Blade structure for wind driven generator

A wind turbine and blade structure technology, which is applied to wind turbine components, wind engines, wind engine control, etc., can solve problems such as high cost, large foundation, and high quality requirements for management personnel, and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

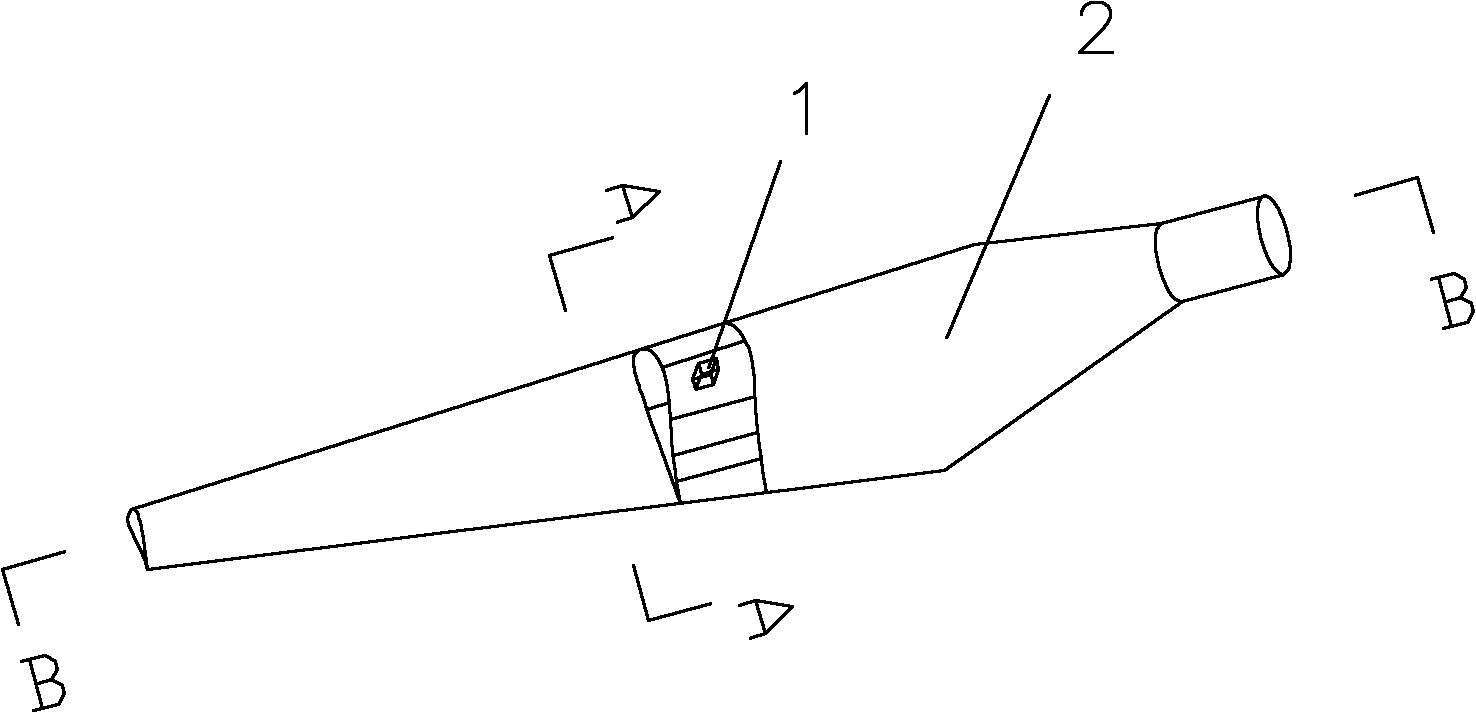

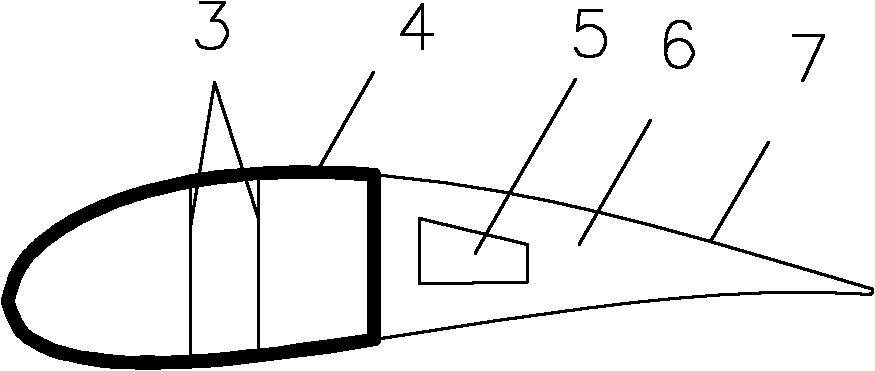

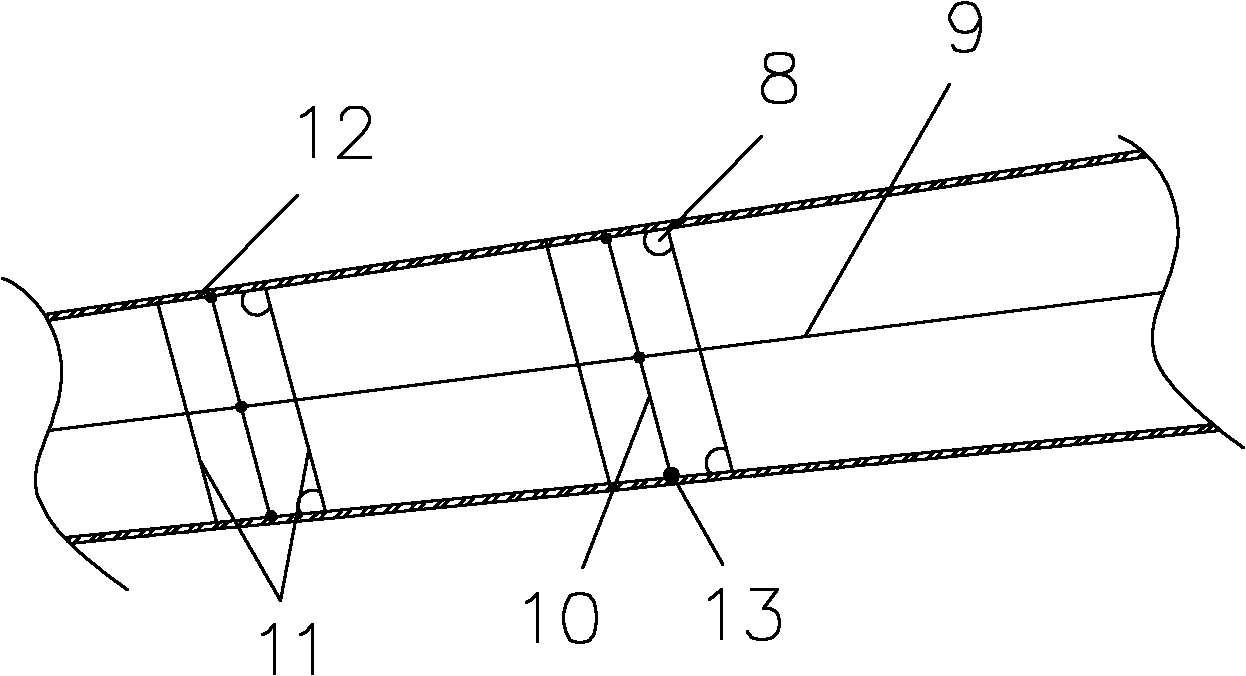

[0010] refer to Figure 1-4 As shown, the blade structure includes air consumption hole 1, baffle plate 3, D-shaped steel longitudinal beam 4, thin plate rib beam 5, foam plastic 6, glass fiber reinforced plastic skin 7, elastic hinge 8, long steel wire 9, short steel wire 10, holes Baffle plate 11, air consumption hole cover plate 12 and hook 13. Among them, such as figure 1 As shown, a plurality of air consumption holes 1 are provided at the place where the windward area in the axial direction of the blade is relatively large; figure 2 As shown, the D-shaped steel longitudinal beam 4 is provided with air consumption holes 1, and the foam plastic 6 is filled between the thin plate rib beam 5 and the glass fiber reinforced plastic skin 7; image 3 As shown, one side of the air consumption hole cover plate 12 is connected with the D-shaped steel longitudinal beam 4 through an elastic hinge; the two ends of the short steel wire 10 are respectively connected with the hook 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com