Anti-buckling steel plate seismic shear wall provided with stiffening ribs

A stiffening rib, steel plate wall technology, applied in earthquake-proof, wall, building components and other directions, can solve the problems of high transportation and installation requirements, complex connections, etc., and achieve the effect of improving shear bearing capacity, clear functions, and high degree of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

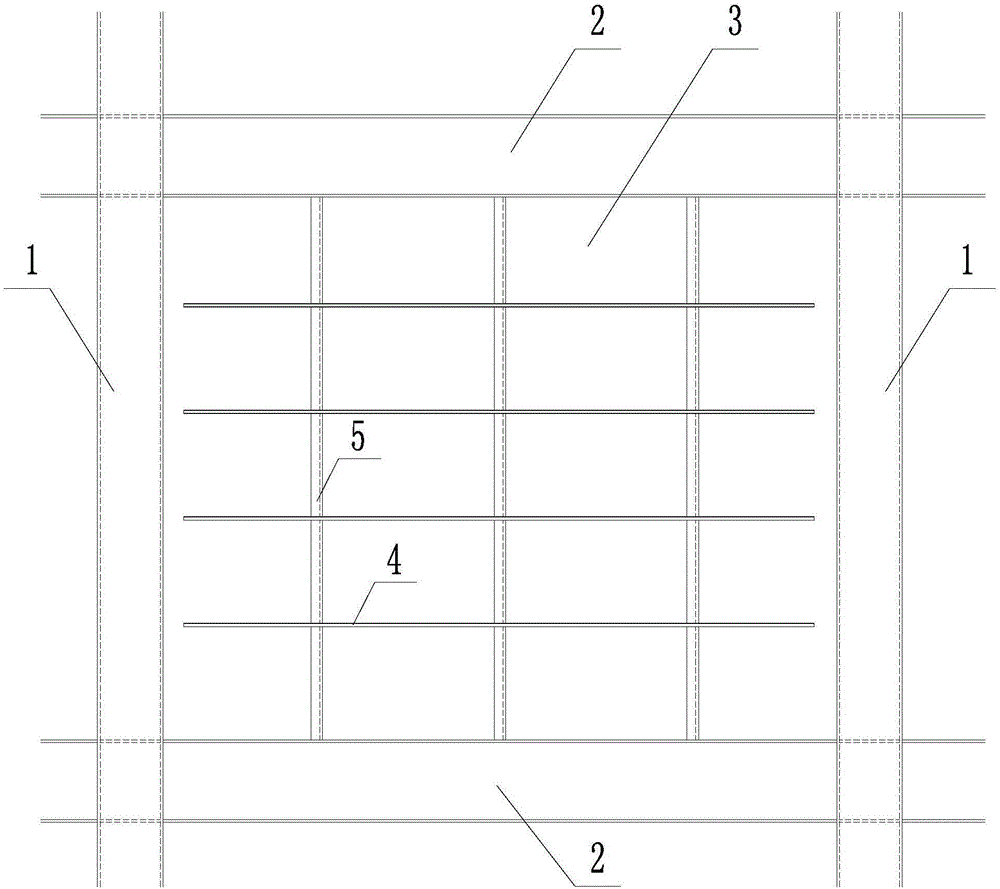

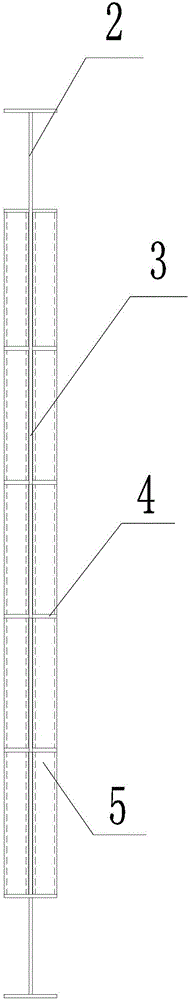

[0040] like figure 1 and figure 2 As shown, the embodiment includes a steel plate wall 3, a transverse stiffener 4, a vertical stiffener 5, a steel column 1 and a steel beam 2, the steel beam 2 adopts an H-shaped steel beam, and the steel plate wall 3 is placed by the steel column 1 and the steel beam In the frame formed by 2, the steel plate wall 3 is welded with steel beam 2 and steel column 1 around.

[0041] The steel plate shear wall bears the horizontal shear force. The surface of both sides of the steel plate wall 3 is evenly spaced and fixed with multiple transverse stiffeners 4. The transverse stiffener 4 is made of T-shaped steel. The wing plate of the T-shaped steel is parallel to the steel plate wall 3. The T-shaped steel The web is perpendicular to the steel plate wall 3. The T-shaped steel can be welded by two steel plates, one as a web and the other as a wing, one end of the web is welded to the middle of the wing to form a T-shaped steel, and the other end i...

Embodiment 2

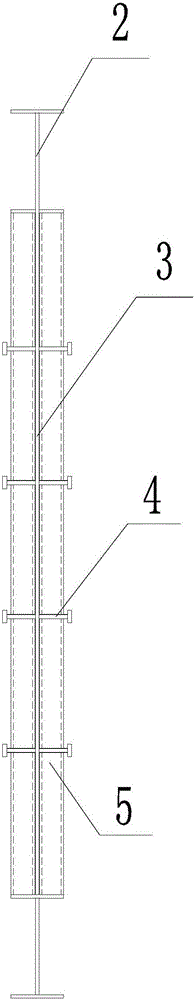

[0045] like figure 1 and image 3 As shown, the embodiment includes a steel plate wall 3, a transverse stiffener 4, a vertical stiffener 5, a steel pipe concrete column and a steel beam 2, the steel beam 2 adopts a box beam, and the steel plate wall 3 is placed by the steel pipe concrete column and the steel beam 2 In the formed frame, the steel plate wall 3 is welded with the steel beam 2 and the steel pipe concrete column around.

[0046] The steel plate shear wall bears the horizontal shear force, and the surfaces of both sides of the steel plate wall 3 are evenly spaced and fixed with multiple transverse stiffeners 4, the transverse stiffeners 4 are made of steel plates, the steel plates are placed horizontally, and the long sides of the steel plates are welded to the surface of the steel plate wall 3 .

[0047] A plurality of vertical stiffeners 5 are fixed at horizontal intervals between the T-shaped steels. The vertical stiffeners do not bear other forces. The vertica...

Embodiment 3

[0050] Including steel plate wall 3, transverse stiffener 4, vertical stiffener 5, steel column 1 and steel beam 2, steel beam 2 adopts H-shaped steel beam, and steel plate wall 3 is placed in the frame formed by steel column 1 and steel beam 2 , steel plate wall 3 is welded with steel beam 2, steel column 1 around.

[0051] The steel plate shear wall bears the horizontal shear force. The steel plate wall 3 is divided into two or three pieces along the height. The T-shaped steel on both sides of the steel plate wall 3 is replaced by the same I-shaped steel. The upper and lower steel plate walls 3 are welded to the I-shaped steel. .

[0052] The steel plate wall 3 and the web of the steel girder 2 are connected to form the same steel plate, and the flange of the steel girder 2 is welded on the steel plate.

[0053] The two sides of the steel plate wall 3 are evenly spaced and fixed with a plurality of transverse stiffeners 4 at intervals up and down. The transverse stiffeners ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com