Double-layer drum reinforced rotor structure of gas compressor of gas turbine

A gas turbine and rotor structure technology, applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve problems affecting the stability and reliability of the rotor structure, achieve the effects of improving rigidity, preventing severe vibration, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

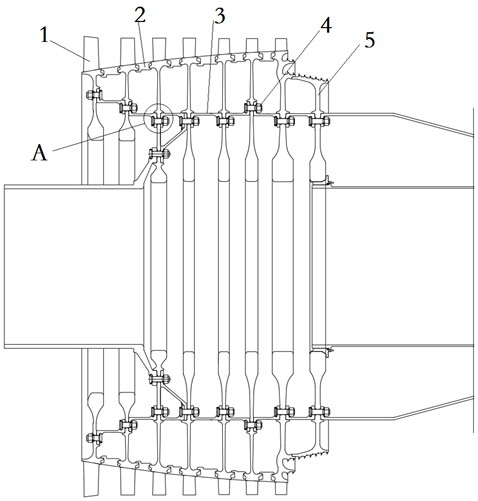

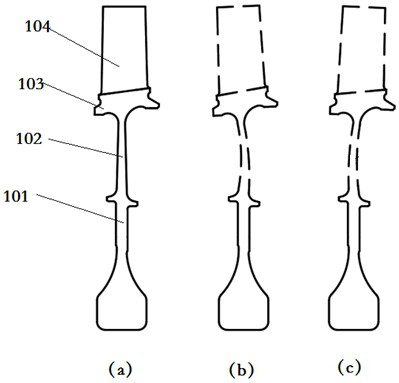

[0032] Such as Figure 1 to Figure 4 As shown, in view of the above problems, this embodiment designs a double-drum reinforced rotor structure of a gas turbine compressor. By slightly deforming the web 102 of the control impeller 1, the web 102 is in a non-working state. It has a certain prestress, and in the working state, the prestress is used to balance or eliminate the new stress generated when the rotor rotates at high speed.

[0033] The rotor structure in this scheme is a double-layer frame structure formed by the working impeller 1, the outer drum 2, the inner drum 3 and the sealing grate disc 5. Wherein, the working impeller 1 includes a first-stage working impeller, a second-stage working impeller, a third-stage working impeller, a fourth-stage working impeller, a fifth-stage working impeller, a sixth-stage working impeller, and a seventh-stage working impeller; The axial direction is arranged in sequence from front to back, wherein the first-stage working impeller ...

Embodiment 2

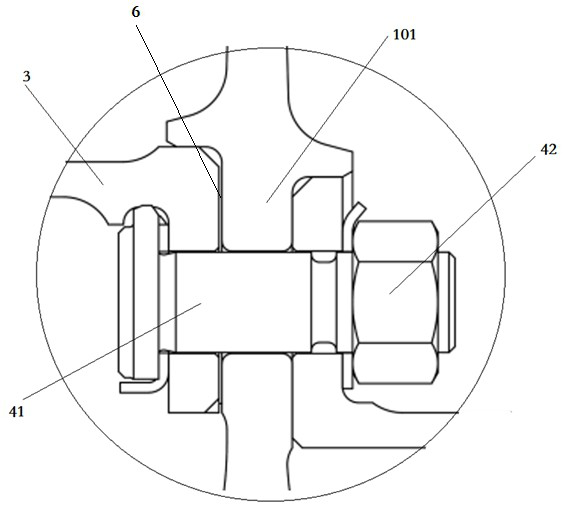

[0040] On the basis of the rotor structure in Example 1, the micro-deformation of the web 102 of the working impeller 1 at each stage is caused by bolts tightening the working impeller 1 and the previous inner drum 3 connected to it, and eliminating the gap between the two. The reserved axial clearance 6 is realized.

[0041] Before using bolts to tighten the web 102 of the corresponding working impeller 1, the axial gap 6 between the working impeller 1 and the inner drum 3 of the preceding stage can be defined as the first gap; Behind the web 102, the axial gap 6 between the working impeller 1 and the inner drum 3 of the previous stage can be defined as the second gap; after the bolt tightens the web 102, the working impeller 1 and its The internal drums 3 of the previous stage can be one of clearance fit, transition fit and interference fit. When the working impeller 1 and the inner drum 3 are in transition fit and interference fit, the micro-deformation of the web 102 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com