Self-supporting friction stir welding method with unequal diameters of upper and lower shaft shoulders and stirring head thereof

A friction stir welding technology with different diameters, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of affecting joint performance, breaking of stirring needles, large welding heat input, etc., to reduce the degree of softening, prevent Fracture, reduce heat input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

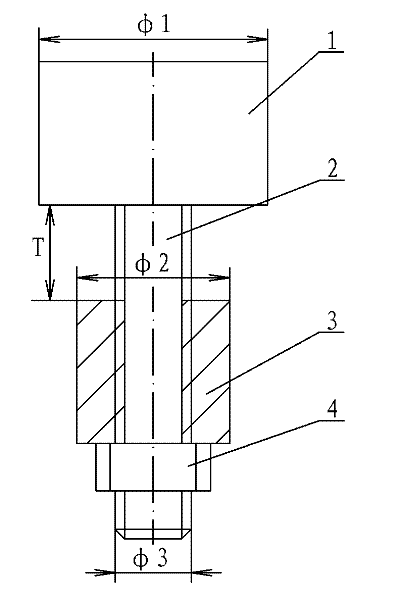

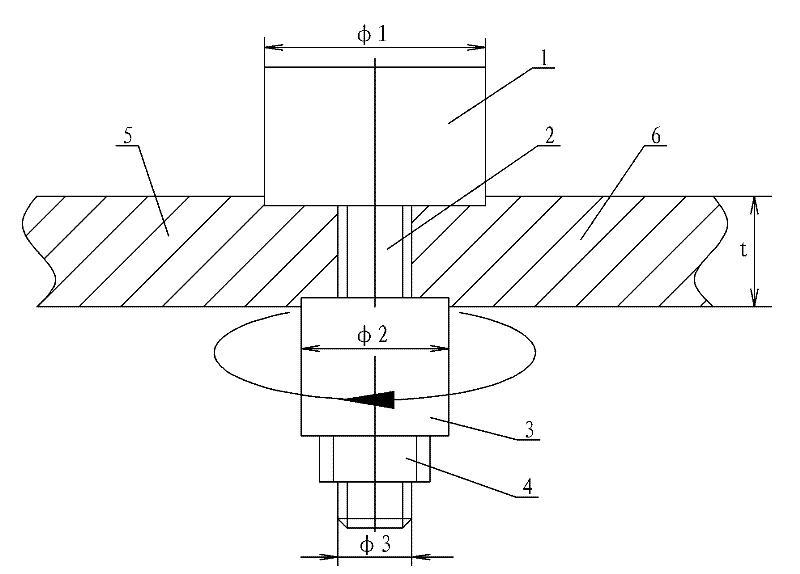

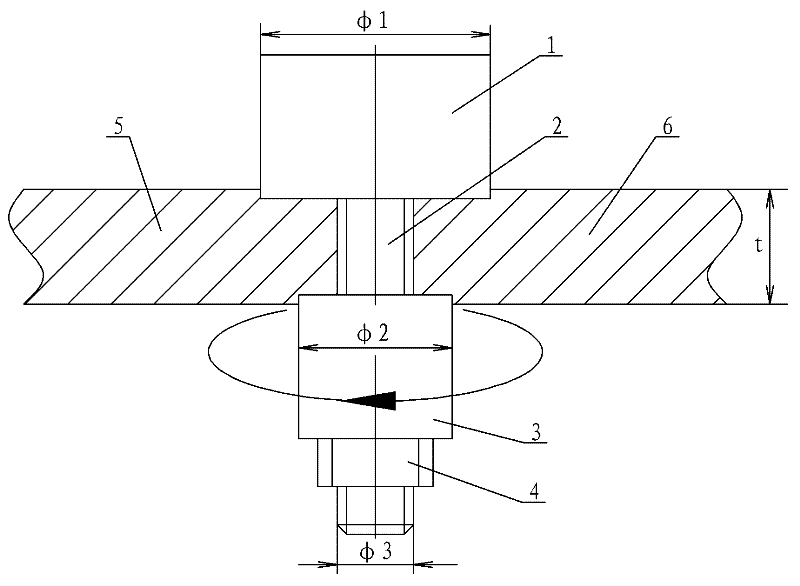

[0008] Specific implementation mode one: combine figure 2 Describe this embodiment, this embodiment is realized by the following steps: Step 1, stirring head size determination: according to the thickness of the first welded workpiece 5 and the second welded workpiece 6, determine the upper shaft shoulder diameter φ1, the lower shaft shoulder diameter φ2 and stirring needle diameter φ3: the diameter of the upper shoulder φ1 is 2.5 to 3 times the thickness t of the workpiece to be welded, the diameter of the lower shoulder φ2 is 2 to 2.5 times the thickness t of the workpiece to be welded, and the diameter of the stirring needle φ3 is the thickness of the workpiece to be welded 1.25 to 2 times of t; the size of each part of the stirring head is selected according to the thickness of the first welded workpiece 5 and the second welded workpiece 6, in order to ensure the stability of the forming of the weld seam and the quality of the joint. Step 2. Determine the use length of th...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 2 Describe this embodiment, the upper shaft shoulder diameter φ1 in step 1 of this embodiment is 3 times of the thickness t of the workpiece to be welded, the diameter of the lower shaft shoulder φ2 is 2 times of the thickness t of the workpiece to be welded, and the diameter of the stirring pin φ3 is the thickness of the workpiece to be welded 1.5 times the thickness t. The size of the above stirring head can ensure the stability of the weld formation. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 To describe this embodiment, in step 2 of this embodiment, the distance T between the lower end surface of the upper shoulder 1 and the upper end surface of the lower shoulder 3 is 0.3 mm smaller than the thickness t of the workpiece. The above values give the best stir welding results. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com