A preparation method of high-density wc-wb-co spherical powder hard surface material

A spherical powder, wc-wb-co technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems that affect the wear resistance and corrosion resistance of the coating, the roughness of the powder surface, and the low bulk density of the powder. , to achieve the effect of improved corrosion resistance, better corrosion resistance, and improved sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]A kind of high-density WC-WB-Co spherical powder hard surface material of the present invention, its formula proportion is counted as: WB powder 15%-38%, Co powder 8%-12%, PEG binder 1.0%- 4.0%, WC powder 50%-75%. A kind of preparation method of high density WC-WB-Co spherical powder hard surface material of the present invention comprises the following process steps:

[0043] (1) Ingredients: ingredients are made according to mass percentage, wherein the addition ratio of WC powder is 50%-75%, the addition ratio of WB powder is 15%-38%, and the addition ratio of metal Co powder is 8%-12%. PEG is a binder, and its addition amount is 1.0%-4.0% of the total mass;

[0044] (2) Wet milling: Put the prepared materials in the ball milling tank, use deionized water or edible alcohol as the ball milling medium, control the mass ratio of the ball to material within the range of 2:1-5:1, and the ball milling time is 20h- 72h;

[0045] (3) Spray drying: the wet-milled WC-WB-Co s...

Embodiment 1

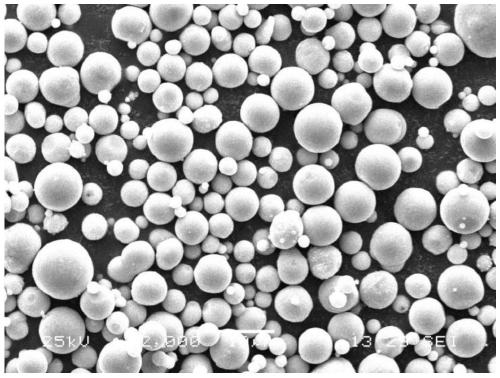

[0057] Example 1, figure 1 It is the SEM electron microscope image of 60WC-30WB-10Co spherical powder, taking the addition ratio of WC powder as 60%, the addition ratio of WB powder as 30%, and the addition ratio of metal Co powder as 10% as an example:

[0058] (1) Batching: batching is carried out according to mass percentage, wherein the addition ratio of WC powder is 60%, the addition ratio of WB powder is 30%, the addition ratio of metal Co powder is 10%, selects PEG as binder, and its addition amount 2.0% of the total mass;

[0059] (2) Wet milling: place the prepared materials in a ball milling tank, use deionized water as the ball milling medium, the mass ratio of balls to materials is 4:1, and the ball milling time is 48 hours;

[0060] (3) Spray drying: the wet-milled slurry is spray-dried by a pressure spray drying tower to prepare a standby mixed material;

[0061] (4) Compression: place the spray-dried powder in a powder press, and press it into a block-shaped e...

Embodiment 2

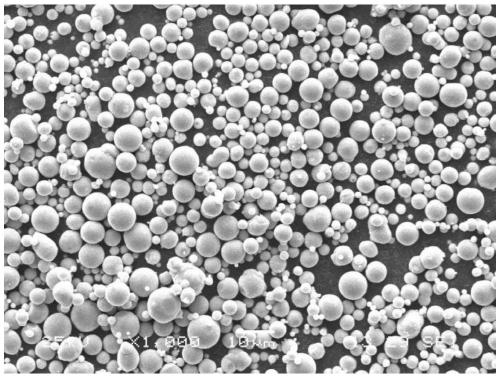

[0067] Example 2, figure 2 It is the SEM electron microscope image of 50WC-38WB-12Co spherical powder, taking the addition ratio of WC powder as 50%, the addition ratio of WB powder as 38%, and the addition ratio of metal Co powder as 12% as an example:

[0068] (1) Batching: batching is carried out according to mass percentage, wherein the addition ratio of WC powder is 50%, the addition ratio of WB powder is 38%, the addition ratio of metal Co powder is 12%, selects PEG as binder, its addition amount 2.2% of the total mass;

[0069] (2) Wet milling: place the prepared materials in a ball milling tank, use deionized water as the ball milling medium, the mass ratio of balls to materials is 3.5:1, and the ball milling time is 60h;

[0070] (3) Spray drying: the wet-milled slurry is spray-dried by a pressure spray drying tower to prepare a standby mixed material;

[0071] (4) Compression: place the spray-dried powder in a powder press, and press it into a block-shaped embryo ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com