Seeding device and seeding pipe

A sowing device and a sowing tube technology, which is applied to the direction of sowing, sowing seeders, and parts of the seeder, which can solve the problems of dirt and weeds being entangled and difficult to remove, and achieve the effect of ensuring cleanliness and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

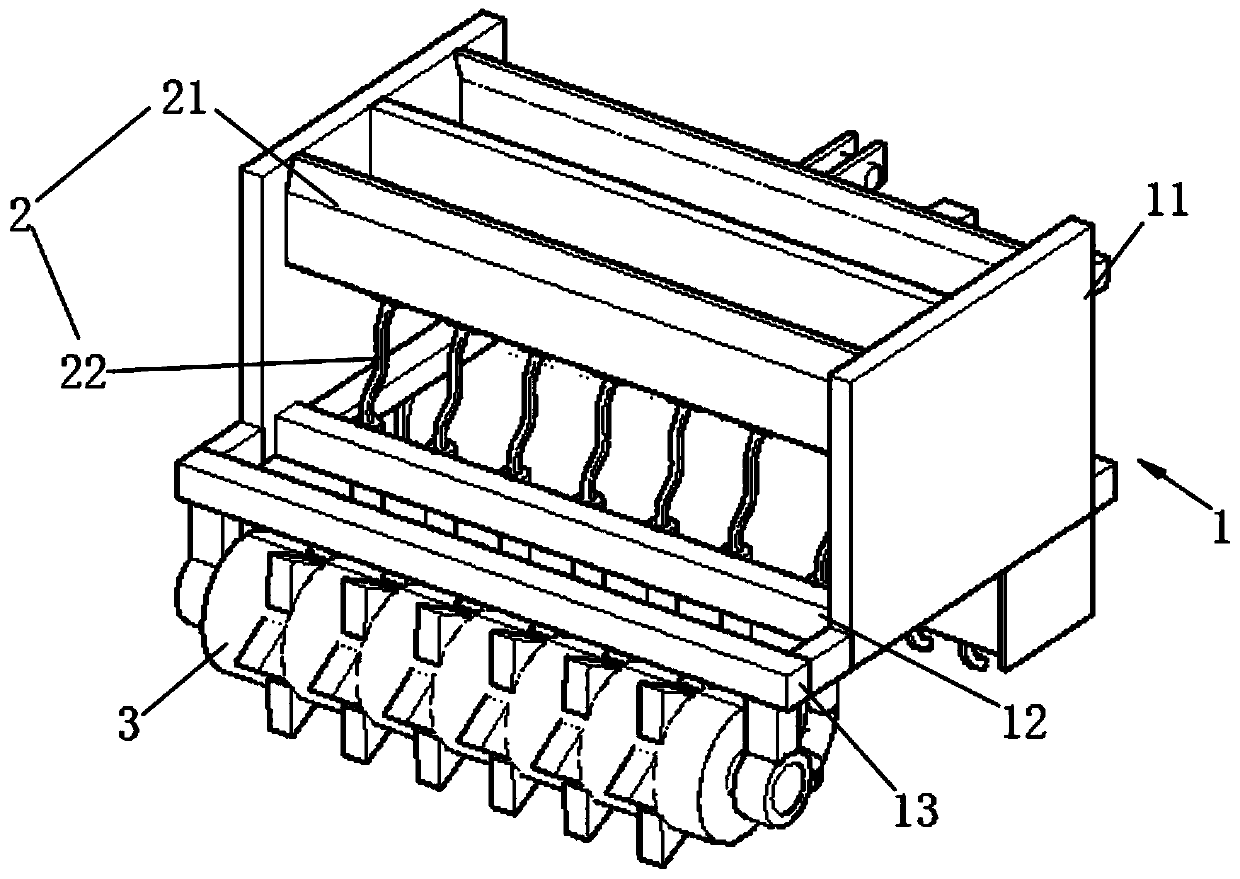

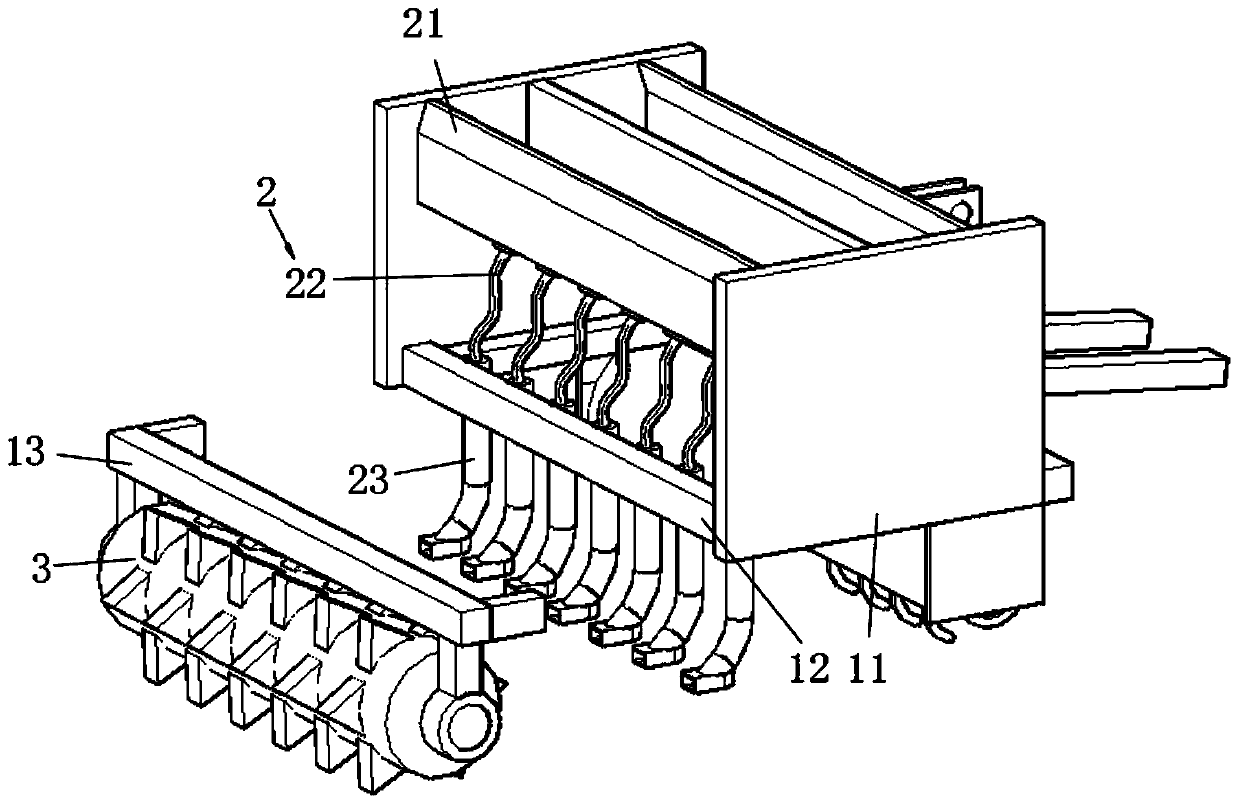

[0032] refer to figure 1 , this embodiment discloses a sowing device and a sowing pipe, including a frame 1 and a sowing assembly 2 . The sowing assembly 2 is fixedly connected to the frame 1 .

[0033] refer to figure 1 and figure 2 , the sowing assembly 2 includes a sowing box 21 , a connecting pipe 22 and a sowing pipe 23 . Described sowing box 21 is fixed on the top of frame 1. The seeding pipe 23 is connected to the bottom of the seeding box 21 through a connecting pipe.

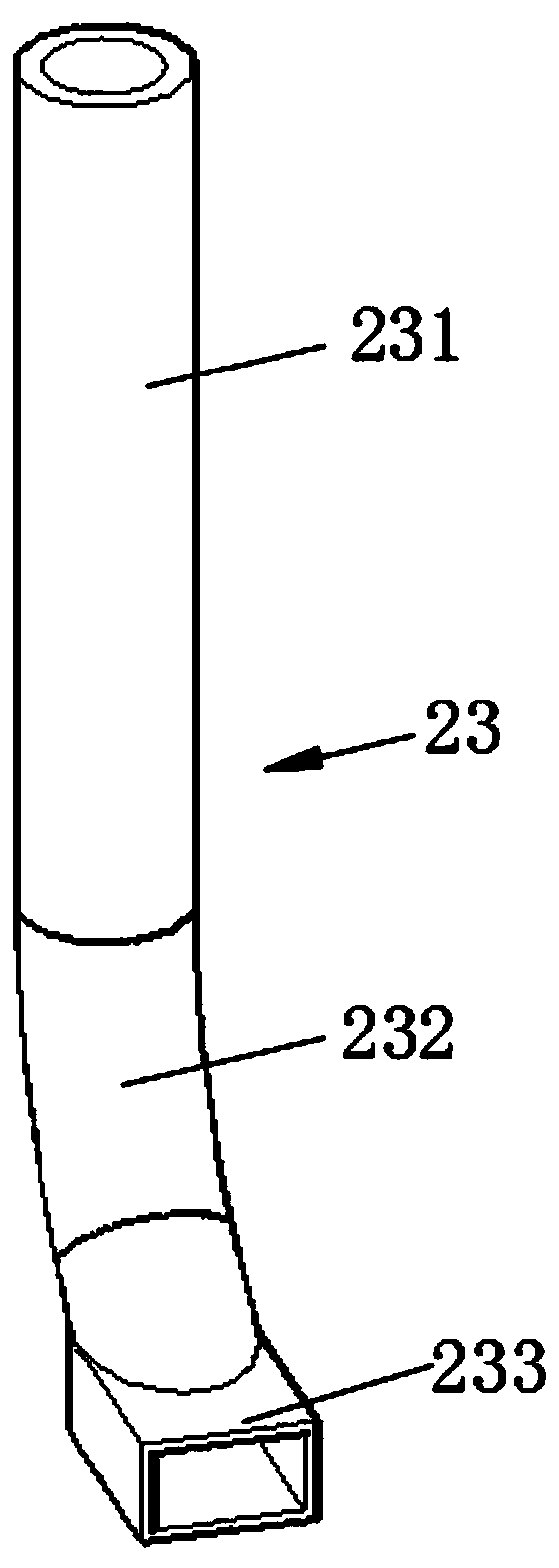

[0034] refer to image 3 , the sowing pipe 23 includes a first section of pipe 231, a second section of pipe 232, and a seeding box 233 with an opening facing the rear side of the sowing direction. The first section of pipe 231 is connected to the bottom of the sowing assembly 2 . The top of the second section of pipe 232 is in fixed communication with the bottom of the first section of pipe 231 . The bottom end of the second section of pipe 232 is inclined to the rear of the sowing direction, ...

Embodiment 2

[0046] refer to Figure 5 , the scraper 32 is a circular shape with notches in the projections of both sides of the eye distributed along the roller body 31 .

[0047] The scraper 32 with a sharp point is prevented from causing secondary damage to the soil after sowing, and the circular curved surface not only does not cause damage to the soil when it contacts the soil, but also can improve the shock effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com