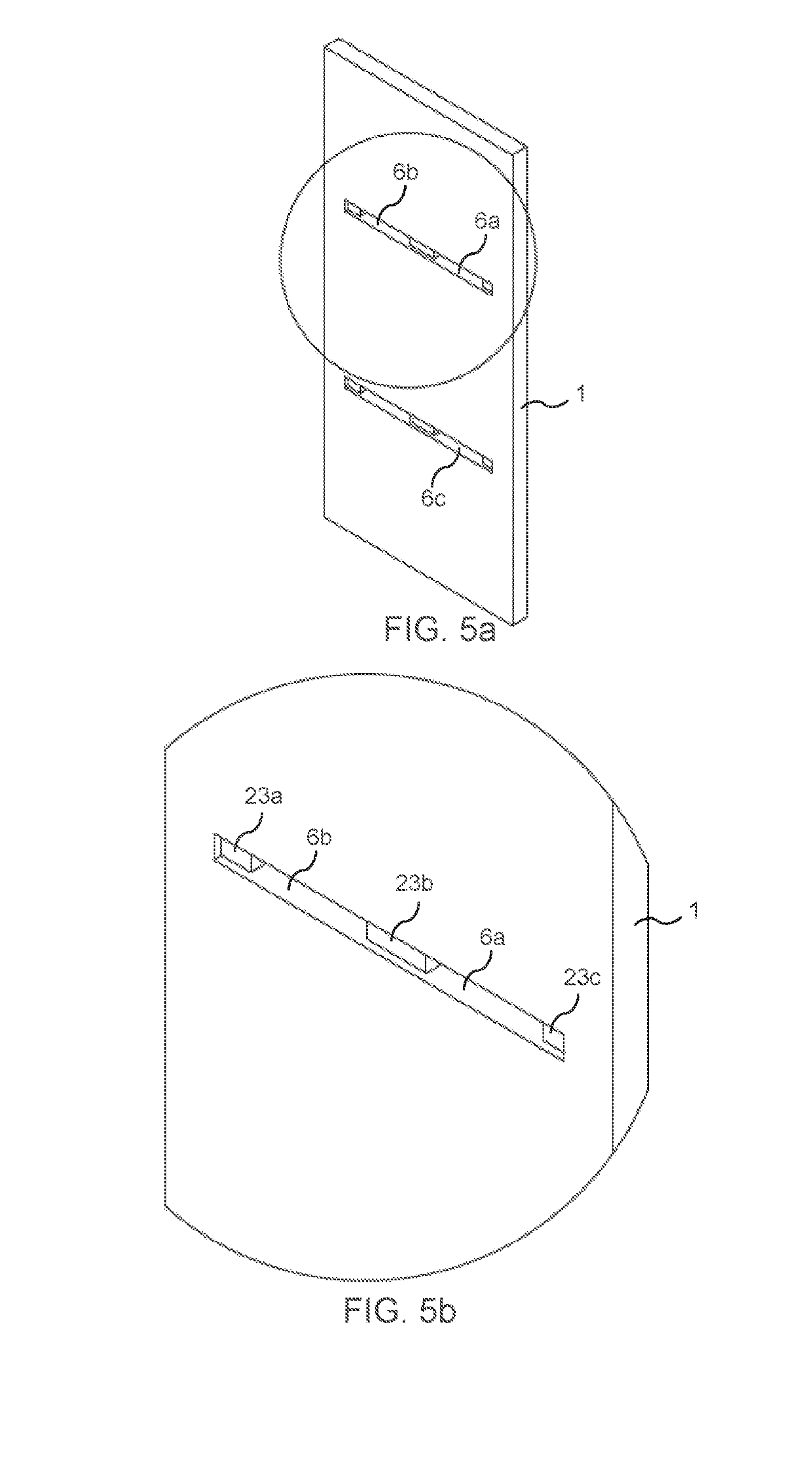

Set of panel-shaped elements for a composed element

ActiveUS20170227031A1Easy to assemble and dismantleSave time and costFurniture joining partsSheet joiningMechanical engineering

Owner:VÄLINGE INNOVATION AB

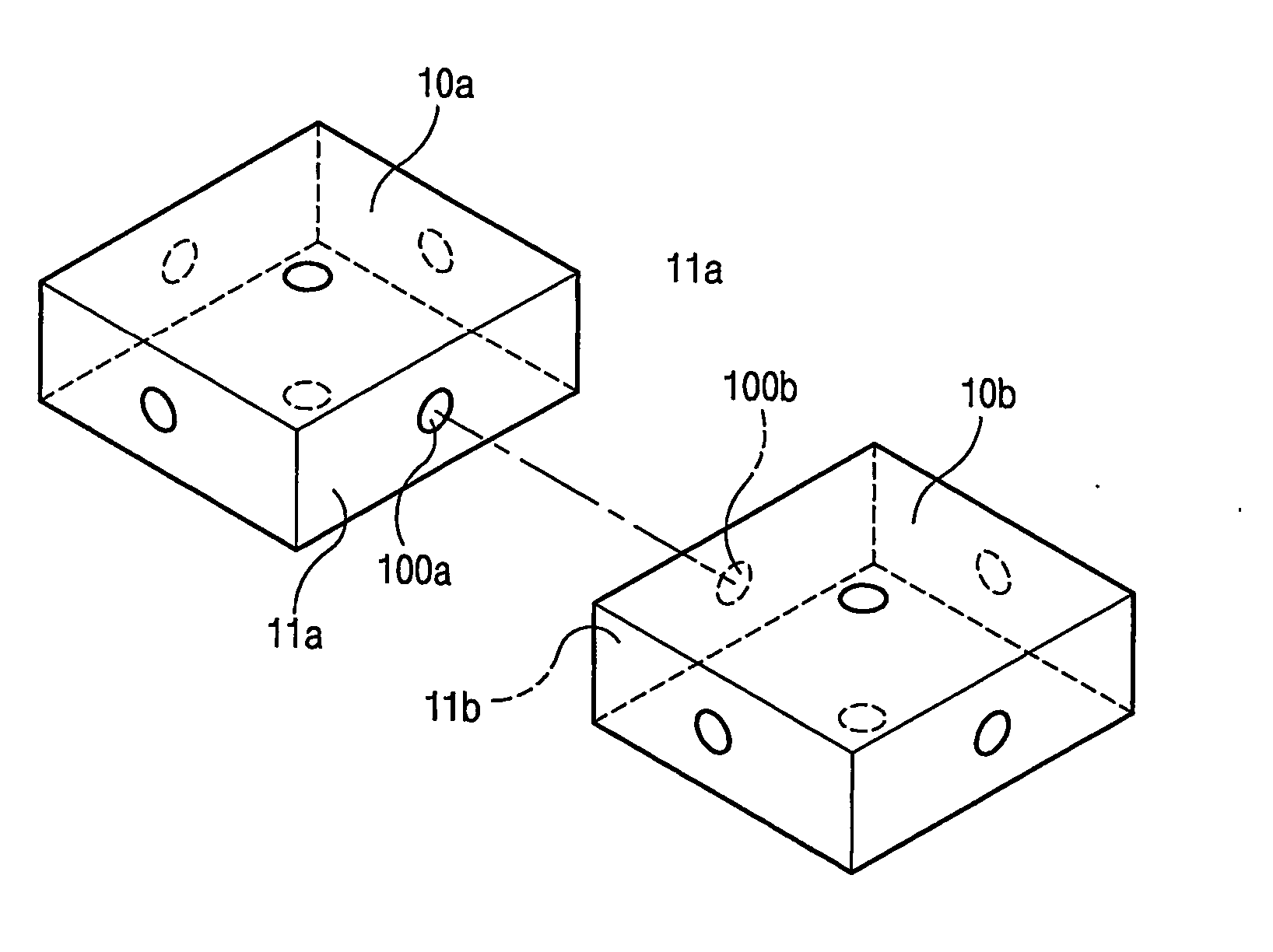

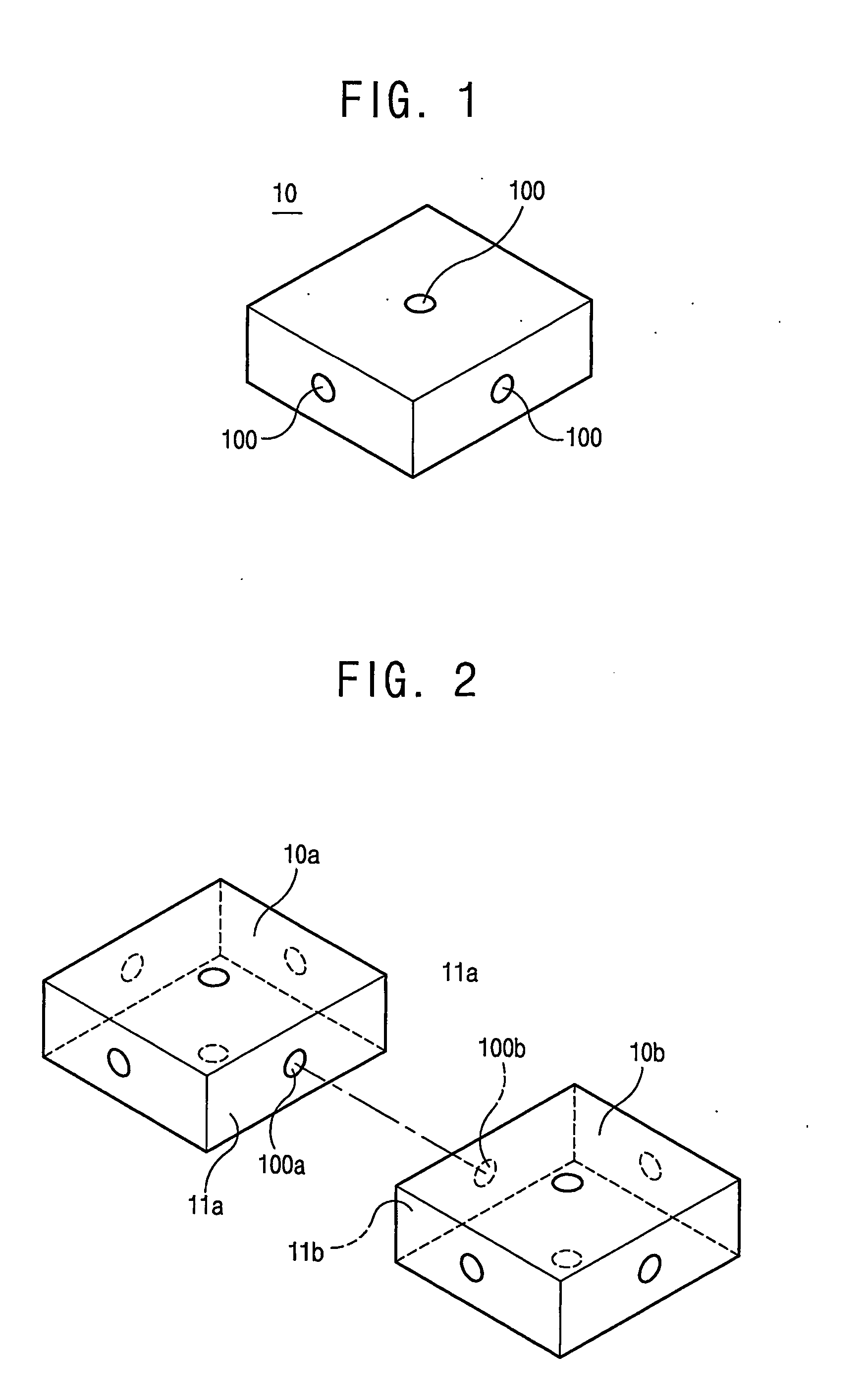

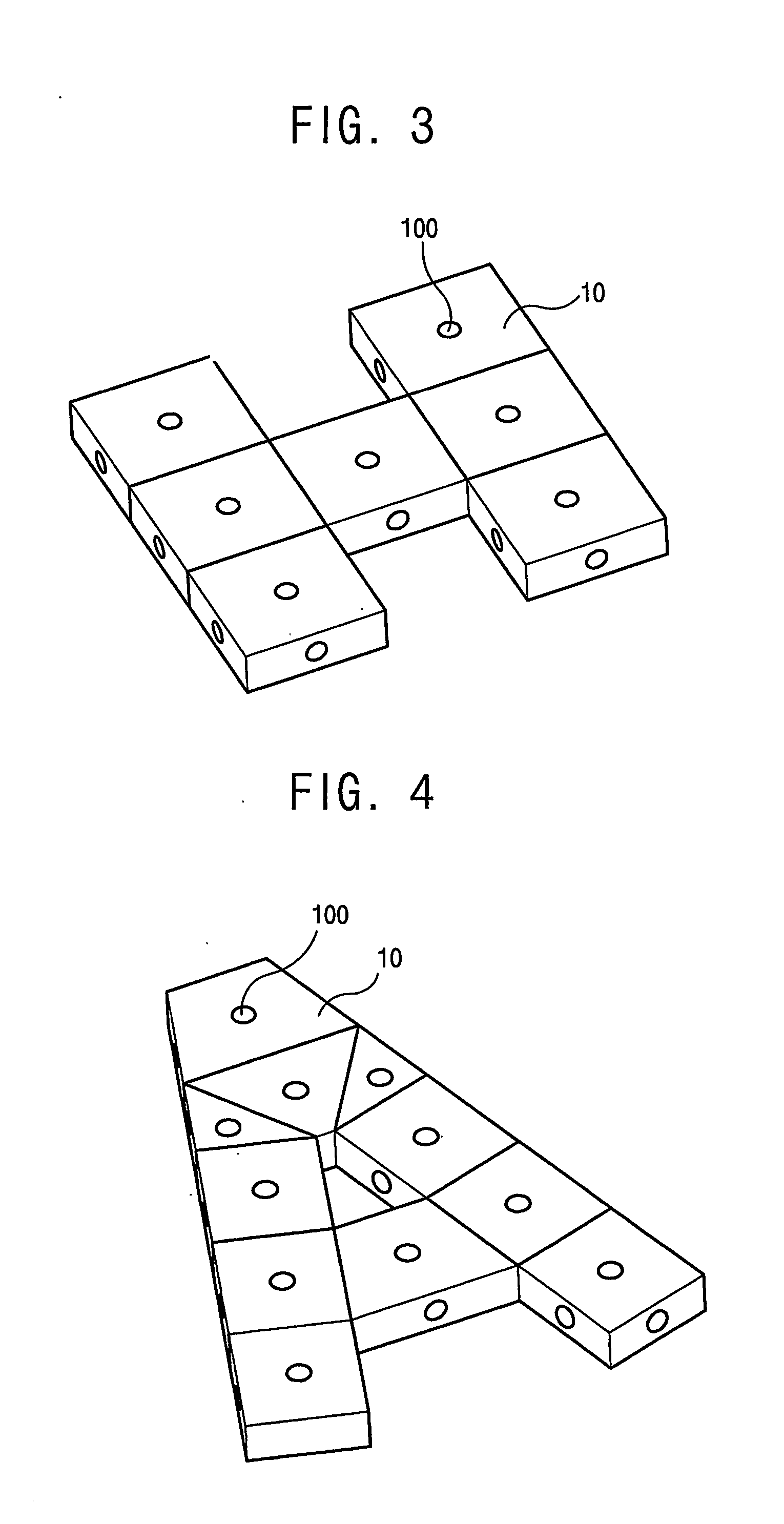

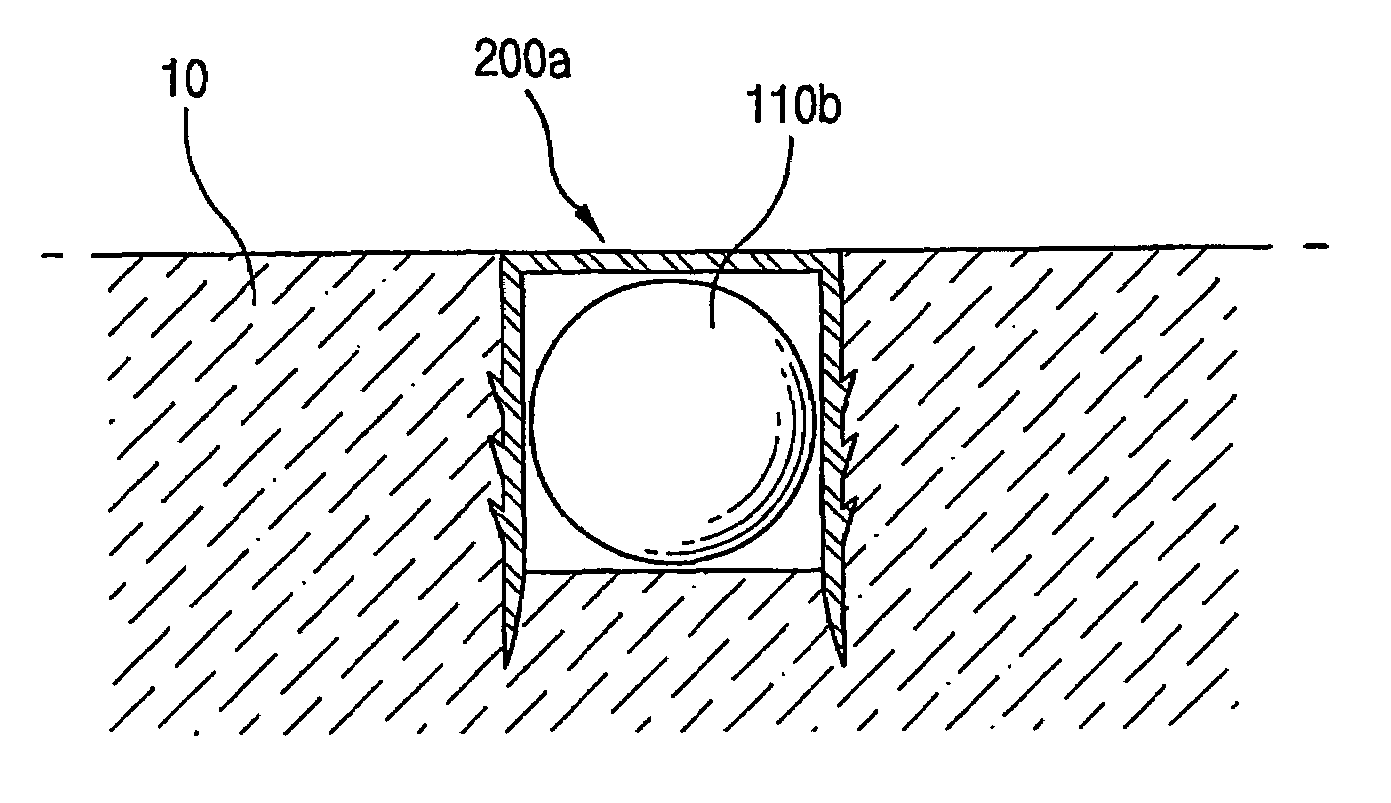

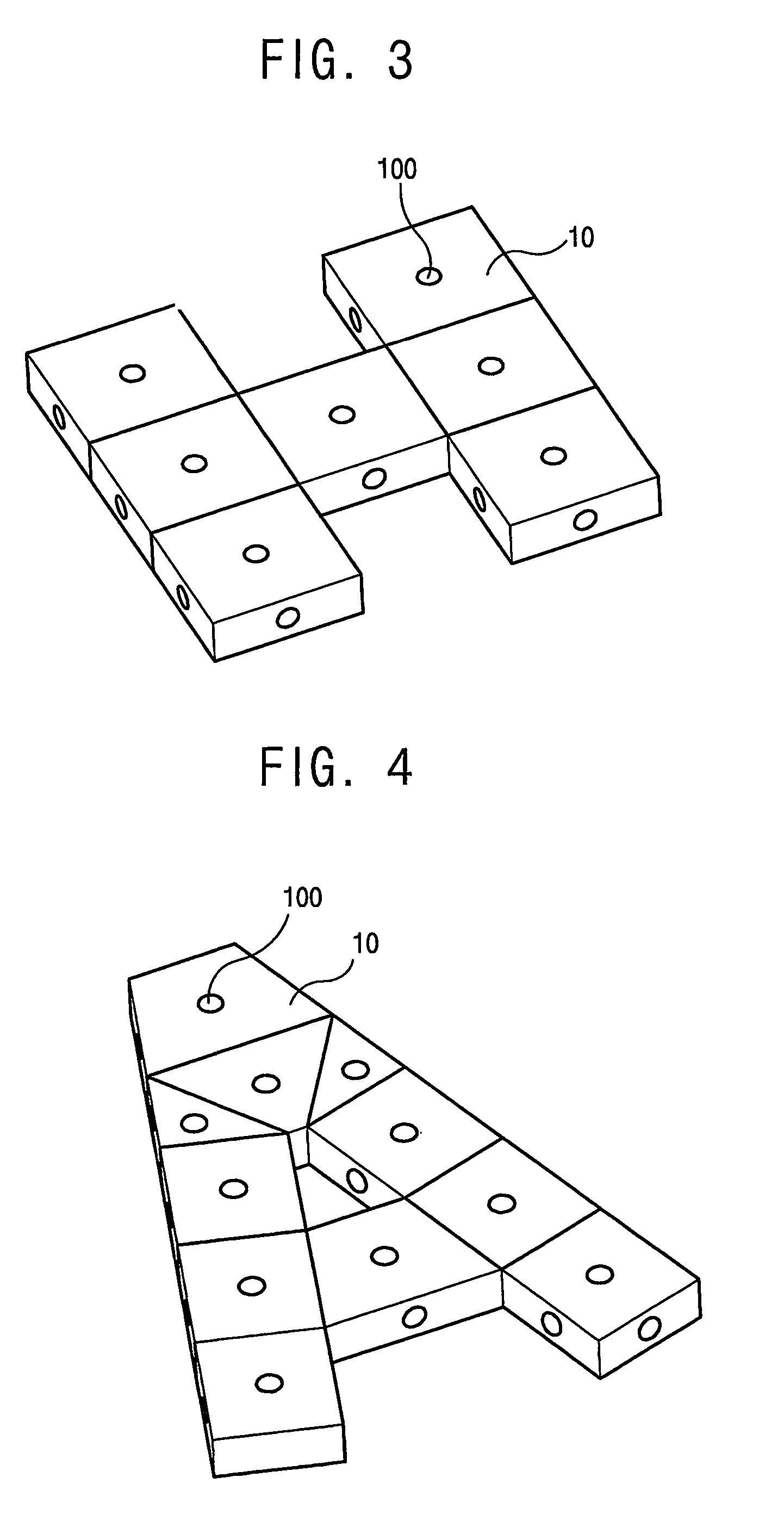

Joining apparatus with rotatable magnet therein and built-up type toy with the same

Disclosed is a built-up type toy having plural parts 10a of polyhedron shape equipped with joining surfaces 11a that are joined with other joining surfaces 11b of other parts 10b. The built-up type toy of the present invention has the parts respectively having magnet portions 10a on the joining surfaces 11a thereof, wherein the magnet portion 100a of the part 10a and the magnet portion 100b on the joining surface 11b of the parts 10b are joined with each other by magnetic force thereof. The built-up type toy of the present invention provides the effects that it is easy to assemble and disassemble, the assemble state is not likely to be demolished easily, and it is helpful to develop the initiative of infant as it can be assemble to various shapes.

Owner:ORDA KOREA CO LTD

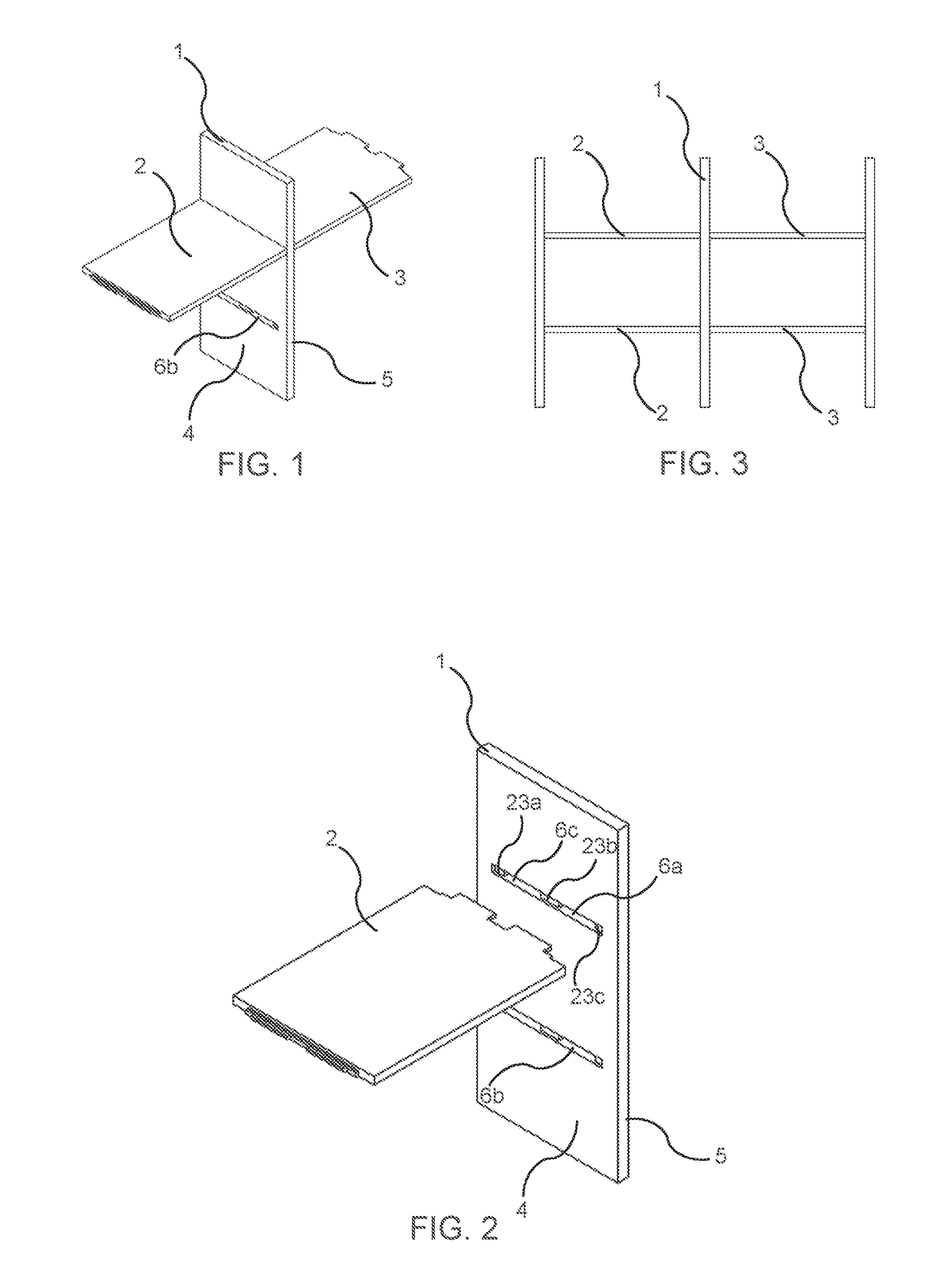

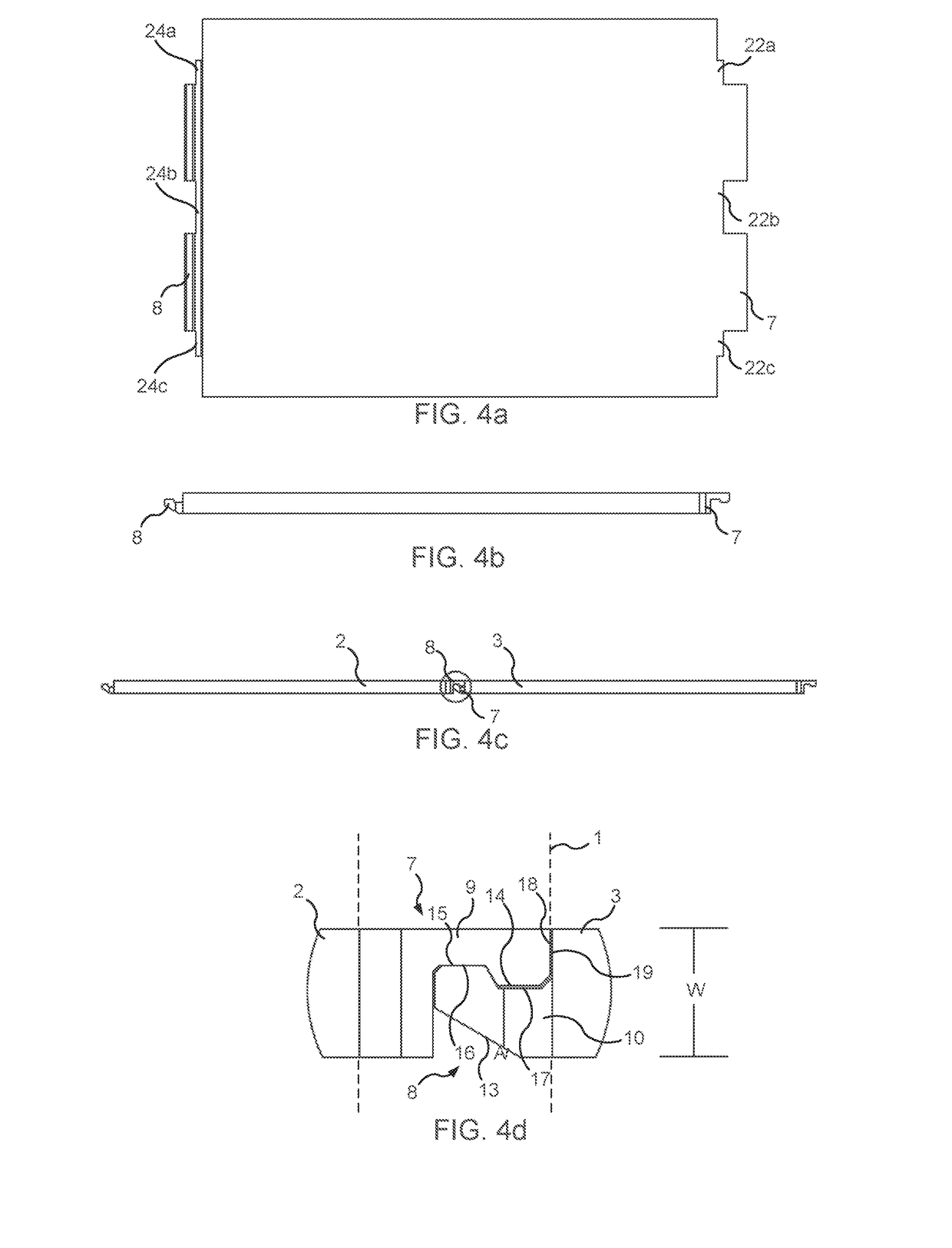

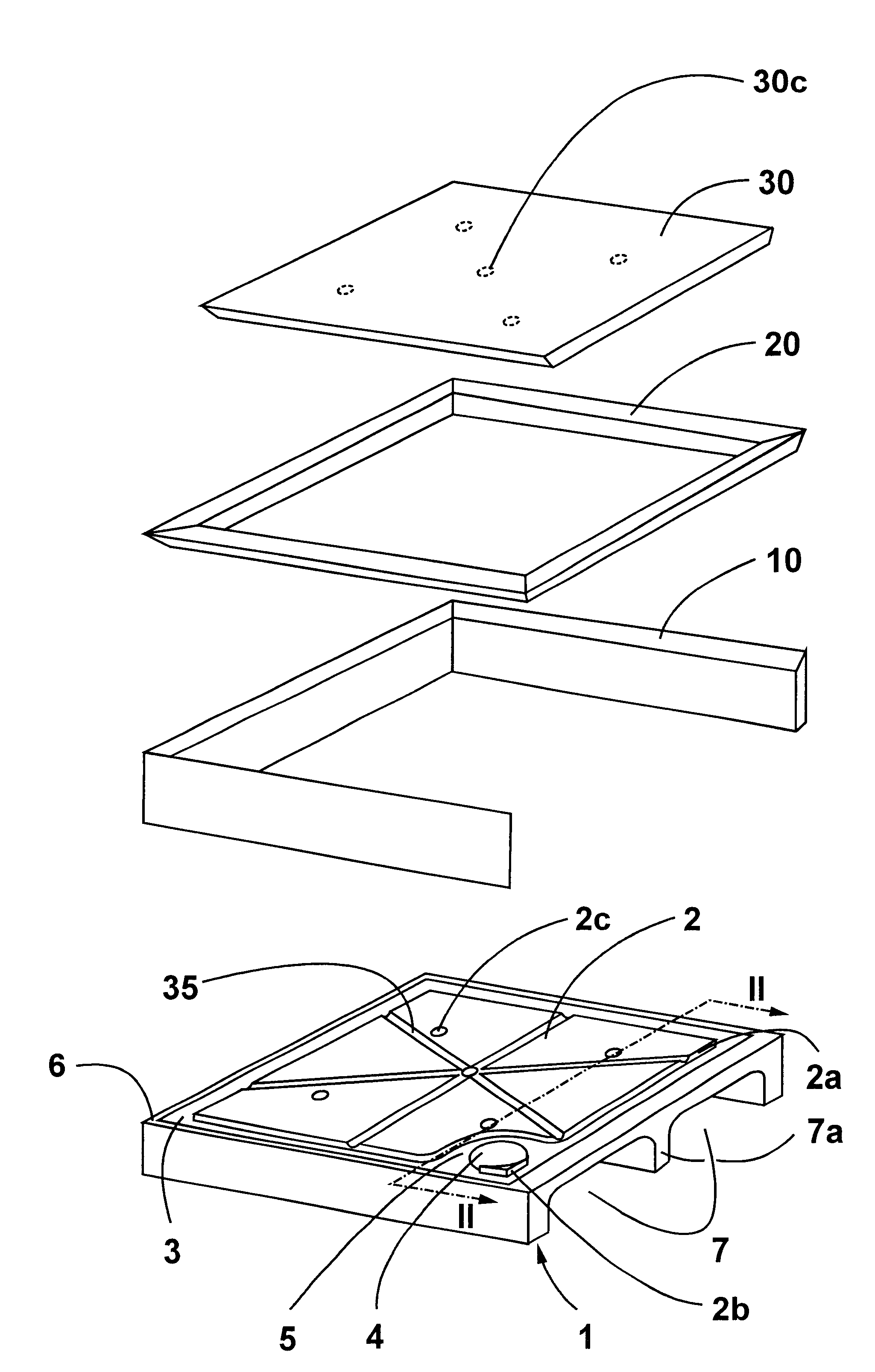

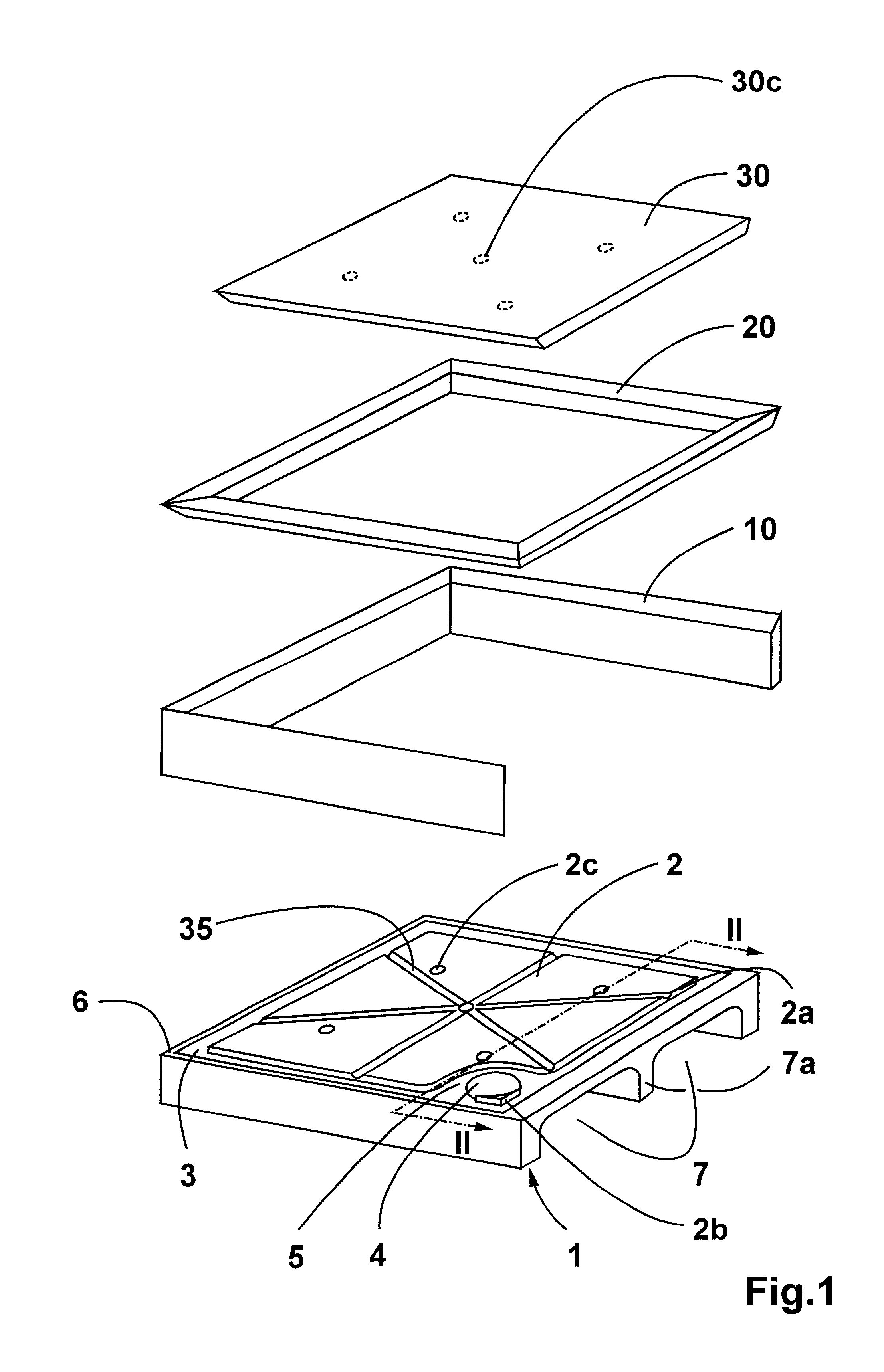

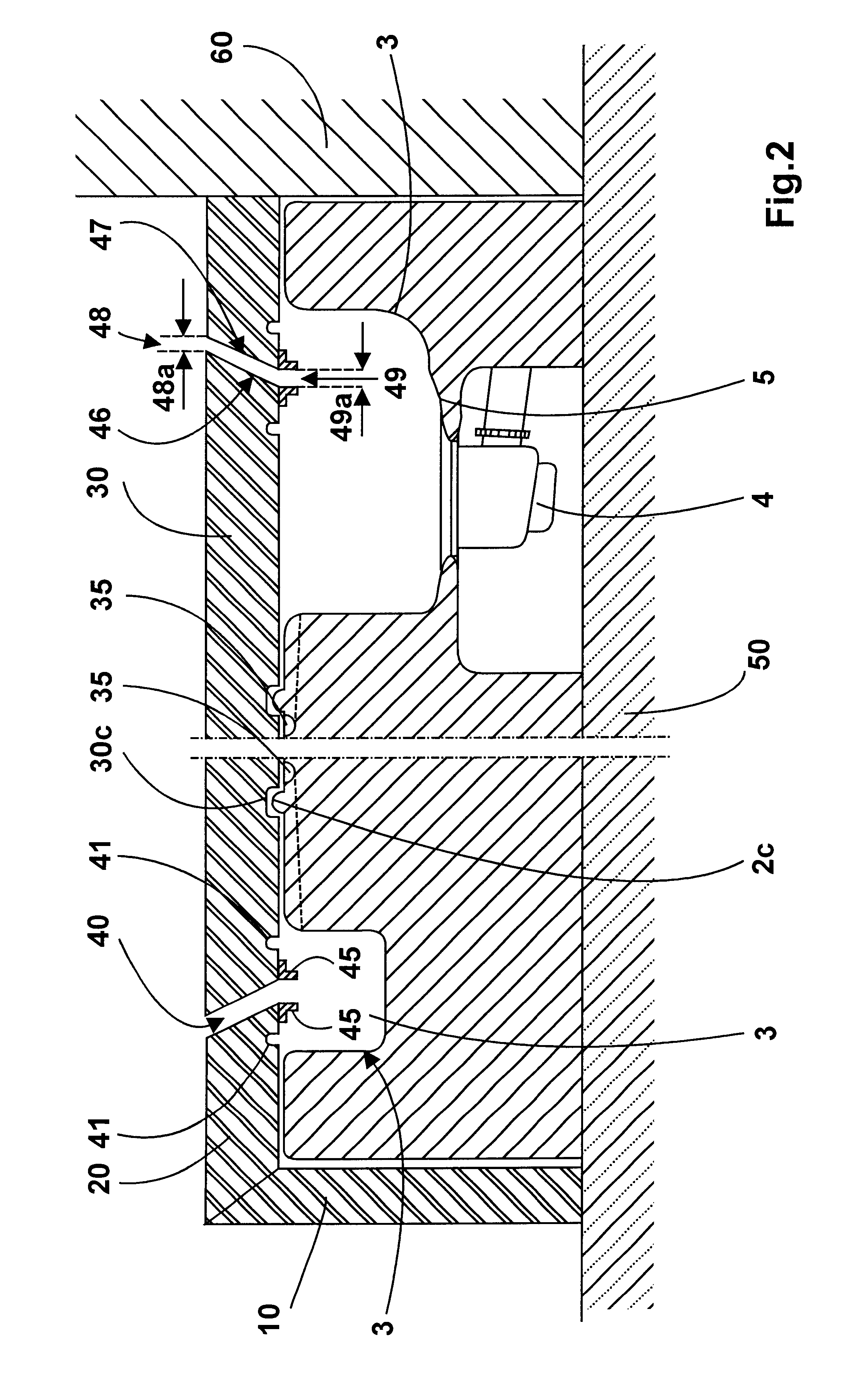

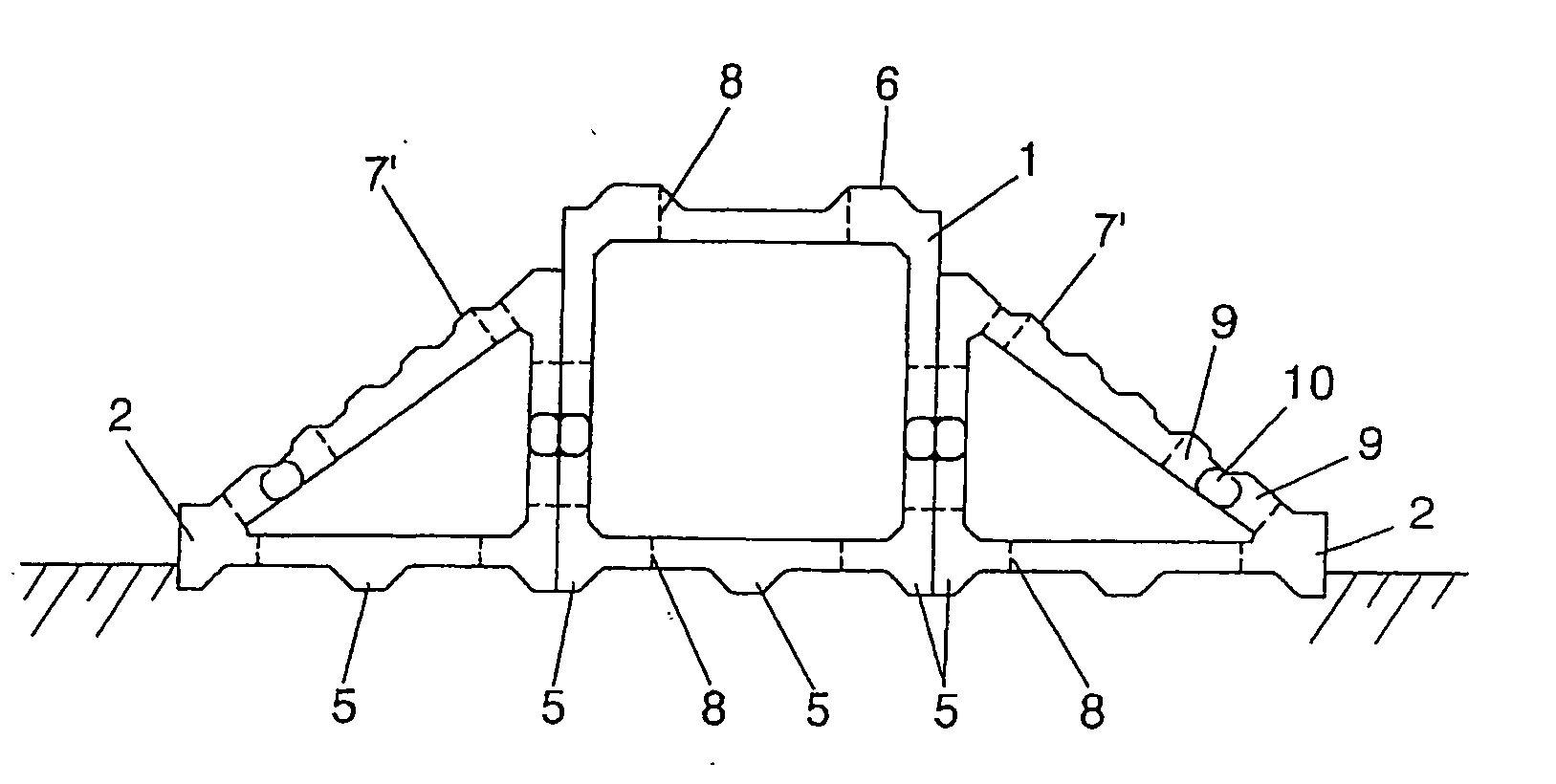

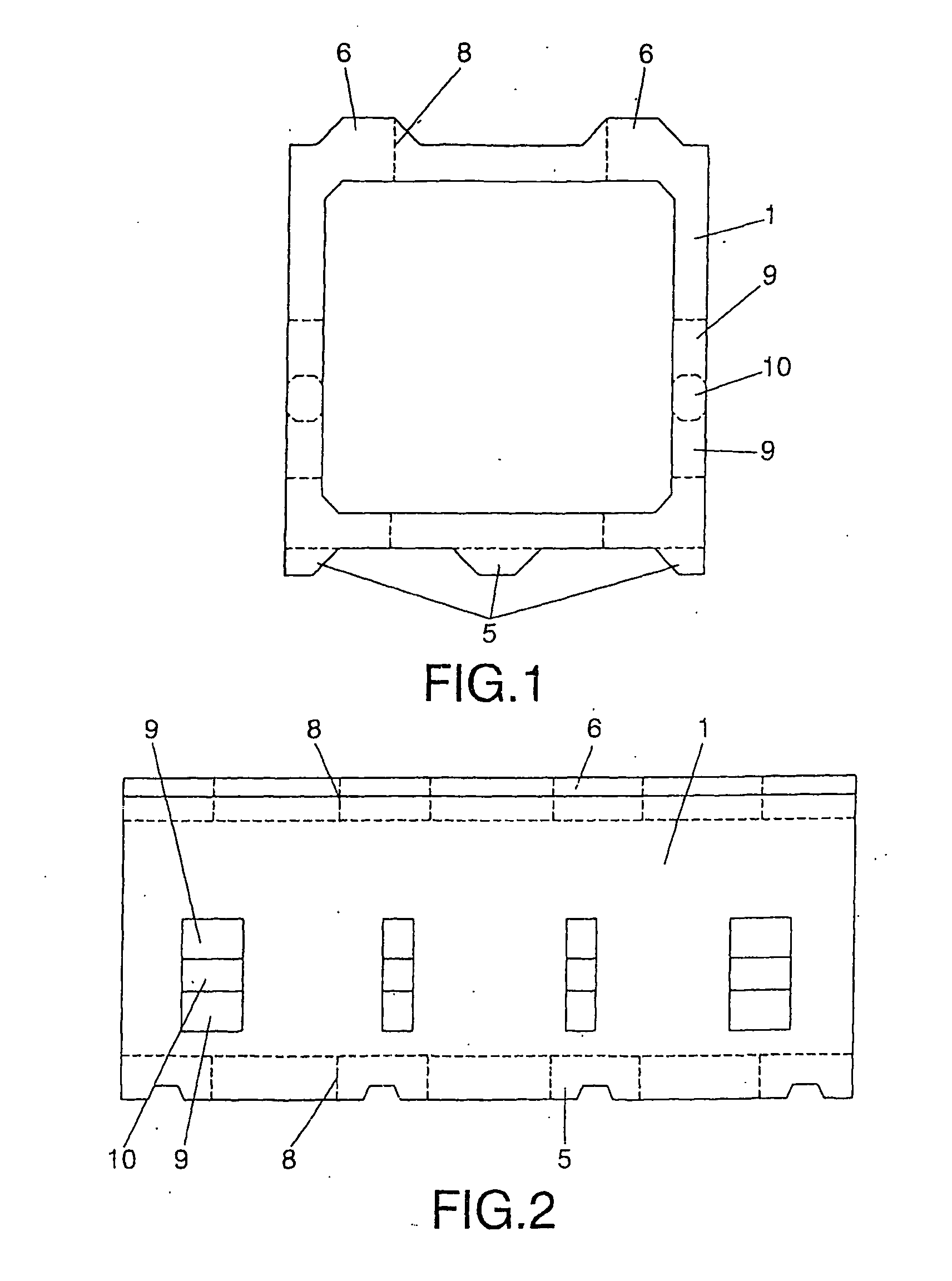

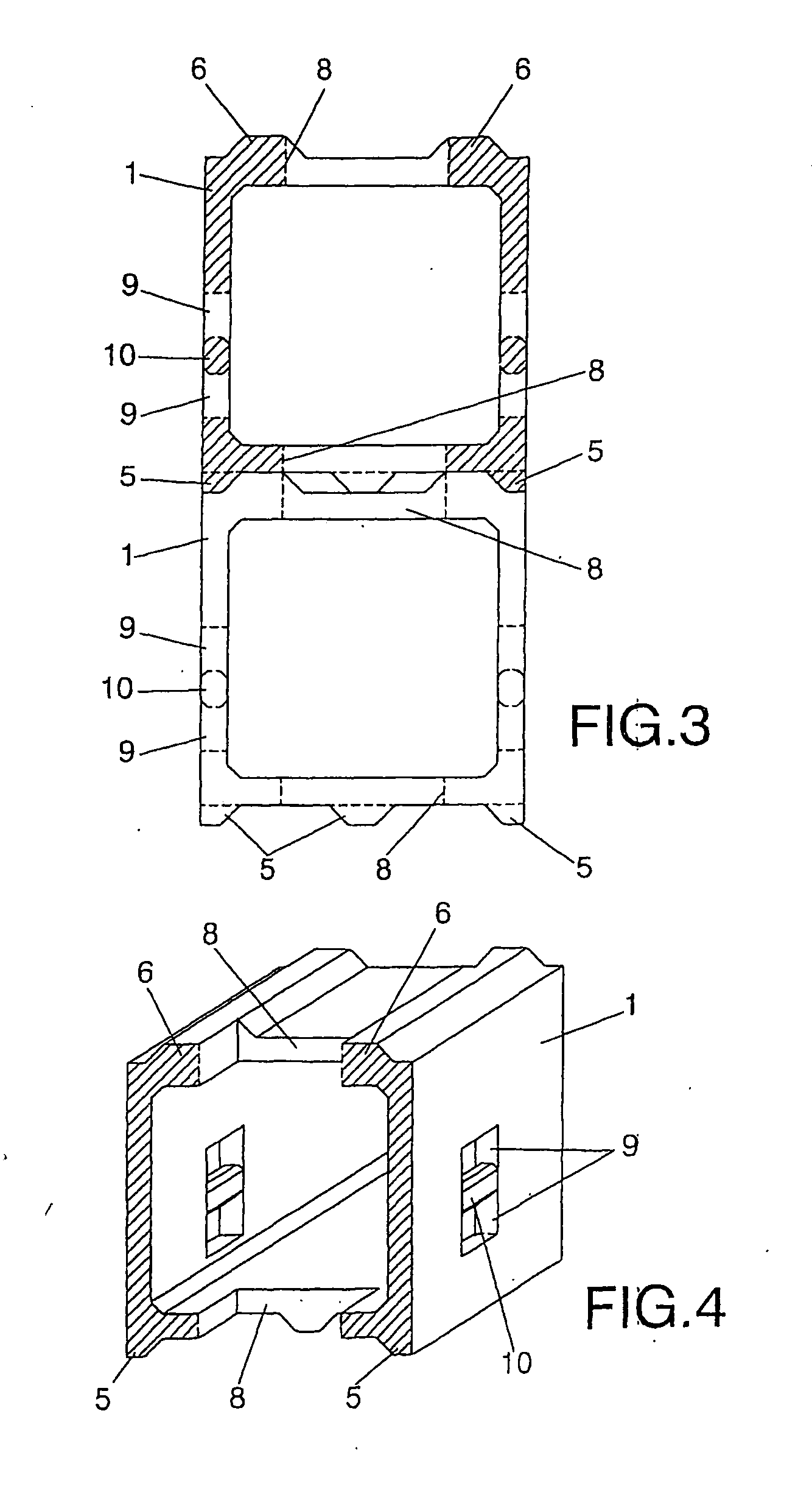

Supporting body for a shower tub

Supporting body (1) being part of a shower tub made of stone, tiles or artificial stone and comprising at least one landing (2) that is surrounded by a margin (6), a channel (3) discharging into a drain (4).

Owner:GERLOFF MICHAEL

Set of panel-shaped elements for a composed element

ActiveUS10415613B2Easy to assembleEasy to dismantleFurniture joining partsSheet joiningEngineeringMechanical engineering

Owner:VÄLINGE INNOVATION AB

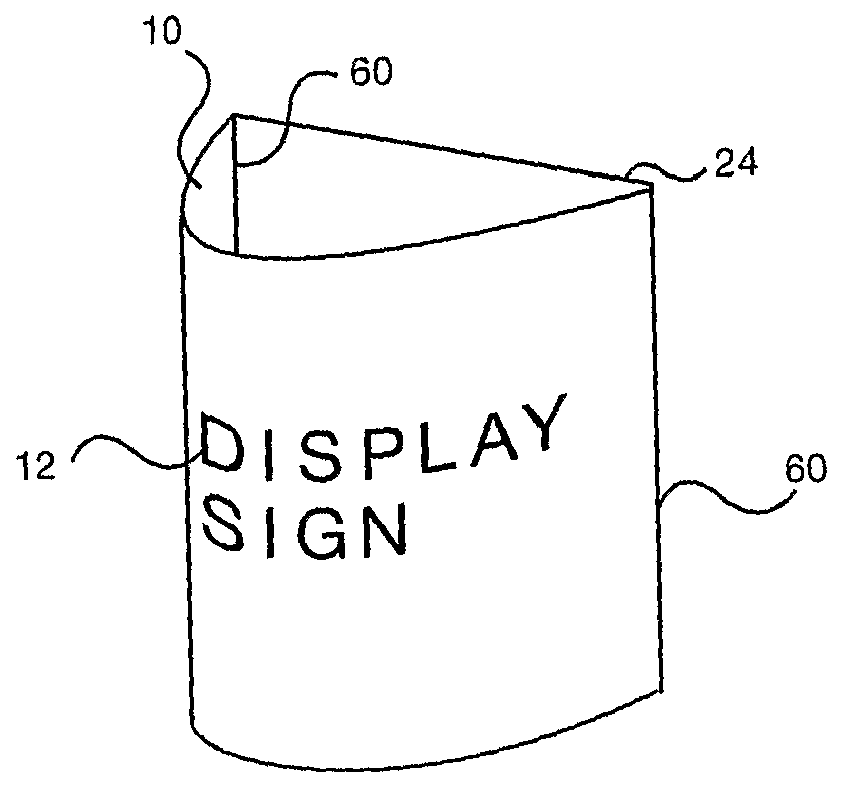

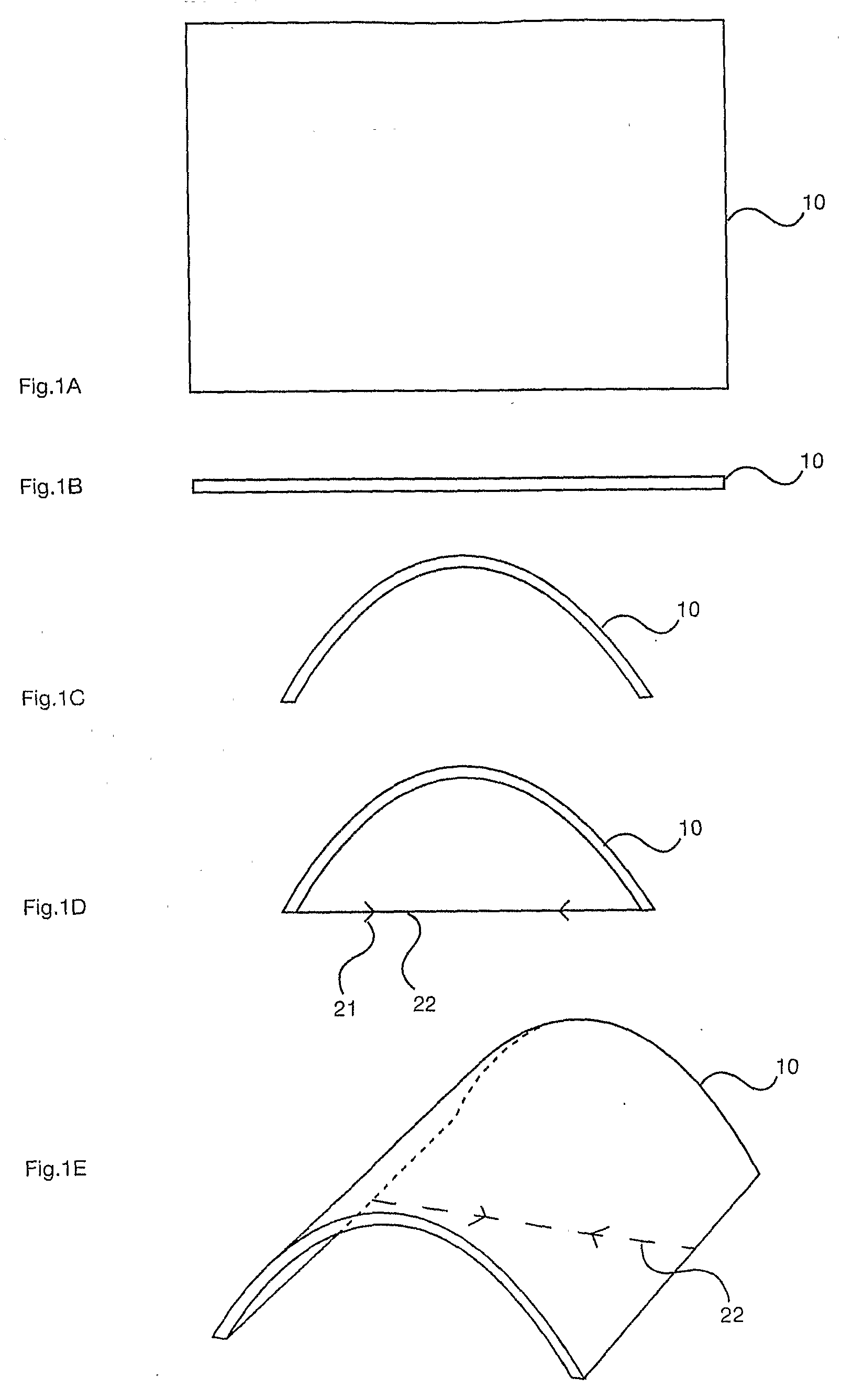

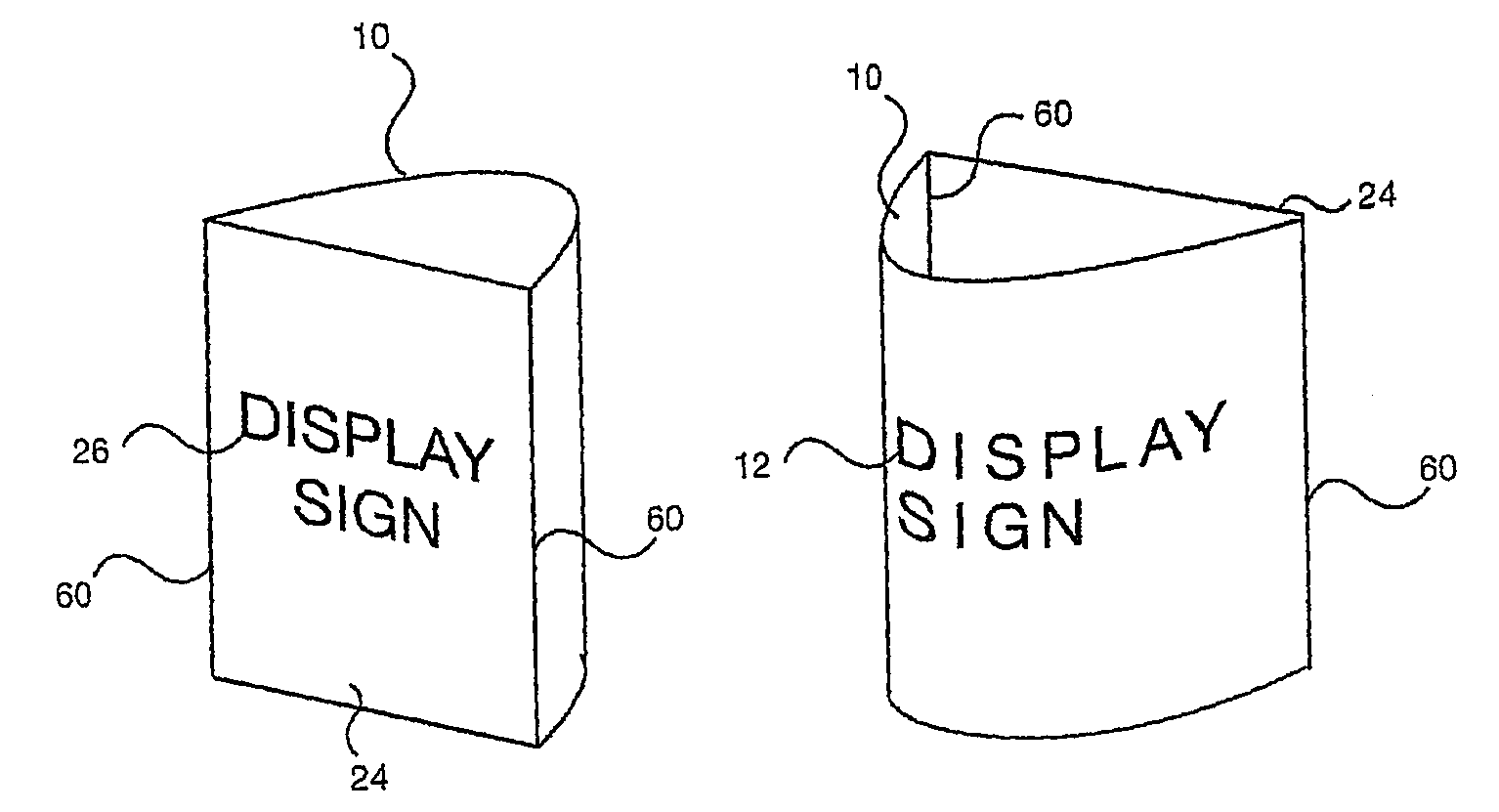

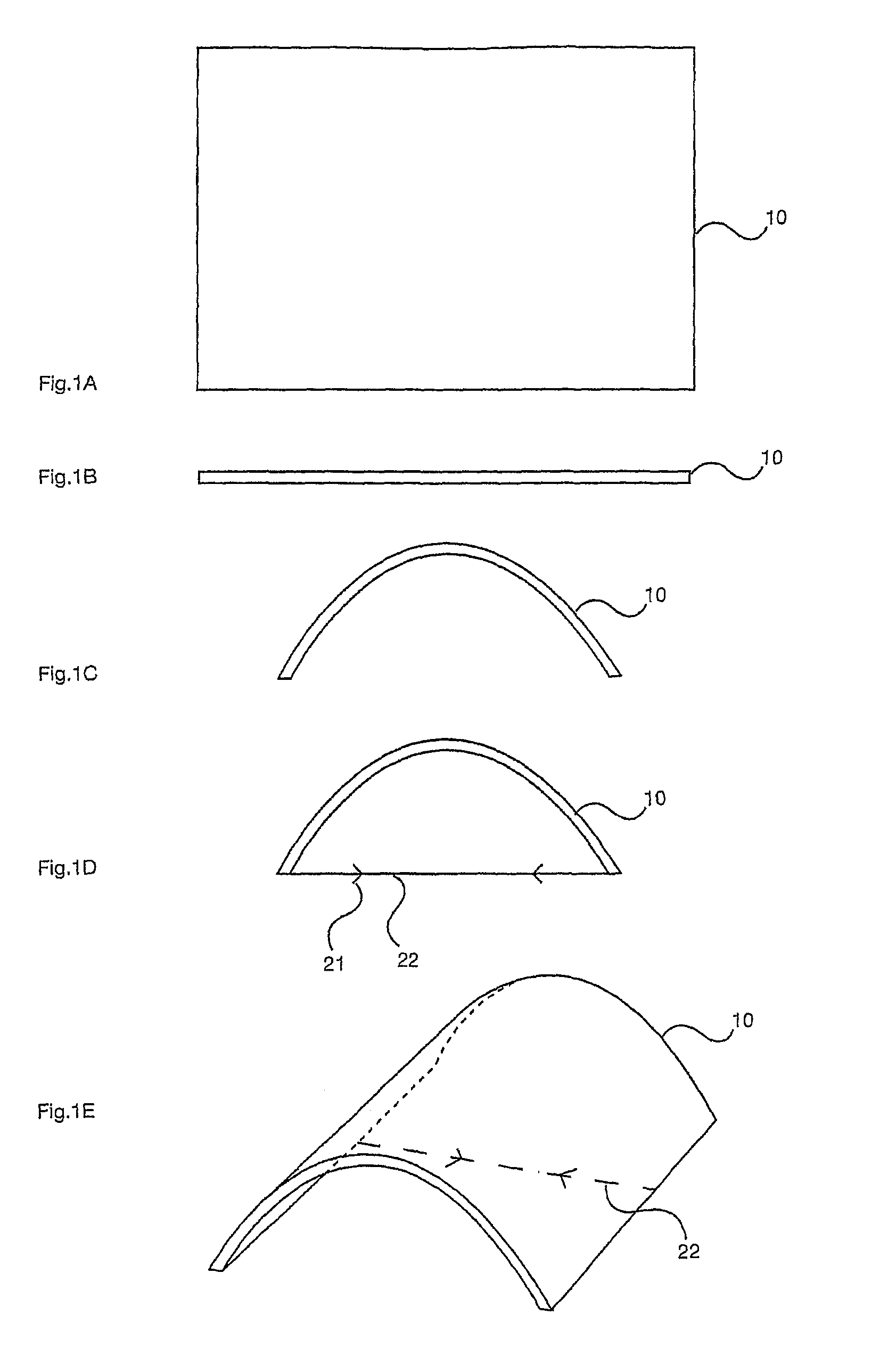

Structural Assembly With a Tied, Flexurally Deformed Panel

InactiveUS20080226846A1More load-bearing capabilityHigh tensile strengthPicture framesSpecial ornamental structuresPrestressed structureGeometric form

An assembly includes a flexurally deformed panel, which is connected to a membrane tie by a linear connector and is tied by the membrane tie to form a geometrically stable pre-stressed structure. More than one panel may be flexurally deformed and tied together in an assembly and more than one membrane tie may be present within an assembly. Panels are typically semi-rigid sheet materials, for example metal sheets, plastic sheets, or sheets of composite materials, such as glass or carbon fibre reinforced plastics or resins. Membrane tie members are typically flexible, for example plastic films, fabrics or nets or arrays of rods or cables. The assemblies have many different geometric forms and many different practical applications. Assemblies may be relatively large, for example demountable and reusable shelters or flat-pack point-of-purchase display assemblies, or may be relatively small, for example a photograph or postcard display system

Owner:CONTRA VISION

Joining apparatus with rotatable magnet therein and built-up type toy with the same

Owner:ORDA KOREA CO LTD

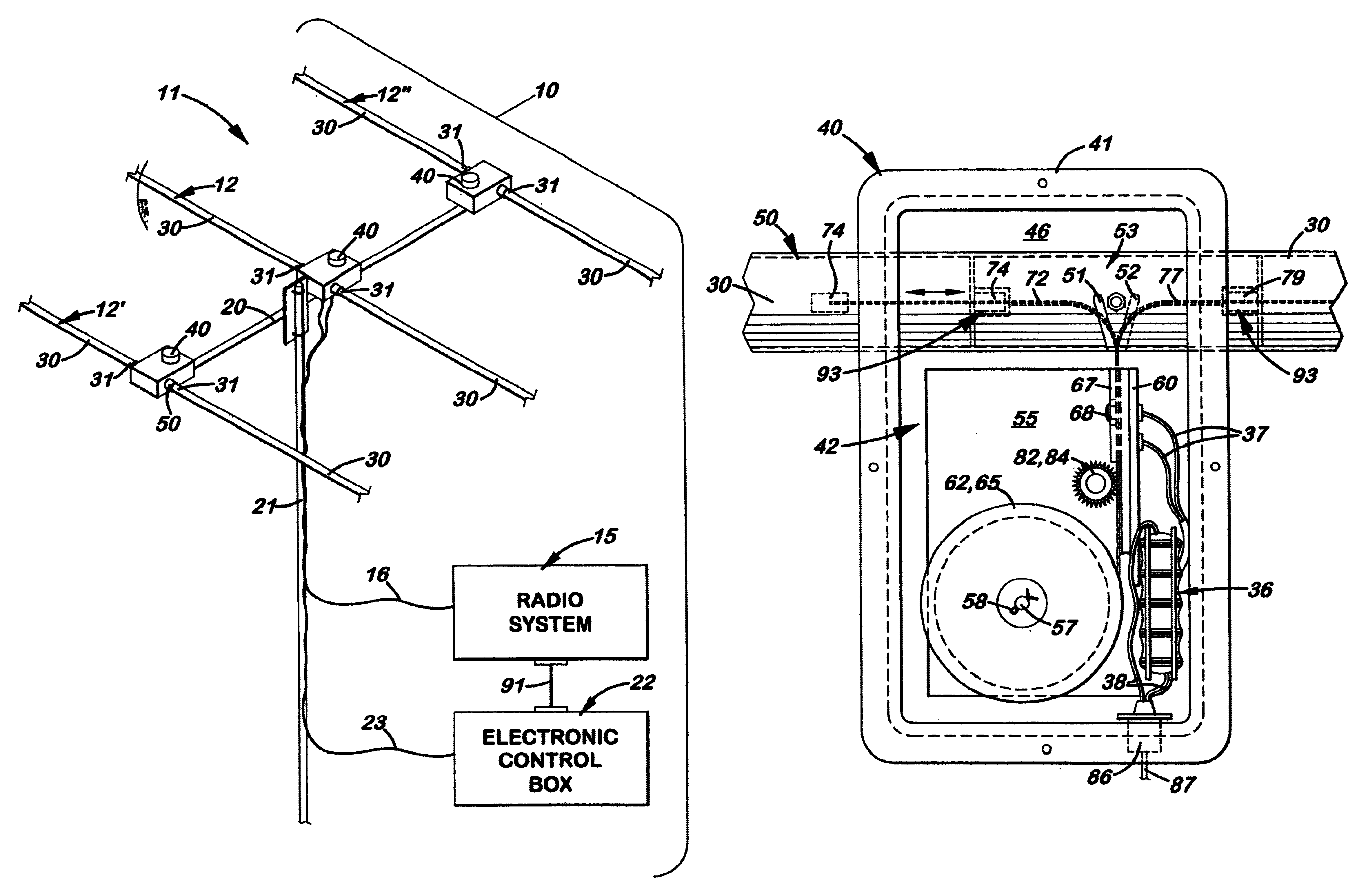

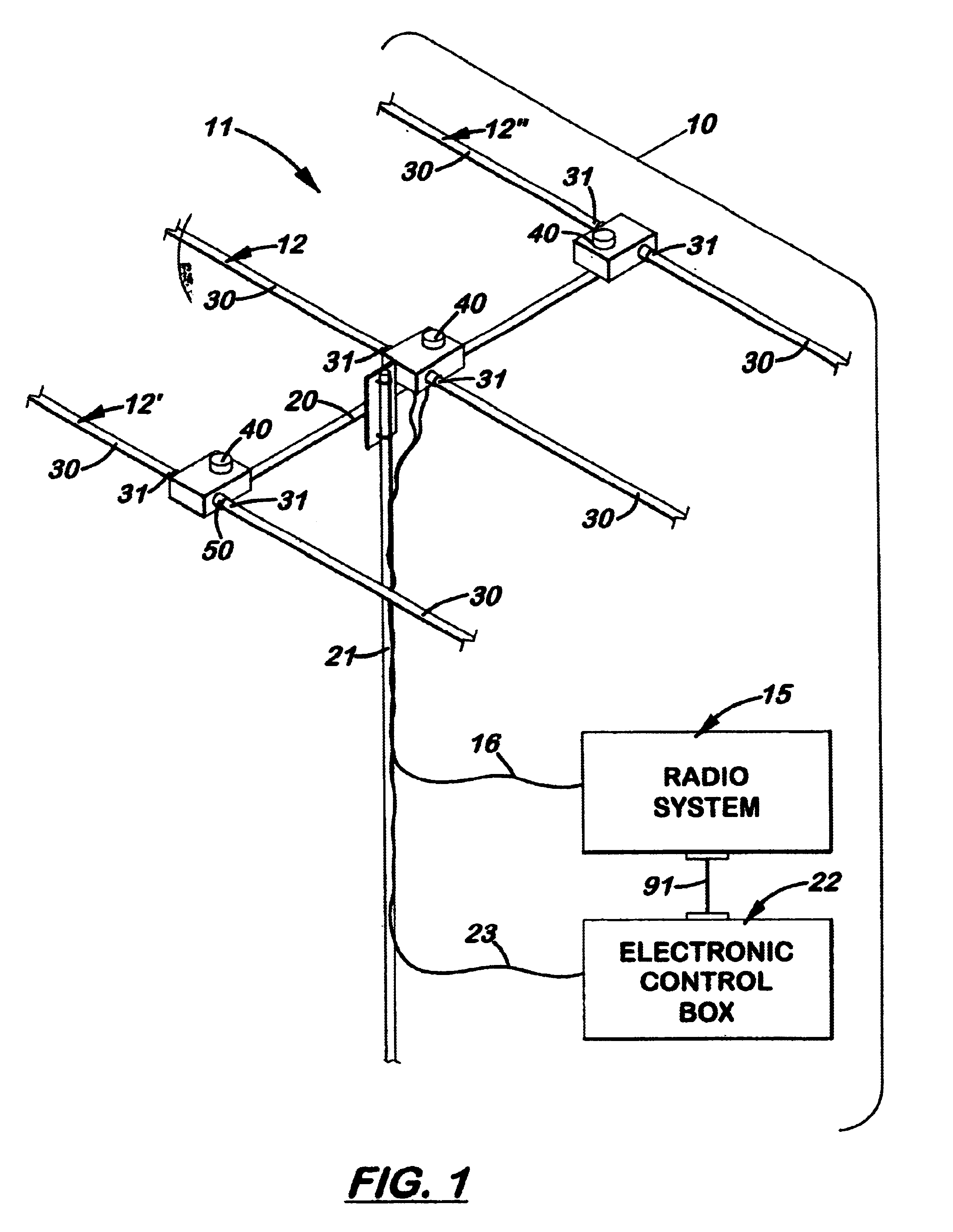

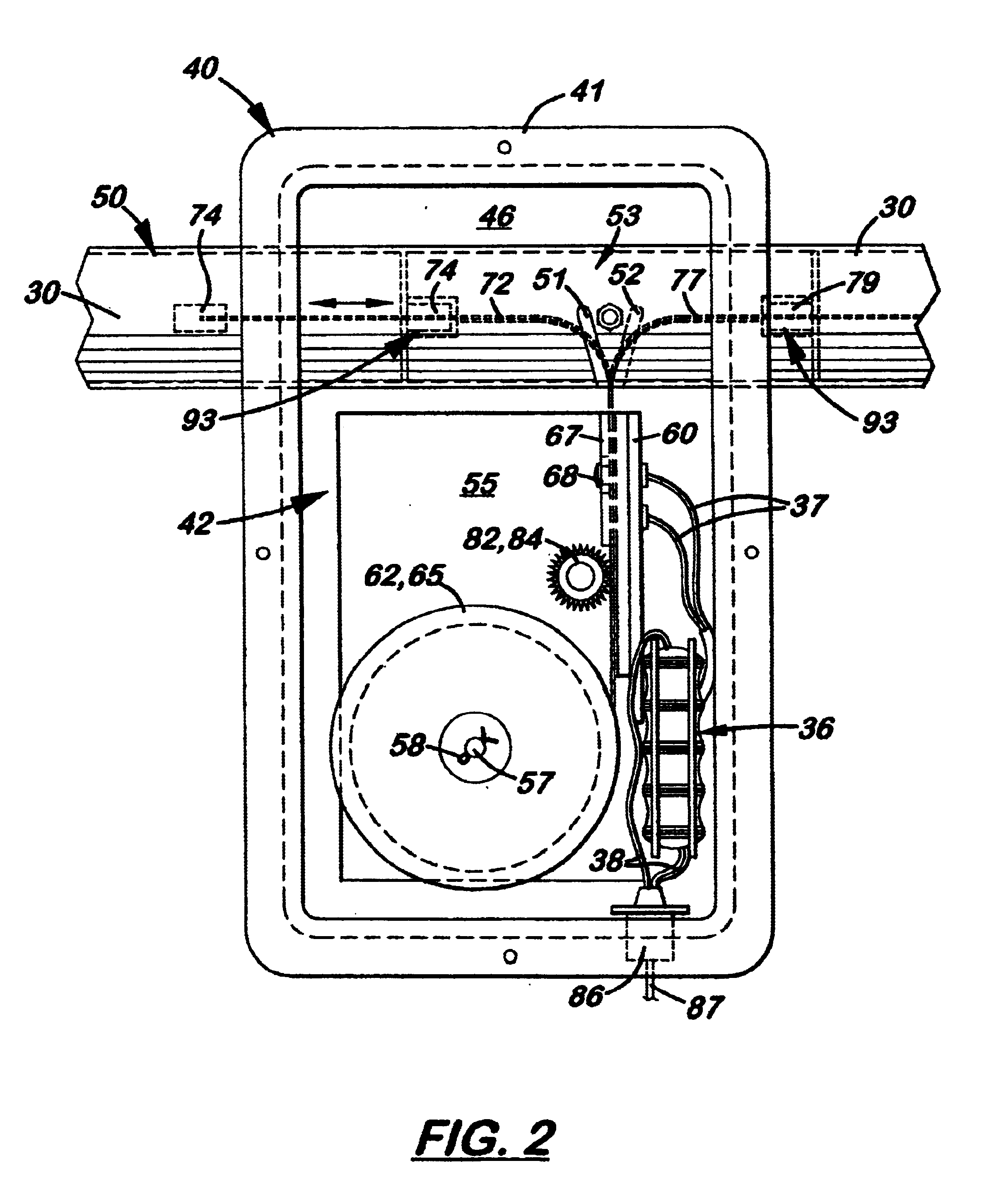

Tunable antenna system

InactiveUS6677914B2Easy to assembleEasy to dismantleResonant antenna detailsIndividually energised antenna arraysElectronic control systemControl system

An antenna system with at least one tunable dipole element with a length adjustable conductive member disposed therein that enables the antenna to be used over a wide range of frequencies. The element is made of two longitudinally aligned, hollow support arms made of non-conductive material. Disposed longitudinally inside each element is a length adjustable conductive member electrically connected at one end. In the preferred embodiment, each conductive member is stored on a spool that is selectively rotated to precisely extend the conductive member into the support arm. The support arms, which may be fixed or adjustable in length, are affixed at one end to a rigid housing. During use, the conductive members are adjusted in length to tune the element to a desired frequency. The antenna is especially advantageous when configured as a Yagi-style antenna that can be optimally tuned at a specific frequency for maximum gain, maximum front-to-back ratio, and to provide a desired feed point impedance at the driven element. The antenna can also function as a bi-directional antenna by adjusting the reflector element to function as a director. An electronic control system allows the length of the conductive members to be manually or automatically adjusted to a desired frequency.

Owner:STEPPIR COMM SYST INC

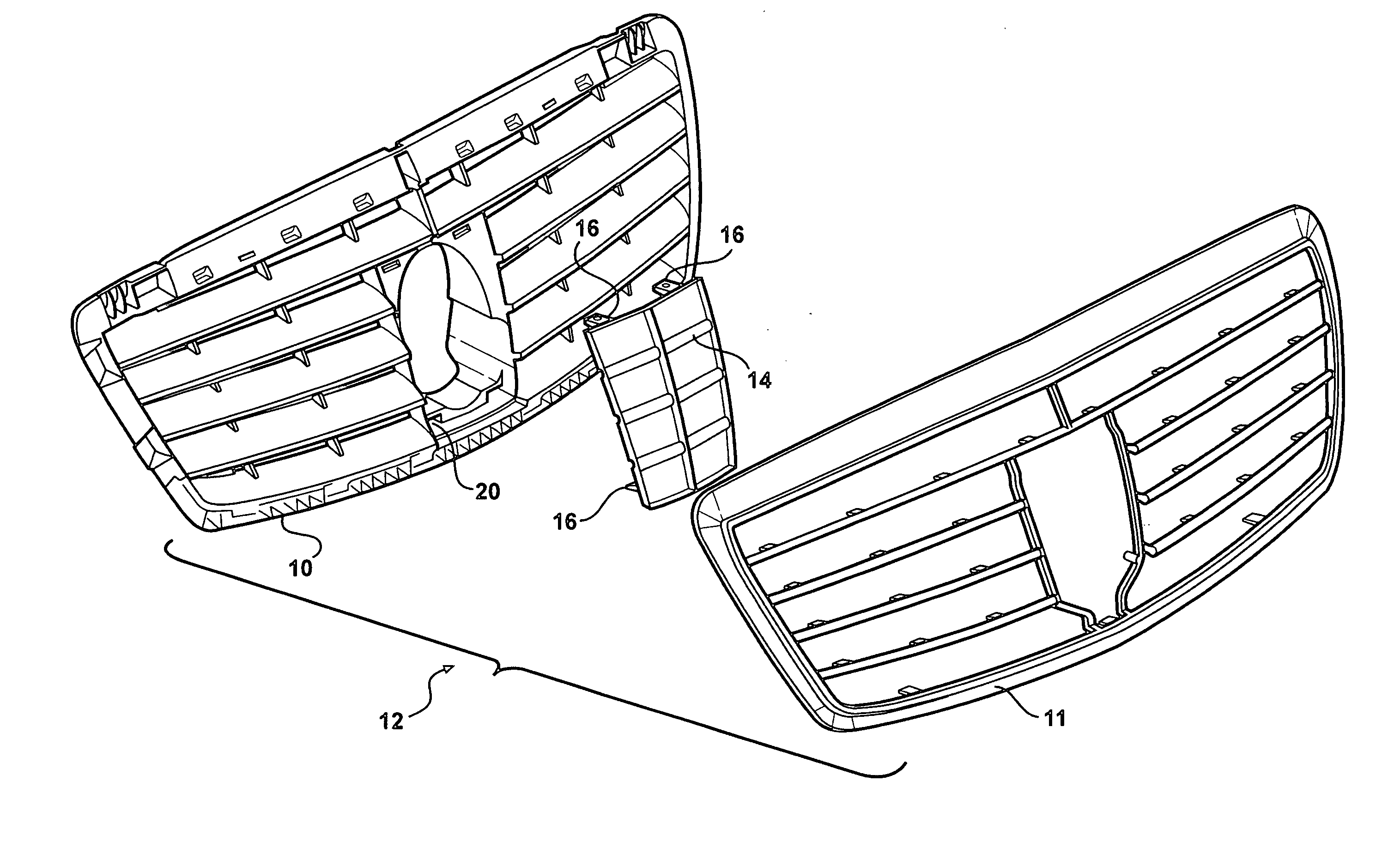

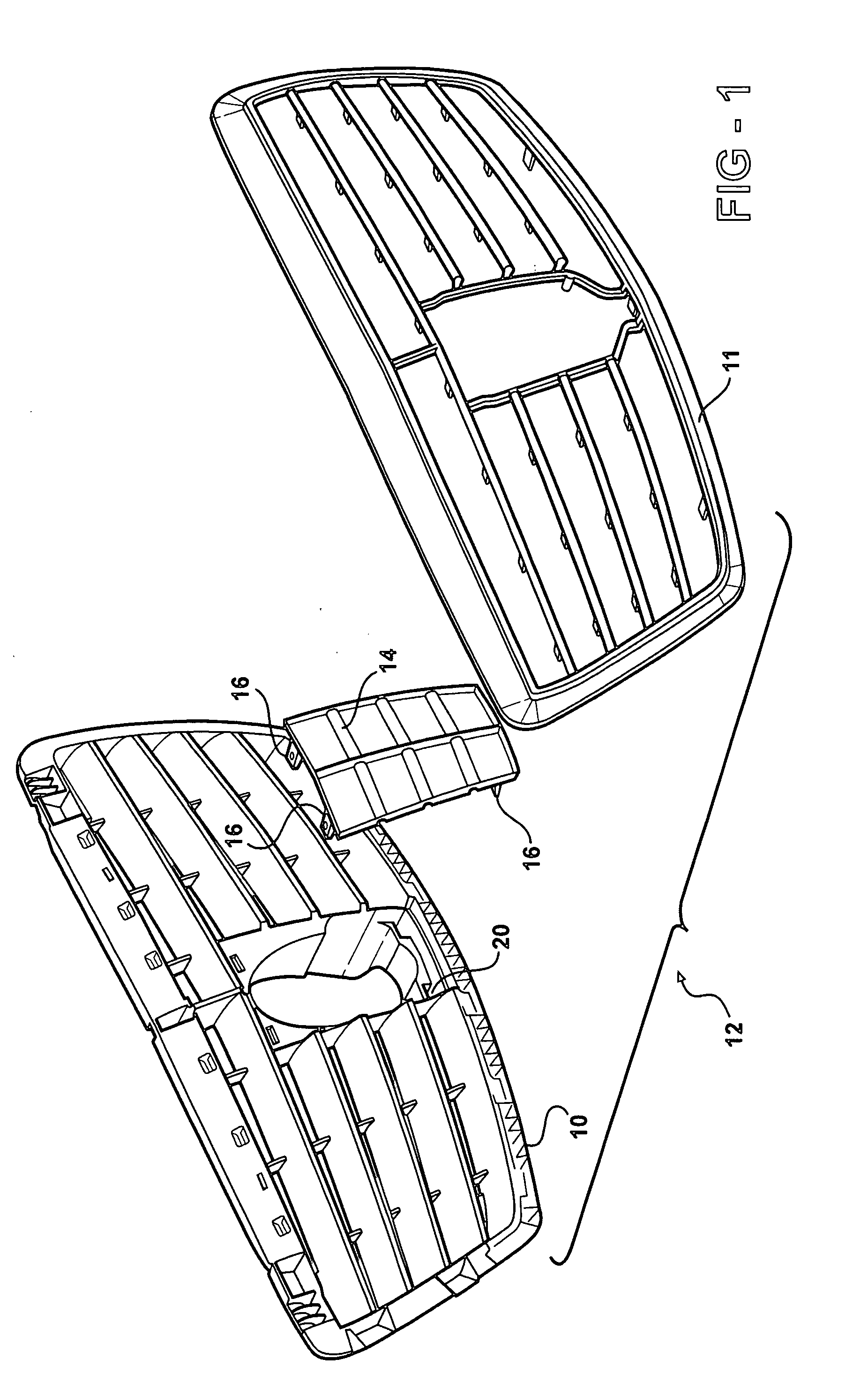

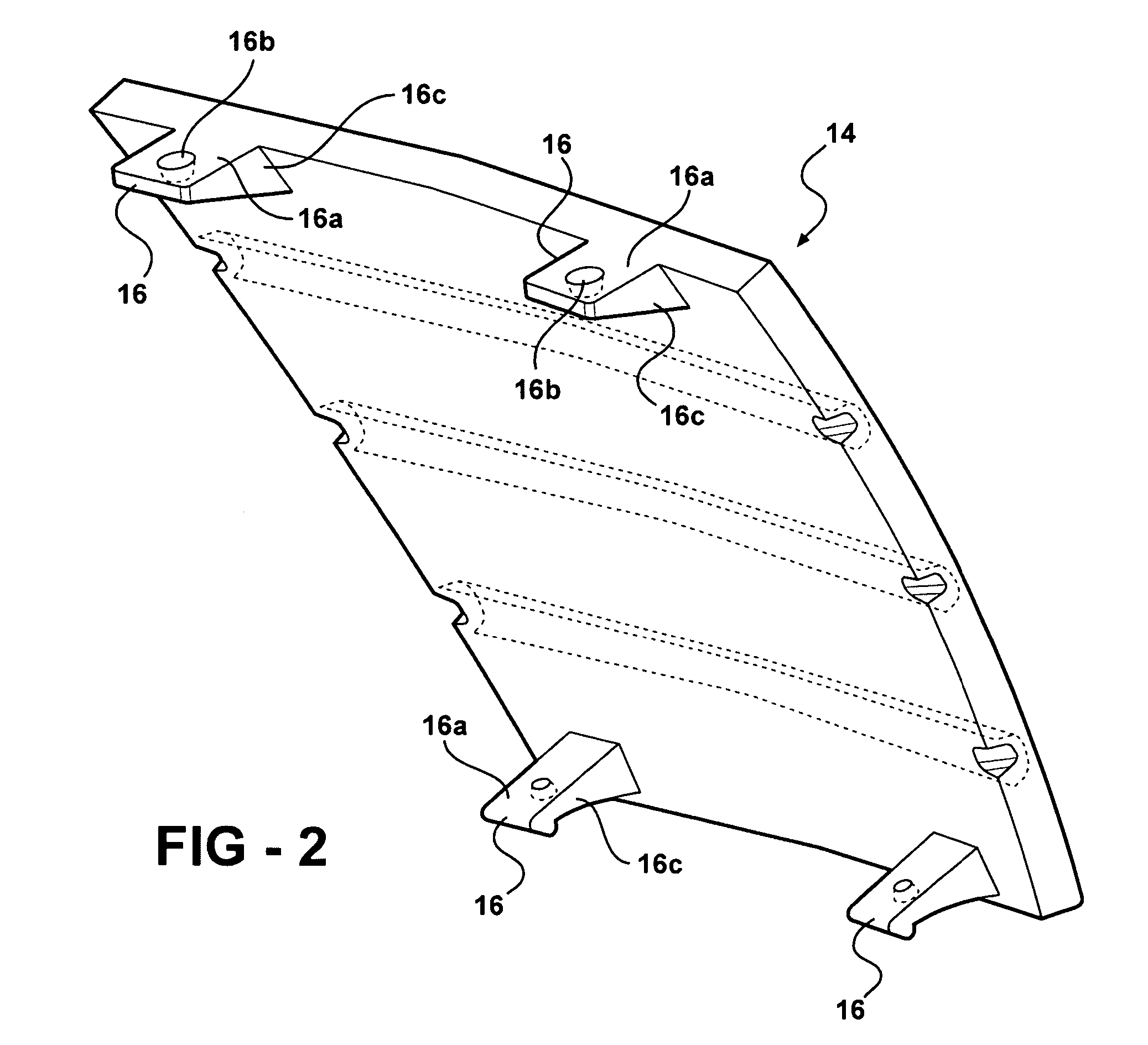

Fixing system

InactiveUS20070137018A1Simple and cheap to produceEasy and cheap to produceSheet joiningPositioning apparatusEngineeringMechanical engineering

A fixing system for fixing a first component to a second component, wherein the first component is formed with at least one tab which can engages with at least one tongue formed on the second component, wherein the minimum of one tab is formed with at least one conical hole with which a projection, particularly a conical projection, provided on the tongue can be brought into engagement by latching therein.

Owner:DECOMA GERMANY

Structure for an adjustable support of monitor

InactiveUS7198240B2Easy to dismantleEasy to assembleDigital data processing detailsCouplings for rigid shaftsEngineeringMechanical engineering

Owner:E LEAD ELECTRONICS

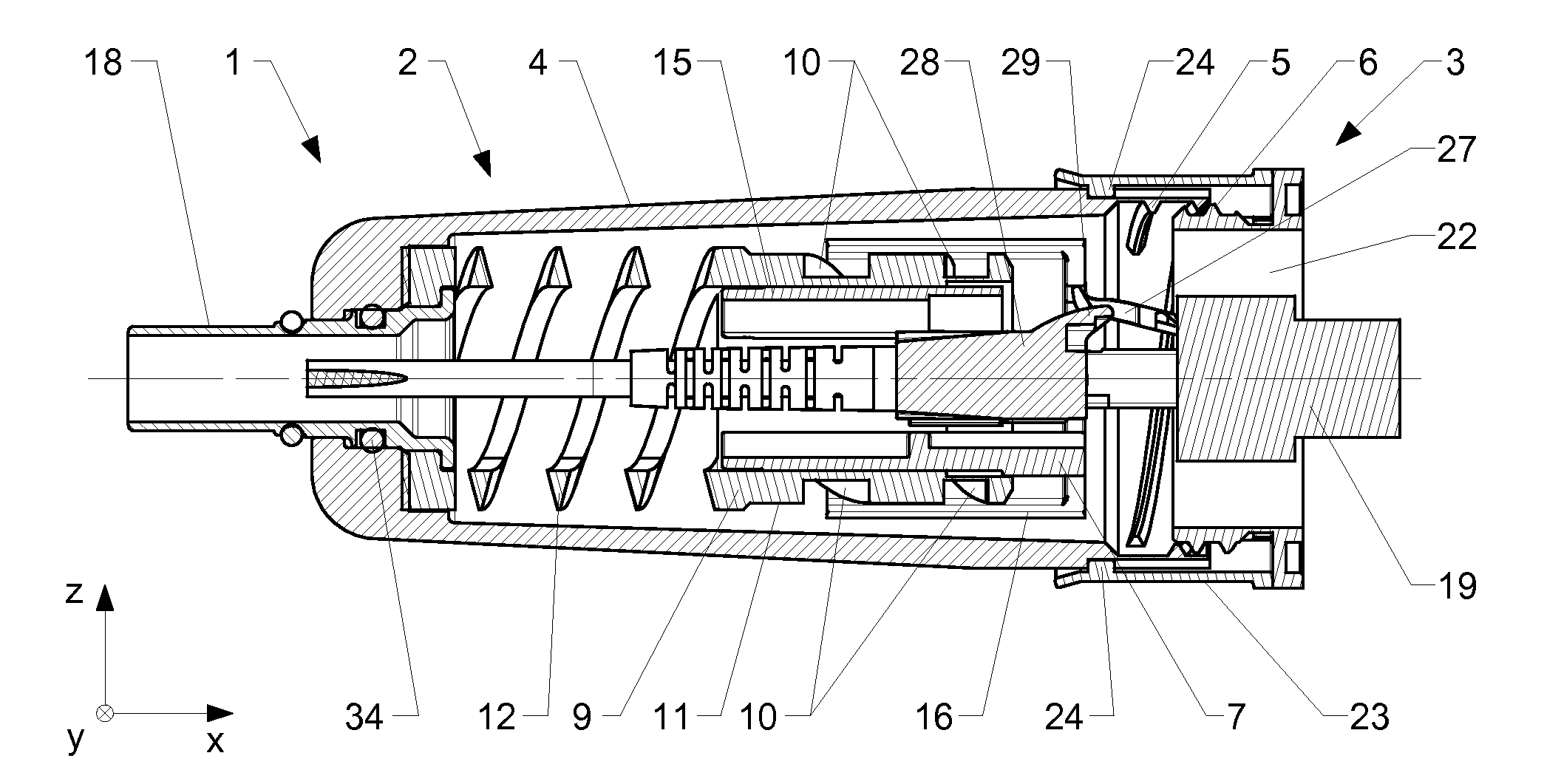

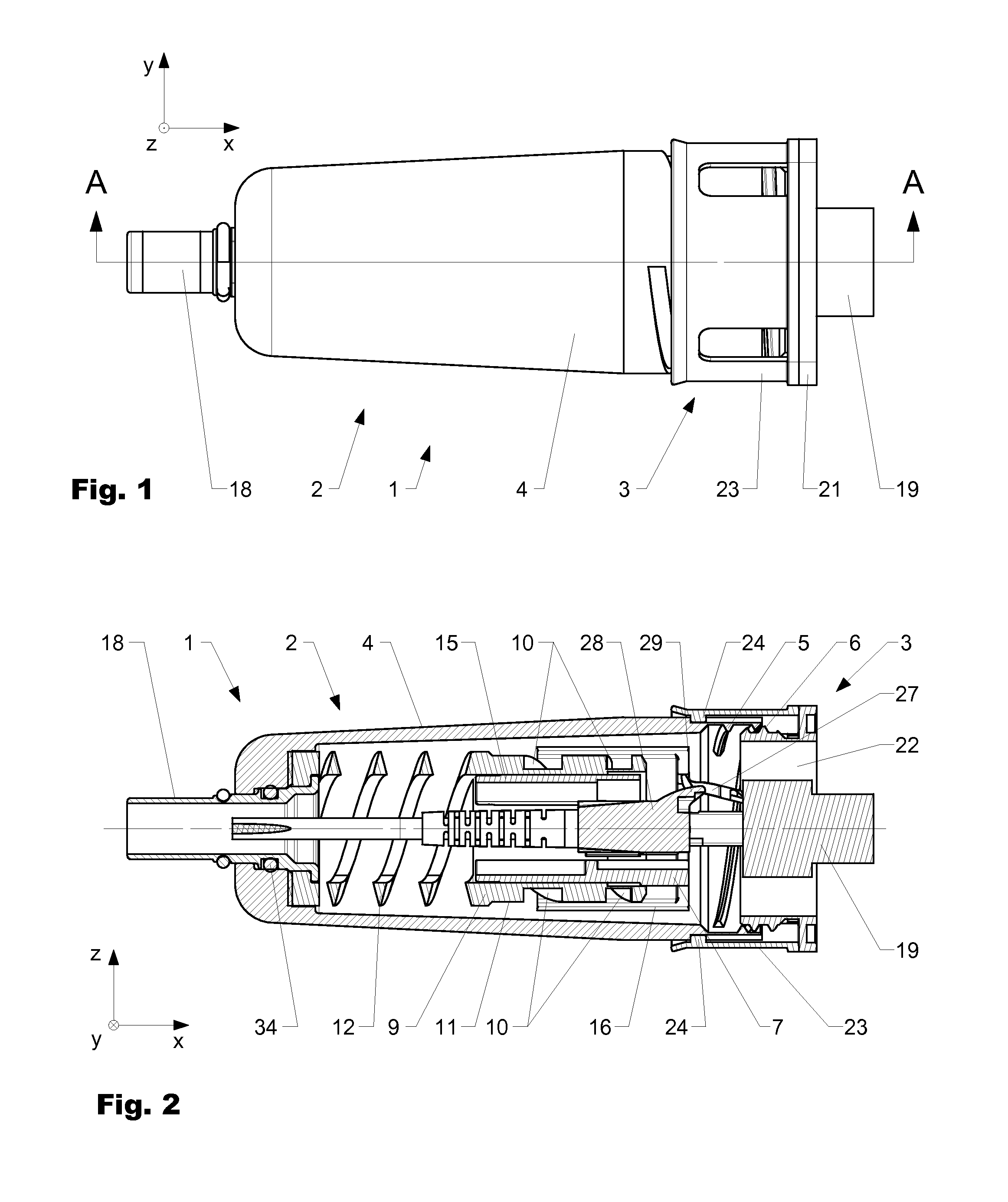

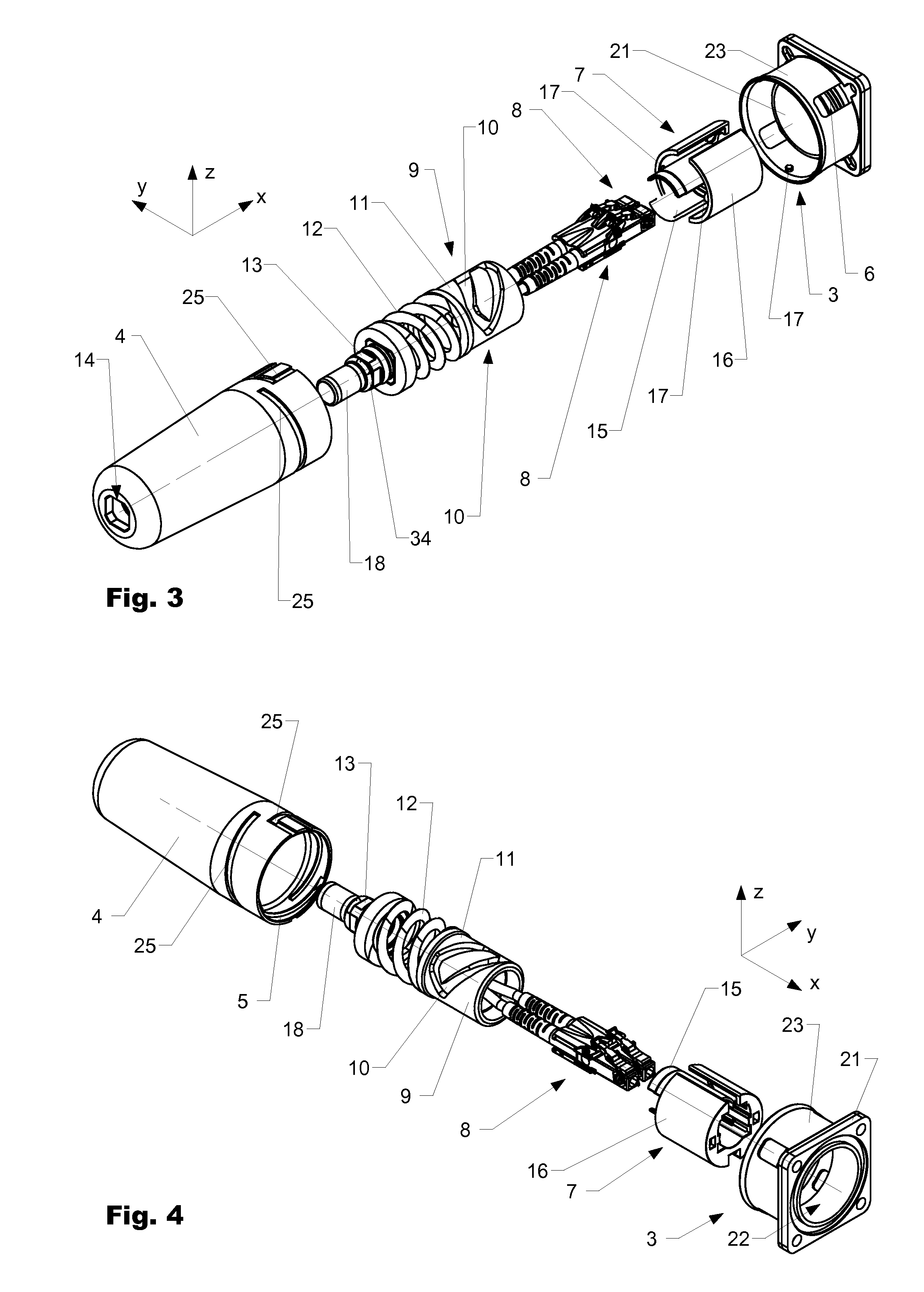

Plug-in device for an optical cable

ActiveUS20120141086A1Simple wayAvoid problemsCoupling device detailsOptical light guidesAxial displacementCable gland

The invention relates to a cable gland (1) having a flange (3) and a plug-in part (2) suited for an operational connection to the flange (3). The plug-in part (2) comprises a locking sleeve (4), and a fastener (7) for a connector (8), said fastener being operatively connected to said locking sleeve by way of a control slide (10). The control slide (10) is configured such that a rotation of the locking sleeve (4) around the longitudinal axis (x) of the plug-in part (2) results in an axial displacement of the fastener (7) in a longitudinal direction.

Owner:HUBERSUHNER AG

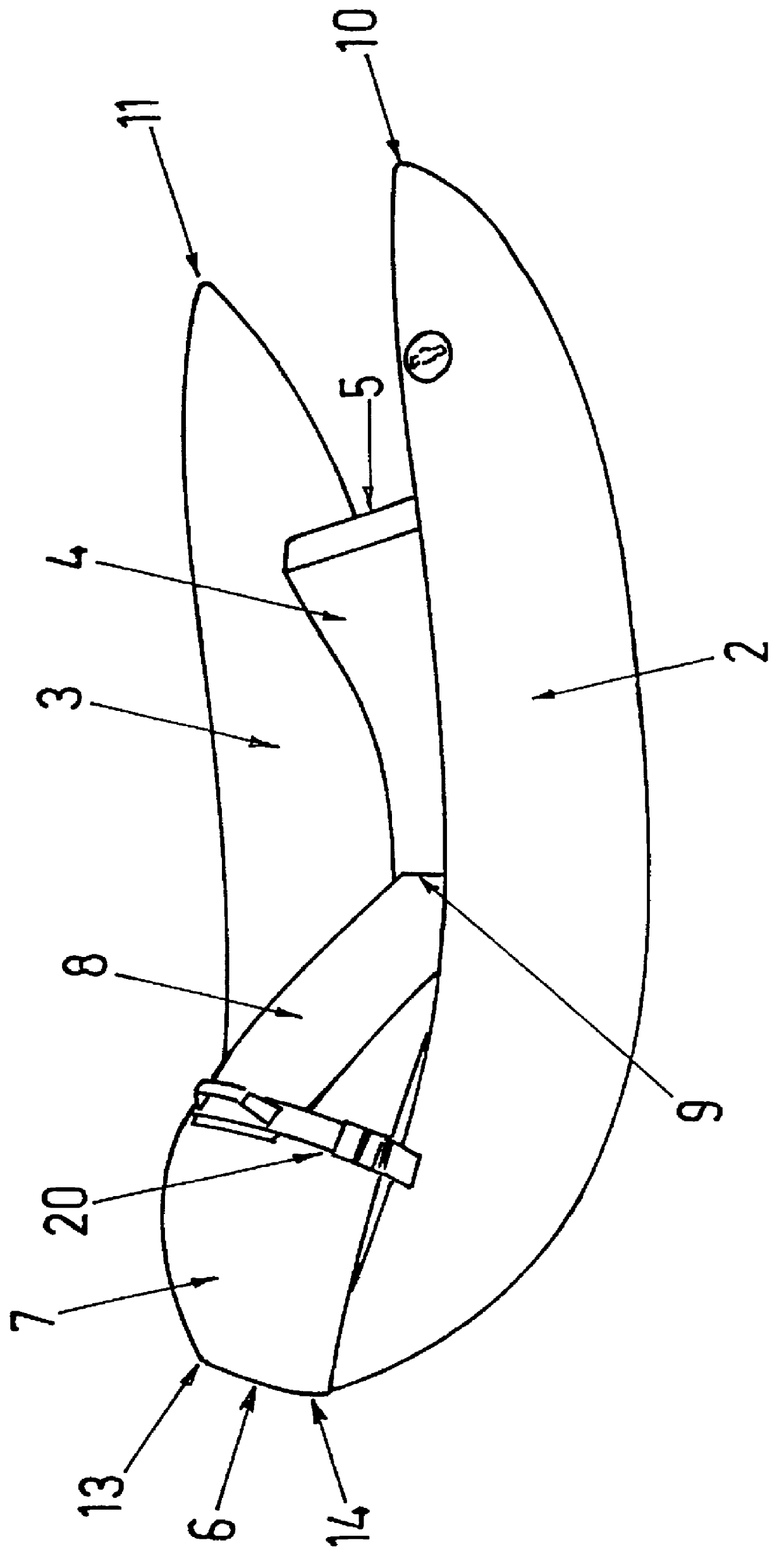

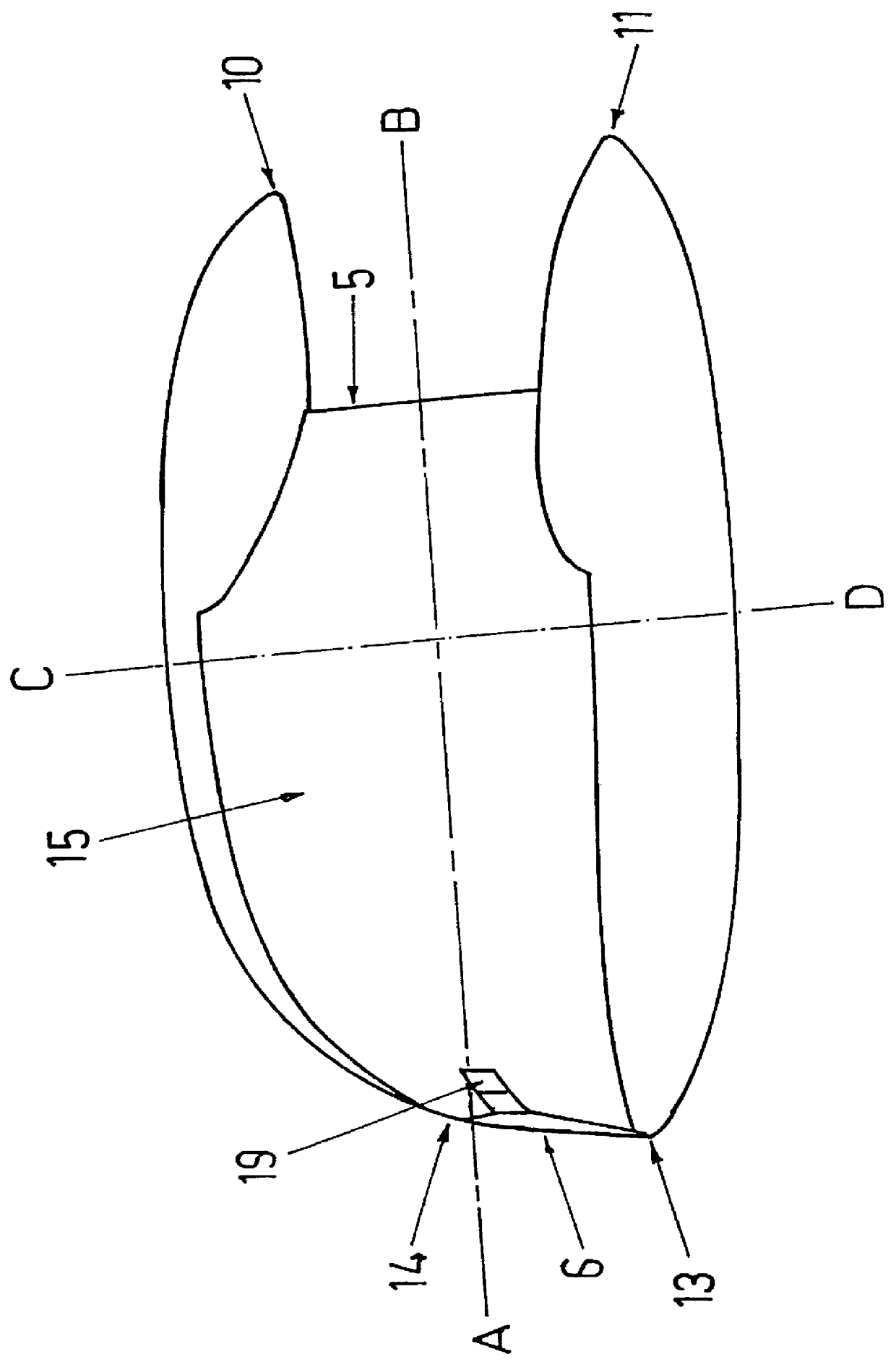

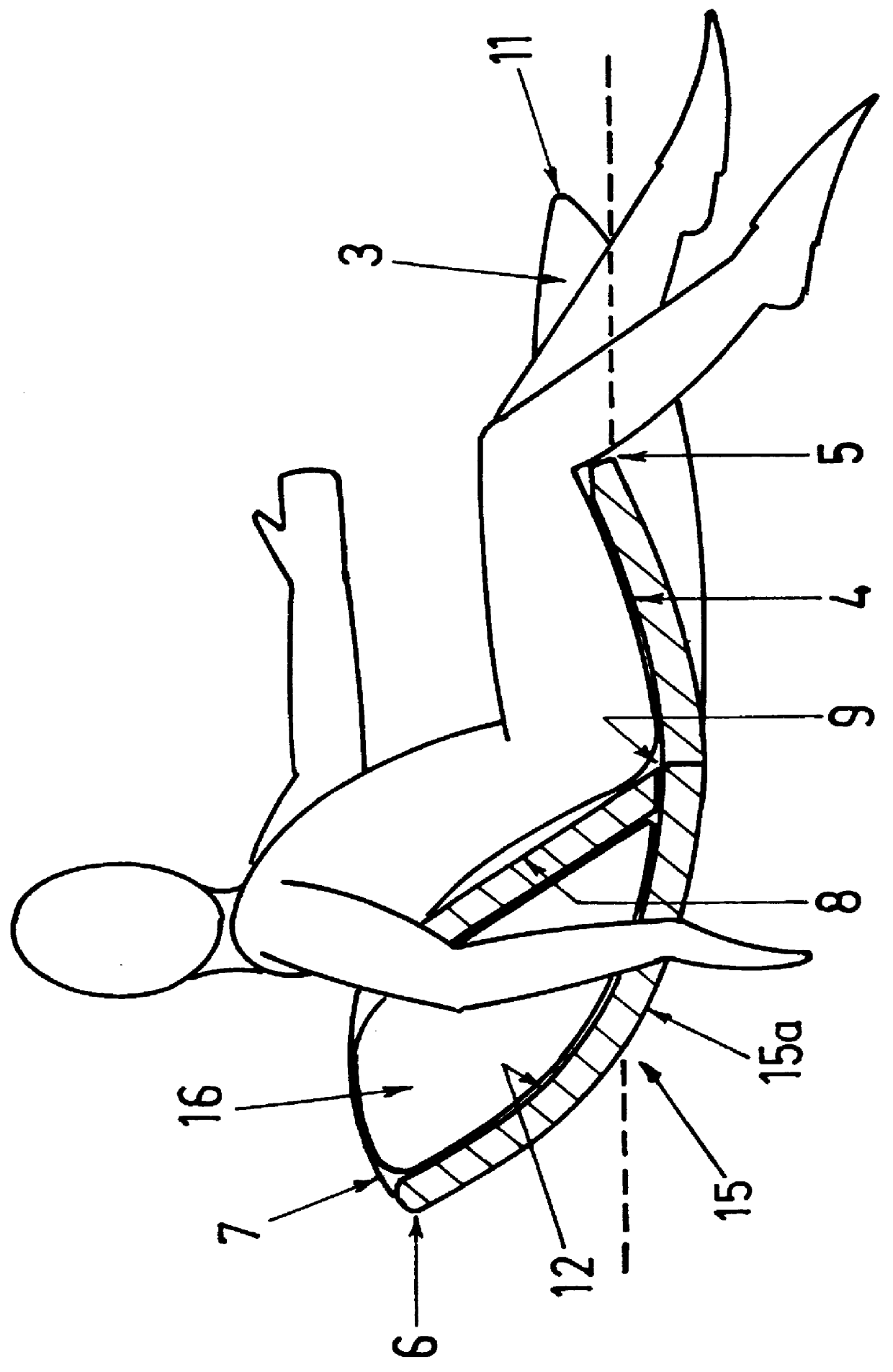

Flotation device

InactiveUS6155899AEfficient propulsionMinimise riskLife-buoysWater sport boardsEngineeringMechanical engineering

PCT No. PCT / NZ97 / 00113 Sec. 371 Date Mar. 8, 1999 Sec. 102(e) Date Mar. 8, 1999 PCT Filed Sep. 12, 1997 PCT Pub. No. WO98 / 10981 PCT Pub. Date Mar. 19, 1998An inflatable chair suitable for white-water use consisting of two inflatable floats (2, 3), rigid / semi-rigid seat base (4), bow hull floor section (12) an adjustable seat back (8) and a waterproof covering (7). The two inflatable floats (2, 3) are circular in cross section and taper at both ends to conical points (10, 11) at the stern and (13, 14) at the bow (6). The floats (2, 3) are separated by a rigid / semi-rigid central section (15) comprised of the seat base (4), bow hull floor section (12) which extends from the bow (6) for a majority of the chair's length, and together with the seat back (8) providing a semi-reclining body position enabling the user to use hands and / or legs for propulsion / manoeuvring.

Owner:BODDY GRAEME JAMES

Cleaning attachment for fluid dispenser nozzles and fluid dispensers using same

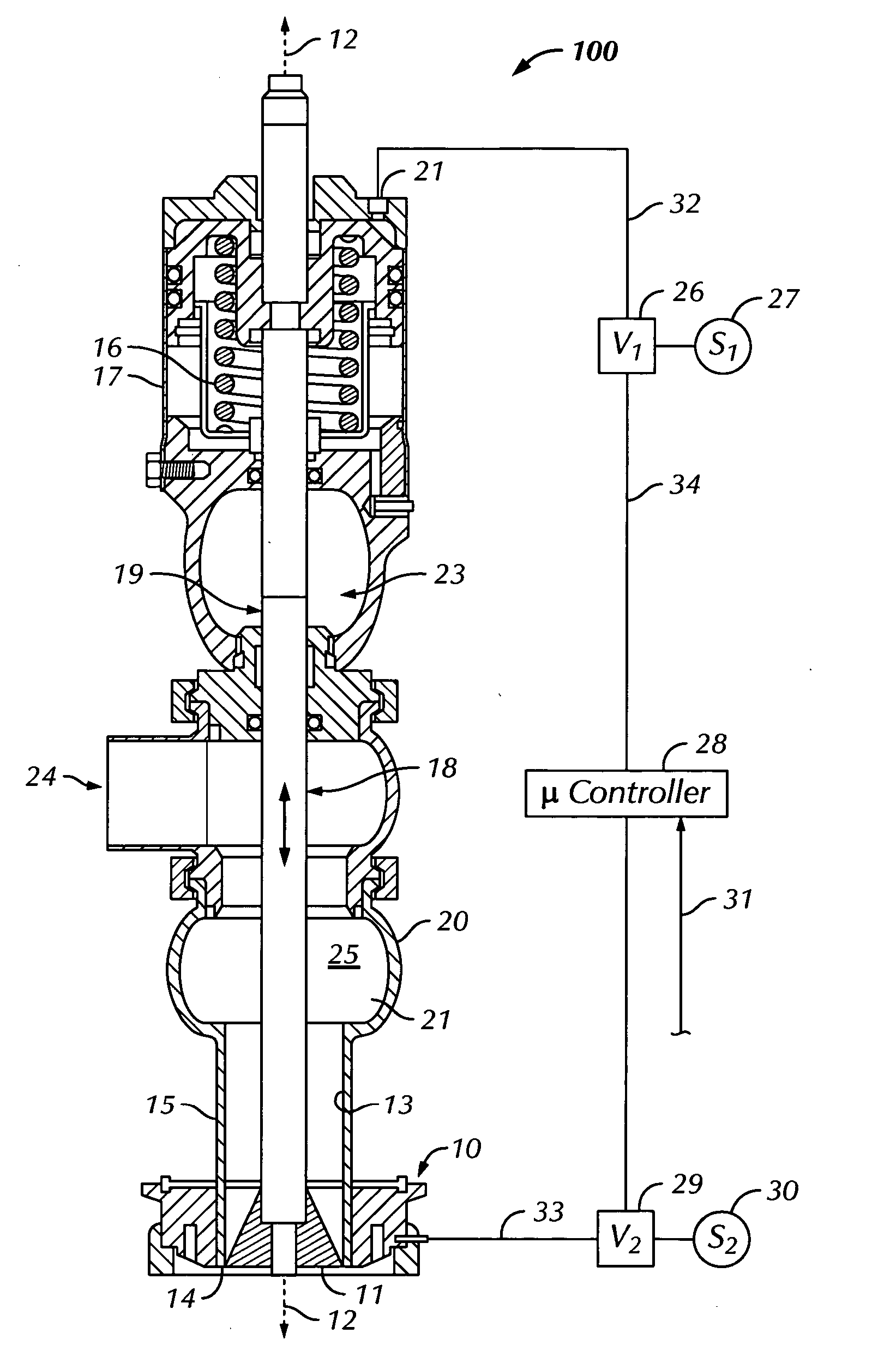

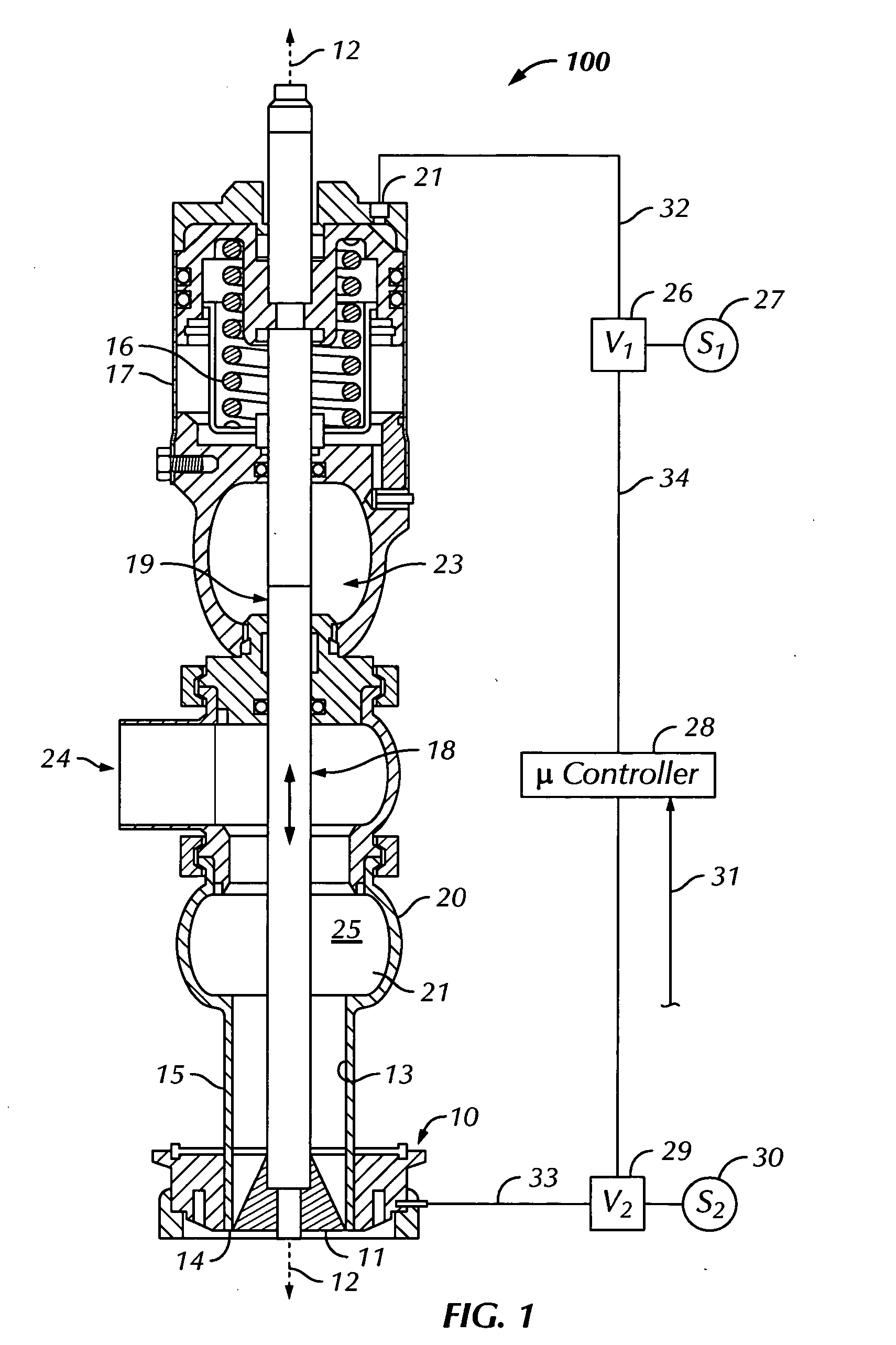

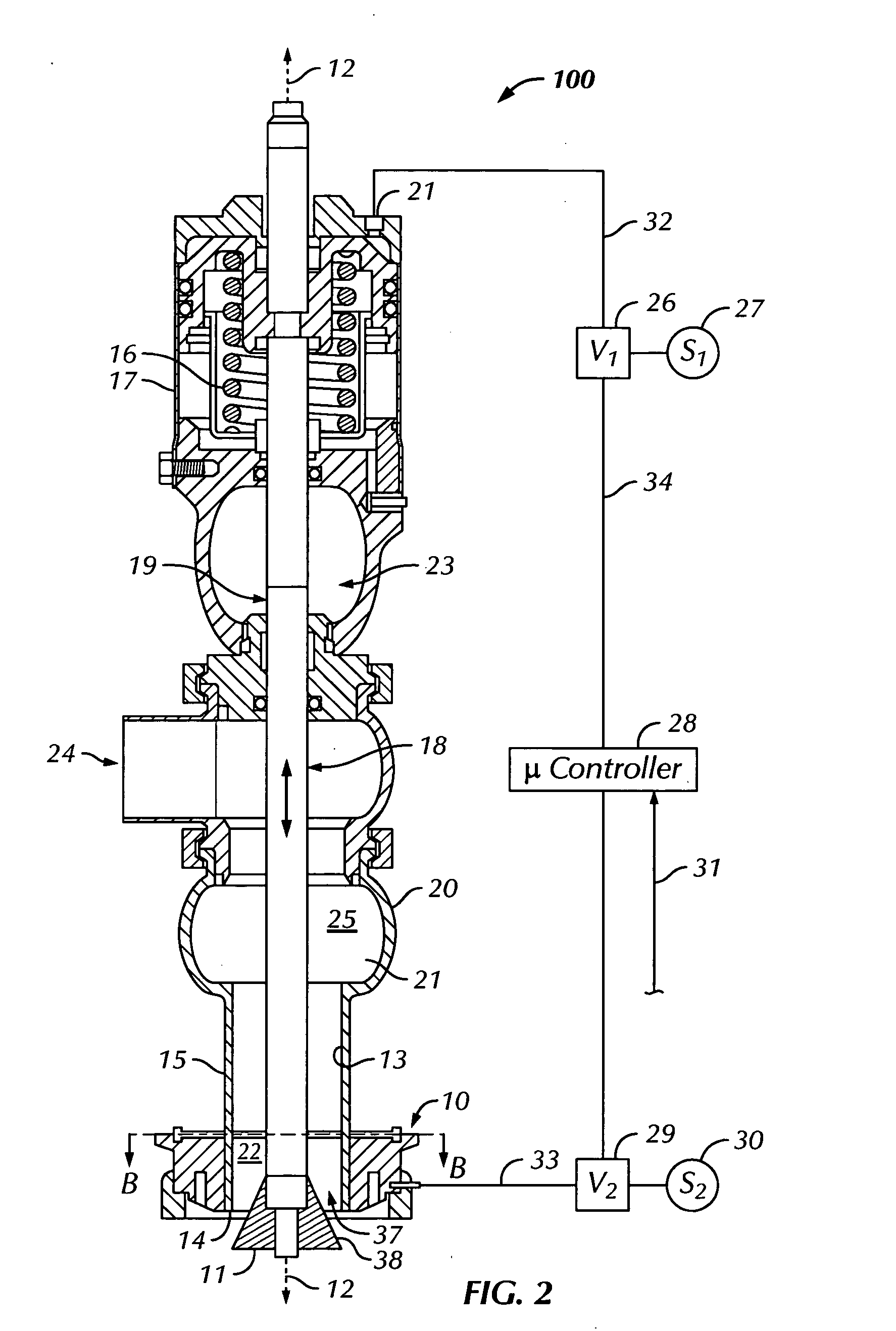

InactiveUS20050056707A1Easy to assembleEasy to disassembleSpraying apparatusLiquid transferring devicesEngineeringVALVE PORT

A nozzle attachment for removing residual material retained on the dispensing nozzle of a fluid dispenser, having a retainer adapted to releasably attach the nozzle attachment to a dispensing nozzle, and a pair of hollow-bodied nozzle attachment components that define, when nested together, an intervening space useful as a gas passageway for pressurized gaseous fluid introduced and directed to a discharge opening at a lower axial end of the nested nozzle attachment components. The gas passageway is adapted to emit gas introduced into the gas passageway as a gas stream in a manner effective to remove residual material clinging to the nozzle. Dispensers using the nozzle attachment are presented, including one using a truncated valve head.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

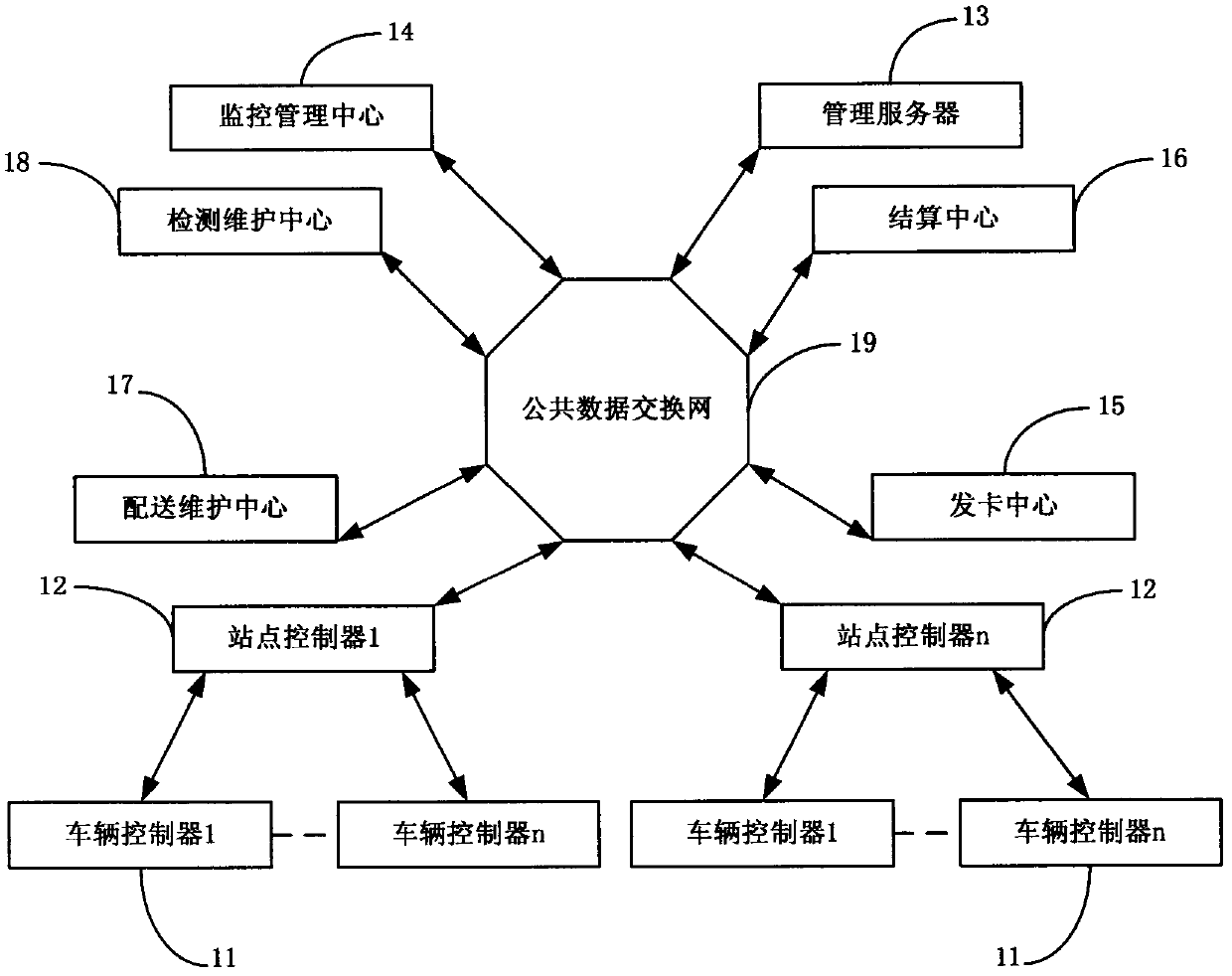

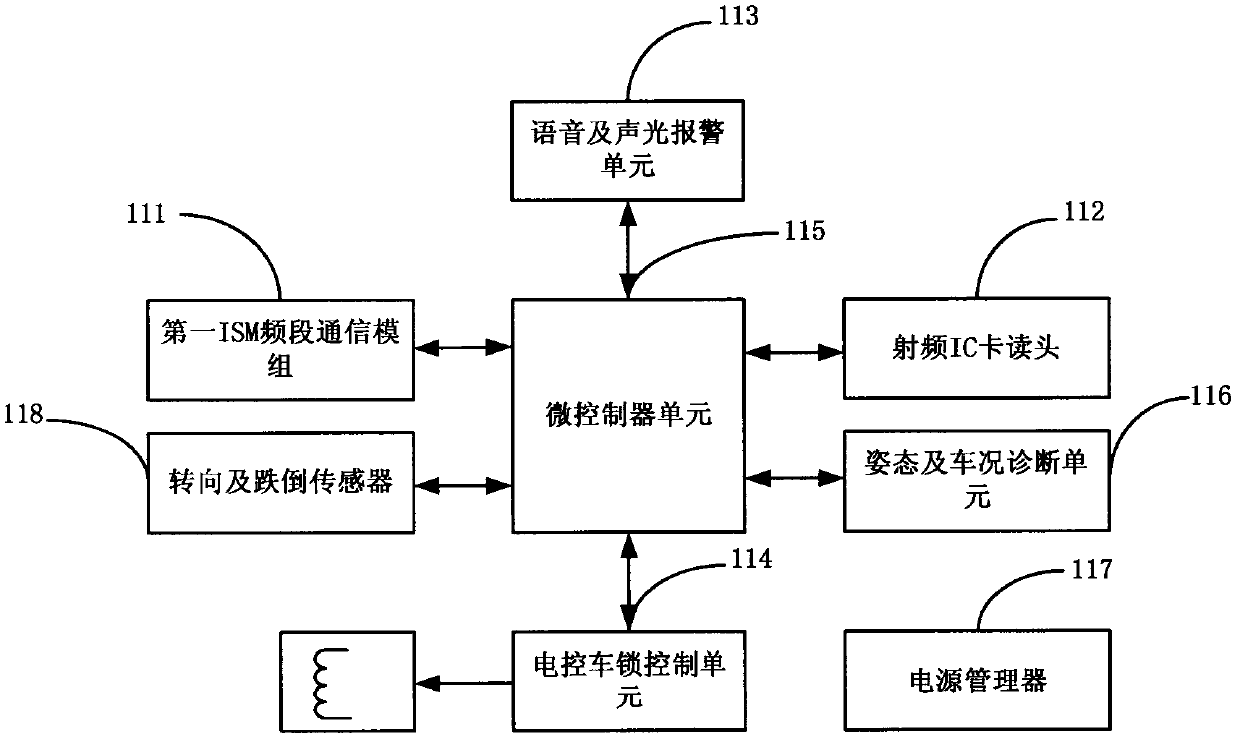

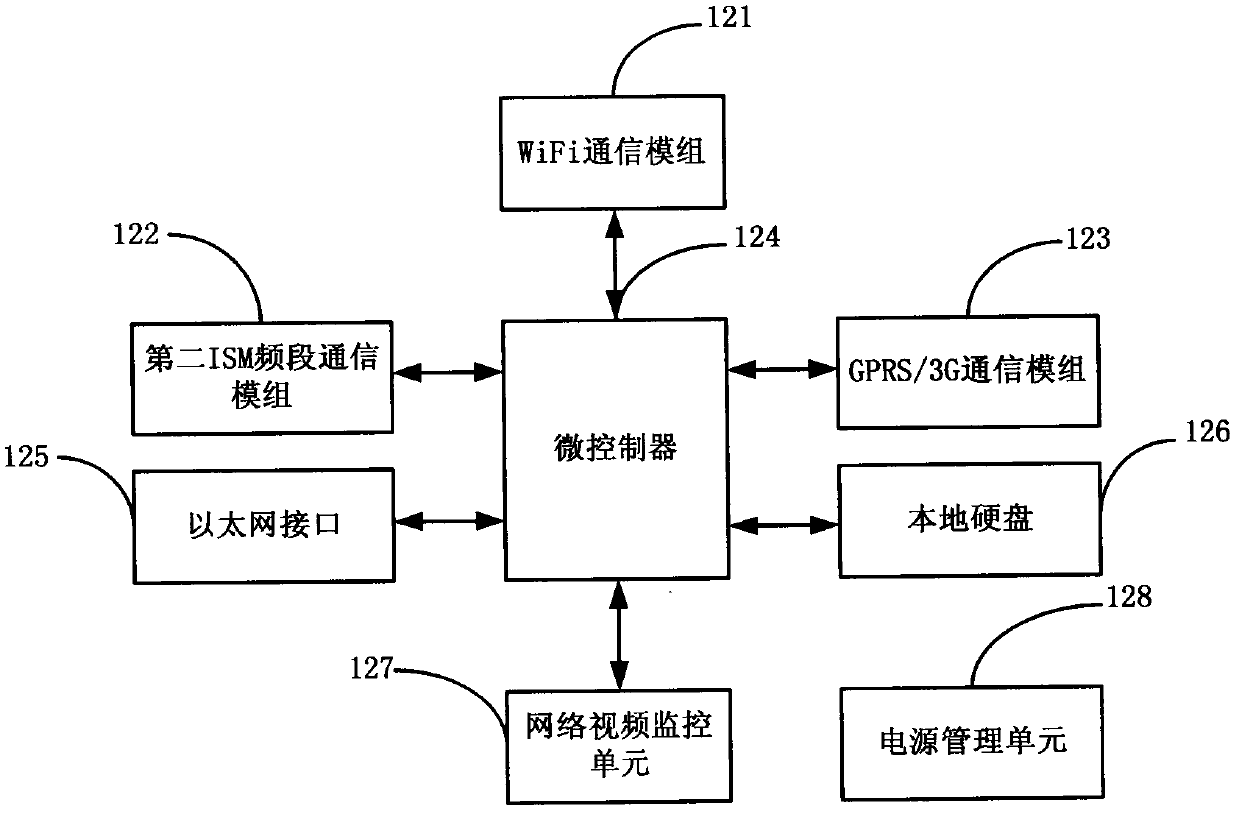

Distributed intelligent lease management system for public bikes

InactiveCN103377520AIncreased parking capacityImprove anti-theft security performanceApparatus for meter-controlled dispensingIntelligent managementManagement system

The invention belongs to the technical field of intelligent management, and provides a distributed intelligent lease management system for public bikes. An open parking management mode is adopted, parking capacity of a station is increased, users can pull out cards to return bikes as long as entering a marked station controller range, and limitations of the number of parking piles are avoided; since a green back-up energy resource is adopted, a temporary station is extremely convenient to set up; a monitoring management center or a management person only needs to reset a maximum allowable parking quantity, and then a system can automatically reset and immediately allows more bike returning operations of the users; a bike controller and an electronic control lock can be completely mounted in a structural frame of each bike, electronic demounting preventing protection is provided, once a non-maintenance person detaches the bike controllers arbitrarily, the bike controllers can enter an intrusion protection state, and the bikes can be locked automatically; meanwhile, a voice alarm function is started, and anti-theft safety performance of the bikes is further improved.

Owner:SHENZHEN XIECHUANG INDAL

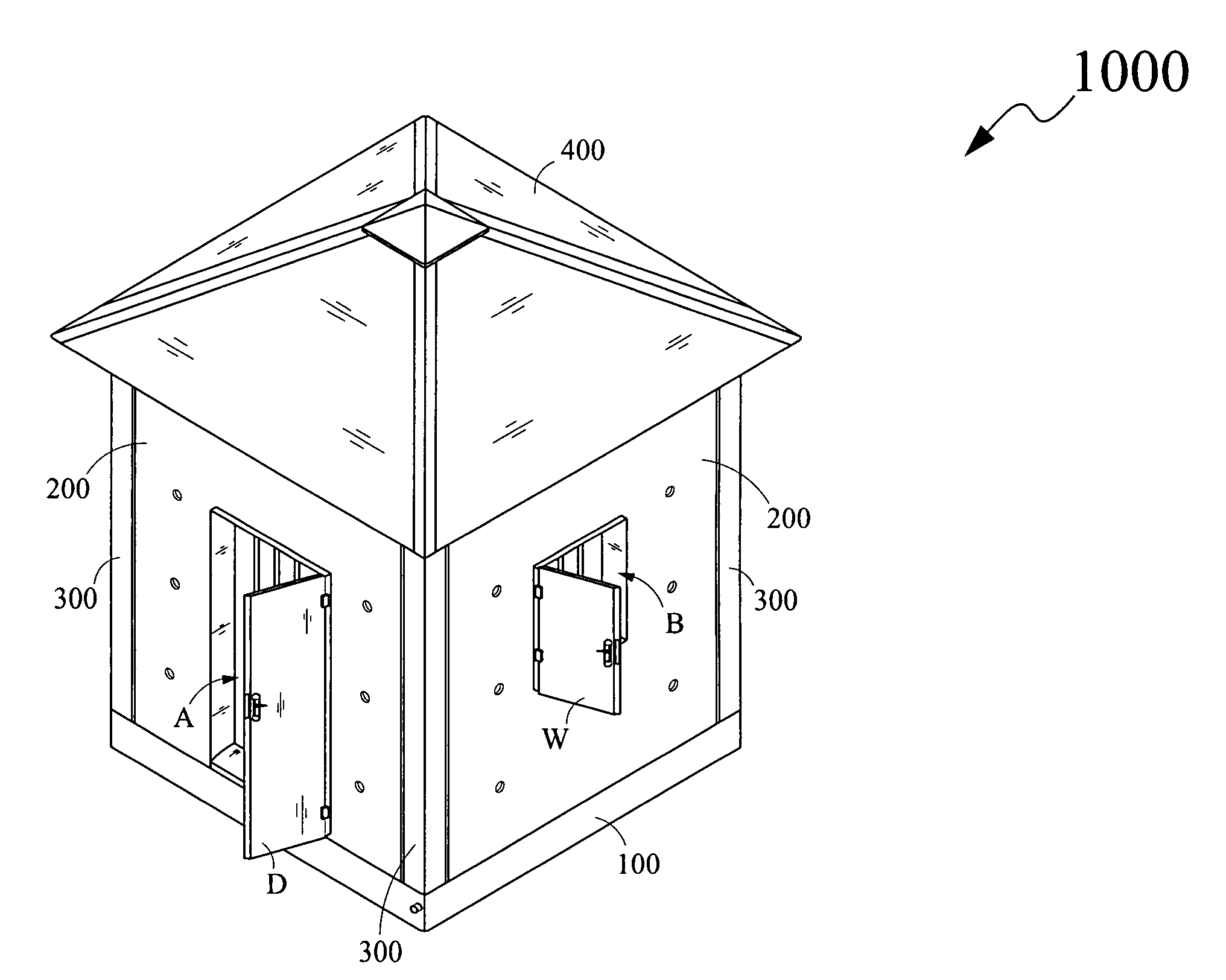

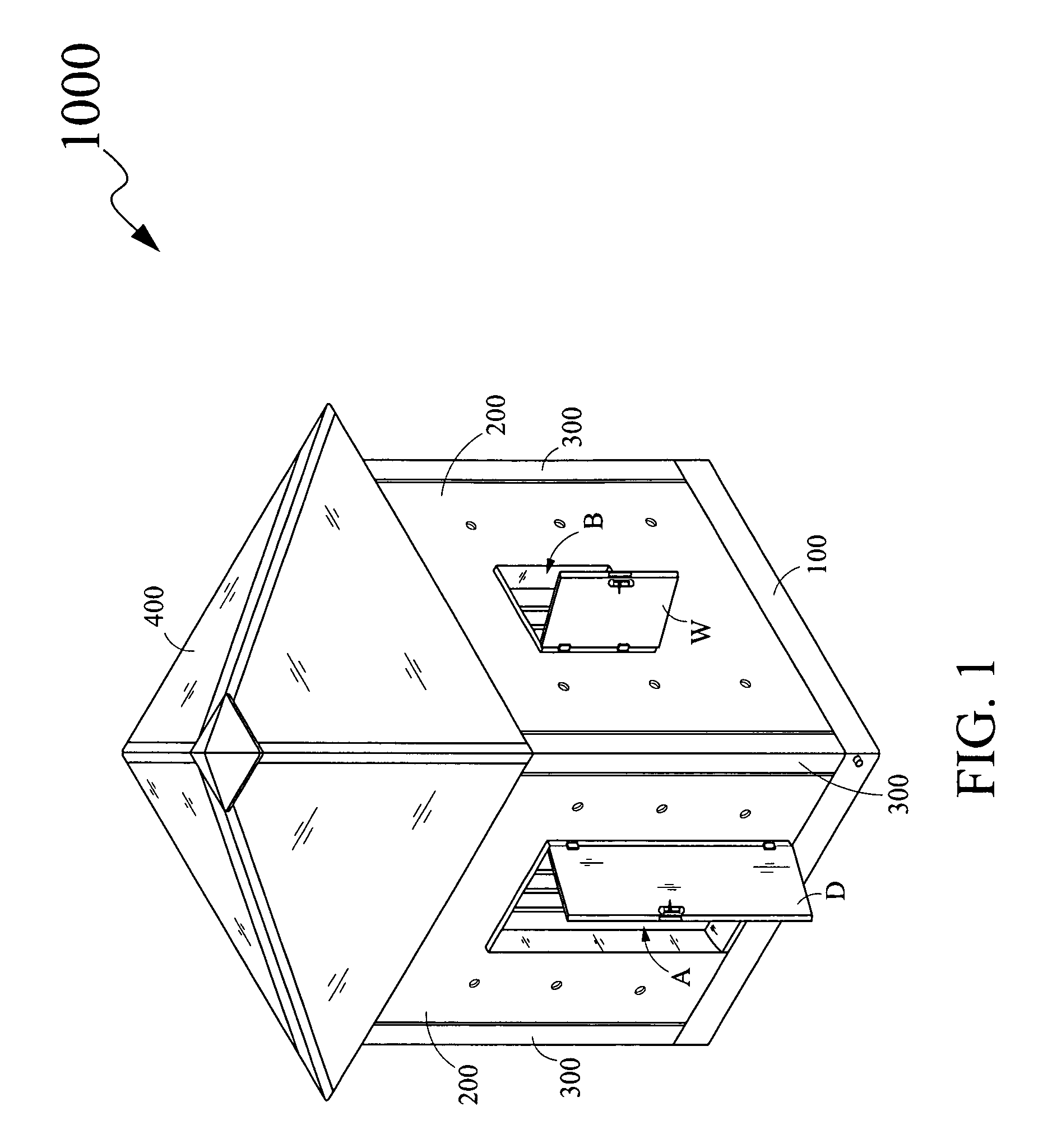

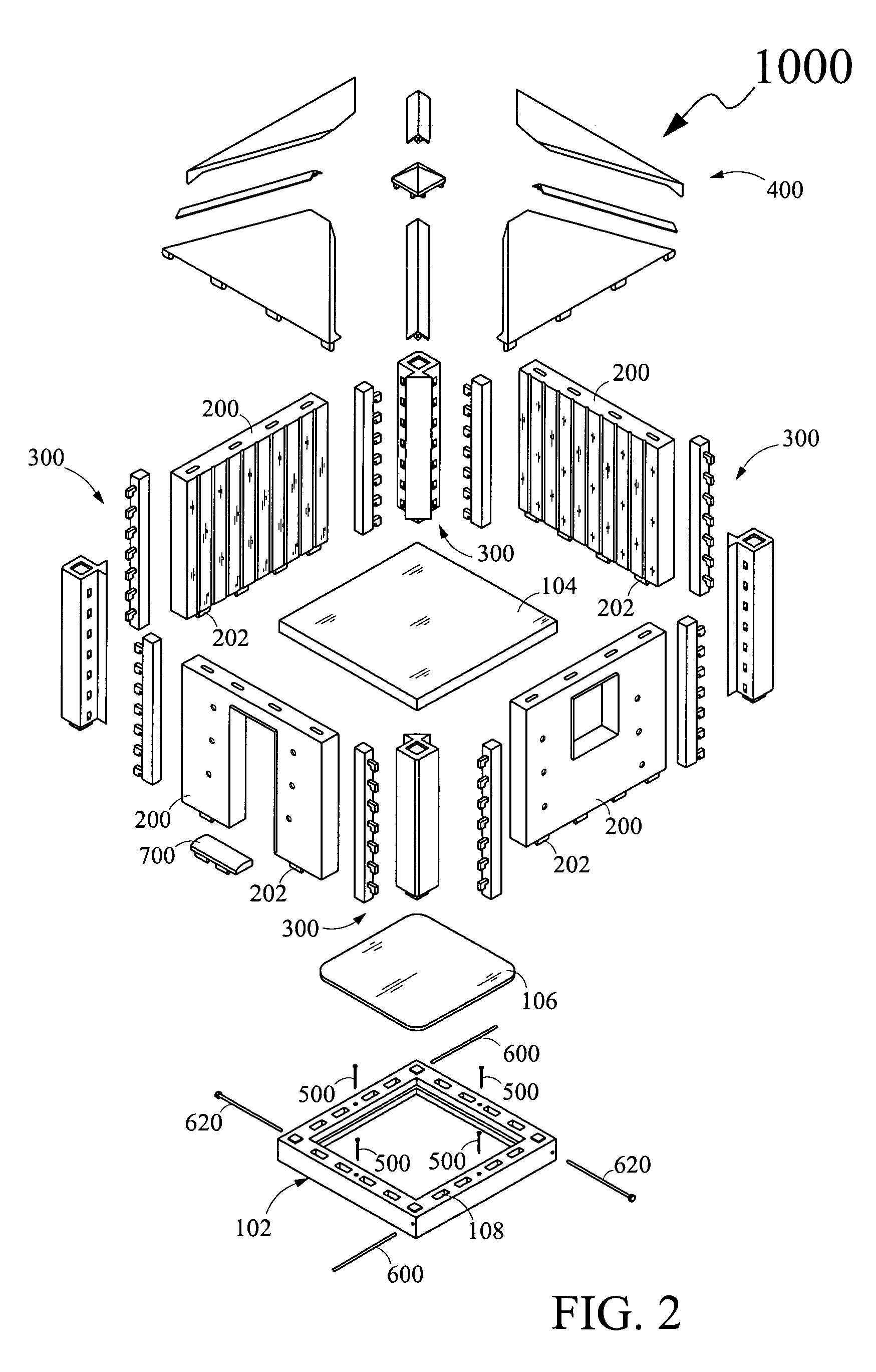

Modular building system

InactiveUS20090313925A1Easy erectionEasy to dismantleBuilding roofsFloorsModular constructionCivil engineering

Disclosed is a modular building system for configuring a building structure. The modular building system includes a foundation member, a plurality of wall members, a plurality of wall-retaining members and a roofing member. The foundation member has a plurality of engaging members that engages with a plurality of complementary engaging members of wall members. The foundation member and the wall members are detachably attached as the engaging members and the complementary engaging members engage to each other and create a space with a top opening. The adjacent wall members are attached by a plurality of the wall-retaining members. Further, the wall member includes a plurality of engagement members that engages with a plurality of complementary engagement members provided on the roofing member to detachably attach the plurality of engagement members on top portion of the plurality of wall members for covering the top opening, thereby configuring the building structure.

Owner:SHELTER TECH

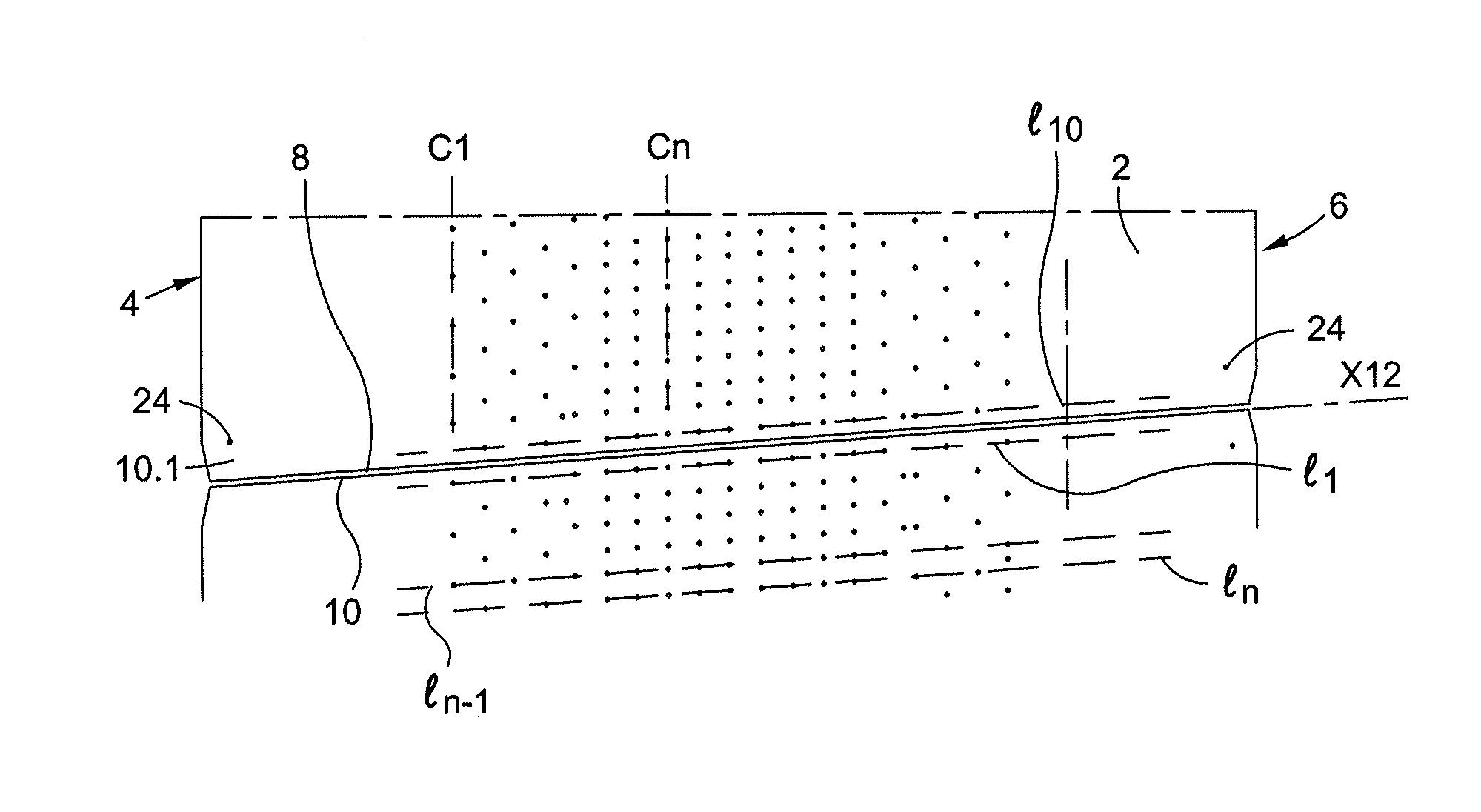

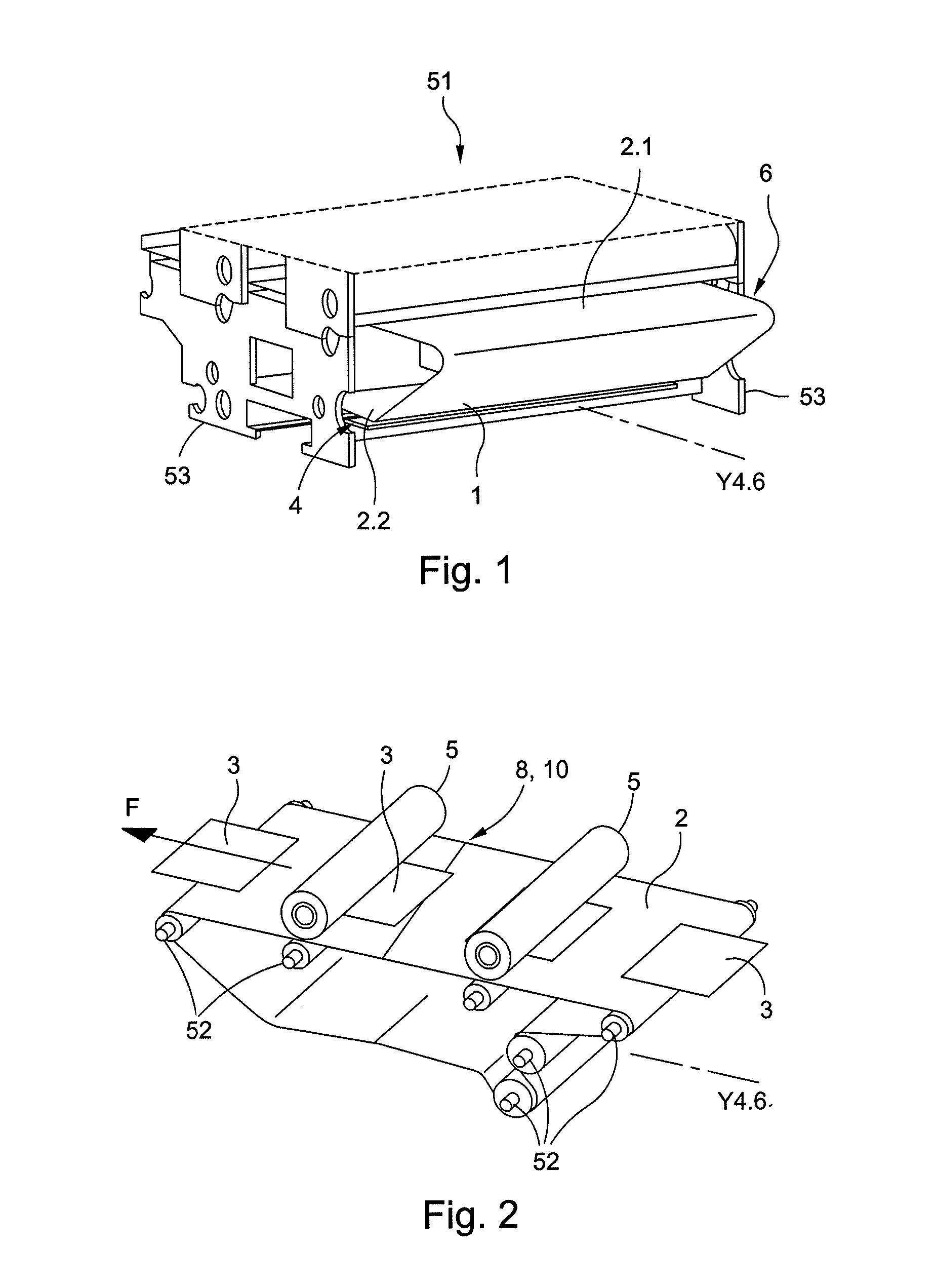

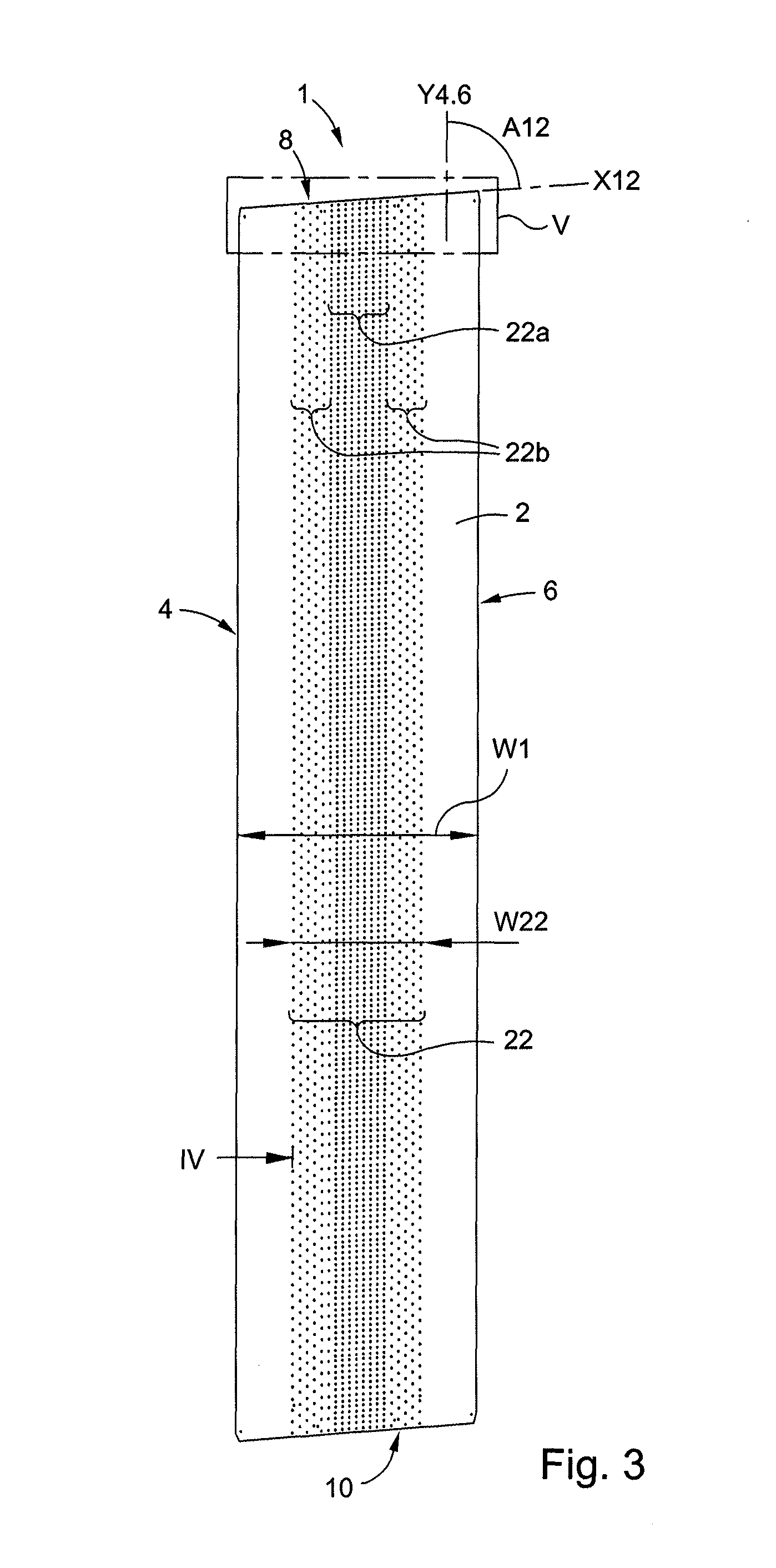

Conveyor belt for plate elements and converting machine comprising such a belt

A conveyor belt for conveying plate elements in a machine for converting the elements that includes a belt body with longitudinal edges, joining edges, and a support surface for supporting the elements, and at least one assembly member arranged to join the joining edges, and extending in a direction of assembly which is oblique to the longitudinal direction, the belt body having a plurality of perforations for obtaining a vacuum on the support surface to immobilize the elements.

Owner:BOBST LYON

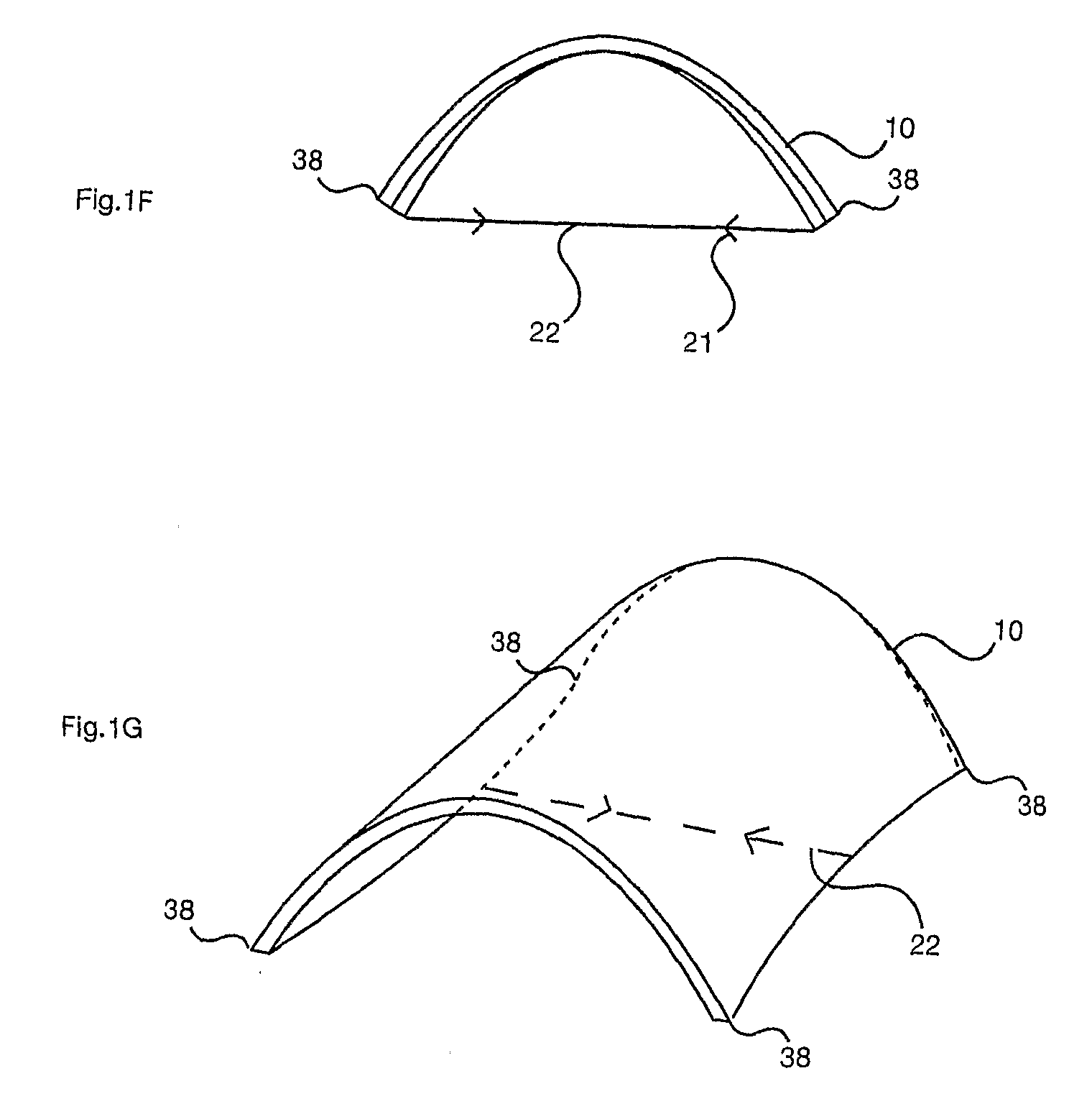

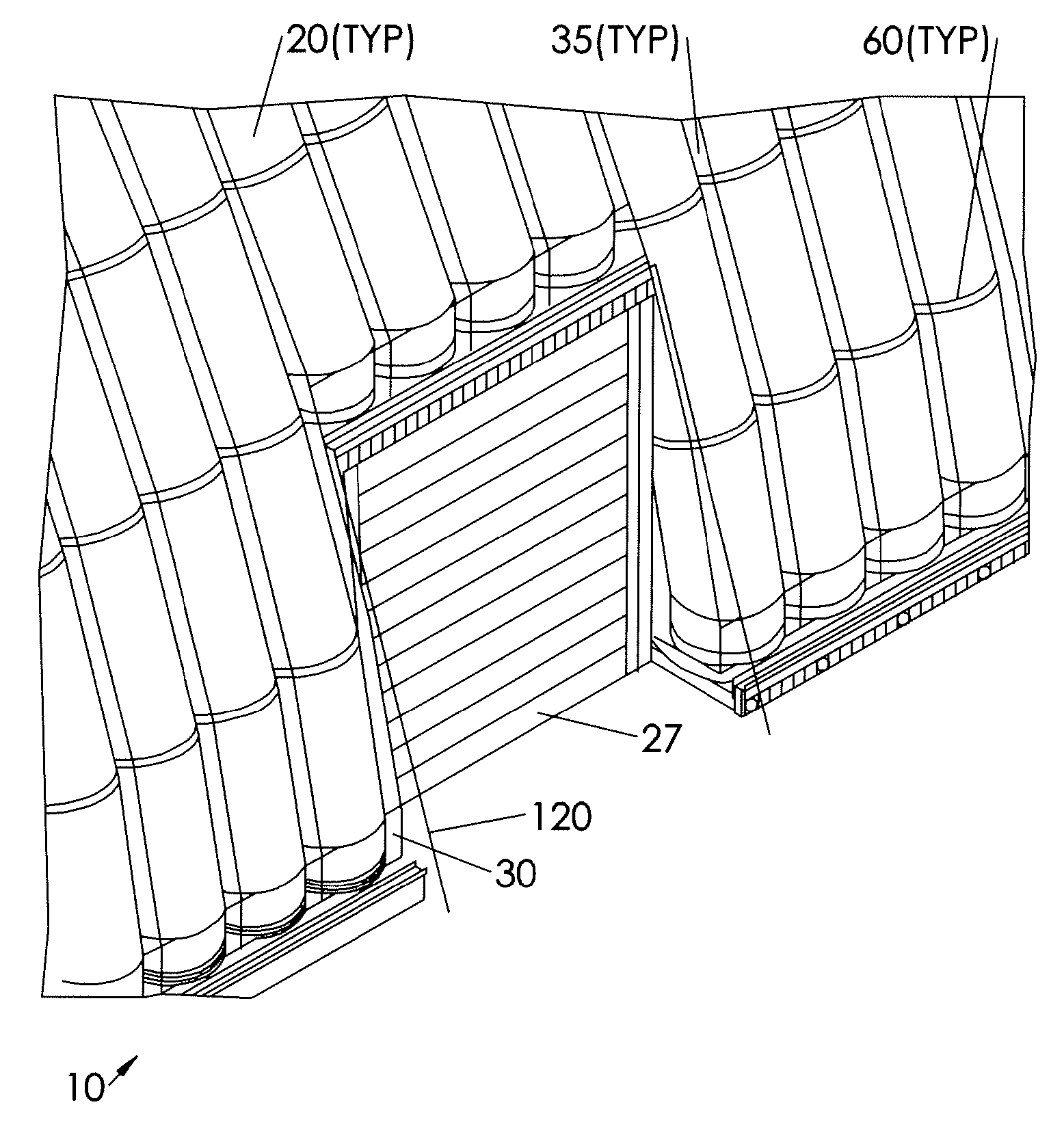

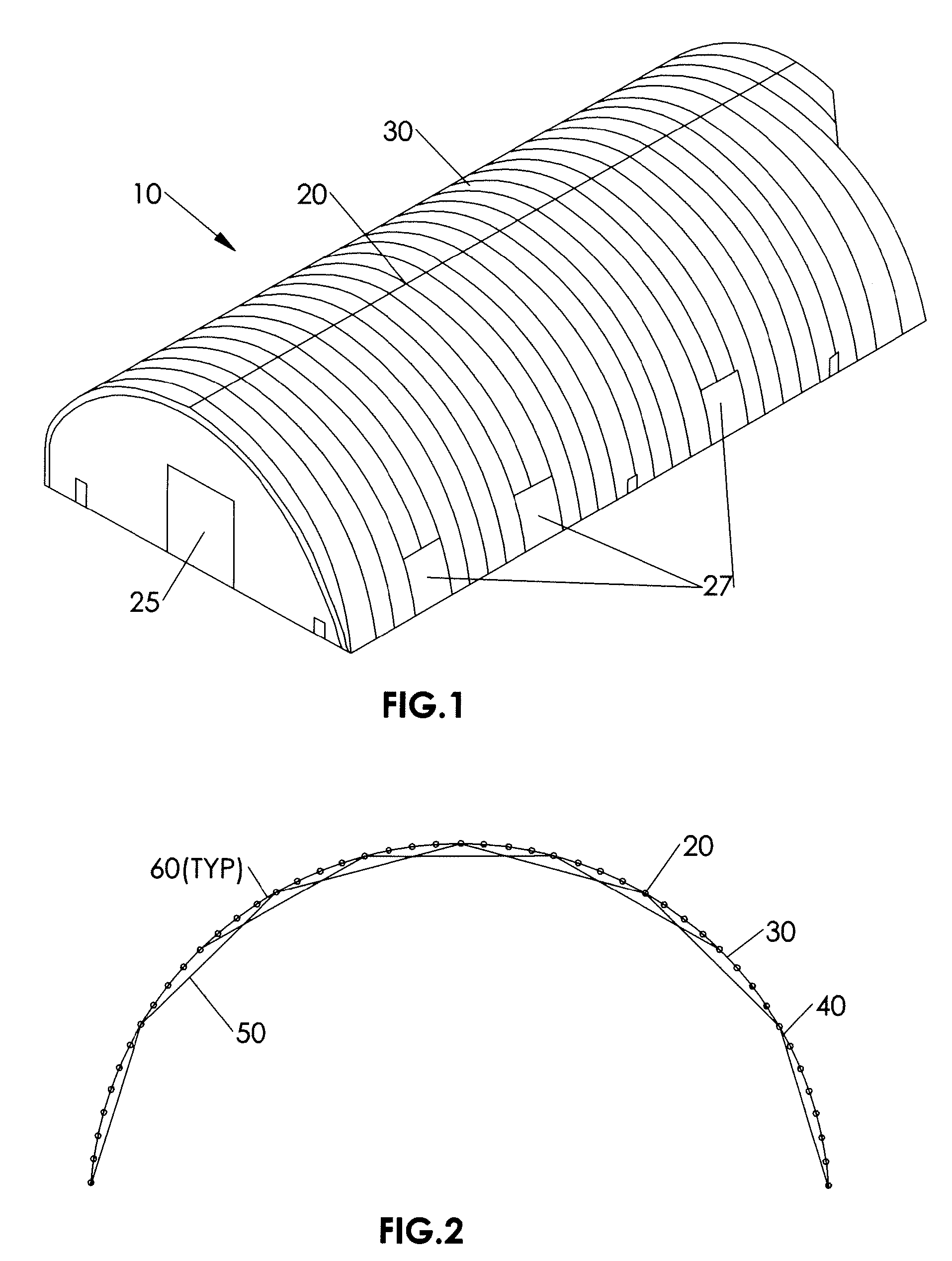

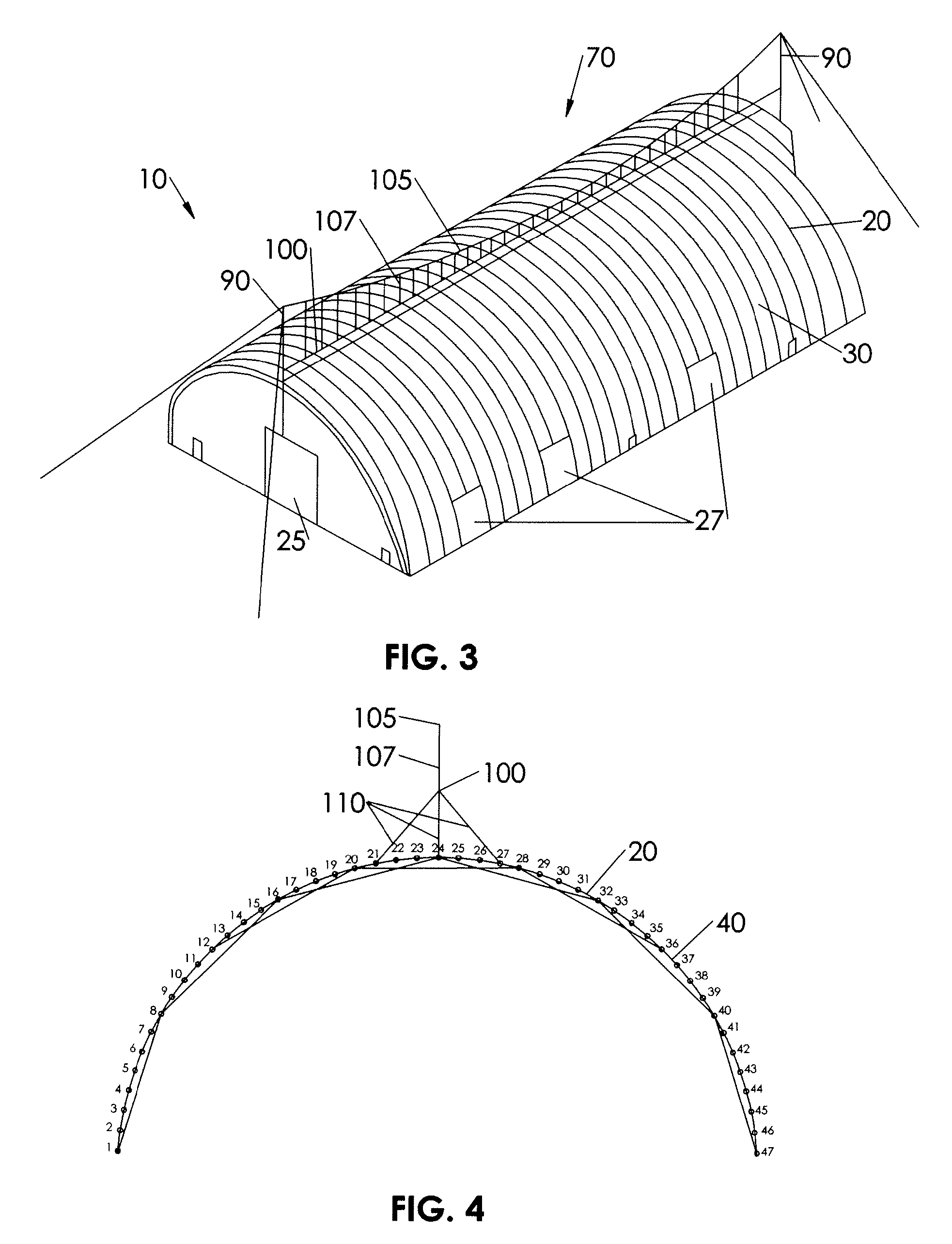

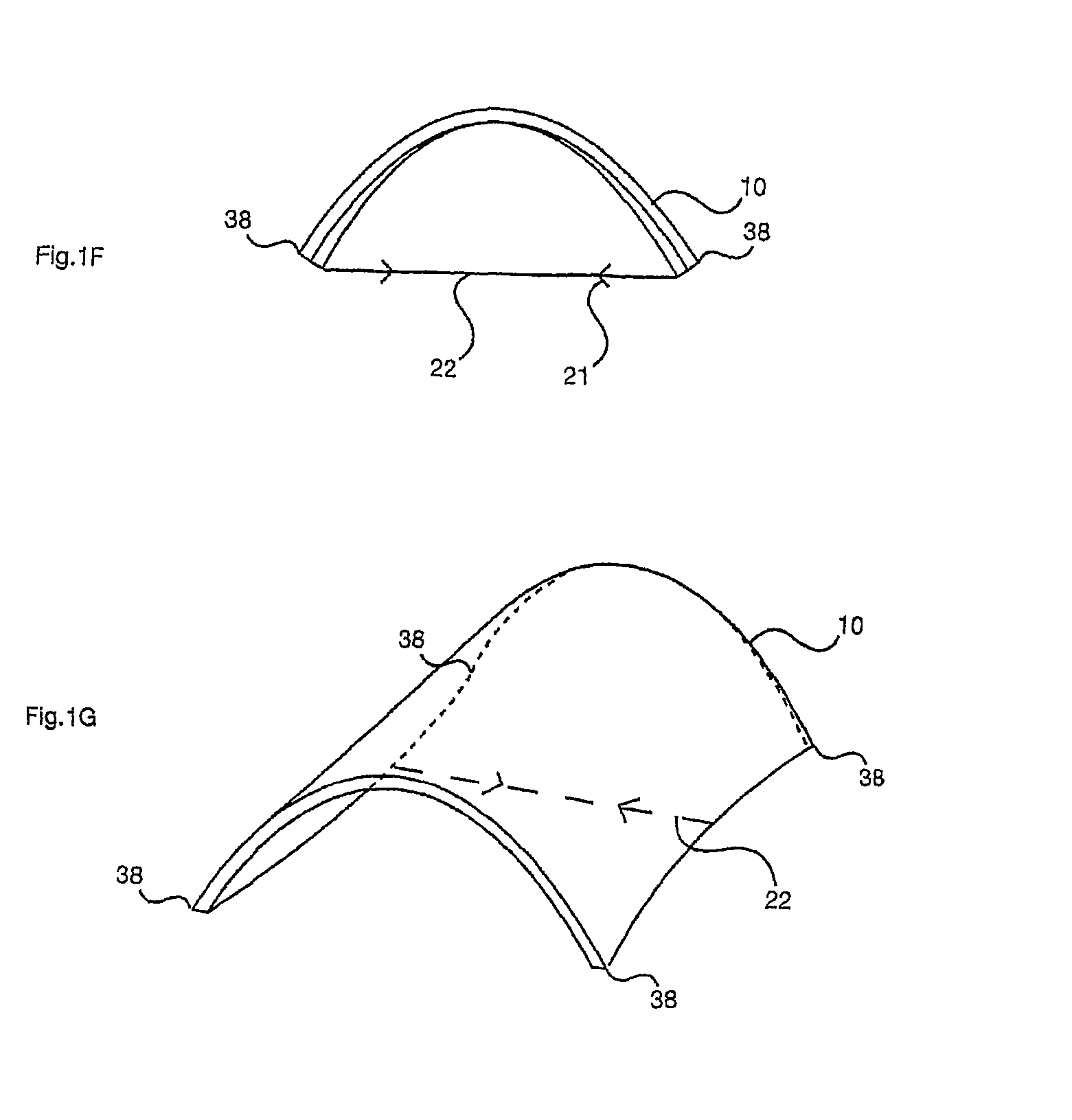

Air Beam with Stiffening Members and Air Beam Structure

InactiveUS20100146868A1Optimize locationEasy to dismantleTents/canopiesBuilding repairsEngineeringMechanical engineering

An air beam structural member having an elongate pneumatic tubular column, a plurality of stiffening members, and means for connecting the tubular column and the stiffening members. An inflatable shelter includes pneumatic tubular columns (arches) covered on both sides by flexible membranes. The columns are placed side by side to create a wall and enclosure of the space. The pneumatic columns are pressurized and keep their shape by means of a set of cables reinforcing them in the plane of the columns. The structure may be supported by an external support structure.

Owner:LUKASIEWICZ STANISLAW +1

Rotation sensor-equipped bearing

ActiveUS20130099107A1Easy to disassembleEasy to dismantleBearing assemblyMeasurement apparatus componentsEngineeringRotation sensor

A bearing unit is provided in an inner peripheral portion of a sensor housing in which a sensor portion is installed. The sensor portion includes a sensor mounting substrate and a sensor fixed to this sensor mounting substrate. The sensor housing is provided with an axially extending substrate mounting groove formed in a direction of a chord which will define the circular section of the outer peripheral surface of the sensor housing. The sensor mounting substrate is mounted on this substrate mounting groove to install the sensor portion within the sensor housing.

Owner:NTN CORP

Structural assembly with a tied, flexurally deformed panel

InactiveUS8215041B2Easily manufactured and subsequently processedEasy to dismantlePicture framesSpecial ornamental structuresCarbon fibersPre stress

An assembly includes a flexurally deformed panel, which is connected to a membrane tie by a linear connector and is tied by the membrane tie to form a geometrically stable pre-stressed structure. More than one panel may be flexurally deformed and tied together in an assembly and more than one membrane tie may be present within an assembly. Panels are typically semi-rigid sheet materials, for example metal sheets, plastic sheets, or sheets of composite materials, such as glass or carbon fibre reinforced plastics or resins. Membrane tie members are typically flexible, for example plastic films, fabrics or nets or arrays of rods or cables. The assemblies have many different geometric forms and many different practical applications. Assemblies may be relatively large, for example demountable and reusable shelters or flat-pack point-of-purchase display assemblies, or may be relatively small, for example a photograph or postcard display system.

Owner:CONTRA VISION

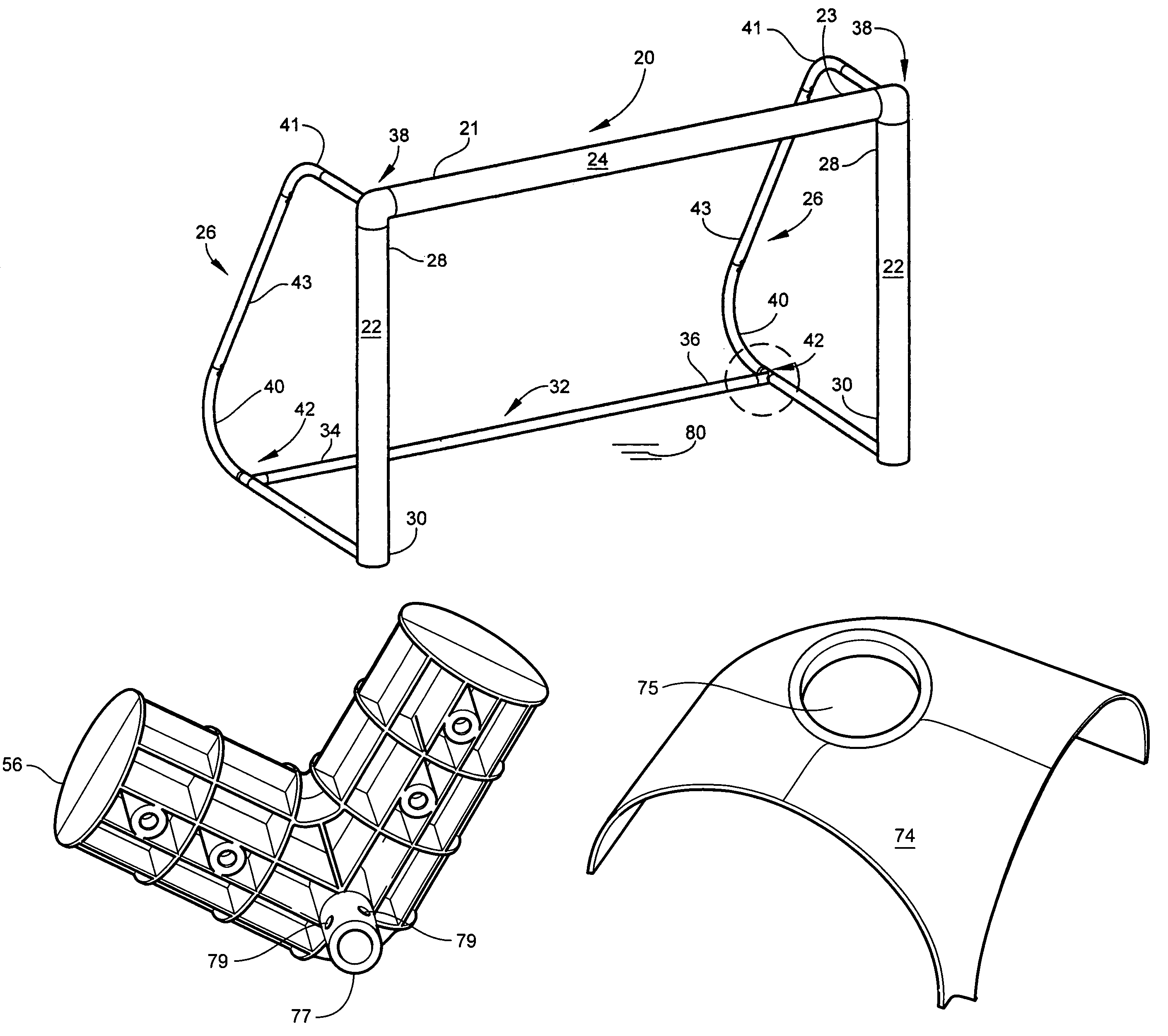

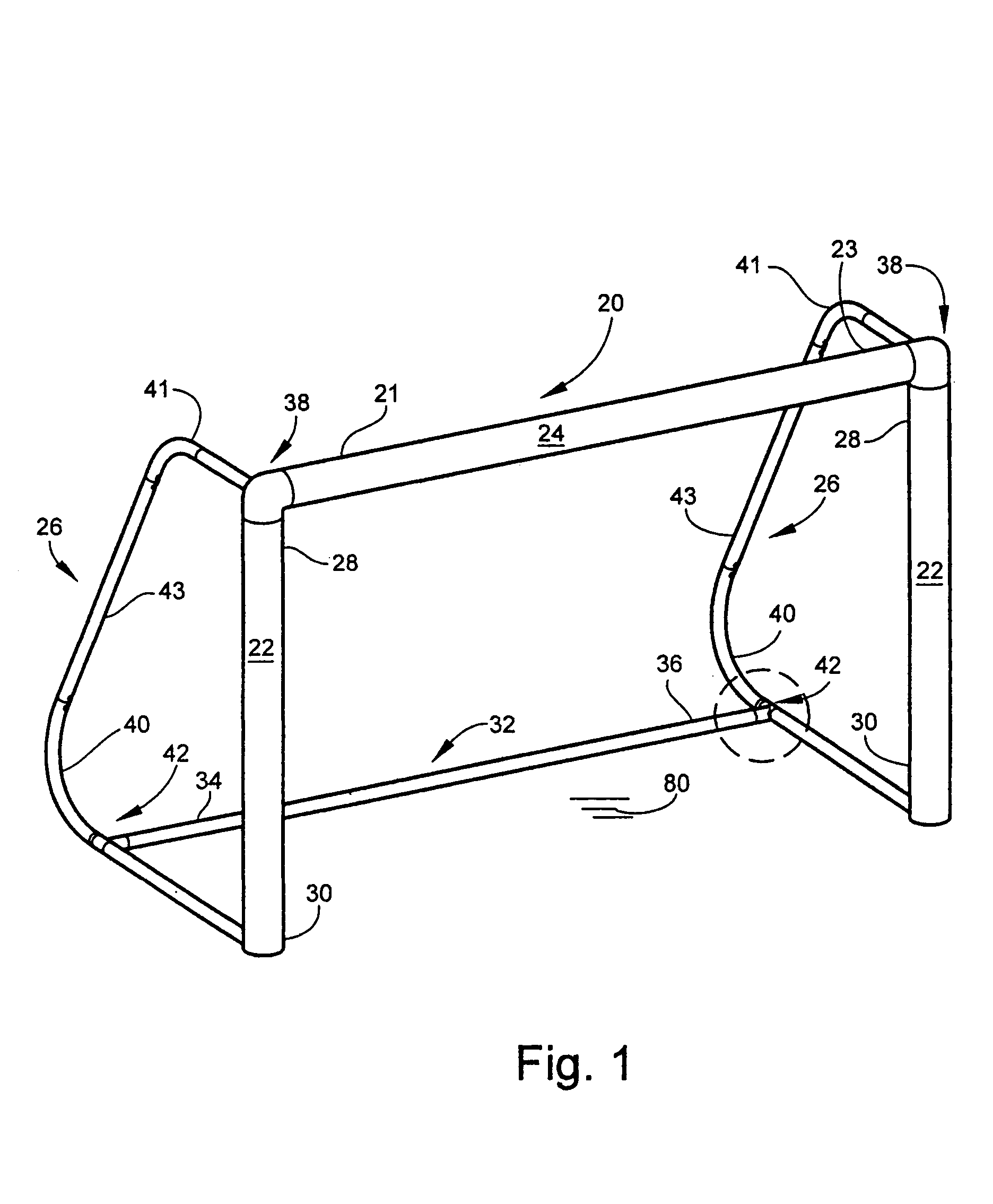

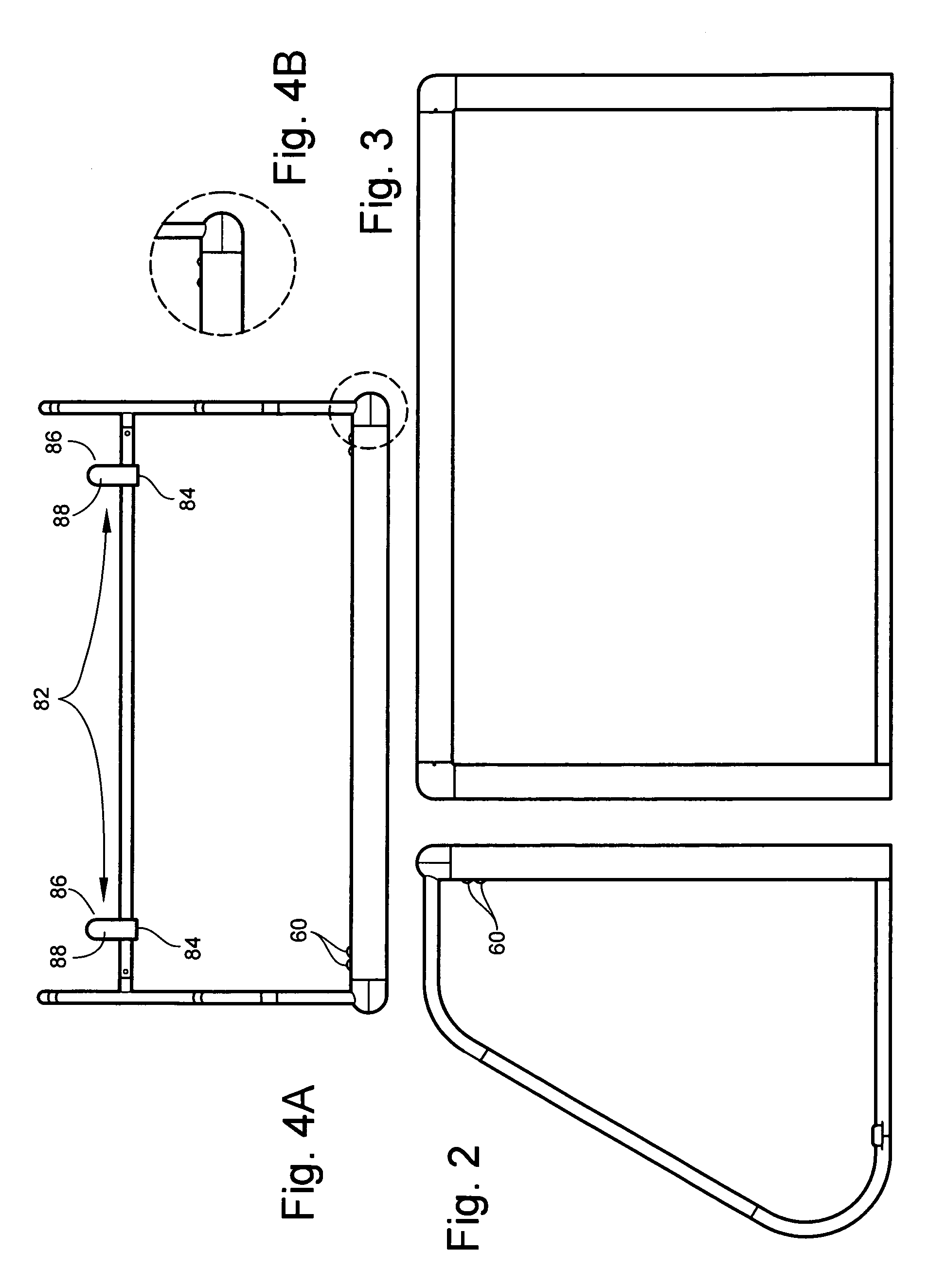

Adjustable and portable soccer goal and molded joint connectors associated therewith

Owner:BRYANT JR OLEN W +1

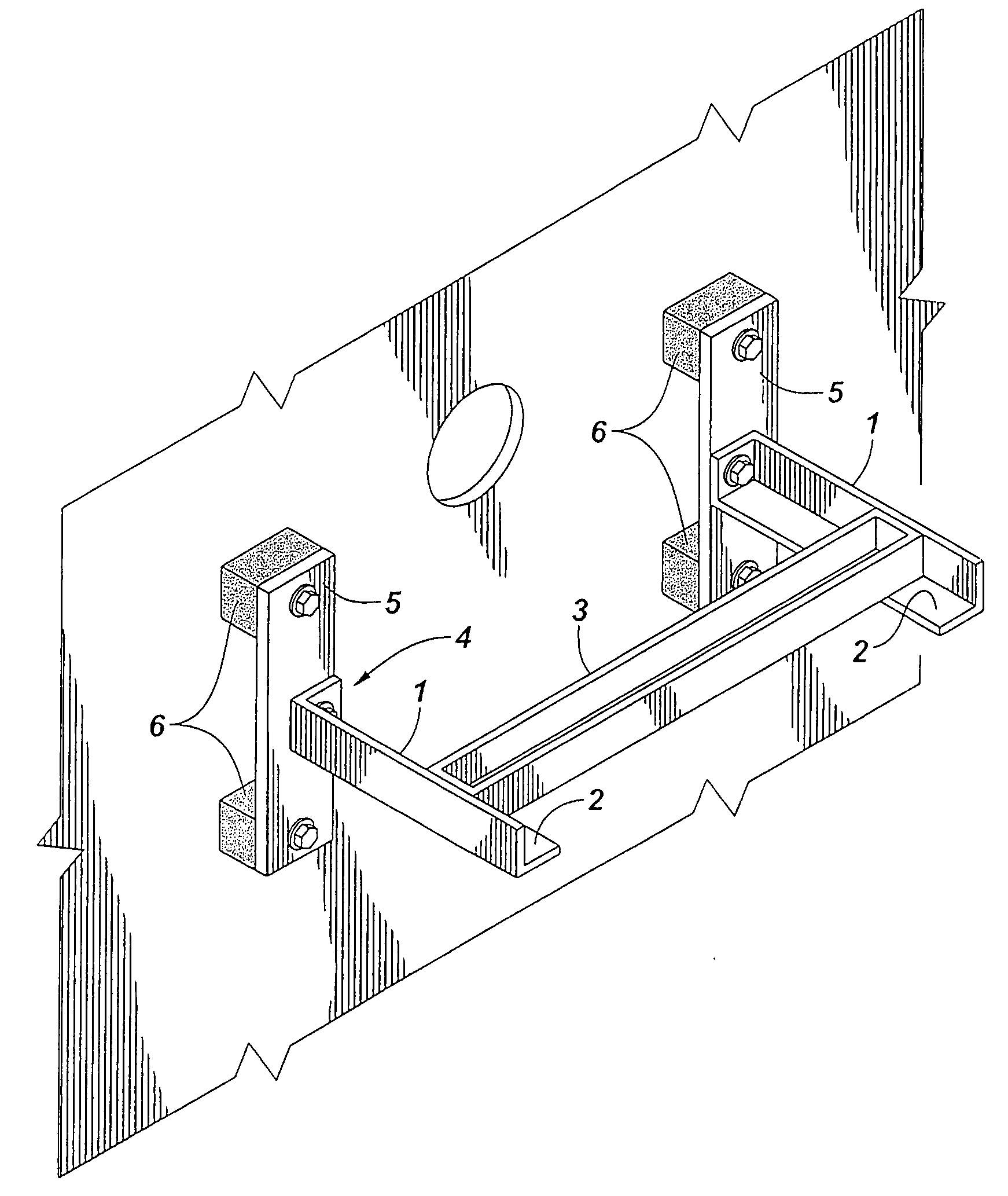

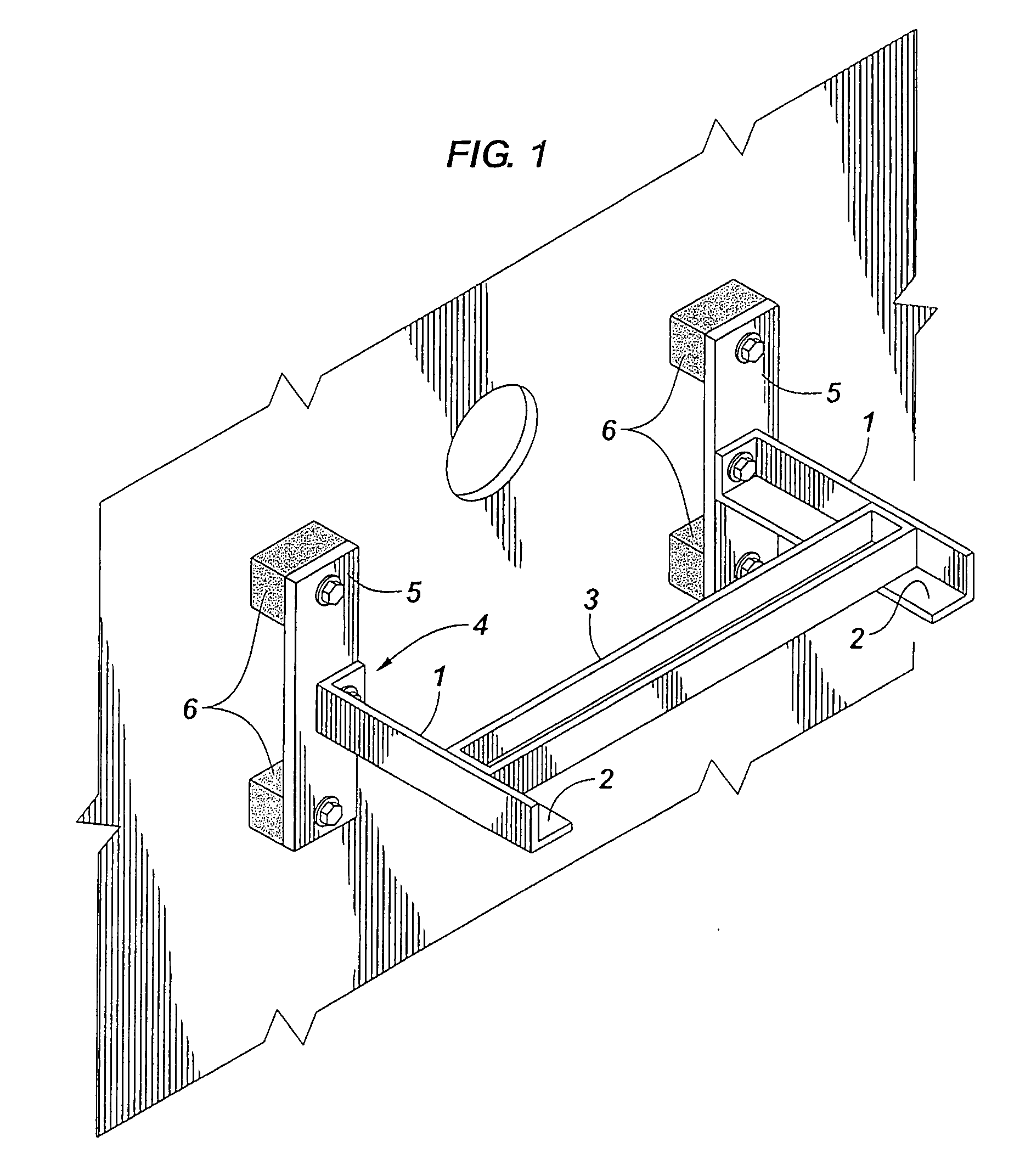

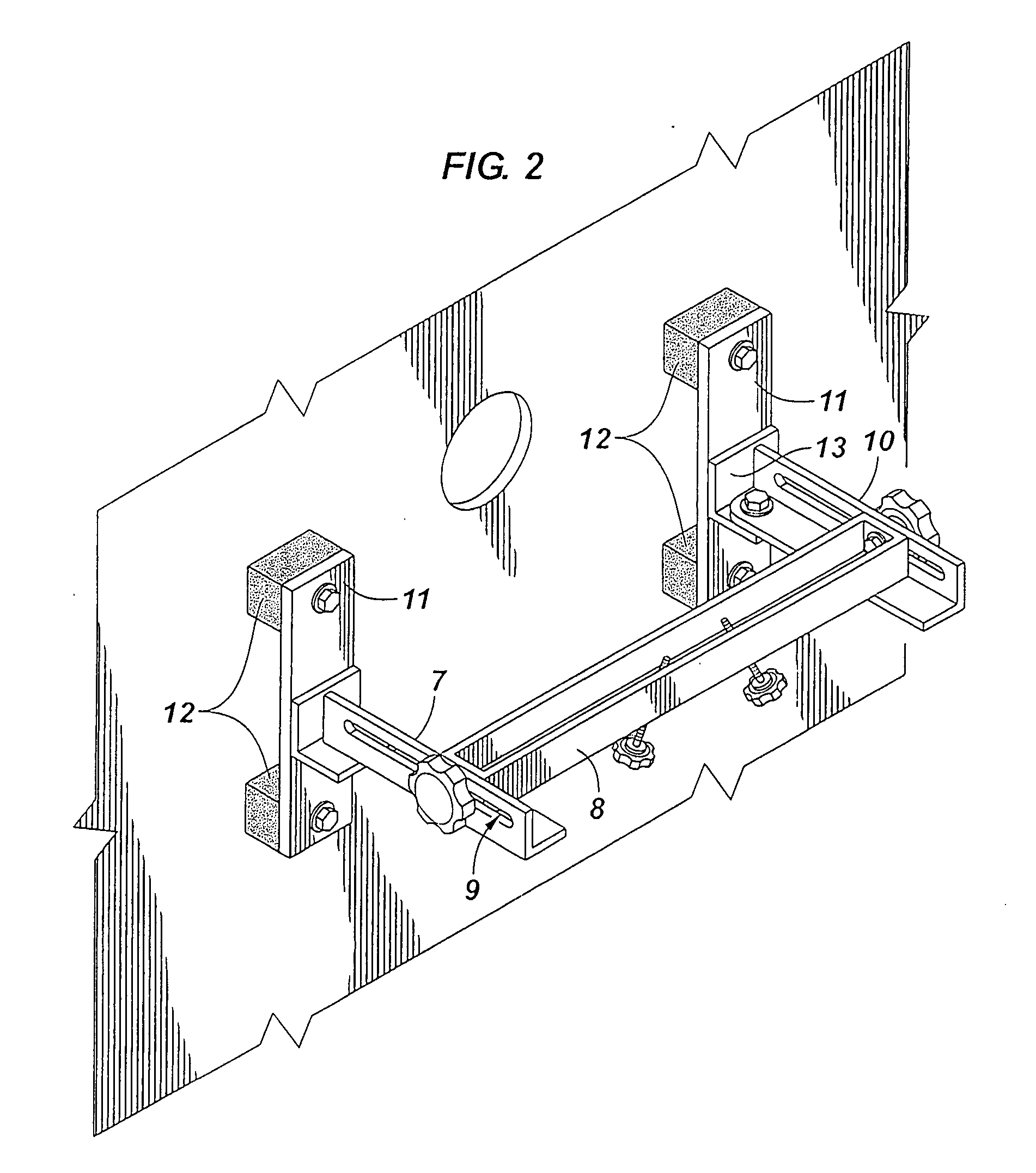

Pipe welding holding device and method for holding pipes with flanges in place during welding to vessel walls and other structures

InactiveUS20090051090A1More setReadily dismantled and movedWelding/cutting auxillary devicesWork holdersPipe weldingFlange

A pipe welding holding device and a method for holding pipes with flanges in place during welding to vessel walls and other structures. The invention provides an easy-to-use mechanical device, and a method, to hold the flange connected to a pipe in place during welding and enables the welder to accurately and reliably set the flange and pipe so that much fewer errors are made in welding than at present, and a method for using said device.

Owner:BARNES JR ROBBIE DEAN

Modular dike for shore protection

InactiveUS20060275081A1Economic and advantageEfficient managementArtificial islandsBreakwatersCouplingEngineering

The invention relates to a modular dike which is intended for shore protection. The inventive dike is based on a reduced number of different prismatic, tubular modules including one quadrangular-section module, two triangular-section modules and a straight trapezoidal-section module. The aforementioned modules are equipped with tongue-and-groove coupling means for the stacking thereof and lateral fixing means such that it is possible to produce a dike of any width, height and section. Moreover, the modules have a thickness of the order of 2.5 metres, a similar height and a length of between 6 and 12 metres. In this way, the dimensions of the modules are suitable for the standard containers that are used to transport goods by road and, more specifically, the constituent modules of the dike can be transported by road on the standard transport network used for the containers. Furthermore, the modules are provided with large lightening holes and, following installation, the modules can be stabilised using, among other means, sand-filled geotextile bags which are disposed therein.

Owner:UNIV POLITECNICA DE VALENCIA

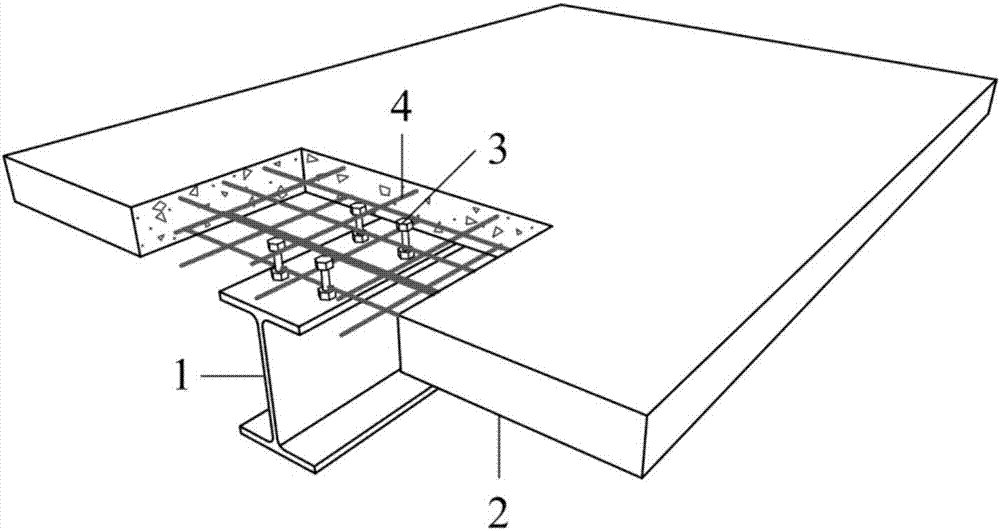

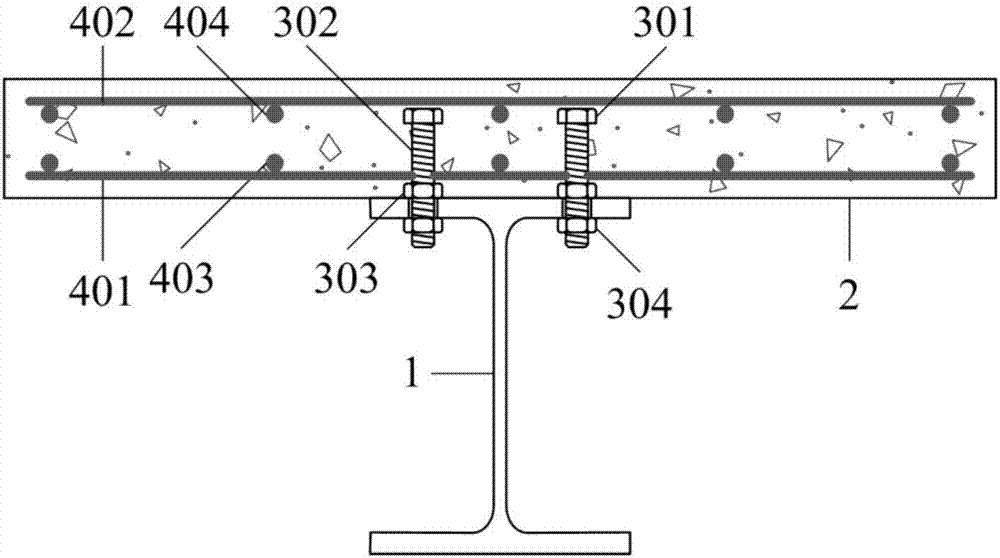

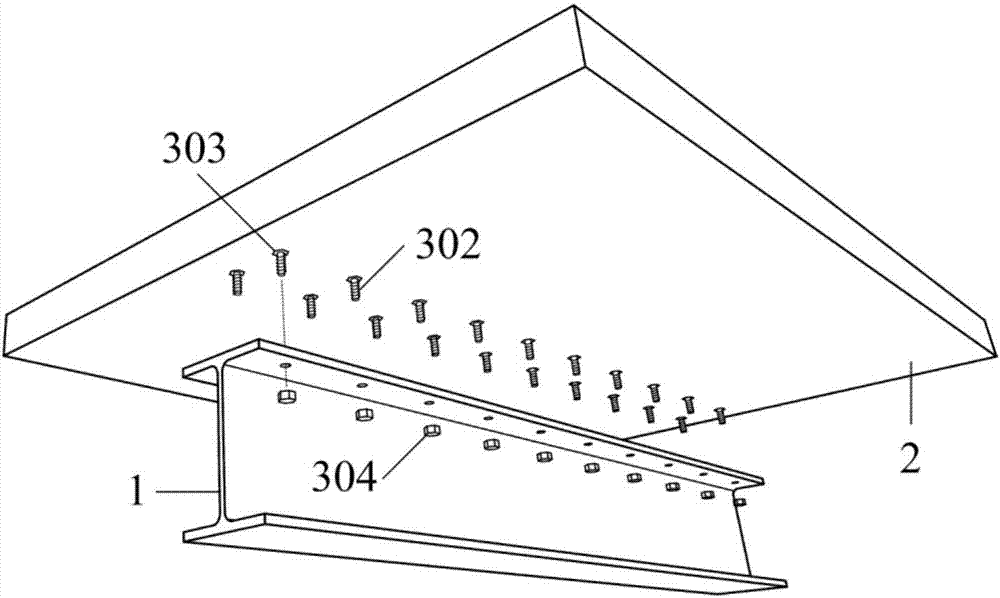

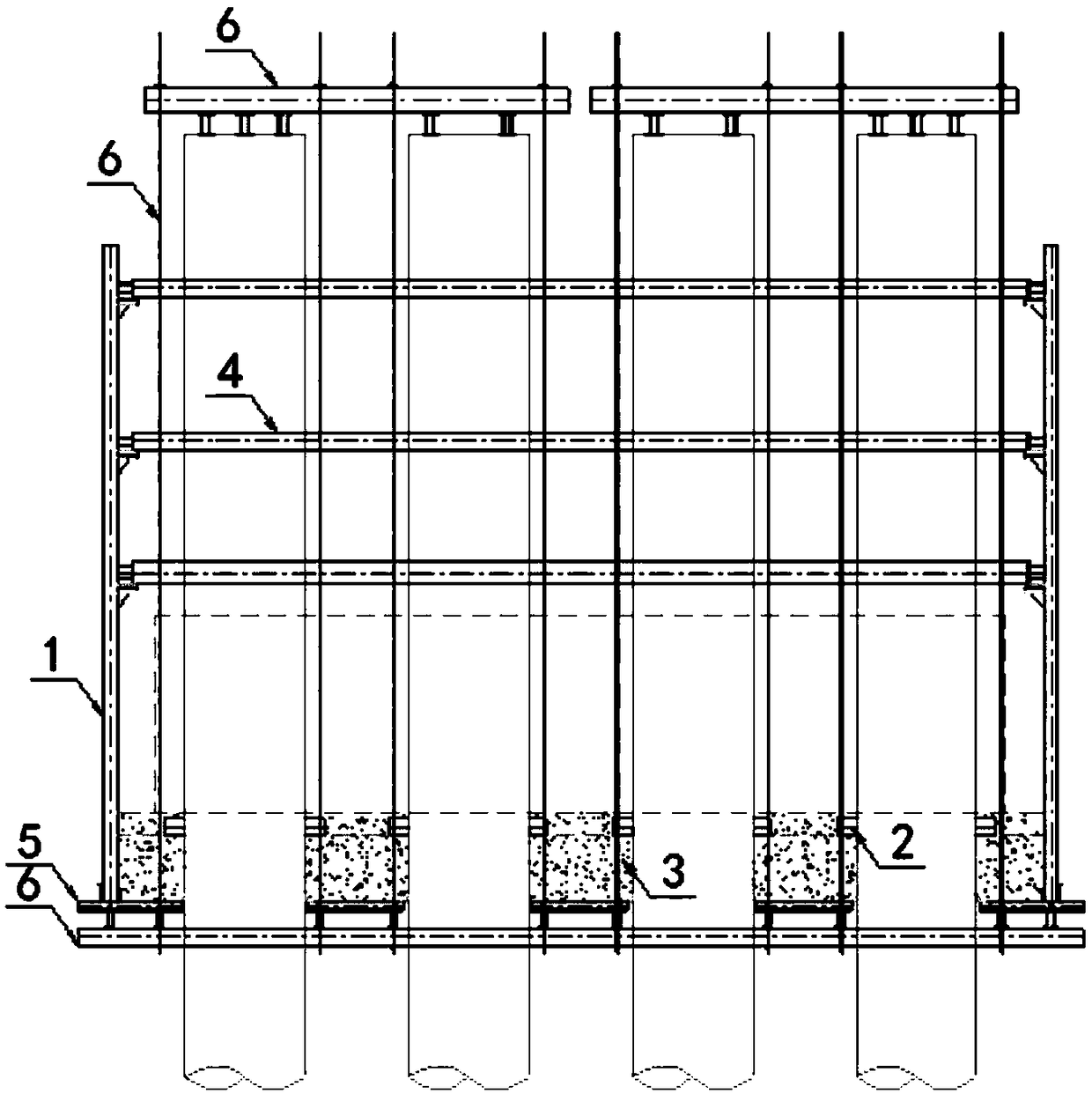

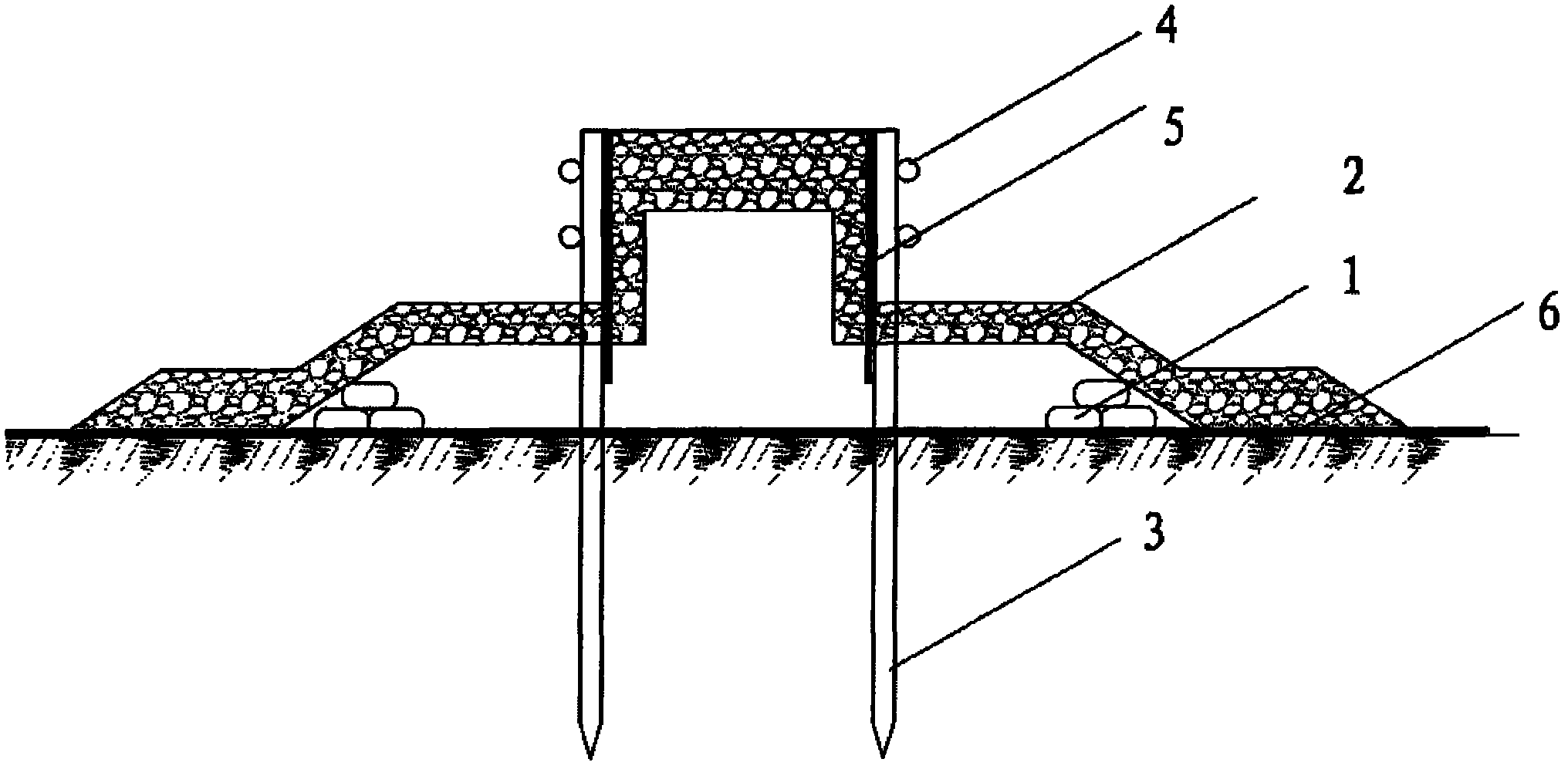

Detachable assembled high-ductility steel-concrete composite beam

InactiveCN107447921AHigh degree of industrializationEasy to processLoad-supporting elementsEngineeringRebar

The invention discloses a detachable assembled high-ductility steel-concrete composite beam and belongs to the technical field of steel structures of structural engineering. A steel beam and a precast concrete floor are assembled through bolts. Bolt holes are reserved in the upper wing edge of the I-shaped steel beam, the bolts are pre-buried at the bottom of the precast concrete floor and welded or mechanically connected with transverse steel bars at the bottom, so that the ductility and the anti-collapse capability of the structure are improved under the action of a strong shock. During assembly, the precast concrete floor is built at the top of the upper wing edge of the I-shaped steel beam, the bolts pre-buried at the bottom of the precast concrete floor penetrate the bolt holes reserved at the upper wing edge of the steel beam, and then the steel beam and the floor are fastened by nuts. When the service life of the structure is up, the bolts are unscrewed and the precast floor and the steel beam are separated to realize disassembly. The novel composite beam has the advantages of a traditional cast-in-place composite beam, is simple in assembly construction, high in speed and low in cost, and can effectively prevent dust raising on a construction site; post-earthquake repair and replacement of damaged members are facilitated; and the detachable assembled high-ductility steel-concrete composite beam can be detached in the service period or after service termination, and has a wide engineering application prospect.

Owner:TSINGHUA UNIV

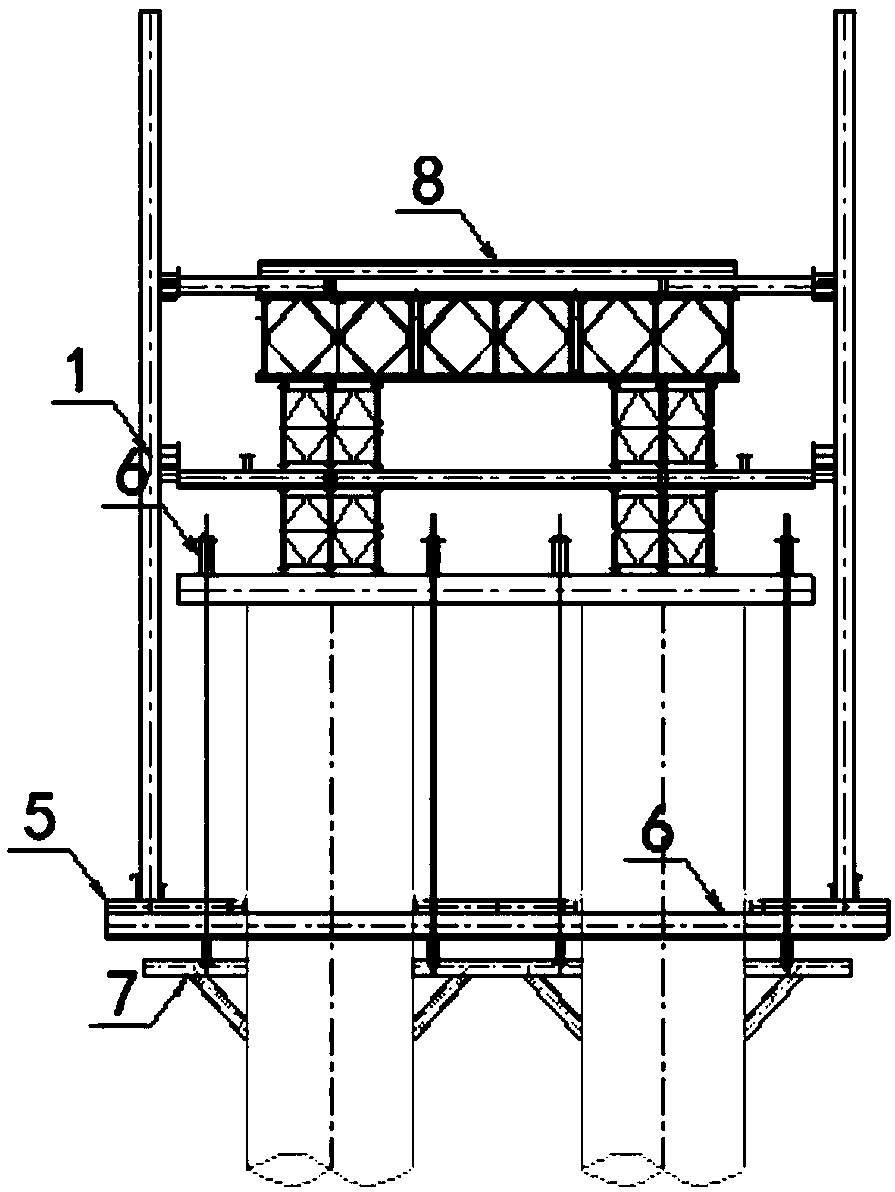

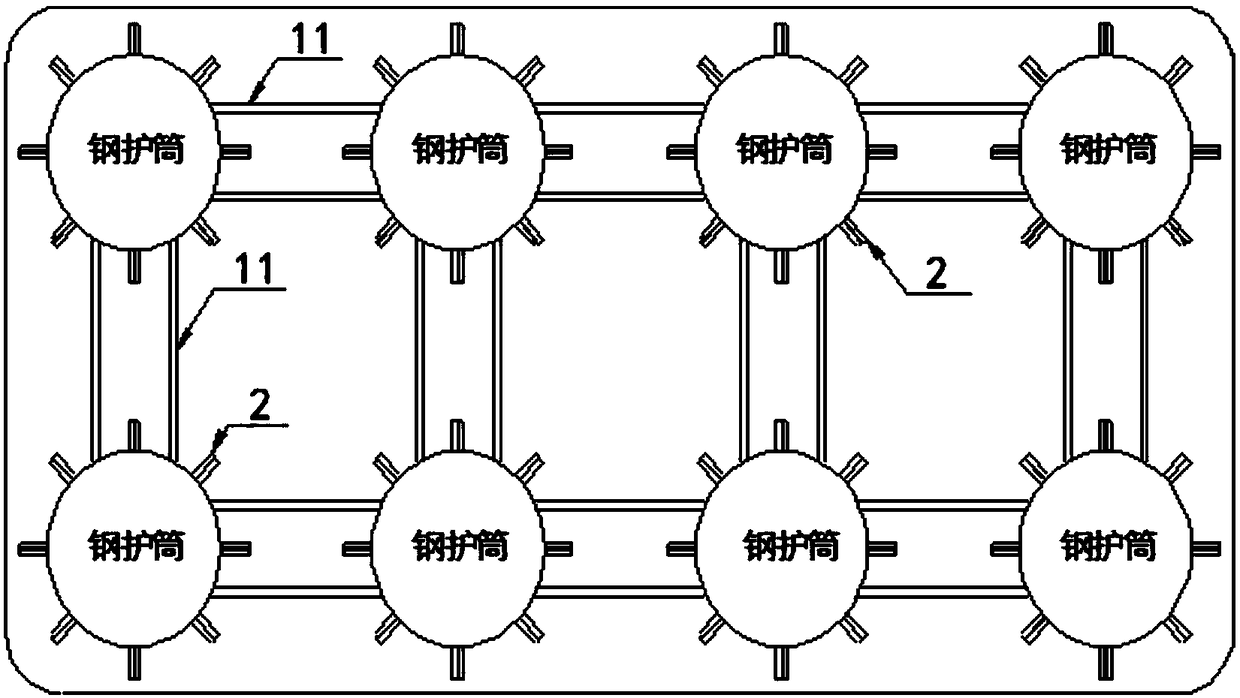

Construction method of deep water high pile bearing platform steel hanging box cofferdam

The invention discloses a construction method of a deep water high pile bearing platform steel hanging box cofferdam. The construction method comprises the following steps: 1) design of a steel hanging box cofferdam: Larson steel plate piles are adopted as wall plates of the steel hanging box cofferdam; 2) assembly and placement of the steel hanging box cofferdam: the steel hanging box cofferdam adopts high assembly and overall placement technologies; 3) bottom cover concrete construction: a bottom cover construction process is performed twice; after primary bottom covering, water in the steelhanging box cofferdam is extracted to a bottom cover surface; and then, the secondary bottom cover concrete casting is performed; and 4) disassembly of the steel hanging box cofferdam: after a bearing platform and part of underwater piers are constructed, the water is injected in the steel hanging box cofferdam to reach balanced inner and outer water levels; and the steel hanging box cofferdam isdisassembled. In the construction method, through the Larson steel plate piles as the wall plates of the steel hanging box cofferdam and twice bottom cover construction process, the construction progress can be accelerated, the economical cost is saved, and the engineering quality is guaranteed.

Owner:CHINA RAILWAY 23RD BUREAU GRP NO 1 ENG

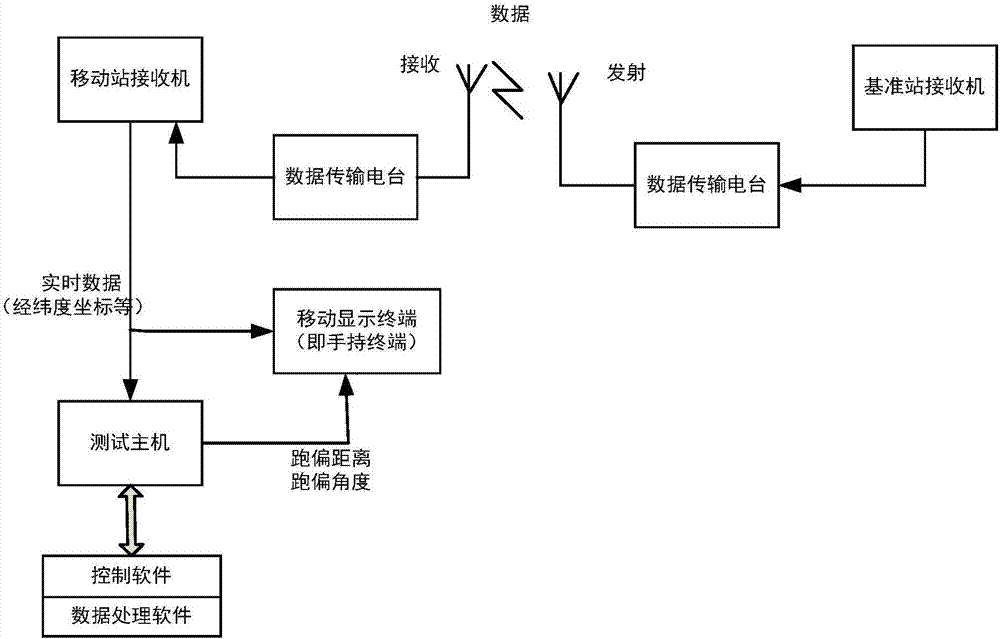

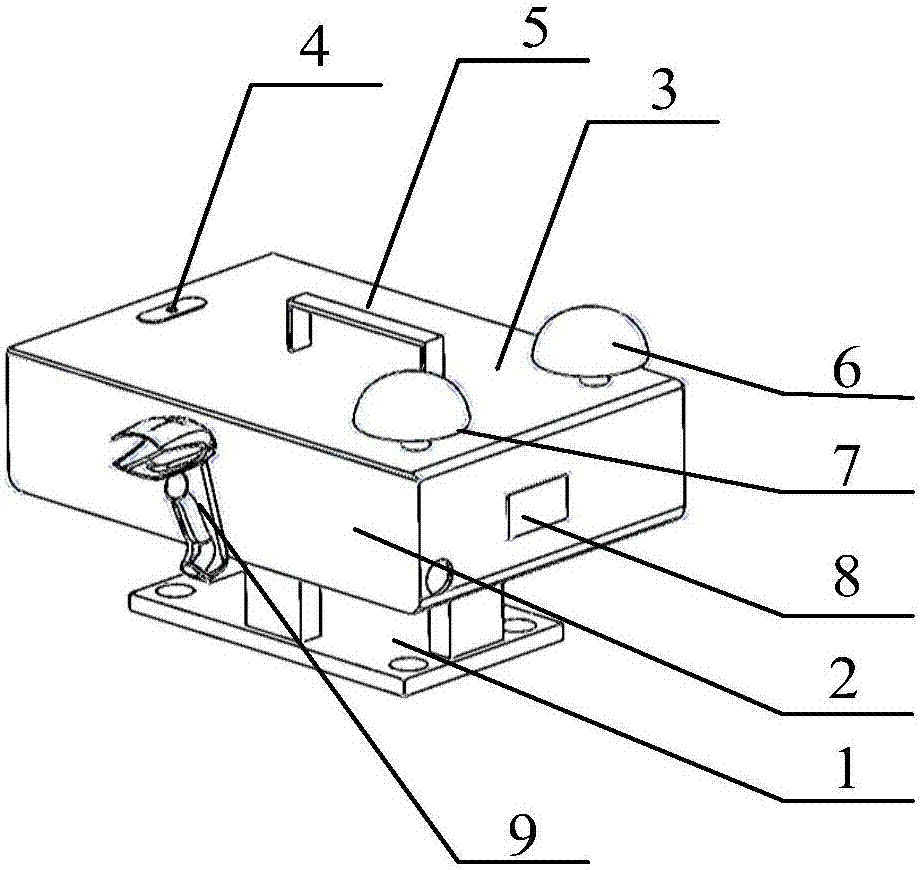

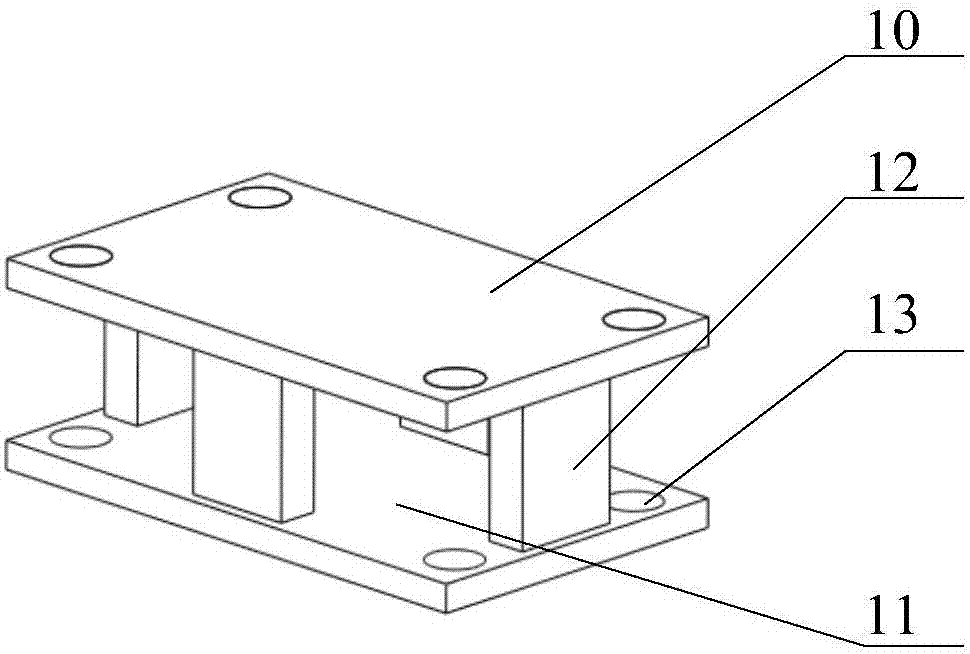

Vehicle-mounted vehicle driving deviation detection apparatus and detection method

InactiveCN107255566AExtended test timeEasy to operateVehicle testingMicrocontrollerCar manufacturing

The invention discloses a vehicle-mounted vehicle driving deviation detection apparatus and detection method. The vehicle-mounted vehicle driving deviation detection apparatus includes a magnetic attraction seat, a vehicle terminal, and a wireless laser bar code scanner. The vehicle terminal is composed of a GPS positioning module, a single-chip microcomputer main control module, a data transmission and display module, an interface module, an alarm module and a power module. The host of a mobile station acquires the vehicle trajectory information in real time and sends the information to a reference station via a radio station in the host, a differential algorithm is formed in the system to obtain the high-precision mobile station coordinate, the deviation amount of the vehicle to be measured is processed and calculated through the main control chip of the single-chip microcomputer main control module, the result of the deviation amount is displayed on a four-bit digital display screen after the testing is finished, and the vehicle speed is displayed in the testing process in real time. The apparatus is simple in structure and convenient to detach, and can realize the display of the deviation amount and the vehicle speed, is suitable for automobile manufacture enterprises to do streamline test, and has wide market potential and application prospect.

Owner:WUHAN UNIV OF SCI & TECH

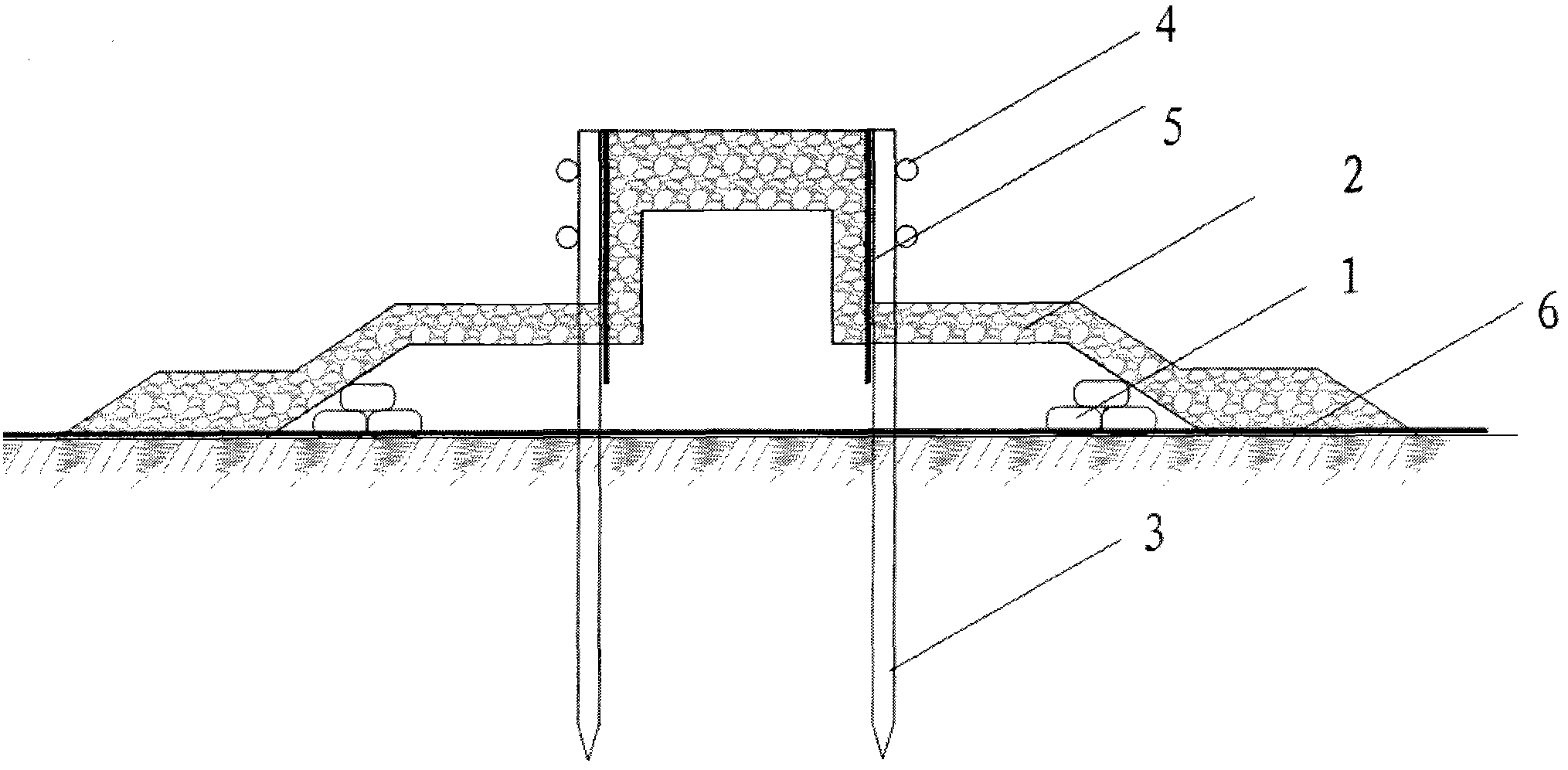

Ecological water retaining dam

InactiveCN102518085AWith interceptionFunctionalEarth-fill damsRock-fill damsRiver networkCrushed stone

The invention discloses an ecological water retaining dam. The whole dam body comprises three parts, i.e. an earth-rock dam body, a timber pile reinforcing structure and an isolating bamboo raft, wherein the earth-rock dam body is in a dual-layer structure; the inner layer is filled with bagged clay; the outer layer is filled with bagged gravel; the timber pile reinforcing structure is used for ensuring the safety and the stability of the dam body; and the isolating bamboo raft is used for reinforcing and isolating turbulence. Due to the adoption of natural material, the ecological water retaining dam disclosed by the invention has the advantages of stable structure, convenience in dismantlement and construction, and having the function of intercepting a water body, water conservation function for controlling the water level, and certain functions of purifying the water quality and repairing ecology as well as a landscape effect; and the ecological water retaining dam is suitable for construction of temporary water dams, short-term use of water dams or water retaining dams for middle and small creeks in river network regions and belongs to the fields of river pollution treatment and environment protection.

Owner:金丹越 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com