Unitary piping inspection well

An integrated, inspection well technology, applied in the field of inspection wells, can solve the problems of long construction period, secondary pollution of the surrounding environment, poor water flow, etc., and achieve the effect of high degree of industrialization, shortened construction period, and tight interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

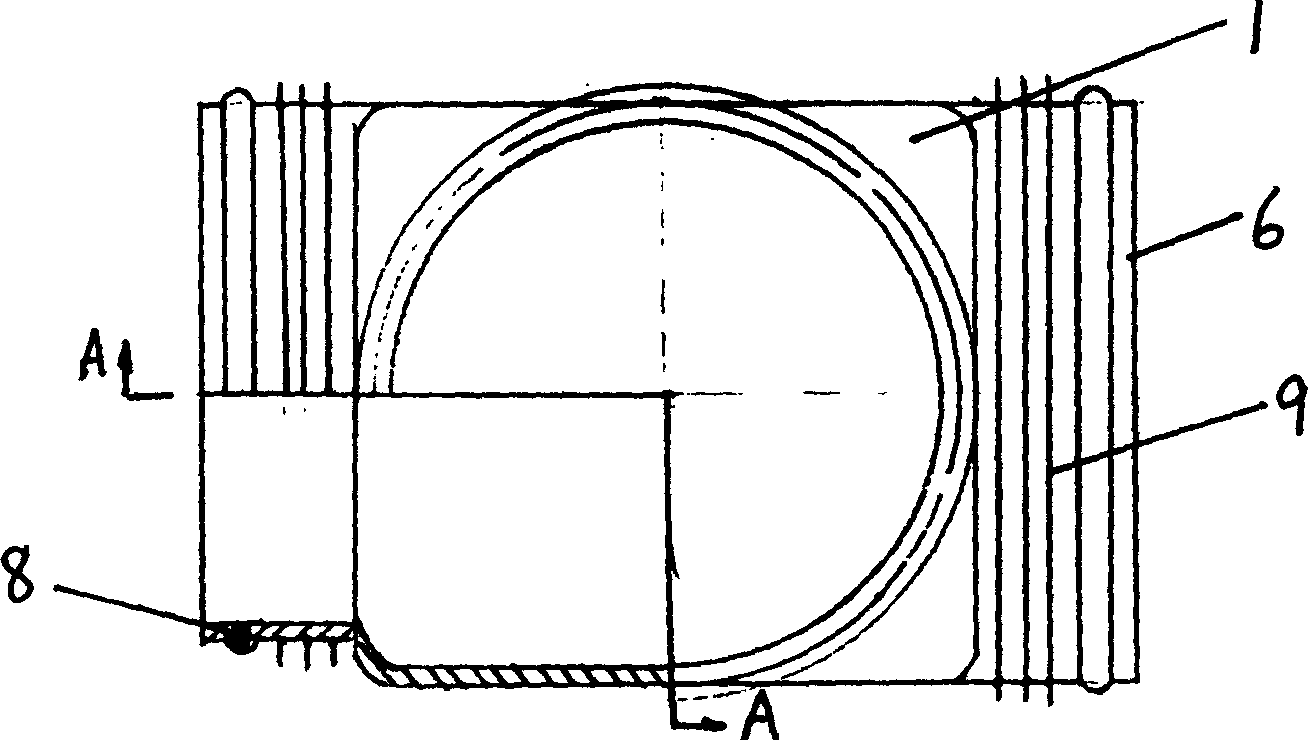

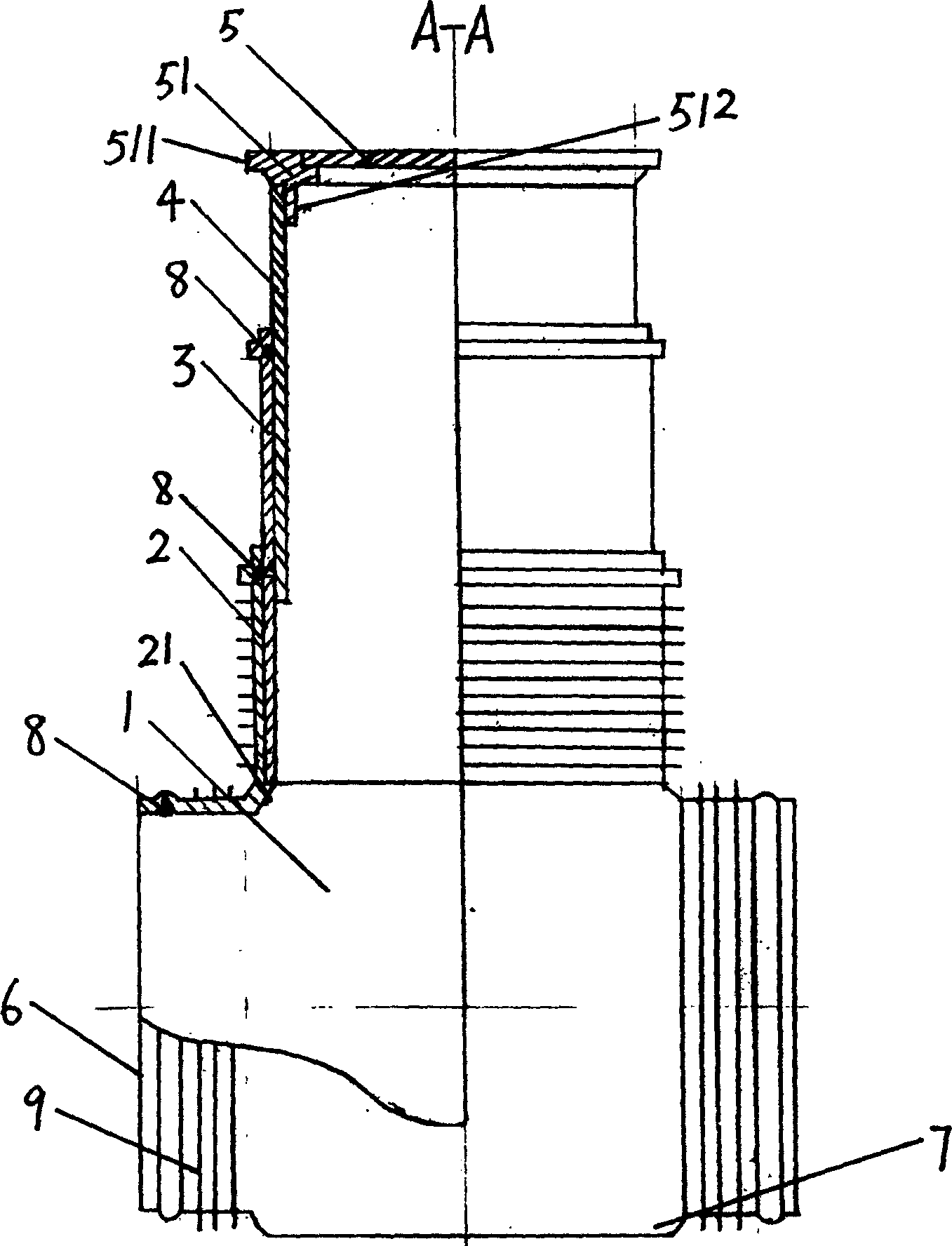

[0023] Embodiment 1: The corresponding two sides of the cuboid-shaped well body 1 are connected and communicated with a main pipeline connection port 6, the bottom of the inner cavity of the well body 1 is a collection part 7, and the upper end of the well body 1 is connected and communicated with a well body socket 2 , the inner wall of the well body socket 2 is close to the inner side wall of the well body 1 to form a ring of bosses 21 that protrude outward in the direction of the center line. The pipe 4 is close to the inner side wall of the connecting pipe 3, and the upper end of the telescopic pipe 4 is fixedly connected with the connecting ring 512 at the lower end of the manhole cover seat 51. A sealing ring 8 is provided on the connecting pipe 3 , the upper port of the well body socket 2 and the inner side wall of the port of the main pipeline connection port 6 away from the well body 1 . A reinforcing rib 9 is provided on the outer side wall of the well body socket 2 ...

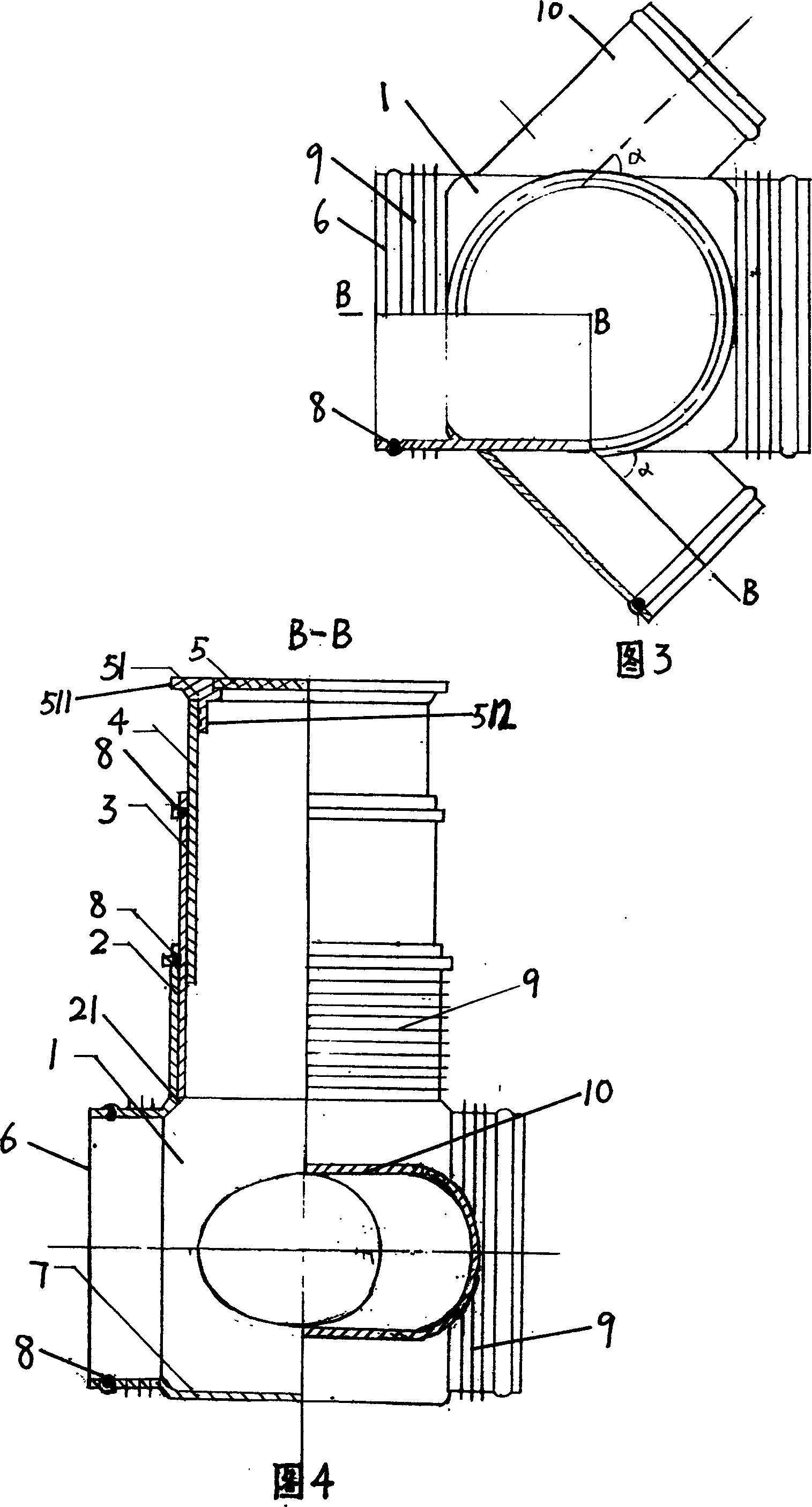

Embodiment 2

[0024] Embodiment 2: The difference from Embodiment 1 is that a pipeline connection port 10 is provided on the other two sides of the well body 1 in communication with each other, and the openings of the two pipeline connection ports face the same main pipeline connection port. A sealing ring is also provided on the inner side wall of the port of the branch pipe connecting port away from the well body. The included angle a between the center line of the branch pipe connection port 10 and the center line of the main pipe connection port 6 is 45°

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com