A prestressed loading device and loading method for a component

A technology of prestressing and prestressing tendons, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of serious stress loss, difficulty in reaching the stress value, and inability to establish test conditions, etc. Achieve the effect of reducing stress loss and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

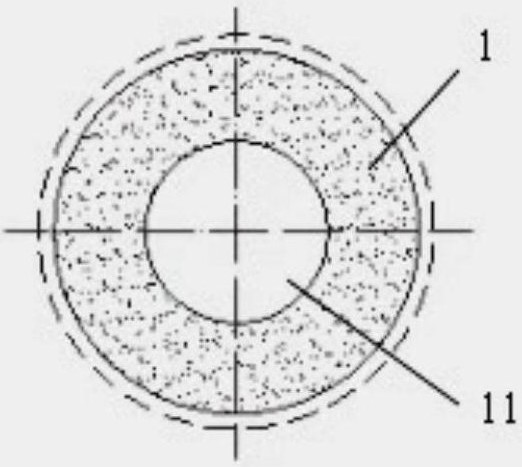

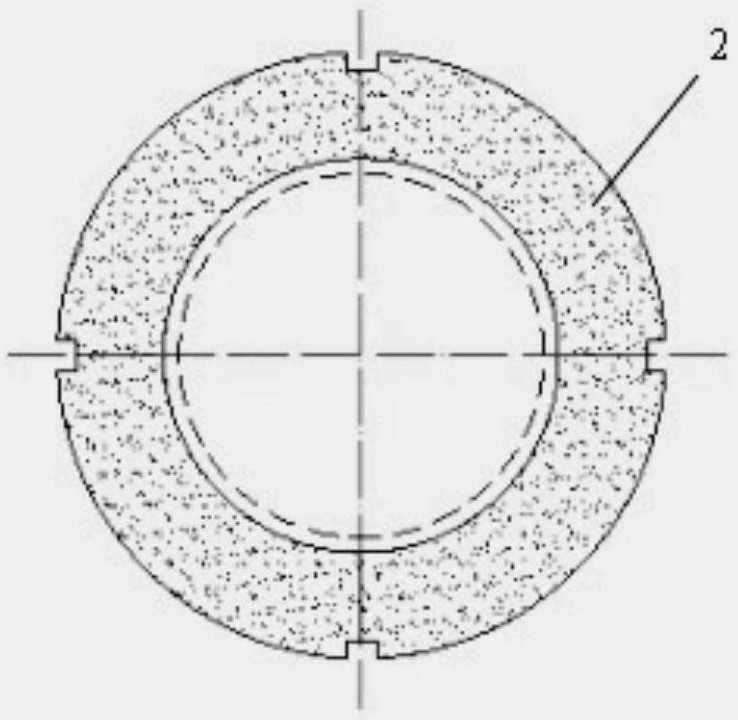

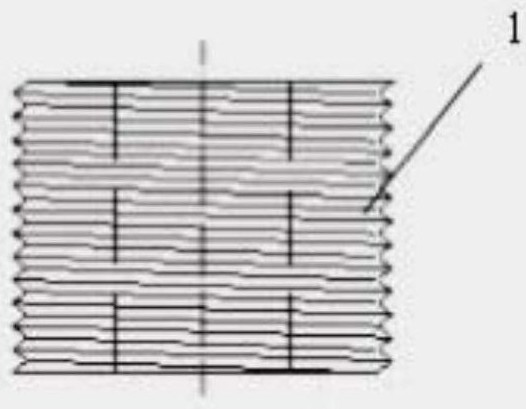

[0026] First aspect, such as Figure 1-4 As shown, the embodiment of the present invention provides a prestressed loading device of a member, including a tensile end anchor and a fixed end anchor: the tensile end anchor includes a first anchor ring 1 and a first clip. The first mounting hole 11 is provided on the first anchor ring 1, the first clip located within the first mounting hole 11, and the outer side of the first anchor ring 1 is connected to a pre-tightening steel sleeve 2; The fixed end anchor includes a second anchor ring and a second separator, and the second mounting hole is opened, the second clip located within the second mounting hole; the tension anchor And the fixed end anchor is respectively used to connect with the tensile end of the member and a prestressed end of the fixed end.

[0027] In this embodiment, since the first clip does not belong to the invention of the present embodiment, figure 1 with image 3 The first clip and the connection relationship of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com