Construction method of deep water high pile bearing platform steel hanging box cofferdam

A technology of high pile cap and construction method, which is applied in basic structure engineering, construction and other directions, can solve the problems of thick back cover concrete, difficulty in underwater dismantling, and difficulty in lowering, so as to shorten the construction period and reduce the input of steel and back cover concrete. , the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] This embodiment provides a construction method for a deep-water high-pile cap steel hanging box cofferdam;

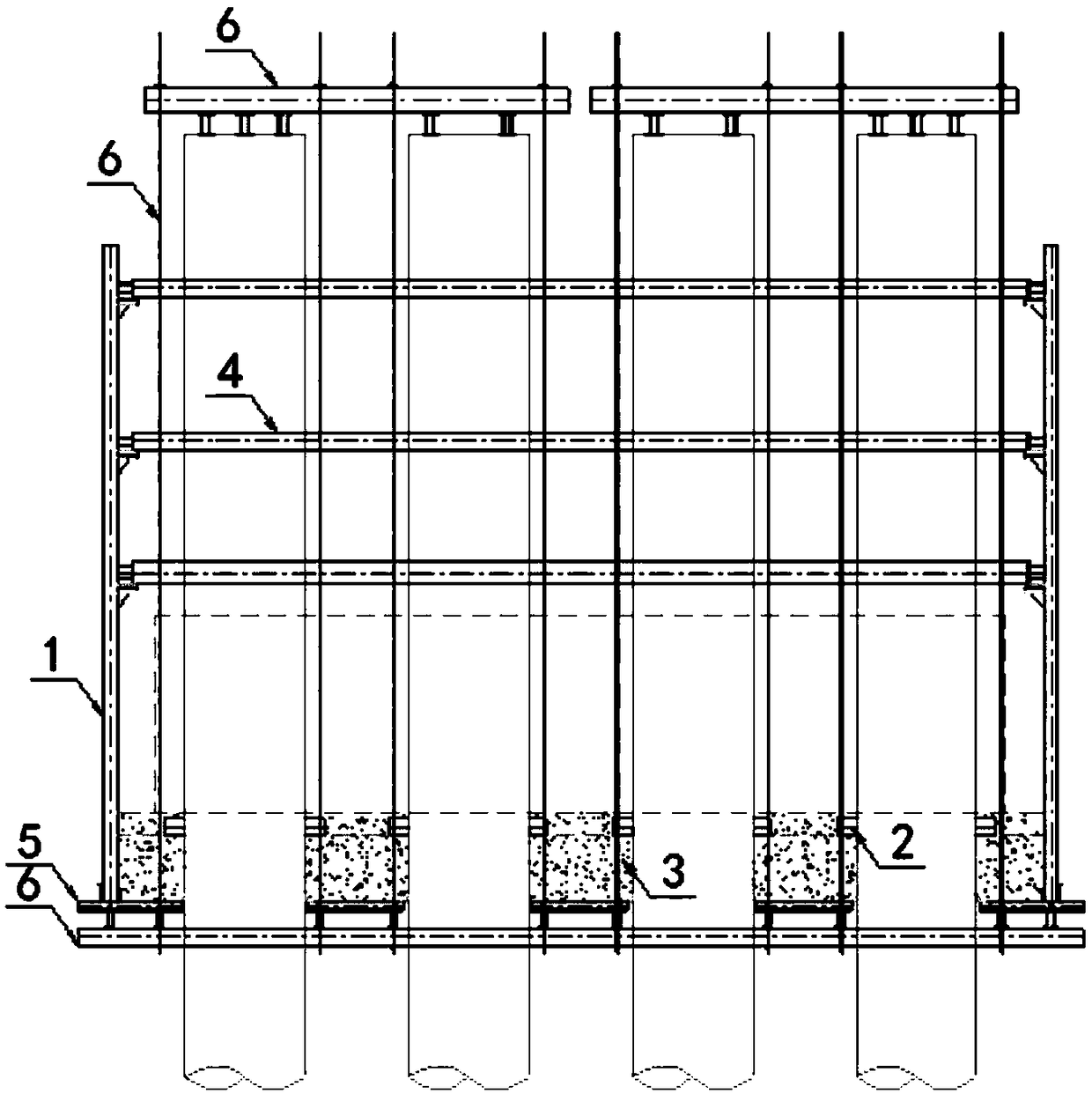

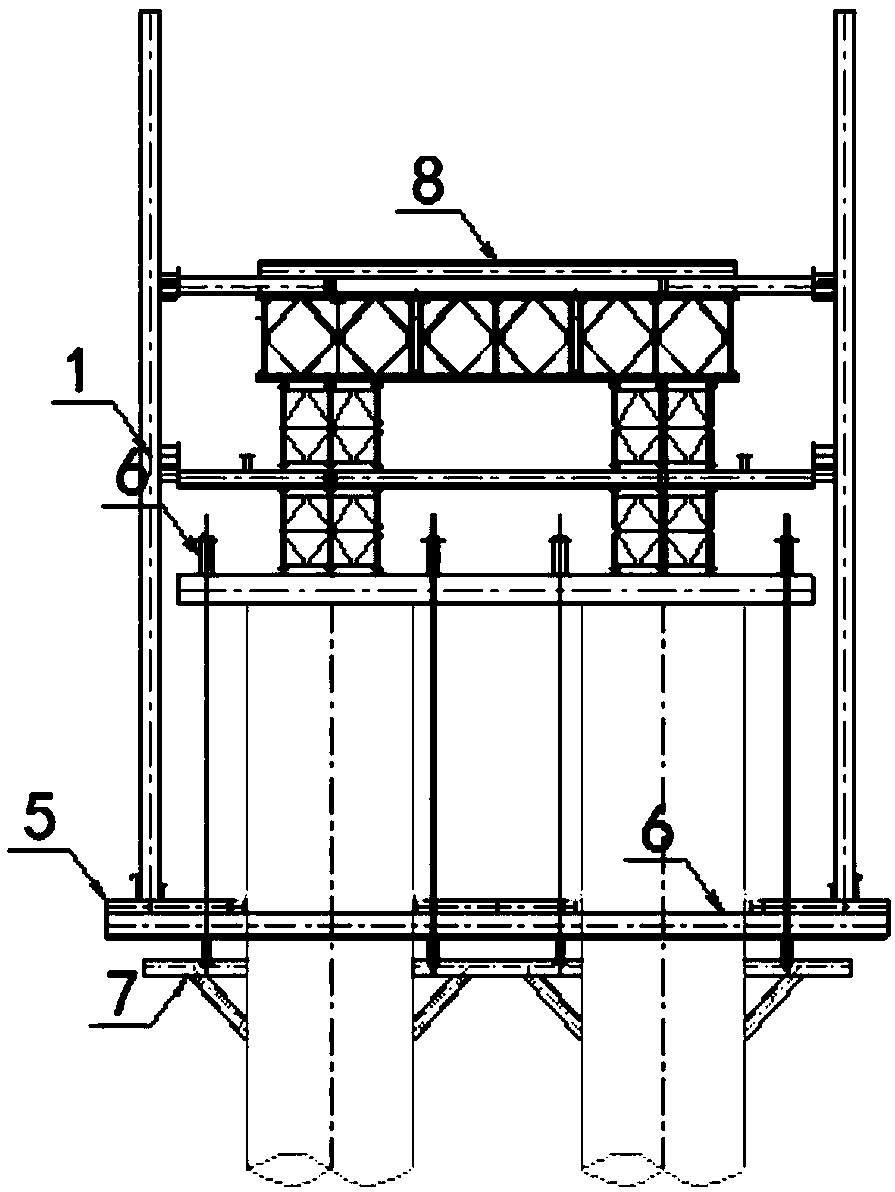

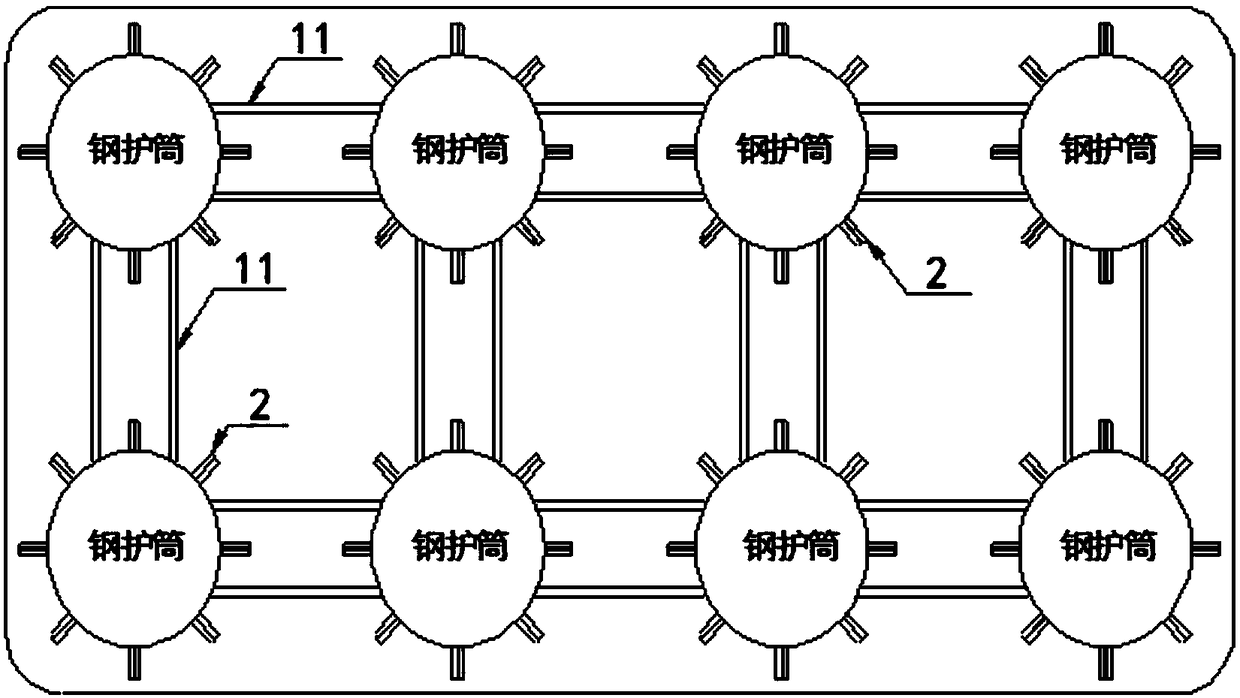

[0034] Such as Figure 1-Figure 5 As shown, the construction method of the deep-water high pile cap steel hanging box cofferdam in the present embodiment comprises the following steps:

[0035] (1) Design of steel hanging box cofferdam: Utilizing the characteristics of Larsen steel sheet pile 1, such as light weight, high strength, easy assembly, and convenient dismantling, it replaces the traditional double-layer truss structure wall plate as the steel hanging box cofferdam wall plate, and the steel floor 5. The inner support of section steel, anti-floating and anti-pressure beam, section steel and precision-rolled rebar hang together to form a steel hanging box cofferdam;

[0036] (2) Assembling and lowering of the steel hanging box cofferdam: the steel hanging box cofferdam adopts high-level assembly and overall lowering technology, and the steel casing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com