Ti(C, N)-based cermet and preparation method thereof

A base metal and ceramic technology, applied in the field of Ti-based cermet and its preparation, can solve the problems of cracks and peeling off of the surface hardened layer, and achieve the improvement of interface bonding ability, wettability and migration. Barrier reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

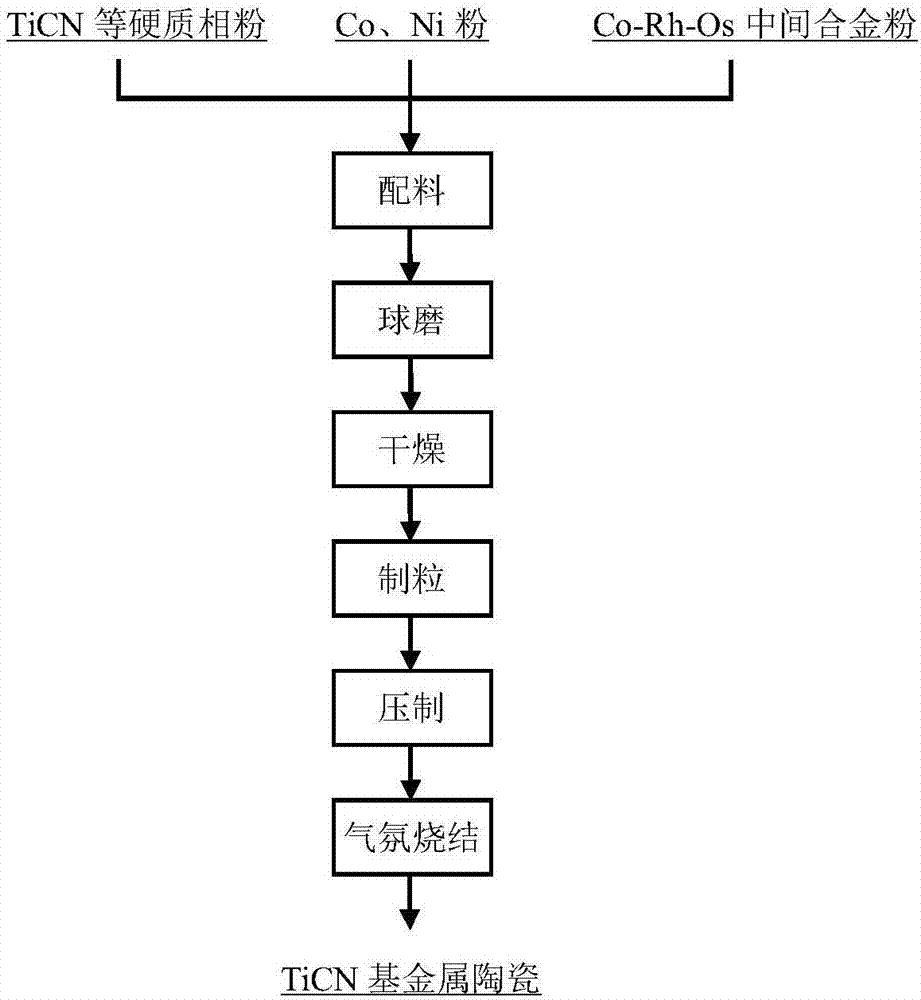

[0039] On the basis of the above, this embodiment further provides a preparation method for preparing the above-mentioned Ti(C,N)-based cermet, which includes the following steps:

[0040] Step 1, preparing master alloy powder;

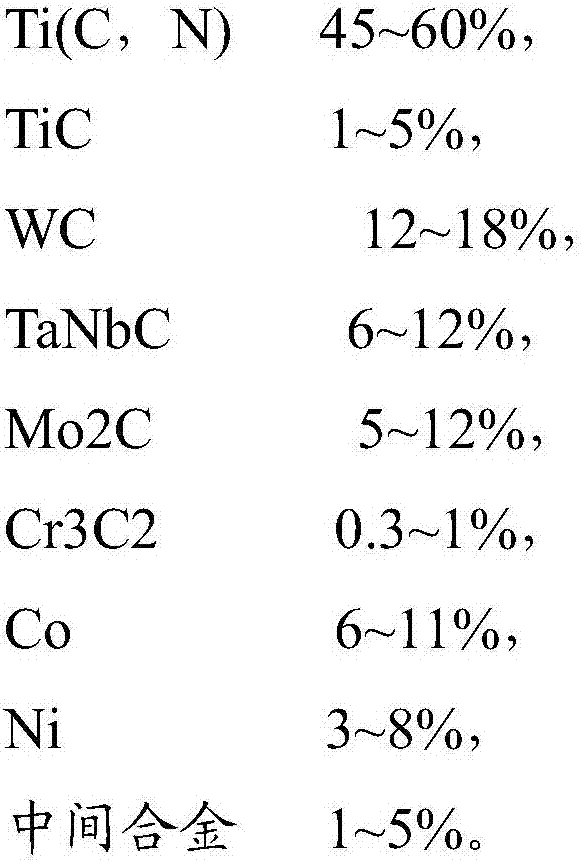

[0041] Step 2, Ti (C, N) powder, TiC powder, WC powder, TaNbC powder, Mo2C powder, Cr3C2 powder, Co powder, Ni powder, and the intermediate alloy powder that step 1 makes are batched by weight percentage;

[0042] Step 3, adding a molding agent to the raw materials obtained in step 2, mixing them uniformly by ball milling, and spray drying to granulate;

[0043] Step 4, molding the mixture obtained in Step 3 to obtain a Ti(C,N)-based cermet compact;

[0044] Step 5. Sintering the Ti(C,N)-based cermet compact obtained in Step 4 in an atmosphere to obtain a Ti(C,N)-based cermet.

[0045] In step 1, when preparing the master alloy powder, Co, Rh, and Os are used as raw materials, and the weight percentage is 10-30% Rh, 5-15% Os, and the balance is Co f...

Embodiment 1

[0057] This embodiment provides a Ti(C, N) based cermet, which uses Ti(C, N), TiC, WC, TaNbC, Mo2C and Cr3C2 as hard phases, Co and Ni as binder phases, Co -Rh-Os master alloy is an additive; the composition of Ti(C, N)-based cermet material is counted as weight percent: Ti(C, N) is 53%, TiC is 3%, WC is 13%, TaNbC is 8%, Mo2C is 6.5%, Cr3C2 is 0.5%, Co is 7%, Ni is 6%, and Co-Rh-Os master alloy is 3%. The components of the master alloy are calculated by weight percentage: the Rh is 25%, Os is 15%, and Co is the balance.

[0058] The preparation method of the Ti(C, N)-based cermet described in this embodiment mainly includes the following steps:

[0059] Step 1, prepare master alloy powder, use Co, Rh, Os as raw materials, carry out batching according to the above-mentioned weight percentage, adopt melting method to prepare Co-Rh-Os master alloy melt, melt described Co-Rh-Os master alloy The body is made of Co-Rh-Os master alloy powder by water atomization method;

[0060] ...

Embodiment 2

[0066] This embodiment provides a Ti(C, N) based cermet, which uses Ti(C, N), TiC, WC, TaNbC, Mo2C and Cr3C2 as hard phases, Co and Ni as binder phases, Co -Rh-Os master alloy is an additive; the composition of Ti(C, N)-based cermet material is counted as weight percent: Ti(C, N) is 55%, TiC is 1.5%, WC is 12%, TaNbC is 8%, Mo2C is 7%, Cr3C2 is 0.5%, Co is 8%, Ni is 5.5%, and Co-Rh-Os master alloy is 2.5%. The components of the master alloy are calculated by weight percentage: the Rh is 25%, Os is 10%, and Co is the balance.

[0067] The preparation method of the Ti(C, N)-based cermet described in this embodiment mainly includes the following steps:

[0068] Step 1, prepare master alloy powder, use Co, Rh, Os as raw materials, carry out batching according to the above-mentioned weight percentage, adopt melting method to prepare Co-Rh-Os master alloy melt, melt described Co-Rh-Os master alloy The body is made of Co-Rh-Os master alloy powder by water atomization method;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com