Wind generating set by using bamboo-based blade

A technology for wind power generators and generators, which is applied to wind power generator components, wind motor combinations, wind power engines, etc. It can solve the problems of poor blade flexibility, affecting the life of the unit, and poor environmental protection, and achieves low cost and low overall cost. The effect of low machine cost and short production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

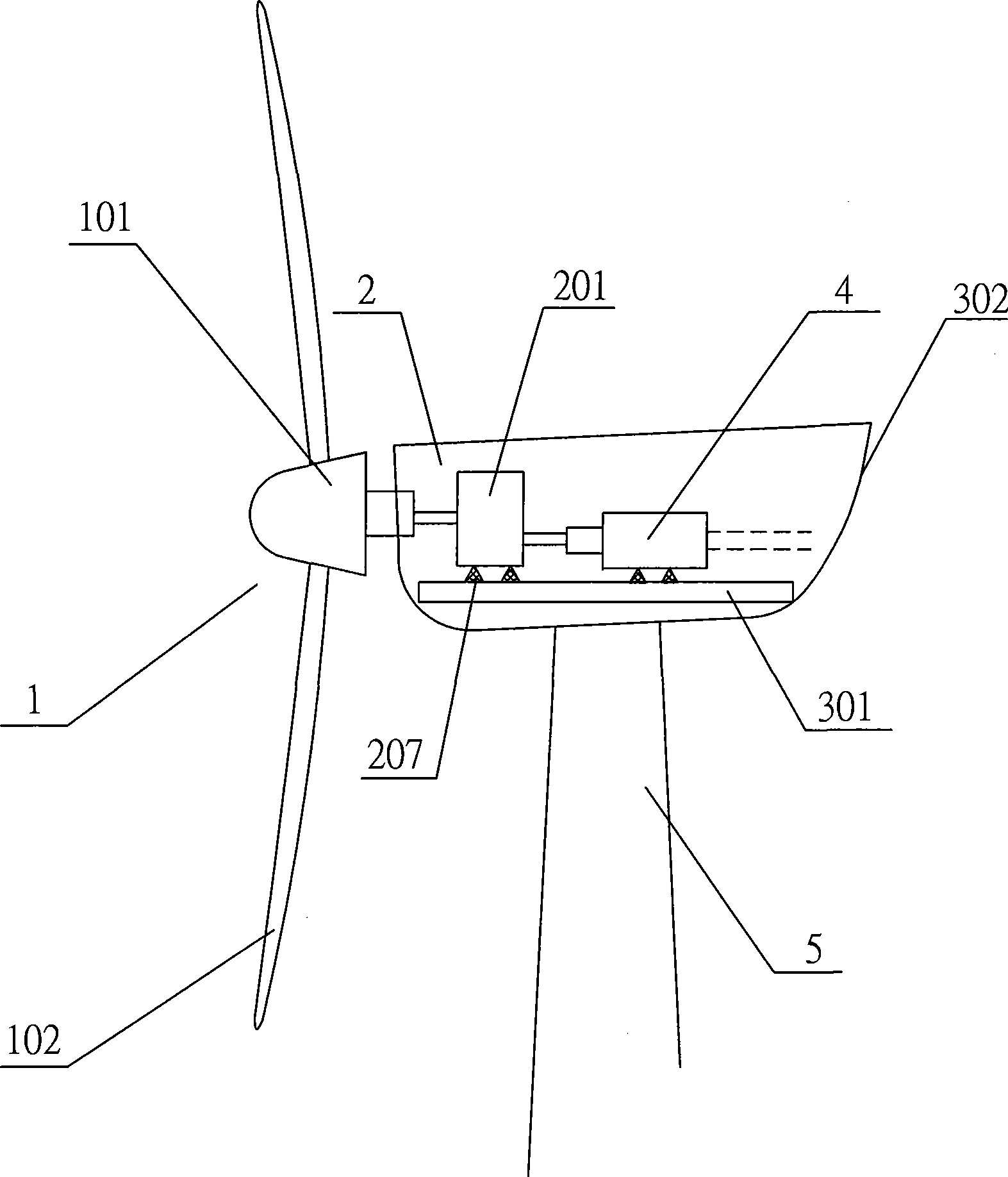

[0018] refer to figure 1 And Fig. 2, a kind of wind power generating set that uses bamboo blade, comprises wind turbine system 1, transmission system 2, generator 4 and tower frame 5, the output end of described transmission system 1 is connected generator 4, and described transmission system The system 2 and the generator 4 are installed on the tower 5. The wind turbine system includes a hub 101 and blades 102. The blades 102 are fixedly mounted on the hub 101. The rotating shaft of the hub 101 is connected to the transmission system 2. The input end is connected, and the paddle 102 is a blade of bamboo composite material.

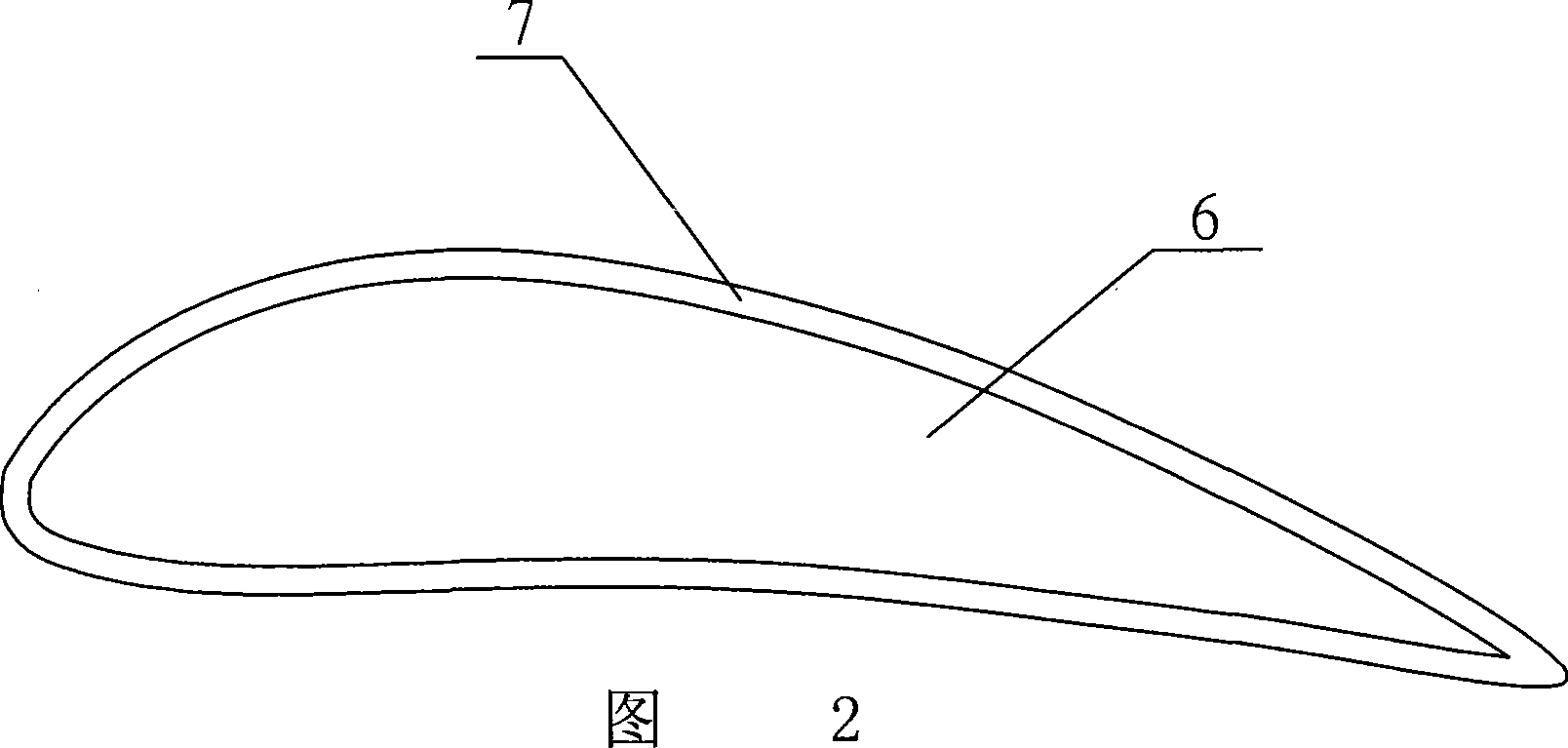

[0019] The paddle 102 includes a bamboo composite material layer 6 and a covering layer 7 , and the covering layer 7 covers the periphery of the bamboo composite material layer 6 .

[0020] A nacelle cover 302 is installed on the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com