Omnidirectional high-accuracy spatial direction fine tuning device

A technology of spatial pointing and fine-tuning device, which is applied to the parts, instruments and other directions of the instrument, can solve the problem that the pointing mechanism is difficult to meet the requirements of use, and achieve the effect of precise fine-tuning and fine-tuning of the pointing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

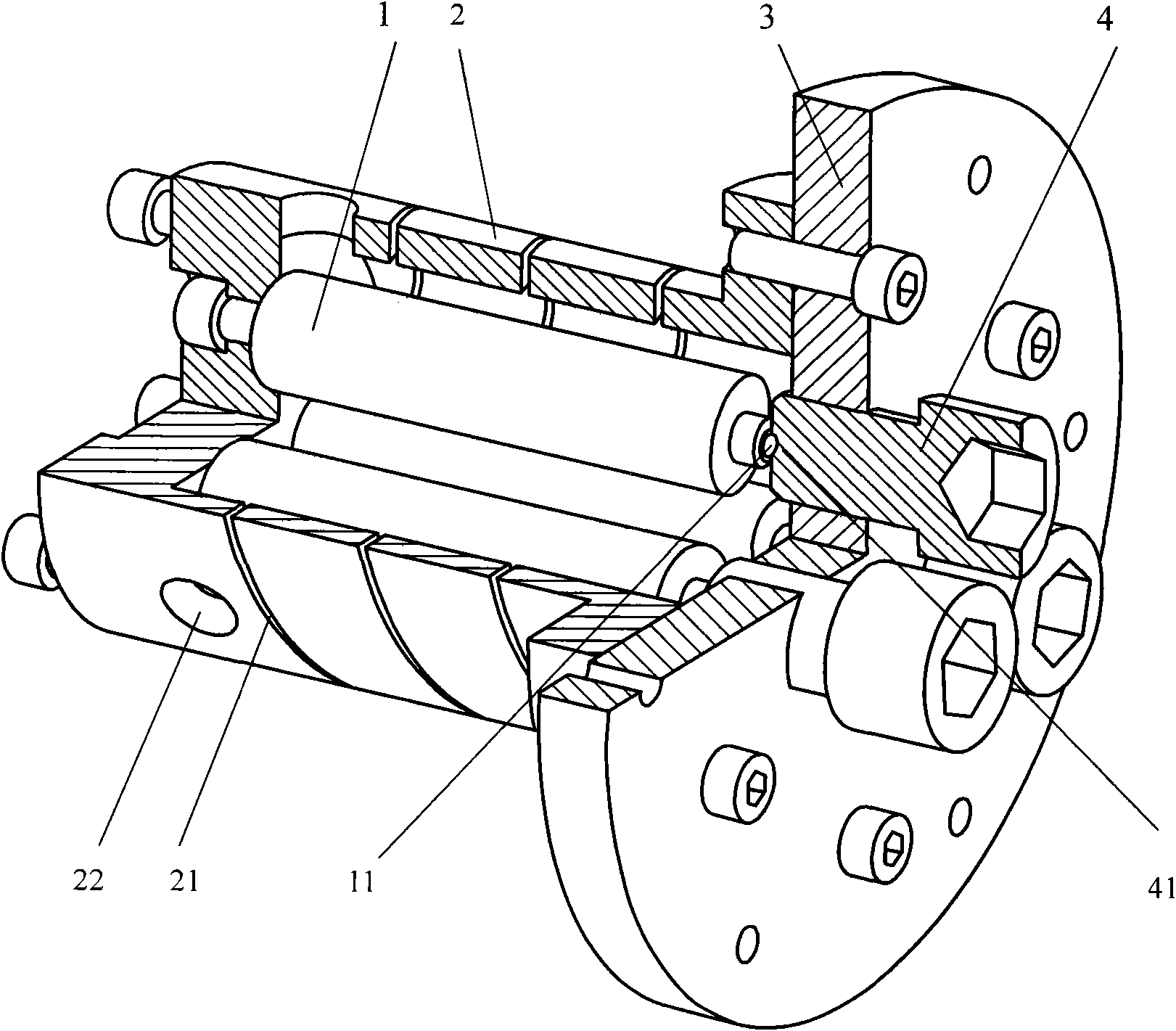

[0017] See attached figure 1 , This embodiment of the present invention is made of a 65Mn type steel pipe with an outer diameter of ¢60mm to make a cylindrical support 2 with a circular flange at one end, and the inner diameter of the support 2 is ¢50mm. The cylindrical surface of the support 2 is provided with a spiral groove 21 axially around the column, and a through hole 22 is provided at the same time for wiring. The bottom plate 3 is cut from an aluminum alloy plate with a thickness of 12mm, is circular, and is fixed on the end face flange of the bracket 2 by coaxial screws. Three piezoceramic drivers 1 are piezoceramic drivers imported from German PI company with the type PSt150 / 10 / 60VS15-VbS, radially and evenly distributed in the bracket 2, one end of which is respectively fixed to the bracket by screws At the bottom of the cylinder of 2, the other end is provided with ball head 11 respectively, and the corresponding ball head 11 of its end of adjusting screw 4 estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com