Stable deviation adjusting method of conveyor

A conveyor, stable technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of belt deviation from the normal transmission direction, conveyed materials falling, belt stuck into idlers, etc., to avoid tilting, The effect of prolonging the service life and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

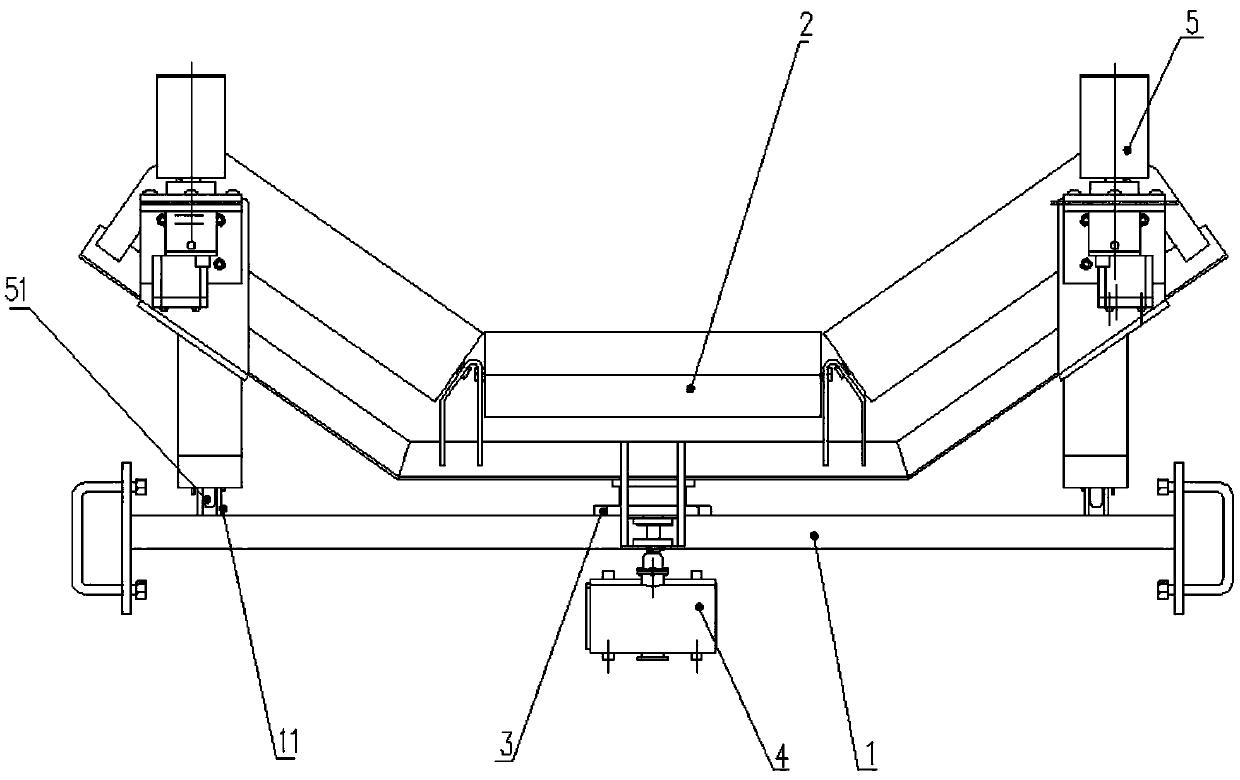

[0016] As shown in the figure, it is a conveyor that can be stably adjusted, including a support roller 2, and the support roller 2 is set on a fixed support frame 1 through a support seat 3, and a fixed support frame 1 is provided between the support seat 3 and the fixed support frame 1. There are rolling support bearings, the drive shaft of a rotary drive part passes through the fixed support frame 1 vertically from the bottom and is inserted into the support seat 3, and an angle sensor is arranged in the support seat 3, and the angle sensor is connected with a controller electric connection, the output end of the controller is connected to the control unit of the rotary drive part, and the two sides of the support roller 2 are respectively provided with limit rotation rollers 5, the limit rotation rollers 5 are vertically arranged, and the limit rotation T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com