A construction method for reinforcing wooden purlins with hoop racks

A construction method and rack technology, which are applied in building maintenance, construction, building construction, etc., can solve the problems that the overall bearing capacity of wooden purlins cannot be improved, and achieve the effect of reversibility, small interference of components in their original state, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

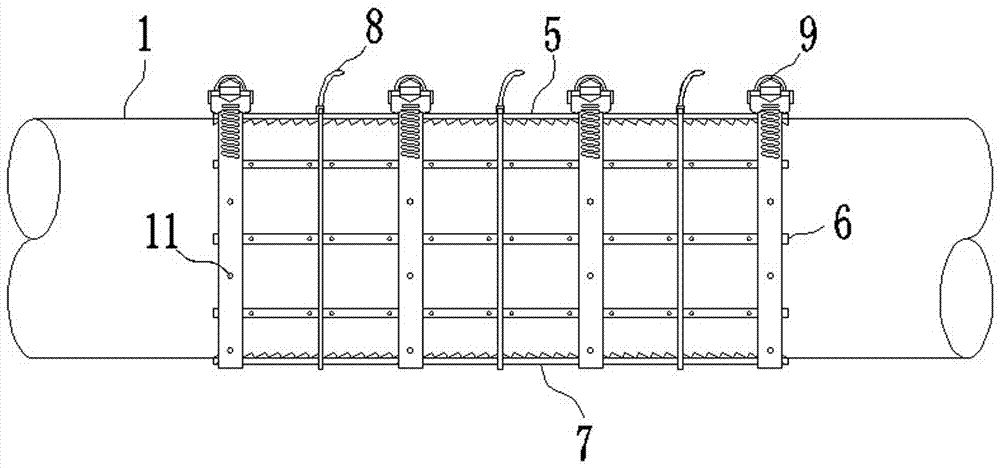

[0028] A construction method for reinforcing wooden purlins with hoop racks, comprising the following steps:

[0029] Step 1: Cleaning and trimming the parts of the wooden purlin 1 that need to be reinforced;

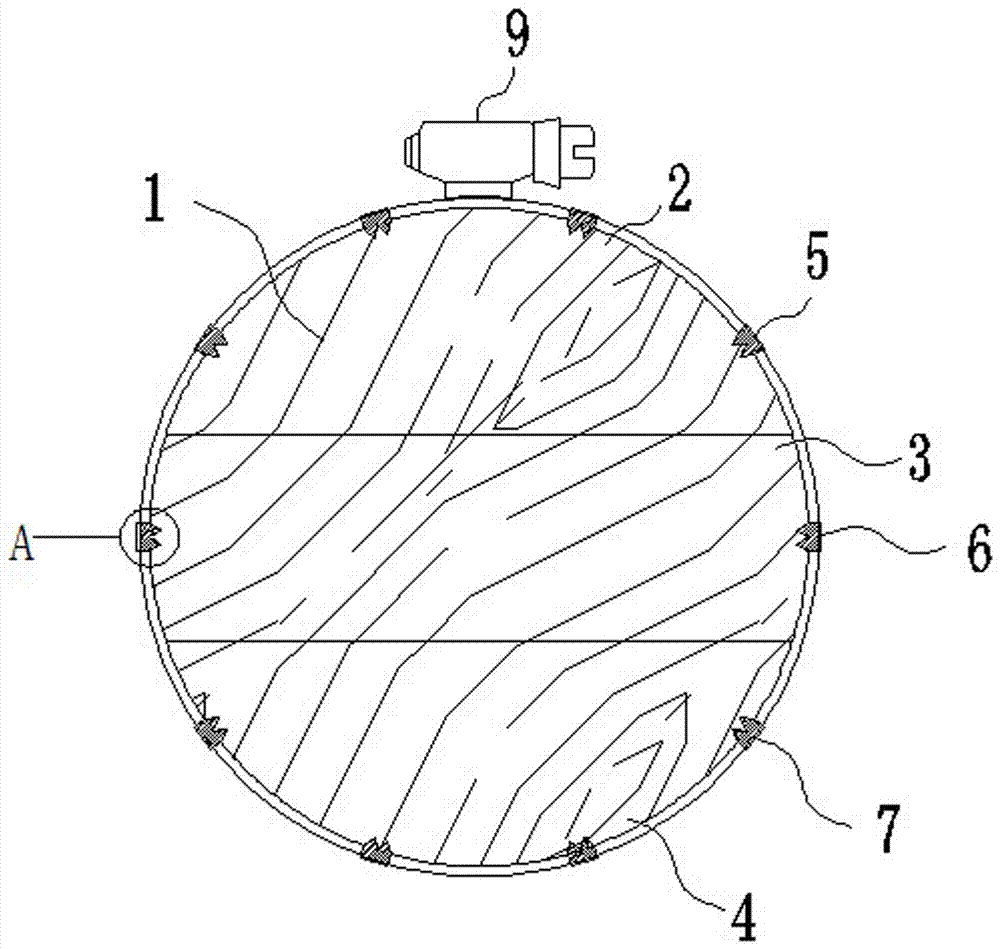

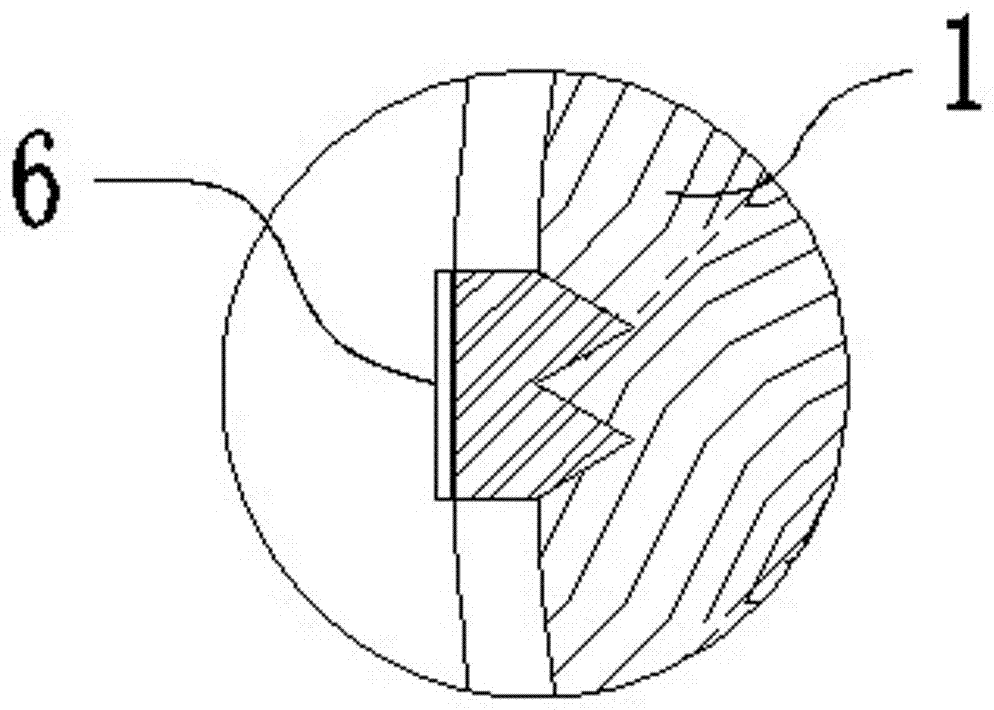

[0030] Step 2: If figure 2 , image 3 As shown, the section of the wooden purlin 1 is divided into three parts from top to bottom, the upper part 2, the middle part 3 and the lower part 4, and at least two plastic tie Figure 6-8 The shown upper rack 5, middle rack 6, and lower rack 7 are fixed on the wooden purlin 1 upper part 2, middle part 3 and lower part 4 after step 1 is cleaned and trimmed. The toothed section of the upper rack 5 is an external support type, sharing the pressure of the compression zone above the central axis of the wooden purlin reinforcement section; the lower rack 7 is an internal pull type, sharing the wooden purlin reinforcement. The tensile force in the tension zone below the central axis of the section; the toothed section of the middle...

Embodiment 2

[0033] For the wooden purlin 1 that has crack, the construction method of clamp rack reinforcing wooden purlin comprises the following steps:

[0034] Step 1: If Figure 4 As shown, the parts of the wooden purlin 1 that need to be reinforced are cleaned and trimmed, and the bamboo wedge 12 coated with the resin adhesive is wedged in the crack where the resin adhesive is applied;

[0035] Step 2: If figure 2 , image 3 As shown, the section of the wooden purlin 1 is divided into three parts from top to bottom, the upper part 2, the middle part 3 and the lower part 4, and at least two plastic tie Figure 6-8 The shown upper rack 5, middle rack 6, and lower rack 7 are fixed on the wooden purlin 1 upper part 2, middle part 3 and lower part 4 after step 1 is cleaned and trimmed. The toothed section of the upper rack 5 is an external support type, sharing the pressure of the compression zone above the central axis of the wooden purlin reinforcement section; the lower rack 7 is a...

Embodiment 3

[0038] The wooden purlin 1 whose cross-section has decayed more than one-third, and the construction method for reinforcing the wooden purlin with the clip rack include the following steps:

[0039] Step 1: If Figure 5 As shown, the parts of the wooden purlin 1 that need to be reinforced are cleaned and trimmed, then the decayed parts are cut off and repaired, and at least one layer of carbon fiber cloth 13 or glass fiber cloth is pasted on the surface of the wooden purlin 1;

[0040] Step 2: If figure 2 , image 3 As shown, the section of the wooden purlin 1 is divided into three parts from top to bottom, the upper part 2, the middle part 3 and the lower part 4, and at least two plastic tie Figure 6-8 The shown upper rack 5, middle rack 6, and lower rack 7 are fixed on the wooden purlin 1 upper part 2, middle part 3 and lower part 4 after step 1 is cleaned and trimmed. The toothed section of the upper rack 5 is an external support type, sharing the pressure of the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com