Assembly type steel structure self-return module based on slotting steel plate shear wall energy consumption

A steel plate shear wall, self-reset technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of large residual deformation of important components, difficult maintenance and reinforcement of the structure, and inability to restore to the original position, so as to reduce maintenance costs. , The effect of saving construction costs and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

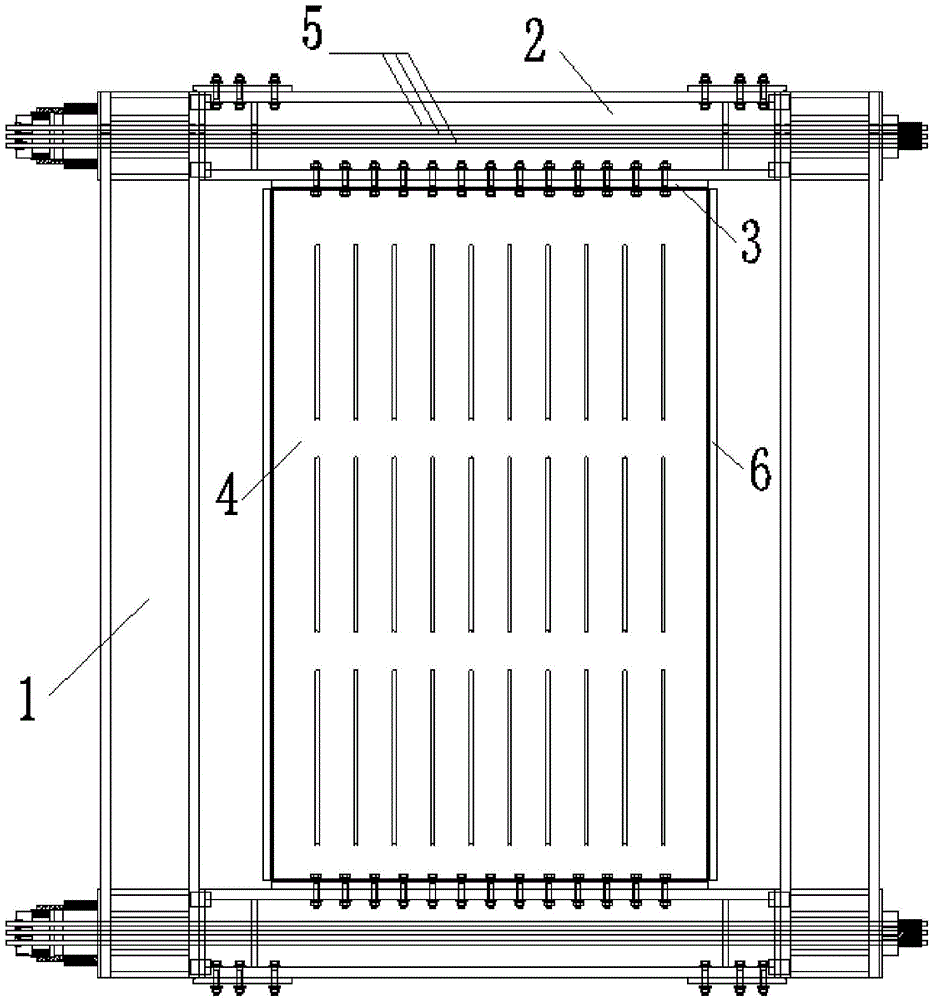

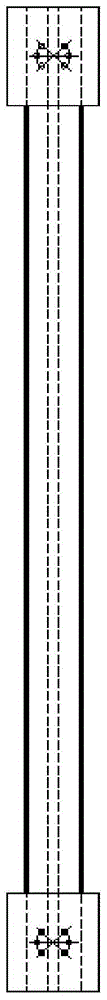

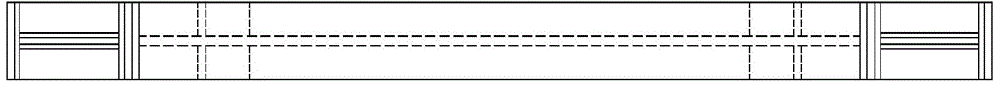

[0030] Embodiment 1: as figure 1 , 2 , 3, a prefabricated steel structure self-resetting module based on the energy dissipation of slotted steel plate shear walls, including two vertical edge members 1, two transverse edge members 2, two connecting members 3 and a slotted In the steel plate shear wall 4, a number of post-tensioned prestressed steel strands 5 are arranged along the two transverse edge members 2 and anchored on the outer flanges of the two vertical edge members 1 to form a prestressed frame; Inside the prestressed frame, two connecting members 3 are arranged at both ends of the slotted steel plate shear wall 4, and are connected to the transverse edge members 2 by high-strength bolts.

[0031] The ends of the vertical edge members 1 are respectively provided with transverse stiffeners 11 to prevent local buckling of the panels and improve the mechanical properties of the members.

[0032] Transverse stiffeners 8 , end plates 9 and cover plates 10 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com