Construction method of environment-friendly tension and compression composite distributed anchor rod

A composite dispersion and construction method technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as economic loss, damage to shield cutter head, construction period stagnation, etc., to reduce long-term stress loss and enhance pullout resistance. Bearing capacity, ensure smooth construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

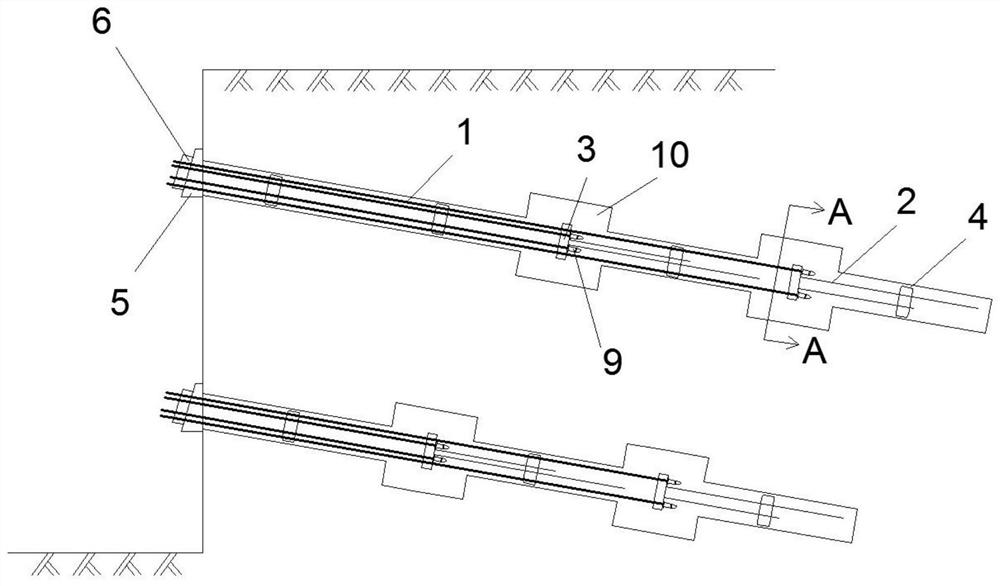

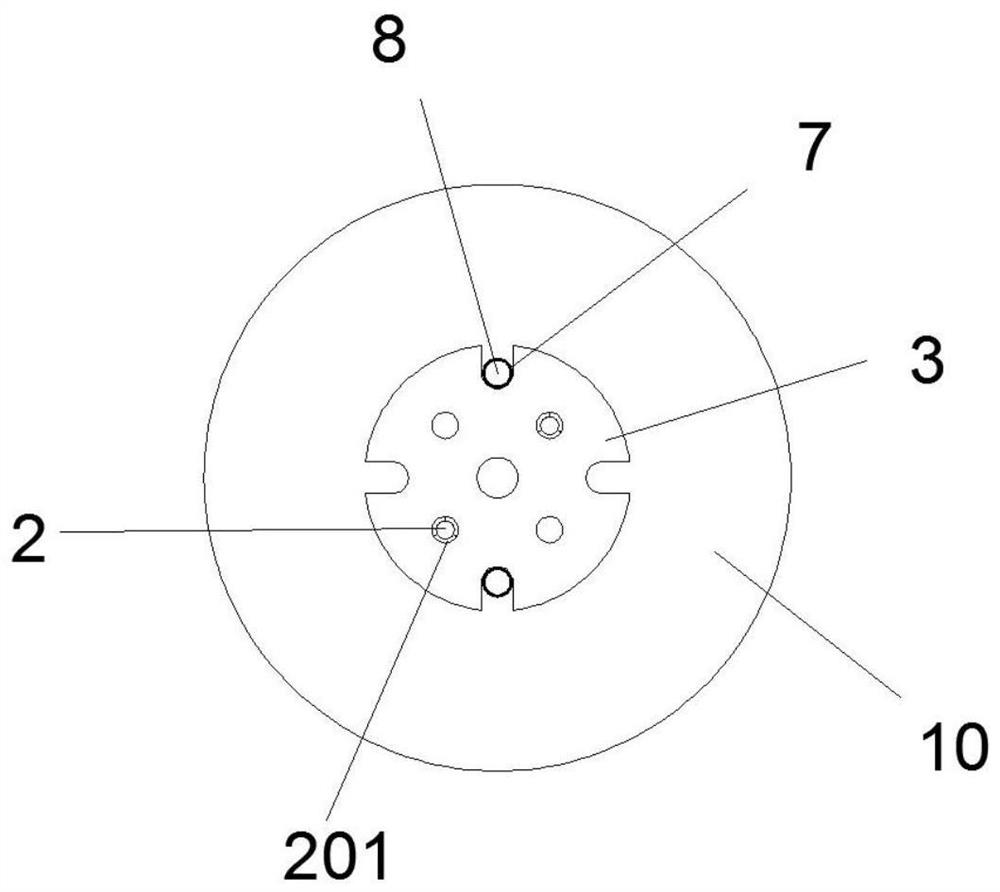

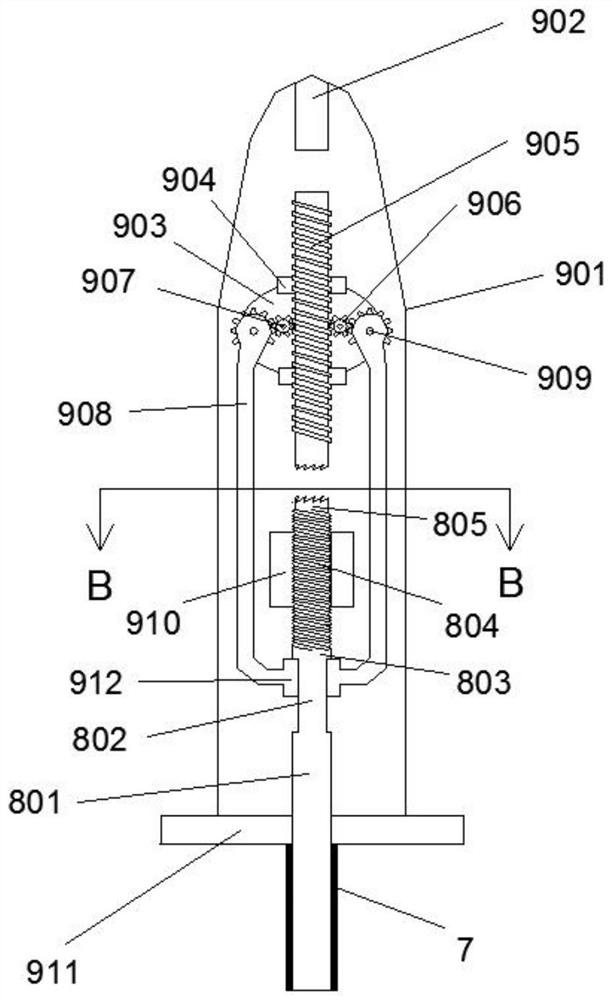

[0041] Such as figure 1 , 2, 3, 4, 5, and 6, an environment-friendly tension-compression composite distributed expansion anchor includes several pressure-type anchors 1, several tension-type anchors 2, and several tension-compression anchor bearing plates 3. A number of anchor rod centering brackets 4, backing plates 5 and anchor heads 6; the pressure type anchor rod 1 is a recyclable pressure type anchor rod, including a plastic sleeve 7, a steel bar body 8 and an unlocking device 9, and the steel bar body The end of 8 is an unlocking end; the unlocking end of the steel bar body 8 includes a first regular section 801, a first diameter-reducing section 802, a second regular section 803, a threaded section 804 and a second diameter-reducing section 805 from bottom to top; The diameter of the second shrinking section 805 is equal to the thread inner diameter of the threaded section 804, and the top section of the second shrinking section 805 is radially sawtoothed; the unlockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com