Displacement self-restraint type prestressed FRP sheet tensioning device and implementation method thereof

A technology of FRP sheets and tensioning devices, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of large operating space, cumbersome operation, and high material consumption, and achieve convenient manual operation, simple operation, and high construction efficiency. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

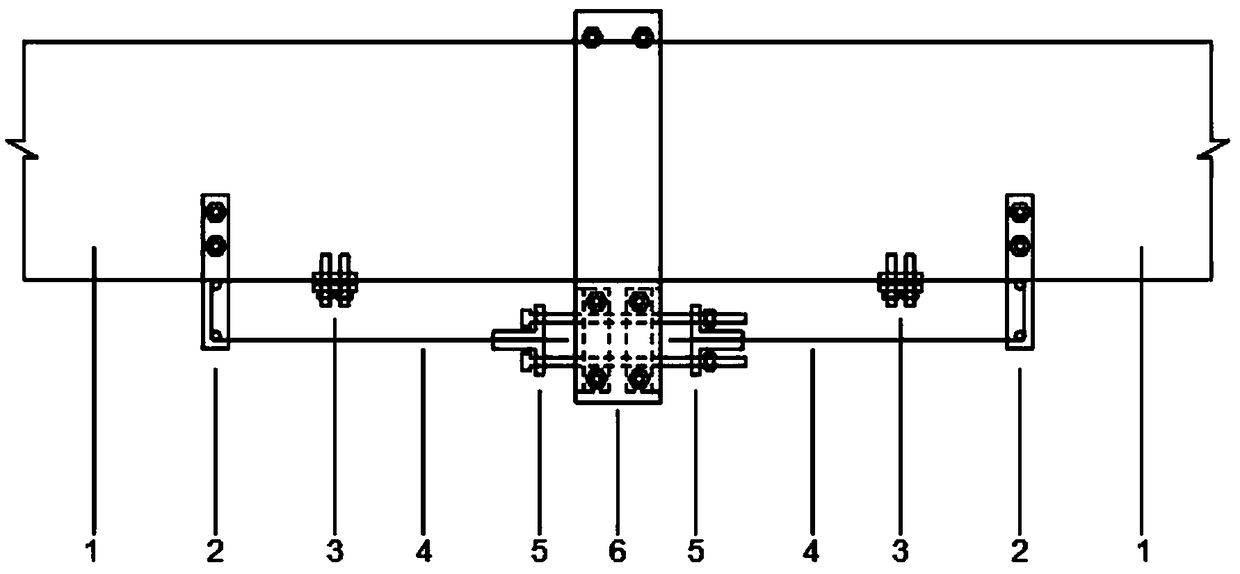

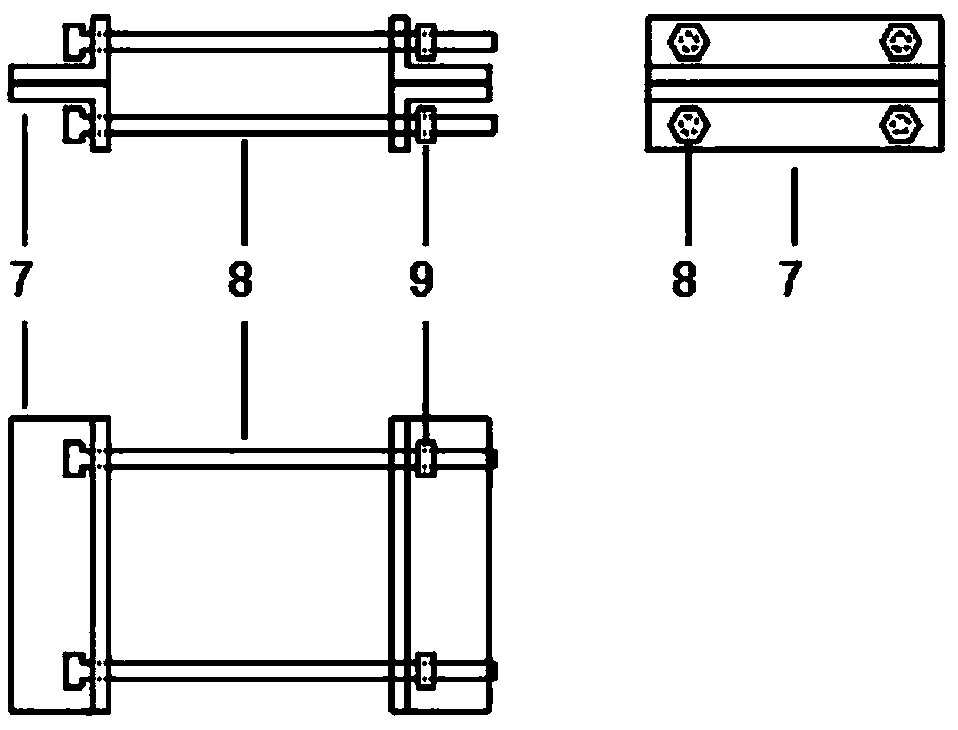

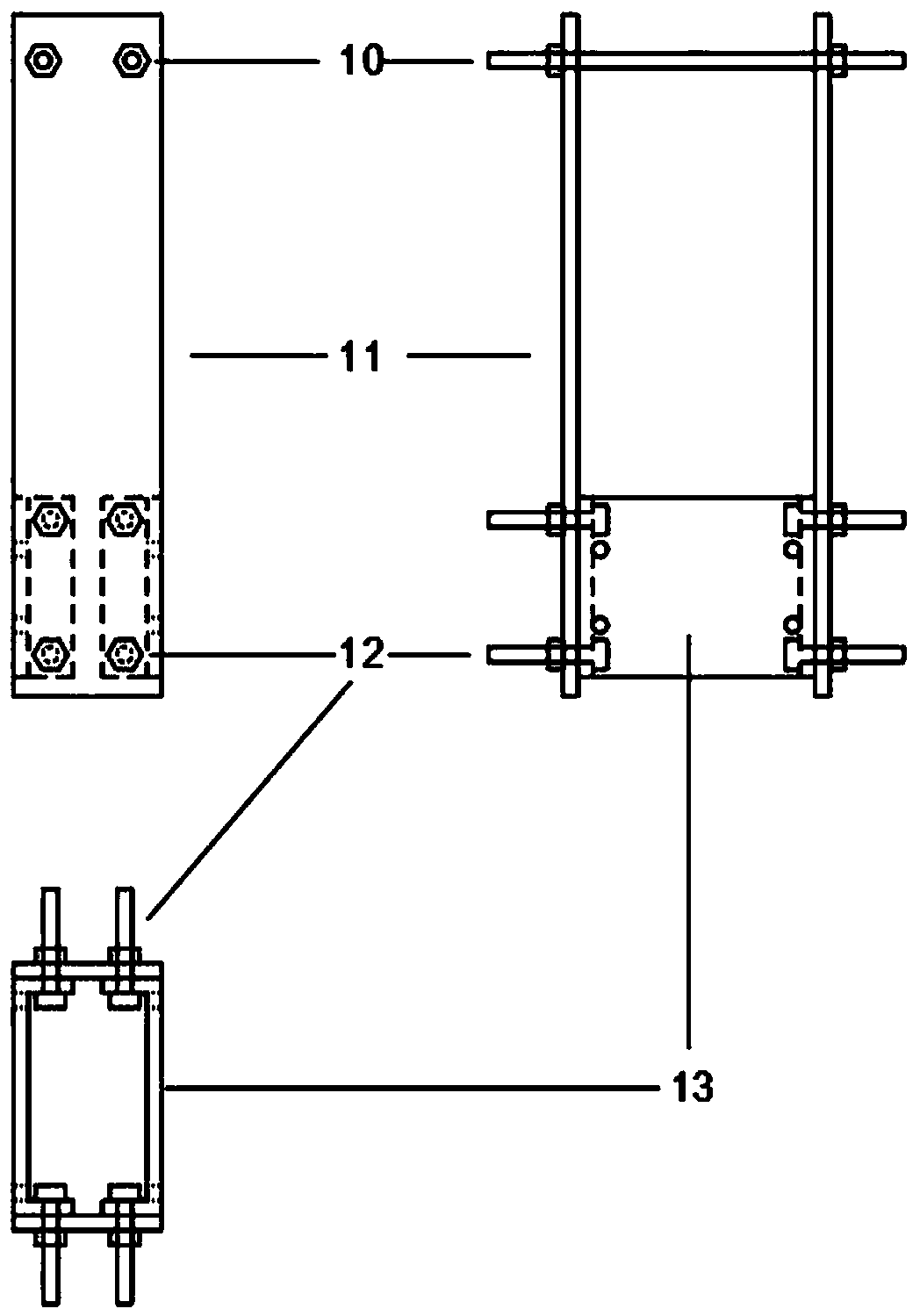

[0039] A displacement self-constrained prestressed FRP sheet tensioning device, the tensioning device includes a steering part 2, a fixed part 3, a tensioning part 5 and a tensioning support part 6; wherein the steering part 2, the fixing part 3 and the tensioning part The support parts 6 are all fixed on the lower surface of the reinforced beam 1, the tension support part 6 is centered and fixed, and the number of the steering parts 2 is 2, which are respectively located on the left and right sides of the tension support part 6. Fixing parts 3 are arranged between the left and right sides of the left and right sides and the steering part 2, the tensioning part 5 is fixedly connected to the tensioning support part 6, one end of the FRP sheet 4 is fixed on one end of the tensioning part 5, and the FRP sheet The other end of 4 passes through the steering part 2 and the fixed part 3 on one side of the tension support part 6, then passes through the tension support part 6, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com