Detachable assembled high-ductility steel-concrete composite beam

A high ductility, concrete technology, applied in the direction of structural elements, building components, elongated structural components used for load-bearing, etc., can solve the problems that hinder the industrialization level of engineering structures, the full life cycle design, the poor ductility of the shear connection structure, the construction process It can improve the ductility, seismic energy dissipation and anti-collapse ability, avoid dust on the construction site, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

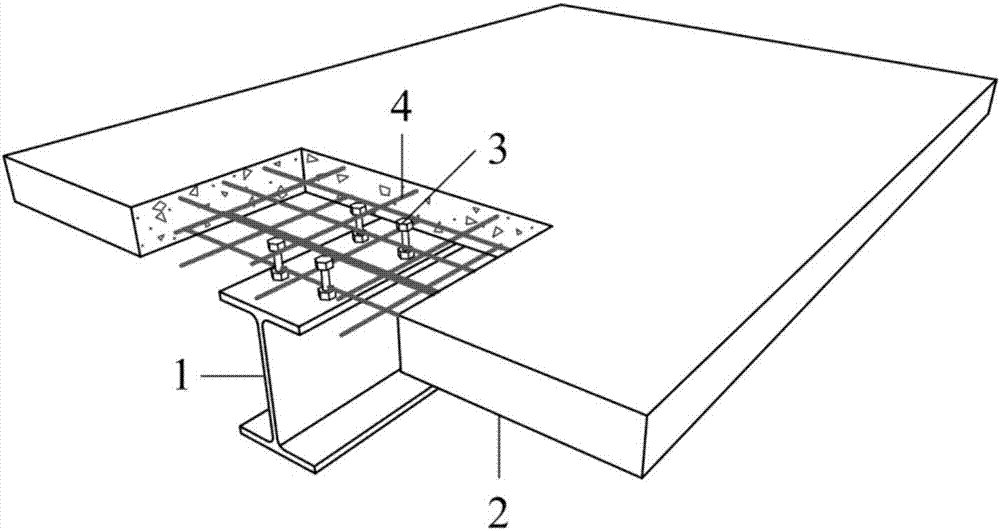

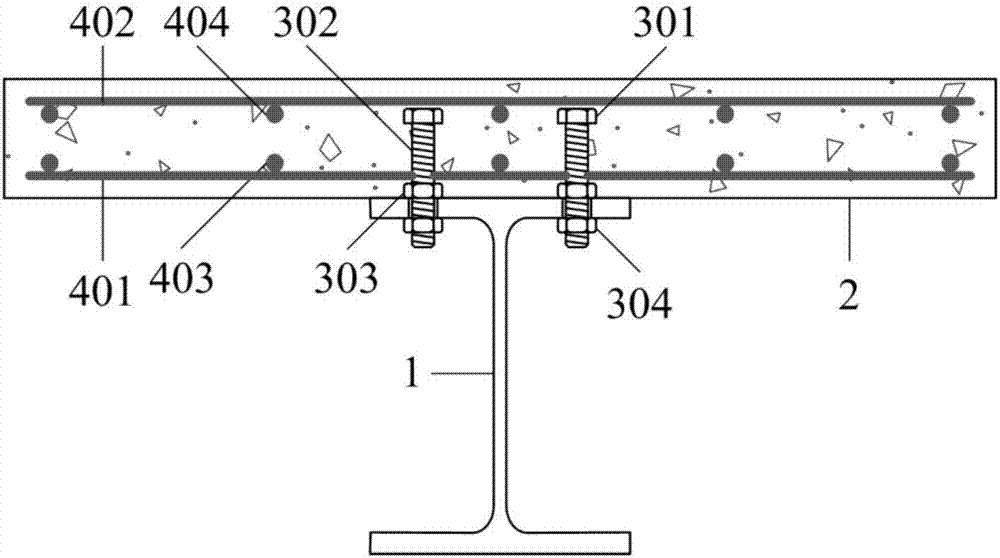

[0039] Such as Figure 1 to Figure 3 The illustrated embodiment 1: the present invention is a detachable assembly type high ductility steel-concrete composite beam, the precast concrete floor 2 is a solid reinforced concrete slab; Horizontal distribution of steel bars 402, bottom longitudinal bars 403 and top longitudinal bars 404; the bolt set 3 includes nuts 301, bolt rods 302, embedded nuts 303 and mounting nuts 304;

[0040] Two rows of bolt rods 302 are pre-embedded at the bottom of the precast concrete floor 2; a row of bolt holes is reserved in the middle of the extensions on both sides of the upper flange of the steel beam 1, and the position of the reserved bolt holes on the upper flange of the steel beam 1 is the same as that of the precast concrete floor 2. The positions of the embedded bolt sets 3 correspond to each other, and the bottom of the embedded nut 303 is flush with the bottom of the precast concrete floor 2;

[0041] The position of the reserved bolt hol...

Embodiment 2

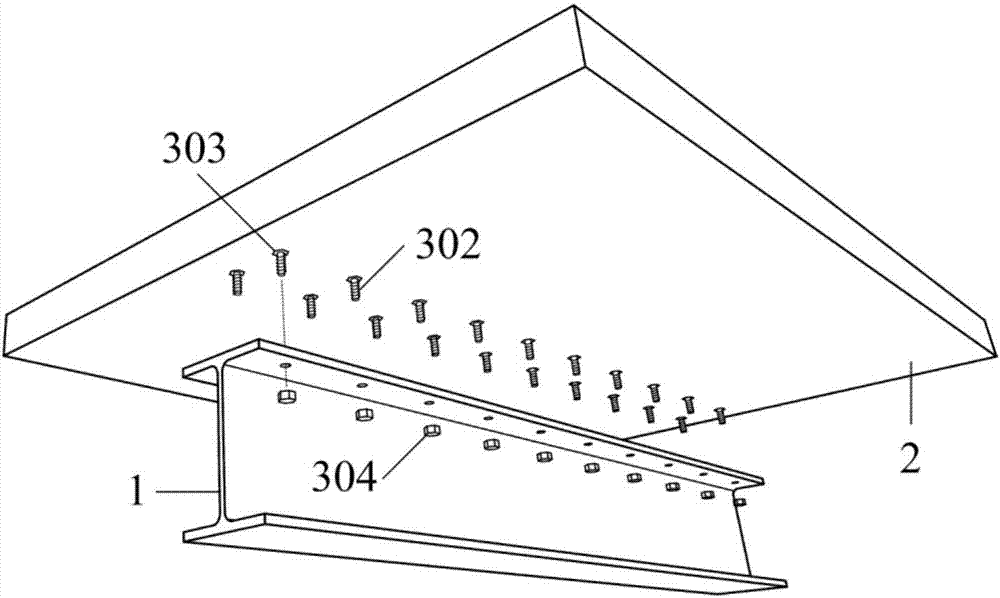

[0043] Such as Figure 4 The shown embodiment 2: the present invention is a detachable assembly type high ductility steel-concrete composite beam, the precast concrete floor 2 is a hollow reinforced concrete slab; Horizontally distributed reinforcing bars 402, bottom longitudinal bars 403 and top longitudinal bars 404; the bolt set 3 includes nuts 301, bolt rods 302 and mounting nuts 304;

[0044] Two rows of bolt rods 302 are pre-embedded at the bottom of the precast concrete floor 2; a row of bolt holes is reserved in the middle of the extensions on both sides of the upper flange of the steel beam 1, and the position of the reserved bolt holes on the upper flange of the steel beam 1 is the same as that of the precast concrete floor 2. The positions of the inner pre-embedded bolt sets 3 correspond to each other, and each bolt rod 302 is simultaneously connected to the bottom transversely distributed reinforcing bars 401 and the top transversely distributed reinforcing bars 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com