Patents

Literature

51results about How to "Reduce stress loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

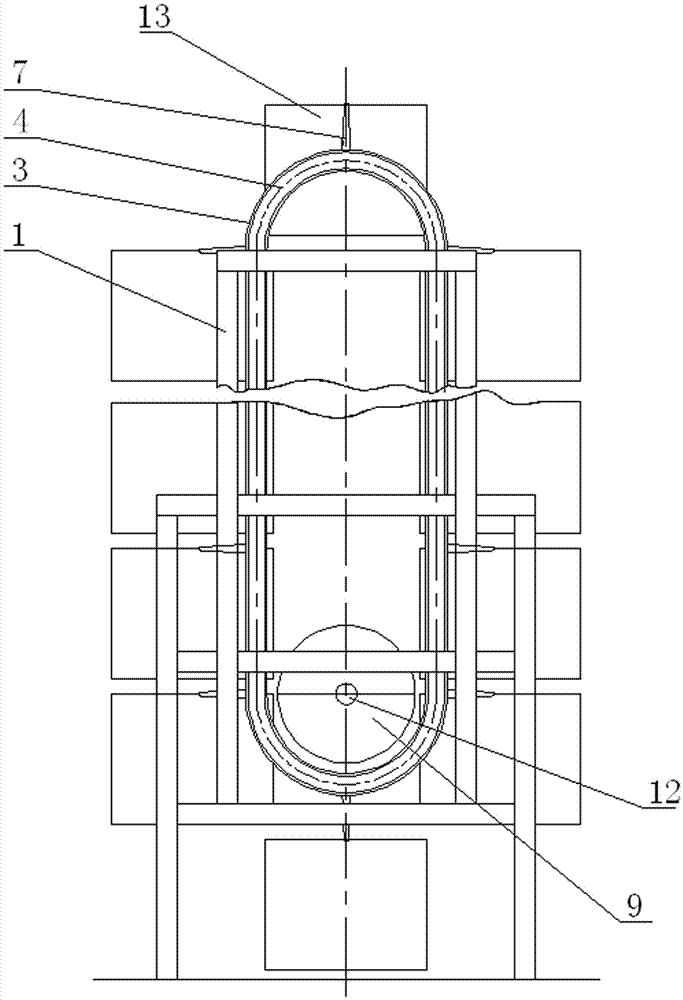

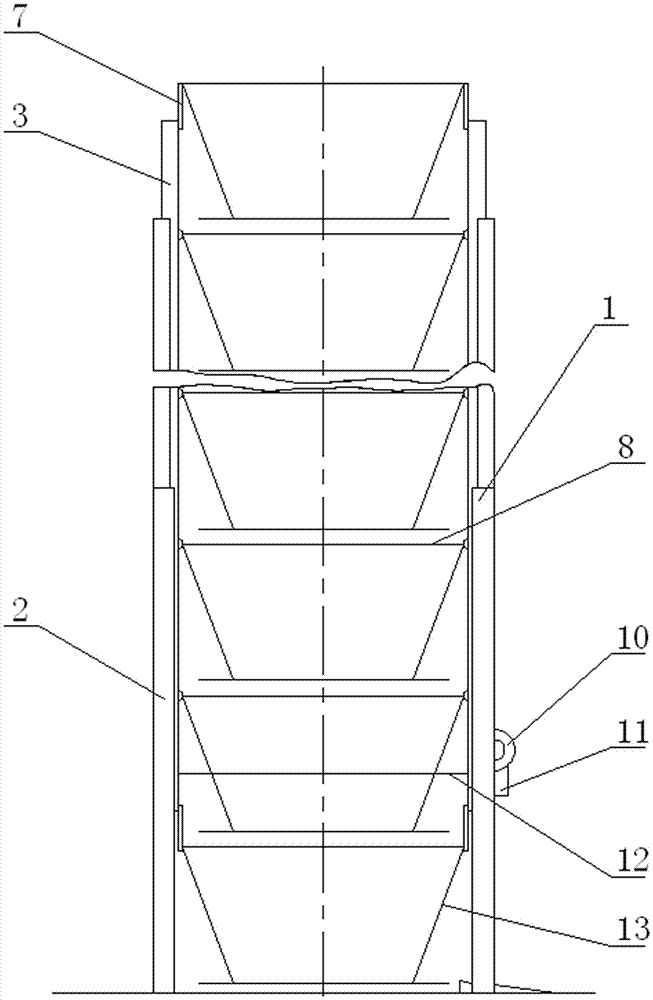

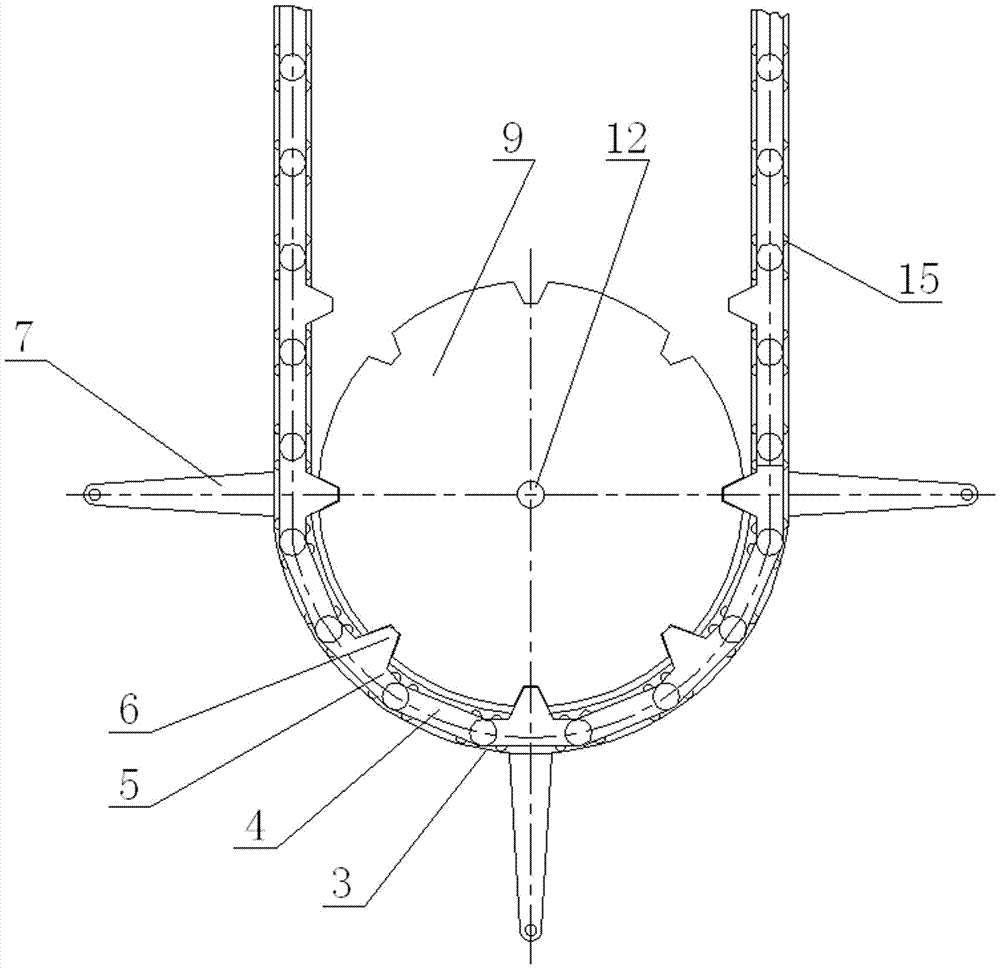

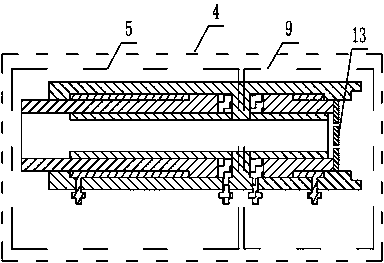

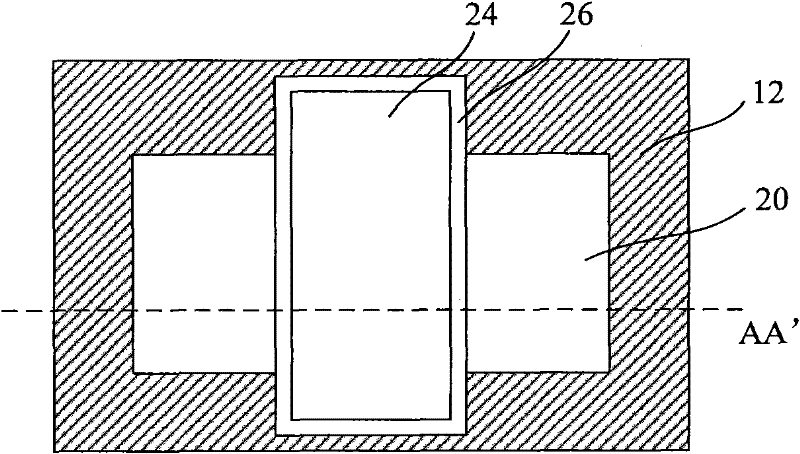

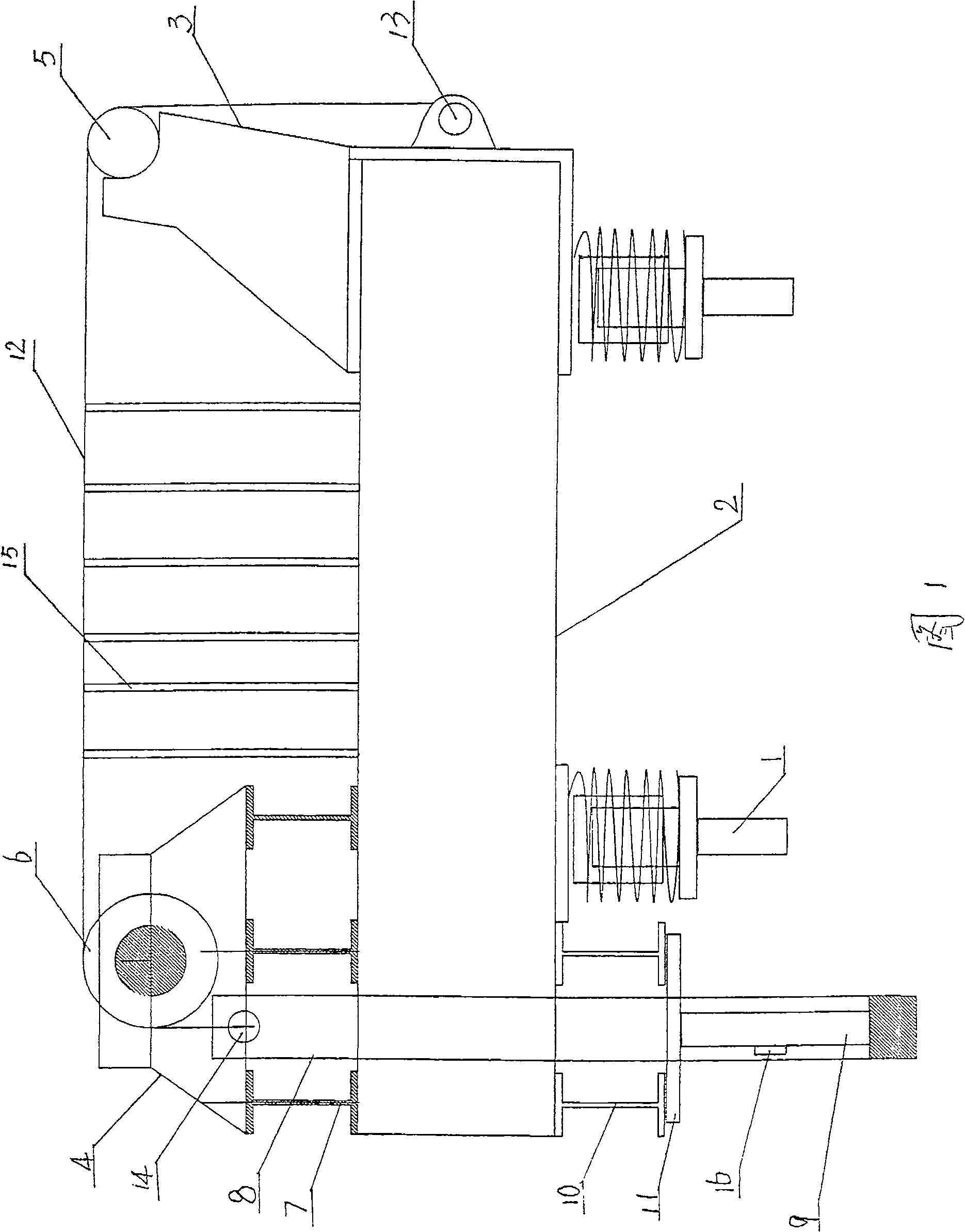

Rail-mounted vertical circulating three-dimensional garage

InactiveCN105442884AAchieve the purpose of accessing the carOutstanding FeaturesParkingsParking spaceEngineering

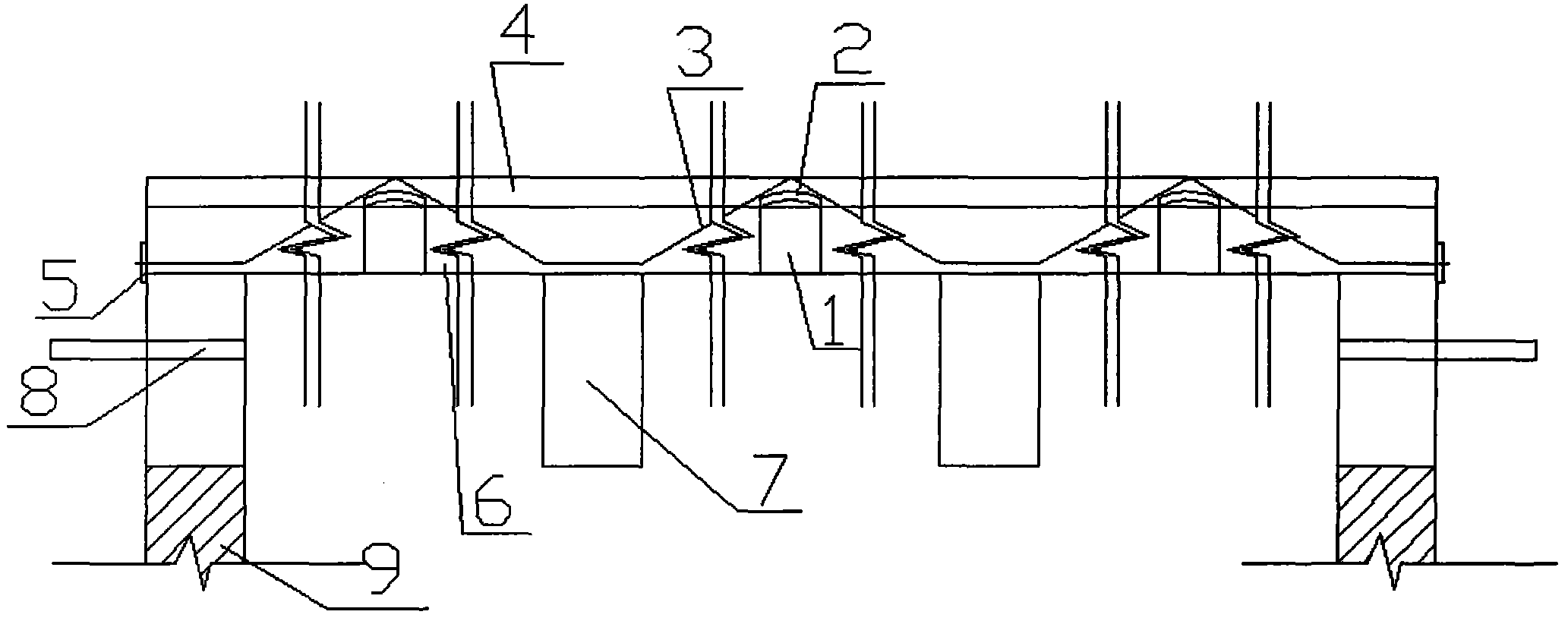

The invention discloses a rail-mounted vertical circulating three-dimensional garage which comprises a body frame, a basket parking unit and a drive chain wheel. The garage is characterized in that the body frame comprises a front frame and a rear frame, the front frame and the rear frame are each provided with a pair of symmetrical chain wheel track grooves in a fastened mode, an idler wheel trolley chain is installed in each chain track groove, the drive chain wheels are symmetrically installed below the front frame and the rear frame respectively and drive the idler wheel trolley chains respectively to move on the vertical face up and down in a circulating mode, the idler wheel trolley chains drive the basket parking unit to move up and down in a circulating mode, and all the components form the rail-mounted vertical circulating three-dimensional garage. The garage has the advantages of being simple and reasonable in structure, safe, reliable, easy to install, convenient to maintain, small in occupied area, large in parking number, and capable of achieving the purpose of increasing parking lots by improving structural strength of the frame and increasing the structural height.

Owner:何文年

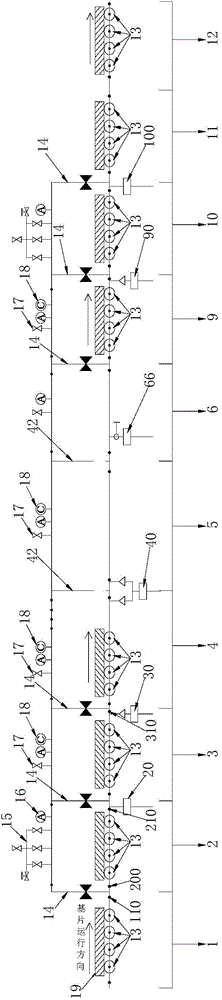

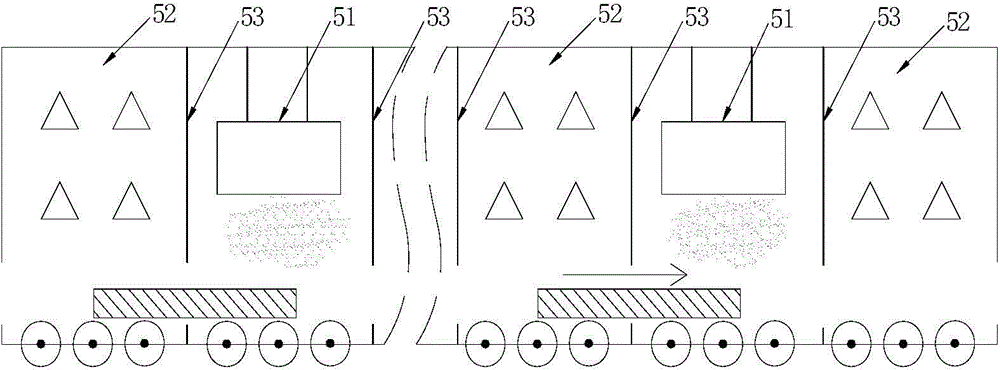

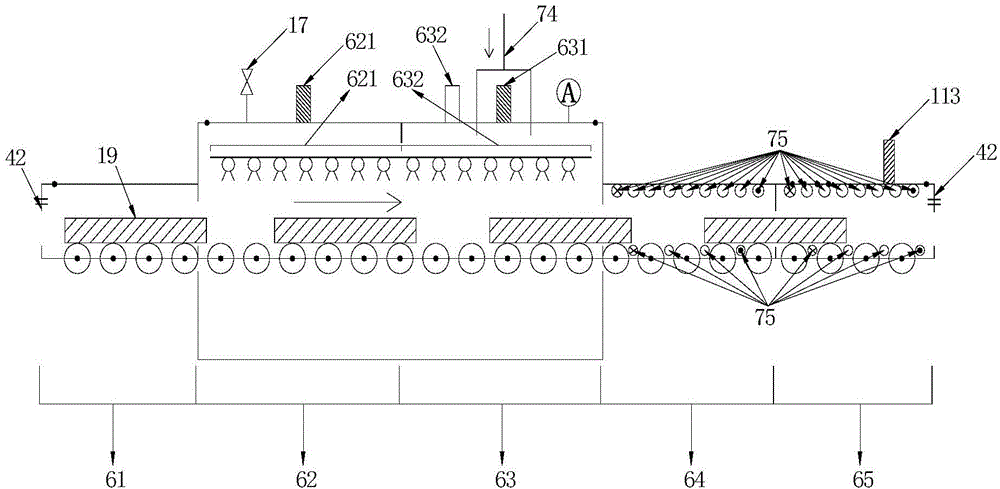

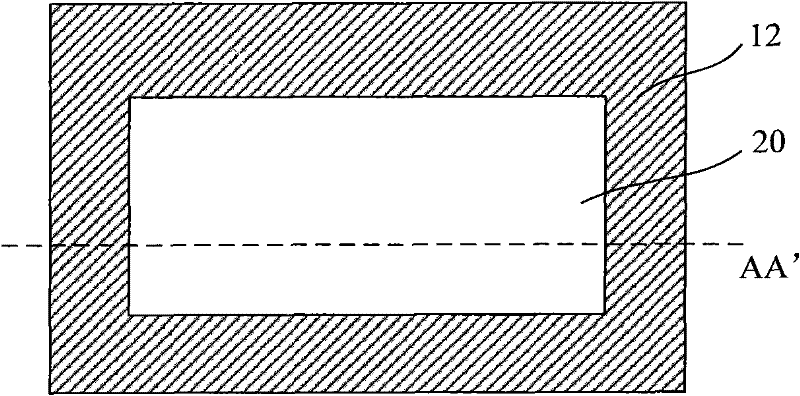

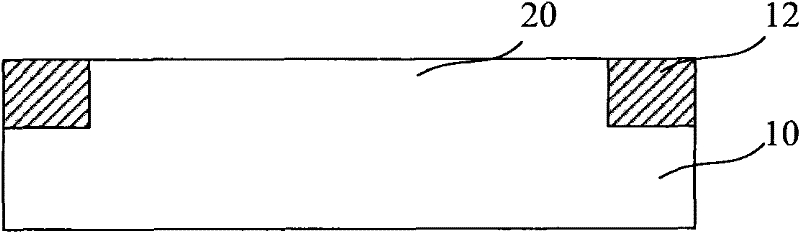

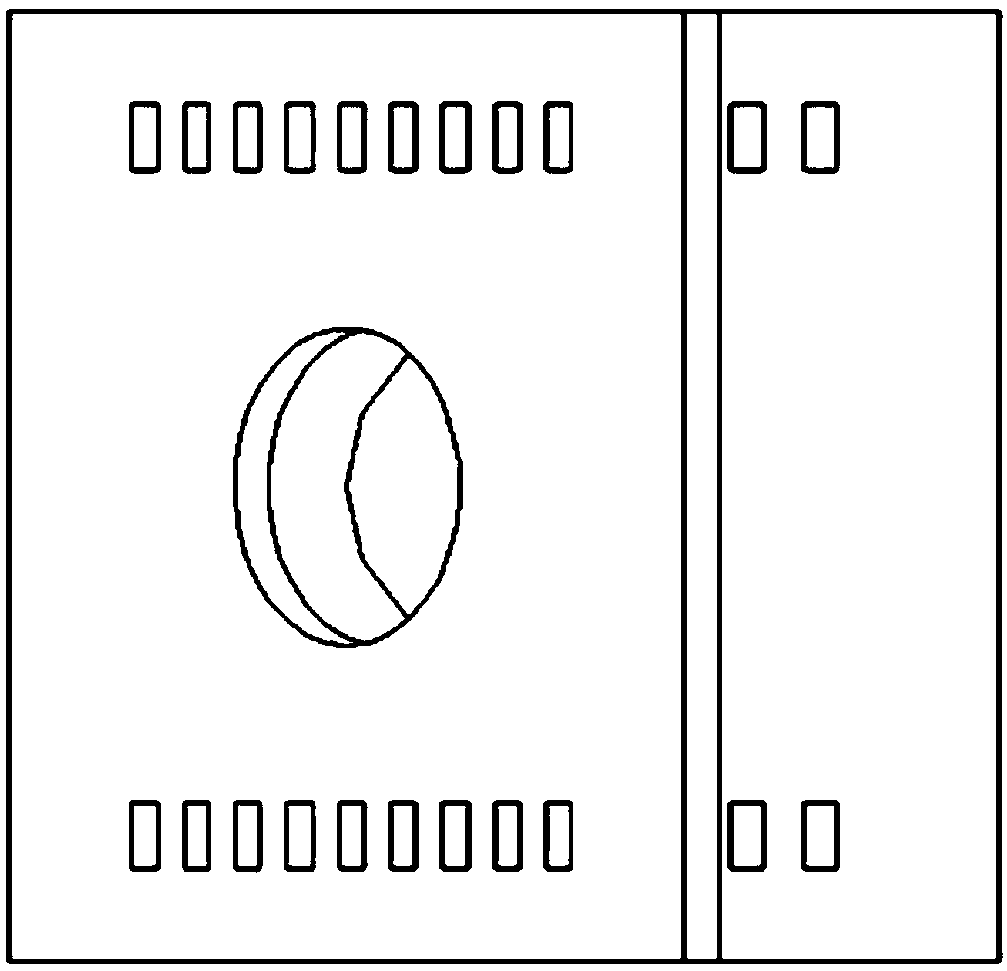

Continuous coating production system of sheet substrates

ActiveCN104060236AReduce stress lossComply with glass safety performance requirementsVacuum evaporation coatingSputtering coatingProduction lineComposite film

The invention discloses a continuous coating production system of sheet substrates. The continuous coating production system comprises a feeding area, a working area and a discharge area, all of which are orderly communicated with each other; the feeding area comprises a sheet feeding table; the working area comprises a plurality of pre-vacuumizing chambers, a first transition chamber, a coating deposition chamber, a quick atmosphere annealing chamber and a plurality of pre-vacuumizing chambers orderly in the coating process flow direction; the discharge area comprises a discharge table; each chamber of the working area is provided with the desired vacuum environment. The continuous coating production system further comprises a transporting device capable of realizing linear transmission; the transporting device penetrates through the whole feeding area, the working area and the discharge area. The continuous coating system has the advantages that the regional continuous film deposition and annealing of a one-layer or multi-layer composite film containing a hot color coating material in the same production line are realized, the production efficiency is obviously improved, and meanwhile, the material loss cost of the material in the off-line annealing process after coating is reduced. Due to unique structural design of the system, the problem of tempering stress loss can be obviously solved; the stress of the tempered glass based smart glass produced by the system is up to the stress standard of the national building energy-saving safety glass, namely greater than or equal to 90Mpa.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

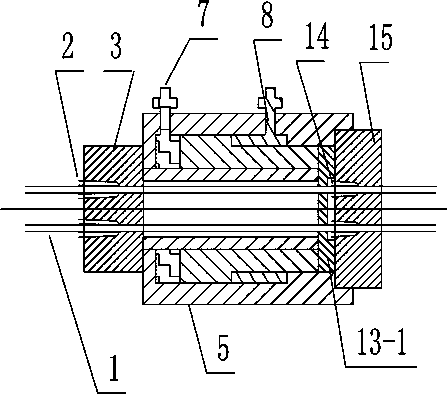

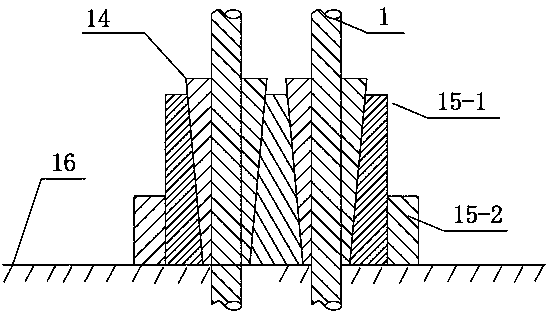

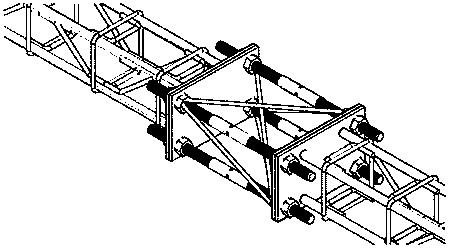

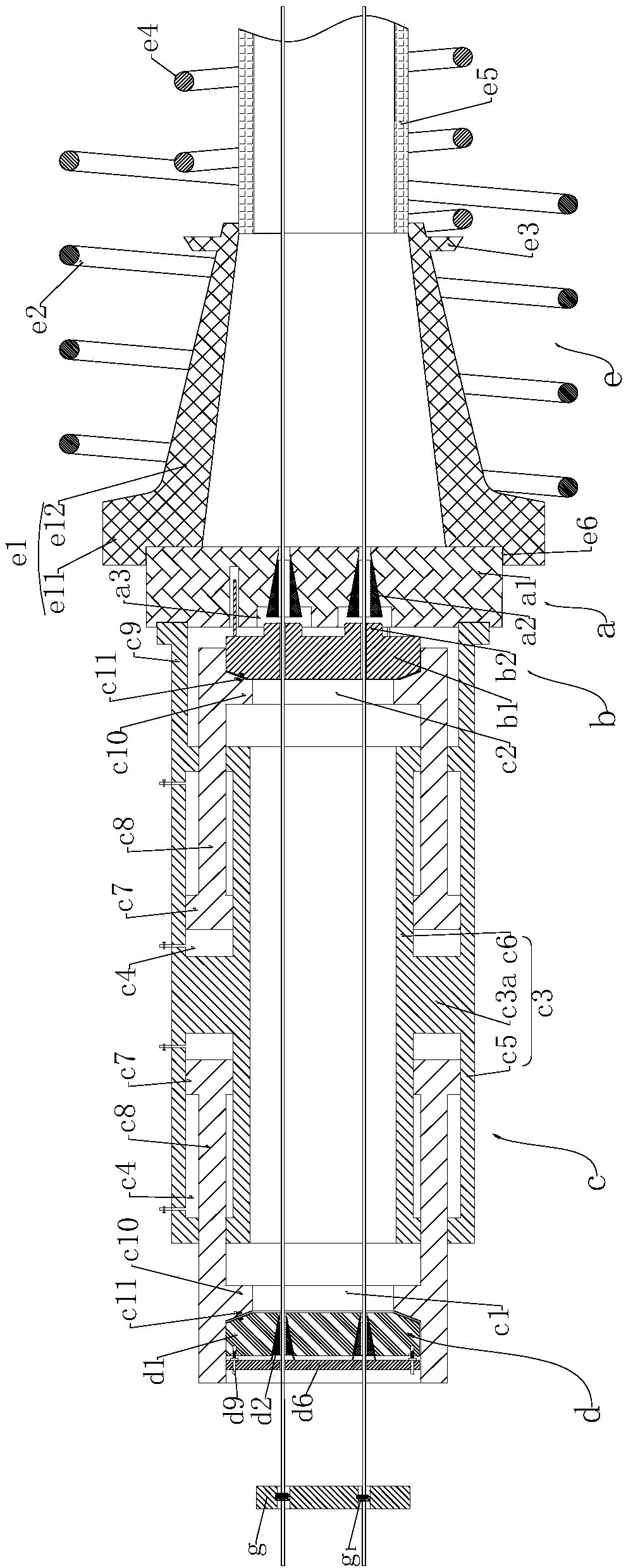

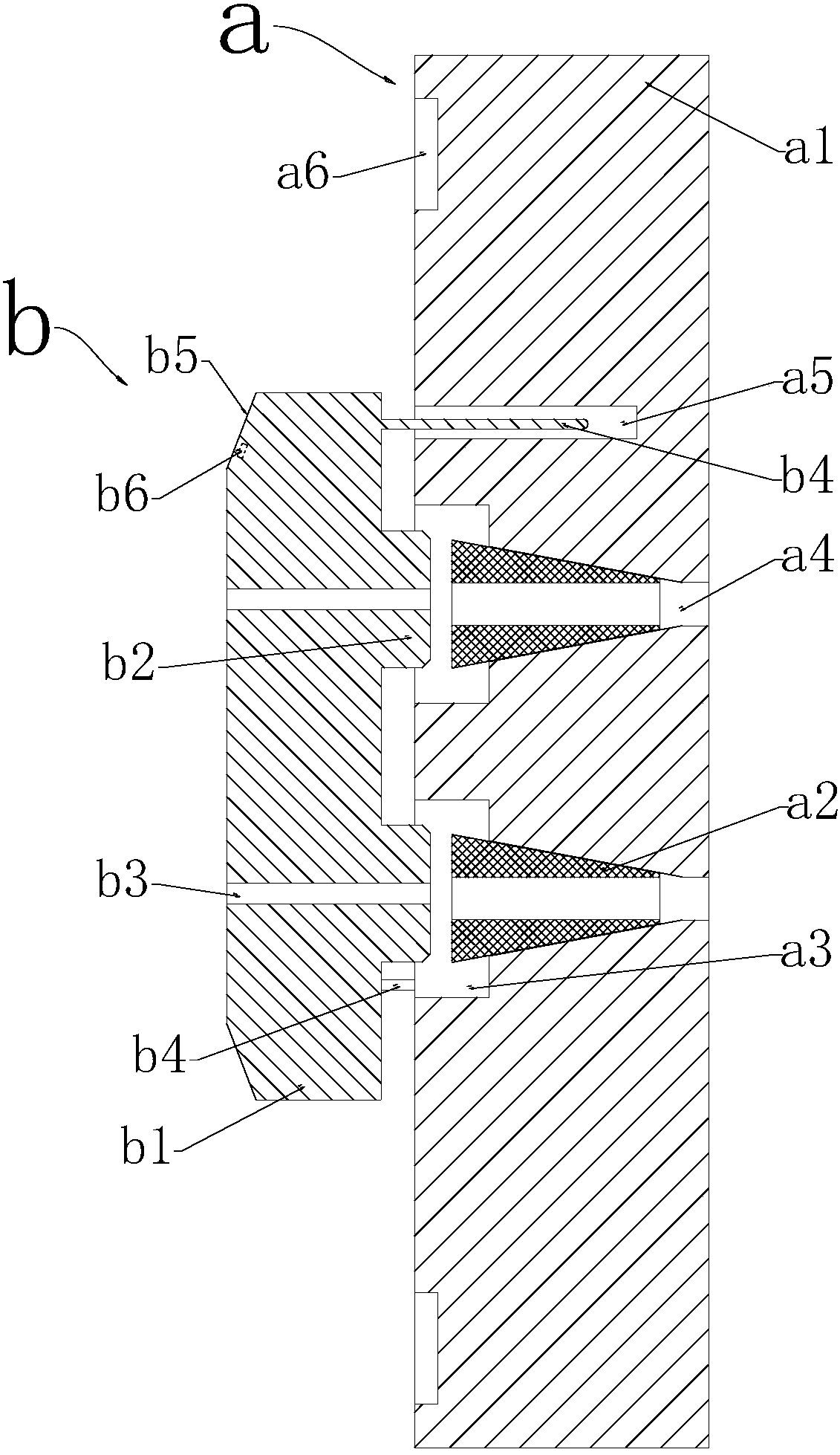

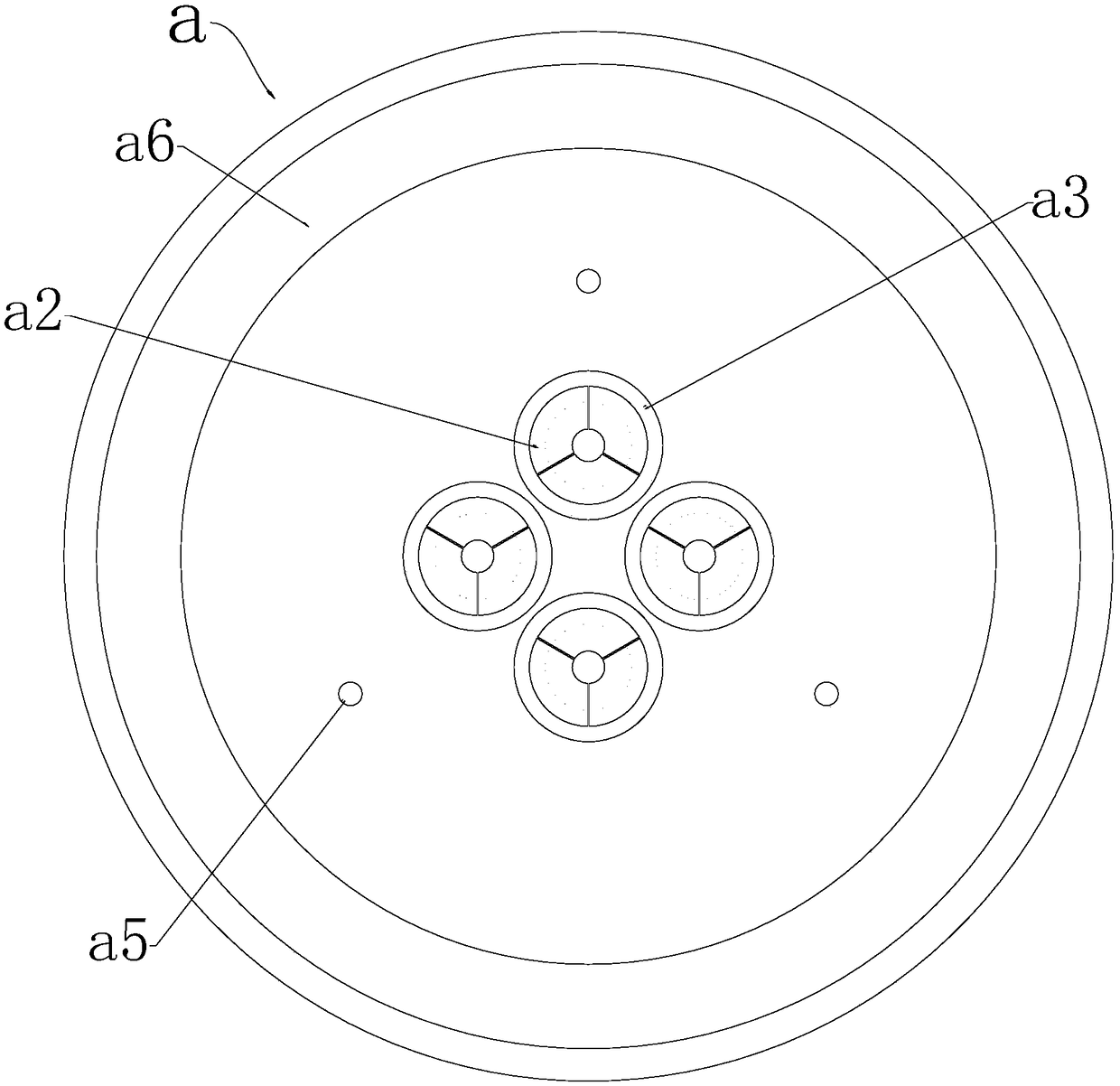

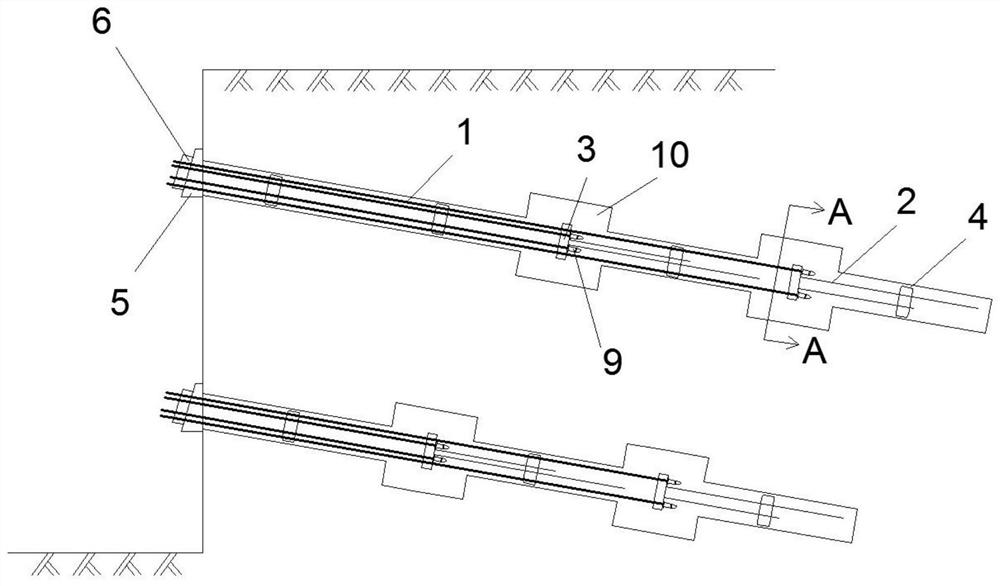

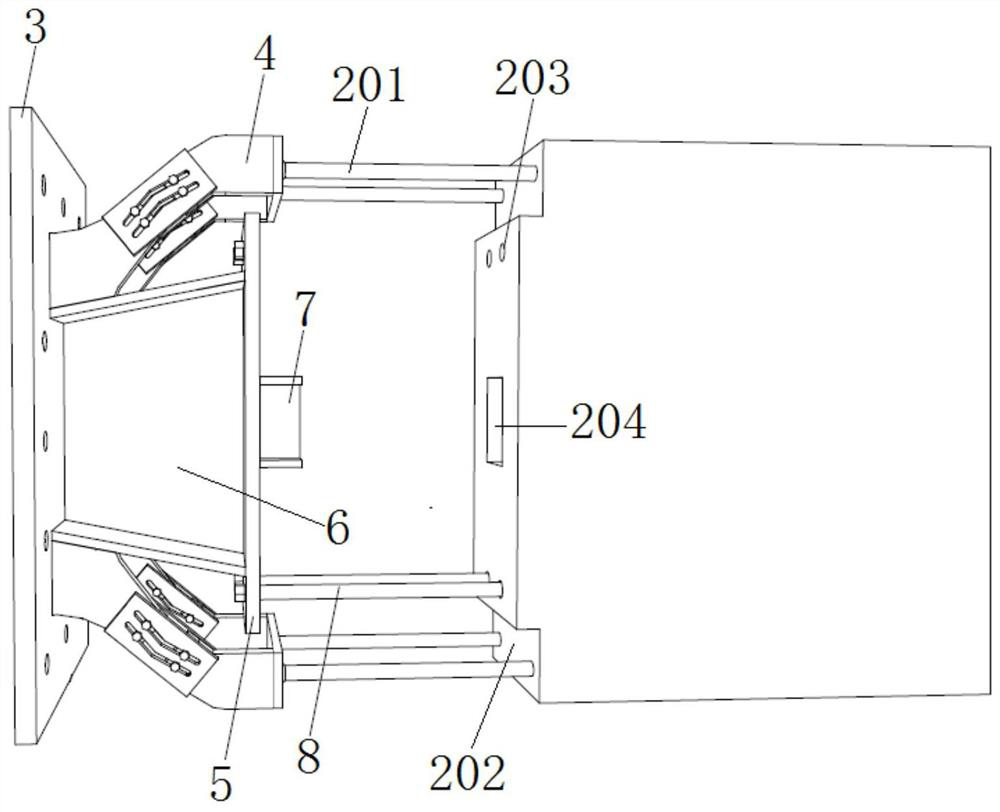

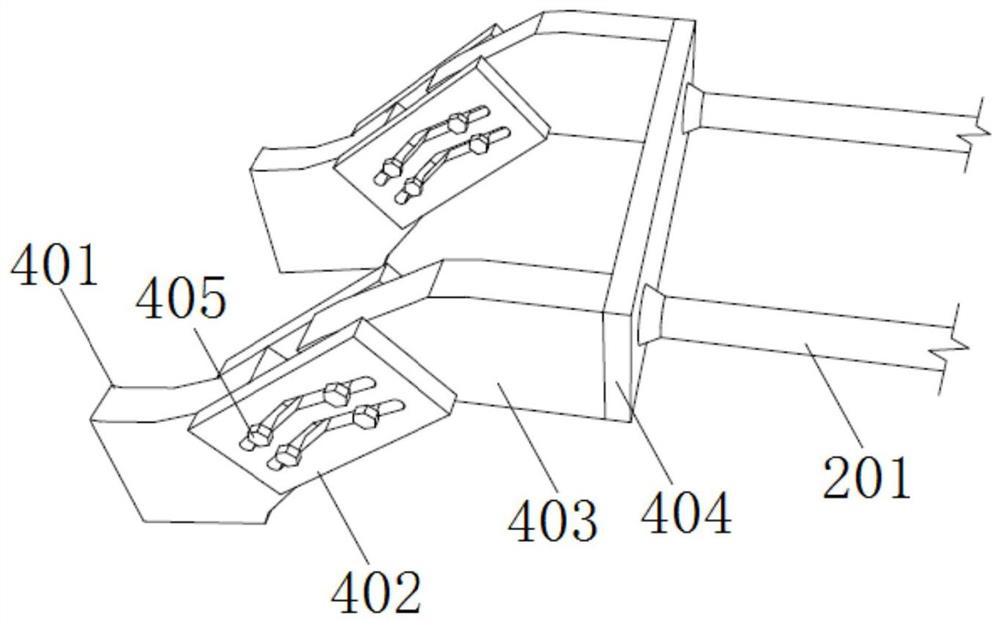

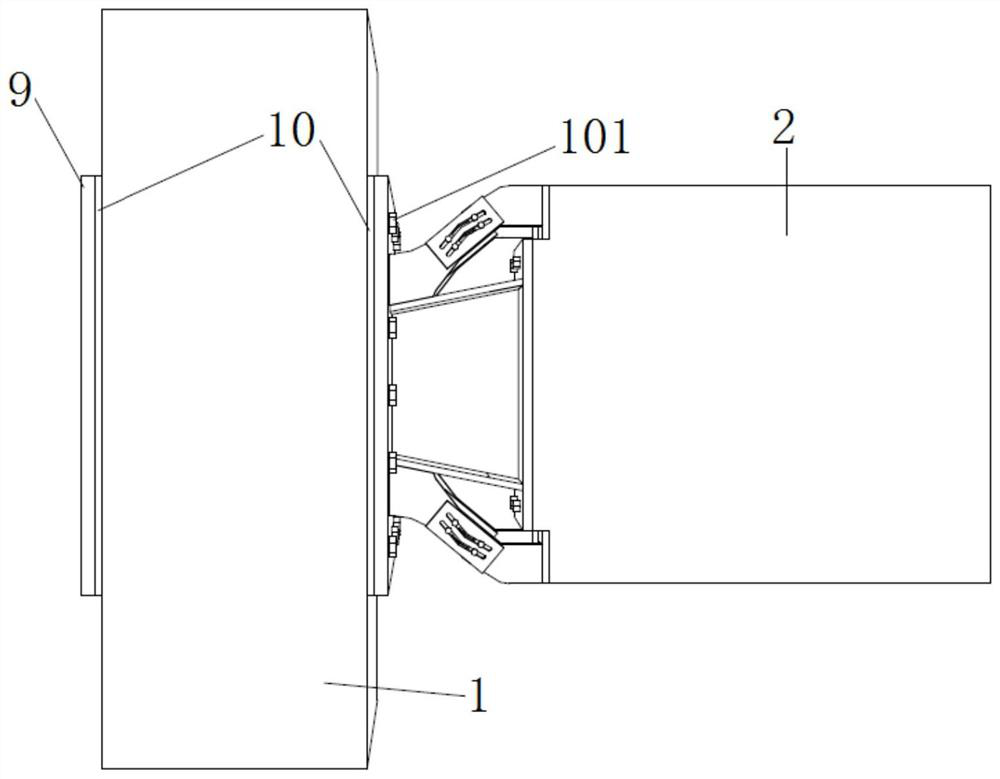

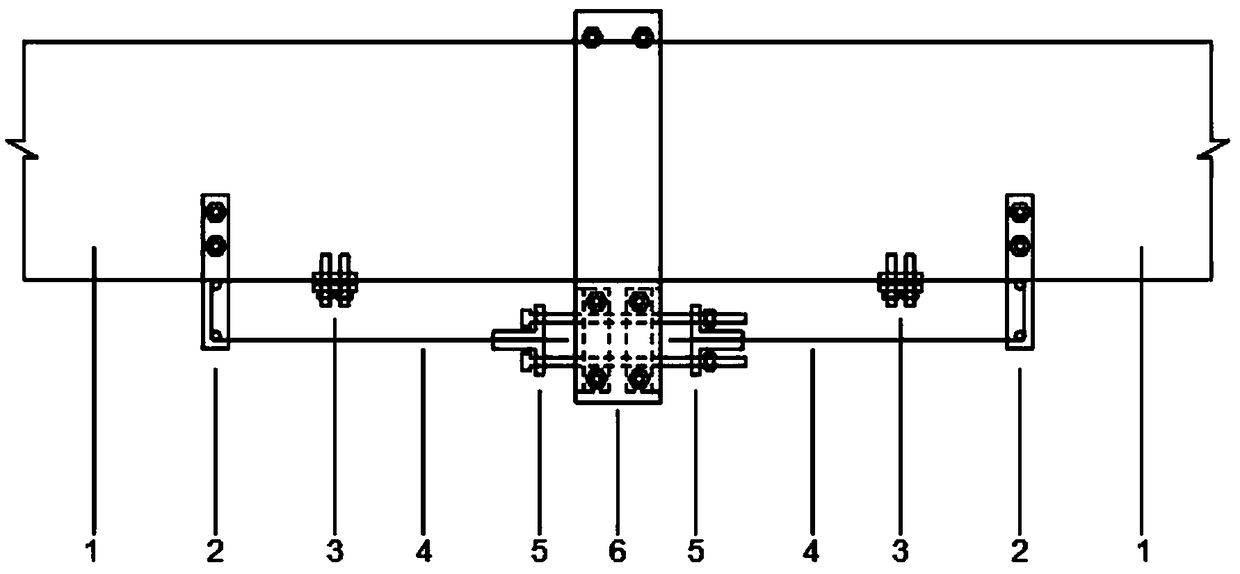

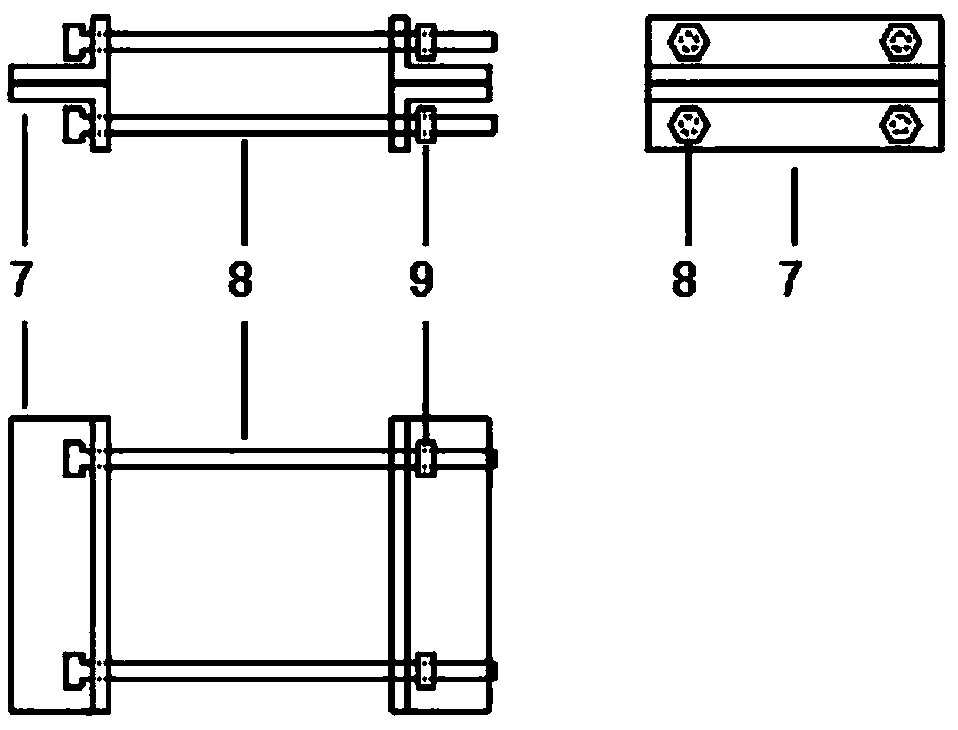

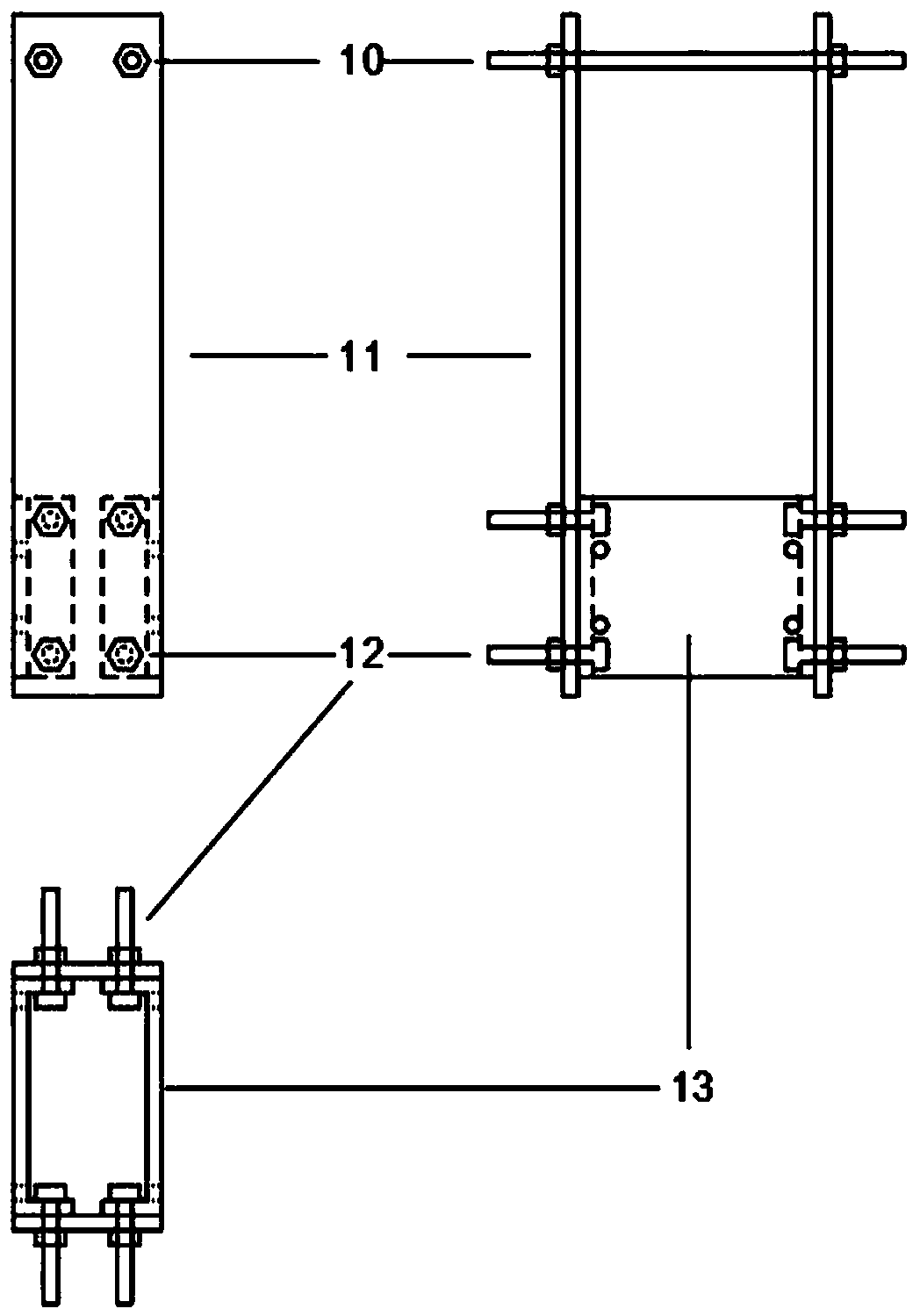

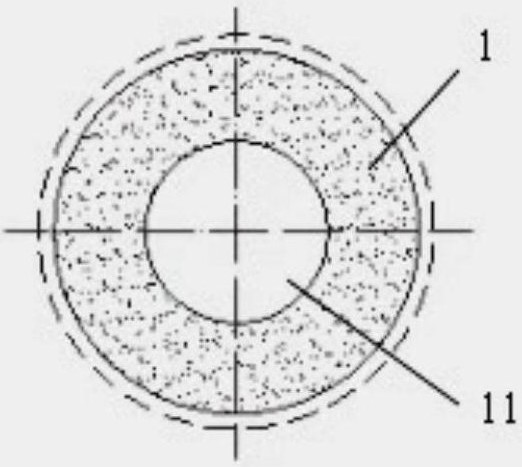

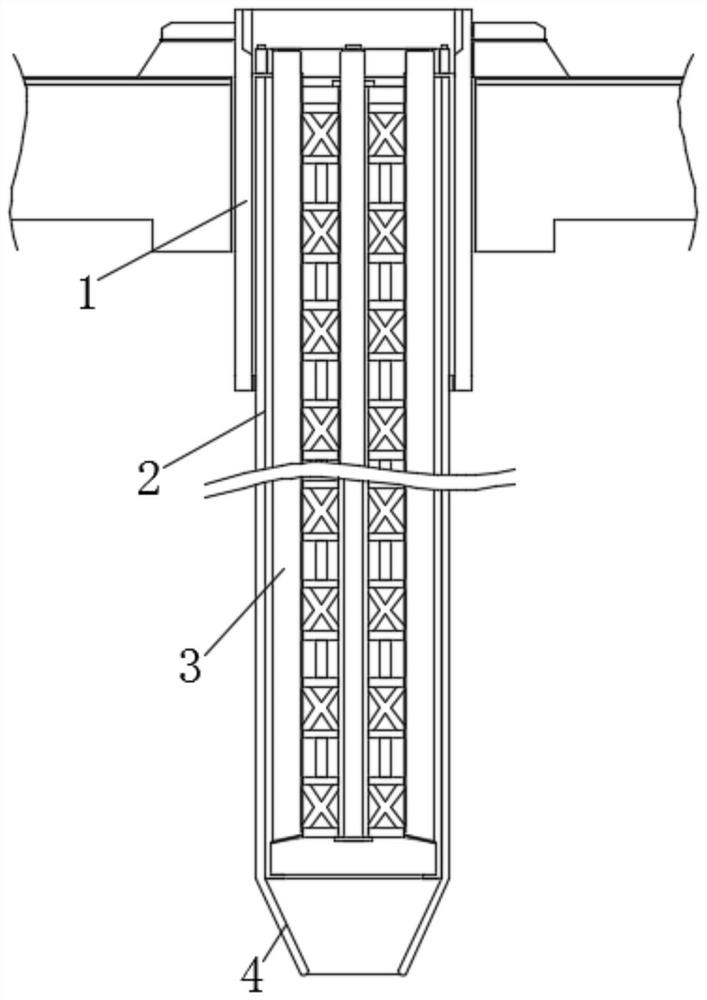

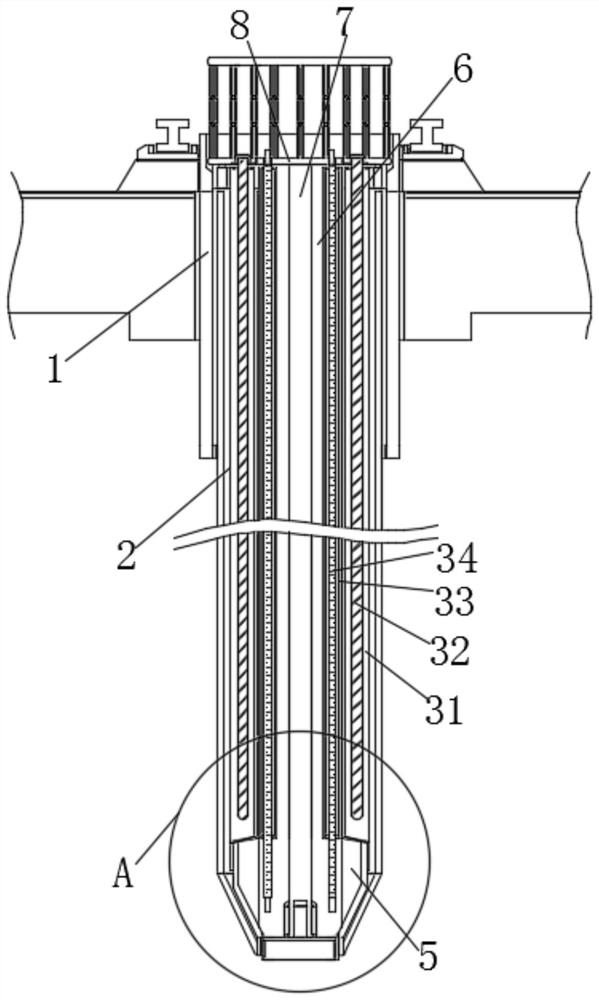

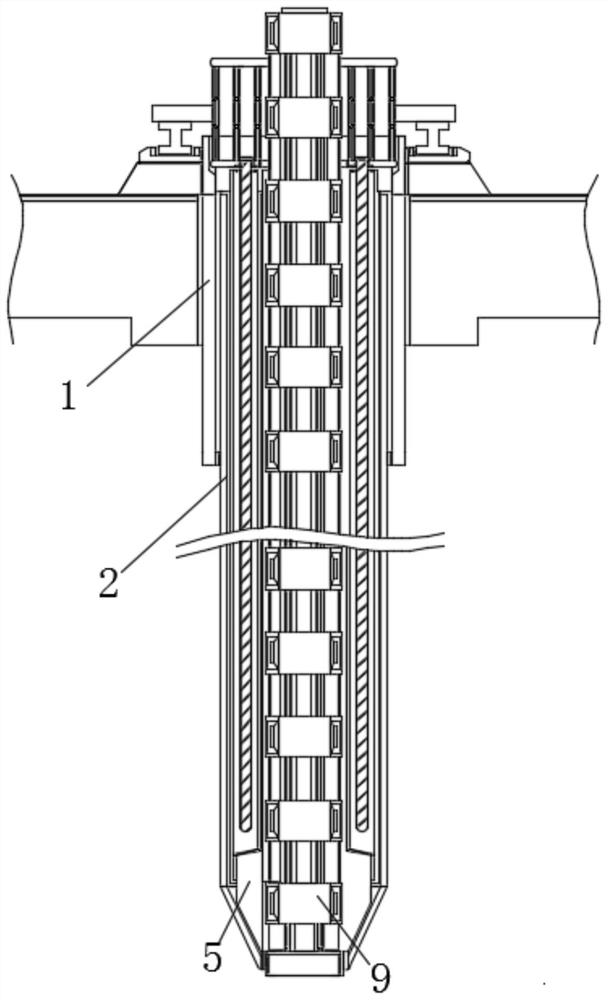

Clip type pre-stress anchor cable active clip feeding and tension locking device and use method

The invention discloses a clip type pre-stress anchor cable active clip feeding and tension locking device and a use method. The clip type pre-stress anchor cable active clip feeding and tension locking device comprises a steel strand, a working anchor, a clip, an anchor matching plate, a tool anchor, a tool anchor clip and a jack, and is characterized in that the jack is a composite center hole jack, one end of the composite center hole jack is provided with a tension jack, and the other end of the composite center hole jack is used for locking a clip feeding and locking jack of the steel strand. The use method of the clip type pre-stress anchor cable active clip feeding and tension locking device includes the steps that after the tensioning force reaches a designed value and is stable, a clip feeding piston of the clip feeding and locking jack pushes the anchor matching plate, the anchor matching plate pushes the working anchor clip to move into a conical wedge hole of the working anchor, and therefore a steel strand bundle is actively wedged and locked. The clip type pre-stress anchor cable active clip feeding and tension locking device and the use method have the advantages that the clip feeding and locking jack pushes the corresponding anchor matching plate so as to enable the clip to move towards the wedge hole of the working anchor, the working anchor clip is wedged into the wedge hole of the working anchor while thrust of the clip feeding and locking jack increases, and therefore the steel strand bundle is clamped tightly; in this way, the steel strand can not be drawn back, the loss value of pre-stress does not need to be estimated, operation is more accurate, and errors are smaller.

Owner:SHANDONG ZHENGYUAN CONSTR ENG +1

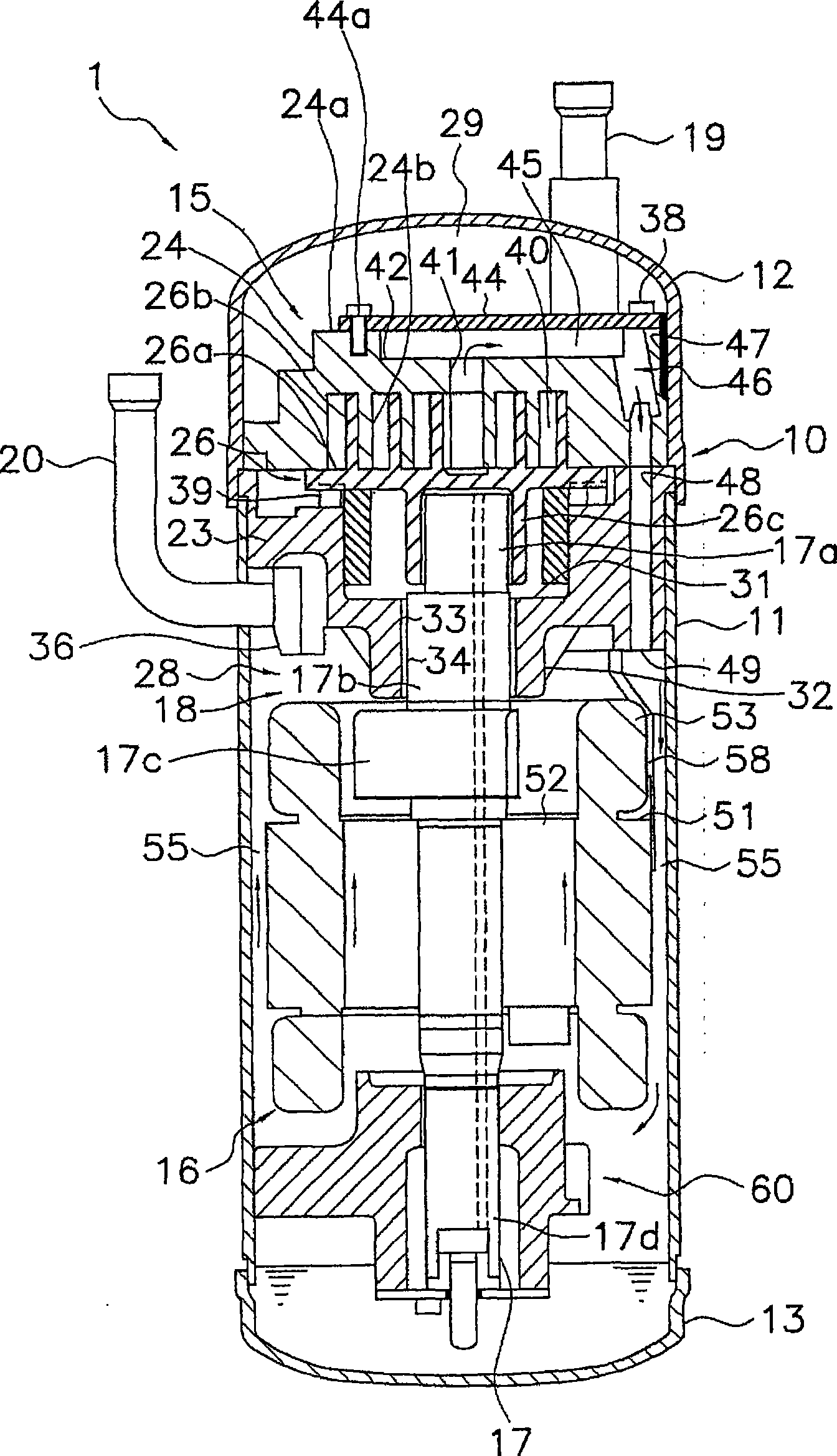

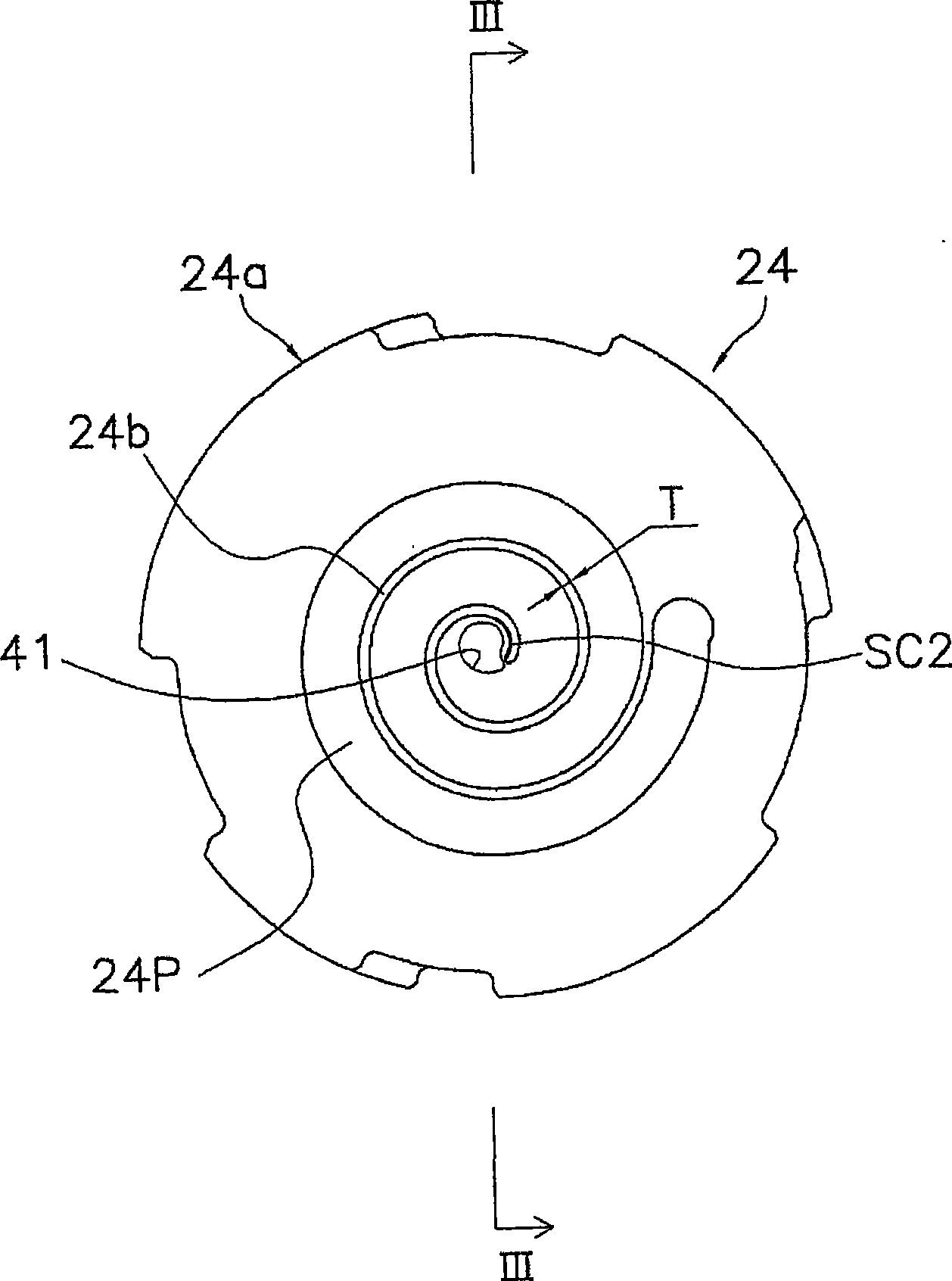

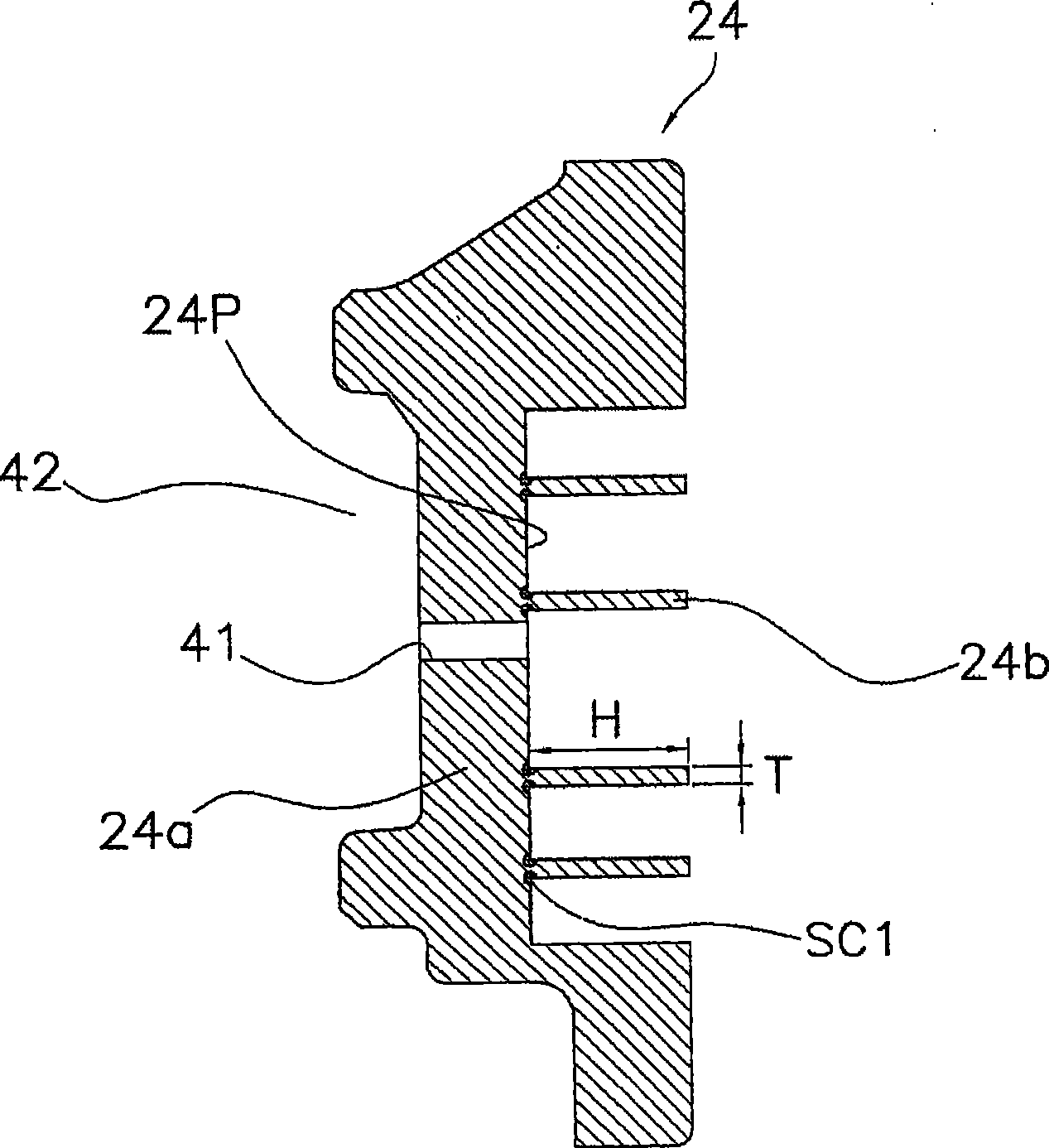

Sliding component of compressor, sliding component base, scroll component, and compressor

ActiveCN101395377AHigh tensile strengthFull durabilityRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsHardnessEngineering

Owner:DAIKIN IND LTD

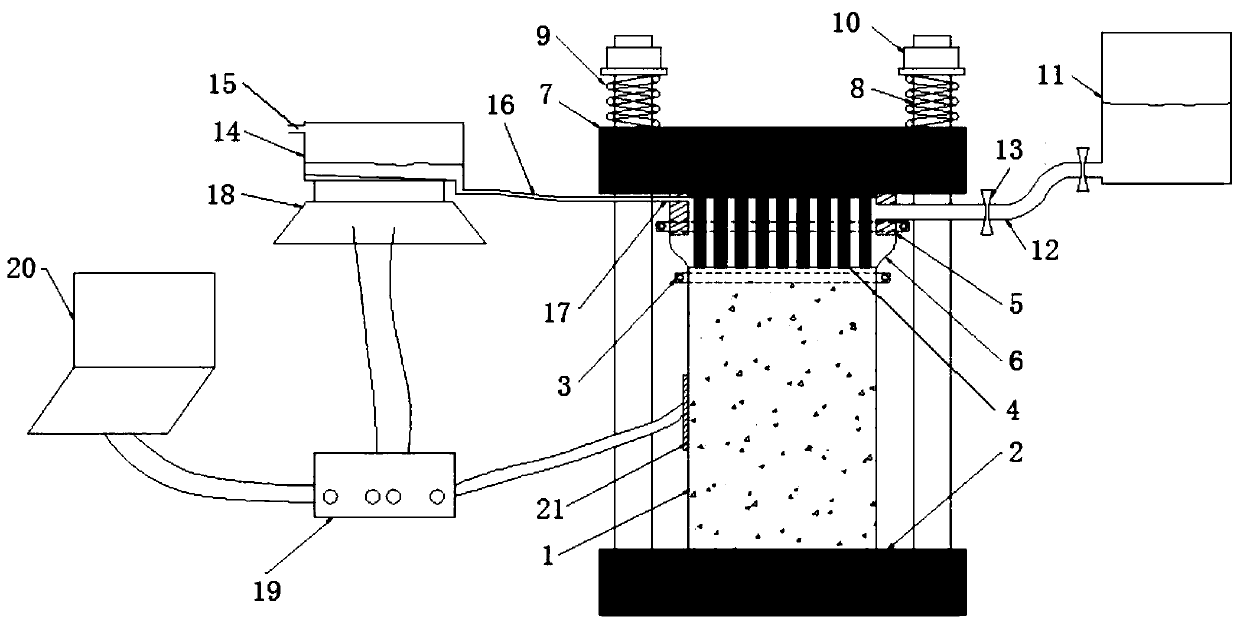

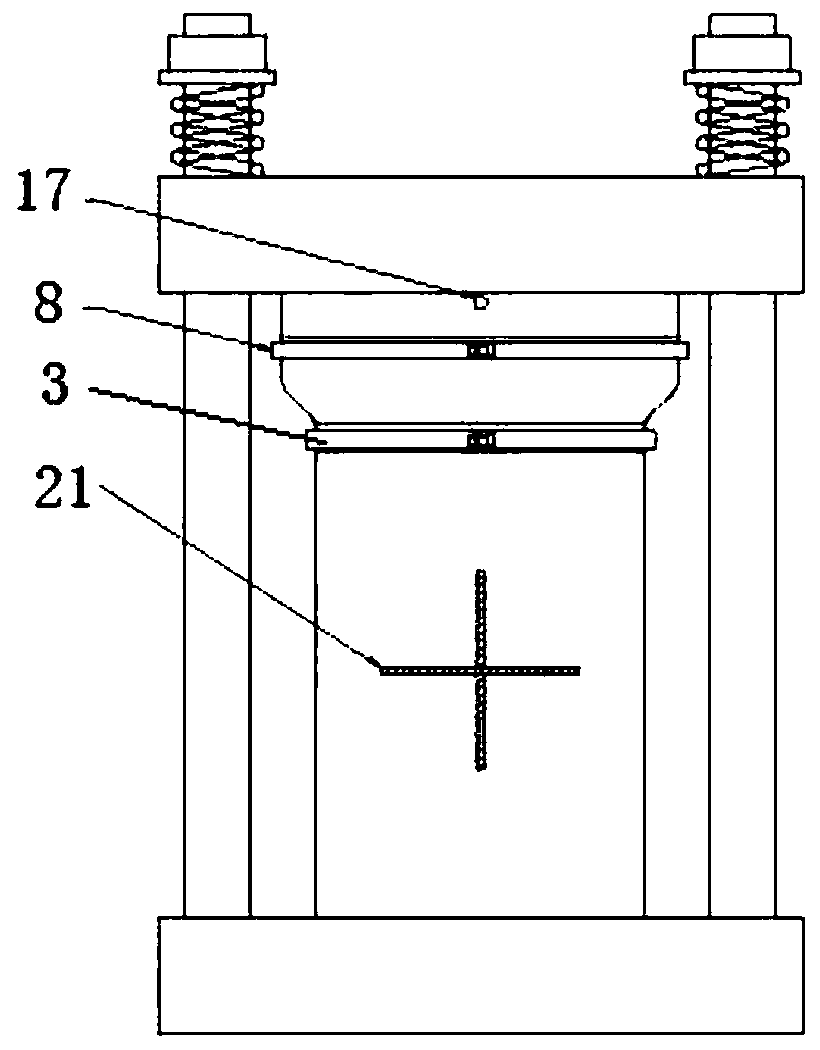

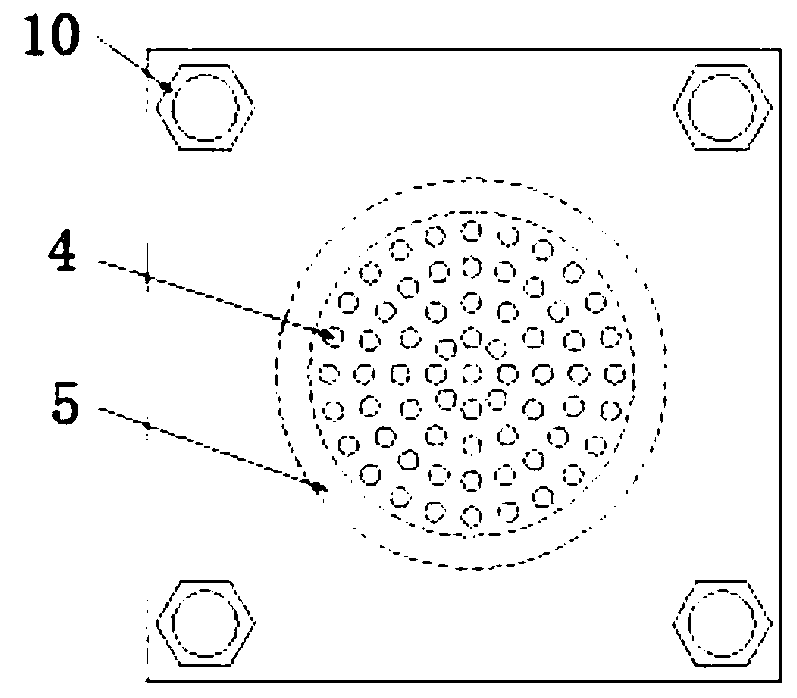

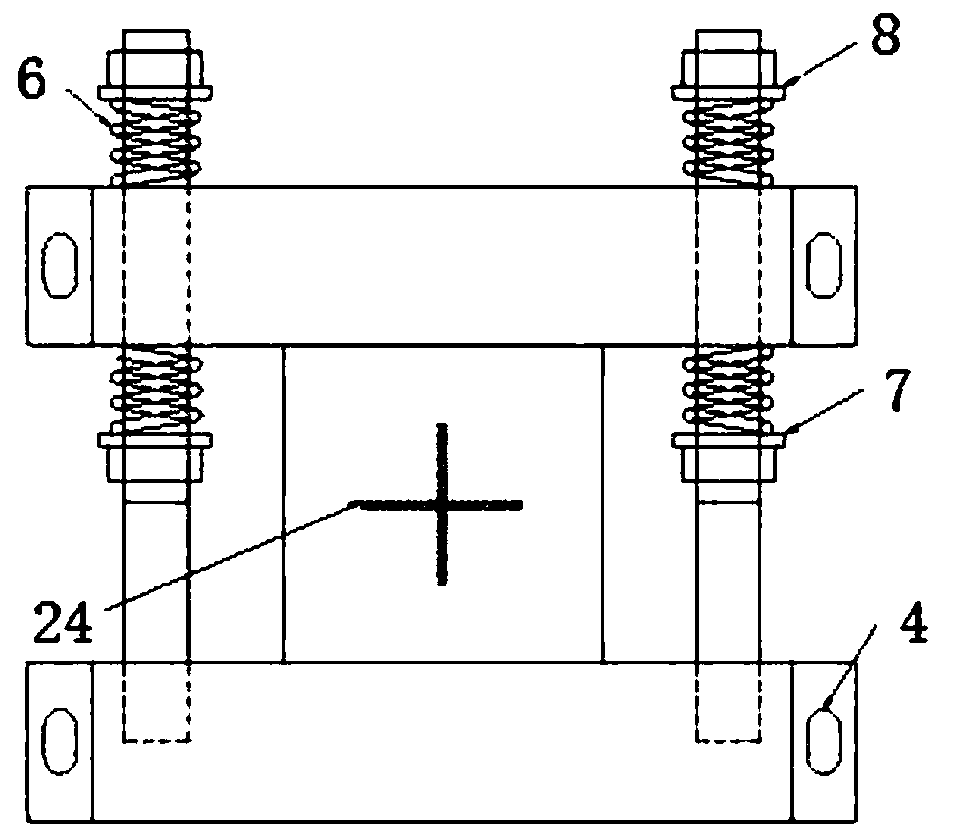

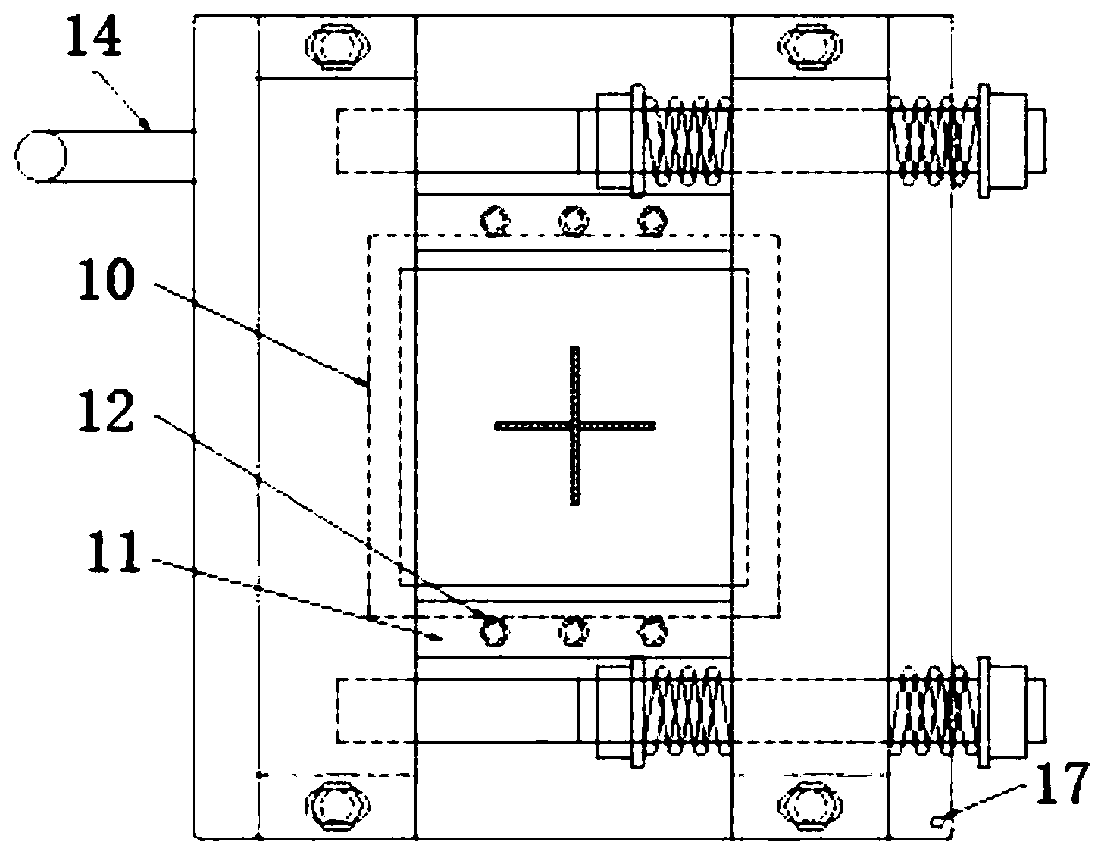

Concrete water absorption rate testing device in parallel sustained load direction

ActiveCN109813626AReduce stress lossHigh precision measurement requirements to reduce capillary water absorptionWeighing by removing componentMaterial strength using tensile/compressive forcesWater storage tankData acquisition

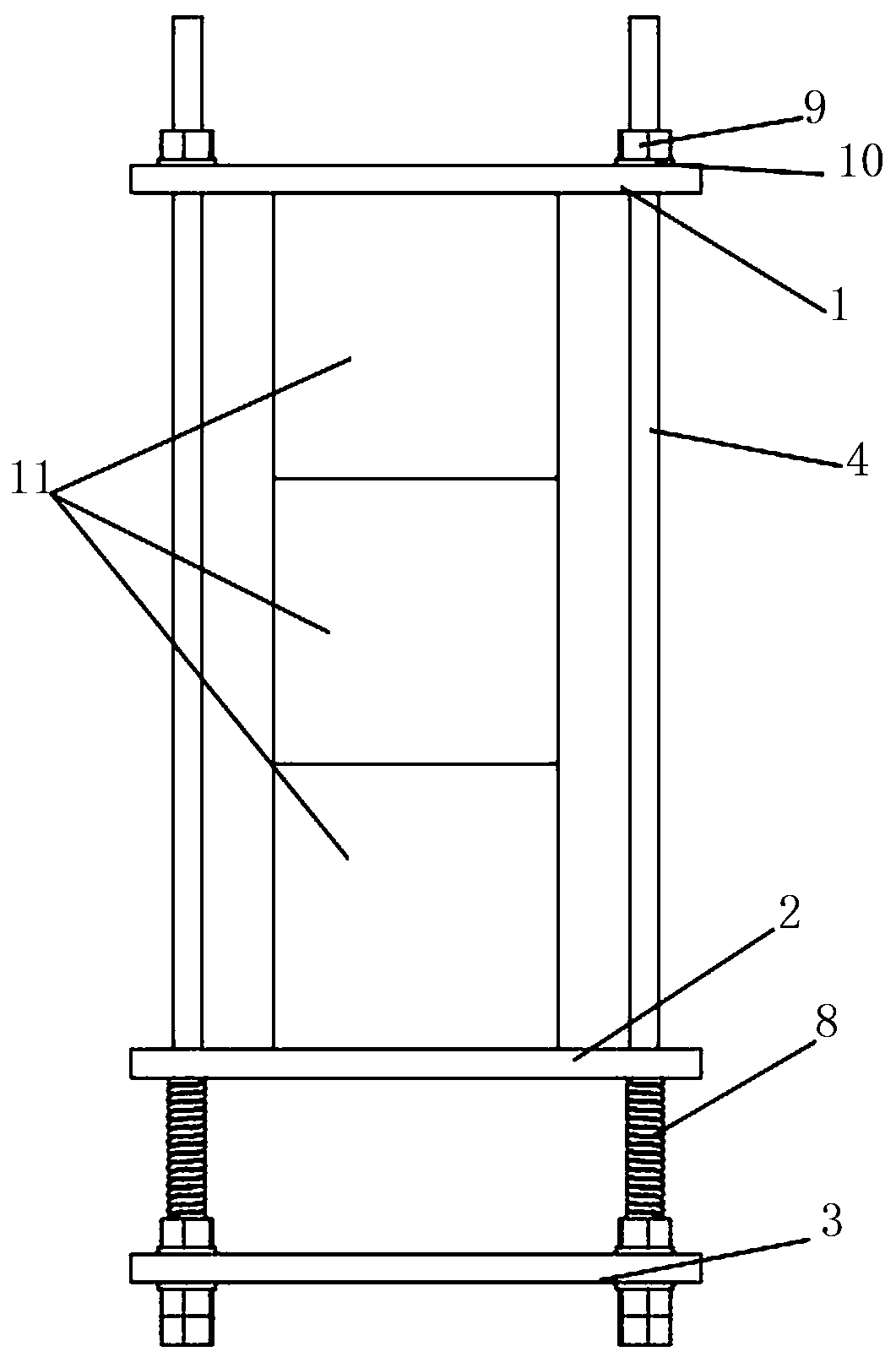

The invention belongs to the technical field of concrete material durability detection equipment, in particular to a concrete water absorption rate testing device in a parallel sustained load action direction. A main body structure comprises a concrete test piece, a lower steel plate, a steel hoop, a steel cylinder group, an annular plate, a silica gel tube, an upper steel plate, a threaded rod, aspring, a nut, a water supply tank, a water injection pipe, a water injection valve, a water storage tank, an air pressure balance hole, a silica gel hose, a water outlet pipe, a mass sensor, a multi-channel data acquisition device, a computer and a strain gauge. The concrete test piece is loaded by using the steel cylinder group so as to realize a concrete water absorption amount test in the parallel sustained load direction, the surface water absorption rate of concrete in the parallel sustained load direction is measured while a continuous load action is applied; the coupling problem of the load action and the concrete water absorption process in the parallel sustained load direction can be solved, and a foundation is laid for researching a concrete adsorption influence mechanism and change rule of the sustained load direction; the device is simple in structure, easy and convenient to operate and friendly in application environment.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

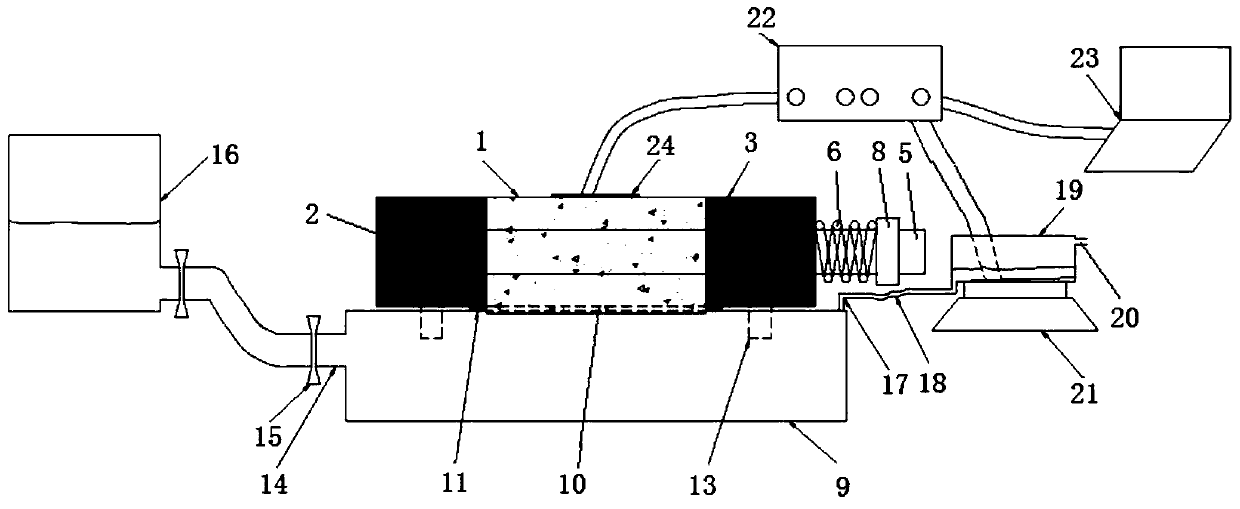

Real-time monitoring device of concrete capillary water absorption rate under load

ActiveCN109781578AReduce stress lossMonitor stress levels in real timeWeighing by removing componentWater storage tankData acquisition

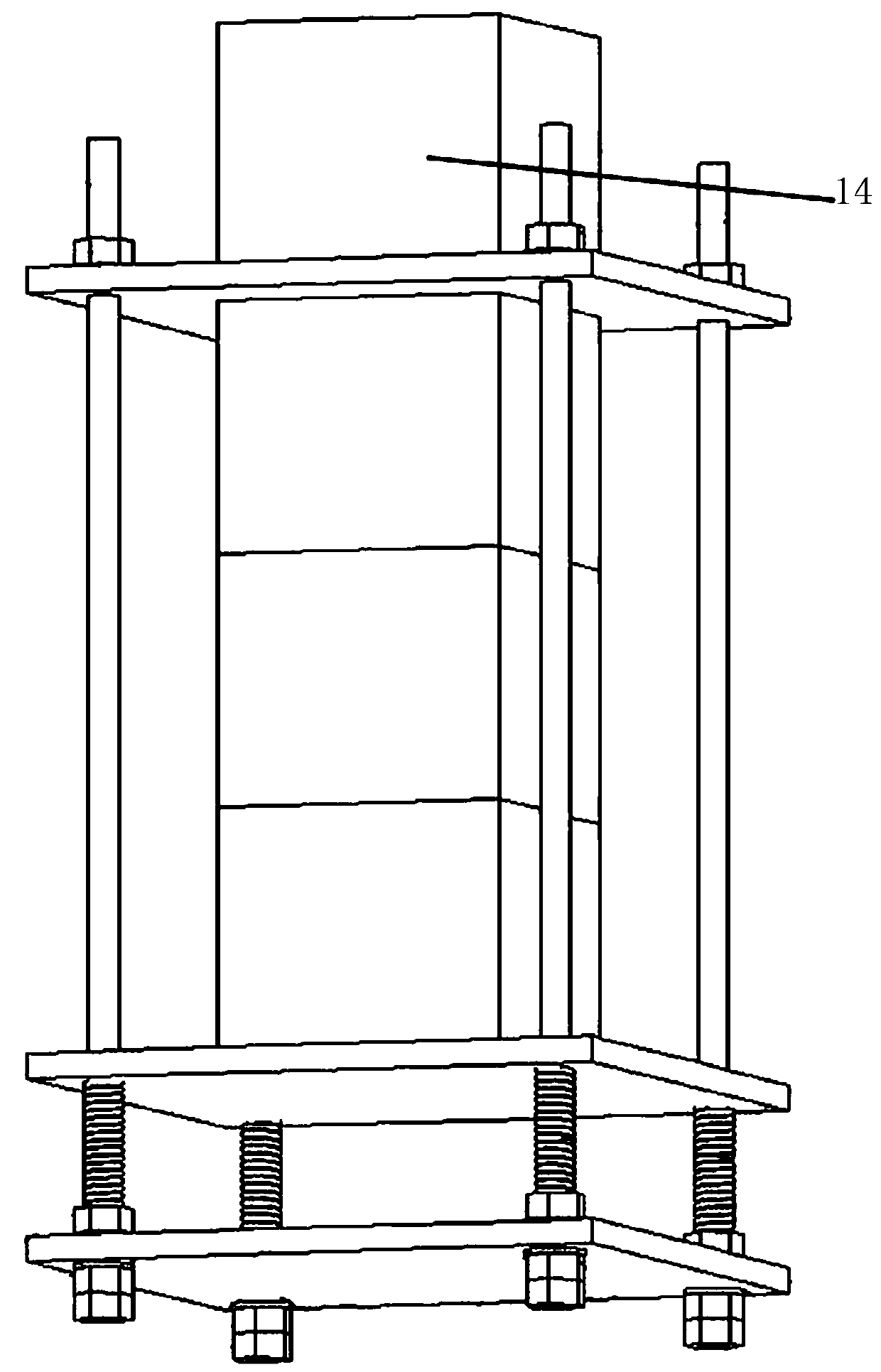

The invention belongs to the concrete material durability monitoring equipment technology field and especially relates to the real-time monitoring device of a concrete capillary water absorption rateunder a load. The main body structure comprises a concrete test piece, a left steel plate, a right steel plate, a preformed hole, a threaded rod, a spring, a pull nut, a pressing nut, a suction box, asealing ring, a cover plate, a number one high strength bolt, a number two high strength bolt, a water injection pipe, a water injection valve , a water supply tank, a water outlet pipe, a silicone hose, a water storage tank, an air pressure balance hole, a mass sensor, a multi-channel data collector, a computer and a strain gauge. Force transmission is performed among the right steel plate, thepull nut and the pressing nut through a spring, and the mass sensor is connected with the computer. The mass reduction amount of the water storage tank and the change rule of time can be transmitted to the computer in real time and a concrete test piece cumulative water absorption curve can be drawn in real time. The capillary water absorption of a concrete test piece is tested continuously in real time, and the high-precision measurement requirements of the capillary water absorption of the concrete test piece under different loads can be realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Stretchable quick stress compensation type steel frame connection structure

The invention discloses a stretchable quick stress compensation type steel frame connection structure used for connecting steel frames in tunnel primary support. The structure is provided with two opposite flange end plates, at least three inner thread connection elements connected with two opposite screws are arranged between the two flange end plates, and the inner thread connection elements are connected with the two screws with opposite thread directions. The structure has the advantages of being convenient to install, good in stability and little in stress loss, and can be used for connecting structural steel frames and grating steel frames in tunnel primary support steel frame stiffening.

Owner:SOUTHWEST JIAOTONG UNIV

Construction method for large-section embedded stiff column base

Owner:HANGZHOU JIANGRUN TECH LIMITED

A kind of semiconductor device and its forming method

ActiveCN102299074AUniform growthReduce gapSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceSemiconductor materials

The invention provides a forming method of a semiconductor device. The method is characterized in that a step of forming source / drain regions comprises the following substeps: determining a junction region and forming an auxiliary layer; with the auxiliary layer, a gate stack structure and isolation regions as masks, removing partial thickness of a semiconductor substrate in an active region to form a groove; and generating semiconductor materials in the groove to fill the groove, wherein the auxiliary layer covers the junction region; and the junction region comprises partial width of activeregion connected with the isolation regions. The invention also provides the semiconductor device. The semiconductor device is characterized in that semiconductor substrate materials are sandwiched between the source / drain regions and the isolation regions. The semiconductor device and the method are beneficial to leakage reduction.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

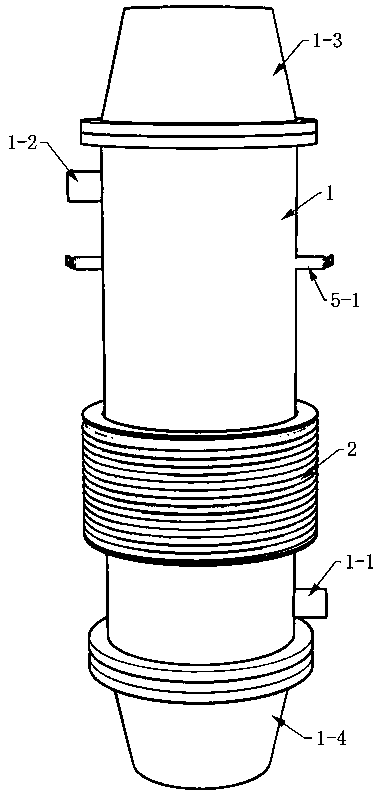

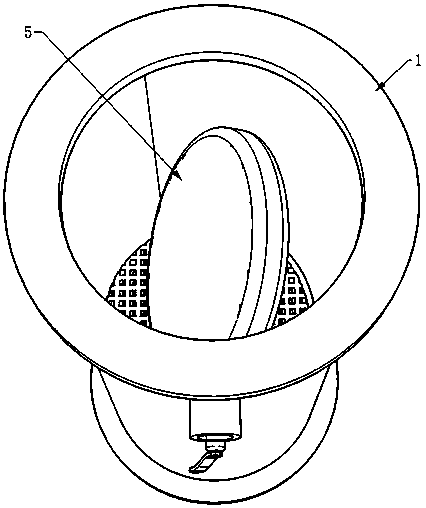

Multi-channel composite electromagnetic filter dust-removing device

PendingCN110141918AFully filteredImprove dust removal efficiencyCombination devicesAirflowMass transfer

The invention discloses a multi-channel composite electromagnetic filter dust-removing device. The device comprises a dust remover cylinder, a coil and a filter layer structure. The device is characterized in that the interior of dust remover cylinder is provided with the filter layer structure, a part, closely attached to the bottom of the filter layer, of the dust remover cylinder is detachablyprovided with a porous filter piece, and a flow limiting plate for controlling airflow flux is arranged in a position located above the filter layer; and the coil is arranged on the periphery of the dust remover cylinder, and the coil covers the outer side position of the filter layer structure. The device provided by the invention can improve dust removal efficiency and improve dust removal effects through a composite dust removal structure; and the device can enhance gas-solid two-phase contact and reduce resistance during mass transfer, and a porous magnetic material in the present application is in a fluidized state in the process of dust removal, so that an influence of bubbling on the mass transfer process is reduced.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

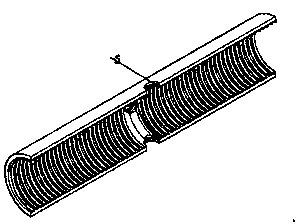

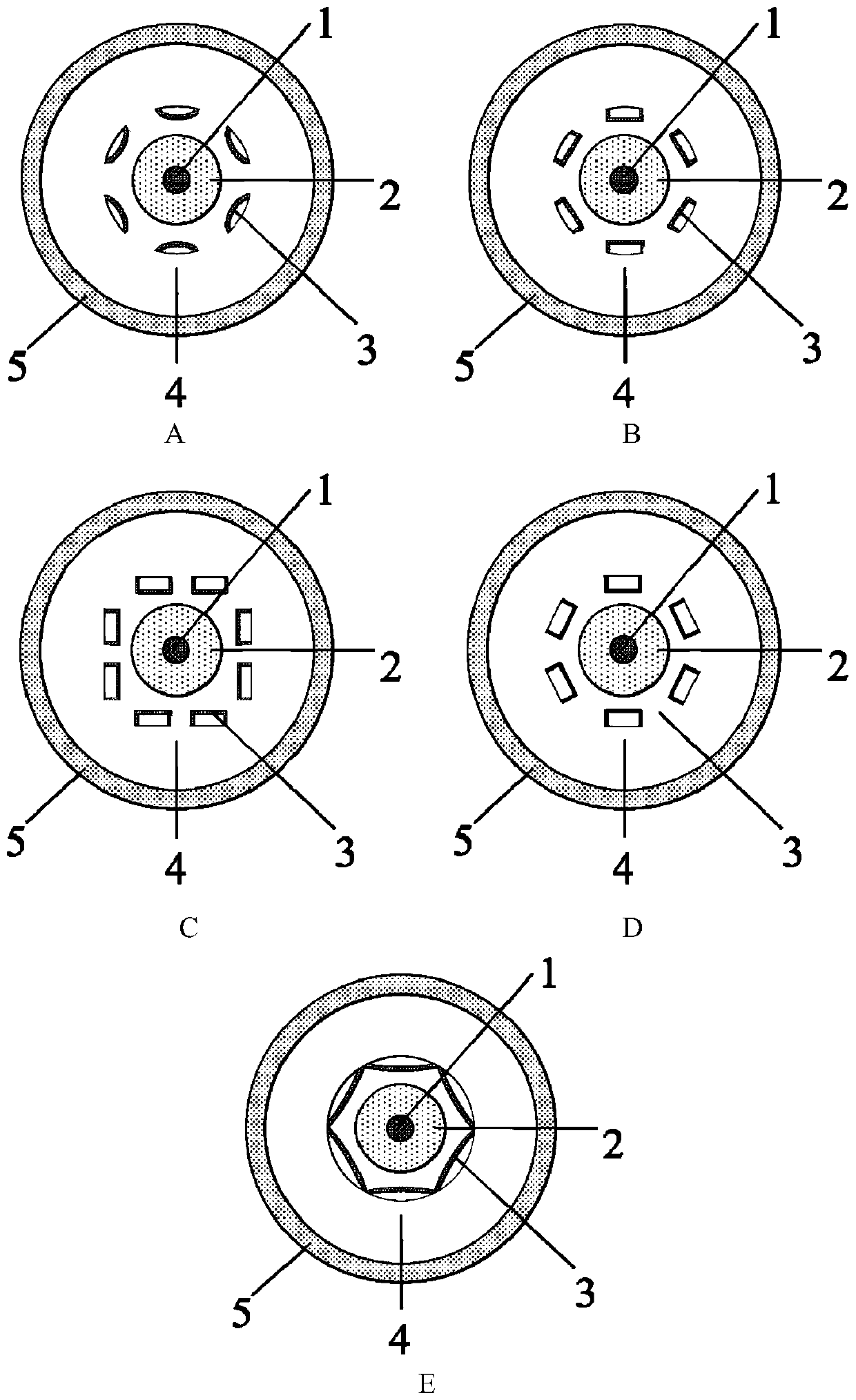

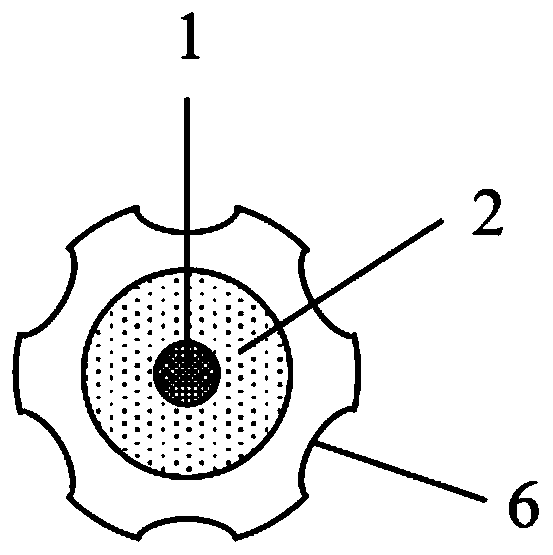

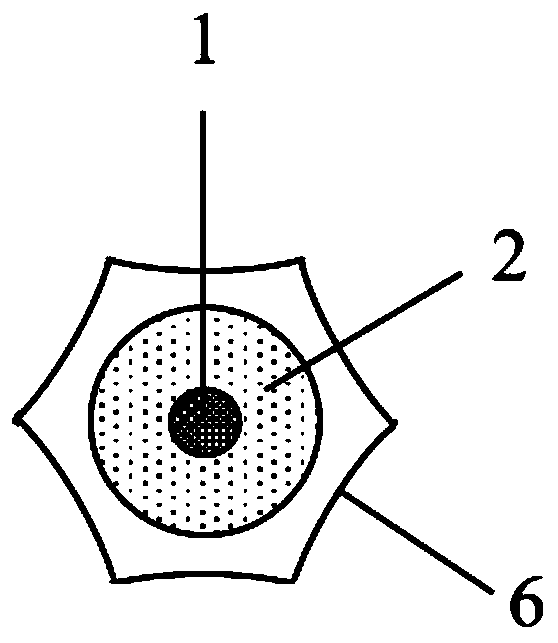

Irradiation-resistant erbium-doped optical fiber for space and preparation method of irradiation-resistant erbium-doped optical fiber

ActiveCN111552028AImprove radiation resistanceReduce lossCladded optical fibreActive medium shape and constructionFiberPhysical chemistry

The invention belongs to the technical field of optical fibers, and particularly relates to an irradiation-resistant erbium-doped optical fiber for the space and a preparation method of the irradiation-resistant erbium-doped optical fiber. The optical fiber solves the problem that the performance of the optical fiber is reduced under a high-energy irradiation condition, and sequentially comprisesan erbium-doped fiber core, a transition layer and a cladding from inside to outside; at least one group of surrounding units are arranged in the cladding; each group of surrounding units are arrangedin the radial direction of the cladding; each group of surrounding units comprises an even number of through holes which are through in the axial direction of the cladding and distributed in the circumferential direction, and a pattern formed by connecting lines of the centers of the through holes is concentric with the erbium-doped fiber core; and the hole wall of each through hole is covered with a hydroxylated carbon nanotube layer. The preparation method comprises the following steps: manufacturing the core rod, processing the groove surrounding the core rod, growing the carbon nanotube layer in the groove, hydroxylating the carbon nanotube layer, treating the sleeve, and performing drawing. Ce and F are introduced into the fiber core, color center generation of the erbium-doped fiberunder a high-energy irradiation condition is reduced, and the hydroxylated carbon nanotube layer is introduced into the irradiation-resistant erbium-doped fiber cladding, so the radiation shielding effect is achieved, and the irradiation resistance of the erbium-doped fiber is greatly improved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

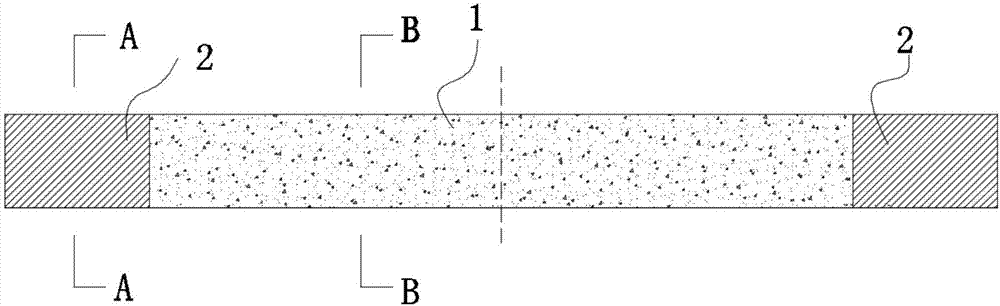

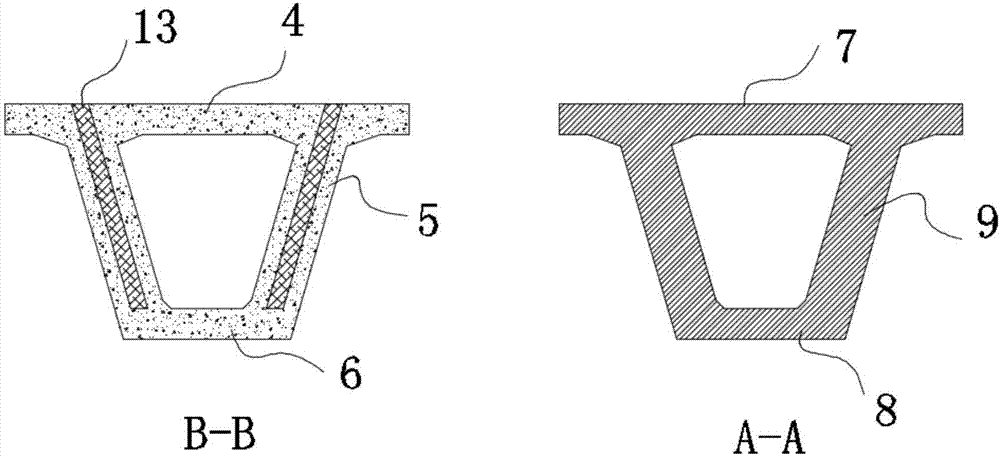

Manufacturing method for prestress small box girder

ActiveCN107984610AQuality improvementIncrease profitCeramic shaping apparatusBridge materialsSteel barBox girder

The invention discloses a manufacturing method for a prestress small box girder. The prestress small box girder is divided into an open groove section located in the middle and anchoring sections located at the two ends, the manufacturing method comprises the following steps that 1, the open groove section is poured, open grooves used for arranging prestress ribs are reserved in a web plate of the open groove section, and two tensioning holes used for tensioning the prestress ribs are preset at intervals for a certain distance at the bottoms of the open grooves; 2, the prestress ribs penetrate through the open grooves reserved in the open groove section, the prestress ribs after penetrating are fixedly connected with steel bar cages of the anchoring sections at the two ends of the prestress small box girder, and the anchoring sections located at the two ends of the prestress small box girder are poured; 3, after the anchoring sections are poured and solidified, the prestress ribs aretensioned downwards by tensioning equipment through two transverse tensioning holes in the bottoms of the open grooves, and the tension value and the elongation value of the prestressed ribs are checked to meet the requirement; and 4, the open grooves in the open groove section are poured, then the third pouring is finished, the tensioning equipment is disassembled after the open grooves are solidified, and then the manufacturing of the whole prestress small box girder is completed. According to the manufacturing method for the prestress small box girder, the grouting in the prestressed tension of the small box girder is denser, and meanwhile, the utilization rate of the prestress ribs is improved.

Owner:WUHAN UNIV +3

Large-span floor slab reinforcing method

ActiveCN103397788AReduce stress lossReduce frictional resistanceBuilding repairsFloor slabPre stress

The invention discloses a large-span floor slab reinforcing method. The large-span floor slab reinforcing method is characterized in that a diverter is arranged in the middle of a concrete floor slab between a wall and one concrete beam, a diverter is arranged in the middle of a concrete floor slab between every two adjacent concrete beams, a polyethylene board adheres to the top of one diverter, the thickness of each polyethylene board is 4mm, the top face of each polyethylene board is made to be a circular arc, the polyethylene boards are arranged at the tops of the diverters, prestressed tendons in the concrete floor slabs are distributed in a zigzag shape, preformed holes are formed in the concrete floor slabs, high-strength plastic casing pipes are embedded into the preformed holes, the diameter of each high-strength plastic casing pipe is 35-40mm, the prestressed tendons are arranged inside the high-strength plastic casing pipes, the inner sides of the high-strength plastic casing pipes are coated by molybdenumdimanganese, and a fine stone concrete layer is arranged on the concrete floor slabs.

Owner:浙江嘉苑园艺景观有限公司

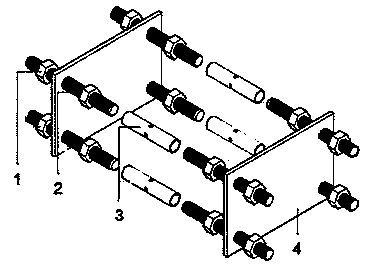

Concrete bearing device and testing method thereof

PendingCN109556968ASimple structureEasy to operateMaterial strength using tensile/compressive forcesMaterials testingStructural engineering

The invention relates to the field of engineering material testing, and particularly relates to a concrete bearing device and a testing method thereof. The device comprises an upper bearing plate, a lower bearing plate and screws evenly distributed at edges of the upper bearing plate and the lower bearing plate; each of the screws sequentially penetrates through the upper bearing plate and the lower bearing plate and can move relative to each other; the device is characterized in that: the lower bearing plate is further provided with a bottom at the lower end, the screw sequentially penetratesthrough the upper bearing plate, the lower bearing plate and the bottom plate, the lower end of the screw rod is fixed to the bottom plate, an elastic device is arranged between the lower bearing plate and the bottom plate; a plurality of concrete test pieces are vertically stacked between the upper bearing plate and the lower bearing plate, and the top of the uppermost concrete test pieces is attached to the bottom of the lower bearing plate, and a concrete pressing block is arranged at the upper end of the upper bearing plate; the concrete test piece is detected by extruding the concrete pressing block in a vertical direction through an external force. The device is simple in structure, easy to operate, convenient to assemble and disassemble.

Owner:NANCHANG UNIV

Sifter

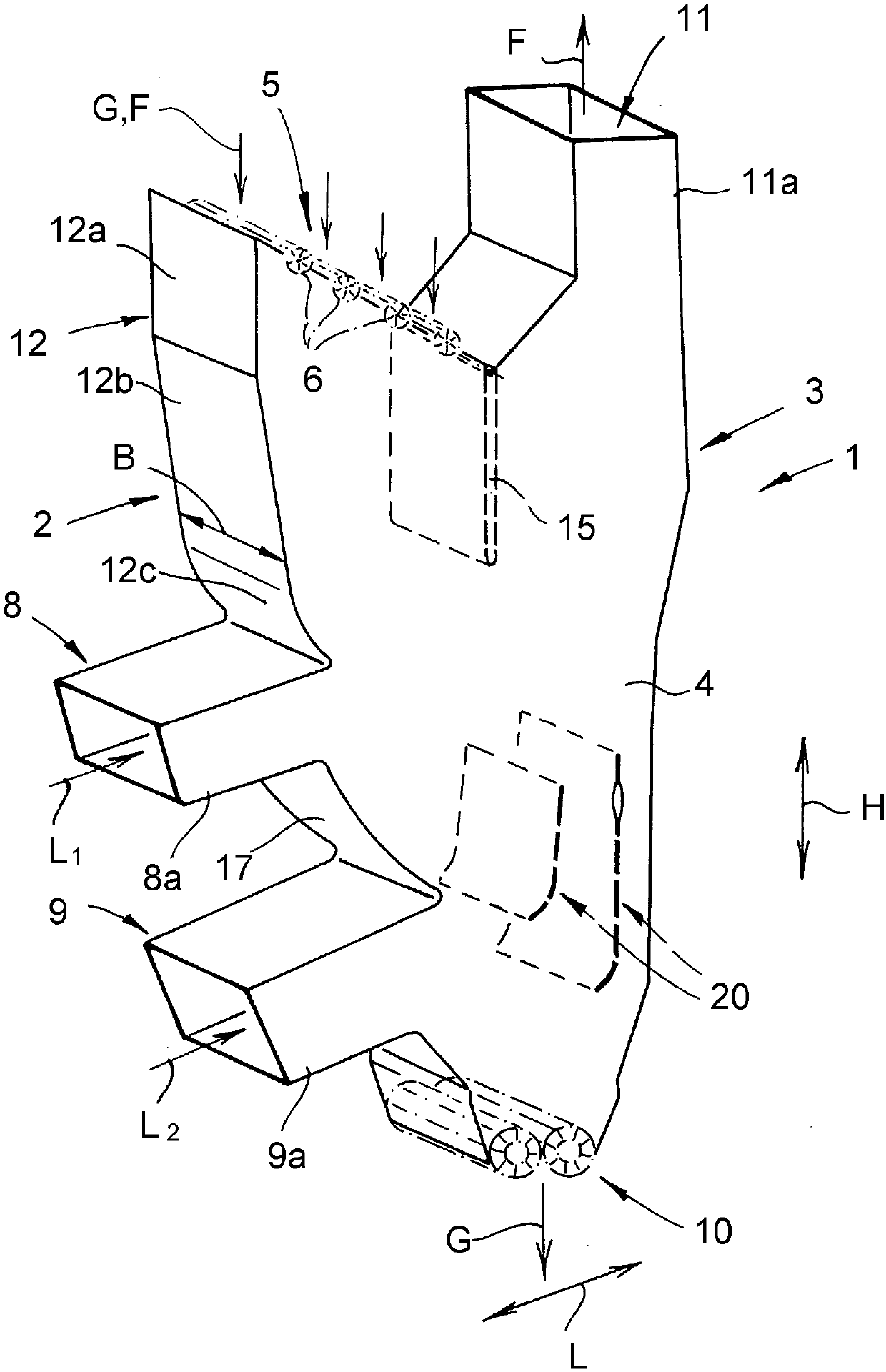

InactiveCN107824450APrevent intrusionPrevent fallingGas current separationDomestic articlesFiberMechanical engineering

The invention relates to a sifter serves for separating coarse particles from a particle-carrying stream during the manufacture of wood material panels, in particular wood fiber panels. The sifter comprises at least one sifter housing having a feed inlet, at least one air inlet, an air outlet, and a coarse feed outlet disposed below the feed inlet. The upper front wall of the screen housing, whichis arranged above the air inlet, is oriented obliquely with respect to the vertical line at least in partial regions. The screening machine is characterized in that the upper edge of the air inlet isaligned in side view above the lower edge of the air inlet or protrudes by an amount (M) from the lower edge.

Owner:SIEMPELKAMP MASCH & ANLAGENBAU GMBH & CO KG

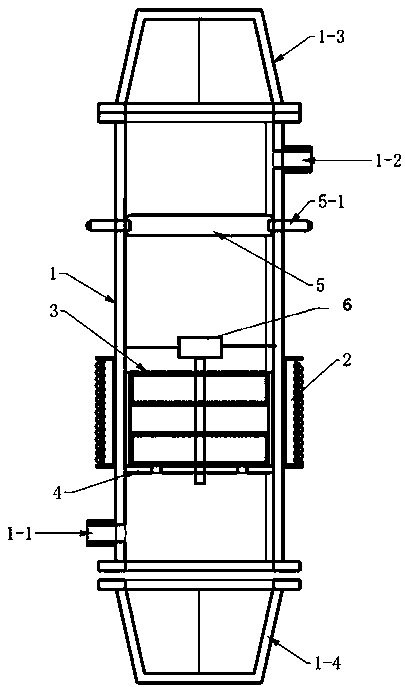

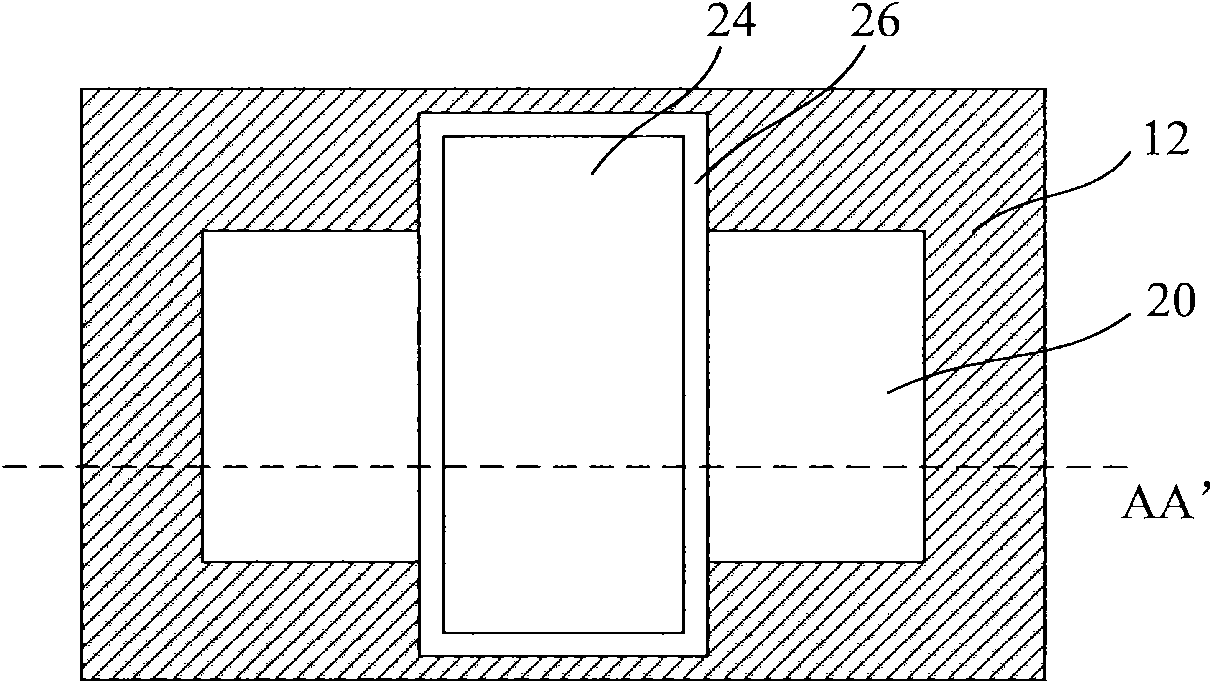

Isolation area, semiconductor device and forming method thereof

InactiveCN102315152AReduce stress lossIncrease the angleSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSource area

The invention discloses an isolation area, which comprises a first groove embedded in a semiconductor substrate and an insulating layer filled in the first groove, wherein the first groove comprises a first side wall, a bottom wall and a second side wall which extends from the bottom wall and is connected with the first side wall, and an included angle between the first side wall and a normal line of the semiconductor substrate is more than a standard value. A forming method of the isolation area comprises the steps of: forming the first groove on the semiconductor substrate, wherein the included angle between the first side wall of the first groove and a normal line of the semiconductor substrate is more than the standard value; forming a mask on the side wall and forming a second groove on the semiconductor substrate by using the mask; and forming an insulating layer to fill the first groove and the second groove. In a semiconductor device and a forming method thereof, a semiconductor substrate material is clamped between the second groove for bearing a semiconductor layer, which is used for formation of a source area and a drain area, and the first side wall and the second side wall. The isolating area and the semiconductor device in the invention are beneficial to decrease of electric leakage.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Cross-linked modification method of polymer phase in magnetic-force- electric coupling effect

The present invention is method of raising the piezoelectric performance and magnetoelectric performance of composite material with cross-linking polymer. The cross-linking polymer for the composite material may be polyvinylidene fluoride, polyethylene, epoxy resin, phenolic resin, unsaturated polyester resin, rubber or nylon. The present invention features that linear polymer is made to form crosslinked structure chemically or through irradiation. The chemical crosslinking process is to adding crosslinking agent or initiator into the composite material and the composite material is formed through mixing and hot pressing. The irradiating crosslinking process includes mixing the cross-linking polymer with the composition material, cold pressing to form at room temperature, and irradiating for crosslinking the polymer in the composite material.

Owner:WUHAN UNIV OF TECH

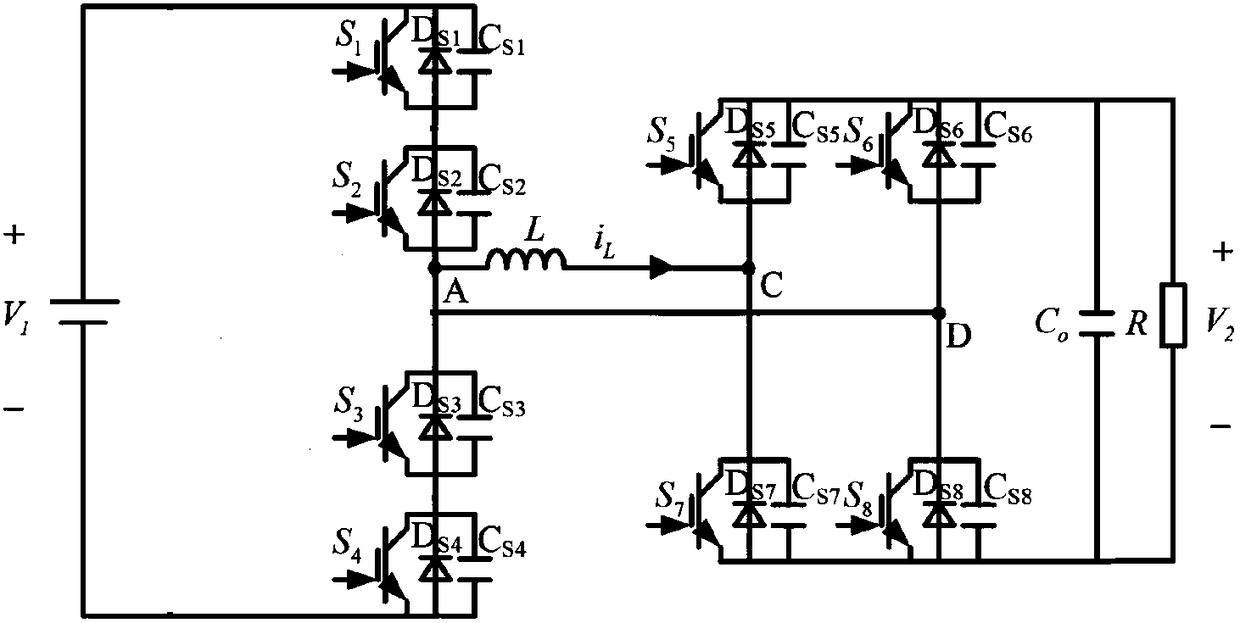

A hybrid bi-directional DC/DC converter

InactiveCN109194141AImprove transmission efficiencyReduce stress lossDc-dc conversionElectric variable regulationThree levelMicrogrid

A hybrid bi-directional DC / DC converter Bi-directional DC / DC convert is commonly used in new energy vehicle, a microgrid and that like have high power density, high efficiency, etc, the converter provided by the invention is based on a hybrid isolated three-level converter, coupled inductor, full bridge circuit, Half-bridge circuit composition, which has the same output and transmission characteristics as the traditional half-bridge converter, In addition, the converter can reduce the stress loss of the switch, greatly improve the transmission efficiency of the converter, and solve the problemof excessive loss of power devices and magnetic components caused by the mismatch of input and output voltages, so as to improve the transmission efficiency of the converter.

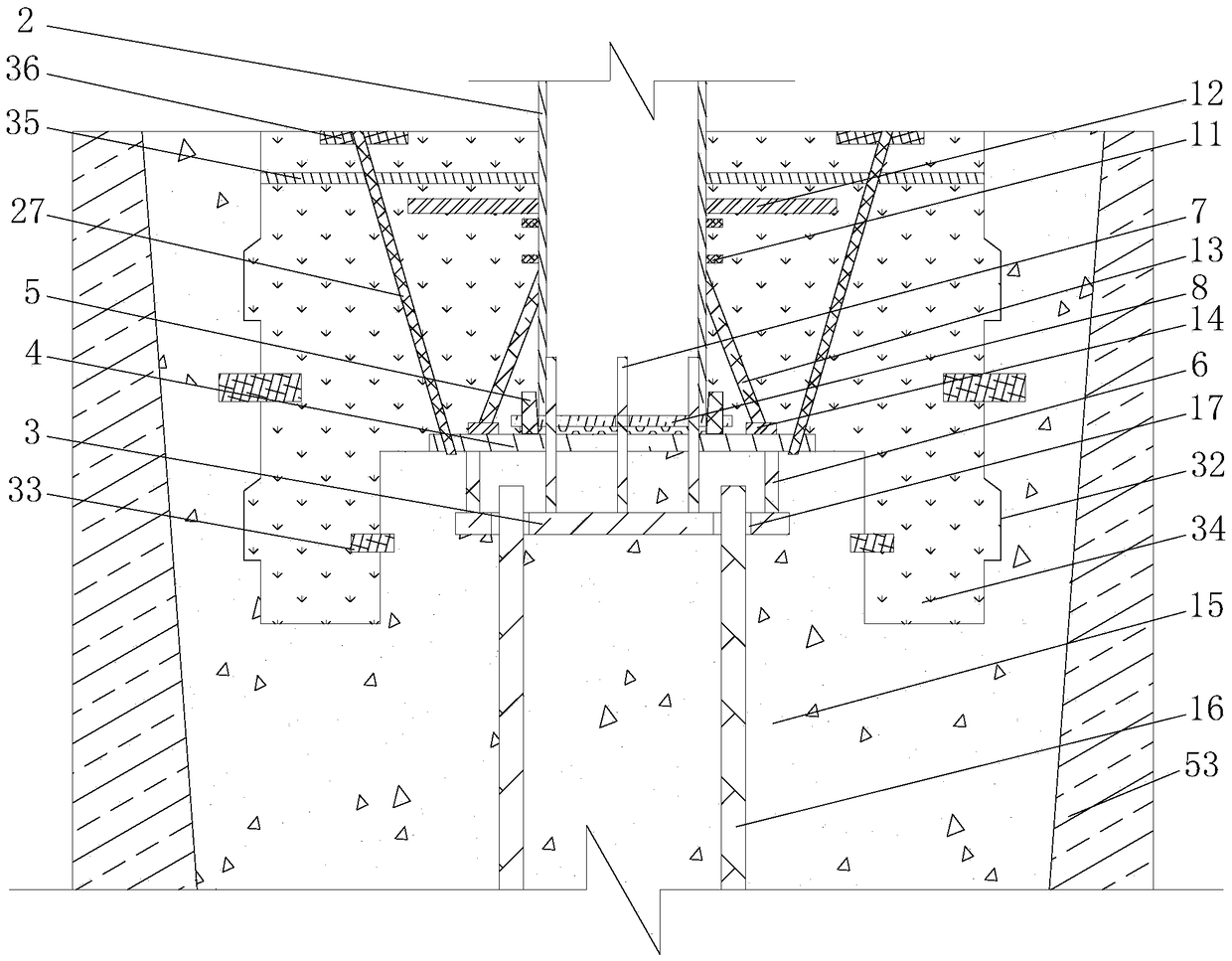

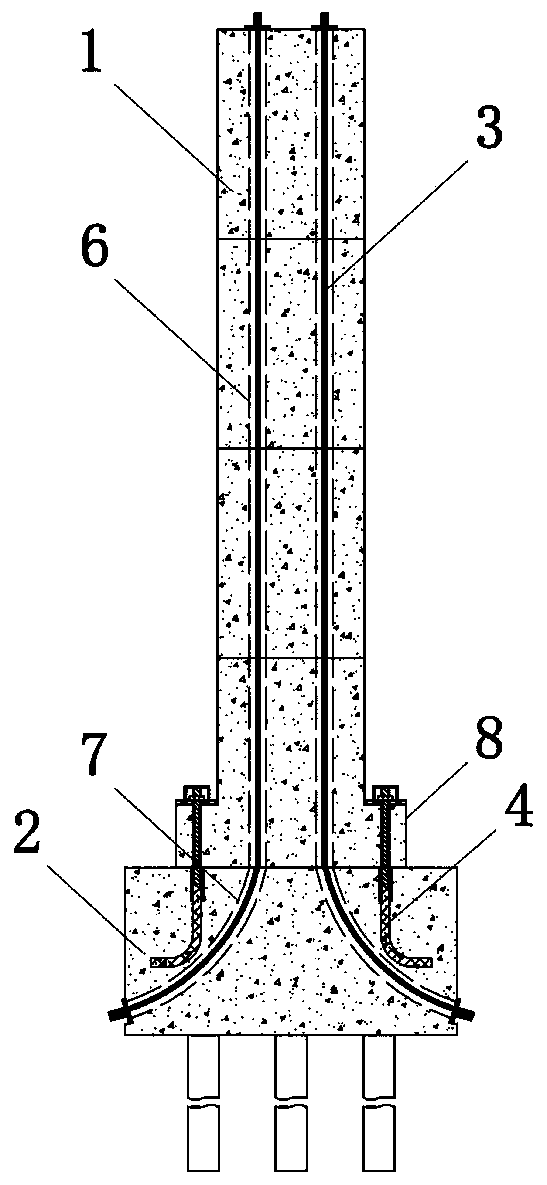

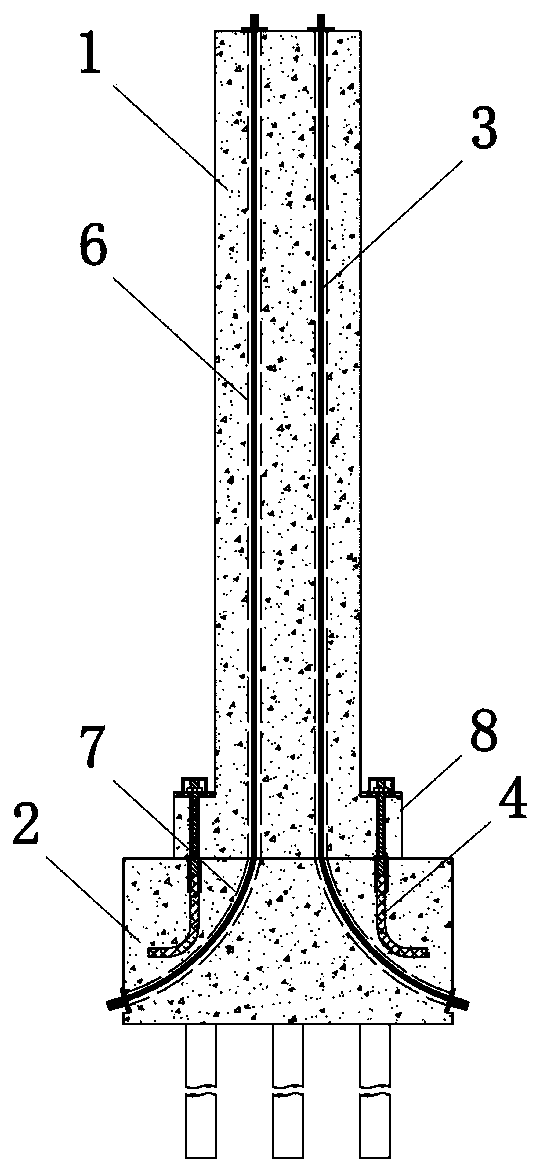

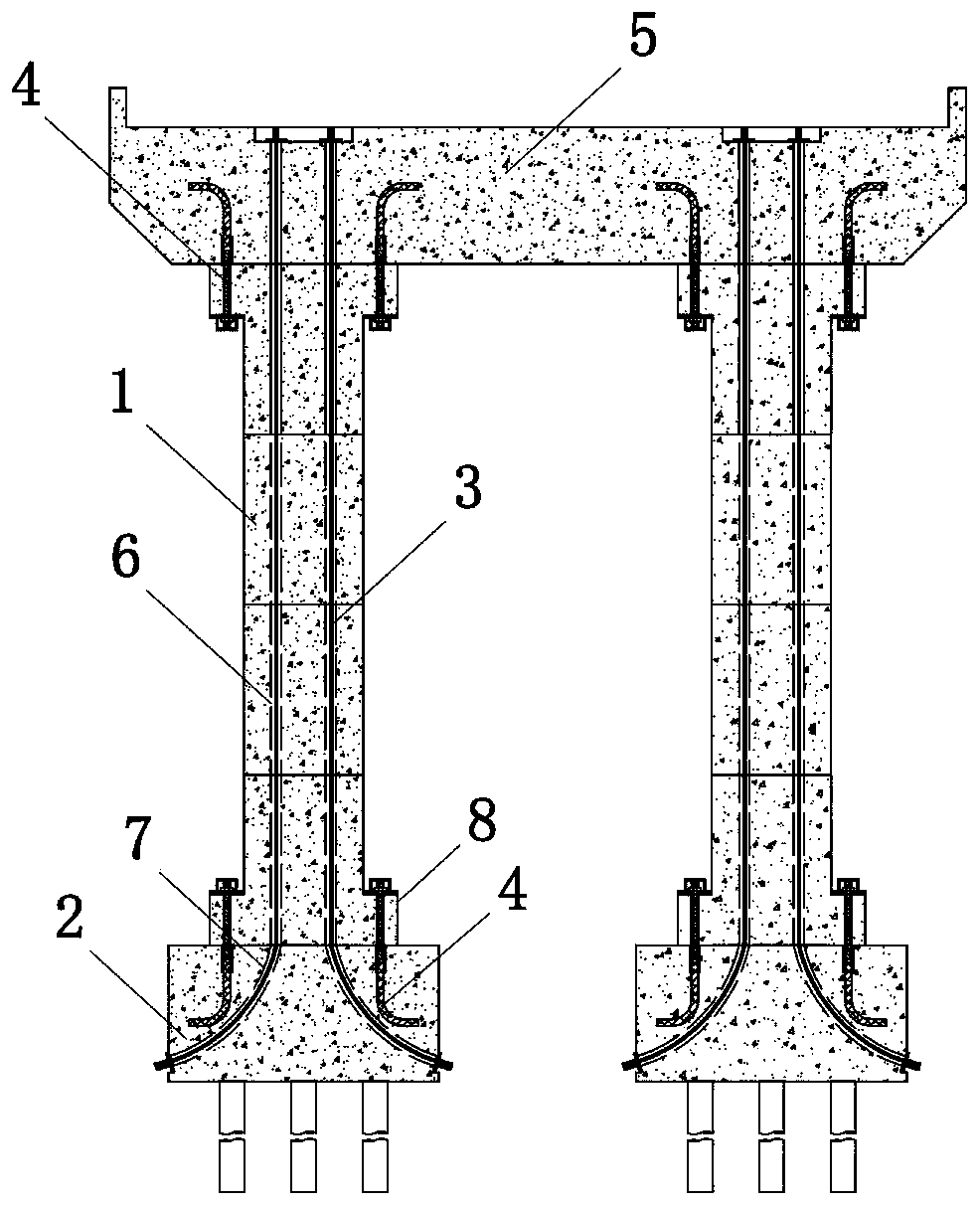

Self-resetting prefabricated assembled pier and construction method thereof

PendingCN111455834AImprove anti-overturn performanceAvoid damage and breakageProtective foundationBridge structural detailsBridge engineeringStress concentration

The invention relates to the technical field of bridge engineering, and discloses a self-resetting prefabricated assembled pier and a construction method thereof. The self-resetting prefabricated assembled pier comprises a prefabricated pier column and a foundation platform and further comprises prestressed tendons and energy dissipation connecting pieces; the prefabricated pier column and the foundation platform are connected into a whole through the prestressed tendons, one end of each prestressed tendon is used for anchoring a carrying structure at the top of the prefabricated pier column,and the other end anchors the foundation platform. The energy dissipation connecting pieces are connected with the bottoms of the prefabricated pier columns and the foundation platform. The assembledpier is simple in structure, convenient to operate and high in construction efficiency, the constructed assembled pier has self-resetting performance and good overturning resistance, the problem thatpier corner parts of existing assembled piers are prone to damage and breakage due to stress concentration is effectively solved, and the damaged parts are easy to repair.

Owner:BEIJING UNIV OF TECH

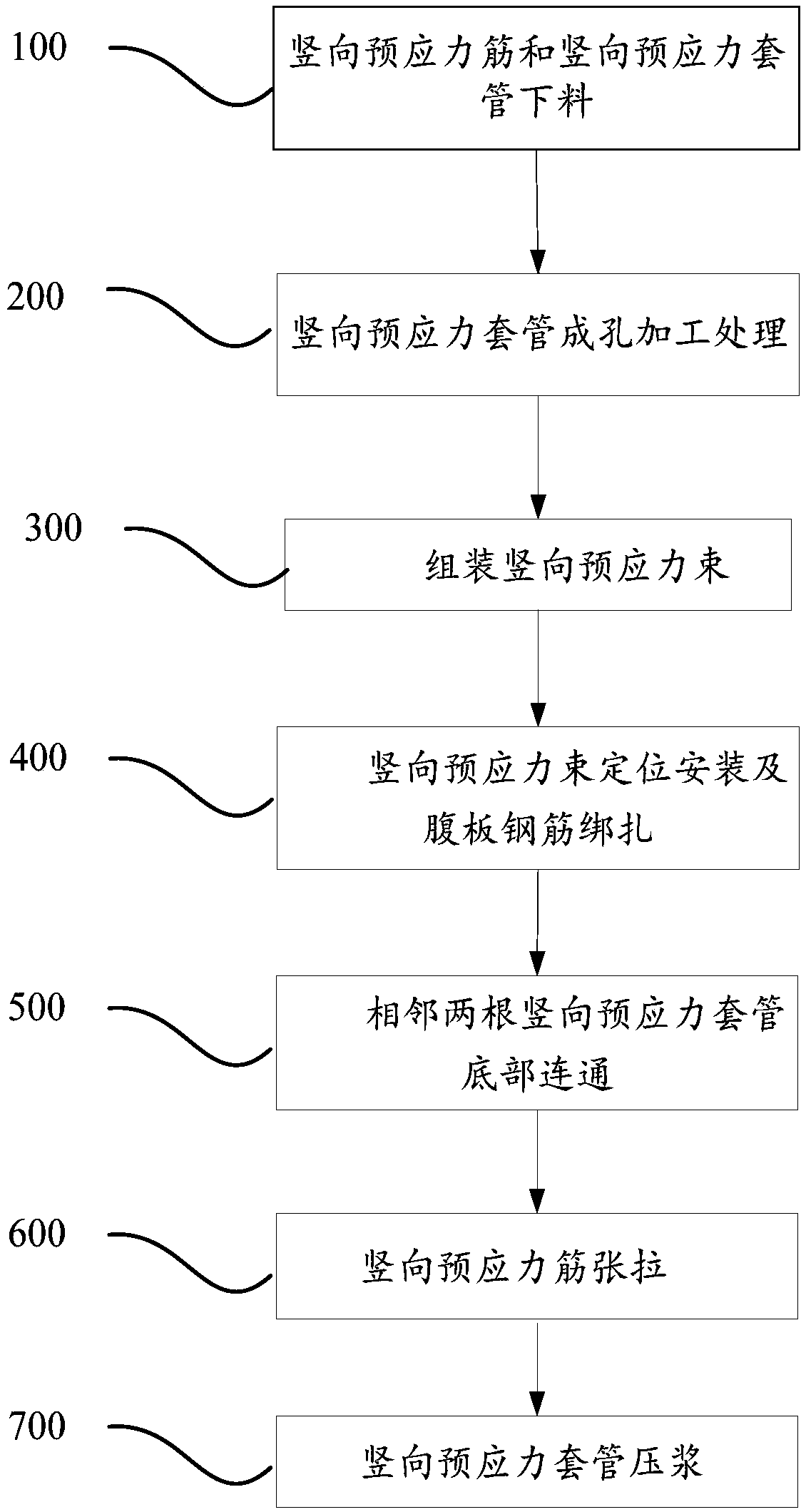

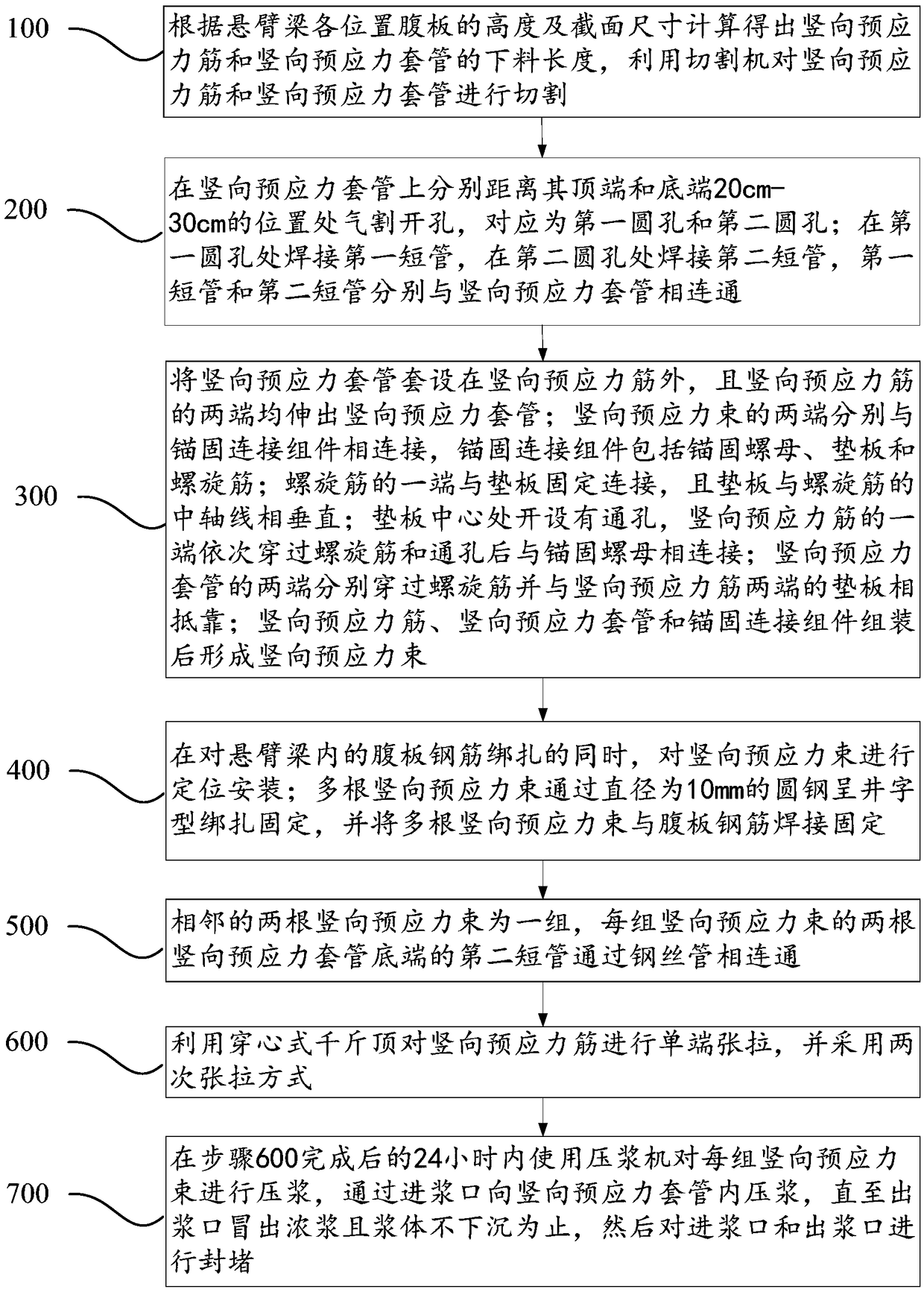

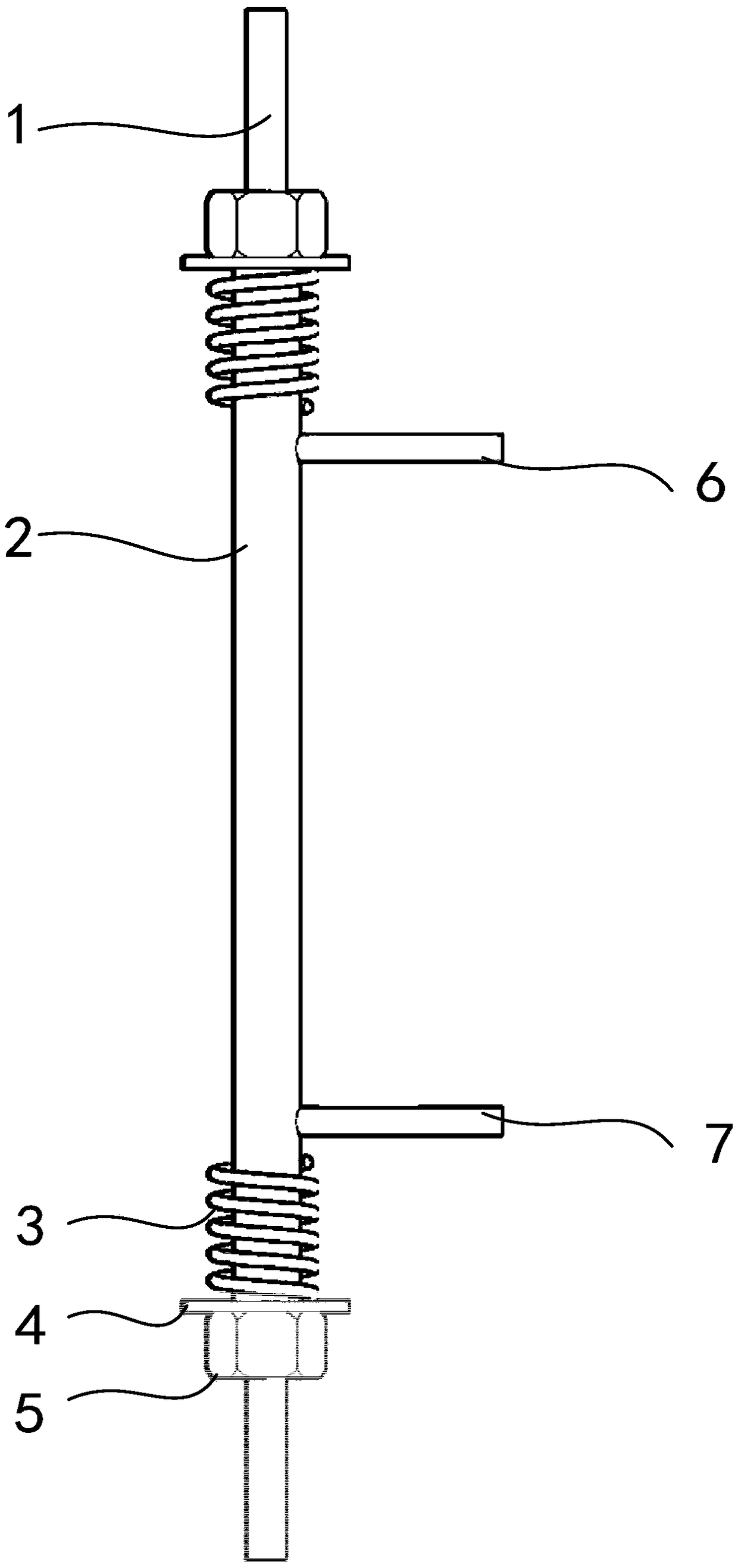

Cantilever beam vertical pipeline grouting double-pipe joint injection construction method

InactiveCN109252449AImprove crack resistanceShorten the timeBridge erection/assemblyBridge materialsCrack resistanceDouble tube

The invention relates to the technical field of bridge construction, in particular to a cantilever beam vertical pipeline grouting double-pipe joint injection construction method. The construction method comprises the following steps: firstly, blanking the vertical prestressed tendon and the vertical prestressed casing; next, the vertical prestressed casing after blanking is processed into holes;next, the vertical prestressed tendon is assembled; next, the assembled vertical prestressed tendons are positioned and installed at the same time of the web reinforcement binding; next, the bottom oftwo adjacent vertical prestressed casing pipes are communicated; next, the vertical prestressed steel bar is tensioned; finally, the grout is pressed into the vertical prestressed casing. By adoptingthe construction method, the grouting in the vertical prestressed tendons can be made more dense and full, so that the bonding effect of the grouting concrete on the prestressed tendons is more prominent, the stress loss of the vertical prestressed tendons is avoided to a greater extent, and the cantilever beam concrete has better crack resistance.

Owner:CHINA RAILWAY SIXTH GROUP +1

Automatic control method for prestressed intelligent tensioning

InactiveCN108612313AEasy to wearAchieve clampingBridge erection/assemblyBuilding material handlingAutomatic controlPre stress

The invention discloses an automatic control method for prestressed intelligent tensioning. The automatic control method comprises the steps of installing a tensioning device; construction of tensioning prestressed tendons by the tensioning device; construction of locking the prestressed tendons by the tensioning device and intelligent controlling over tensioning construction by a controller. Theautomatic control method has the beneficial effects that a tensioning telescopic part of a bidirectional jack works first, the prestressed tendons are tensioned to a predetermined stress value, and then a jacking telescopic part works to push a reverse pressing plate to push and press a working jacket, so that a working anchor clamps the prestressed tendons, sliding of the prestressed tendons canbe reduced; compared with a traditional tensioning system, the automatic control method can reduce stress loss, avoid excessive tensioning, better control the tensioning process and improve the tensioning effect, and realize intelligent tensioning monitoring and control by combining with the controller; and intelligence and convenience are achieved, and control accuracy is high.

Owner:重庆恒佳工程技术咨询有限公司

Angle adjustable anchor cable cushion plate

ActiveCN109025069AReduce stress lossSolve hard requirementsBuilding reinforcementsCushionBuilding construction

The invention discloses an angle adjustable anchor cable cushion plate, which comprises: an upper cushion plate, angle adjustment gears and a lower cushion plate. One end of the upper cushion plate isconnected to one end of the lower cushion plate. Both sides of the upper cushion plate and the lower cushion plate are provided with gear grooves, in which the angle adjustment gears are disposed. The center of the upper cushion plate is provided with a first round hole, and the center of the lower cushion plate is provided with a second round hole. The angle adjustable anchor cable cushion plateprovided by the invention can effectively solve the rigid requirements for the inclined planes of beams, reduces the formworking construction difficulty and technical requirements, improves the beamconstruction speed, and also improves the anchor cable tensioning quality. By adjusting the angle between the two cushion plates, adjustment can be conducted according to the position of the anchor cable and the actual angle of a curtain to make the upper cushion plate perpendicular to the anchor cable, thus reducing the stress loss caused by insufficient anchor cable tensioning or the angle.

Owner:HUNAN CITY UNIV

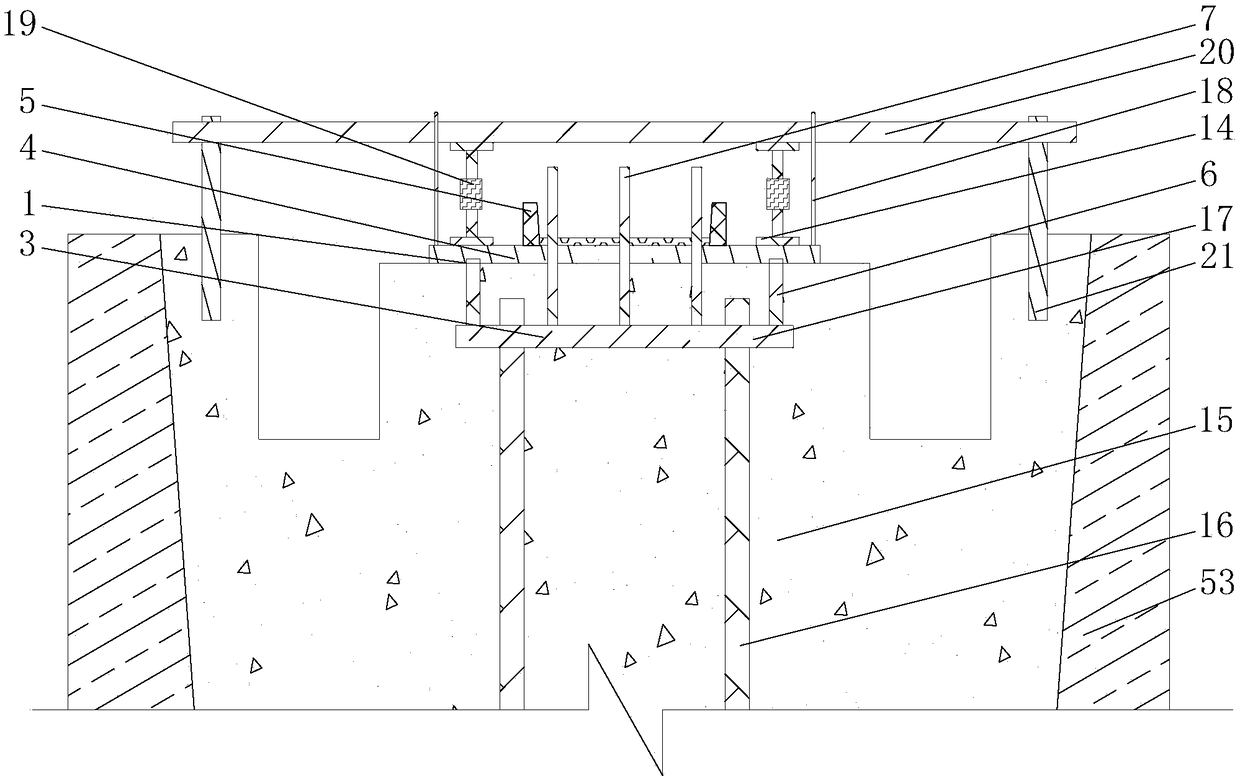

A method for hoisting and positioning control of prestressed steel beams in tower columns

The invention relates to a hoisting and positioning control method for prestressed steel strands of tower columns, which comprises the following steps: selecting a beaming platform, and setting a conduit for beaming on the beaming platform according to the length of the steel strands; threading the steel strands one by one into the conduit; braid the lower end of the steel beam; then braid the upper end of the steel beam, and install the 1# anchor plate, use the steel strand card to lock the steel strand on the 1# anchor plate; #Anchor plate, use the hoop to tighten the 1# and 2# anchor plate; send the steel strand into the reserved hole; remove the hoop used to anchor the two anchor plates, take away the 2# anchor plate, and complete the steel beam installation; install a tension jack on the remaining 1# anchor plate, use 10%‑20% of the tension stress as the initial tension force, complete the unlocking of the temporary lock of the card and adjust the straightness and slack of the steel beam, and then enter In the prestressing and tensioning construction stage, the present invention has the advantages of simple operation, time saving and high working efficiency.

Owner:SINOHYDRO BUREAU 11 CO LTD

Construction method of environment-friendly tension and compression composite distributed anchor rod

ActiveCN112962594AReasonable stress distributionThe problem of unresolved stress concentrationBulkheads/pilesSocial benefitsPlate pressure

The invention discloses a construction method of an environment-friendly tension and compression composite distributed anchor rod. Anchor rods involve a pressure type anchor rod, a tension type anchor rod and a tension and compression anchor rod bearing plate, wherein the pressure type anchor rod is a recyclable pressure type anchor rod and comprises a steel bar rod body and an unlocking device, the construction method of the anchor rod comprises the following seven steps of 1) positioning; (2) drilling; (3) loading an anchor; (4) primary grouting; (5) secondary grouting; (6) tensioning and locking; and (7) recycling the pressure anchor. According to the construction method, the problems that an anchor rod is concentrated in stress, poor in anchoring performance, large in long-term stress loss, limited in adjacent engineering construction, environment-friendly and the like are effectively solved, the anchor rod which is reasonable in stress distribution, high in uplift bearing capacity, free of influence on surrounding construction, environmentally friendly, recyclable, capable of saving energy and reducing emission is provided, and the construction method has wide application prospects and remarkable economic and social benefits.

Owner:DALIAN UNIV OF TECH

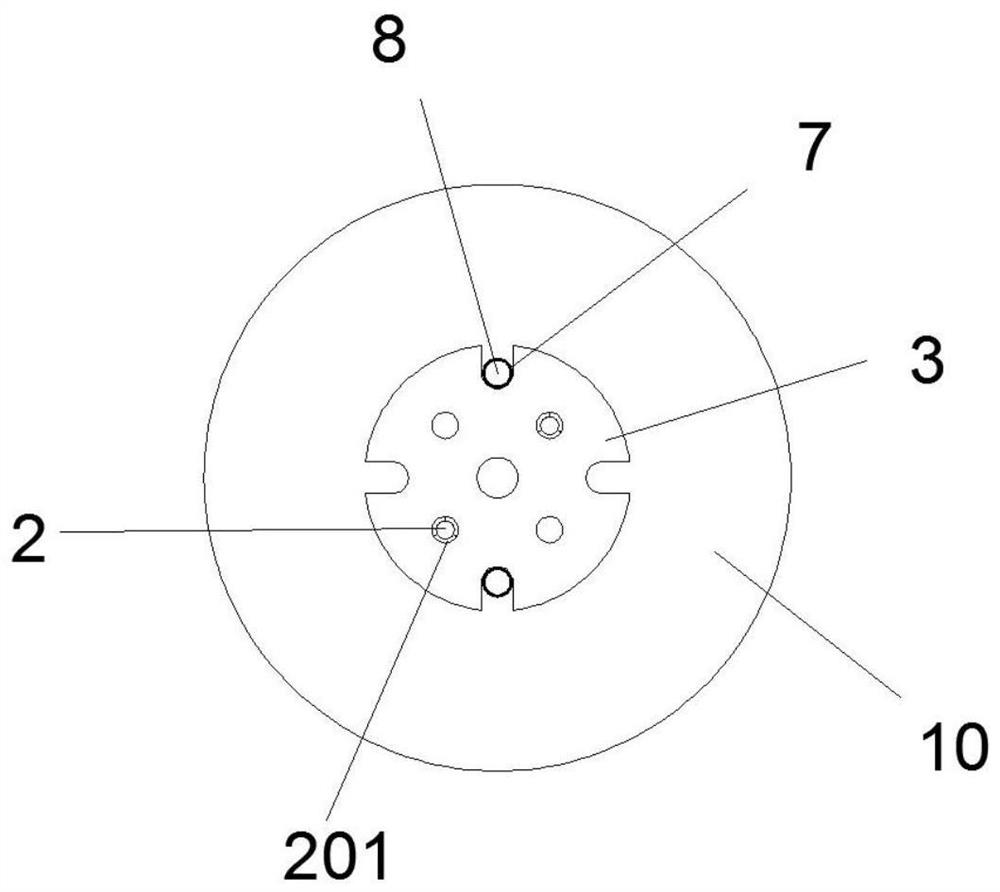

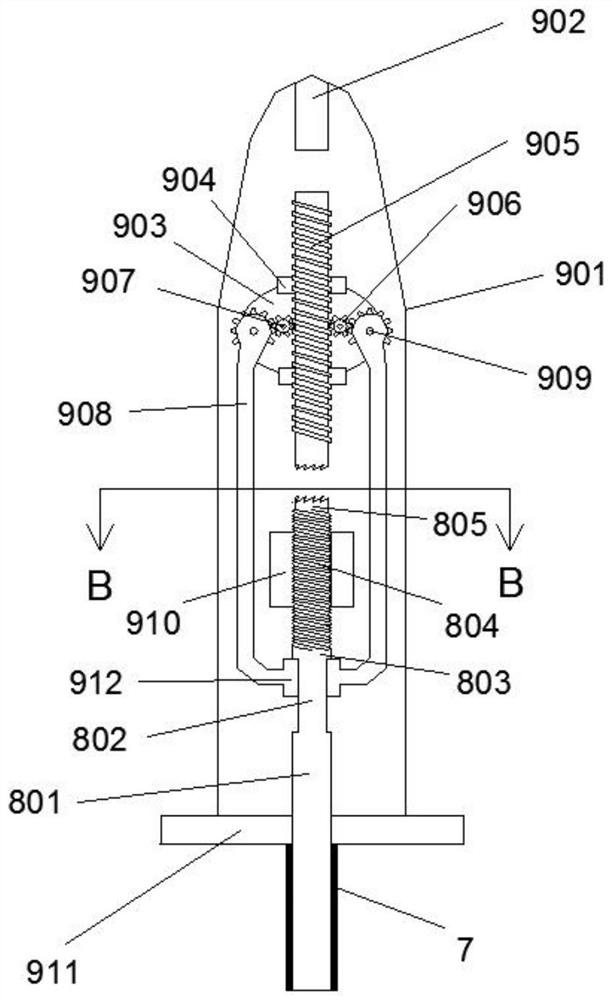

Stretching jack

ActiveCN100528733CSmall indentationReduce stress lossLifting devicesPrestressed concrete beamGear wheel

The invention discloses a tensioning jack, which belongs to the technical field of jacks and comprises a cylinder body. One end of the cylinder body equipped with a support is connected with an end cover, and the other end is connected with a large gear with a sleeve through a bearing. The gear shaft, one end of the gear shaft is fixedly connected with the pinion, the large gear and the small gear mesh with the intermediate gear respectively, and the intermeshing pinion, intermediate wheel and large gear are installed in the gearbox; the cylinder is provided with a nozzle connected to the piston , There is an observation window on the cylinder body; the inner cavity of the cylinder is a stepped hole, and a piston rod is arranged in the hole, and a piston is set on the piston rod, and a sealing ring is provided on the connecting part between the piston and the cylinder body on both sides of the oil nozzle, and the piston is connected One end of the pointer and the other end of the pointer are located at the observation window of the cylinder body, and a return spring is provided in the inner cavity of the cylinder body; the invention saves material, time and has high tensioning precision, and is suitable for ballastless track plates and similar short The prestressed concrete of slabs and short beams is a special machine for tensioning with steel rods (PC rods) and locking with threaded anchors.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

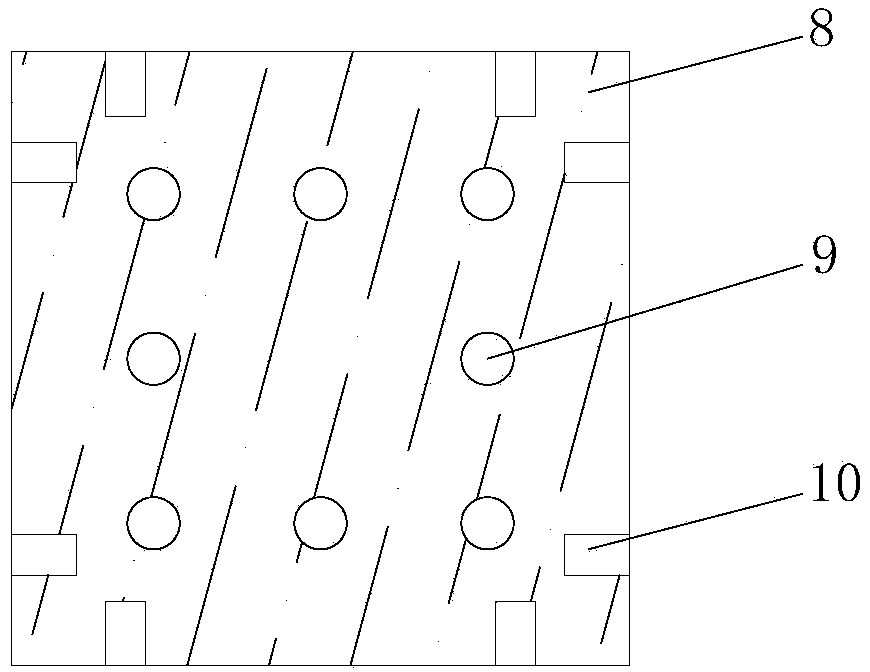

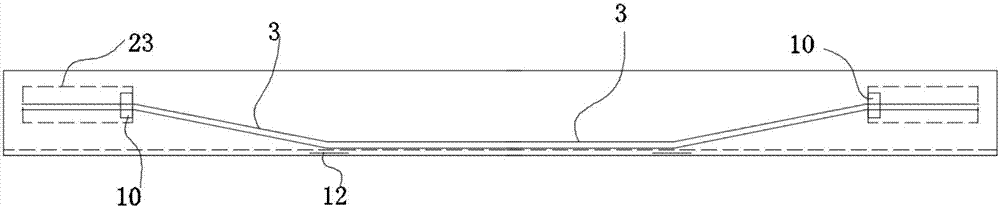

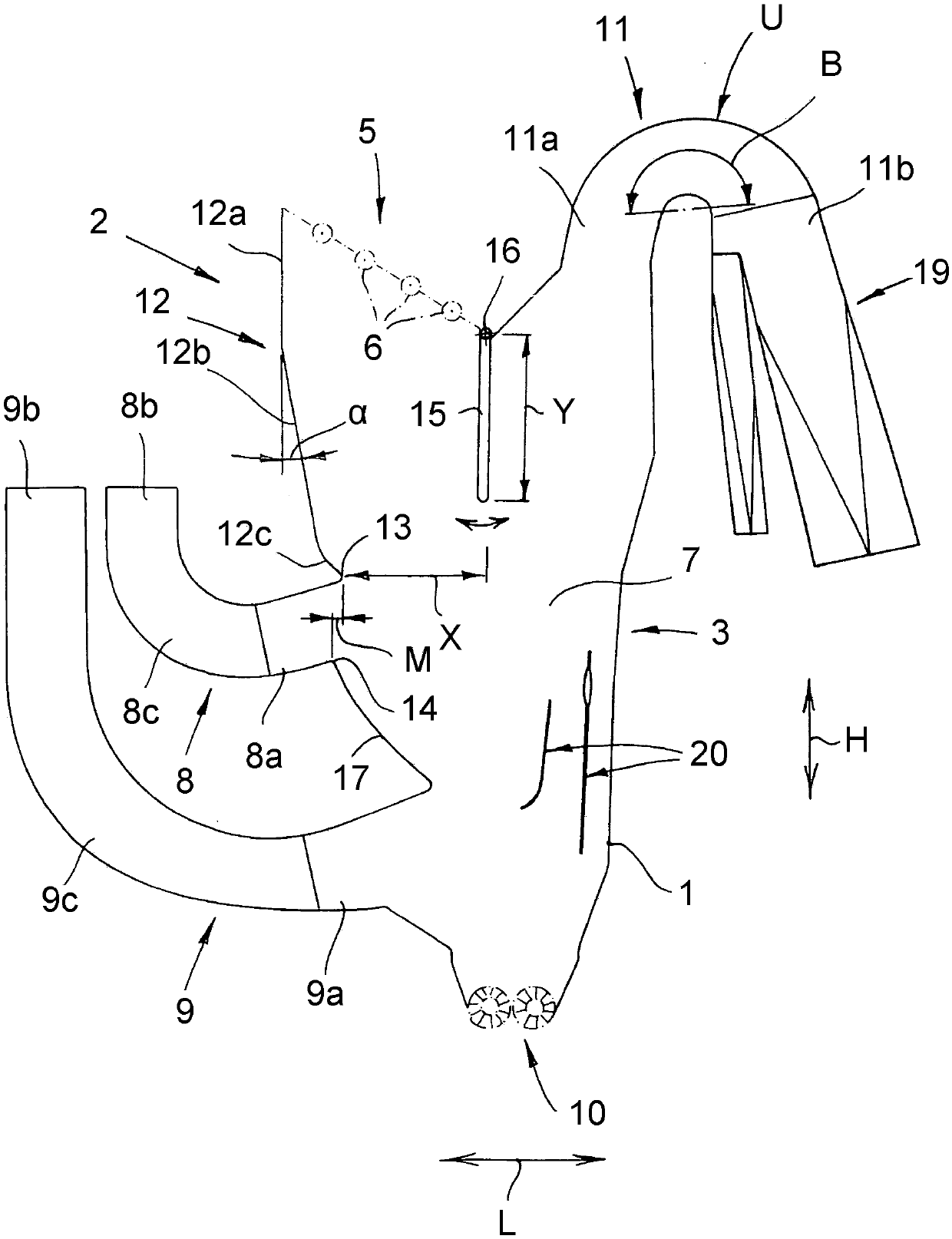

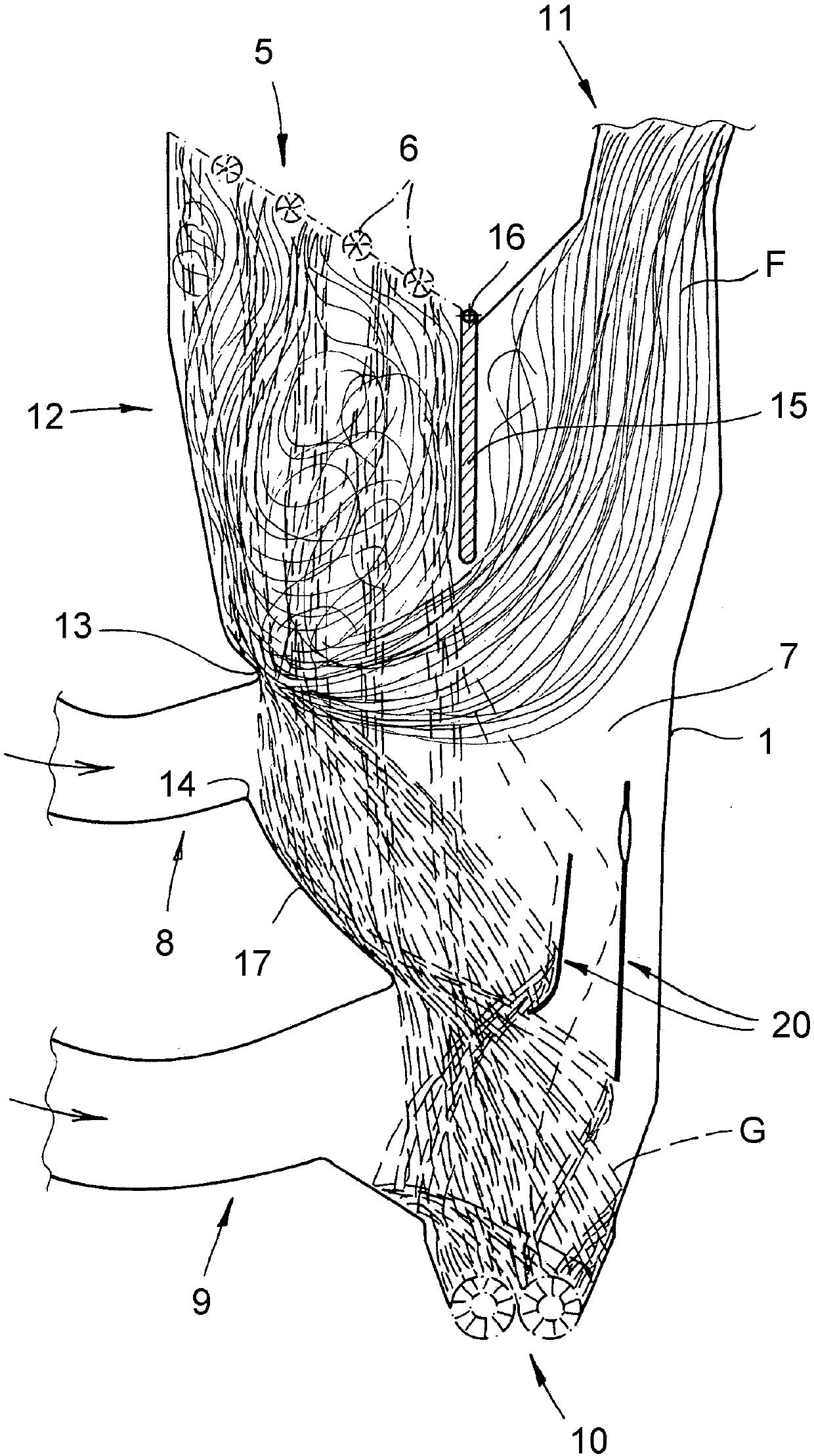

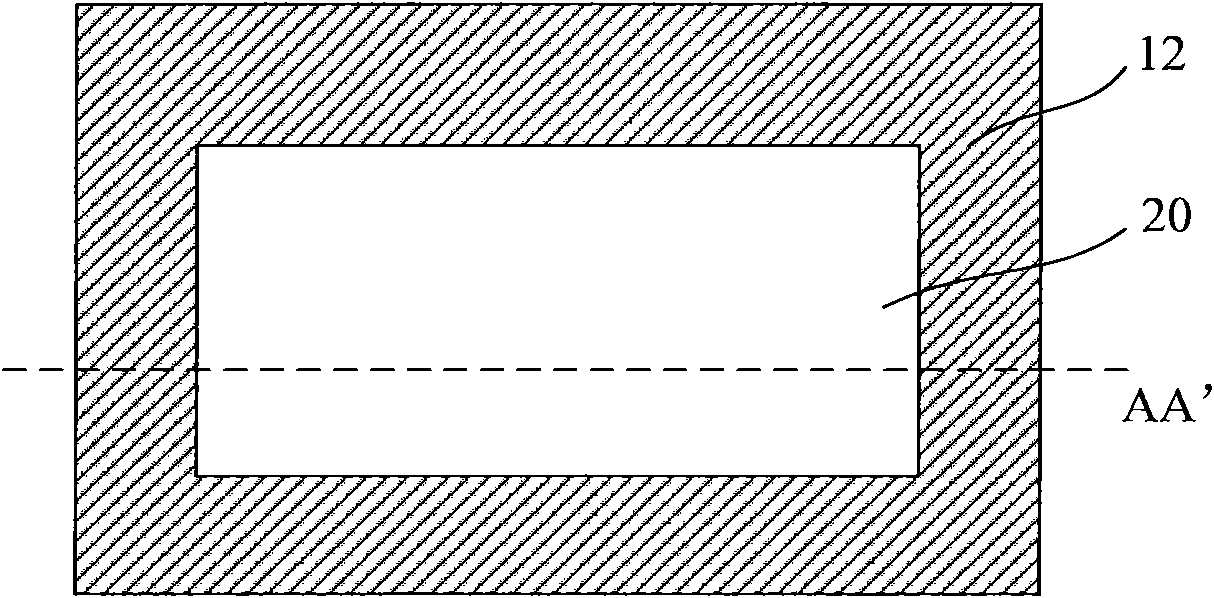

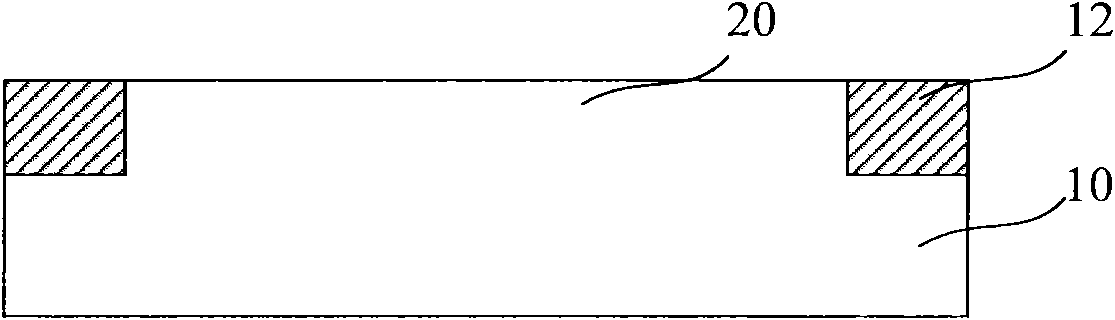

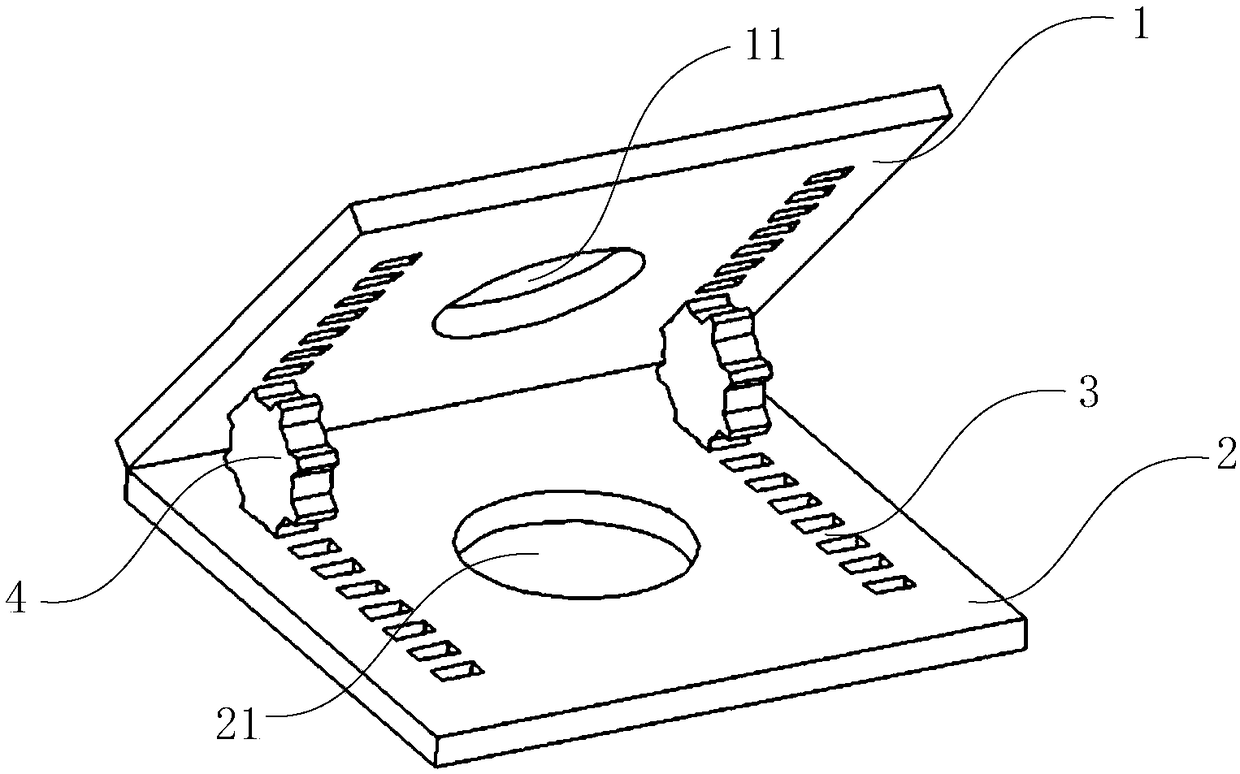

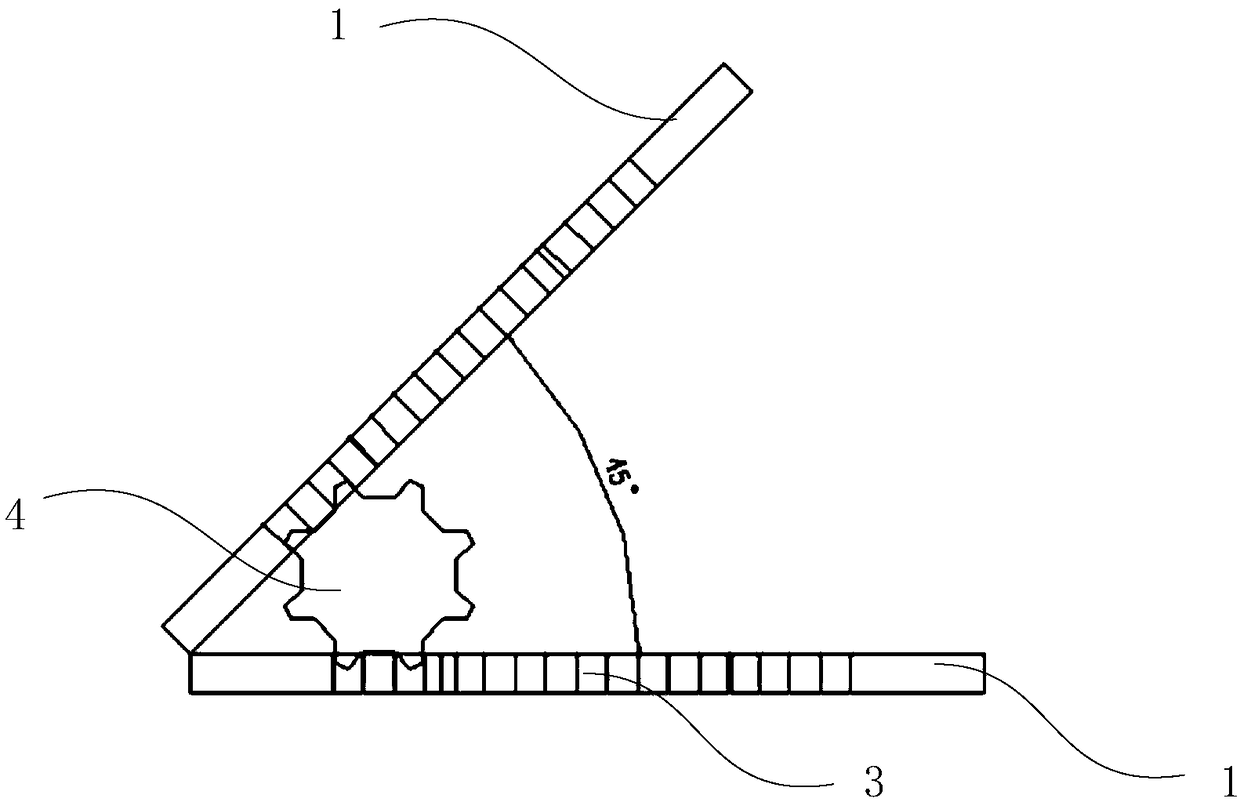

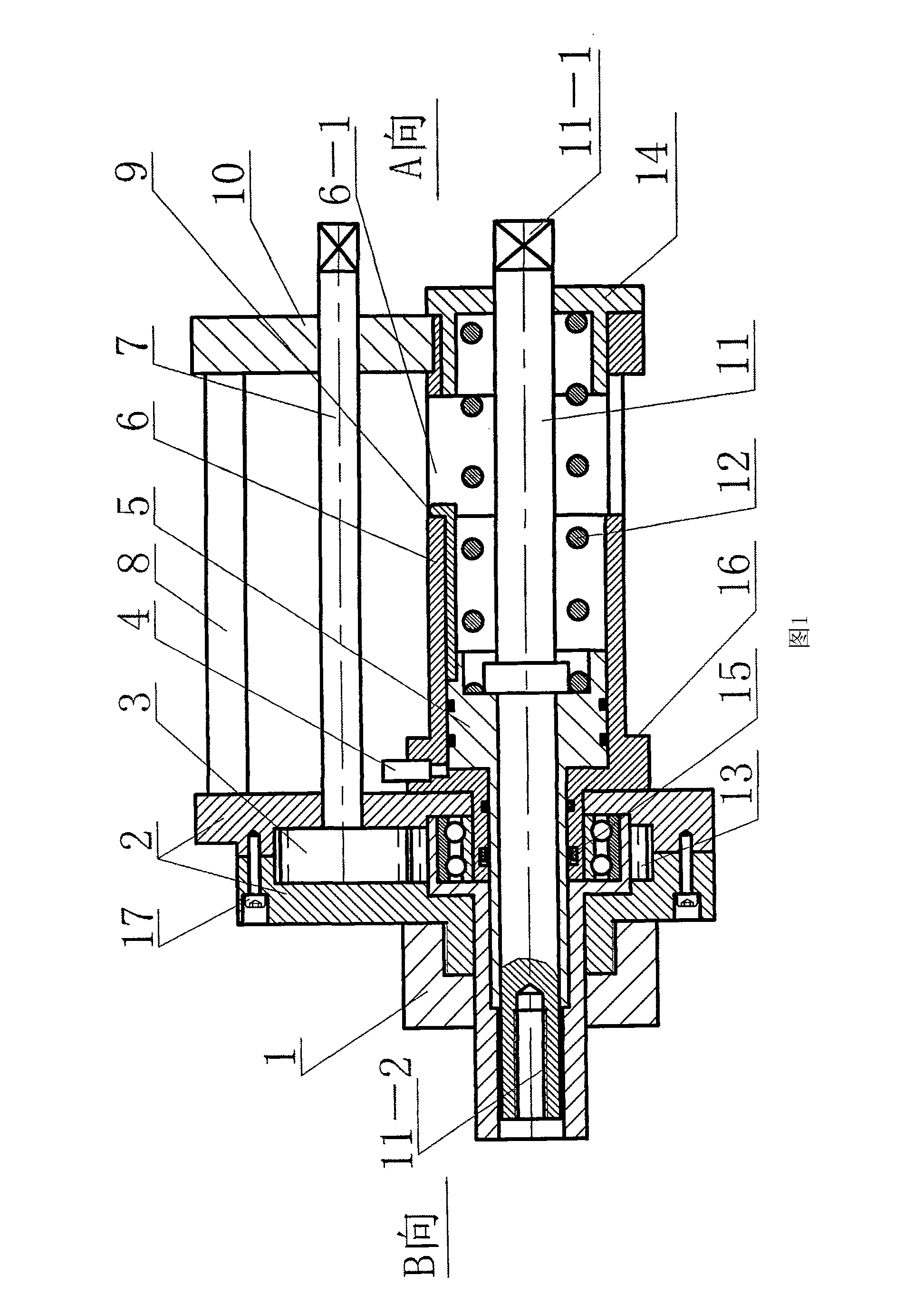

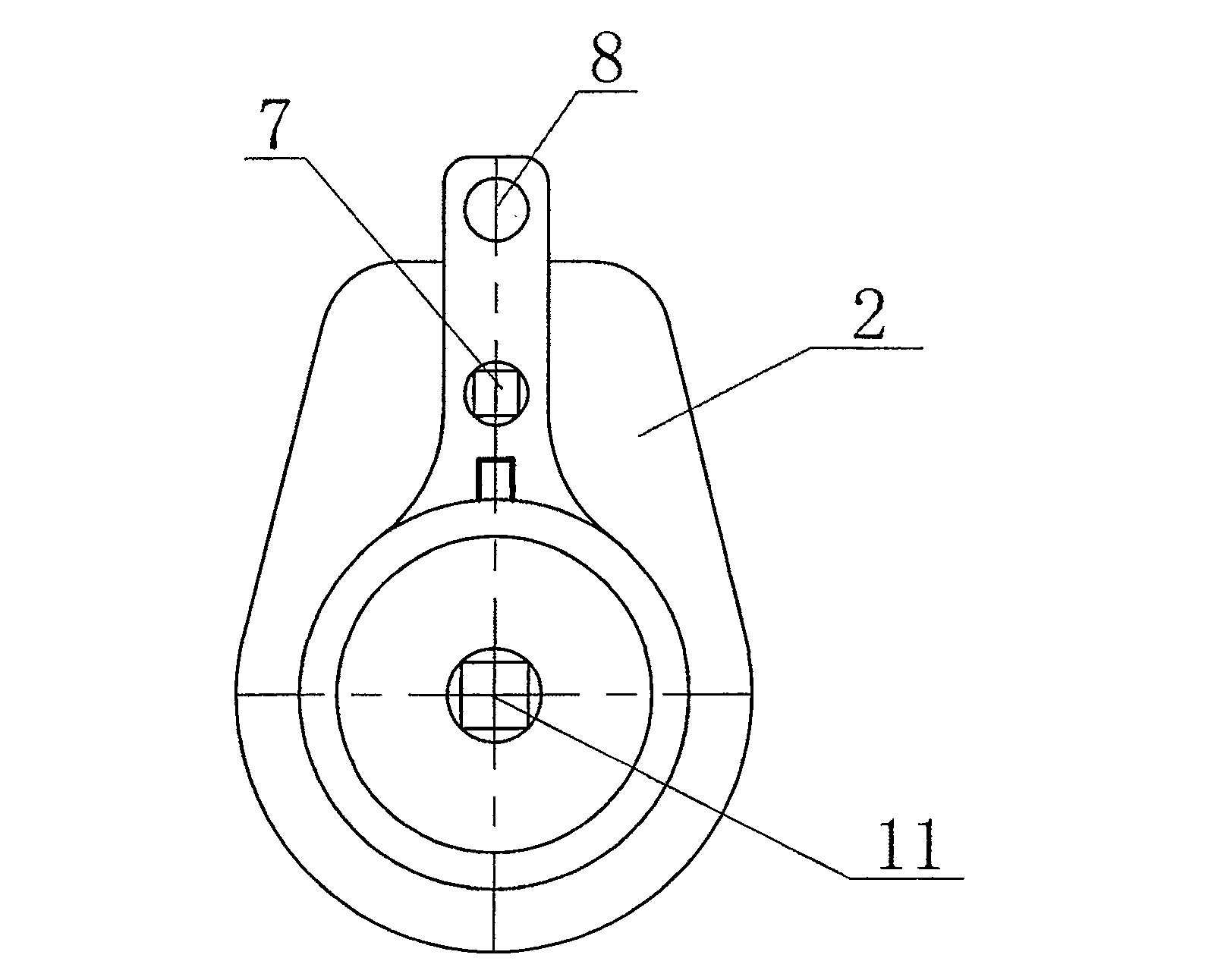

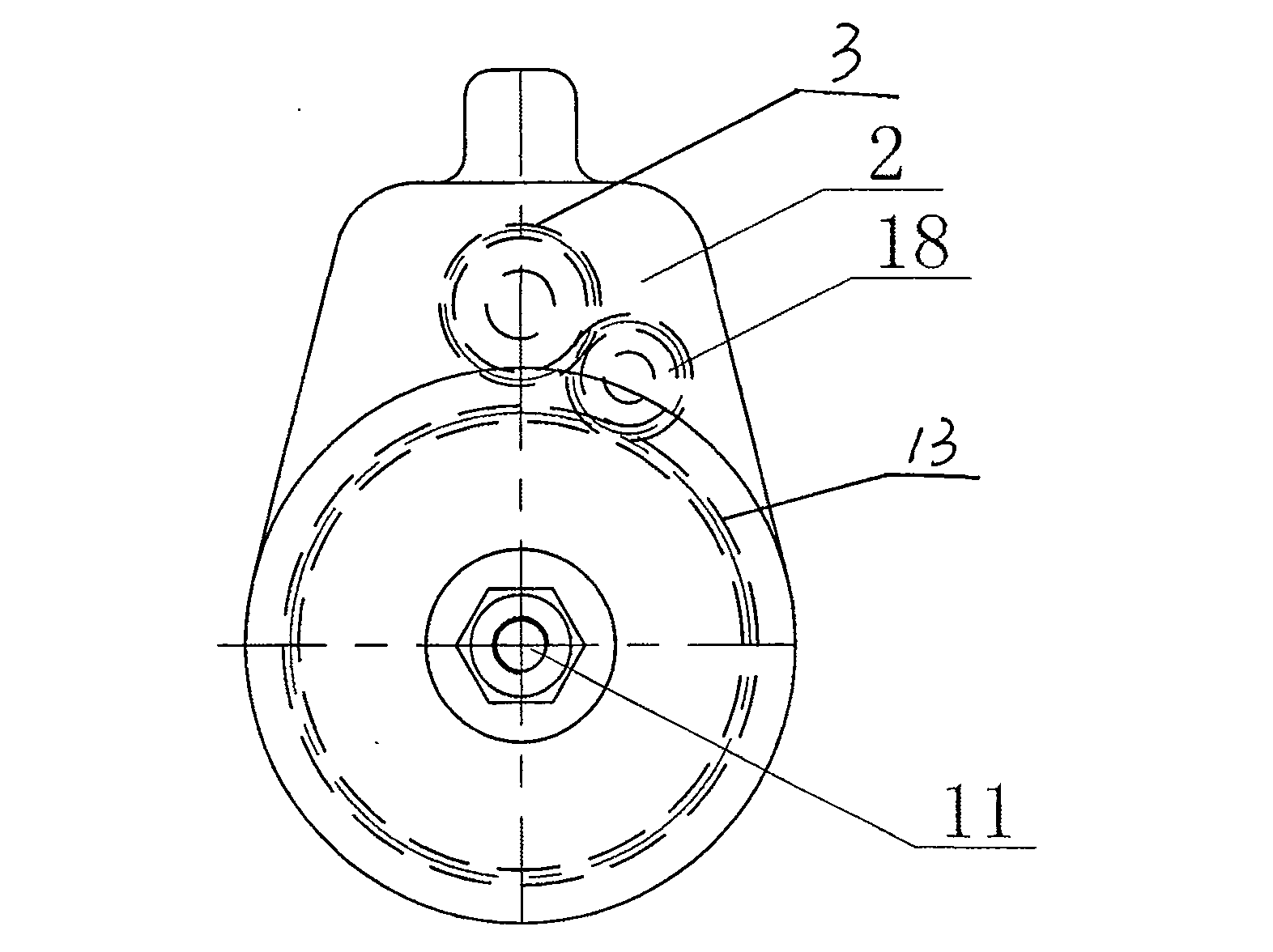

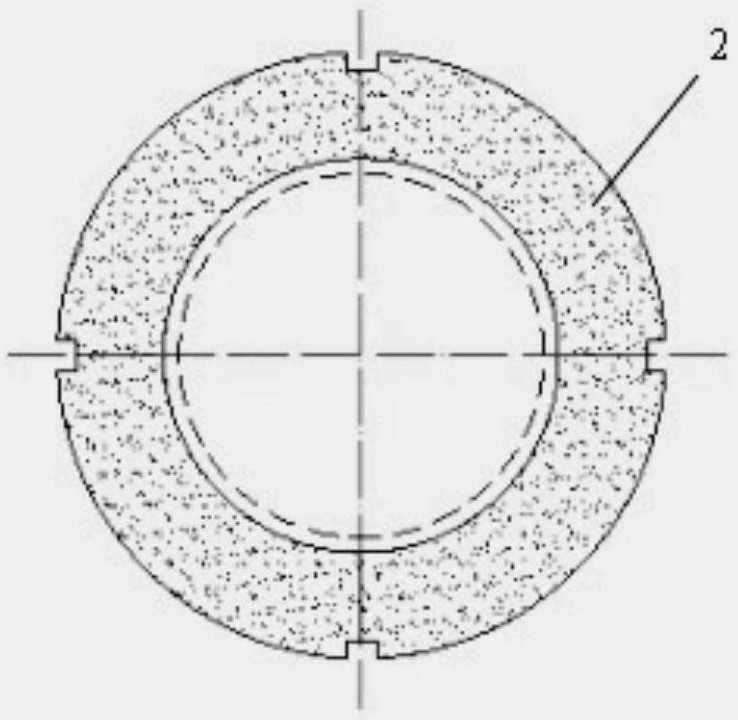

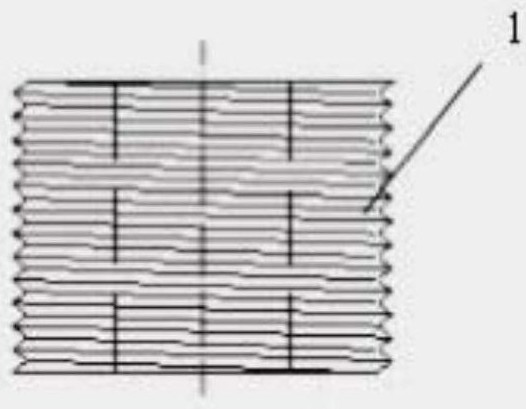

Prestressed carbon fibre cloth stretching bed seat

InactiveCN100478523CReduce stress lossEven by forceBridge erection/assemblyBuilding material handlingFiberCarbon fibers

The invention discloses a pre-stress carbon fiber cloth tension table, wherein a group of lifting cylinders (1) is mounted under a bridge beam (2), one end of the bridge beam (2) is mounted with an anchor element (3) above while the anchor element is mounted with a roller shaft (5), a tension element (4) with a roller shaft (6) via a group of connectors (7) is mounted above another end of the bridge beam (2), at least two beams (10) are connected under the bridge beam (2) at same side of the tension element (4), a bearing plate (11) is connected under the two beams (10), the base of a group of tension cylinders (9) is mounted on the bottom of a frame tension clamper (8), and the tension clamper (8) is suspended at one end of the carbon fiber cloth. The invention can uniformly force pre-stress on the carbon fiber of carbon fiber cloth, with less stress consumption of pre-stress carbon fiber cloth at the load process to make construction simple and safe.

Owner:江苏高速公路工程养护有限公司

A self-resetting beam-column energy-dissipating connector and its construction method

ActiveCN113529945BImprove shear resistanceGood self-resetting performanceProtective buildings/sheltersShock proofingClassical mechanicsStructural engineering

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Displacement self-restraint type prestressed FRP sheet tensioning device and implementation method thereof

ActiveCN109339457ATo achieve the reinforcement effectEasy to operateBuilding material handlingEngineeringBuilding construction

Owner:SOUTHEAST UNIV

A prestressed loading device and loading method for a component

ActiveCN109507049BReduce stress lossImprove reliabilityMaterial strength using repeated/pulsating forcesPre stressArchitectural engineering

The embodiment of the invention discloses a component prestress loading device and a loading method, which relate to the research field of aging tests of prestressed concrete structures, and improve the reliability of component prestress loading. A prestressed loading device for a component, including a tension end anchor and a fixed end anchor: the tension end anchor includes a first anchor ring and a first clip, and a first anchor ring is provided with a first The installation hole, the first clip is located in the first installation hole, the outer side of the first anchor ring is connected with a pre-tightening steel sleeve; the fixed end anchor includes a second anchor ring and a second clip, A second installation hole is opened on the second anchor ring, and the second clip is located in the second installation hole; the tension end anchor and the fixed end anchor are respectively used to connect with the member The tension end and the fixed end of the prestressed tendon connection. The embodiments of the present invention are mainly used for prestressed loading of concrete components.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Prestressed post-inserted composite anchor cable uplift pile and on-site loading equipment thereof

The prestressed post-inserted composite anchor cable uplift pile comprises a pile casing, an outer steel bar frame is inserted into the inner side of the pile casing, a cone-shaped body with a guide device is arranged at the bottom of the outer steel bar frame, an inner steel bar cage is inserted into the inner side of the outer steel bar frame, and the inner steel bar cage is arranged in the outer steel bar frame. A hollow pipe is fixedly connected to the axis of the bottom of the interior of the inner reinforcement cage, a concrete pouring channel is formed in the center of the interior of the hollow pipe, and through openings are evenly formed in the bottom of the outer side of the concrete pouring channel. Through the structural cooperation of the pile casing, the outer steel bar frame, the inner steel bar cage and the latticed column, the structural system of the uplift pile is made to be well arranged during installation work, a positioning guide structure between the structures can be formed through structural traction of the guide mechanism, it is guaranteed that vertical installation of the uplift pile body is more accurate and centered, and the construction efficiency is improved. The phenomena of inclination and position deviation of the post-inserted uplift pile are reduced, and meanwhile the tensile stress of the uplift pile body in the working state is eliminated.

Owner:CHINA ACAD OF BUILDING RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com