Unit forwarding rubber trolley of track crane

A technology of lifting the whole machine and rubber, which is applied in the direction of the lifting device, etc., can solve the problems of shortening the service life of the tire, a large amount of manpower and material resources, and hindering the traffic on the site, so as to achieve the effect of prolonging the service life, reducing the cost and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

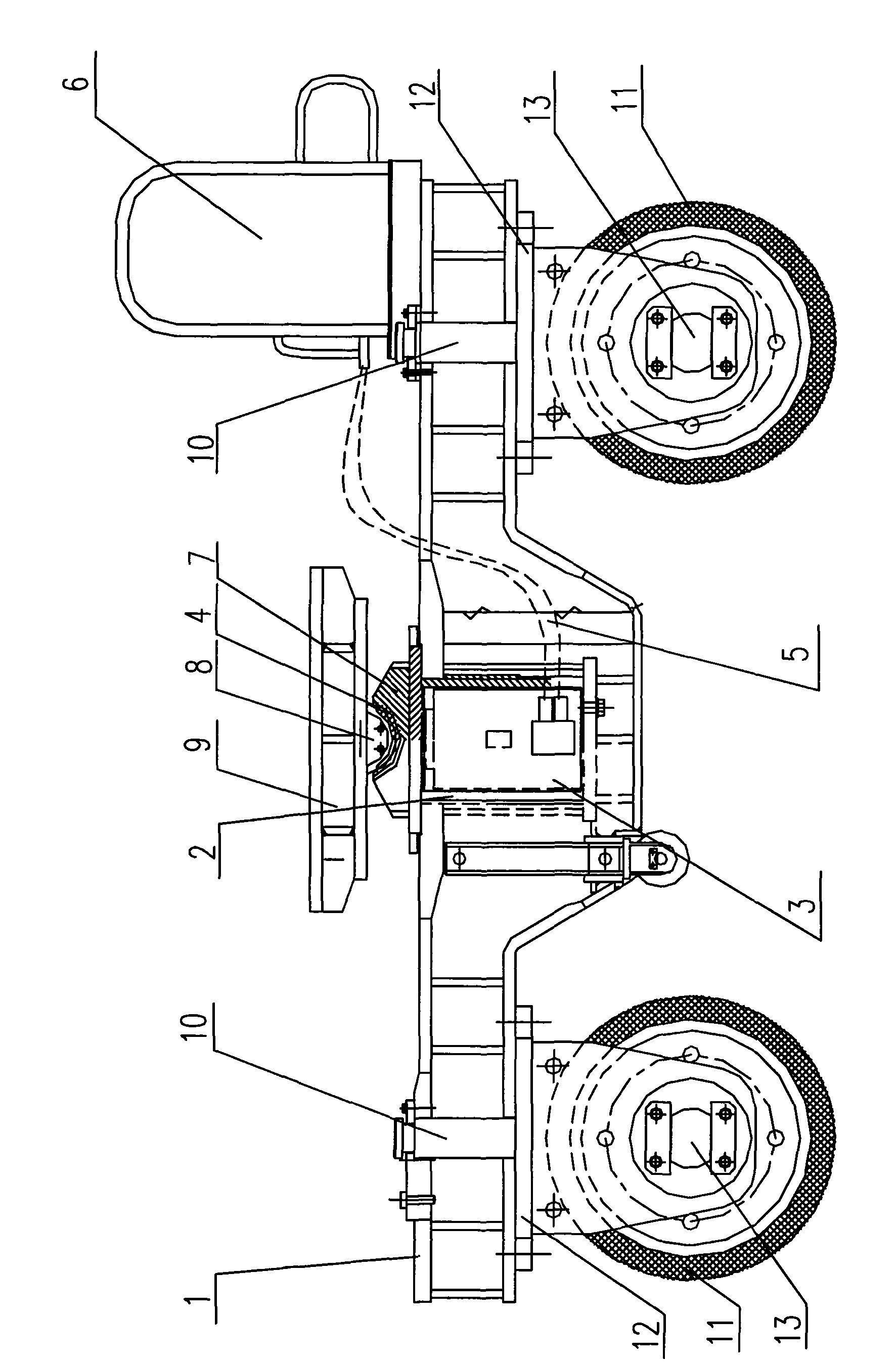

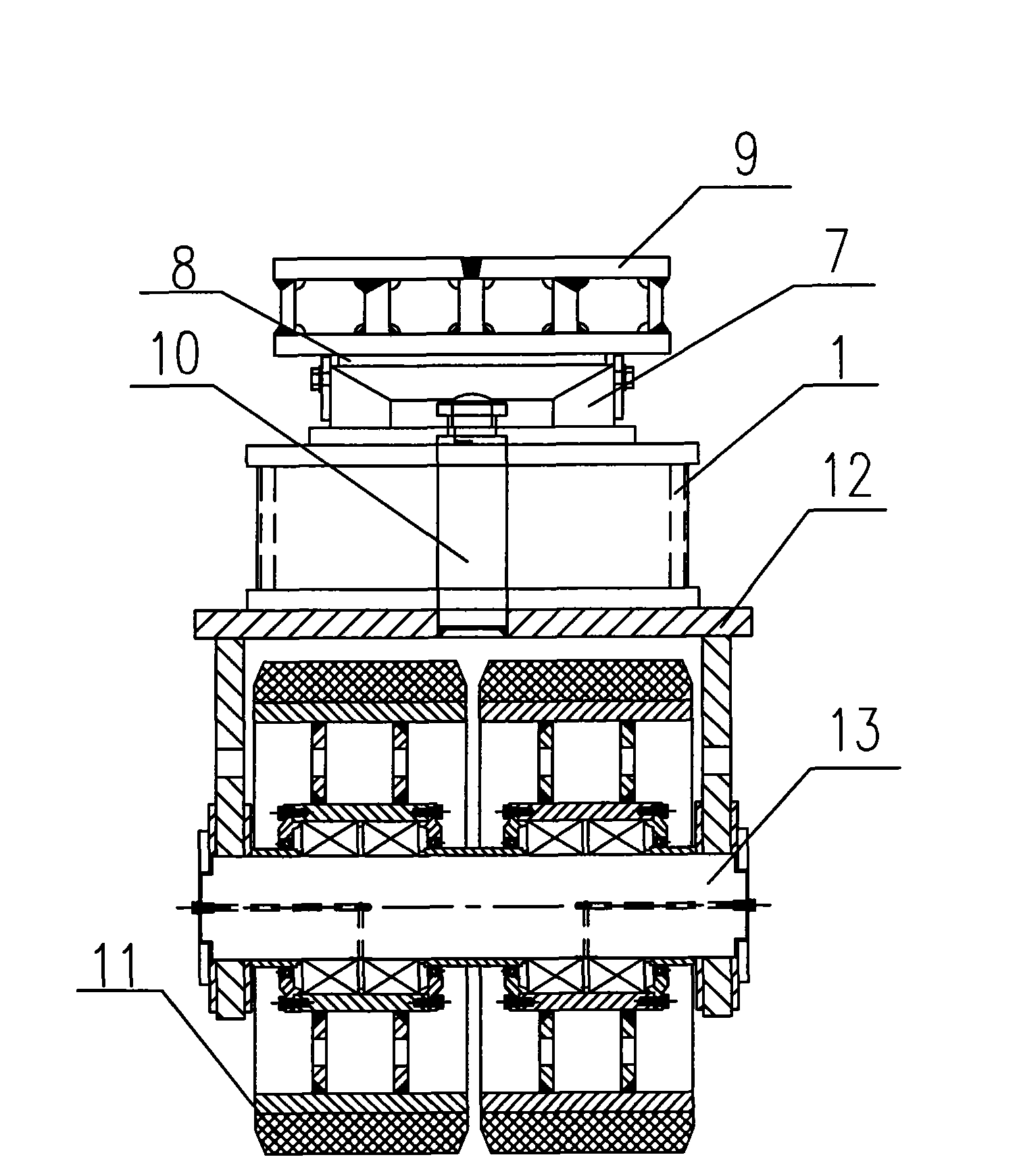

[0018] like figure 1 It shows an embodiment of the rail crane transfer rubber trolley of the present invention, the rail crane transfer rubber trolley includes a balance beam 1, an inner groove 2 is arranged at the center of the balance beam 1, and a jack 3 is arranged in the inner groove 2 And the oil cylinder 4, the oil cylinder 4 is connected to the hydraulic tank 6 placed outside one end of the balance beam 1 through the high-pressure oil pipe 5, and the upper end at the center of the balance beam 1 is placed with a lower support seat 7, and the bottom of the lower support seat 7 is connected to the upper part of the jack 3, The lower support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com