Patents

Literature

405results about How to "Improve wet strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

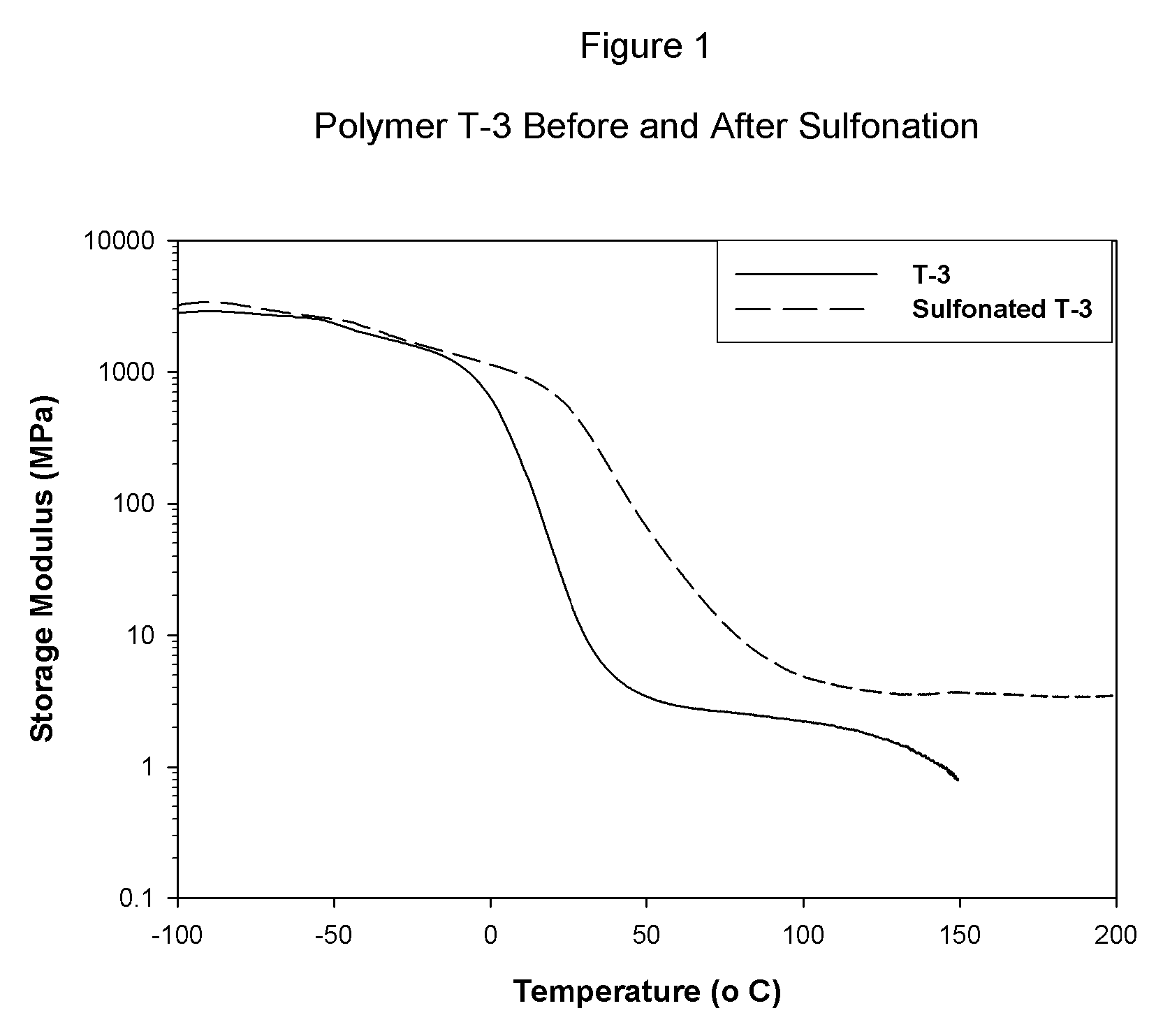

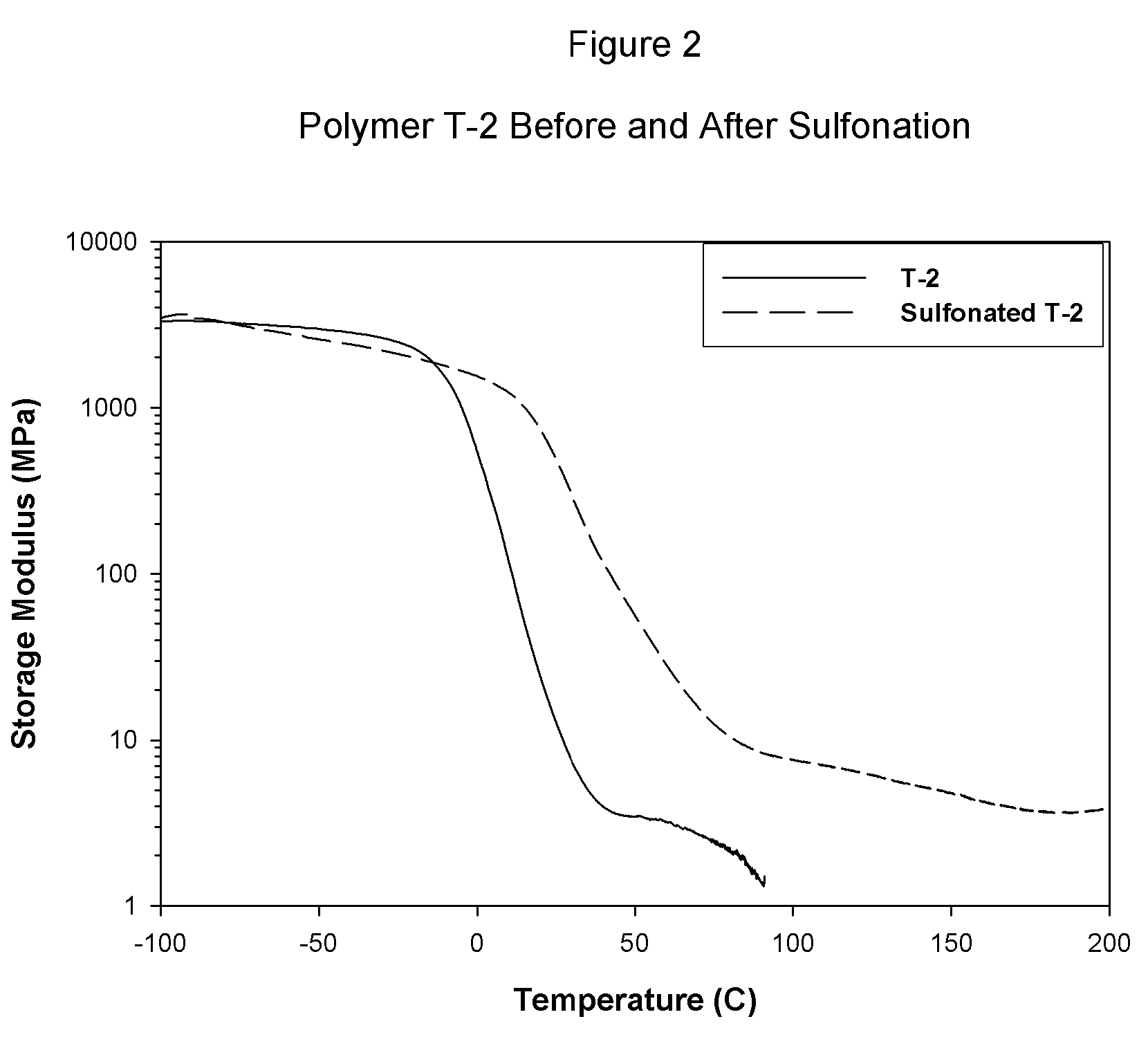

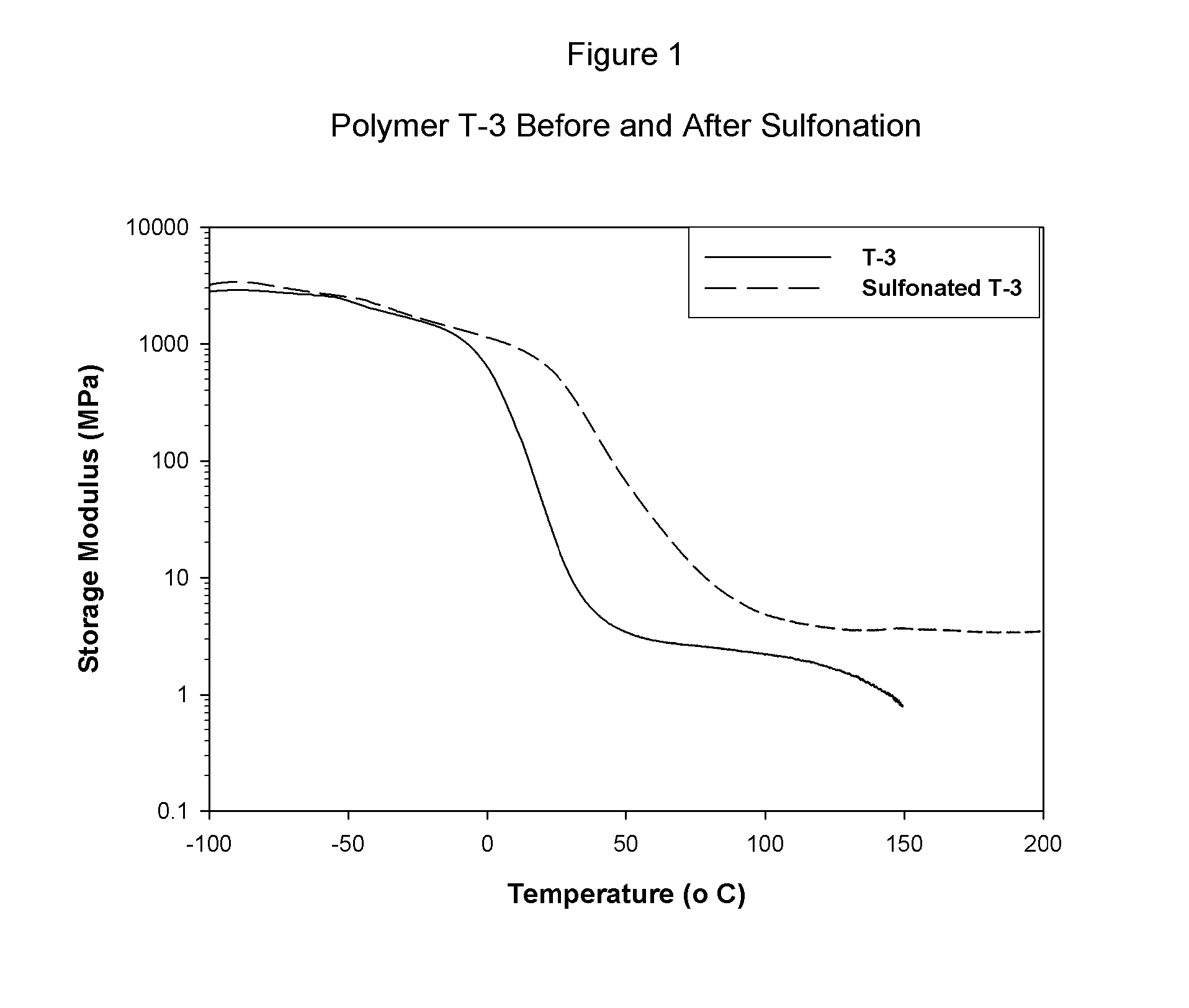

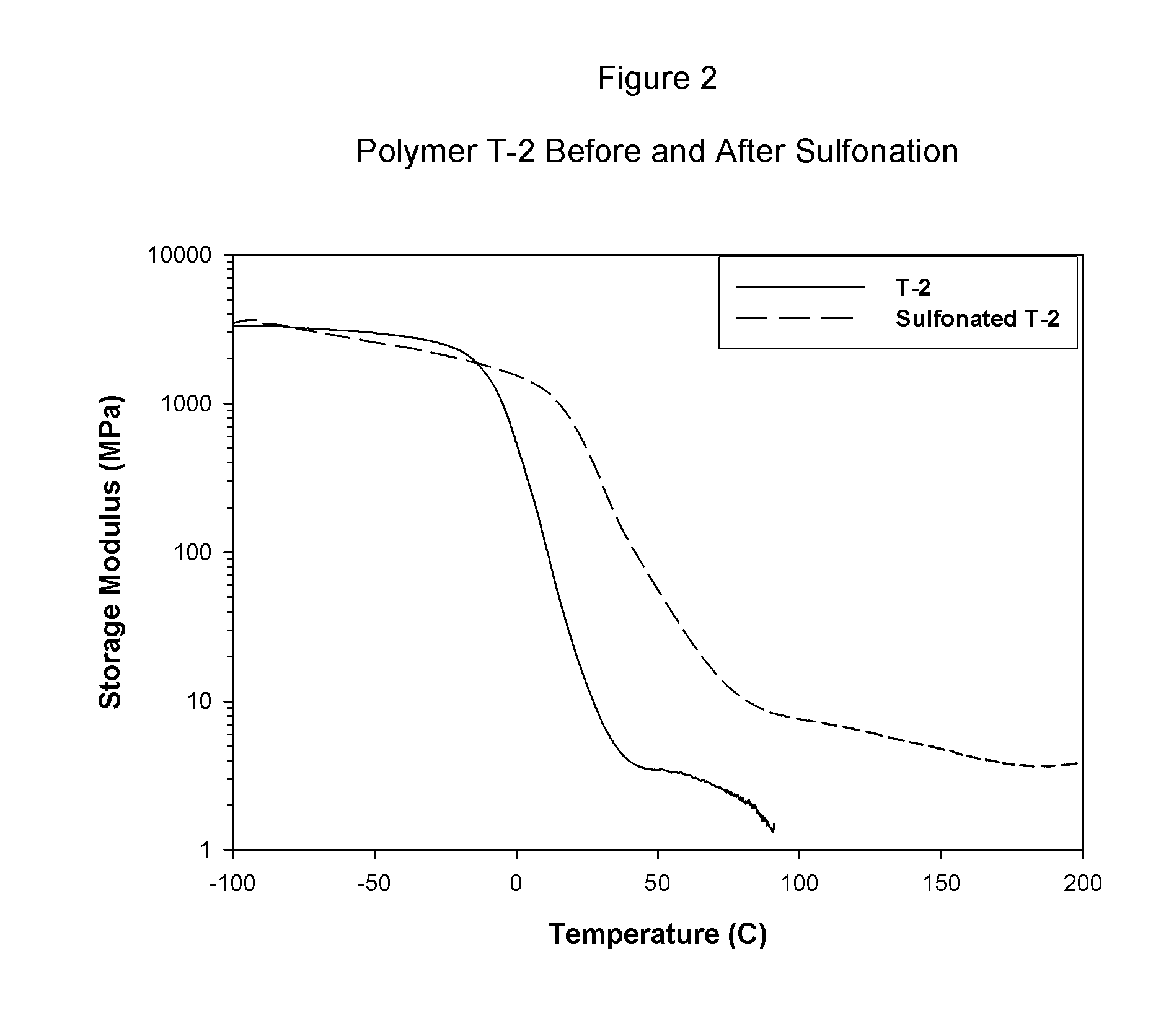

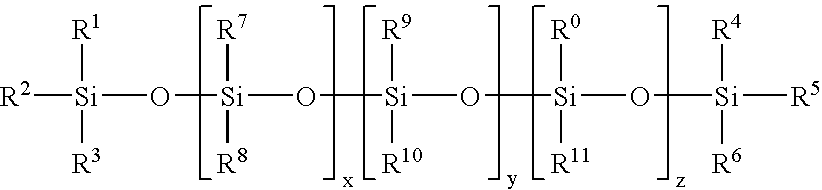

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS7737224B2Reduced responseHigh propertySemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS20070021569A1High water transport propertyImprove wet strengthSemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

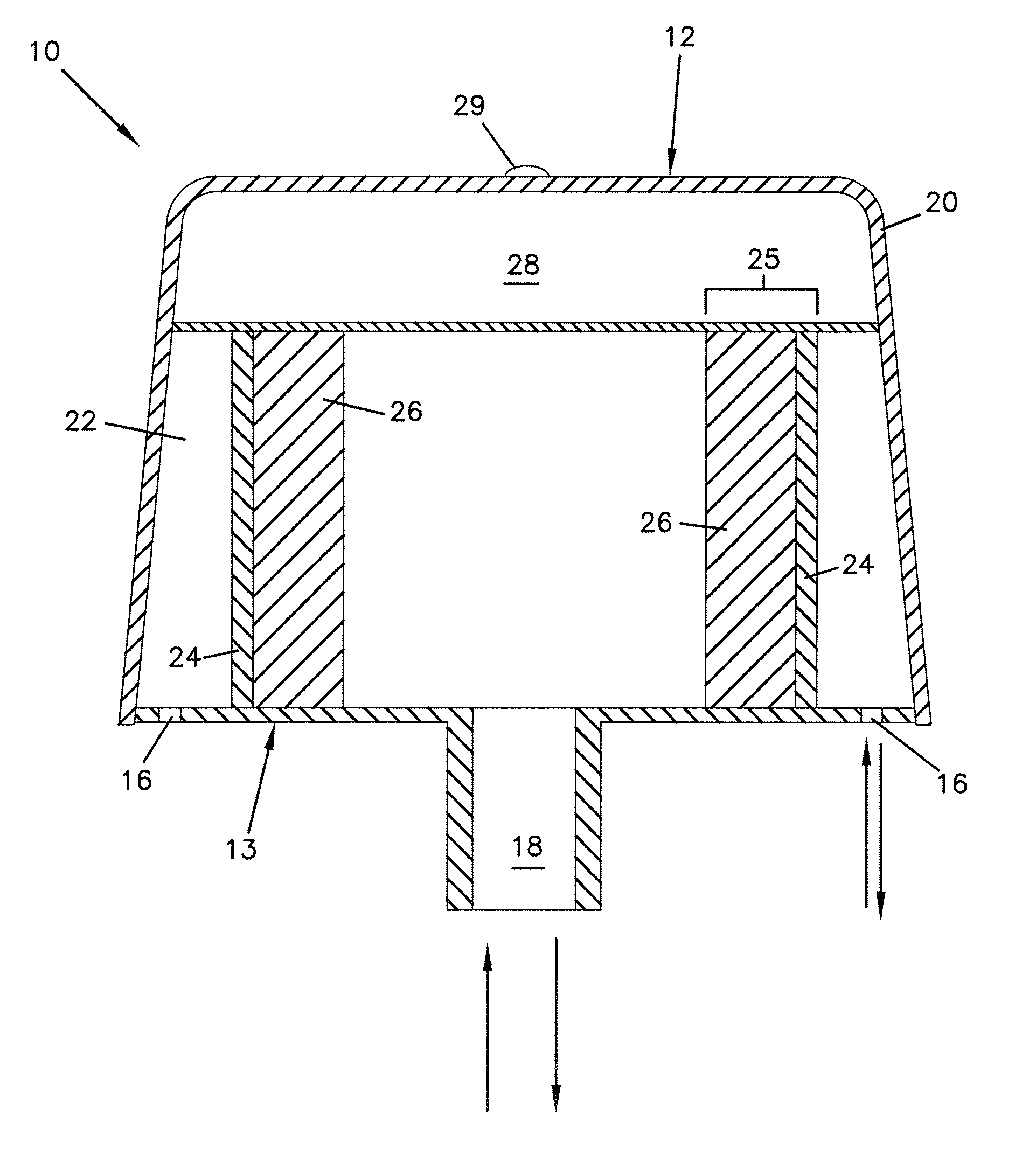

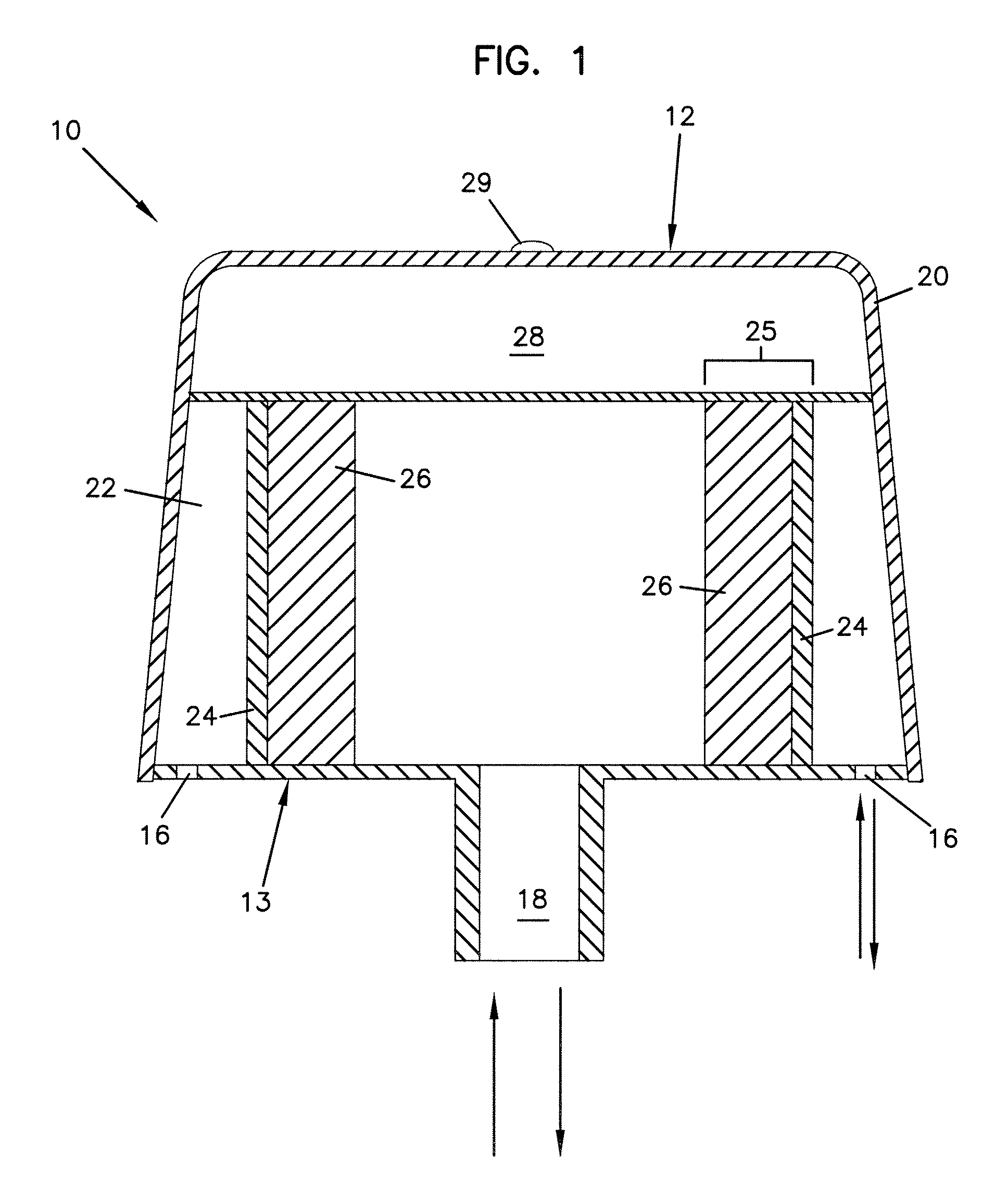

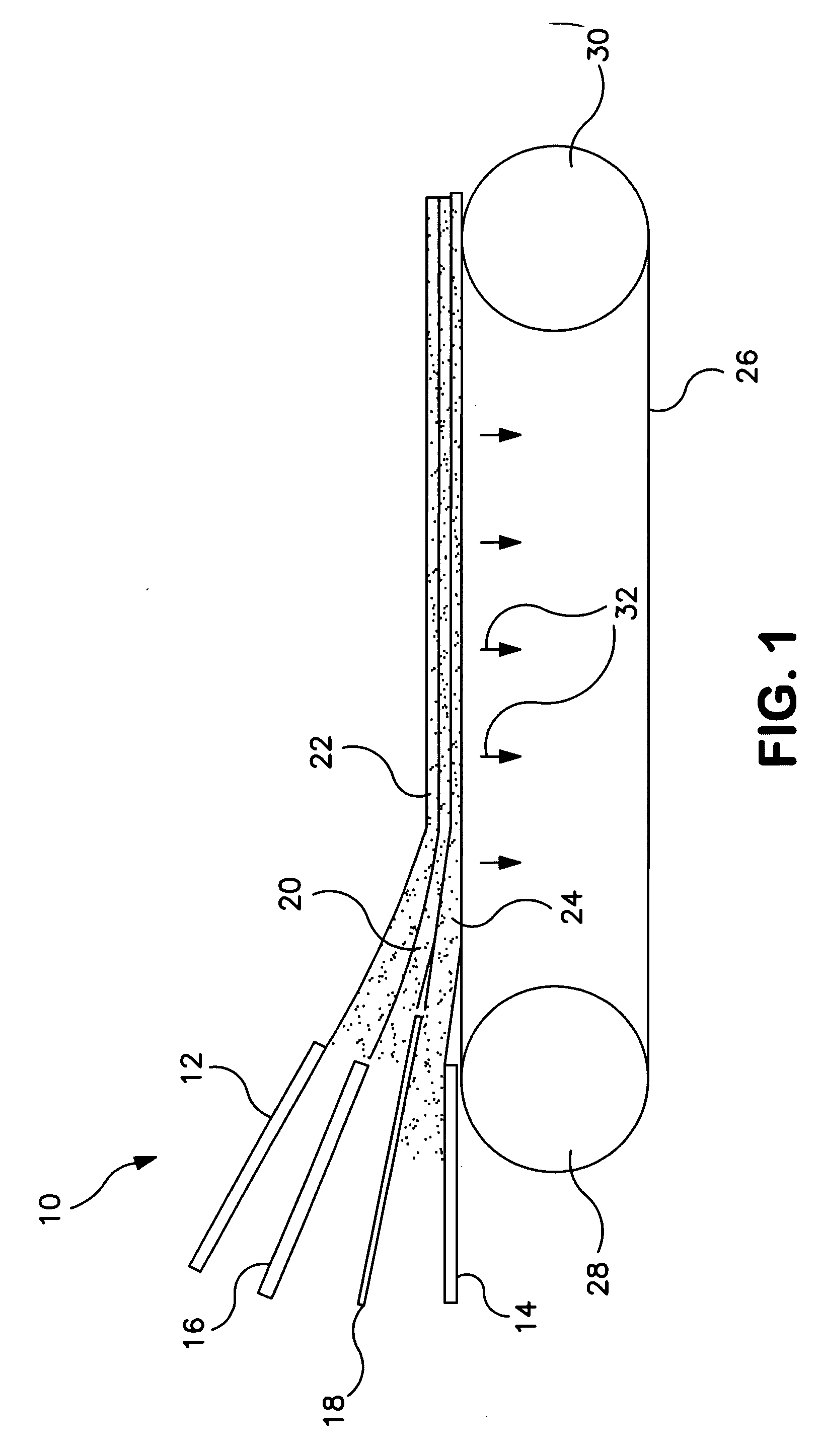

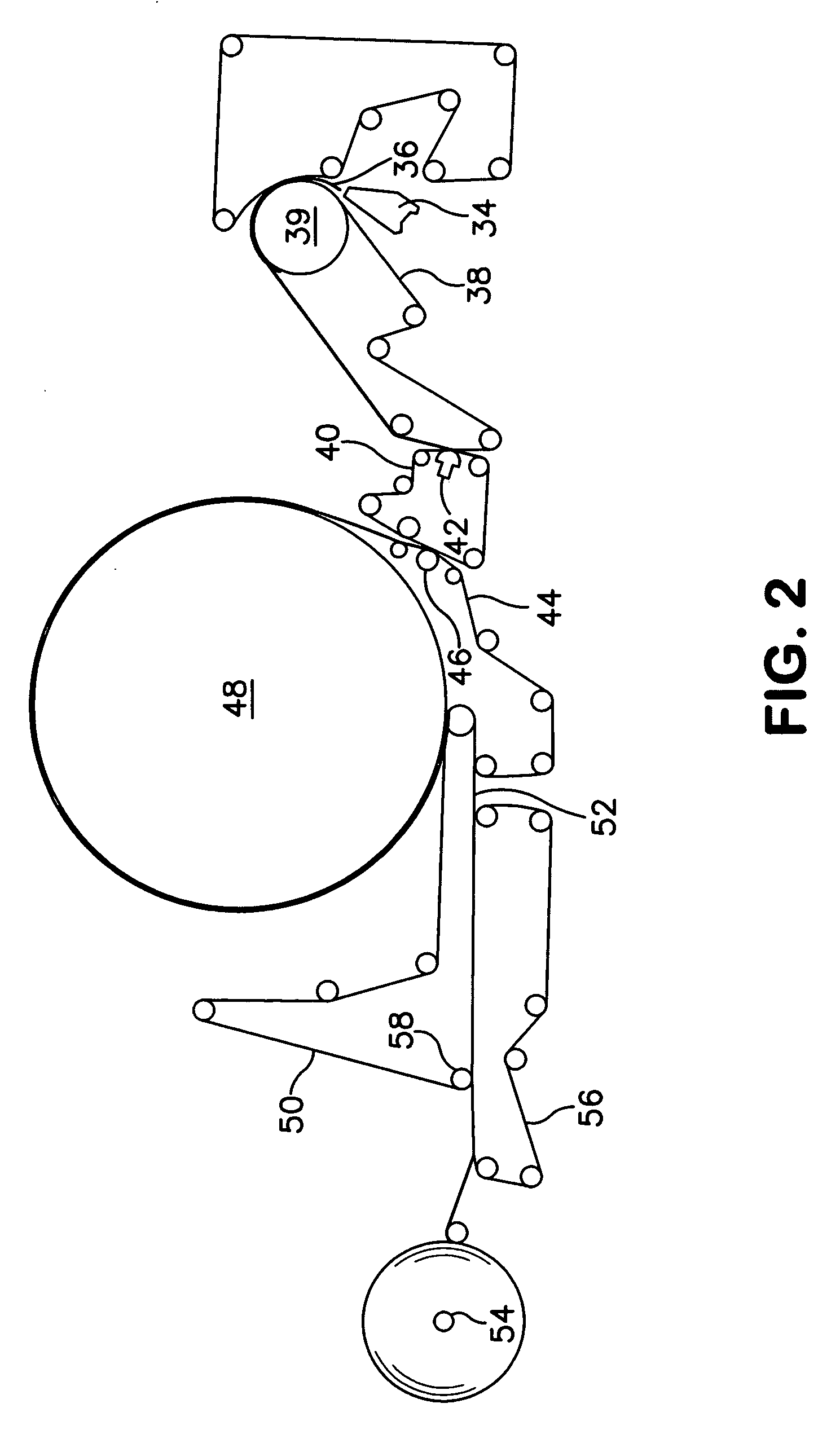

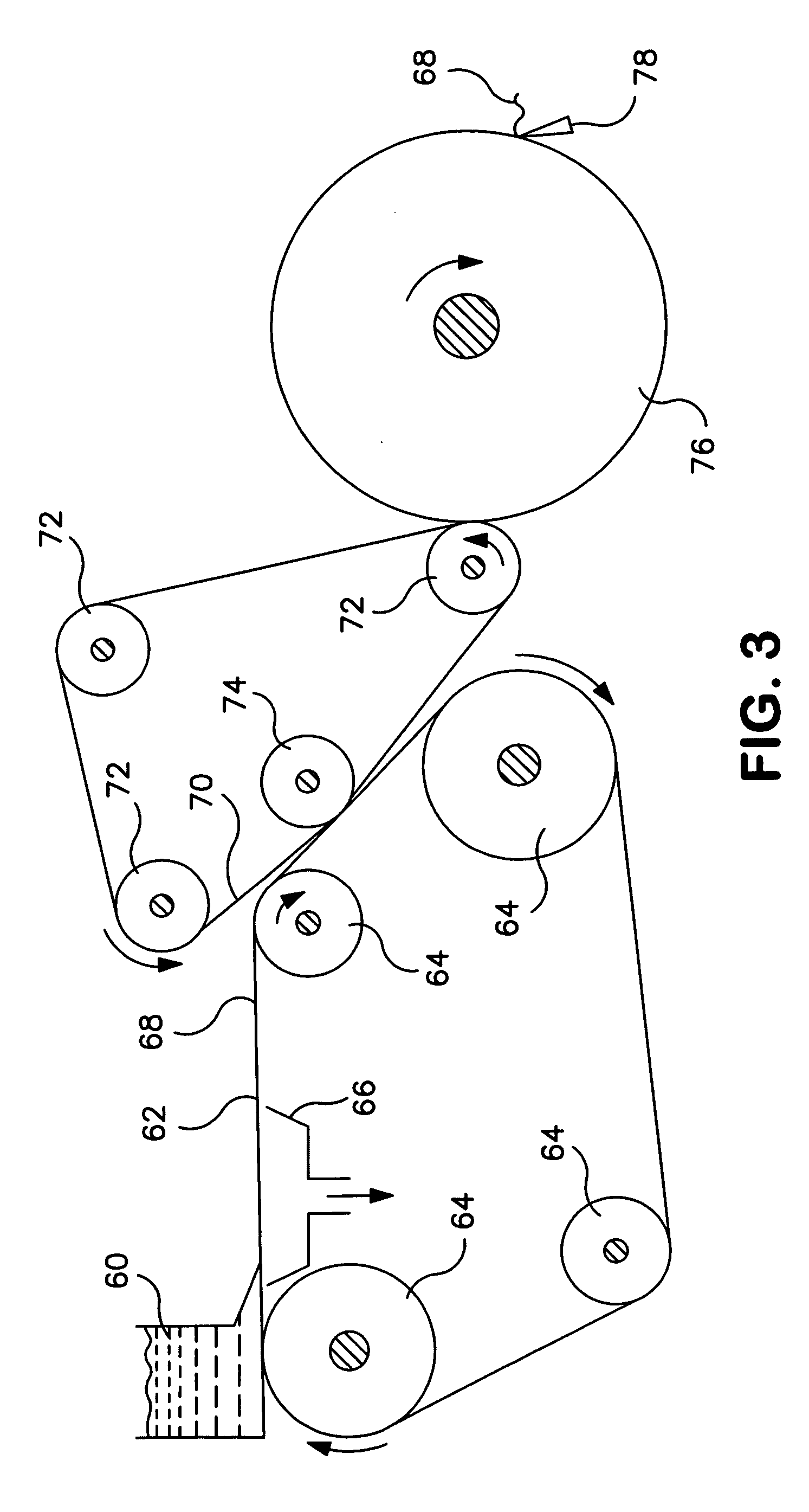

Filter medium and breather filter structure

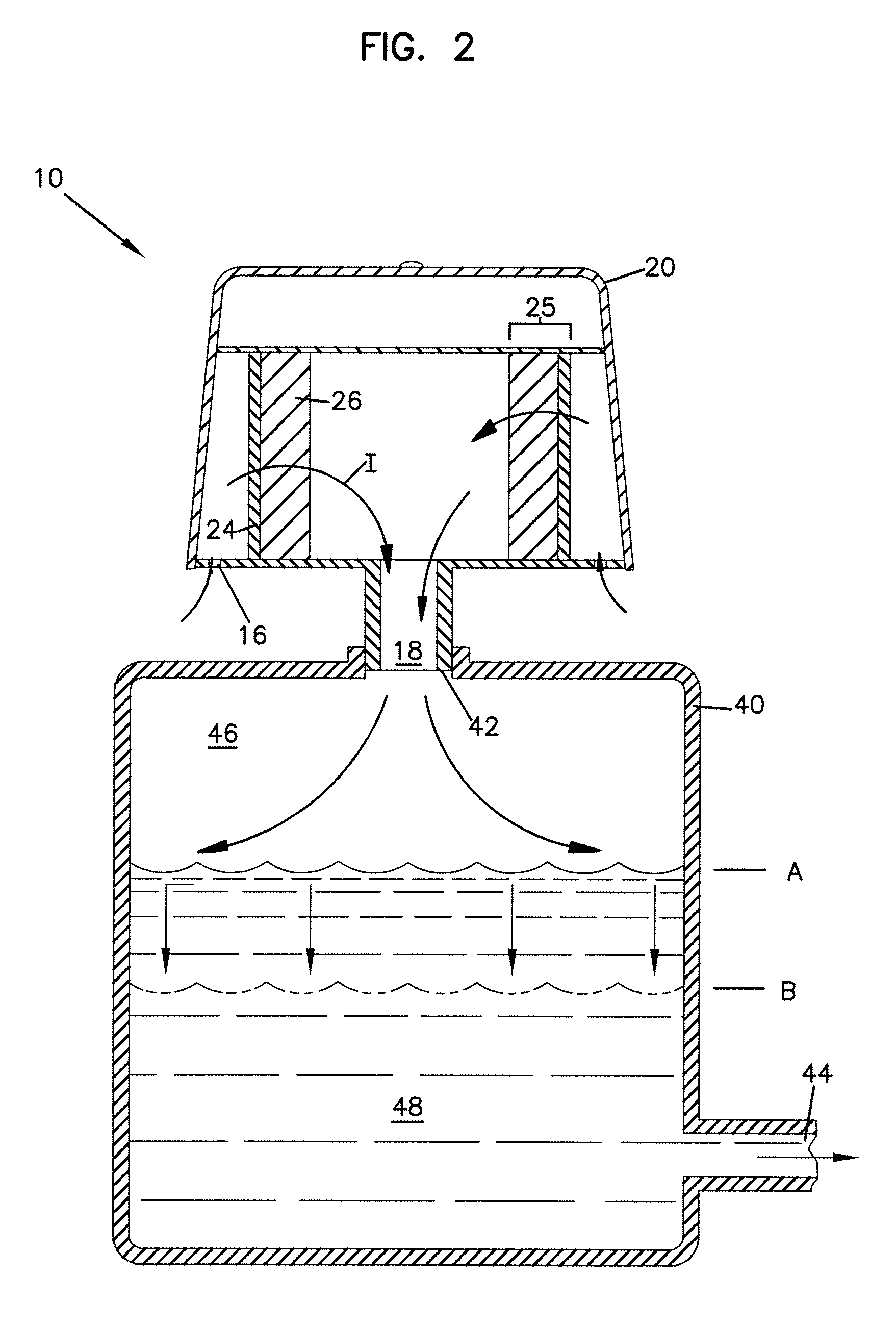

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

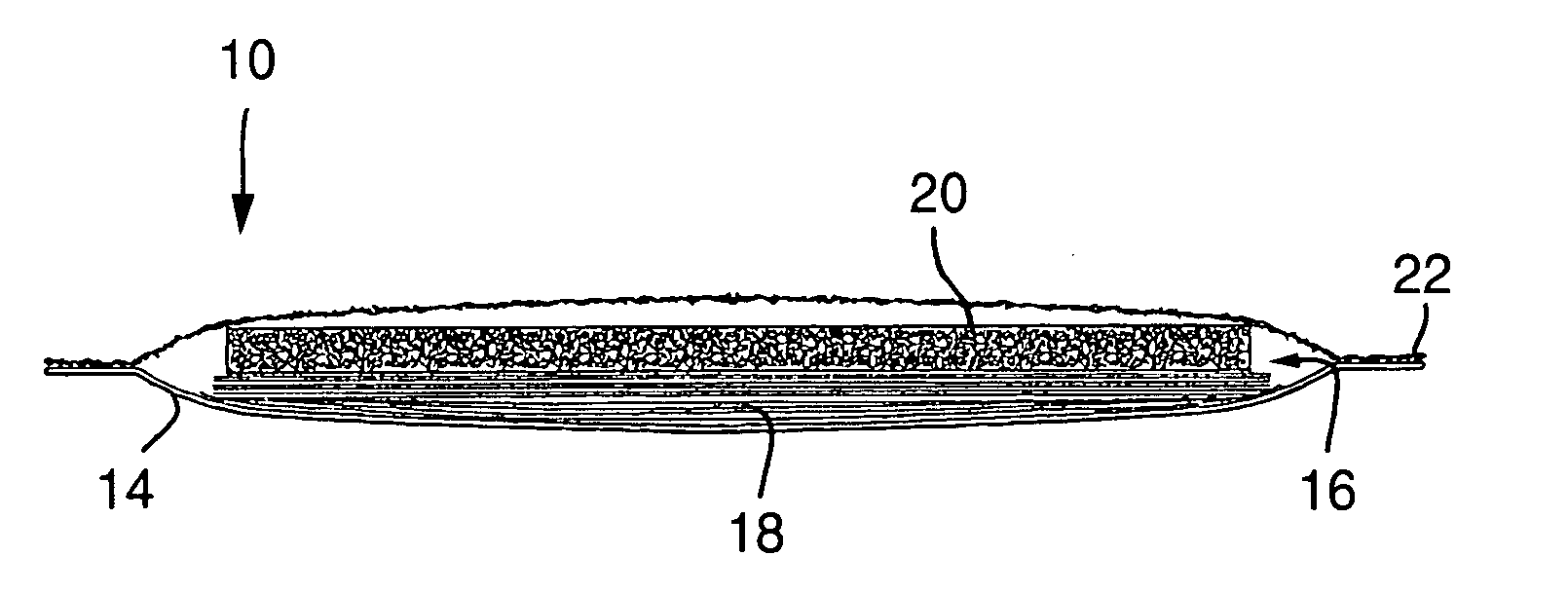

Disposable scrubbing product

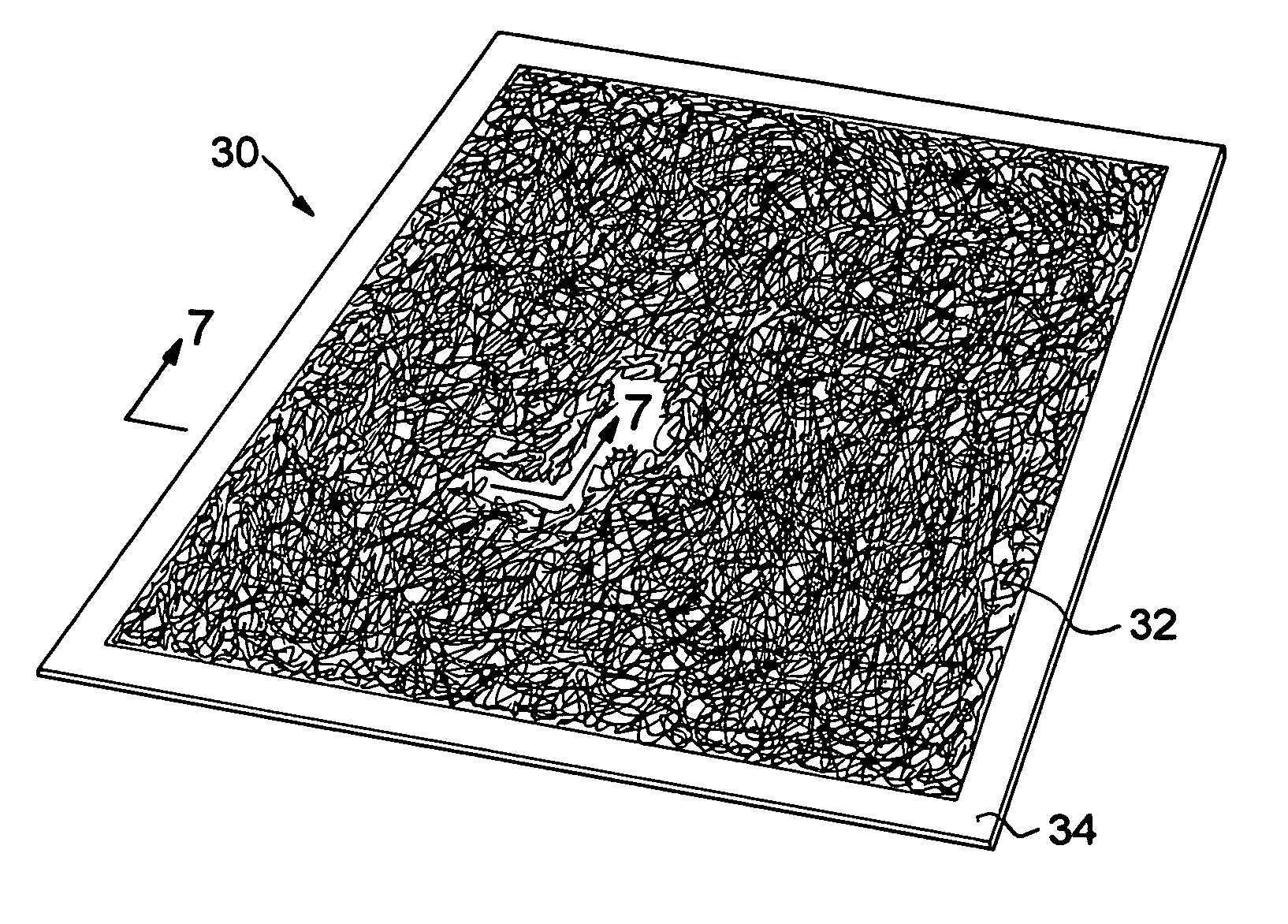

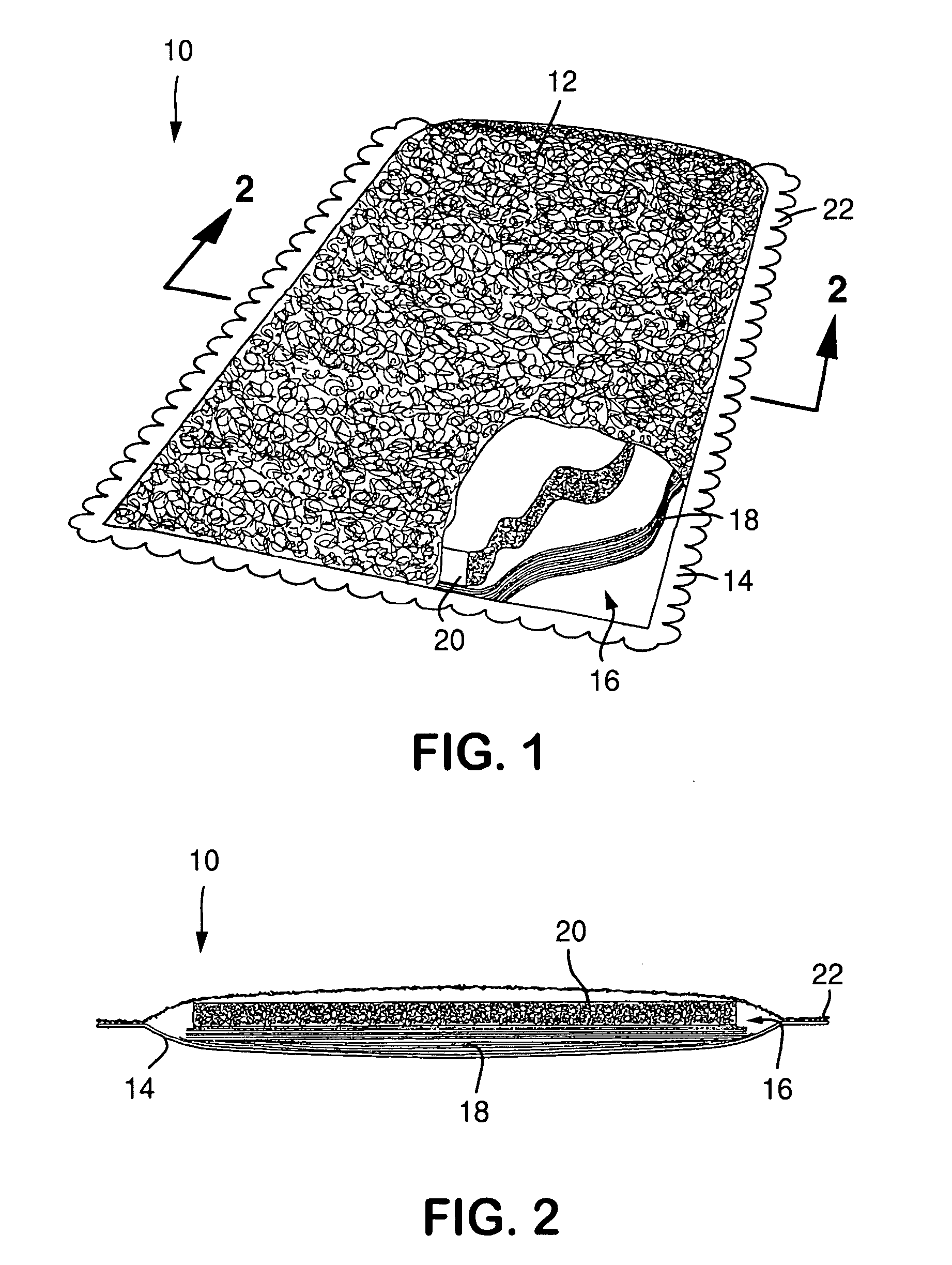

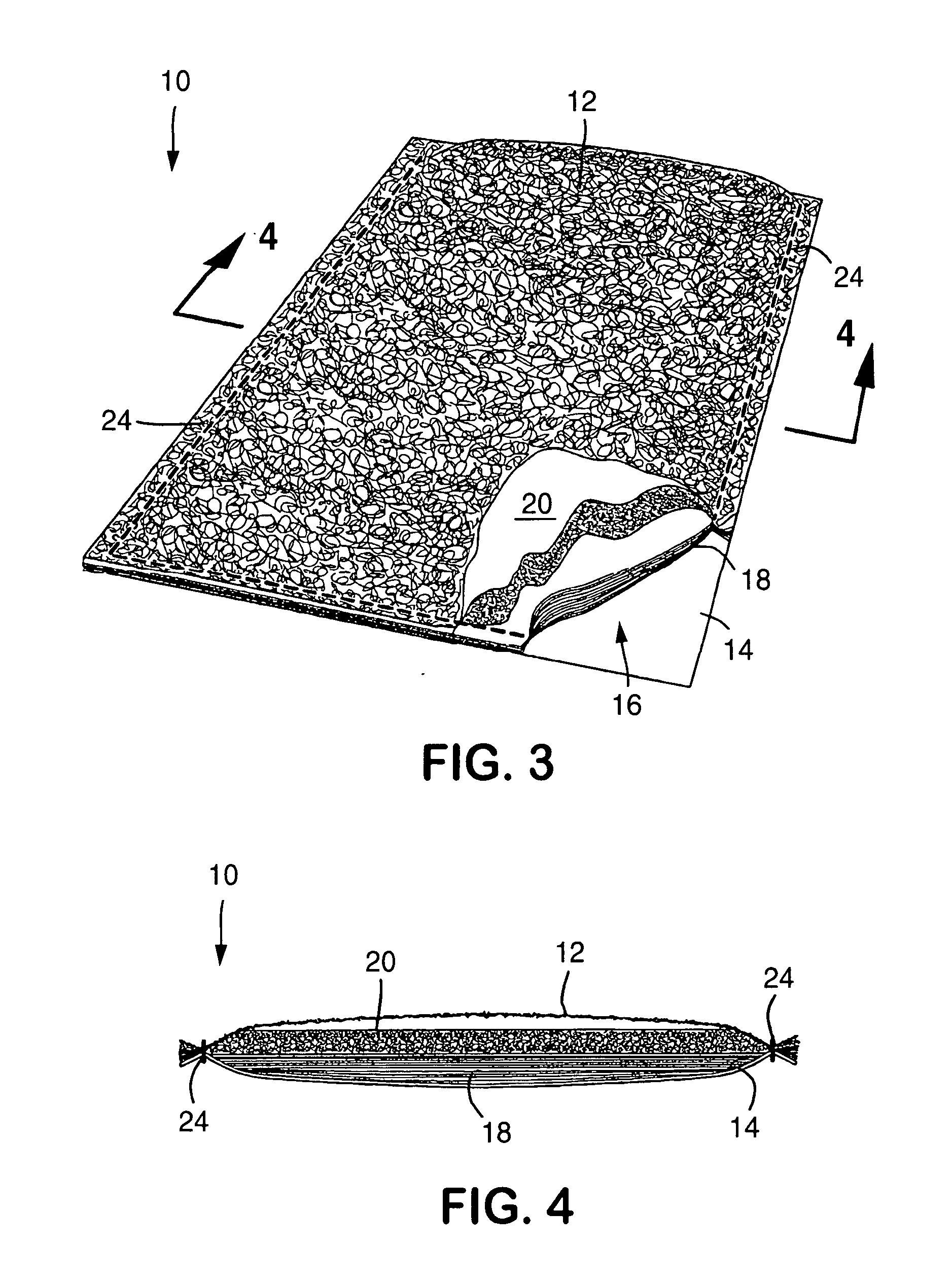

InactiveUS20050130536A1High yieldResists effect of waterPersonal careCarpet cleanersEngineeringFibrous layer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, the abrasive layer comprises multifilamentary aggregate fibers. In one embodiment, the absorbent fibrous layer is an uncreped, through dried paper web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Premoistened tissue products

InactiveUS20070137811A1Reduced strengthImprove wet strengthBiocideNatural cellulose pulp/paperBiomedical engineering

Premoistened wiping products are disclosed. The premoistened wiping products contain one or more wetlaid tissue webs. The tissue webs may contain an additive composition which includes a thermoplastic resin. Once the additive composition is applied to the web, the web is embossed forming liquid resistant embossments. The embossments also form bond areas that can bond multiple plies of the tissue webs together. Once embossed, the one or more tissue webs are then contacted with a wiping solution in order to form the premoistened product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

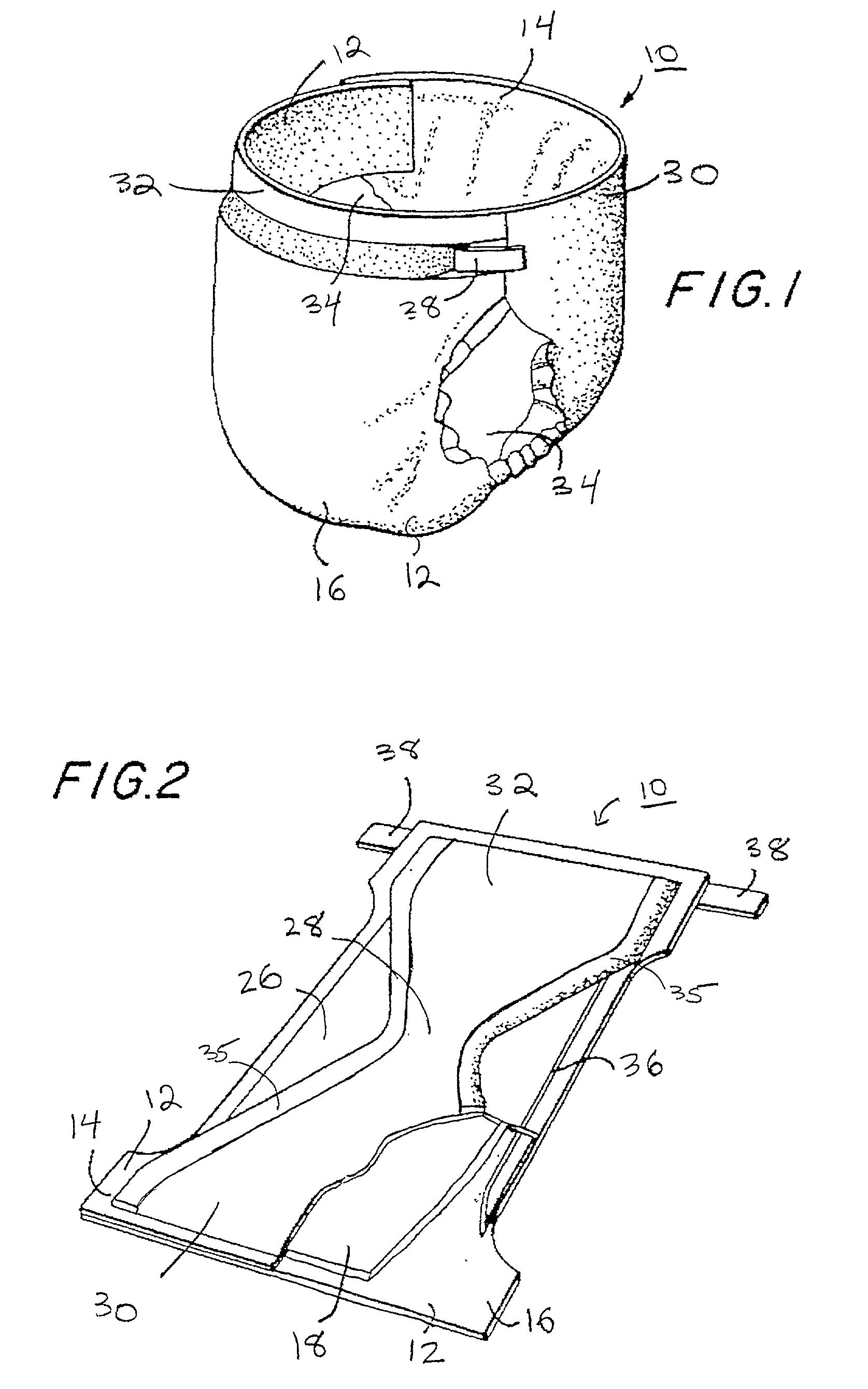

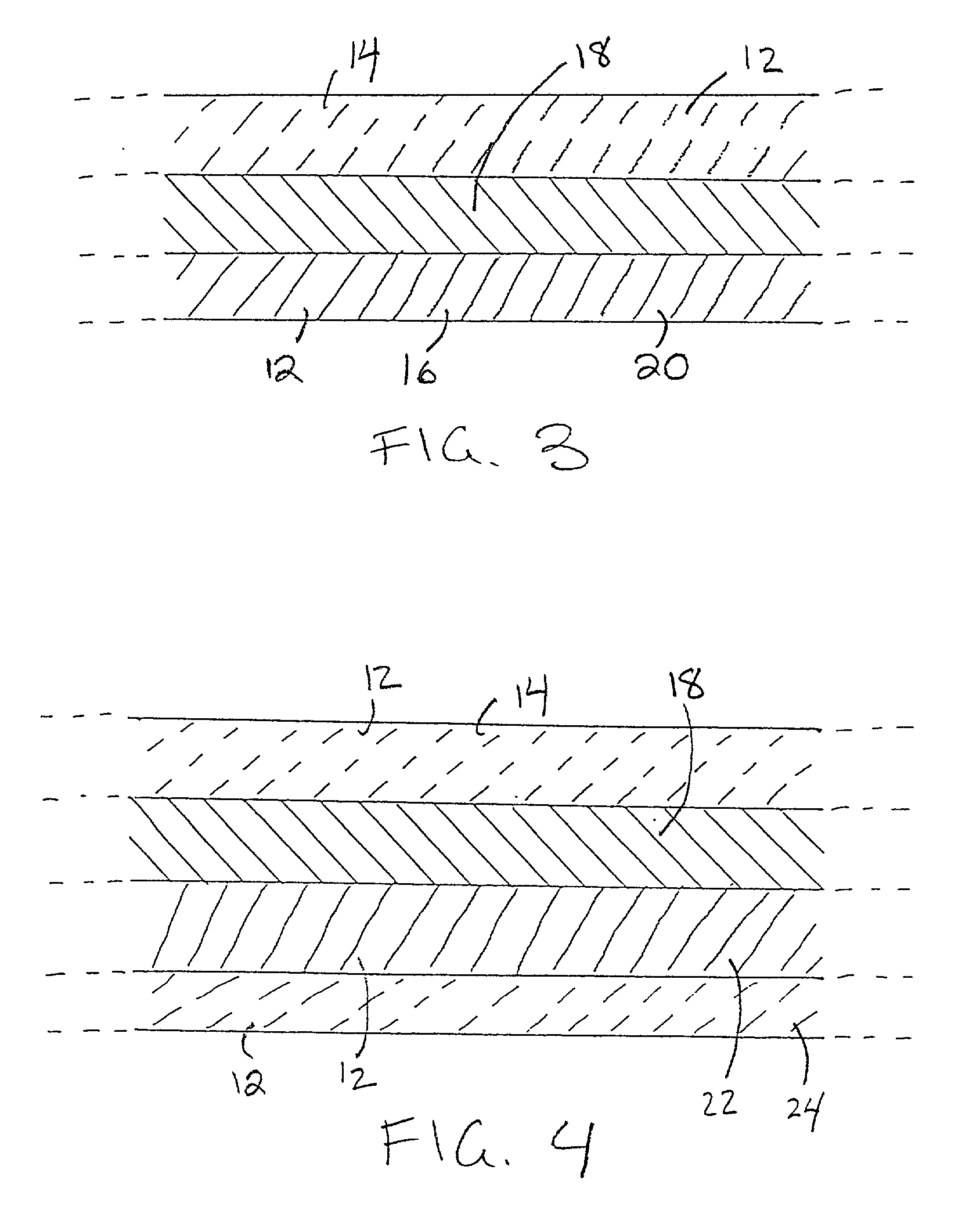

Composite cleaning products having shape resilient layer

InactiveUS20060135026A1Resists effect of waterMaintain stiffnessCarpet cleanersLayered productsPersonal careEngineering

The present invention discloses a disposable cleaning product for use in household cleaning or personal care applications. The cleaning product of the invention is a multi-layer laminate product and may include at least two distinct layers, an abrasive layer and an absorbent layer. The absorbent layer contains a sponge-like member optionally in combination with a plurality of cellulosic fibrous webs. The sponge-like member can be made from various materials. For example, in one embodiment, the sponge-like member comprises one or more layers of a spunbond web containing crimped, bicomponent filaments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Water disintegratable cleansing wipes

InactiveUS7285520B2Improve wet strengthClean skinCosmetic preparationsToilet preparationsCleansers skinSufficient time

Cleansing wipes comprising a film forming polymeric material and a cleansing agent stored in dry form are disclosed. The cleansing wipes are water disintegratable such that upon contact with water, the cleansing wipes release the cleansing agent and begin to dissolve / disperse into the water. Full dissolution / dispersion of the cleansing wipes occurs in about 60 seconds or less after contact with water to allow for a sufficient time for cleansing of the hands or other skin area.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Degradable disposable diaper

A degradable disposable diaper includes one or more sheets made of polyolefin with the polyolefin including a prodegradant causing the sheet to degrade. The prodegradant includes a metal compound such as a metal selected from the group consisting of cobalt, cerium, and iron. The preferred metal compound is a metal carboxylate. The polyolefin is preferably polyethylene or polypropylene. A secondary polyolefin may be used to aid the incorporation of the prodegradant into the primary polyolefin. A filler may also be used with the polyolefin and prodegradant. The filler preferably has a particle size less than 150 mesh and is free of water. The filler is preferably calcium carbonate having a 1 to 10 micron particle size. The sheet contains between about 0.001 and about 15 weight % prodegradant and most preferably between about 0.01 and about 3 weight % prodegradant. The sheet also includes up to about 15 weight % filler. The diaper also includes a degradable absorbent core.

Owner:EPI ENVIRONMENTAL PROD

A low-cost precision casting method for titanium alloy and titanium-aluminum alloy

InactiveCN102294436AIncrease contentControl quality costFoundry mouldsFoundry coresPolyvinyl alcoholTitanium alloy

The invention relates to a method for precisely casting a titanium alloy and a titanium aluminum alloy with low cost, which relates to a method for precisely casting the titanium alloy and the titanium aluminum alloy, and solves the technical problem that cast pieces have low surface quality and internal quality in the conventional method for lowering the cost of precisely casting the titanium alloy and the titanium aluminum alloy by using electrically-fused alumina and silica sol. The method comprises the following steps of: preparing a surface layer binder from zirconium sol, silica sol, a wetting agent JFC, n-octyl alcohol, polyvinyl alcohol and latex; adding calcium carbonate, alumina, titanium dioxide and zirconia to prepare a surface layer coating; preparing a shell surface layer; preparing a shell back layer by a universal method for precisely casting the titanium alloy; dewaxing and sintering to obtain a shell; and casting the titanium alloy or the titanium aluminum alloy by using the shell so as to obtain a titanium alloy cast piece or a titanium aluminum alloy cast piece. Compared with a precise casting method by purely using a zirconium-based binder and a zirconia fireproof material, the method has the advantage that raw material cost is lowered by 30 to 70 percent and the method can be used for civil titanium alloy cast pieces and titanium aluminum alloy cast pieces for common aviation.

Owner:HARBIN SHITAI NEW MATERIAL TECH & DEV

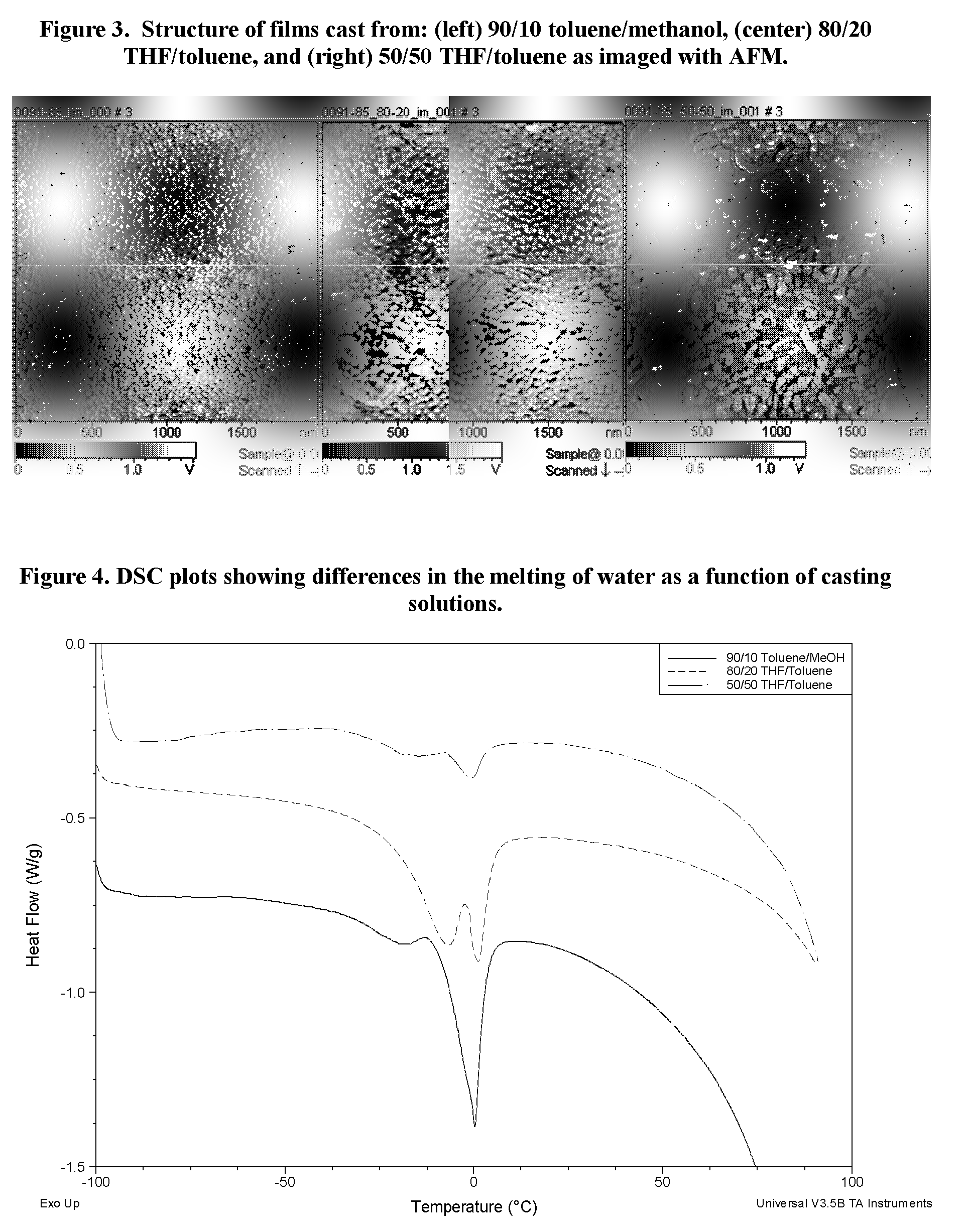

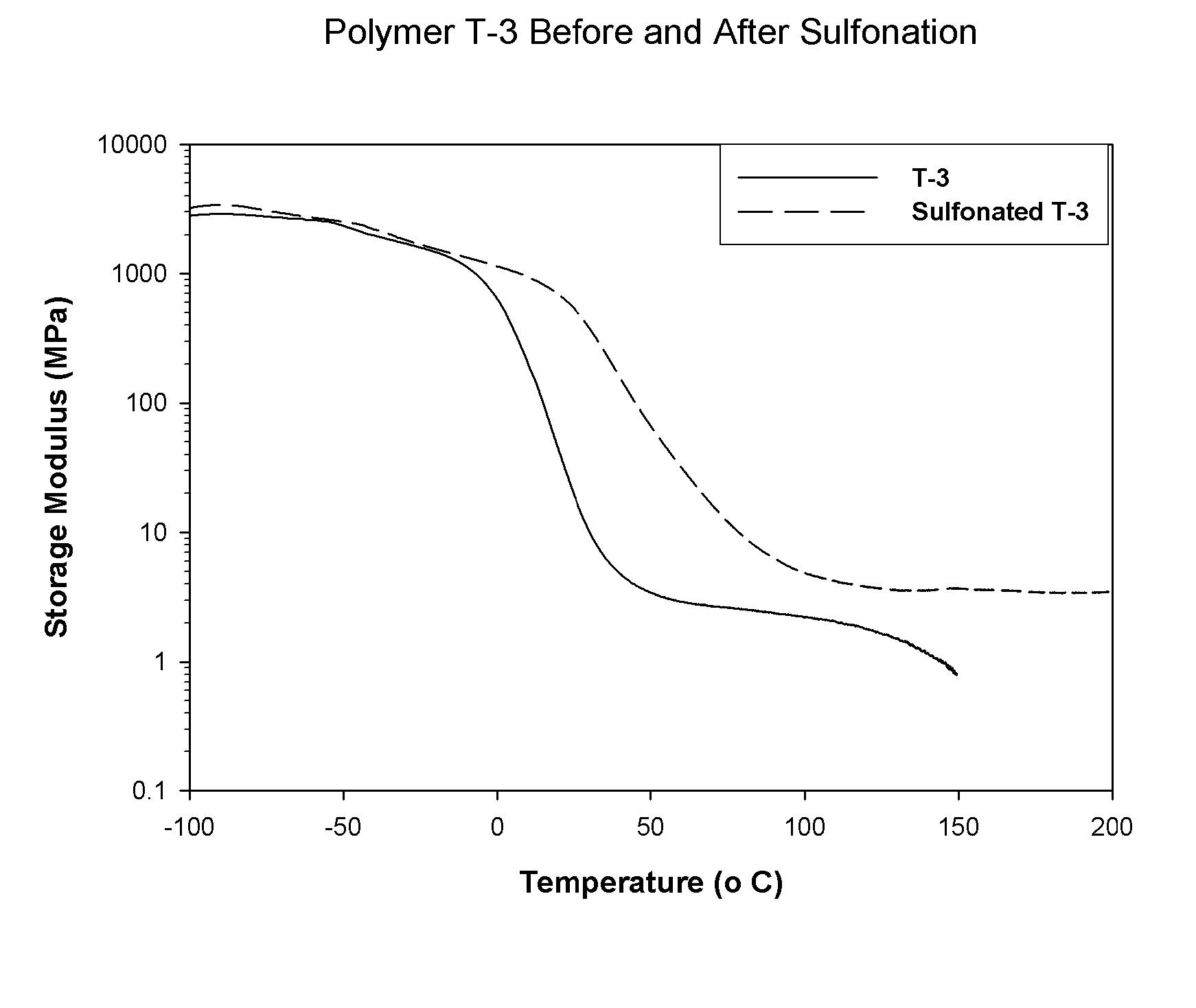

Method for making sulfonated block copolymers, method for making membranes from such block copolymers and membrane structures

ActiveUS8012539B2Reduced responseHigh propertySemi-permeable membranesMembranesPolymer scienceAlcohol

The present invention relates to an improved method for making sulfonated block copolymers and to methods for making membranes from such block copolymers. In particular, the present invention relates to an improved method for making sulfonated block copolymers having at least two polymer end blocks that are resistant to sulfonation and at least one polymer interior block that is susceptible to sulfonation where the sulfonation agent is C2 to C8 acyl sulfate. In the improved process the residual carboxylic acid formed from the C2 to C8 acyl sulfate is converted to C1 to C4 alkyl esters by contacting the residual carboxylic acid with at least a 0.9:1 molar ratio of a C1 to C4 alcohol to residual carboxylic acid, resulting in an improved sulfonated block copolymer solution. The present invention further relates to the use of such sulfonated block copolymer solutions to prepare various membranes and other articles.

Owner:STEPAN COMPANY

Thermosetting adhesives comprising a resin having azetidinium functional groups

InactiveUS20070054144A1Improve wet strengthFast curingCosmetic preparationsToilet preparationsAdhesiveEpichlorohydrin

Termosetting adhesives for use in e.g., particleboard or fiberboard, wherein the adhesives comprise a resin having azetidinium functional groups, can provide fast tack-building and curing, as well as ultimately excellent bonding characteristics. Preferably, the azetidinium-functional resin is formed from the reaction product of a polyamidoamine and epichlorohydrin.

Owner:GEORGIA PACIFIC CHEM LLC

Cellulose Articles Containing an Additve Composition

ActiveUS20080295985A1Improve propertiesImproved grease resistanceNatural cellulose pulp/paperSpecial paperSpecific volumeCellulose fiber

In one embodiment, the present invention provides a method of forming a cellulose article having a specific volume of less than 3 cc / gm. The method includes the step of incorporating cellulose fibers with a compound, wherein the compound includes an aqueous dispersion. The aqueous dispersion may have at least one polymer selected from the group consisting of an ethylene-based thermoplastic polymer, a propylene-based thermoplastic polymer, and mixtures thereof; at least one polymeric stabilizing agent; and water. In certain embodiments, a combined amount of the at least one polymer and the at least one stabilizing agent comprises about 25 to about 74 volume percent of the aqueous dispersion.

Owner:DOW GLOBAL TECH LLC

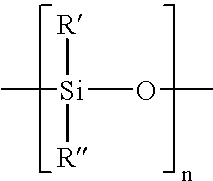

Soft and durable tissue products containing a softening agent

InactiveUS20060137842A1Reduce hydrophobicityHigh retention rateNatural cellulose pulp/paperMechanical working/deformationCellulose fiberAcid anhydride

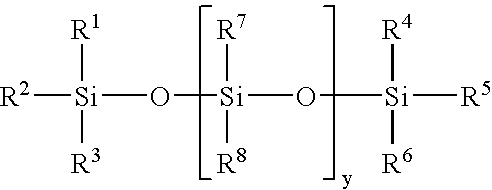

Fibrous products containing a durable softening agent are disclosed. The softening agent generally comprises a polysiloxane containing a plurality of first functional groups. In order to improve the wet retention of the softening agent on cellulosic fibers, the softening agent is reacted with a retention agent. The retention agent generally comprises a cationic polymer having a second functional group. In one embodiment, for instance, the softening agent contains epoxy groups or anhydride groups, while the retention agent contains amine groups. Products that may be made according to the present invention include tissue products, wipes and other absorbent articles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Antimicrobial polymer latexes derived from unsaturated quaternary ammonium compounds and antimicrobial coatings, sealants, adhesives and elastomers produced from such latexes

InactiveUS6900265B2Improve propertiesImprove water sensitivitySpecial tyresCoatingsElastomerPolymer science

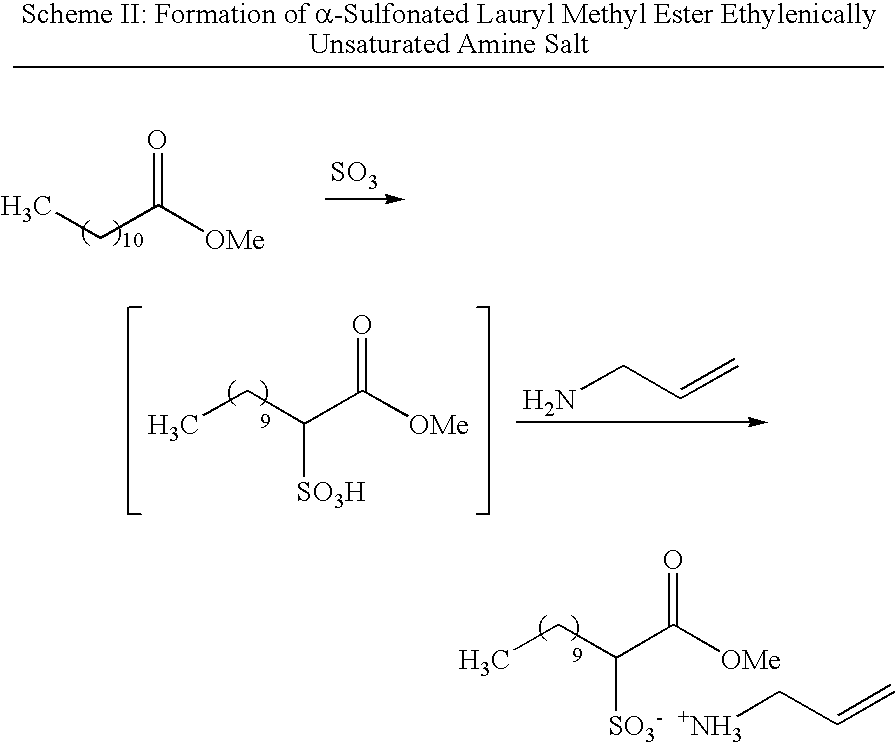

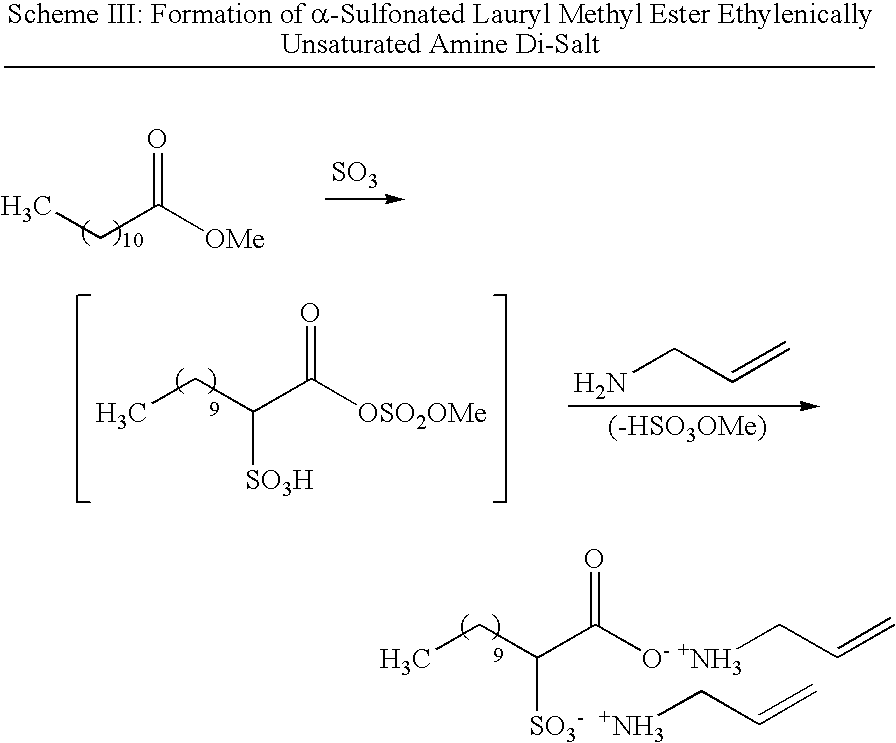

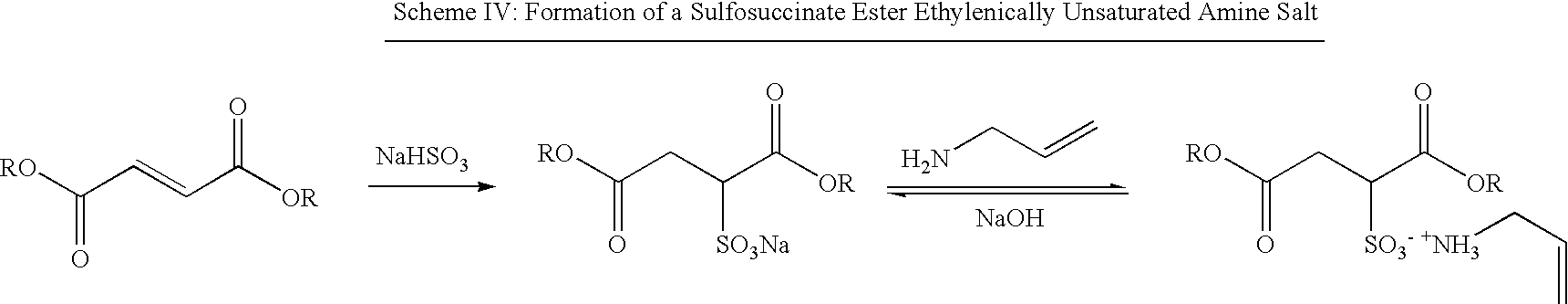

An improved method of making CASE materials is provided, wherein the method utilizes a polymer latex derived from at least one ethylenically unsaturated monomer and at least one polymerizable surface active agent. The polymerizable surface active agent is capable of co-polymerization with traditional monomers and is preferably substantially completely consumed during the course of the polymerization. Latex polymers produced by the method of the present invention are well suited for use in coatings, adhesives, sealants, elastomers. Additionally, the present invention relates to improved coating, adhesive, sealant and elastomer (CASE) materials utilizing polymer latexes derived from various monomers and ethylenically unsaturated amine salts of sulfonic, phosphoric and / or carboxylic acids.

Owner:STEPAN COMPANY

Method for production of a hydroentangled airlaid web and products obtained therefrom

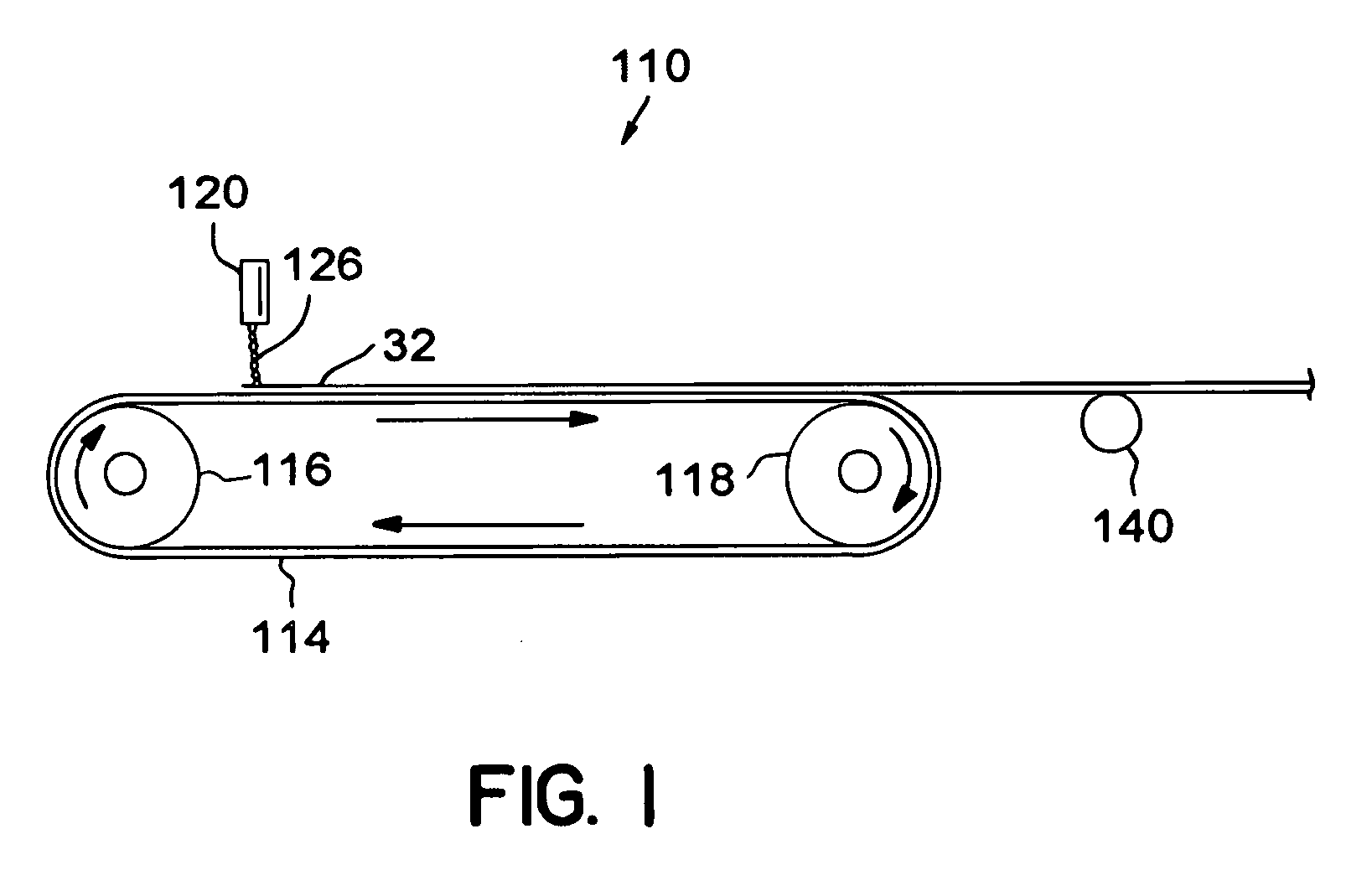

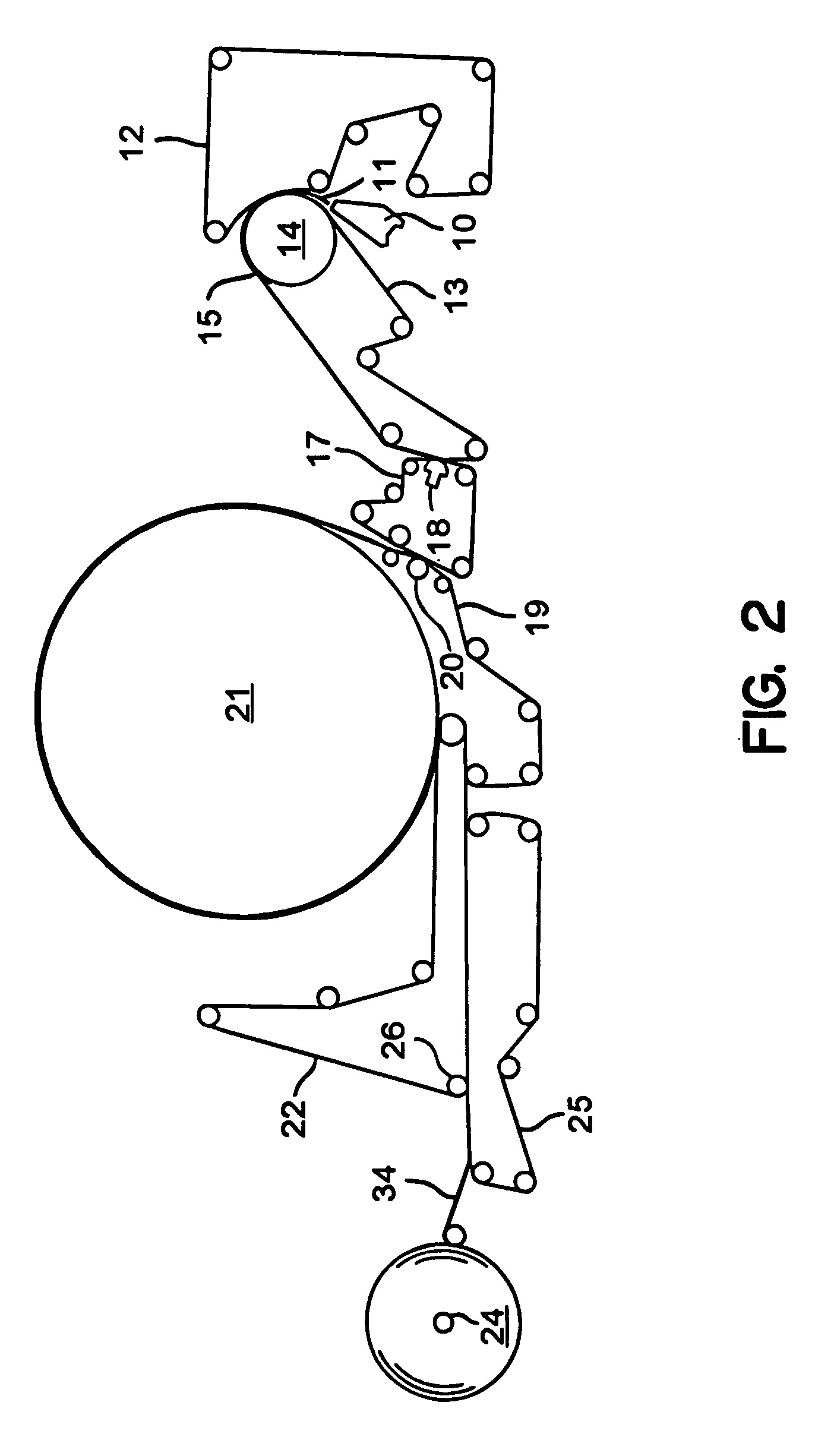

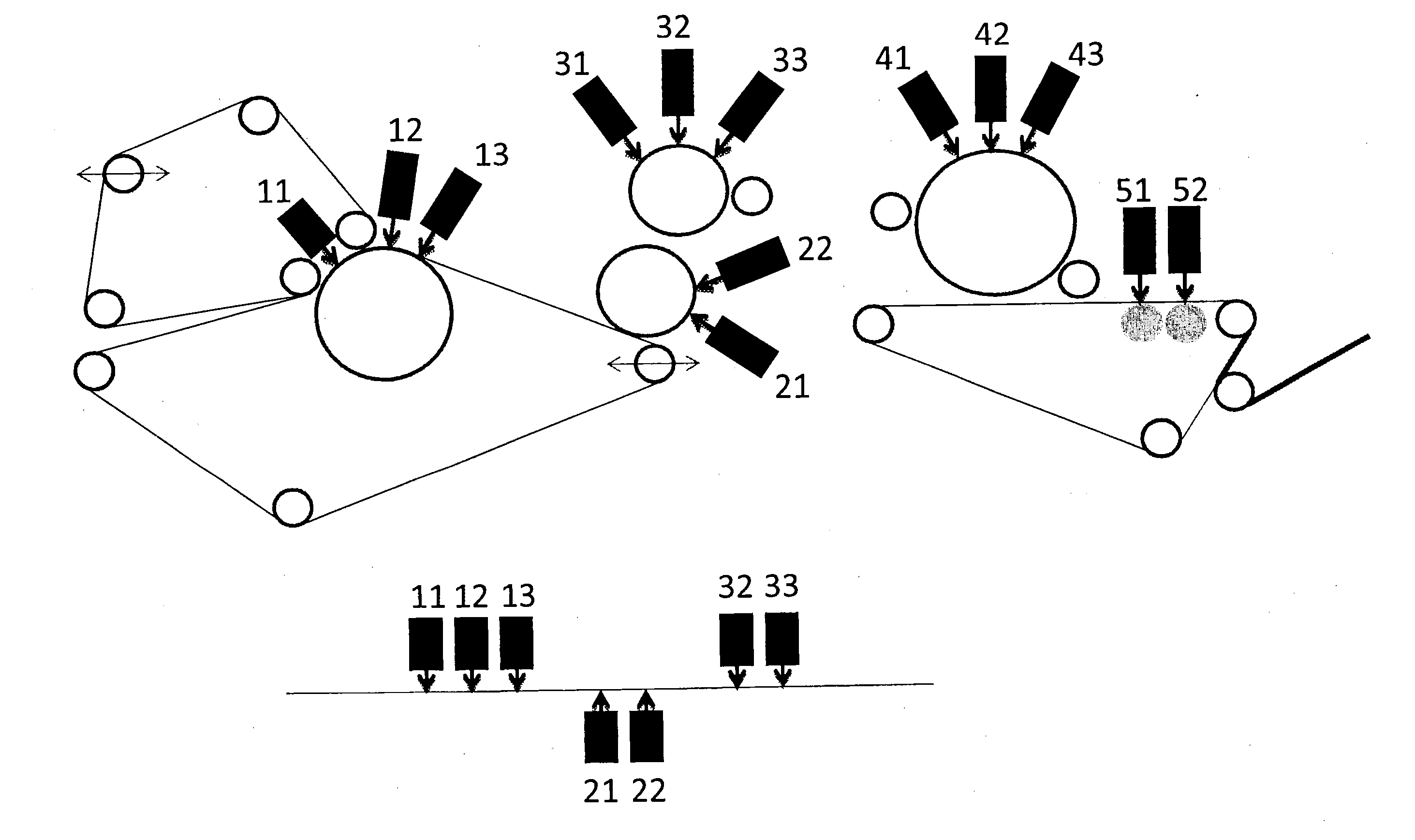

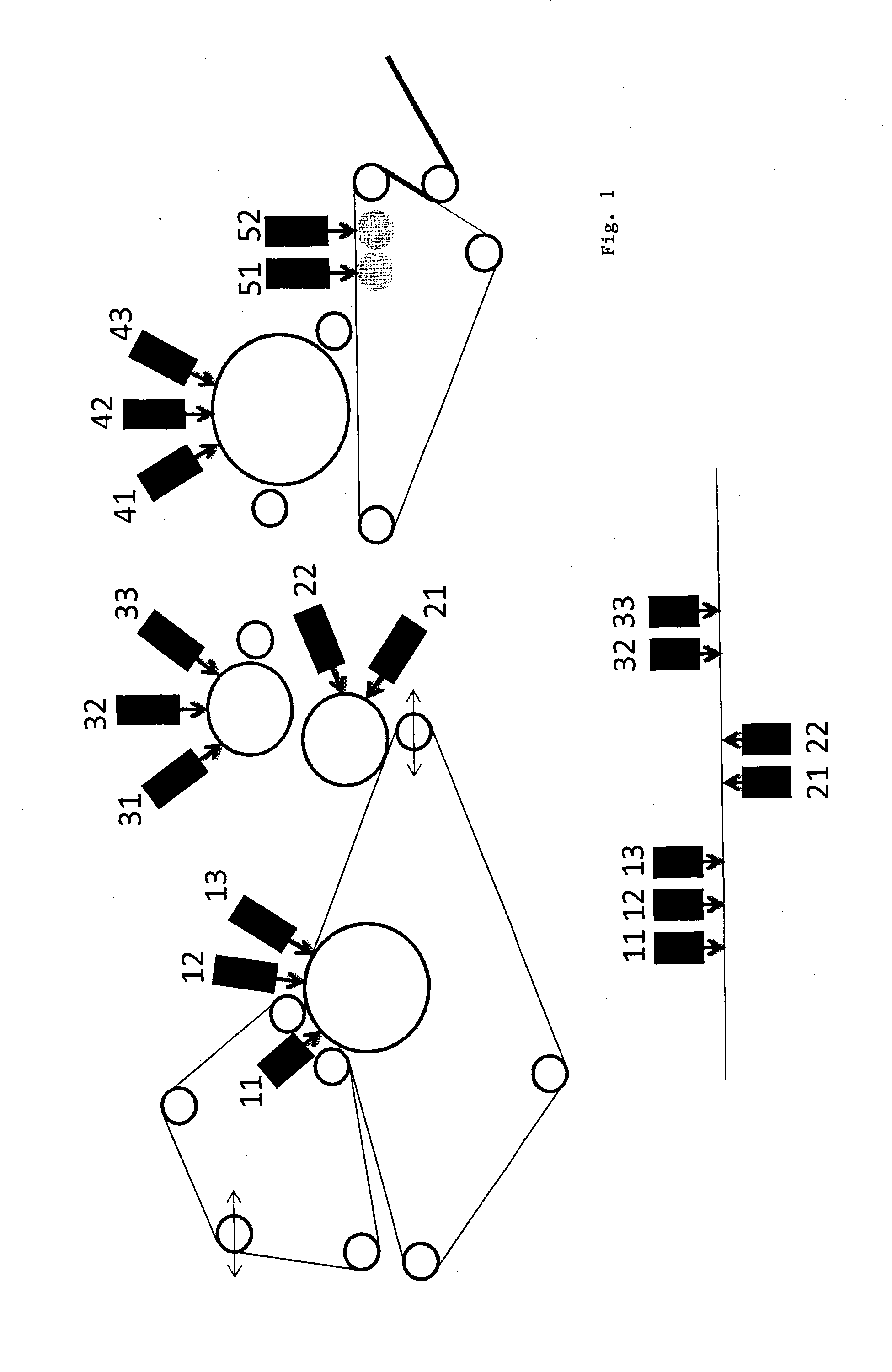

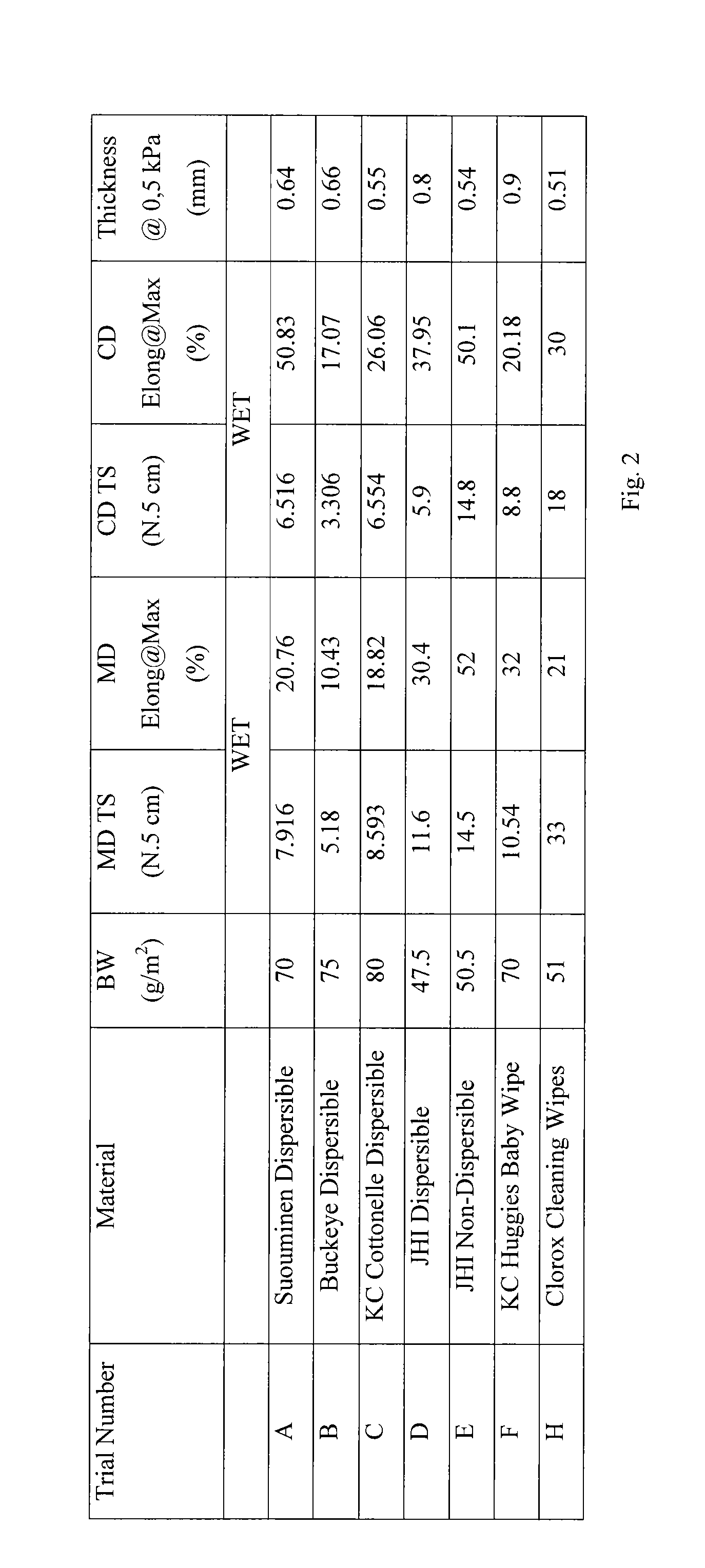

ActiveUS20140170402A1Minimal processing operationHigh wet tensile strengthCosmetic preparationsToilet preparationsThermal bondingNatural fiber

A method to prepare nonwoven webs which have good MD and CD strength, and are water disposable is provided. The method includes hydroentangling an airlaid web of no less than 50% by weight of natural cellulose fibers having a fiber length of no more than 3.5 mm and no more than 50% by weight staple fibers having a fiber length of no less than 8.0 mm. The airlaid web is not laid on a precursor web and no adhesive, binder or thermal bonding fibers are utilized. The airlayering and hydroentangling are conducted in a continuous operation. Products may be obtained according to the method of this invention that meet municipal guidelines for flushability.

Owner:GLATFELTER HLDG (SWITZERLAND) AG

Acylated chitosan wound dressing, and preparation method and application thereof

ActiveCN102727925AAvoid infectionGood hygroscopicityPackage sterilisationPharmaceutical delivery mechanismFiberWound dressing

The present invention relates to an acylated chitosan wound dressing, and a preparation method and application thereof. The wound dressing has high moisture absorption and high wet strength, forms into transparent gel after water absorption and swelling, does not adhere to a wound during contact with the wound, and can be conveniently and integrally removed. The wound dressing of the invention is prepared from acylated chitosan fibers containing carboxyl; and the acylated chitosan fiber is an acylated modified chitosan with an acylation degree of substitution of 0.10-0.50 in chitosan structure unit. As the wound treatment dressing, the acylated chitosan has effects of hemostasis and antibiosis and is especially suitable for the treatment of chronic wounds; and the high moisture absorption provides a moist environment for wound healing, and the wound dressing can rapidly absorb exudate and blood on wound surface to promote wound healing.

Owner:FOSHAN UNITED MEDICAL TECH

Thermosetting adhesives comprising a resin having azetidinium functional groups

InactiveUS7781501B2Improve wet strengthFast curingCosmetic preparationsToilet preparationsAdhesiveEpichlorohydrin

Owner:GEORGIA PACIFIC CHEM LLC

Functionalized block copolymers, method for making same, and various uses for such block copolymers

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to lithiation and each B block is a polymer block susceptible to lithiation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers not having hydrogen on a para benzylic carbon center, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) para-substituted styrene having hydrogen on a para benzylic carbon center (vi) 1,1-diphenylethylene, (vii) 1,2-diphenylethylene and (viii) mixtures thereof. After lithiation, the lithiated polymer is reacted with at least one graftable functional molecule selected from the group consisting of an electrophilic graftable molecule containing a functional group and an electrophile. Preferred are carbon monoxide and ethylene oxide. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

Carboxylated lignin based binders

InactiveUS20110159768A1Improve curing speedEasy curingSpecial tyresWoven fabricsLignosulfonatesWet strength

The present invention provides binder compositions comprising an ethylenically unsaturated carboxy acid grafted lignin or lignosulfonate component, and an oxazoline-functional group containing polymer or resin component, the two components in a solids weight ratio of from 50:50 to 98:2. As formulated, the compositions may comprise from 40 to 98 wt. % of the acid grafted lignosulfonate, preferably, 50 wt. % or more. Preferably, the binder composition further comprises one or more in situ acid generator compound to insure more rapid cure on heating or pressing. The binder enables the provision of low cost composite materials comprising a majority component derived from natural materials, and having a reasonable wet strength.

Owner:CRESCIMANNO STEPHEN A +1

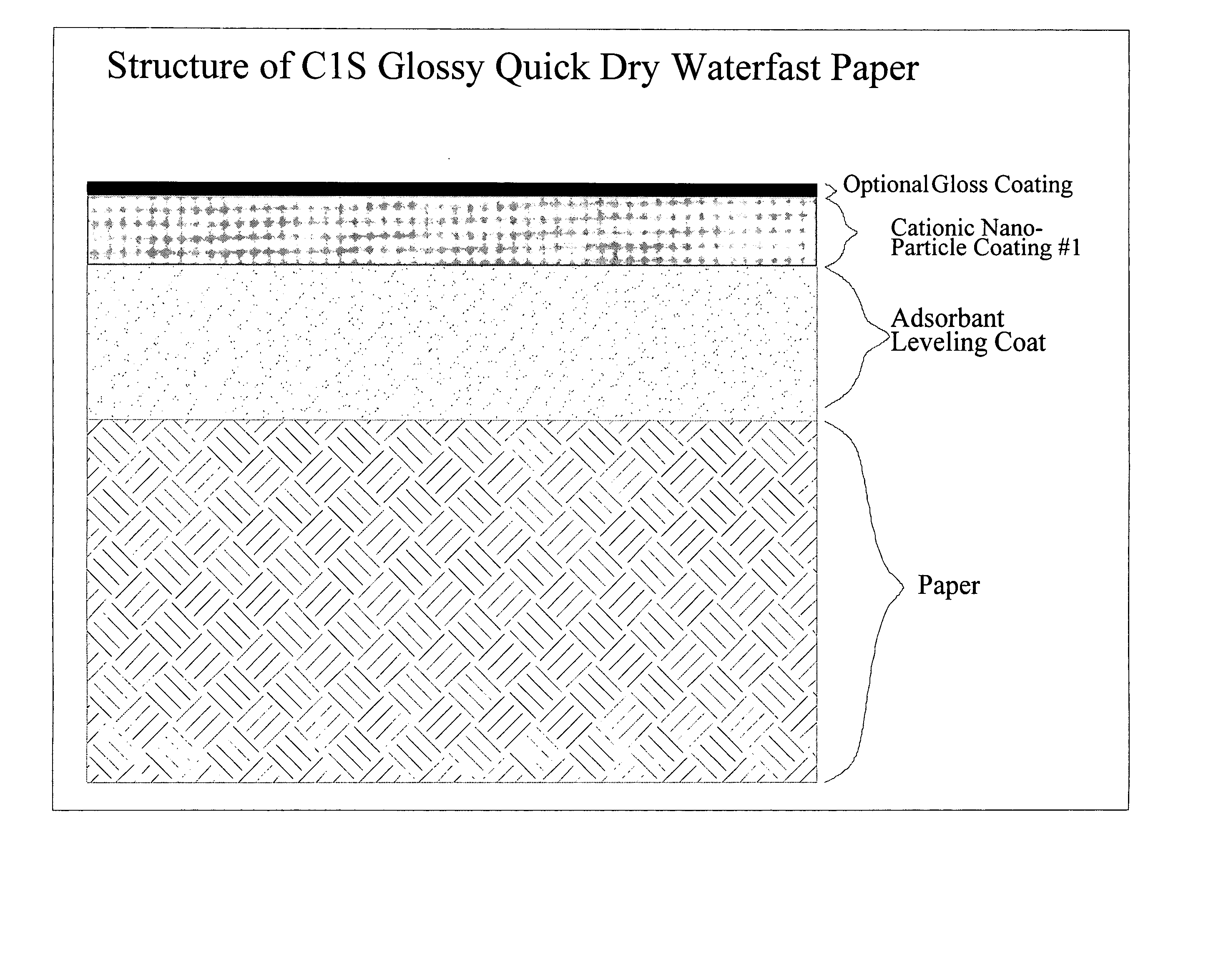

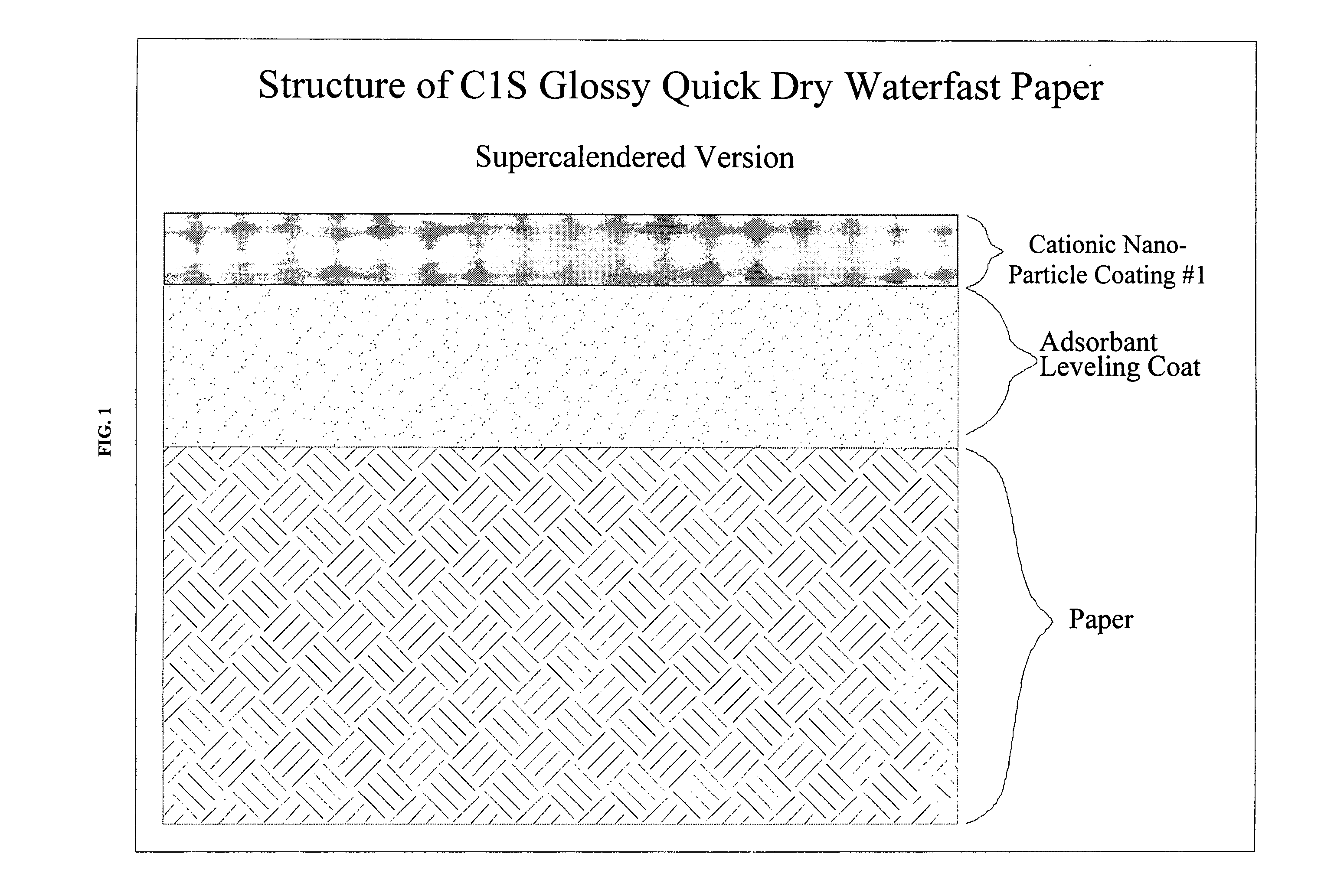

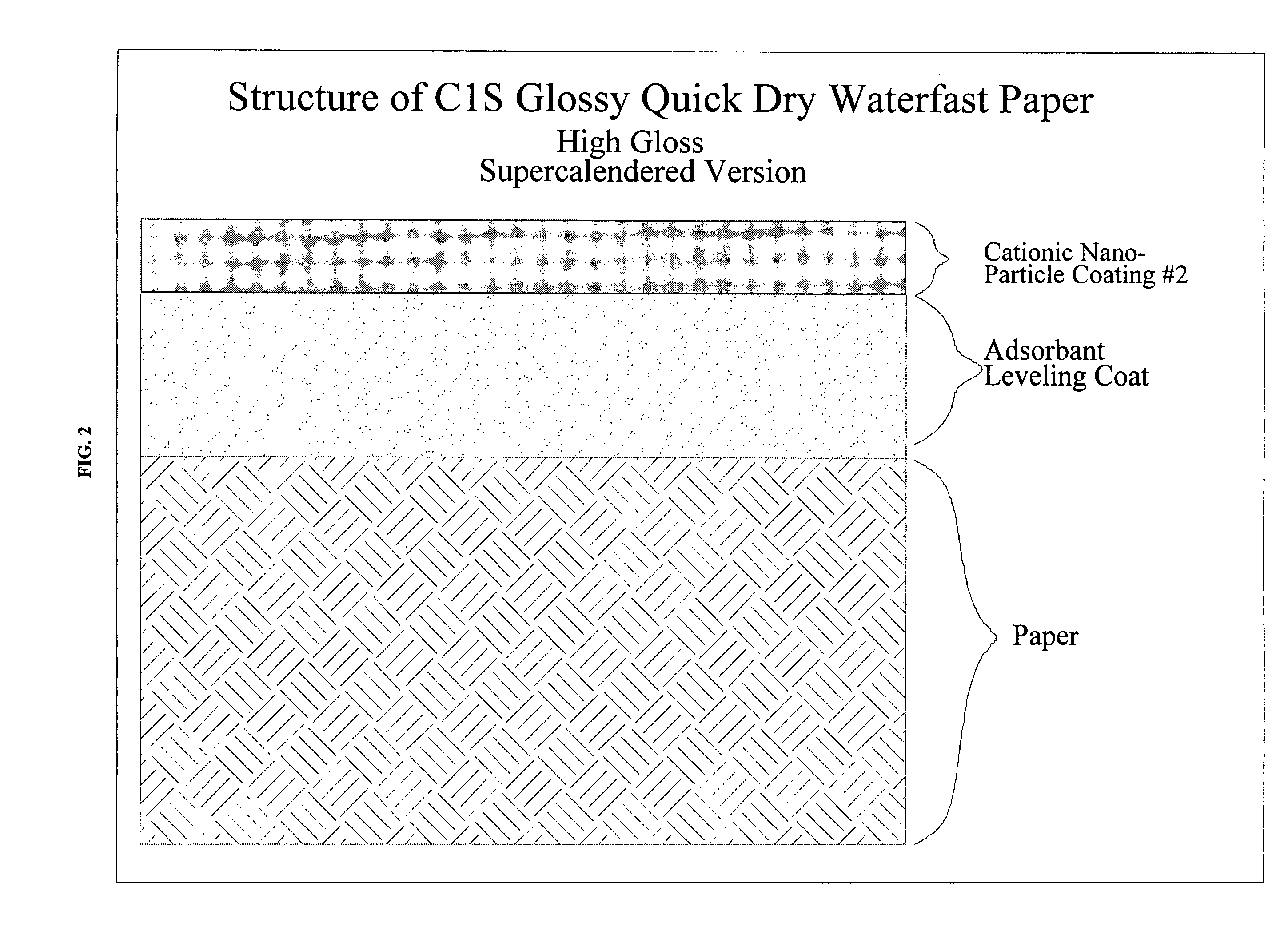

Quick drying, waterfast inkjet recording media

InactiveUS20050041084A1Quality improvementHigh quality imagingDuplicating/marking methodsCoatingsNanoparticleInk printer

This patent describes an inkjet printable recording media that dries quickly to produce a waterfast, water-resistant and smudge-resistant print. The media is especially well-suited for the growing field of digital photography where a durable photo-like print is desired, and for high-speed commercial inkjet printing. The invention provides novel coatings, coated media, and methods of use. In particular, the coatings comprise a porous, water-absorbent base coating, a water-resistant ink-receptive coating comprised of nanoparticle-sized pigments, and, optionally, a glossy top coating. The novel coated media comprises an inkjet printable substrate having multiple coating layers, and provides high quality, waterfast images. When used on an inkjet printer, the coated media permits the ink to dry almost instantly to produce a waterfast, high gloss image.

Owner:GLATFELTER CORP

Method for making sulfonated block copolymers, method for making membranes from such block copolymers and membrane structures

ActiveUS20090280255A1Reduced responseHigh propertyMembranesSemi-permeable membranesPolymer scienceAlcohol

The present invention relates to an improved method for making sulfonated block copolymers and to methods for making membranes from such block copolymers. In particular, the present invention relates to an improved method for making sulfonated block copolymers having at least two polymer end blocks that are resistant to sulfonation and at least one polymer interior block that is susceptible to sulfonation where the sulfonation agent is C2 to C8 acyl sulfate. In the improved process the residual carboxylic acid formed from the C2 to C8 acyl sulfate is converted to C1 to C4 alkyl esters by contacting the residual carboxylic acid with at least a 0.9:1 molar ratio of a C1 to C4 alcohol to residual carboxylic acid, resulting in an improved sulfonated block copolymer solution. The present invention further relates to the use of such sulfonated block copolymer solutions to prepare various membranes and other articles.

Owner:STEPAN COMPANY

Polyvinylamine treatments to improve dyeing of cellulosic materials

InactiveUS7214633B2Improve wet strengthEasy to dyeDecorative surface effectsFibre treatmentCellulosePolymer interaction

Textile materials, including paper webs, treated with a polyvinylamine polymer and a second agent that interacts with the polyvinylamine polymer is disclosed. The second agent added with the polyvinylamine polymer can be, for instance, a polymeric anionic reactive compound or a polymeric aldehyde-functional compound. When incorporated into a paper web, the combination of the polyvinylamine polymer and the second agent provide improved strength properties, such as wet strength properties. In an alternative embodiment, the polyvinylamine polymer and the second polymer can be applied to a textile material for increasing the affinity of the textile material for acid dyes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

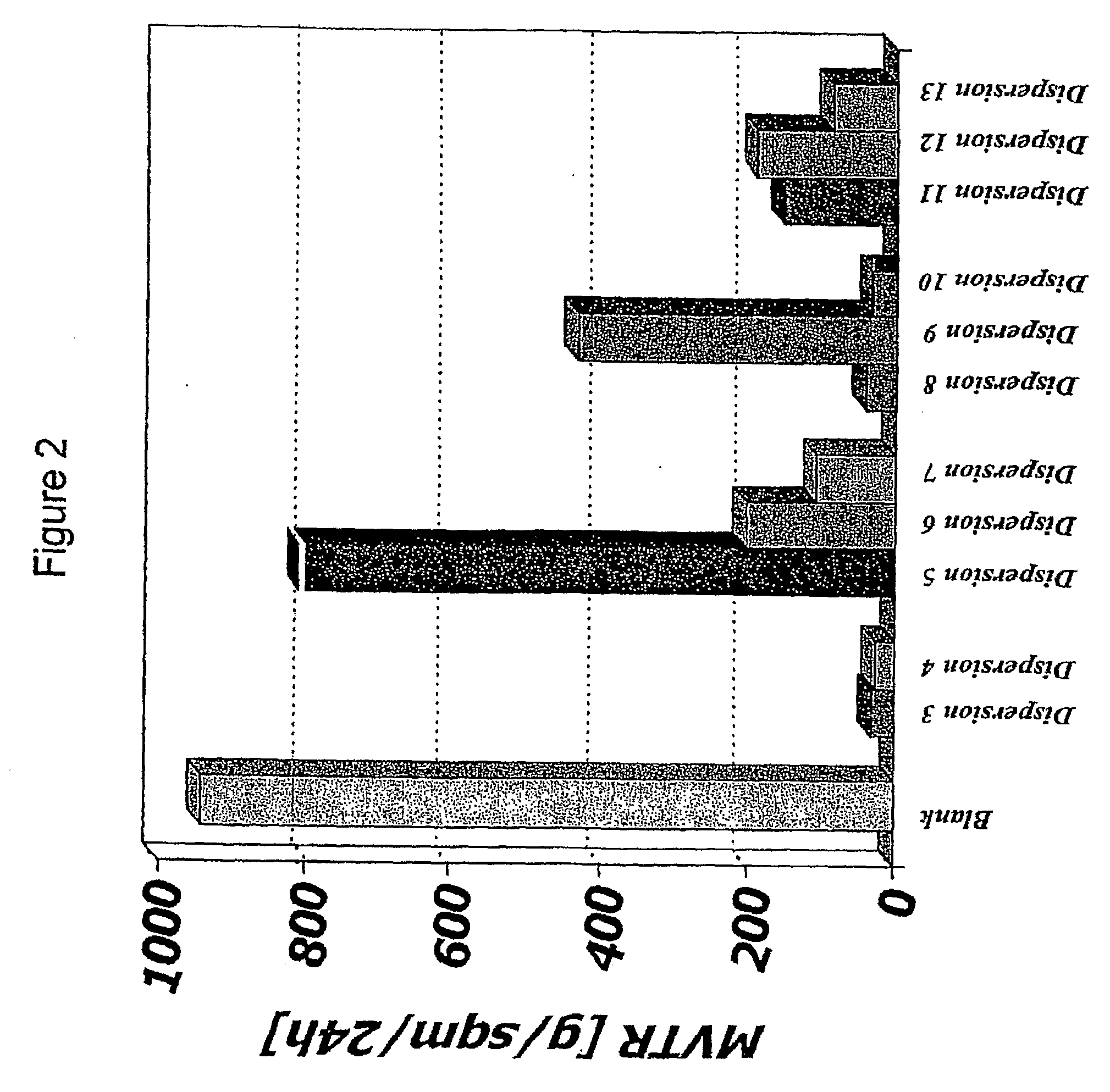

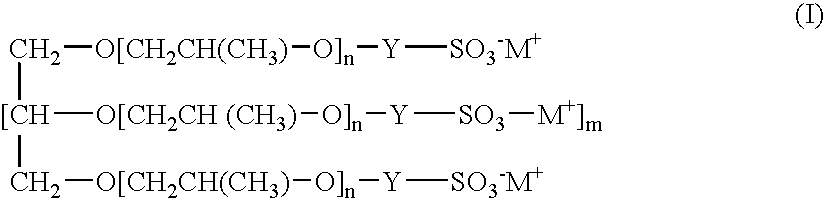

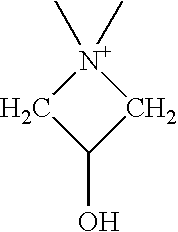

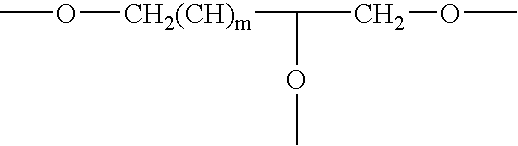

Fabric care composition

InactiveUS20040023836A1Increase the rate of moisture transport through the fabricImprove comfortOrganic detergent compounding agentsGrip property fibresCelluloseCross-link

Polymers which are capable of self-cross-linking and / or of reacting with cellulose can be used in the treatment of fabric comprising cellulosic fibres to enhance the feeling of comfort when a garment comprising the fabric is worn. The enhanced feeling of comfort is due, at least in part, to an increase in the rate of moisture transport through the fabric. The polymers may be used in conjunction with a liquid or soft solid derivative of a cyclic polyol or of a reduced saccharide resulting from 35 to 100% of the hydroxyl groups in the polyol or the saccharide being esterified or etherified.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Moisturizing eye mask prepared from bacterial cellulose

InactiveCN102784071AReliable hardnessGood flexibilityCosmetic preparationsToilet preparationsBiotechnologyMembrane surface

The invention discloses a moisturizing eye mask prepared from bacterial cellulose. The method for preparing a moisturizing eye mask from bacterial cellulose comprises: inoculating 1-2 rings of activated inclined seed Gluconacetobacter xylinum into a medium, and conducting oscillating culture to obtain a seed solution; then inoculating the seed solution into the medium, fully oscillating the bacterial solution obtained by mixing the seed solution and the medium to make them mixed uniformly, then conducting stationary culture, thus generating a bacterial cellulose membrane floating on the solution surface, flushing the generated bacterial cellulose membrane with water to remove the medium and impurities on the membrane surface, then immersing the membrane in an alkali solution to remove thalli and residual medium from the membrane, and finally flushing the membrane with distilled water till the pH value of the membrane is measured up to 7-7.2, thus obtaining a bacterial cellulose wet membrane, which is then cut into an eye mask. The eye mask has the advantages of good moisturizing property and biological tissue compatibility, no toxicity, harmlessness, and simple material processing technology.

Owner:SHANGHAI INST OF TECH

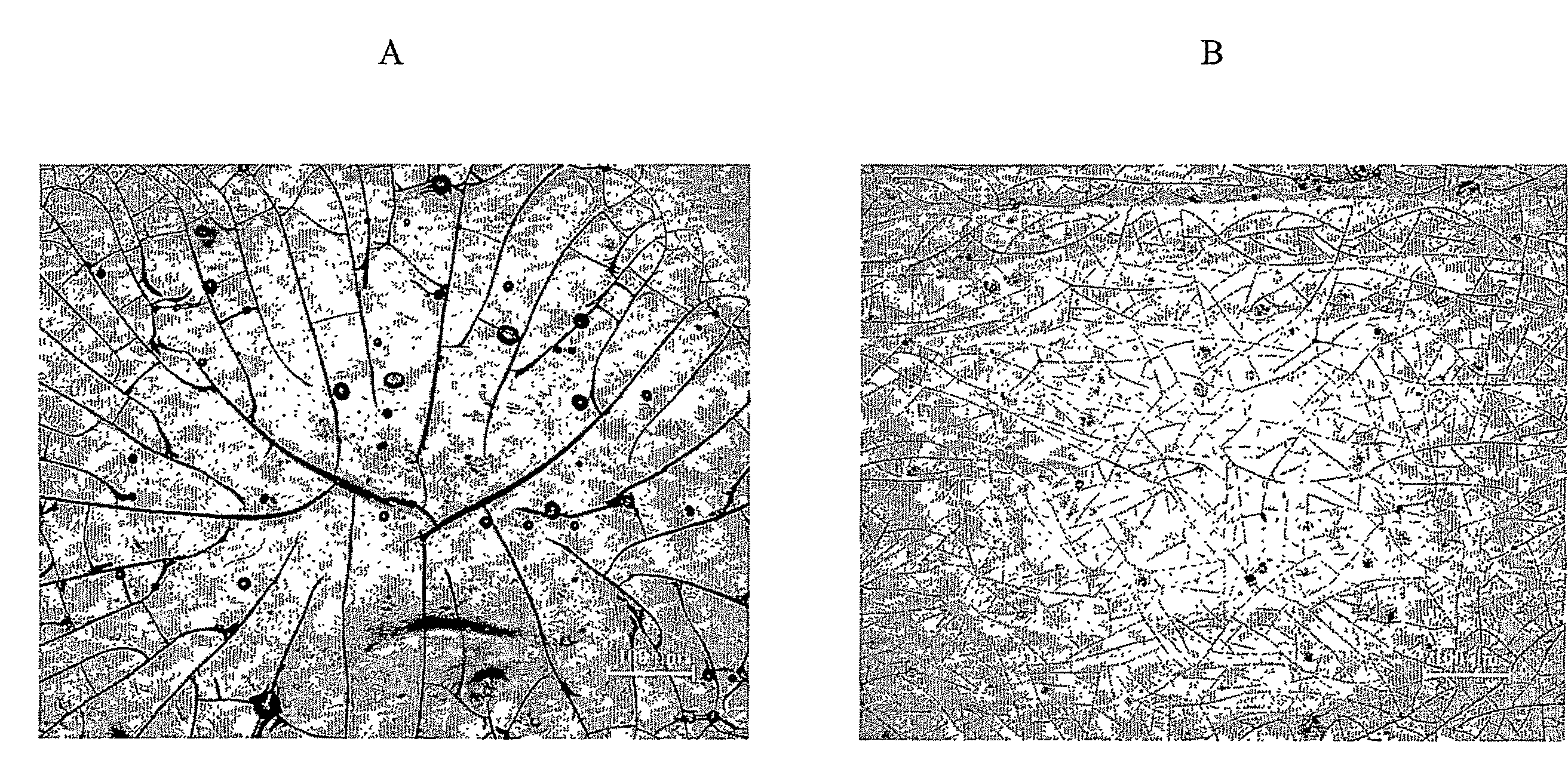

Latex Adhesives Derived From Ionic Strength Induced Soy Protein Complexes

InactiveUS20080287635A1Easy to operateHigh strengthPeptide preparation methodsFiberProtein molecules

Macro hydrophobic clusters and complexes of soybean globular proteins were observed using TEM (Transmission Electron Microscope). Upon unfolding, hydrophobic groups of the proteins became exposed toward the surface of the protein and actively interacted with other hydrophobic groups of other protein molecules, thereby forming hydrophobic bonding. The hydrophobic bonding resulted in hydrophobic protein clusters, the formation of which was affected by the degree of protein unfolding, protein structure, and hydrophobic components. Such hydrophobic clusters followed the global minimum free energy theory and formed spherical like structures with diameters ranging from 100 nm to 3000 nm. Such an understanding lends applicability to many uses in adhesives, molding composites, surfactants for oil-water systems, bio-based interior construction paints and paper coatings, fiber production, and metal powder molding applications.

Owner:SUN XIUZHUI +2

Novel lead-acid storage battery clapboard and preparation method thereof

The invention discloses a novel lead-acid storage battery clapboard, which belongs to the technical field of storage batteries. The novel lead acid storage battery clapboard consists of the following raw materials in part by weight: 38 to 41 parts of superfine glass cellucotton, 7 to 10 parts of bicomponent organic fiber, 0.5 to 0.6 part of sulfuric acid, and 0.1 to 0.2 part of wet strength agent; and the novel lead acid storage battery clapboard is prepared through the processes of pulping, processing and conveying of sizing materials, paper-making from paper pulp for the clapboard, drying by a drying box, reeling, clapboard processing and the like. The lead-acid storage battery clapboard has the advantages of high porosity, low resistance, high wet strength and good anti-puncture capability, and compared with a pure glass fiber clapboard, the wet strength is improved by nearly 70 percent, the anti-puncture capability is improved by about 45 percent, and the wet resilience force is improved by 5 to 11 percent.

Owner:YIHECHENG GRP CO LTD

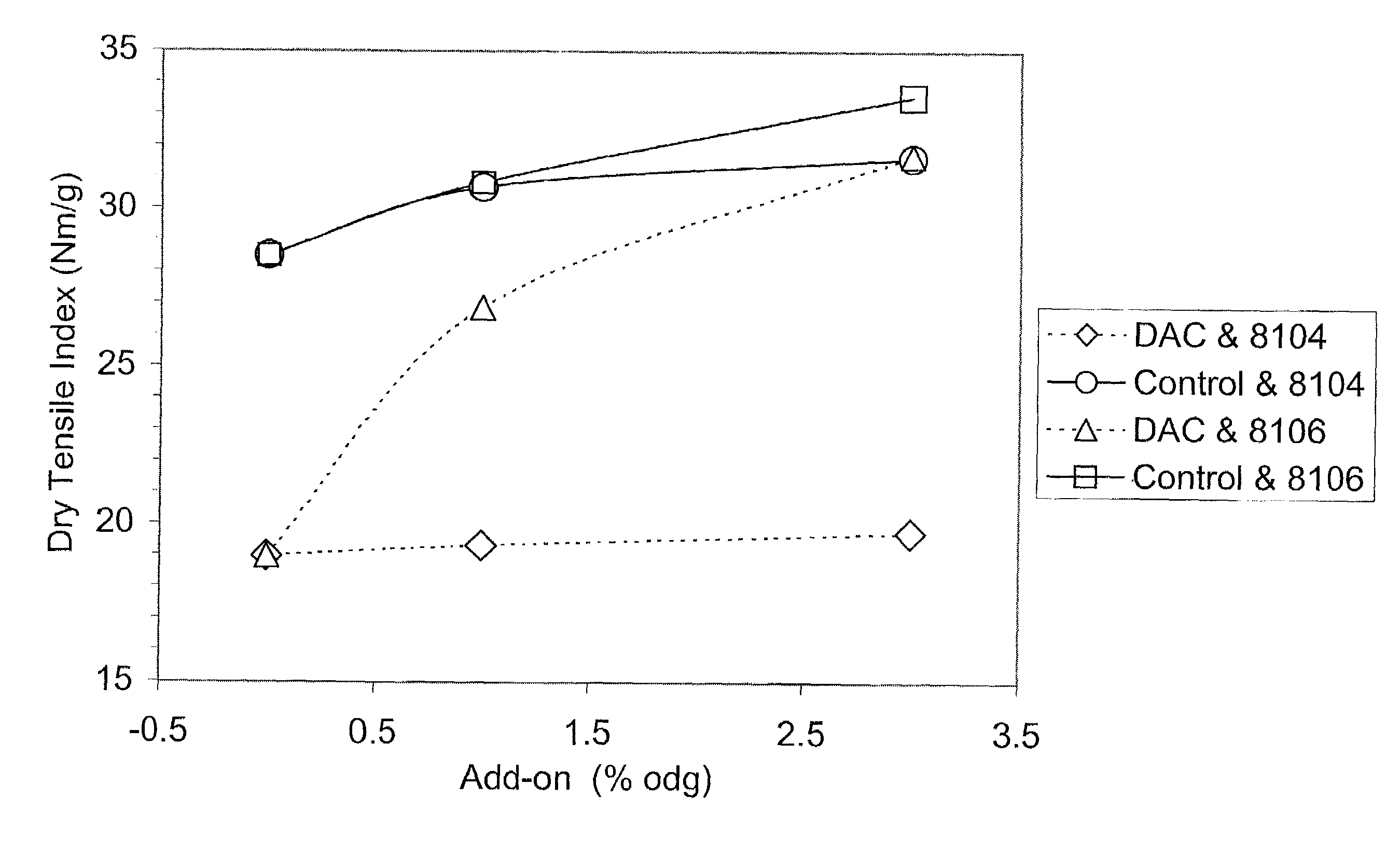

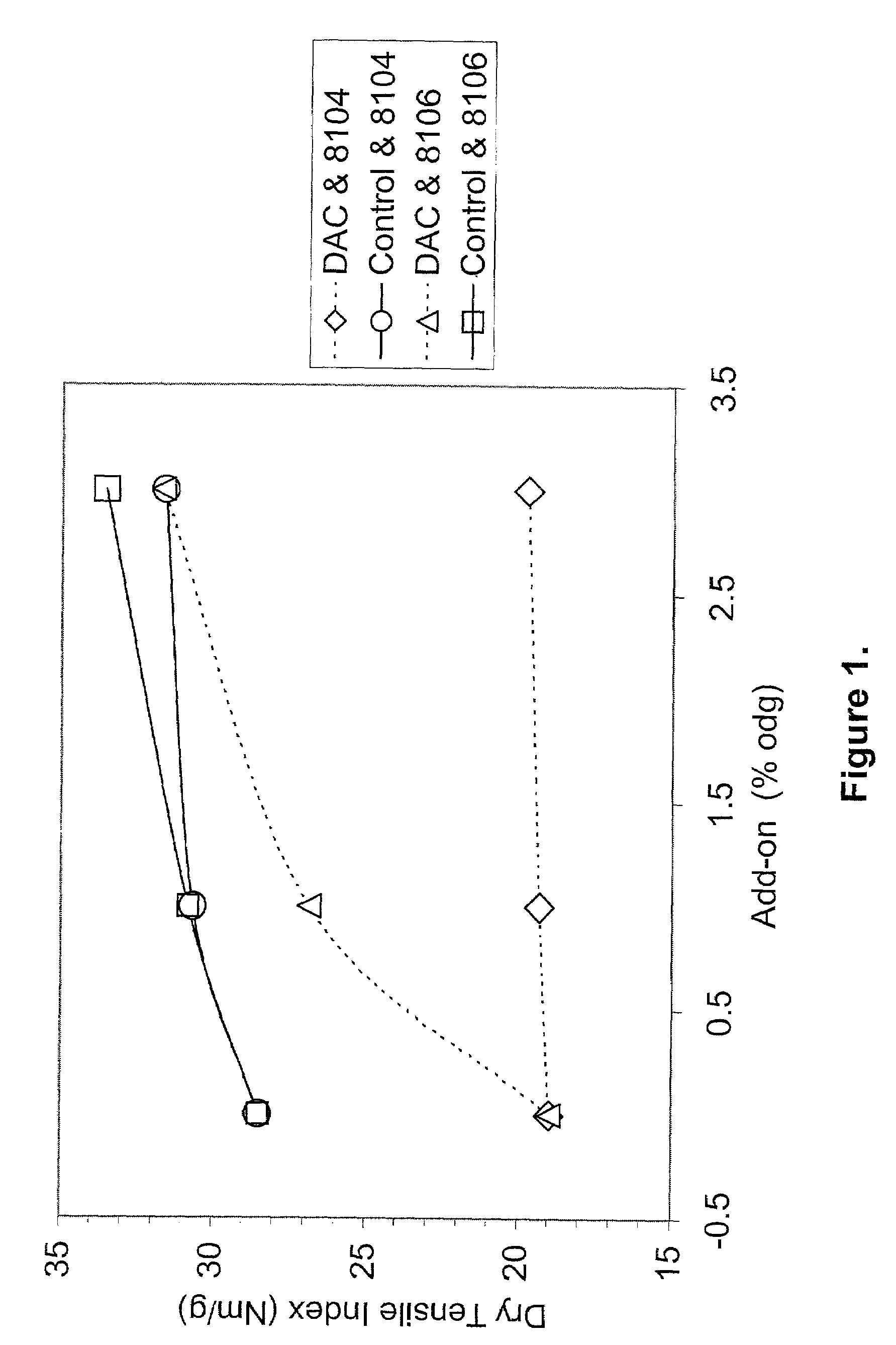

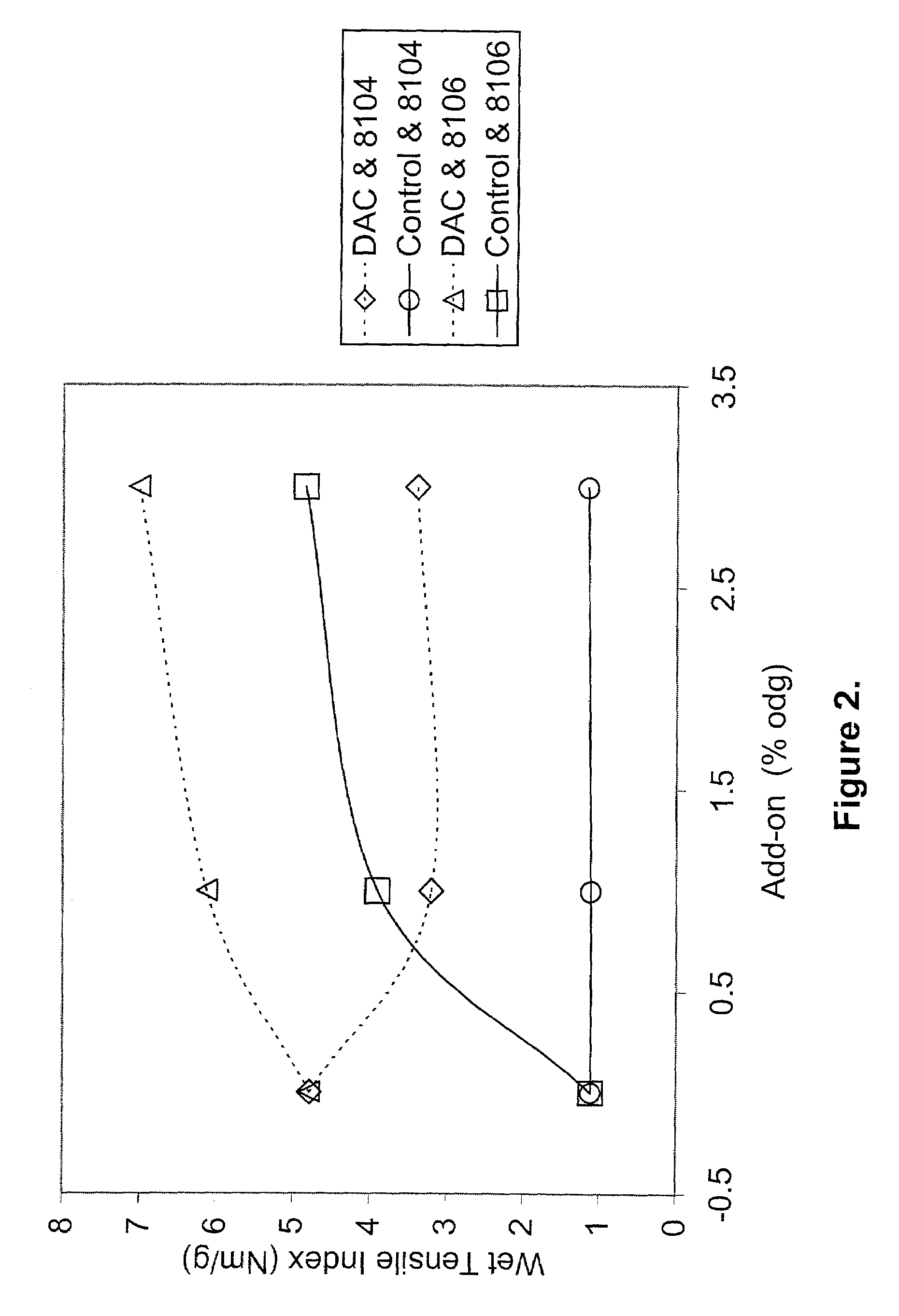

Wet strength and softness enhancement of paper products

InactiveUS7041197B2Improve wet strengthLess additivesNatural cellulose pulp/paperSpecial paperChemistryPolyelectrolyte

A method for making paper to enhance its wet strength includes adding separately to a cellulosic paper pulp furnish the following additives to form a treated pulp: a cationic wet strength resin whose cationic sites bond to anionic sites of cellulose fibers contained in the paper pulp furnish, and a hydrophobically modified anionic polyelectrolyte whose anionic sites bond with cationic sites of the cationic wet strength resin.

Owner:GPCP IP HLDG LLC

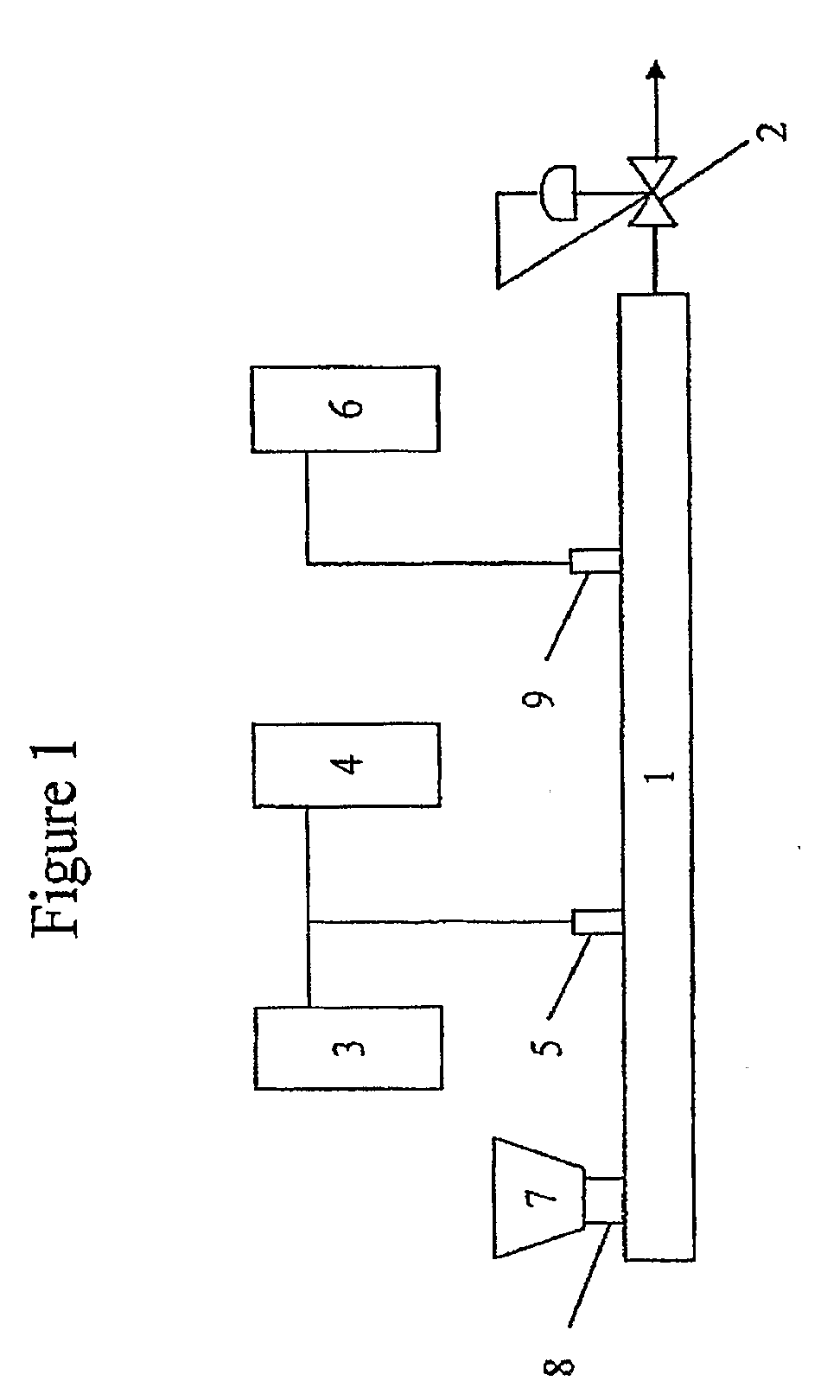

Method for preparing organosilicon modified paper sheet humidifying strong agent

InactiveCN101302731AImprove wet strengthImprove surface water resistanceReinforcing agents additionCross-linkEpoxy

The invention discloses a preparation method of a paper wet strengthening agent that is modified by organic silicon, which comprises the following steps: firstly combines the raw materials of dibasic acid and polyhydric amine into a polyamine intermediate compound of daiamid. A certain amount of the polyamine intermediate compound of daiamid, epoxy chloropropane and an organosilane coupling agent are taken to react under certain temperature so as to achieve certain viscosity, and the reaction is halted by adding acid, thus obtaining the paper wet strengthening agent that is modified by organic silicon. The preparation method of the paper wet strengthening agent that is modified by organic silicon can reduce the usage of the epoxy chloropropane and lower the organic chlorine content in discharged substances; the cross-linked product greatly increases molecular weight and active crosslinking points of molecular chain sections. The product of the paper wet strengthening agent that is modified by organic silicon achieves greatly raised retention degree, can improve not only the wet strength of paper but also the paper physical performance such as folding resistance, tensile strength and dry strength, etc., and the superficial water-proof performance of paper can be greatly raised if the paper wet strengthening agent is coated on the surface of paper.

Owner:SHAANXI UNIV OF SCI & TECH

Biodegradable algae liquid plastic film and preparation method thereof

ActiveCN102212214AImprove wet strengthImprove water retentionClimate change adaptationPlant protective coveringsCarboxymethyl cellulosePlastic film

The invention provides a biodegradable algae liquid plastic film, which is characterized by comprising the following components in parts by weight: 100 parts of algae extract, 2-10 parts of polyacrylate alginate jelly resin, 50-70 parts of lignosulfonate, 10-20 parts of humic acid, 20-30 parts of molasses or biochemical fulvate or a mixture of molasses and biochemical fulvate at a weight ratio of 1: 2, 10-20 parts of carboxymethyl cellulose and 300-500 parts of water. In addition, the invention also provides a preparation method of the algae liquid plastic film.

Owner:BEIJING LEILI MARINE BIOINDUSTRY INC

High-intensity molecular sieve and preparation method thereof

InactiveCN102502692AHigh mechanical strengthReduce wear rateFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AMolecular sieveHigh intensity

The invention relates to a high-intensity molecular sieve and a preparation method thereof. The method comprises the following steps: uniformly mixing molecular sieve material and a binder so as to obtain molecular sieve quality A; adding structure intensifier into the molecular sieve quality A so as to obtain molecular sieve quality B, and then obtaining the high-intensity molecular sieve through forming, drying, roasting and cooling the molecular sieve quality B in sequence. The molecular sieve prepared by using the method provided by the invention not only has excellent mechanical strengthand also is low in abrasion ratio.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com