Patents

Literature

558results about How to "Conducive to manual operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

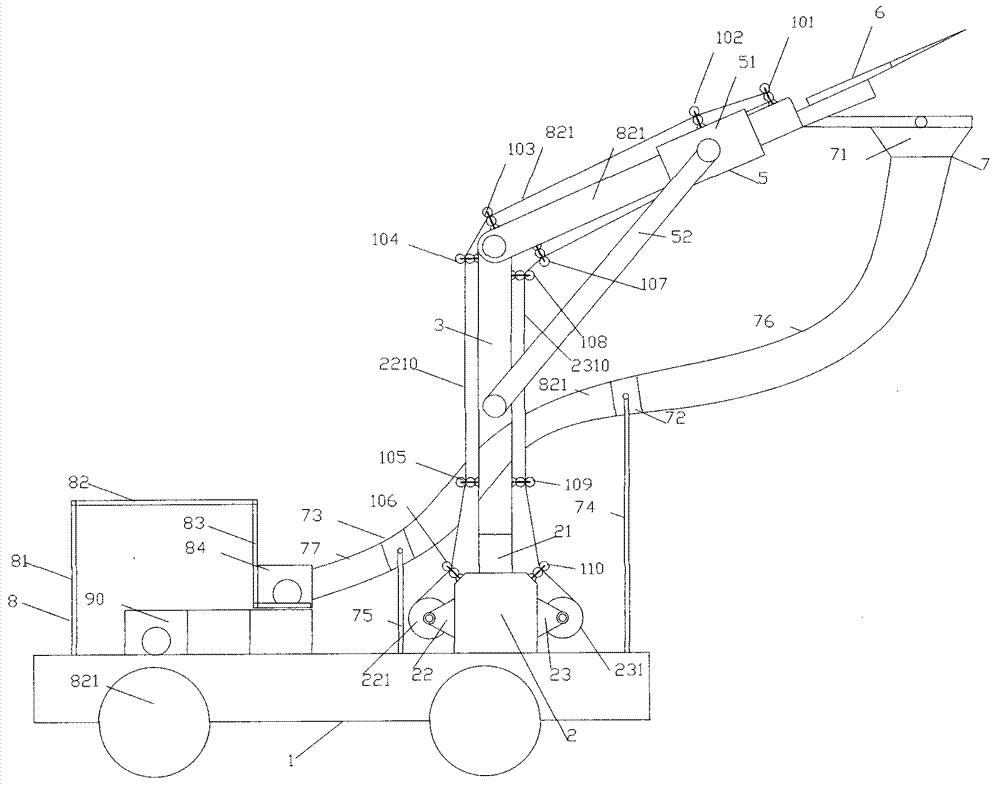

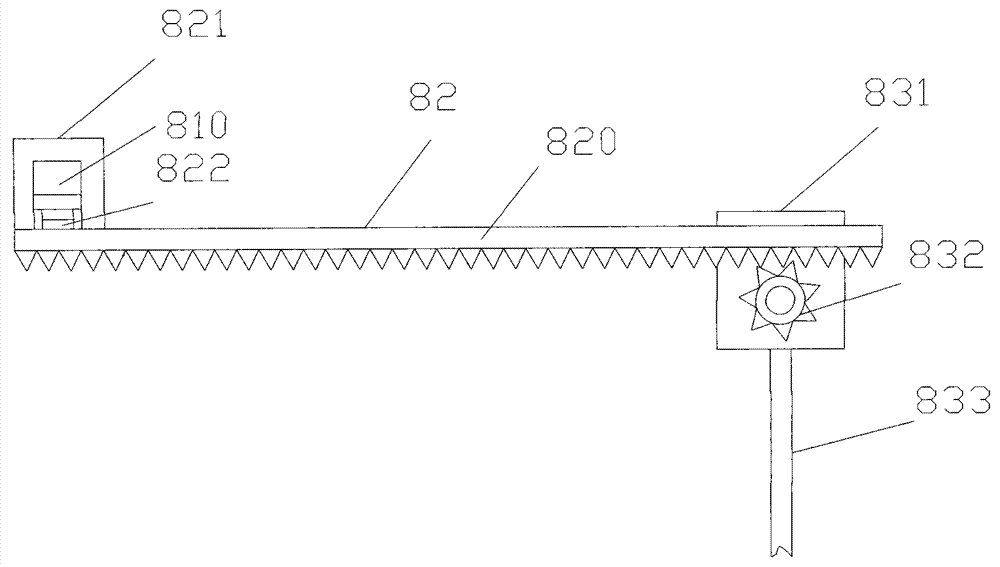

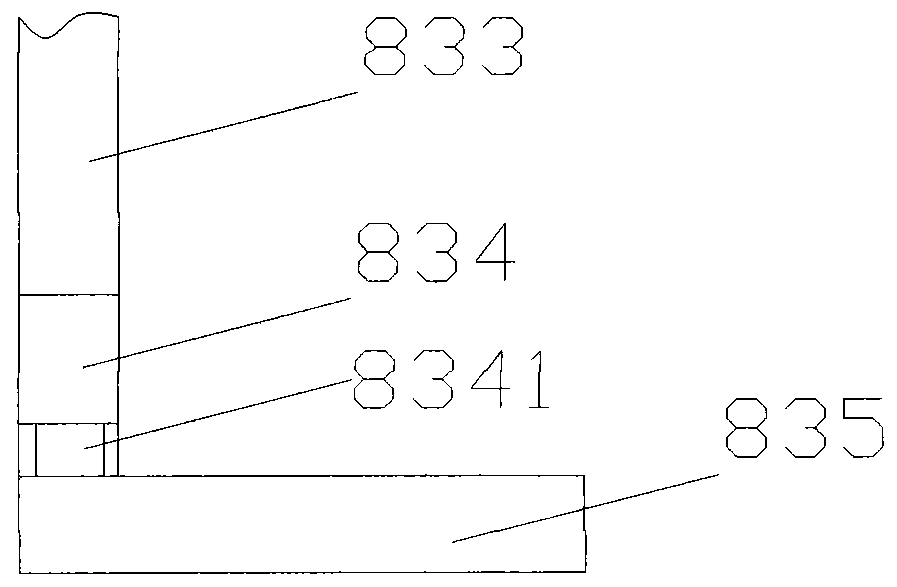

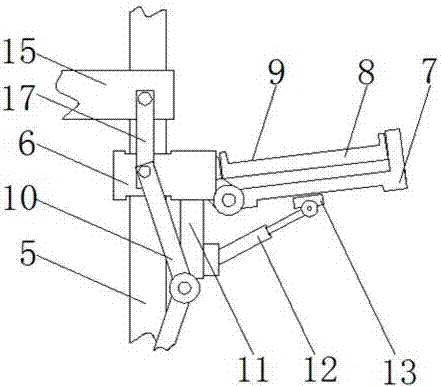

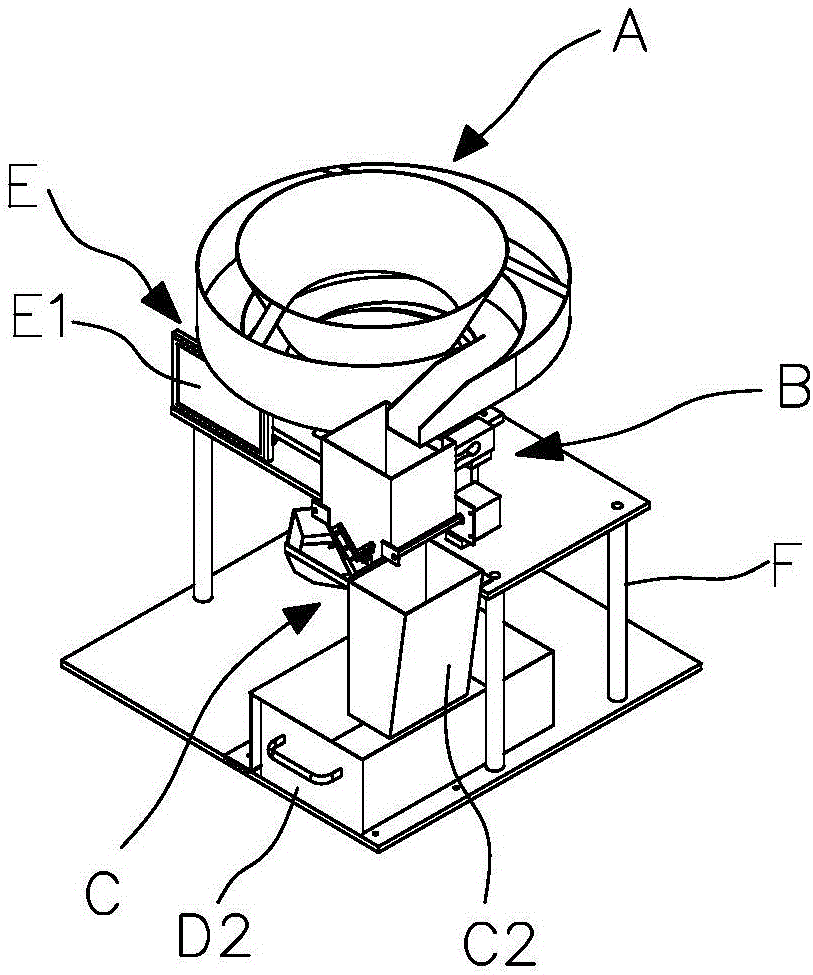

Apple picking machine and method for operating same

ActiveCN104255193AOptimization pathEasy to collectPicking devicesPulp and paper industryUltimate tensile strength

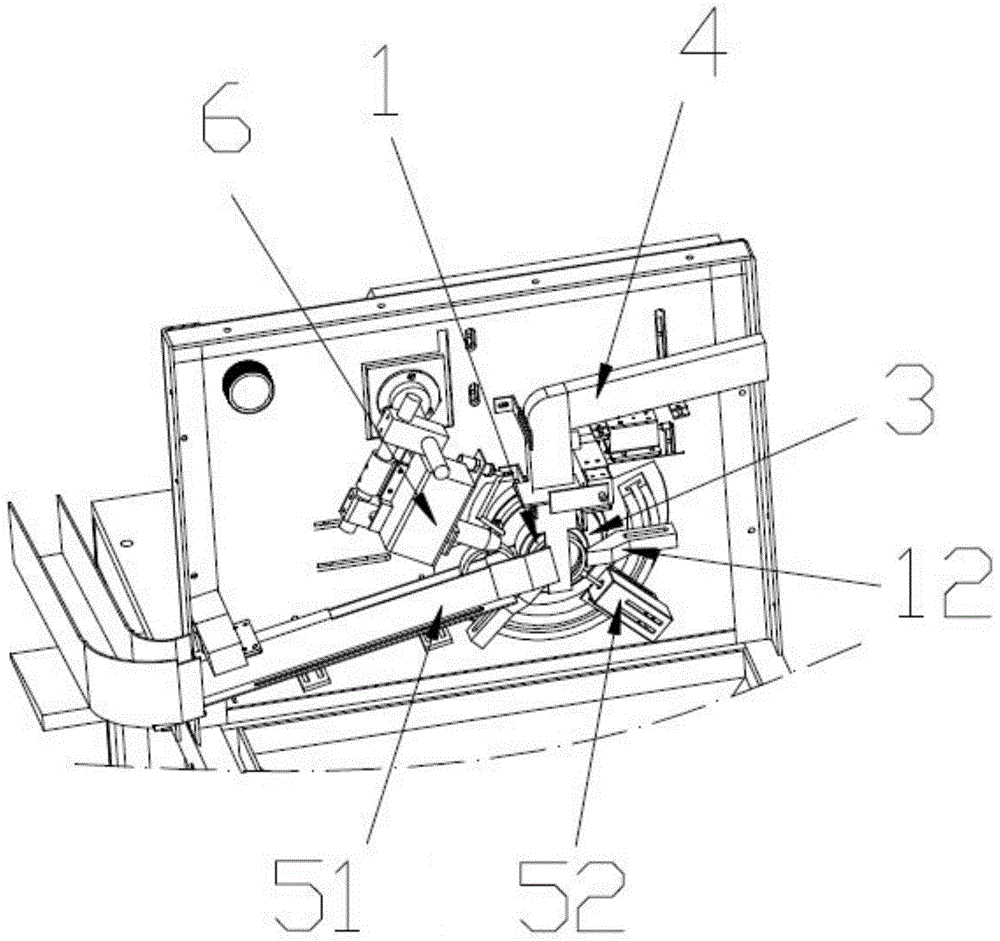

The invention discloses an apple picking machine and a method for operating the same. The apple picking machine comprises a framework, a shearing mechanism, an adjusting mechanism, a collecting channel, an accommodating mechanism and an apple box. The adjusting mechanism comprises a support column, a rotary column and a crank-slider mechanism; the bottom of the support column sleeves a base, and the top of the support column is hinged to an end of the rotary column; the crank-slider mechanism comprises a slider and a connecting rod, the slider sleeves the rotary column, one end of the connecting rod is hinged to the rotary column, and the other end of the connecting rod is hinged to the support column; the shearing mechanism is arranged on the top of the rotary column. The apple picking machine and the method have the advantages that the height of shears can be conveniently controlled via the crank-slider mechanism, and the apple picking machine can be controlled via motors and is simple in operation and low in labor intensity; an electromagnet is arranged at the tail of a handle of the shears, so that the apple picking machine can be conveniently manually operated, and the labor intensity can be reduced; the apple picking machine is provided with the collecting channel, so that apples can be conveniently collected while bruise due to an accommodating machine can be effectively prevented; the apples can be automatically placed by the accommodating mechanism which is matched with the apple box, and accordingly the labor time can be saved.

Owner:刘宝帅 +1

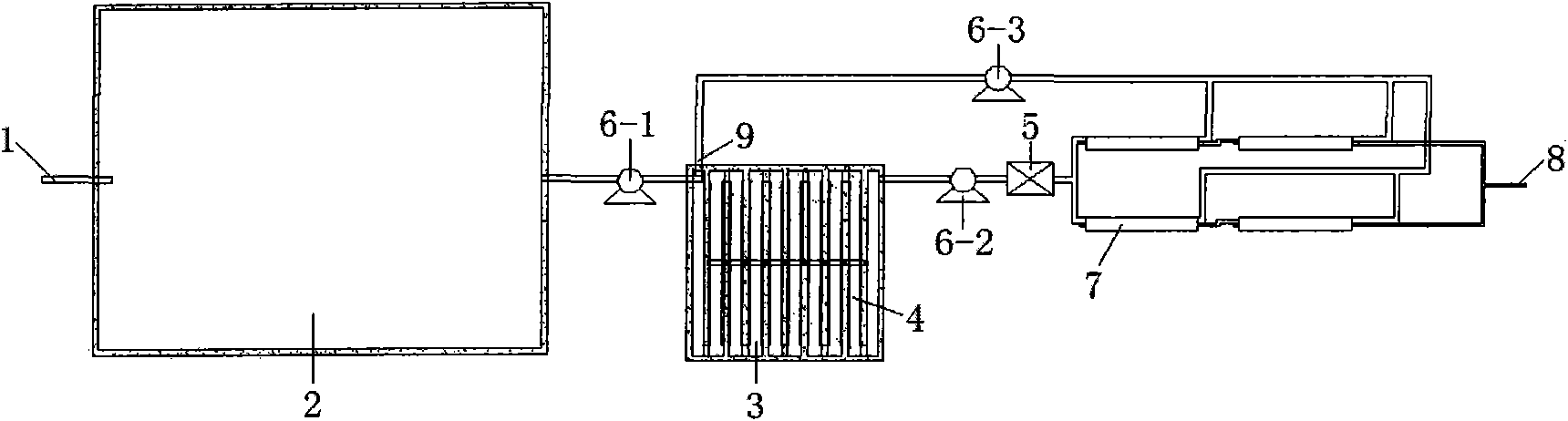

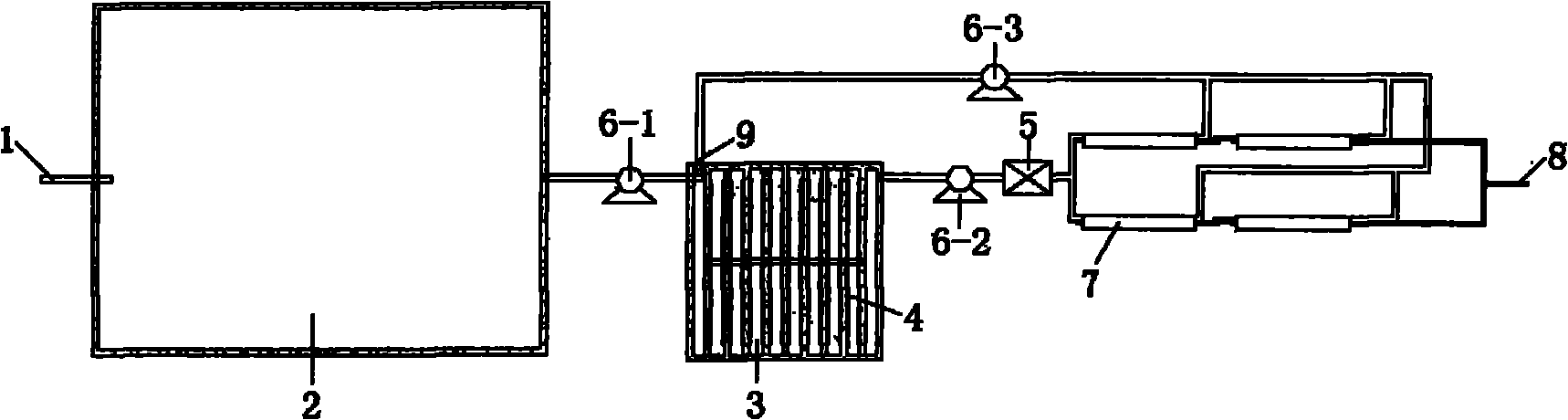

Electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater

InactiveCN101921032AEfficient use ofLess investmentWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectricityElectrolysis

The invention discloses an electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater, comprising a liquid inlet pipe, an adjusting tank, an electrolytic deposition device, a three-dimensional fixed bed device, a safety filter, three circulating pumps, a membrane assembly, a clear water outlet and a condensed liquid reflex hole, wherein the connection of various components is detailed in the description. The invention has the advantages that: by combining the electrolytic deposition technology with the membrane separation technology, the device has the advantages of less investment, high handle capacity, low energy consumption, high benefit, easy industrialization and easy implementation of the comprehensive utilization of resources; the effluent discharge after reaching standards and the recycling are realized, the heavy metal resources in the wastewater are effectively recycled; and automation degree is high and manual operation is simple and convenient, the complete recovery and zero discharge of heavy metals can be basically realized and water resources are completely recycled and the wastewater is deeply purified.

Owner:PEKING UNIV

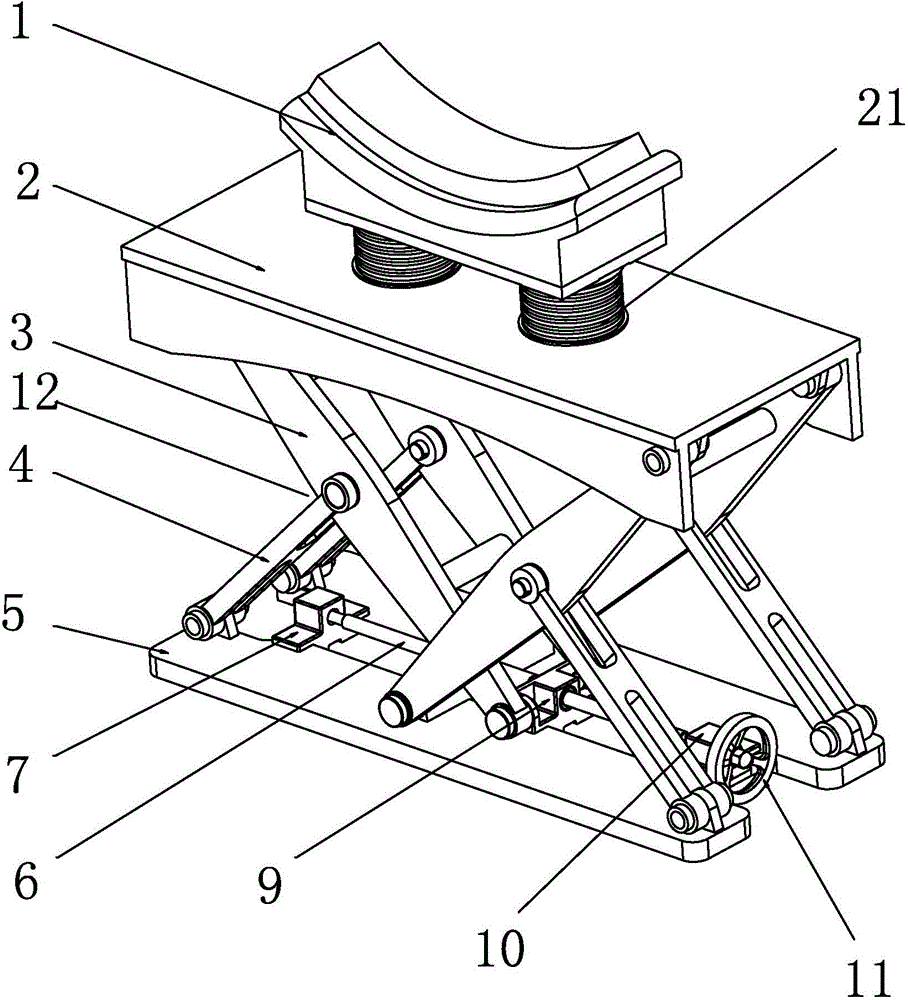

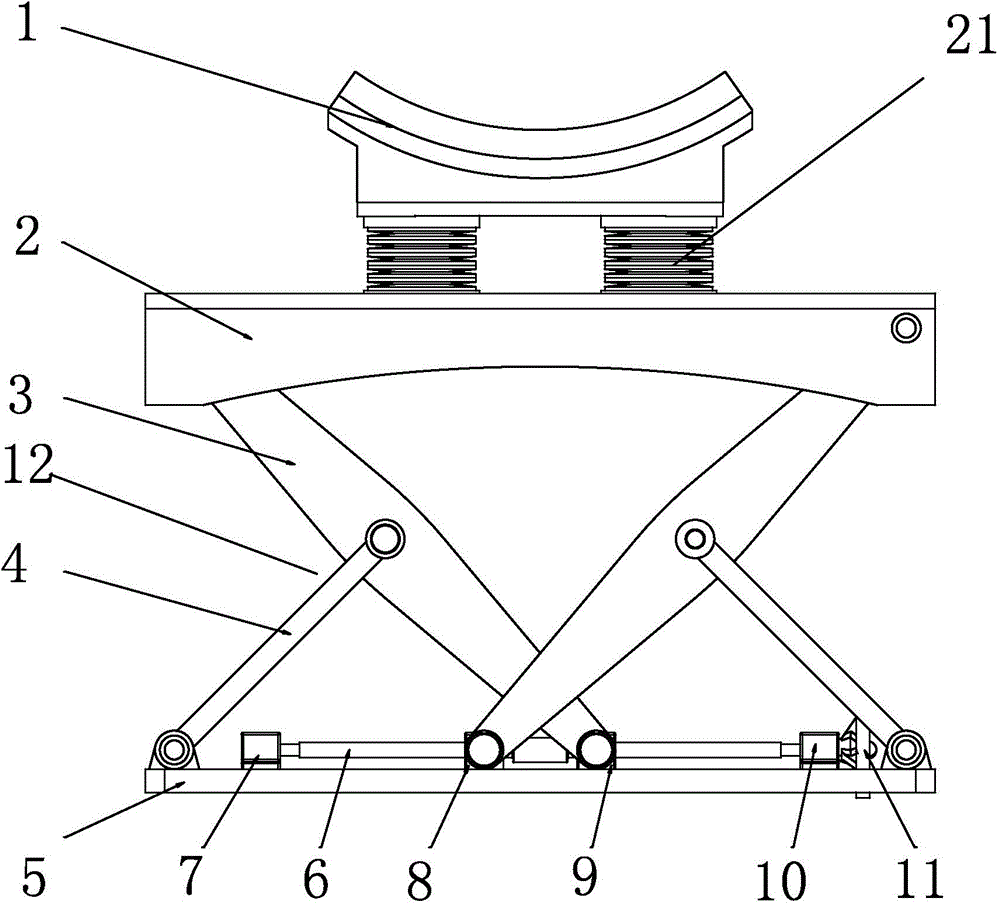

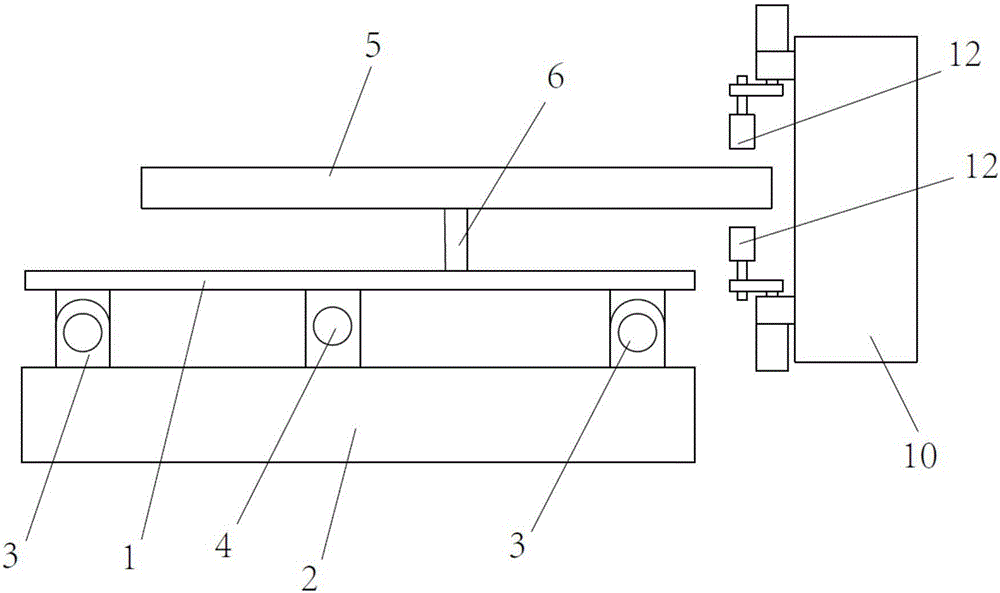

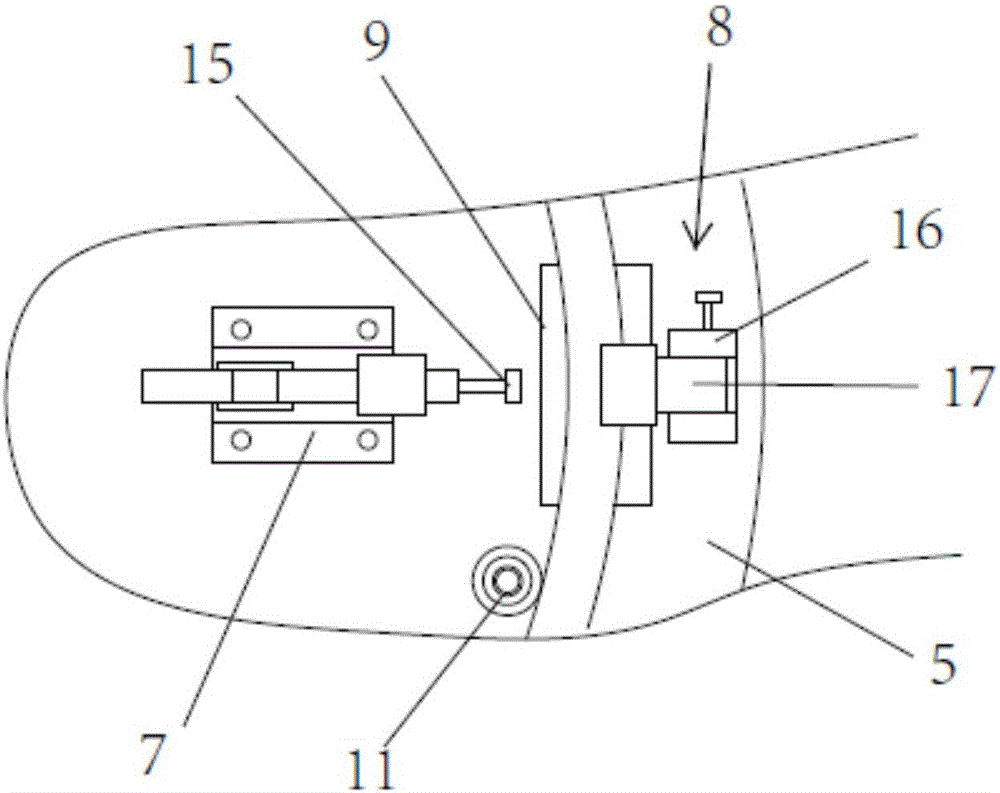

Scissors fork lifting type auxiliary supporting mechanism capable of being locked at random position

InactiveCN104944315AThe overall structure is simple and reliableSave spaceLifting framesEngineeringSpace requirements

The invention relates to a scissors fork lifting type auxiliary supporting mechanism capable of being locked at a random position. The scissors fork lifting type auxiliary supporting mechanism comprises a bracket and a top plate below the bracket. The bracket is fixedly connected with the top plate through two disc springs, a base plate is positioned below the top plate, a screw is horizontally arranged in the length direction of the base plate, a hand wheel is installed on the outer side of one end of the screw, and the middle of the screw is in threaded connection with a first sliding block and a second sliding block which are arranged at intervals. When the hand wheel is rotated, the first sliding block and the second sliding block can perform opposite-direction movements in the axial direction of the screw, four groups of linkage mechanisms are further arranged between the top plate and the base plate, the upper ends of the linkage mechanisms are hinged to the top plate, the lower ends of the linkage mechanisms are hinged to the first sliding block and the second sliding block respectively, and the first sliding block and the second sliding block can drive each group of linkage mechanisms to perform lifting movements when moving. The supporting mechanism can reliably support a product and have a large displacement lifting function, can perform fine adjustment of the vertical position, can be reliably locked at the random position, is small in vertical dimension and meets the installing space requirements.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

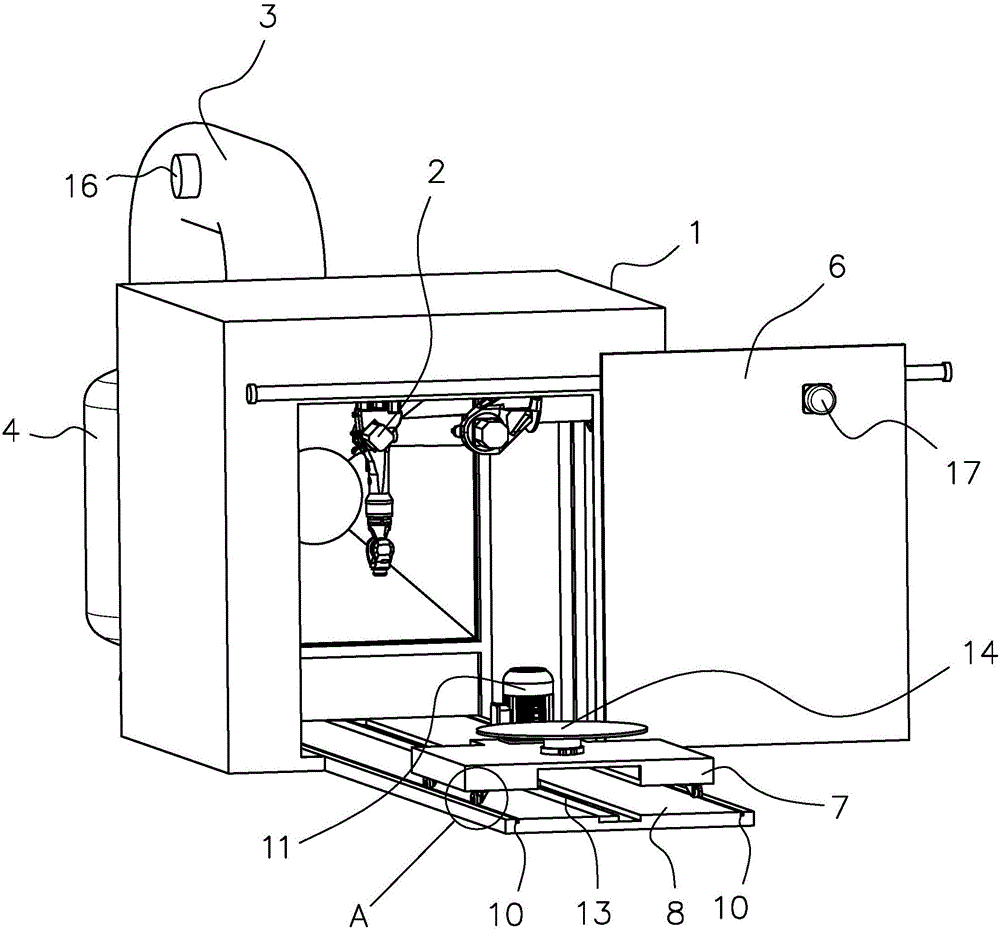

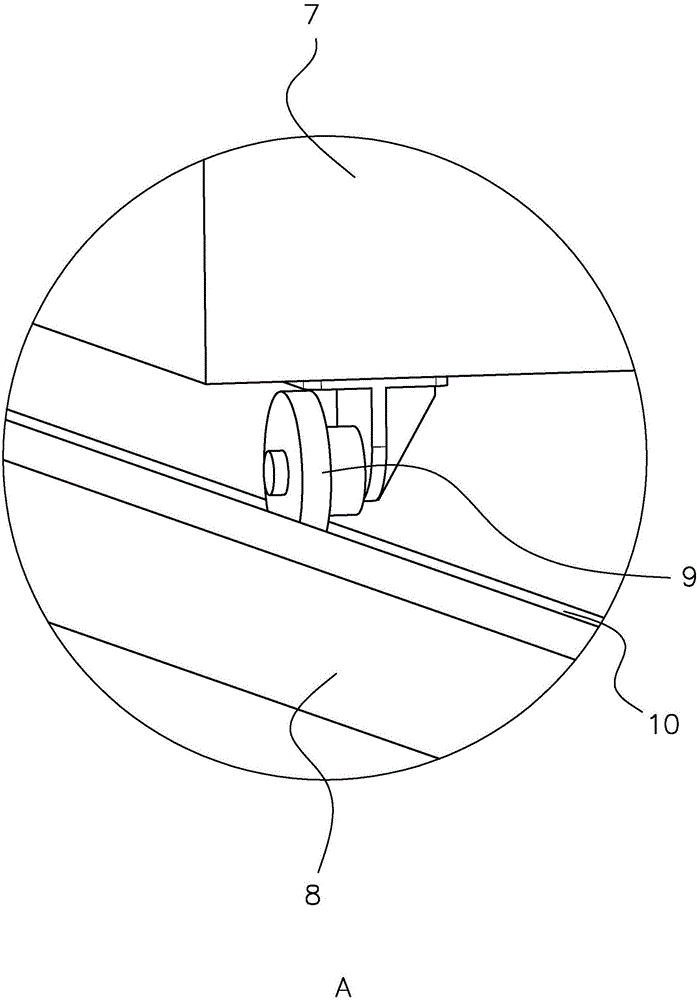

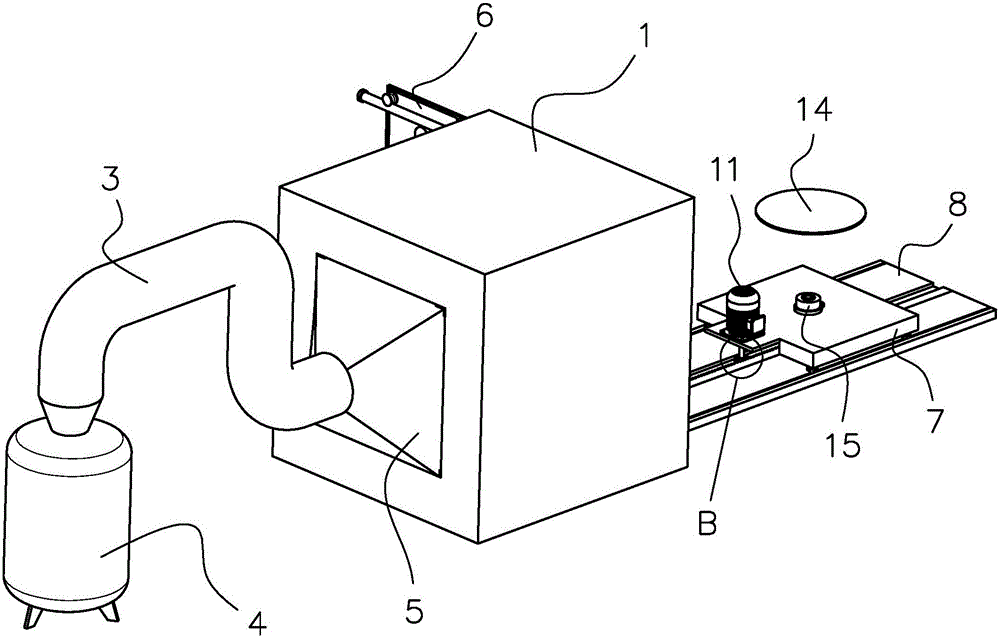

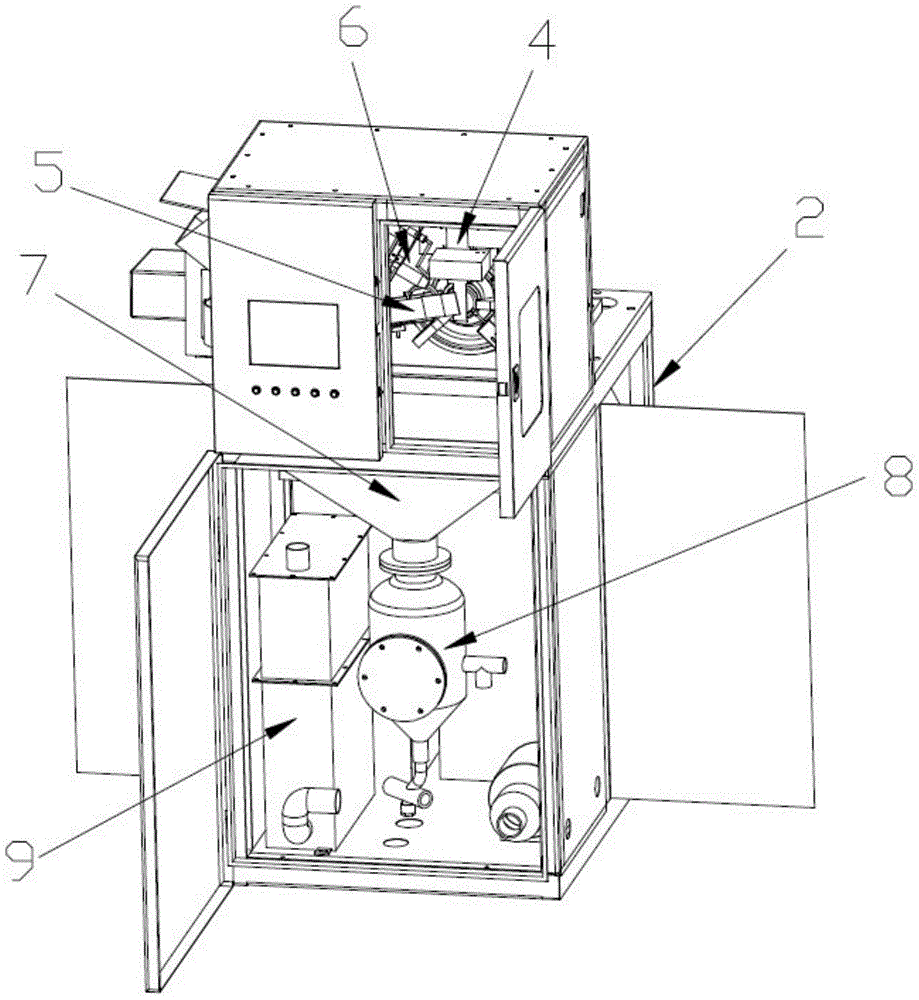

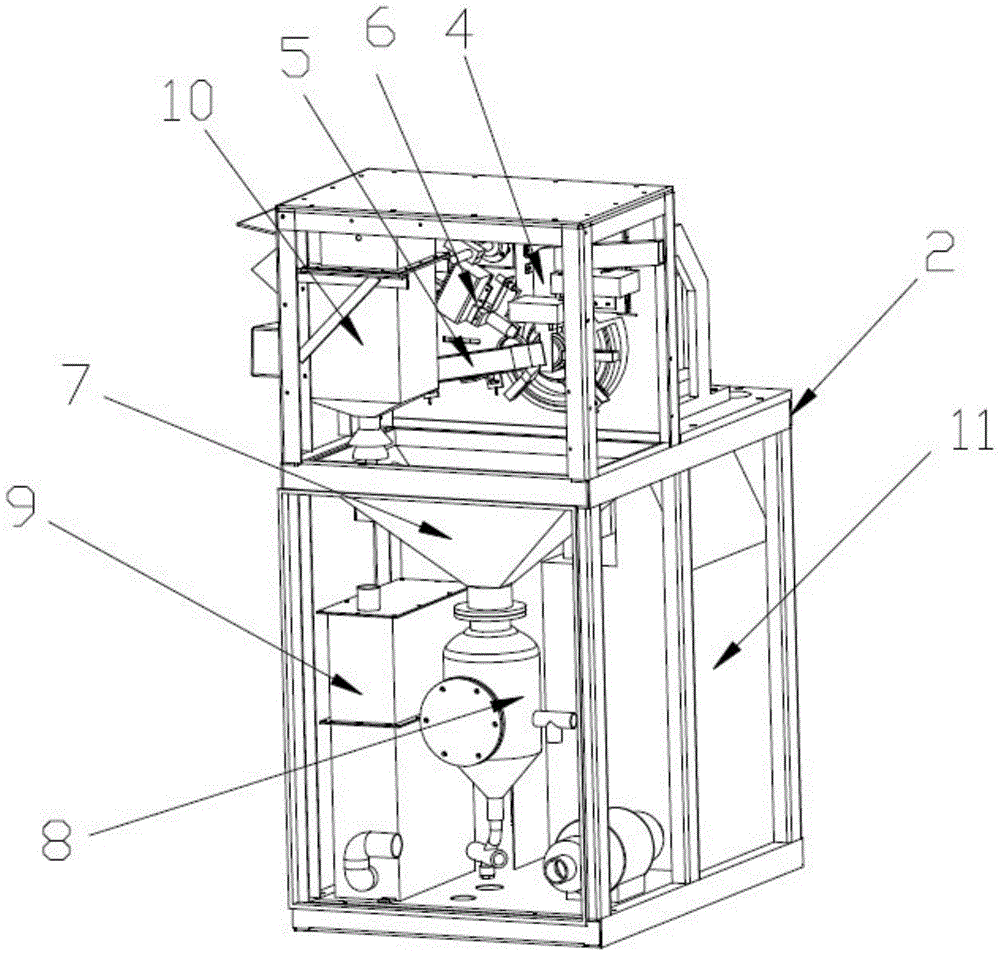

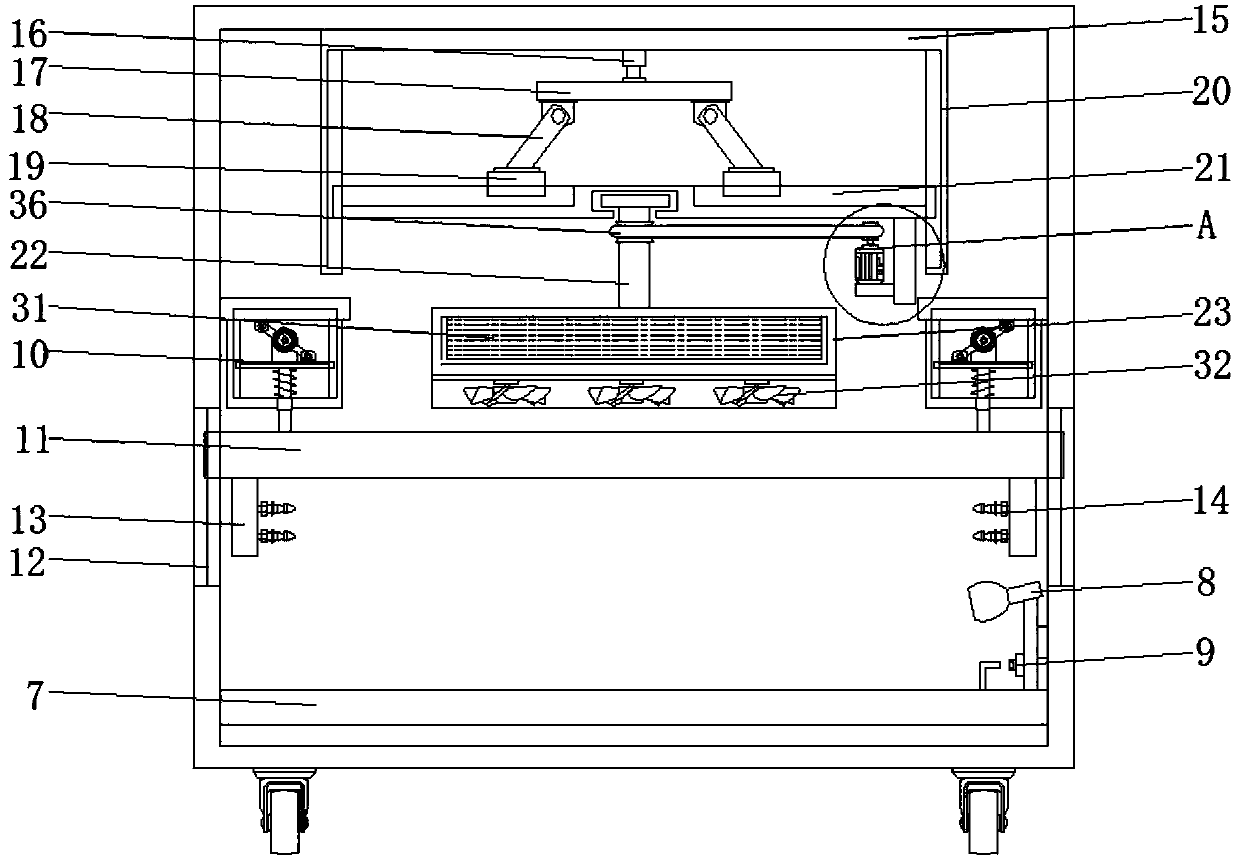

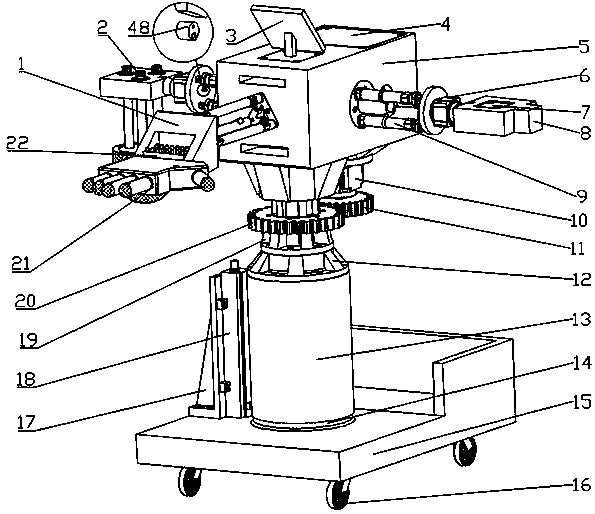

Full-automatic purging device for motor parts and cabinet

ActiveCN105964622AComprehensive purge operationEasy to operateProgramme-controlled manipulatorDirt cleaningRobotic armEngineering

The invention discloses a full-automatic purging device for motor parts and a cabinet, and solves the problem that manual purging of the cabinet is difficult. The main point of the technical scheme lies in that the full-automatic purging device for the motor parts and the cabinet comprises a dedusting chamber, a conveying mechanism used for pulling the cabinet to enter the dedusting chamber, and a rotating mechanism used for enabling the cabinet to perform autogiration, and further comprises a dust collection device used for removing dust in the dedusting chamber through suction, wherein a mechanical arm used for purging the cabinet is mounted inside the dedusting chamber. According to the full-automatic purging device for the motor parts and the cabinet, the device can integrally and comprehensively complete purging operation for the cabinet, the purging is carried out through adopting the mechanical arm, the track of a probe of the mechanical arm is controlled through programming software, the purpose that the entire cabinet is purged is achieved, the dust collection device can discharge dust in the dedusting chamber, the device not only can clean the cabinet but also can clean the parts of motors like traction motors and auxiliary motors, and the adaptability is high.

Owner:英聚德铁路动车配件(苏州)有限公司

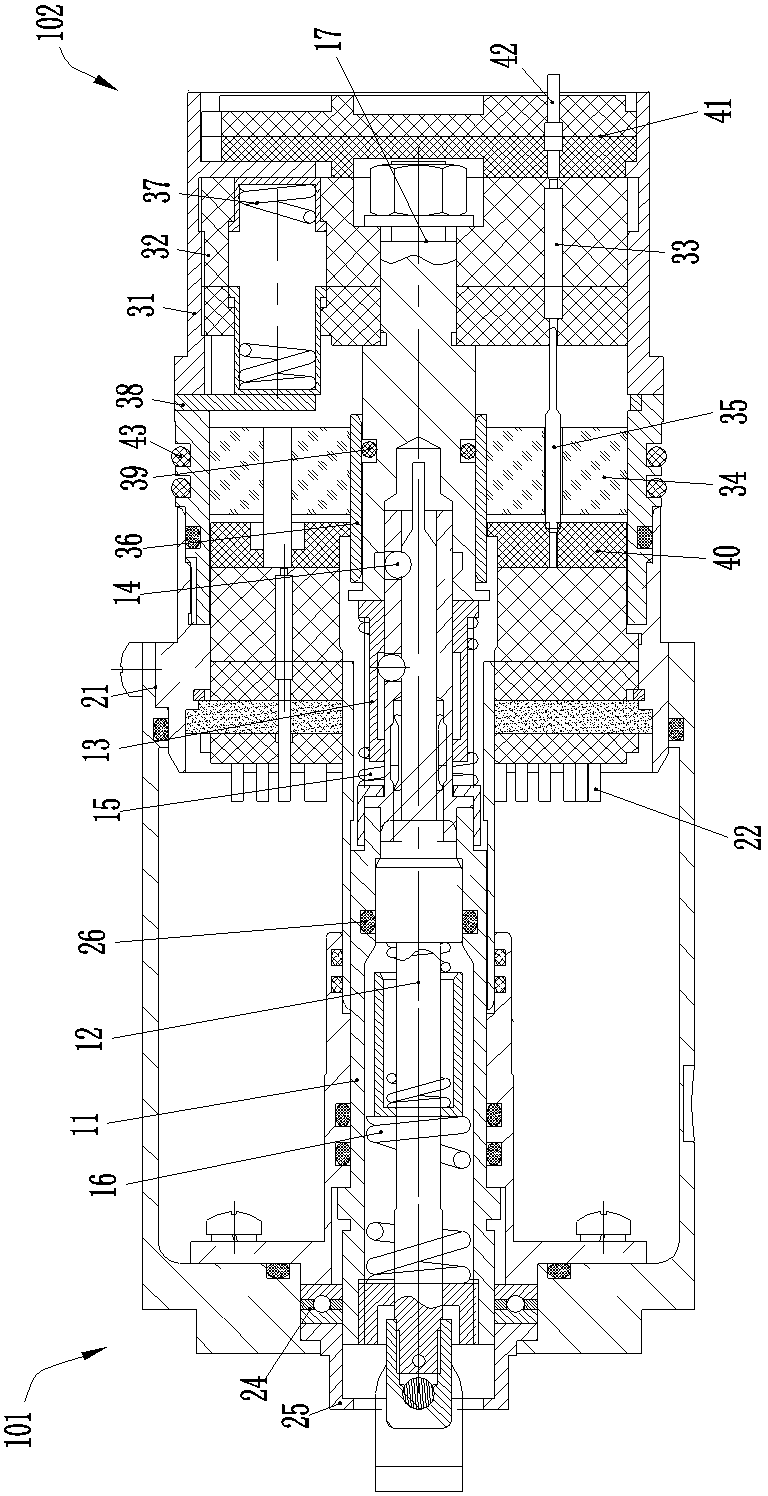

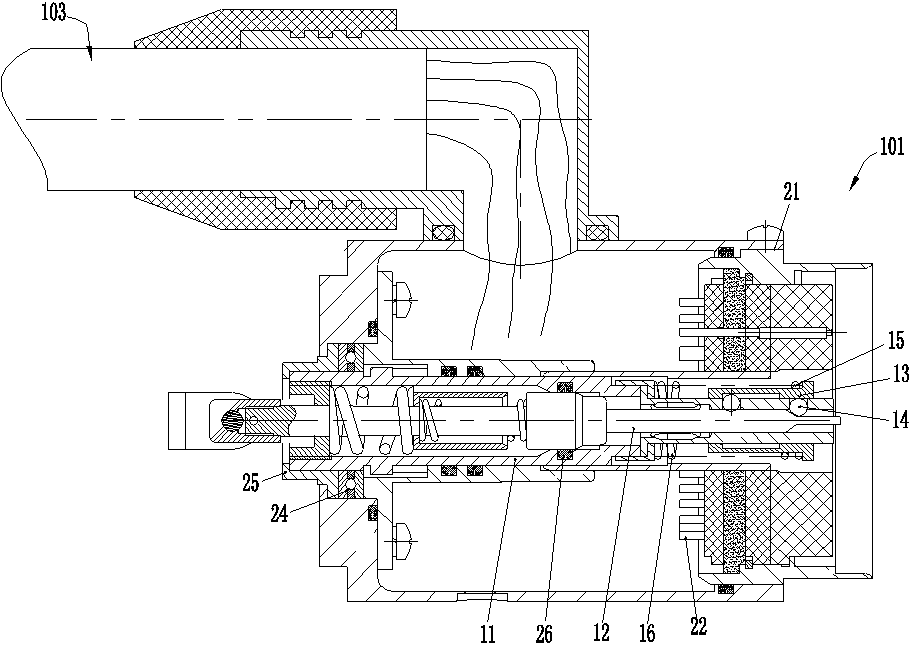

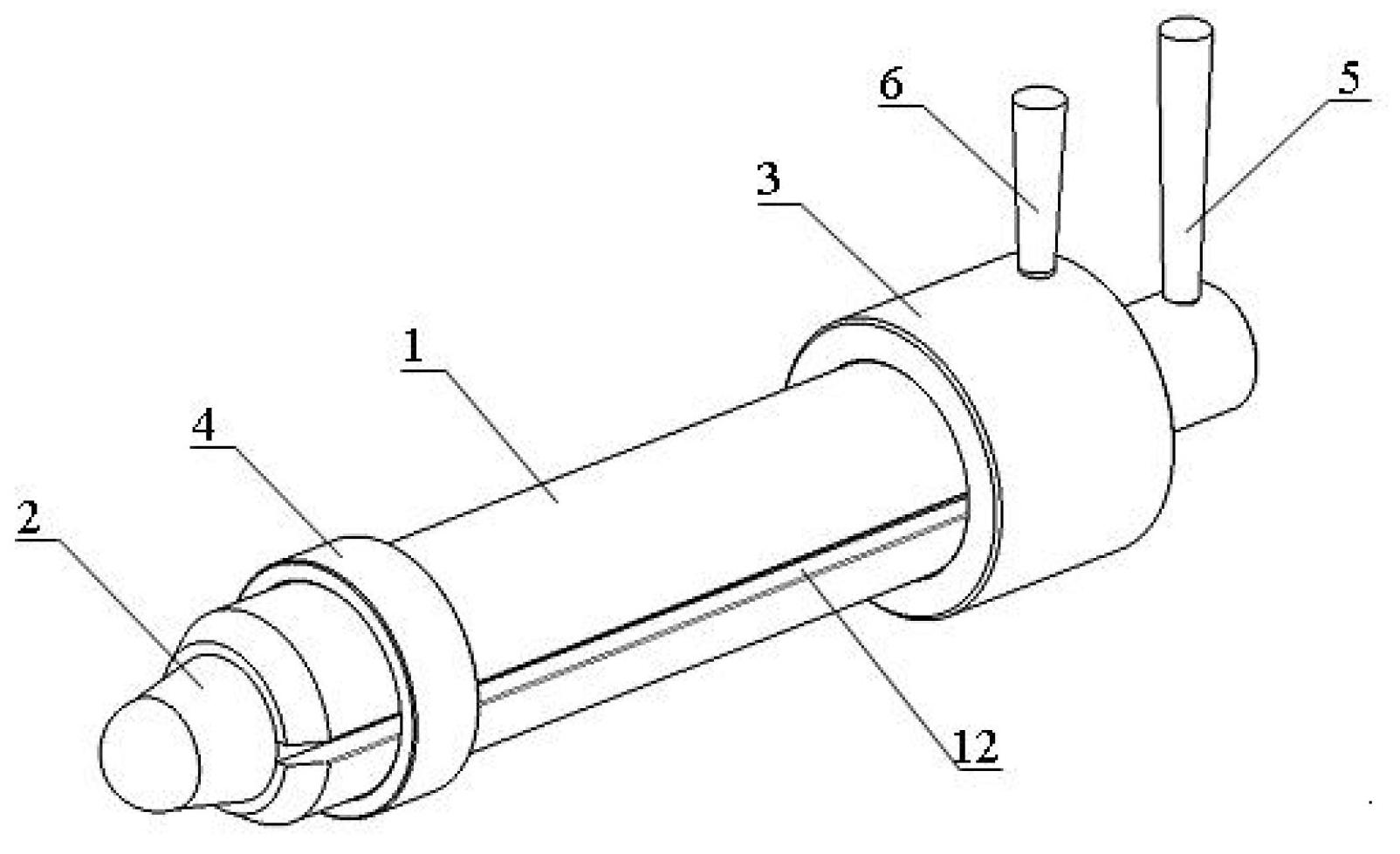

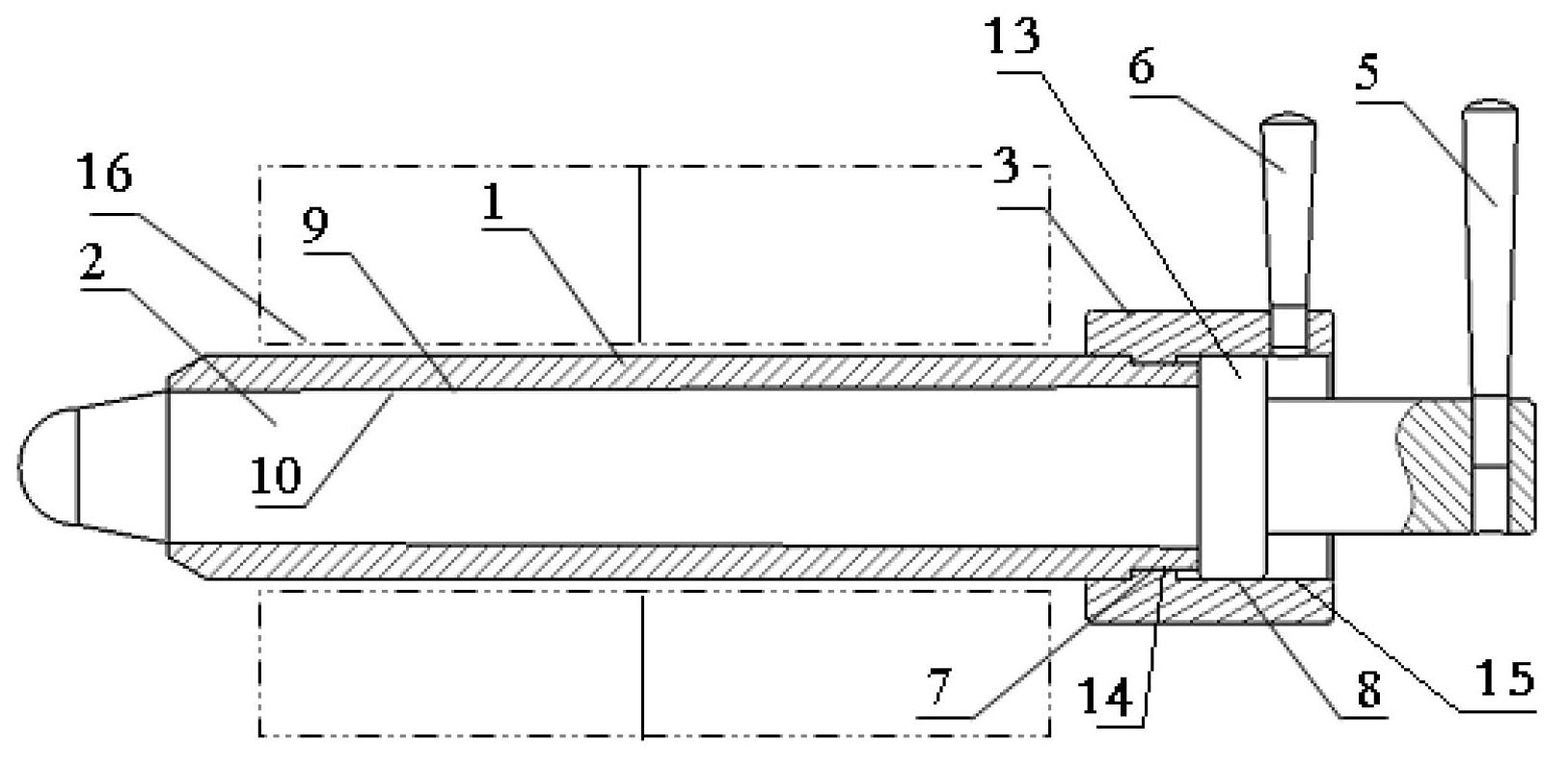

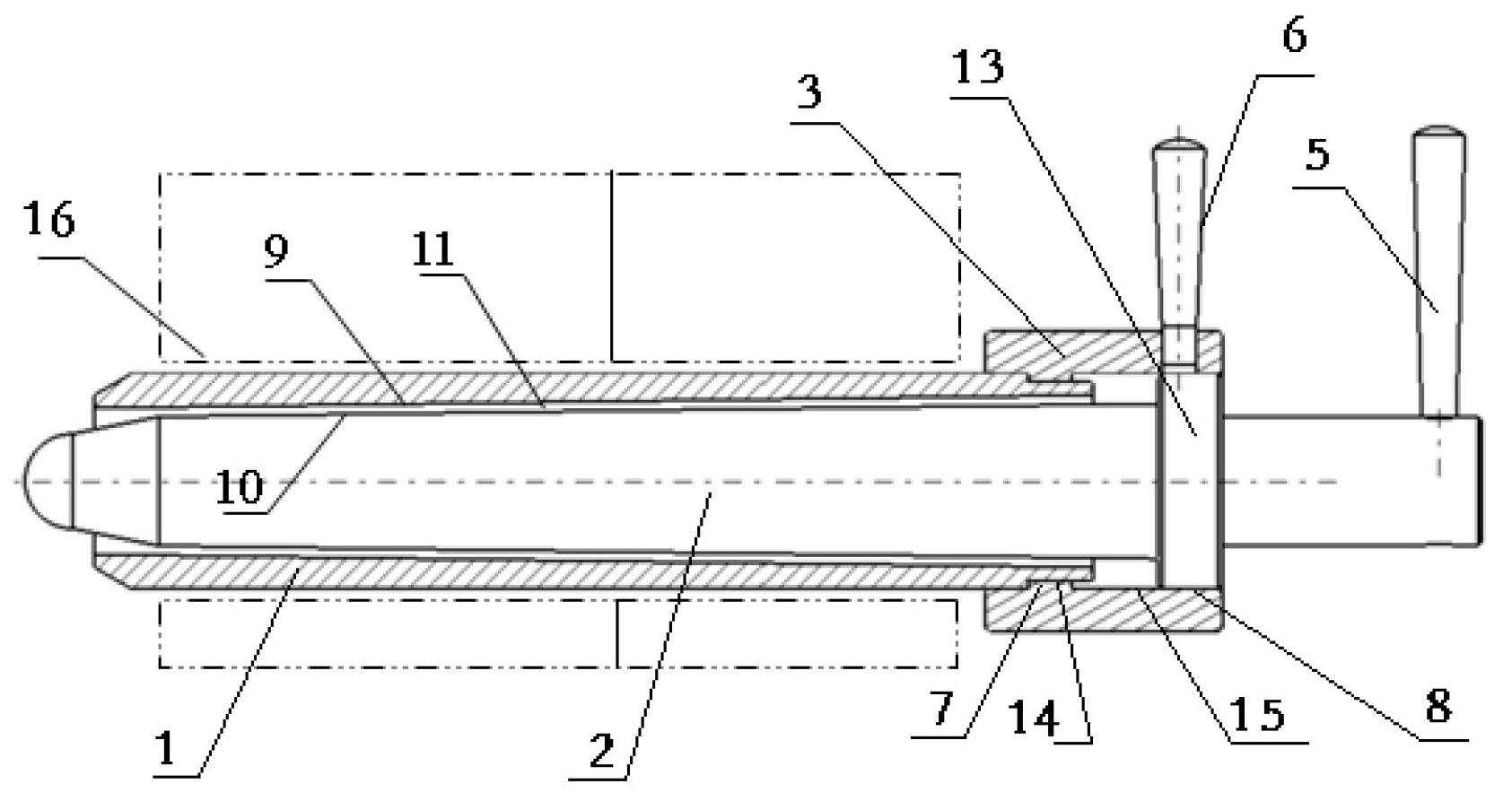

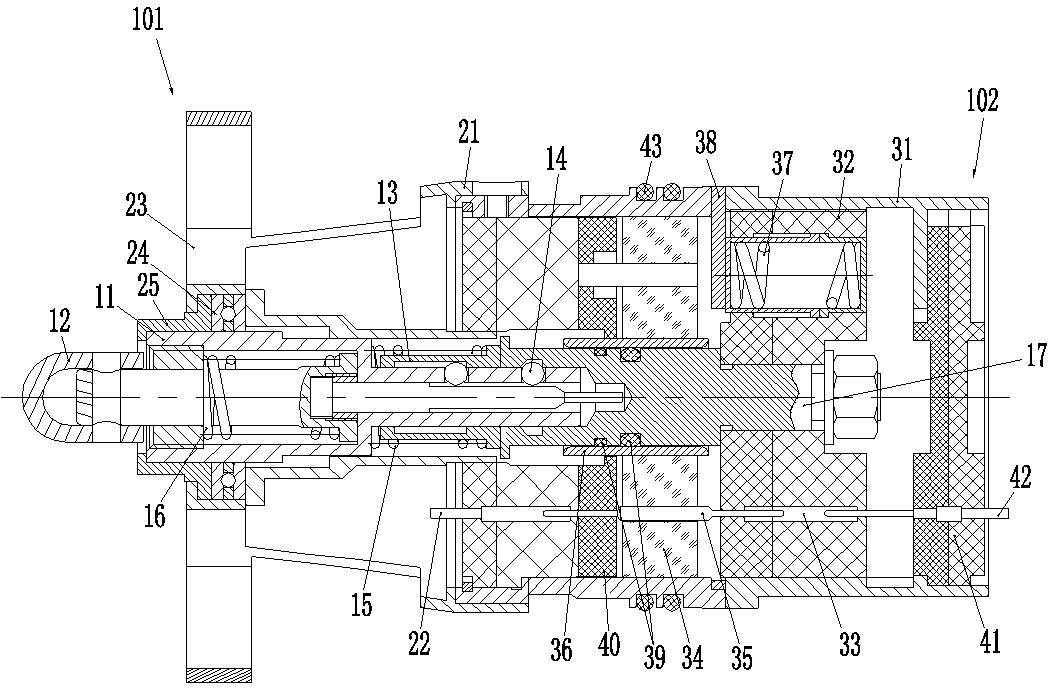

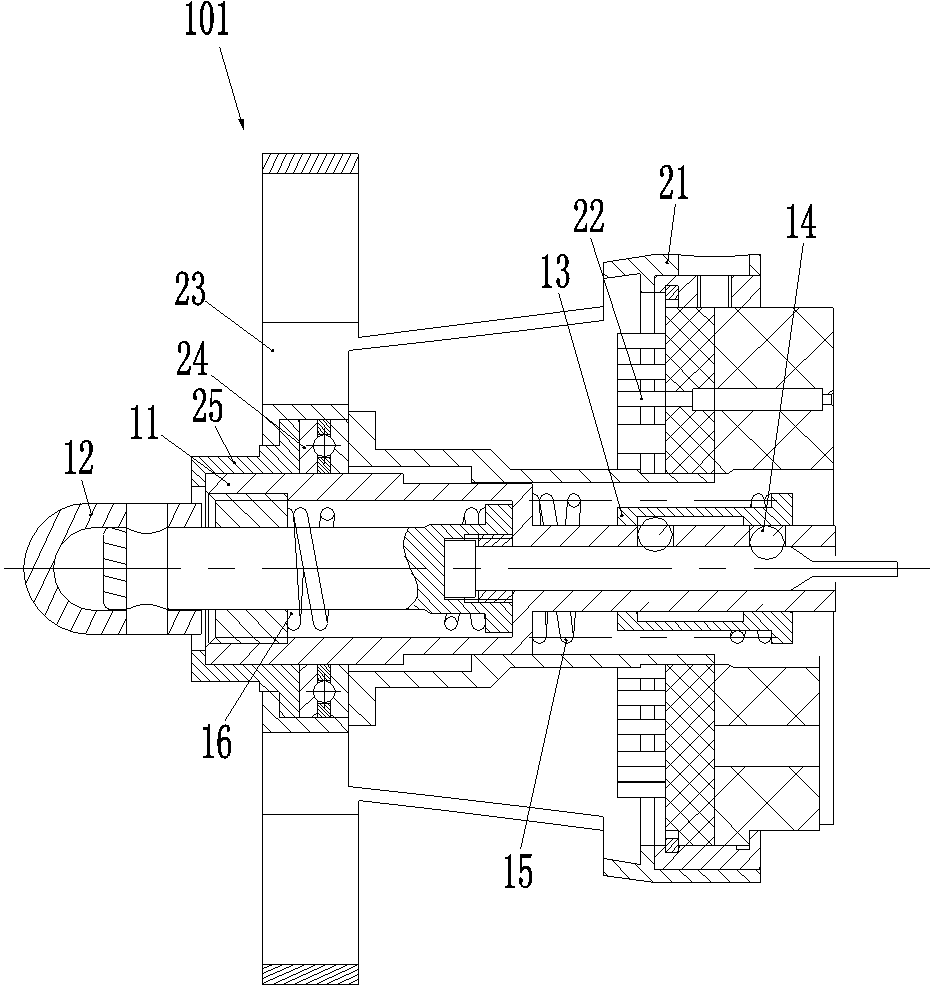

Underwater separation electric connector and plug thereof

ActiveCN103280666AAvoid short circuitTo achieve short-circuit proofCoupling device detailsElectricitySteel ball

The invention relates to the field of electric connectors, in particular to an underwater separation electric connector and a plug thereof. The plug comprises a plug casing, wherein a mandrel casing pipe, a mandrel, a sliding sleeve, a steel ball, a pushing and pressing spring and a locking spring are arranged in the plug casing; a rotating part is also arranged on the plug casing; the mandrel casing pipe is arranged in the plug casing in a laterally slidable manner; the rotating part and the mandrel casing pipe form a lead screw nut mechanism for driving an adapted locking ring to reciprocate; a sealing section is arranged on one of the mandrel and the mandrel casing pipe; a sealing matched structure is arranged on the other one of the mandrel and the mandrel casing pipe; the sealing section and the sealing matched structure are mutually matched to block off the front part and the rear part of an inner hole in the mandrel casing pipe; and when the mandrel casing pipe and the adopted locking ring are unlocked and continuously pull the mandrel backwards, the sealing section and the sealing matched structure are staggered at the front part and the rear part and two ends of the inner hole in the mandrel casing pipe are communicated. According to the underwater separation electric connector assembly, the pressure relief separation is realized and the prevention of short circuit in the process that a socket is separated from the plug and after the socket is separated from the plug can be also realized.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

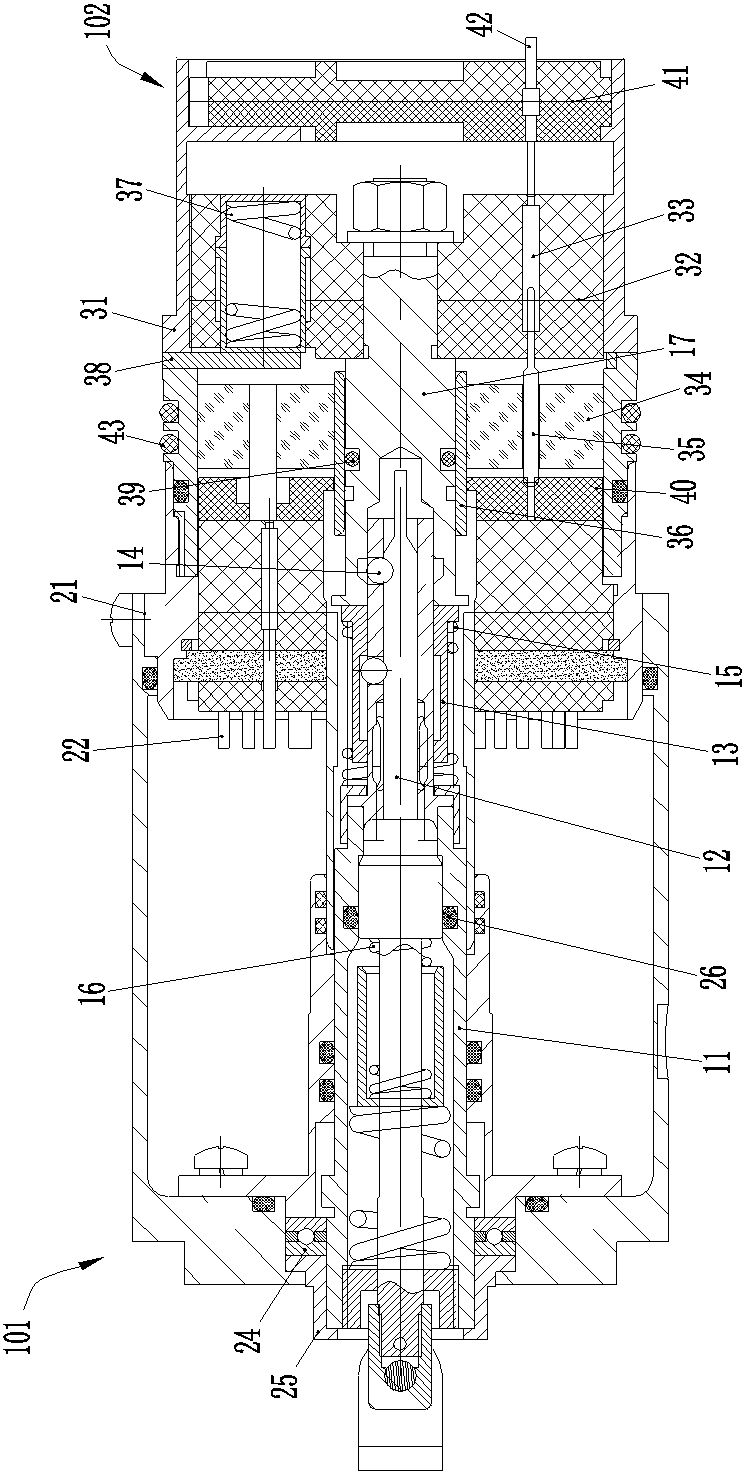

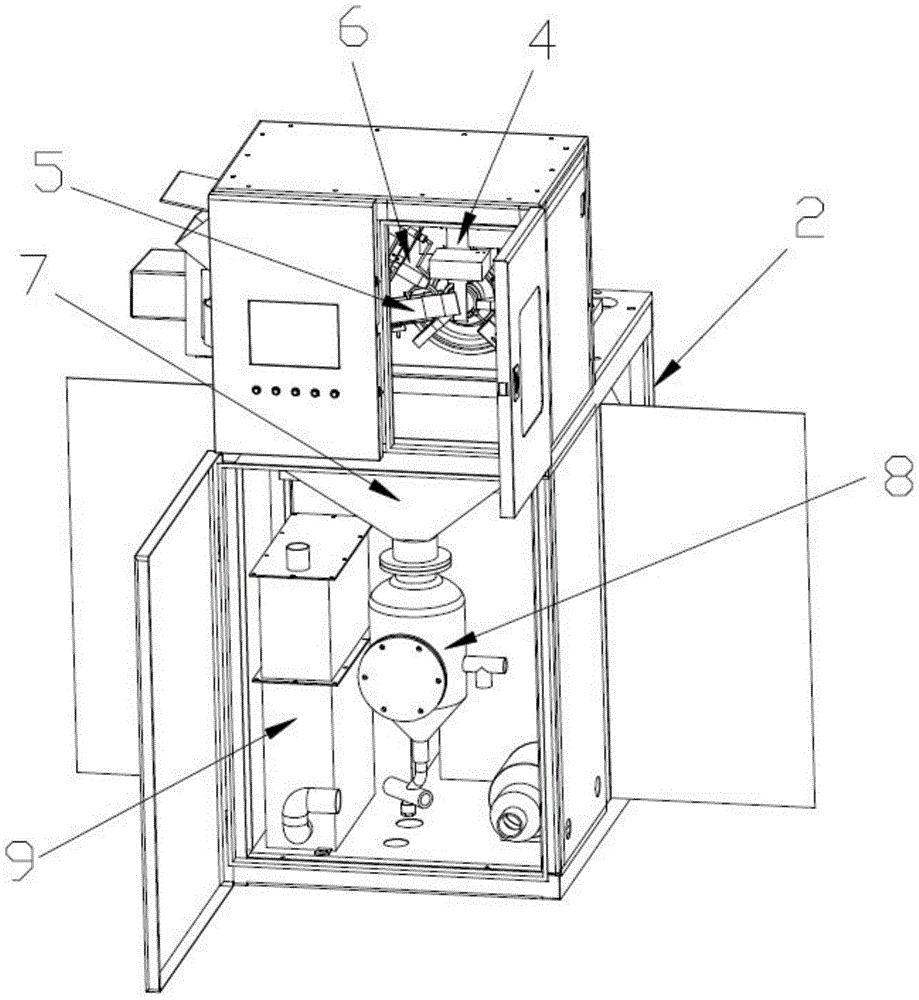

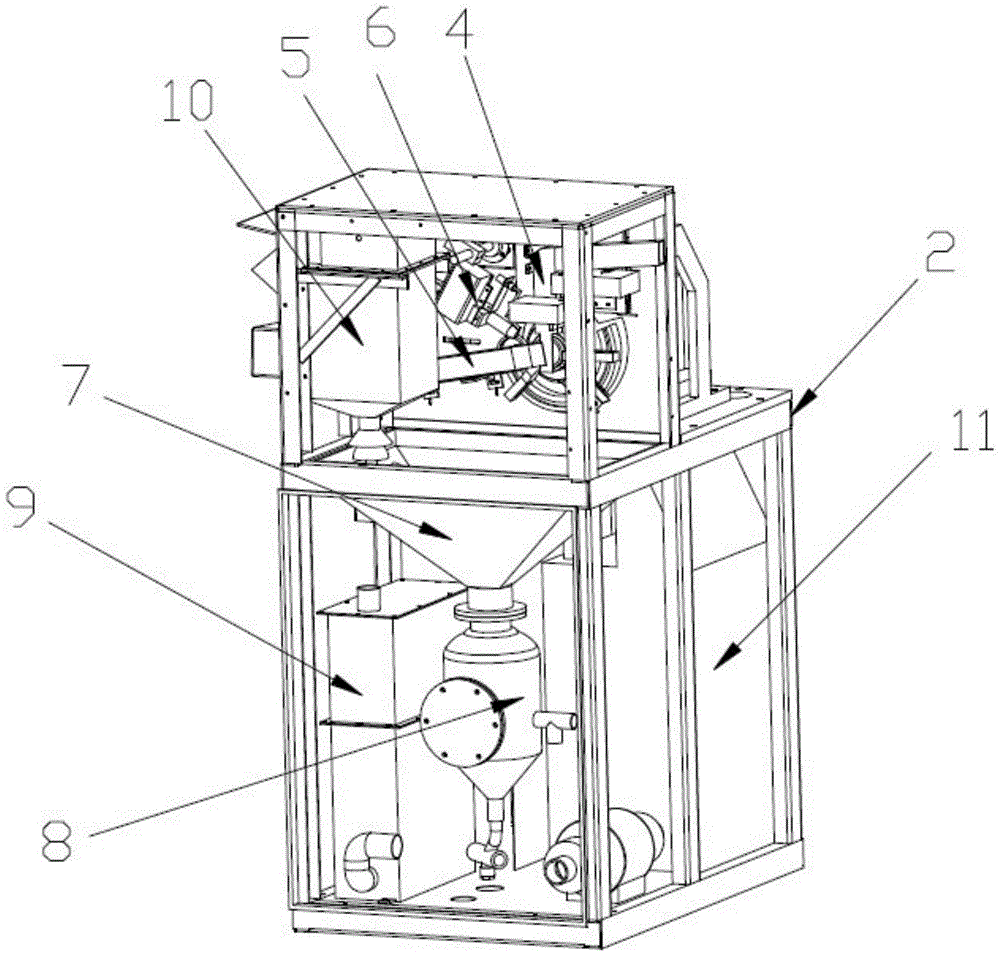

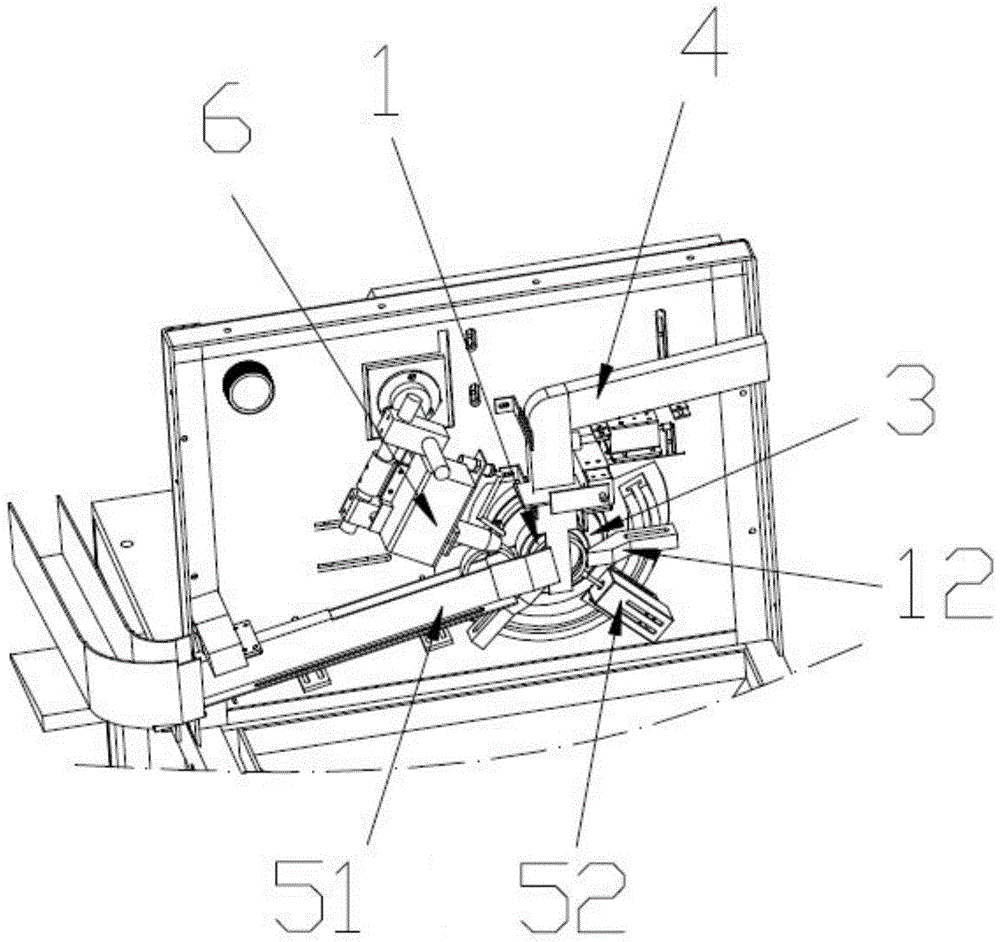

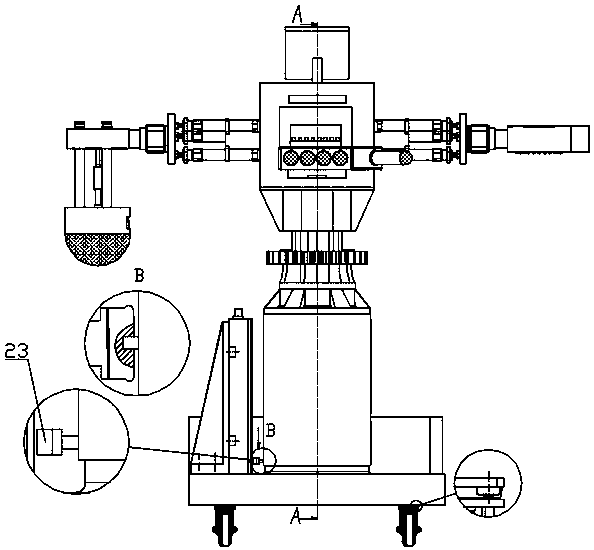

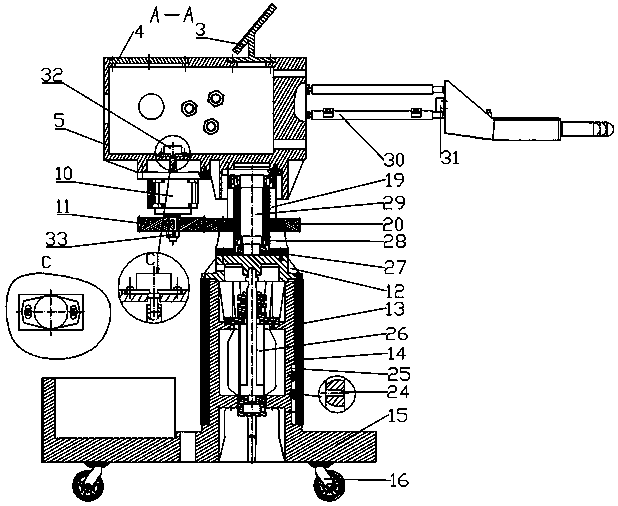

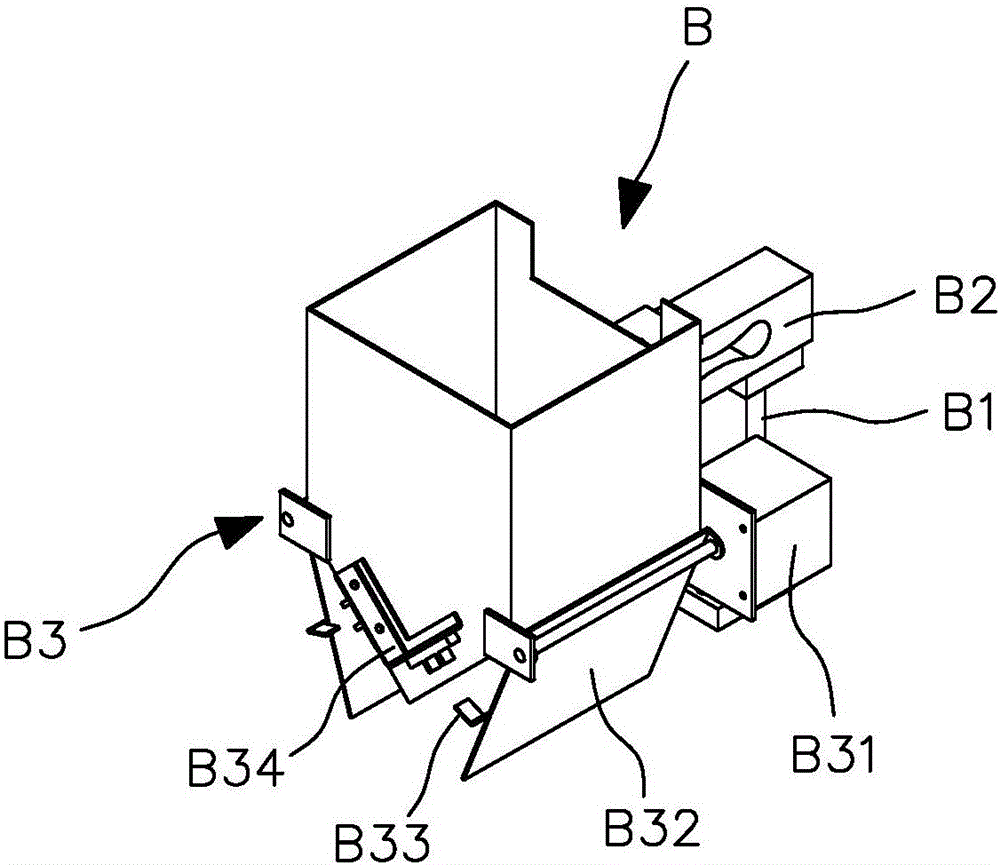

Strengthening and grinding machine for bearings

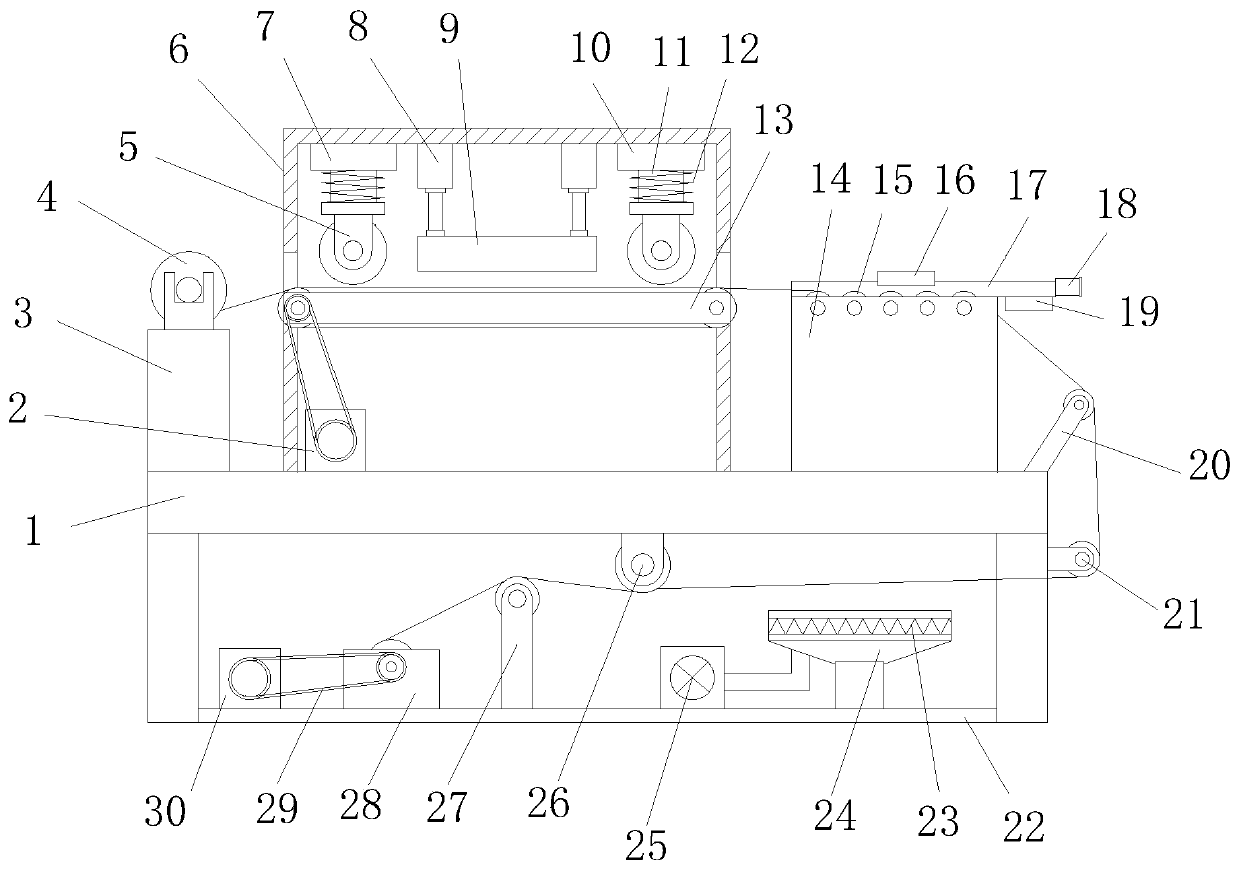

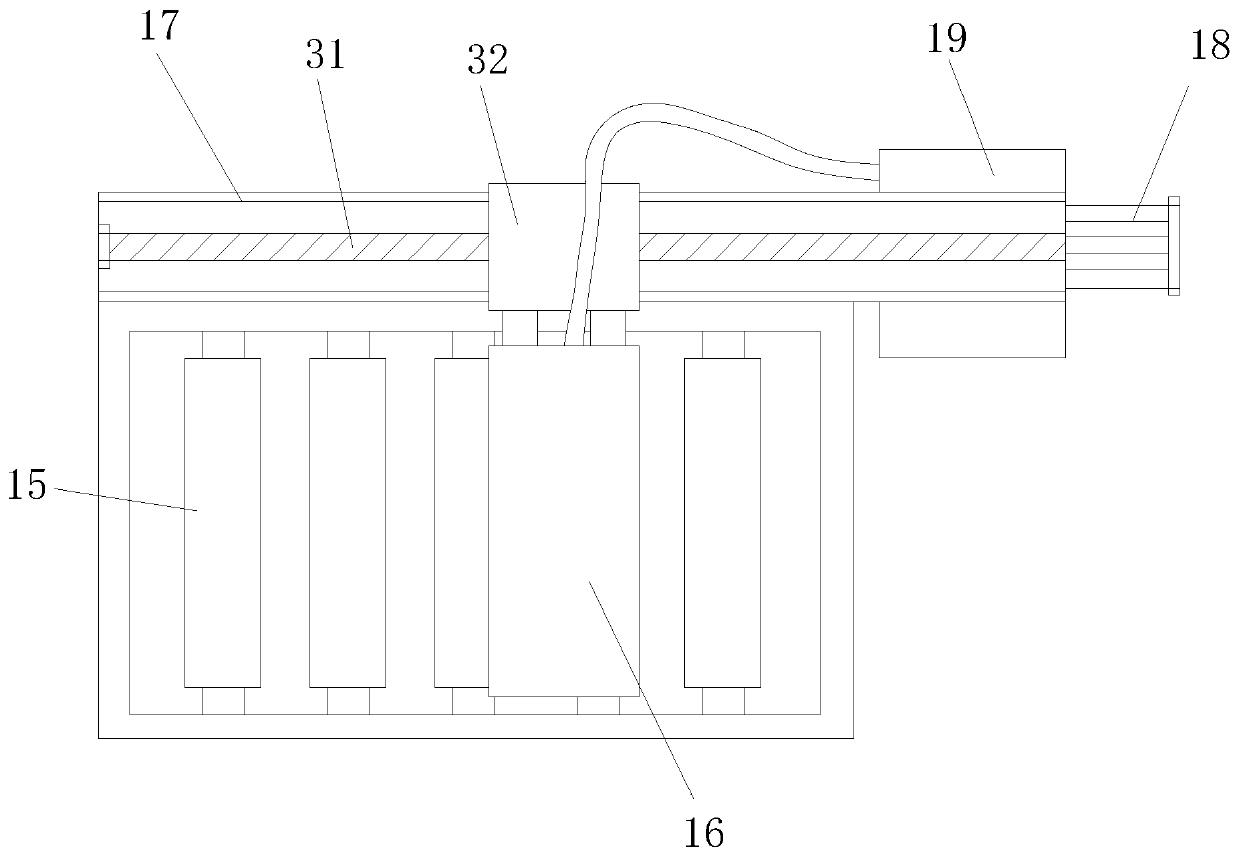

ActiveCN104942664AThe structure of the feeding mechanism is simpleEasy manual operationRevolution surface grinding machinesGrinding work supportsEngineeringElectromagnetic valve

The invention discloses a strengthening and grinding machine for bearings. The machine comprises a rack, an electromagnetic coreless clamp arranged on the rack and used for clamping the bearings, a feeding and discharging mechanism arranged on the rack, an abrasive material spraying device arranged on the rack and a control unit, wherein the feeding and discharging mechanism comprises a feeding mechanism and a discharging mechanism; the feeding mechanism comprises a feeding channel and two electromagnetic valves arranged on the feeding channel, the feeding channel extends to the position above the electromagnetic coreless clamp from top to bottom, and the electromagnetic valves are connected with the control unit; the discharging mechanism comprises a discharging channel and an electromagnetic pushing mechanism, an inlet of the discharging channel is located in one side of the electromagnetic coreless clamp, the electromagnetic pushing mechanism is located on the lower side of the electromagnetic coreless clamp, and the electromagnetic pushing mechanism is connected with the control unit. The feeding mechanism in the strengthening and grinding machine for the bearings has the advantages of simple structure, convenience in control, low manufacture cost and the like, can convey one workpiece each time and is good in reliability.

Owner:GUANGZHOU UNIVERSITY

Efficient embossing machine for textile wall paper production

InactiveCN110126451AAvoid damageLow investment costCovering/liningsRotary pressesPaper productionPulp and paper industry

The invention discloses an efficient embossing machine for textile wall paper production. The machine comprises a rack, a uniform pressing device, a stamping device, a drying device and a coiling device, wherein a distributing roller storing rack is fixedly arranged at the upper left end of the rack, and a distributing roller is rotatably mounted at the upper end of the distributing roller storingrack; the uniform pressing device is arranged at the right side of the distributing roller storing rack; the stamping device is arranged at the right side of the uniform pressing device and is fixedly mounted at the upper right side of the rack; a first guide roller is fixedly arranged at the upper right end of the rack; a second guide roller is arranged in the middle of the right side of the rack; a third guide roller is arranged in the middle of the bottom part of the rack; a separating plate is arranged at the inner lower part of the rack; the drying device is arranged at the upper right side of the separating plate; a fourth guide roller is arranged in the middle of the upper part of the separating plate; and the coiling device is arranged at the upper left side of the separating plate. The machine is simple in structure, multifunctional, good in use effect, and high in production efficiency; the product quality is effectively ensured; and the machine is beneficial for popularization.

Owner:苏州前航实业有限公司

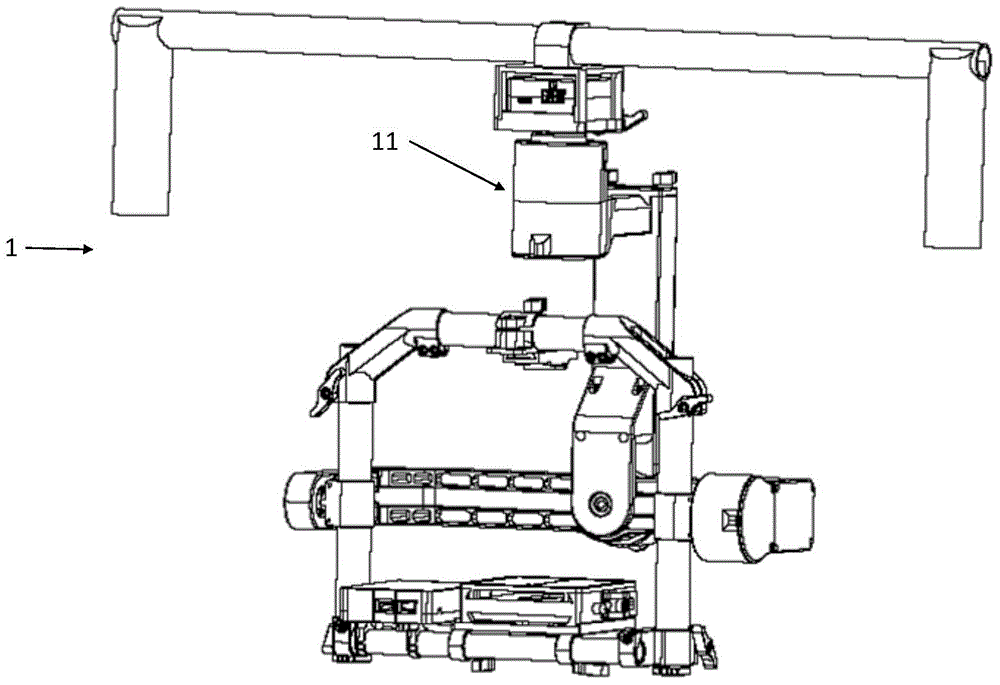

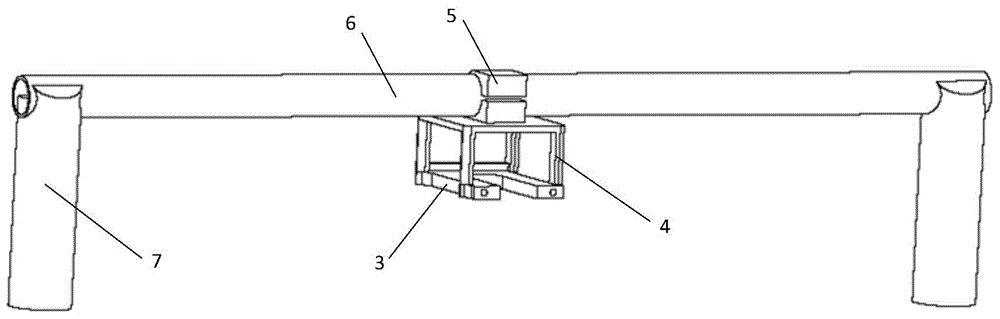

Airborne handheld quick switch holder and shooting method thereof

The invention provides an airborne handheld quick switch holder and a shooting method thereof. The airborne handheld quick switch holder can be quickly switched from an airborne holder to a handheld holder, is easy to disassemble, and can achieve the gravity center balance by a gravity center adjusting device of the airborne holder to quick adjust the gravity center. The switch holder comprises a rod, a handle, a fixing part, a connecting part, a clamping part and the gravity center adjusting device, wherein the handle is arranged on the rod; the fixing part is fixed on the rod; the connecting part is fixedly connected with the fixing part; the clamping part is fixedly connected with the connecting part; the gravity center adjusting device can be driven and can rotate around a plurality of driving shafts; the gravity center adjusting device is provided with a chuck which can be detachably clamped and fixed at the clamping part or an aircraft; a cavity for accommodating the chuck is formed between the connecting part and the clamping part; the clamping part and the connecting part adopt an integral structure or are fixed into a whole through a fastening device.

Owner:ZEROTECH (BEIJING) INTELLIGENCE TECH CO LTD

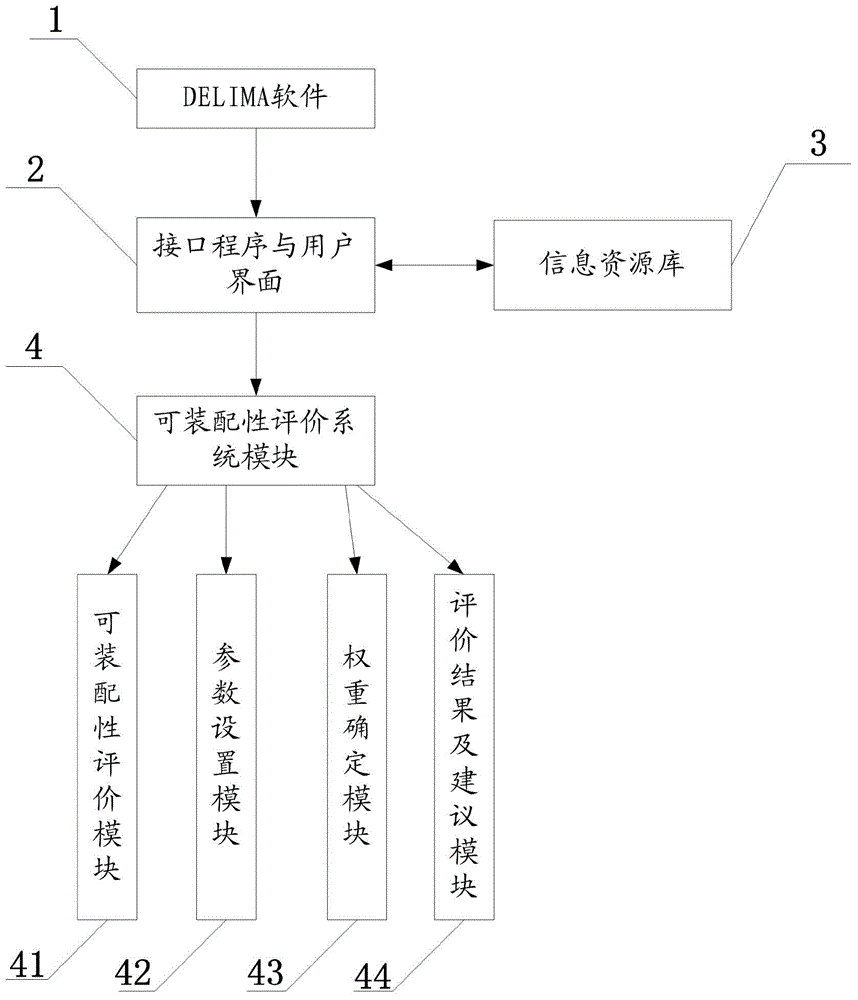

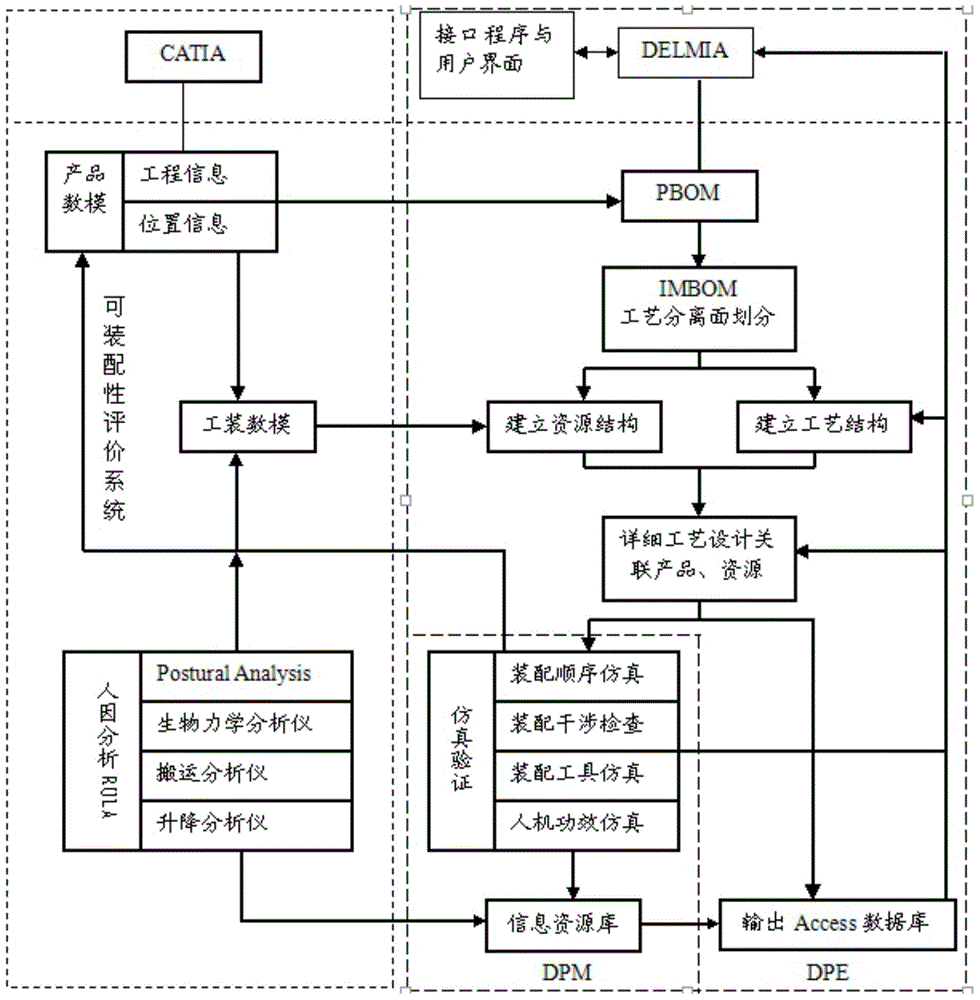

Complex production assembling ability evaluation system and method based on DELMIA

InactiveCN103605843AImprove coordinationImproving NC Machining SimulationSpecial data processing applicationsOil productionSecondary development

The invention discloses a complex production assembling ability evaluation system and method based on DELMIA. The method includes: using an analyzer to perform human factor analysis and simulation verification; by CATIA, performing product numerical simulation and tool numerical simulation on the received information; calling CATIA three-dimensional modeling software to build the mathematical model of a complex product, diving process parting faces through PBOM, and building a resource structure and a process structure; designing the related product and resource with detailed process and applying the products and resource to simulation design and an output resource database; by a data resource database, saving the data of simulation verification and human factor analysis, and by an Access database, transmitting the data to a user interface through DELMIA. The method has the advantages the part-level assembling ability evaluation models and product assembling ability evaluation models are built, secondary development is performed on the DELMIA software module, and the complex product assembling ability evaluation prototype system is built; each assembling operation step is evaluated first, then all the assembling operations are evaluated, and accordingly the influence on product assembling ability can be comprehensively considered as a whole.

Owner:XIAN TECHNOLOGICAL UNIV

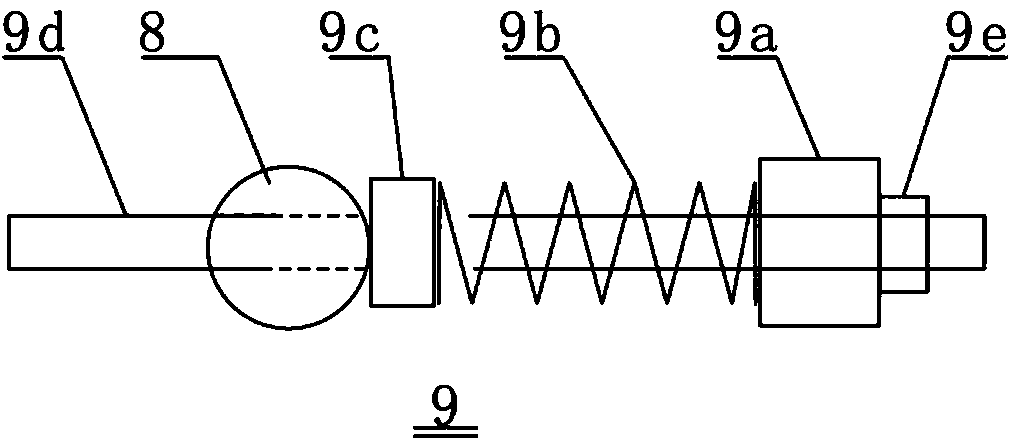

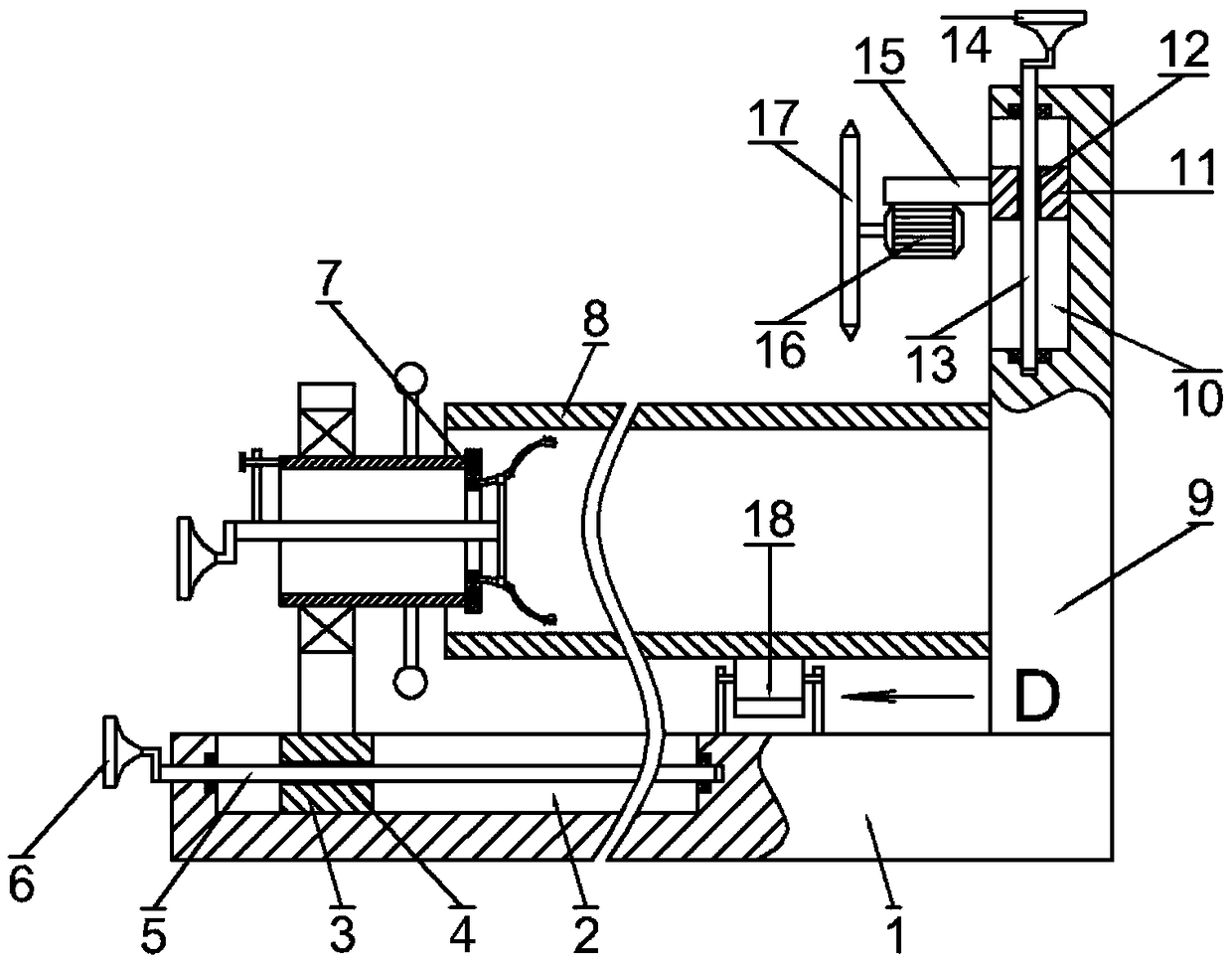

A bearing strengthening grinding machine

ActiveCN104942664BSimple structureConducive to manual operationRevolution surface grinding machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses a strengthening and grinding machine for bearings. The machine comprises a rack, an electromagnetic coreless clamp arranged on the rack and used for clamping the bearings, a feeding and discharging mechanism arranged on the rack, an abrasive material spraying device arranged on the rack and a control unit, wherein the feeding and discharging mechanism comprises a feeding mechanism and a discharging mechanism; the feeding mechanism comprises a feeding channel and two electromagnetic valves arranged on the feeding channel, the feeding channel extends to the position above the electromagnetic coreless clamp from top to bottom, and the electromagnetic valves are connected with the control unit; the discharging mechanism comprises a discharging channel and an electromagnetic pushing mechanism, an inlet of the discharging channel is located in one side of the electromagnetic coreless clamp, the electromagnetic pushing mechanism is located on the lower side of the electromagnetic coreless clamp, and the electromagnetic pushing mechanism is connected with the control unit. The feeding mechanism in the strengthening and grinding machine for the bearings has the advantages of simple structure, convenience in control, low manufacture cost and the like, can convey one workpiece each time and is good in reliability.

Owner:GUANGZHOU UNIVERSITY

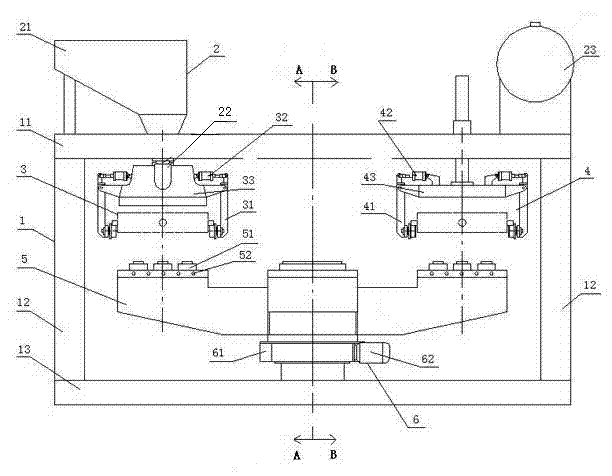

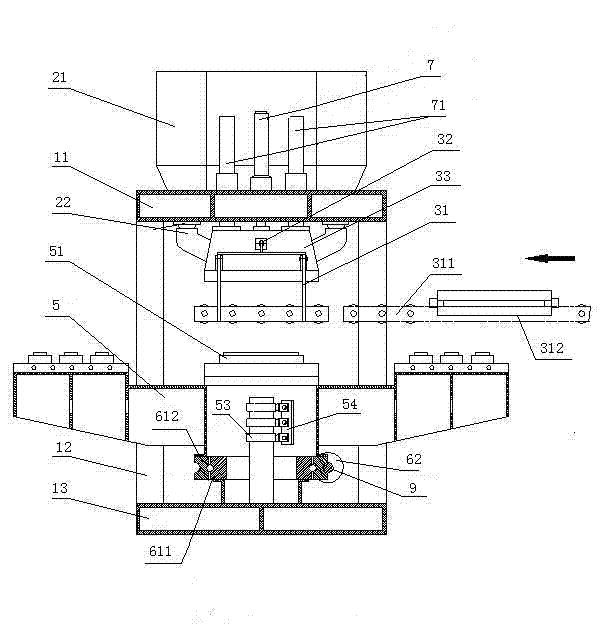

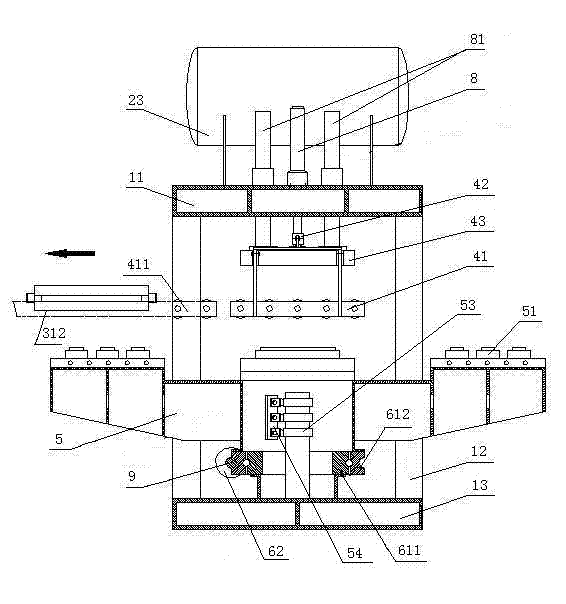

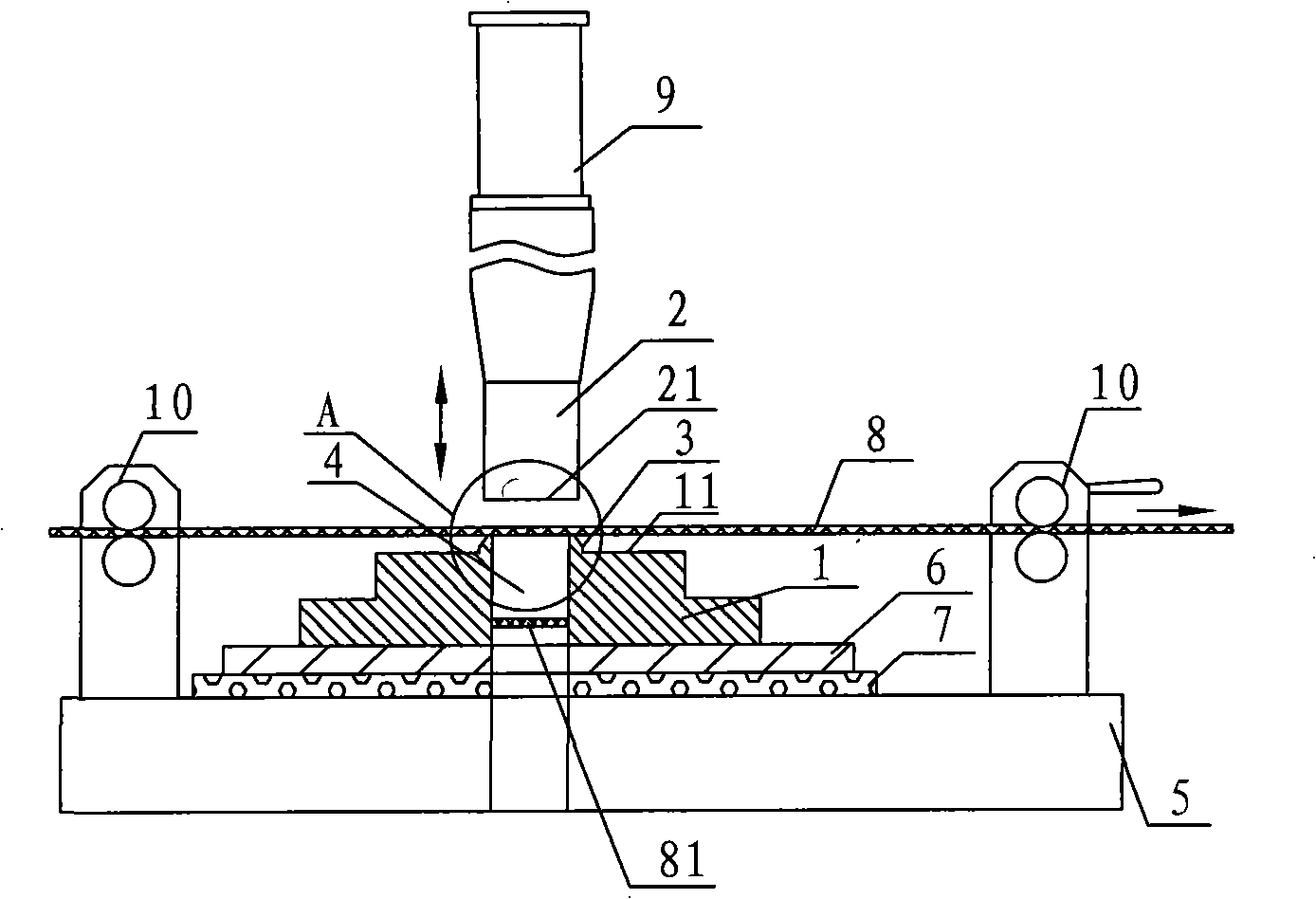

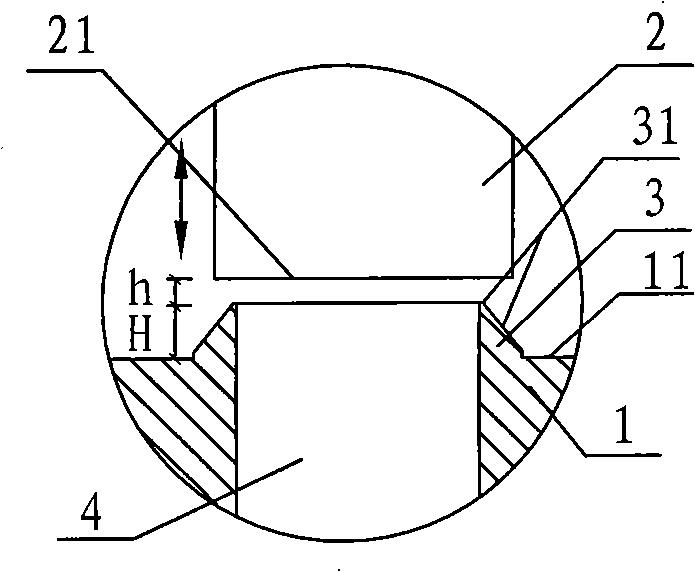

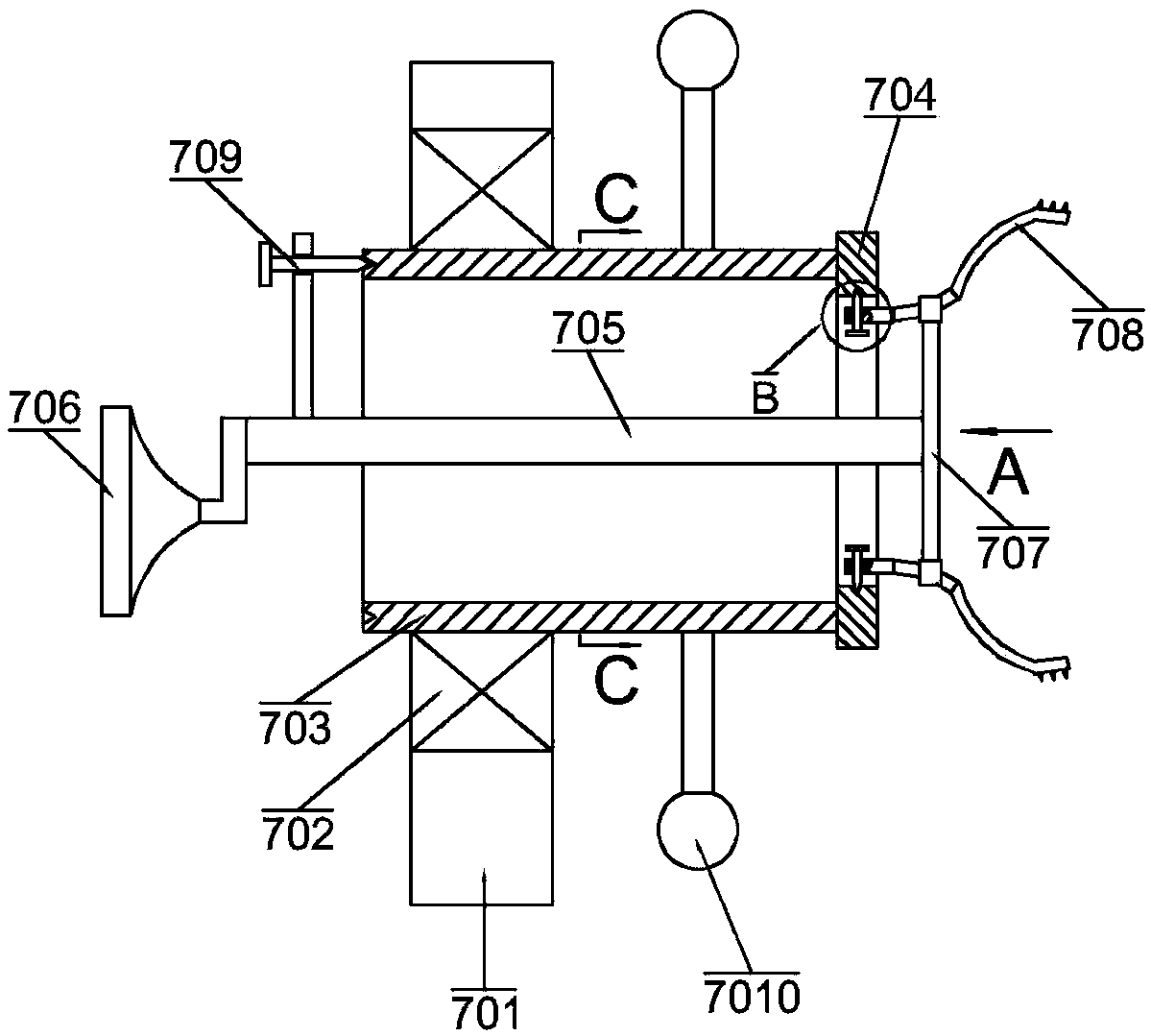

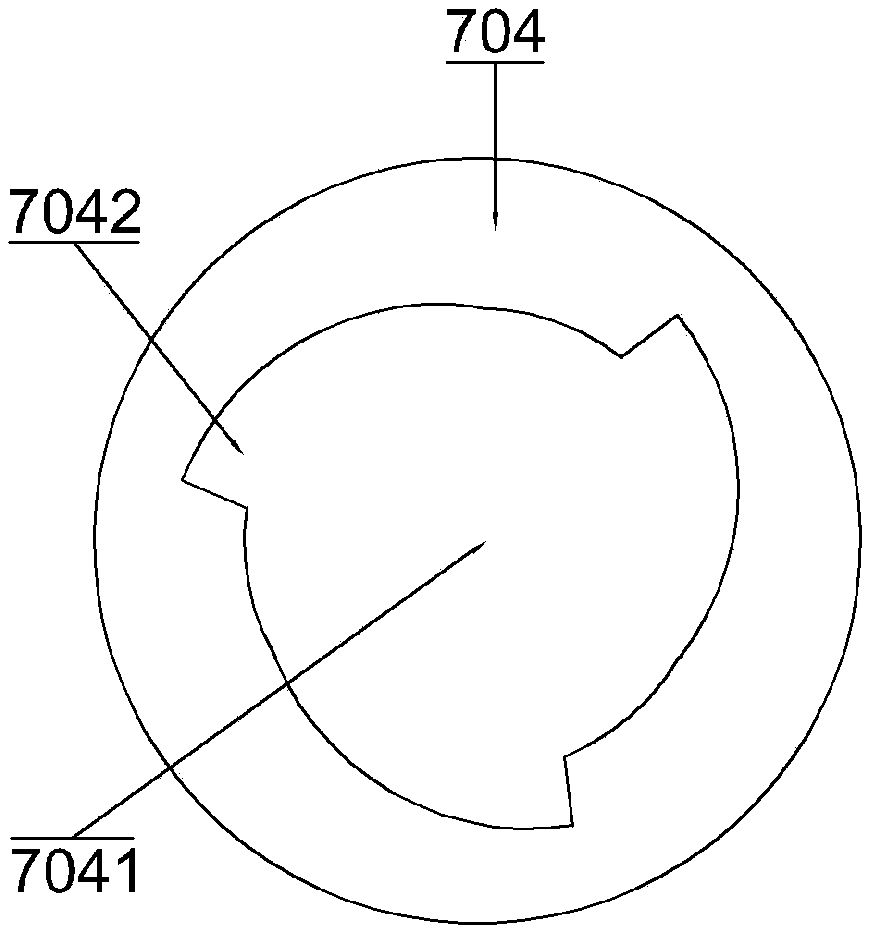

Equipment and method for improving sand lined casting efficiency

ActiveCN103203434AImprove efficiencyReasonable structural designMoulding machinesIndustrial engineeringCasting

The invention relates to equipment and a method for improving sand lined casting efficiency, and belongs to the technical field of iron sand lined casting. The equipment comprises a supporting frame composed of an upper beam, a base and a vertical pillar between the upper beam and the base, a sand adding and jetting device, and a rotating mechanism arranged on the base. The equipment is characterized by further comprising a four-station working platform, a lifting type sand jetting head and a lifting type roller bed opening and closing mechanism, wherein the four-station working platform is fixed on the rotating mechanism; the lifting type sand jetting head is connected at one side of the upper beam, and the lifting type roller bed opening and closing mechanism is connected at the other side; the lifting type sand jetting head and the lifting type roller bed opening and closing mechanism are respectively arranged on left and right sides; and the four-station working platform is arranged below the lifting type sand jetting head and the lifting type roller bed opening and closing mechanism. The equipment disclosed by the invention is reasonable in structure and design, convenient to clean mold, high in sand lined casting efficiency and convenient for users to operate.

Owner:浙江省机电设计研究院有限公司

Frame for manufacturing yeast and frame type yeast manufacturing fermentation method

ActiveCN102358876ABreak through the status quo of the extremely low utilization rate of curved roomsIncrease profitAlcoholic beverage preparationBiotechnologyProcess engineering

The invention discloses a frame for manufacturing yeast and a fermentation method using the frame to manufacture the yeast. Used yeast blocks are placed on the yeast frame, thereby increasing yield of unit area of yeast rooms and improving utilization rate of the yeast rooms. Temperature and humidity of the yeast blocks can be regulated flexibly by flexibly regulating the number of piles and rowsof the yeast arrangement and the height between piles of yeast blocks, thereby resolving the problem that temperature and humidity of a traditional yeast manufacturing method are difficult to adjust,reducing yeast turning times and reducing labor intensity of workers.

Owner:SICHUAN TUOPAI SHEDE WINE

Quick-release positioning pin structure

InactiveCN102678711AOvercome only shear forceOvercome the situationSnap-action fastenersBoltsAxial forceEngineering

The invention discloses a quick-release positioning pin structure which is composed of a positioning pin sleeve, a quick-release pin and a quick-release screw sleeve. The positioning pin sleeve is in taper fitting with the quick-release pin, the quick-release screw sleeve is matched with external threads of the positioning pin sleeve and the quick-release pin respectively through internal threads, and force application handles are respectively arranged on the quick-release screw sleeve and the quick-release pin. Mechanical radial force of a butting hole site is transformed to axial force by utilizing taper, the condition that traditional cylindrical latch pin only has shearing force and friction force, the extraction strength of the cylinder pin is greatly reduced, manual operation is convenient, and a quick-release positioning function is realized.

Owner:XIAN AIRCRAFT IND GROUP

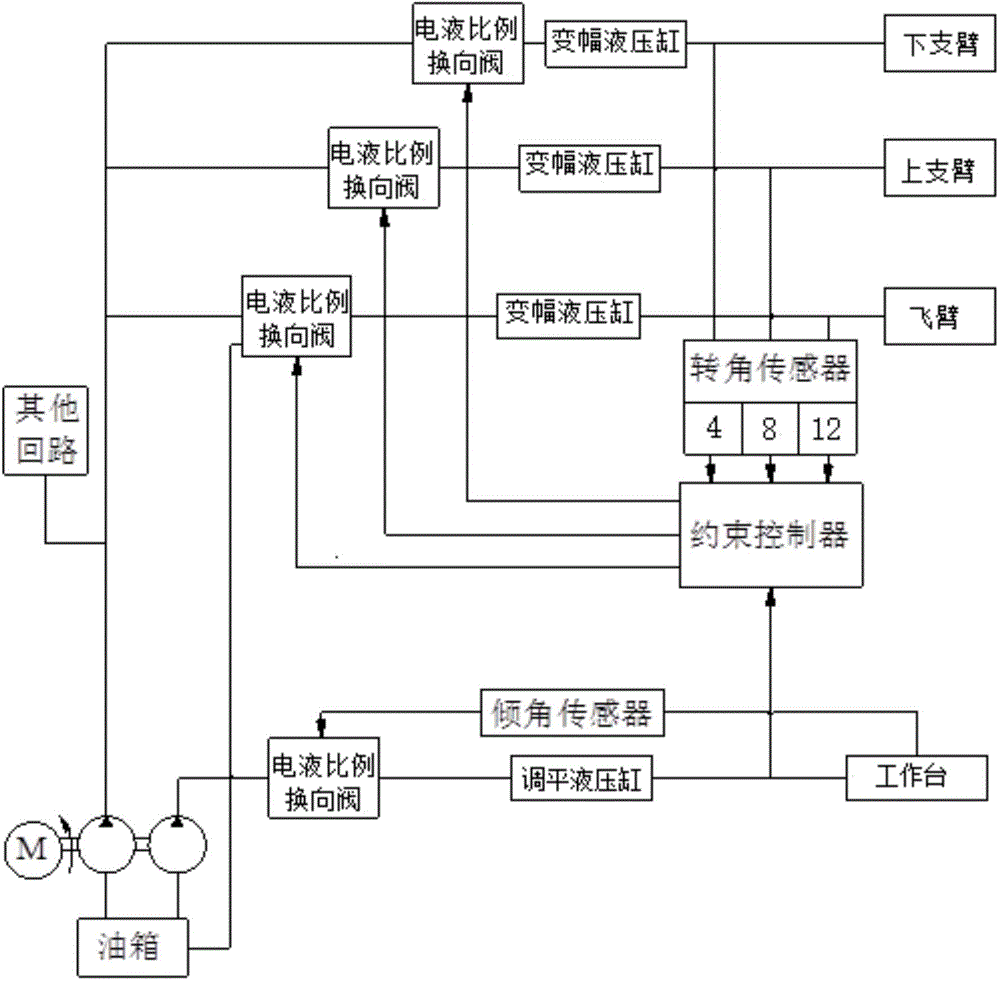

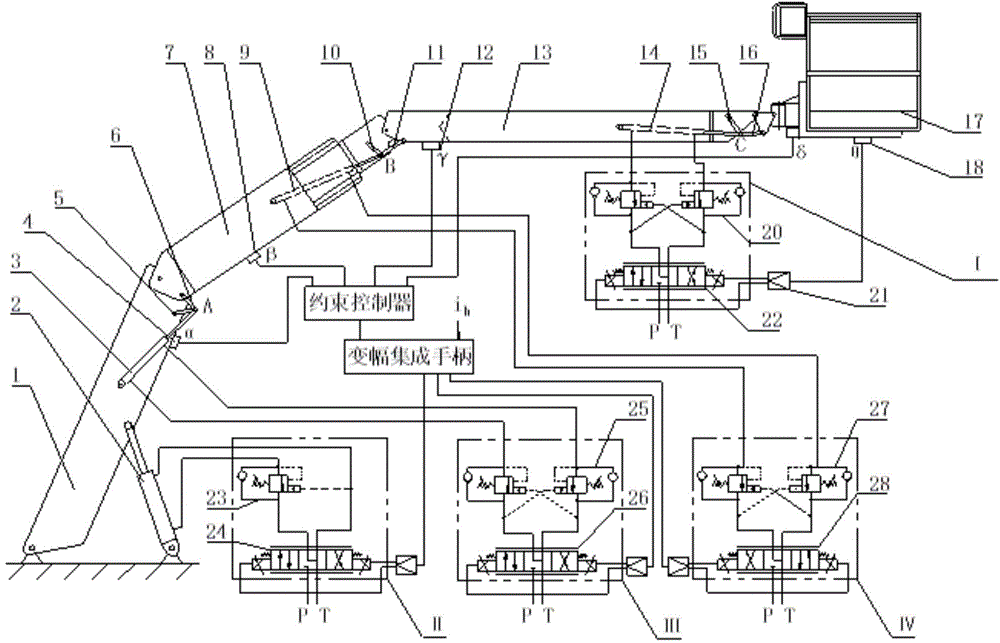

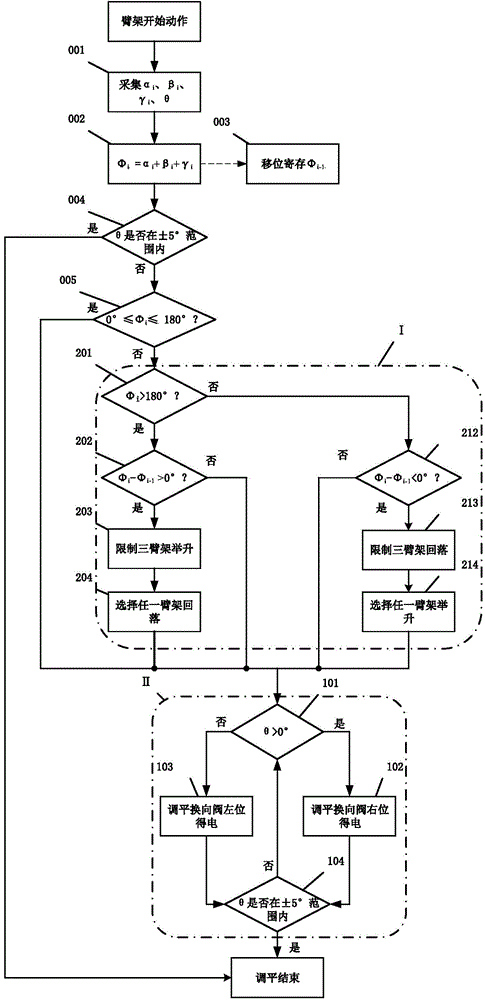

Overhead working truck leveling system based on boom limit and control method thereof

InactiveCN104860239ARealize automatic leveling functionSolving the Insufficient Balanced Flow SupplyServomotor componentsLifting devicesHysteresisControl system

The invention discloses an overhead working truck leveling system based on boom limit and a control method thereof. Through the adoption of the boom limiting control method, after sampling is implemented by using sensors, an amplitude-variation system and a levelling system are introduced to limit and control booms, so that the levelling function of an operation platform can still be achieved when a workbench outputs a smaller levelling angle (equal to or smaller than 180 degrees) and a larger amplitude-variation angle (equal to or smaller than 260 degrees) is formed through boom lifting, the levelling function of the workbench can be achieved while the workbench is lifted in a large space, the lifting amplitude angles of arms are matched with smaller levelling output angles through the limiting and control on the booms, and the difficulty of levelling output is effectively reduced; besides, the booms are consistent with an automatic workbench levelling system in starting and stopping, so that the levelling hysteresis is low; moreover, the workbench serves as a single controlled object, so that the system is simple and easy to control.

Owner:CHANGAN UNIV

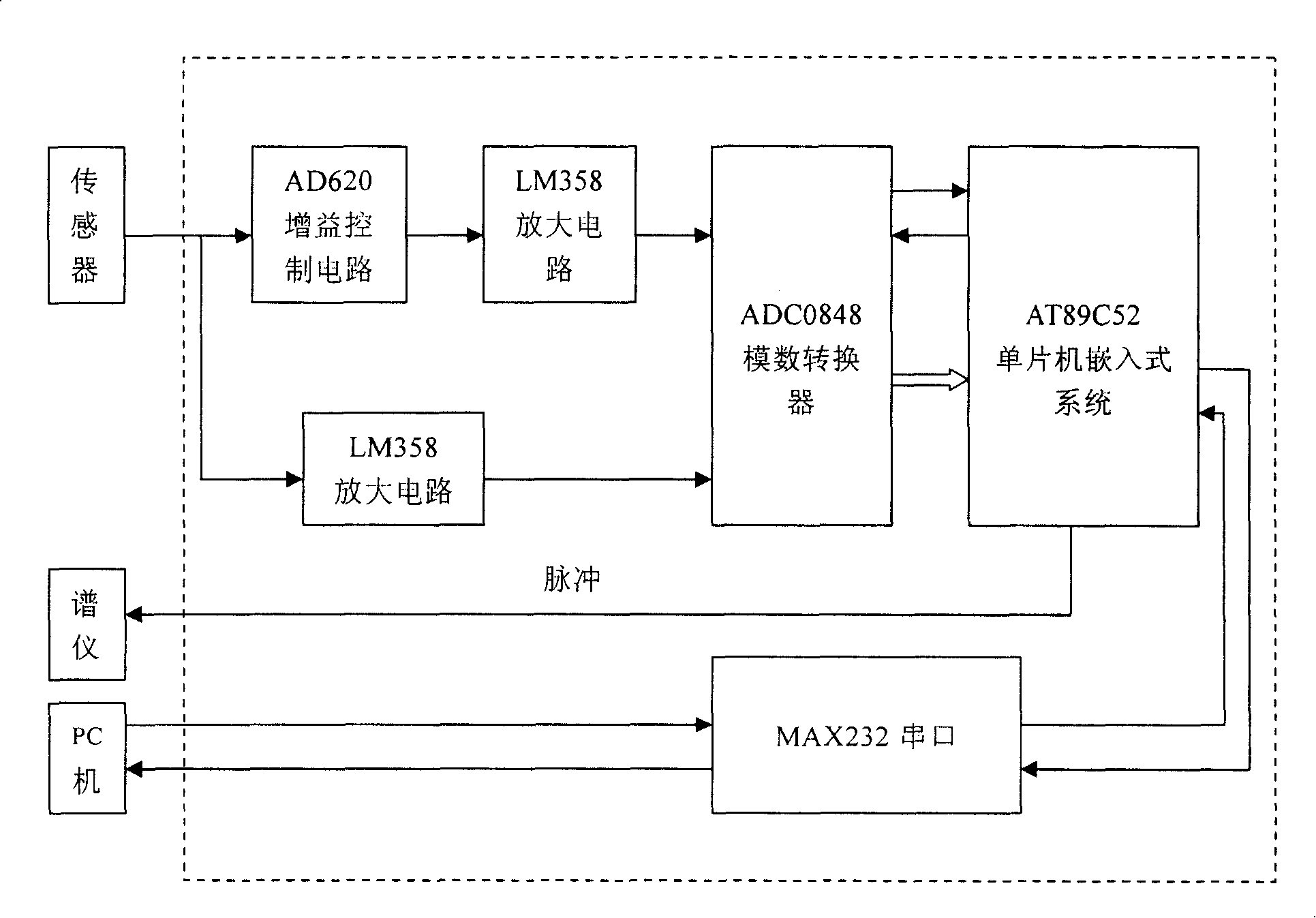

Respiration /ECG gated apparatus for magnetic resonance image-forming system

InactiveCN101191830AImprove image qualityHigh image resolutionCatheterDiagnostic recording/measuringInformation processingEcg signal

The invention discloses a respiratory and ECG gating device used in a MRI system, relating to the MRI technology, wherein an information processing system is an embedded system taking a singlechip as the processing core; a sensor is used to capture respiratory and electrocardio signals which are amplified and subject to analog-to-digital conversion and input into the singlechip to be processed, and used as well to input the respiratory and electrocadio signals into a computer through a serial port for displaying the essential information on the screen of the computer which returns the information of the threshold preset in a man-computer interaction way to the device through the serial pore; the singlechip operates the threshold signal, i.e., control pulses, according to the generation sequence of the threshold and transmit the threshold signal to an alpha spectrometer. The device of the invention is simple, flexible, reliable and low in cost, and ensures the real timing and accuracy of the captured signals and clear image of the MRI system.

Owner:BEIJING WANDONG MEDICAL TECH CO LTD +1

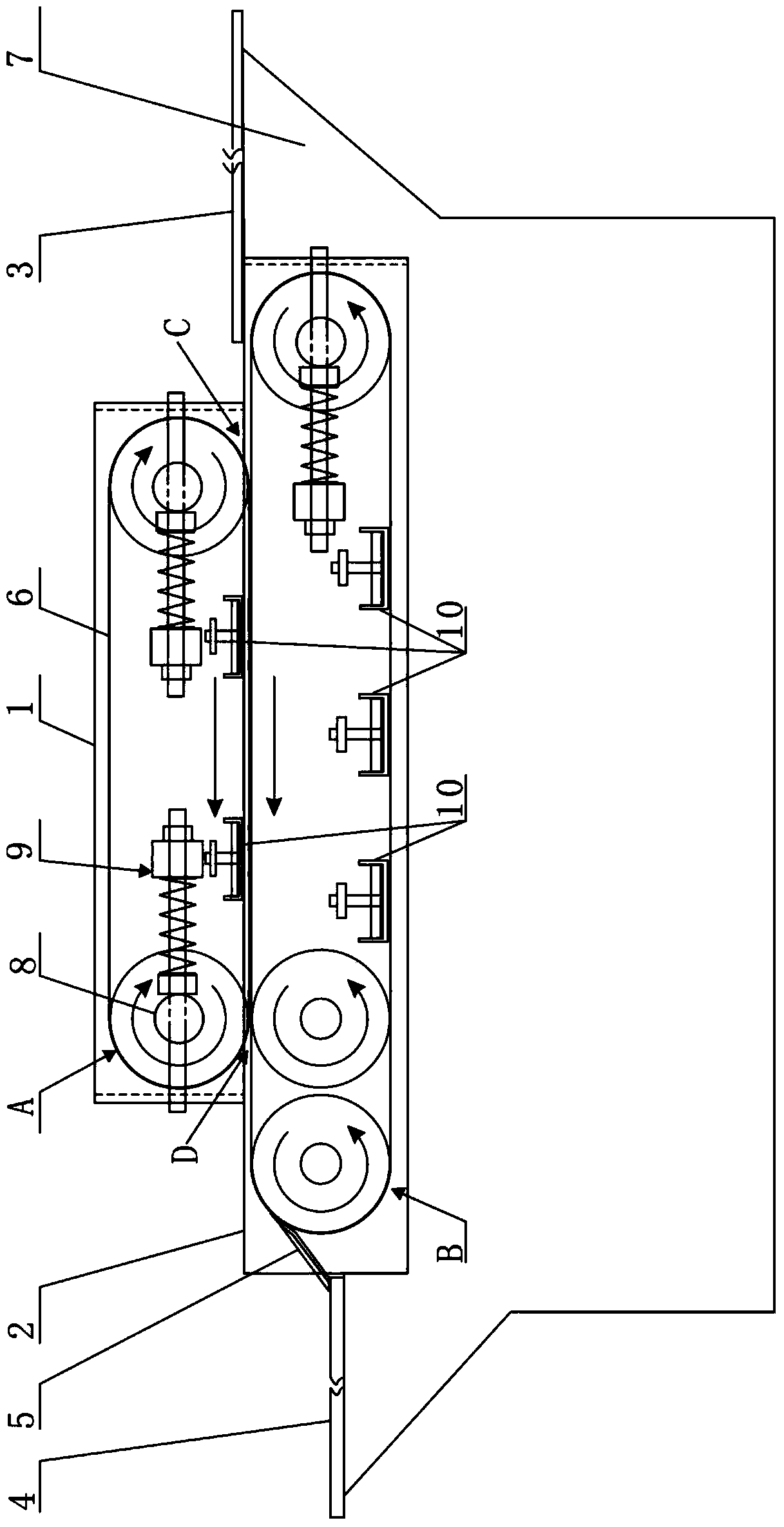

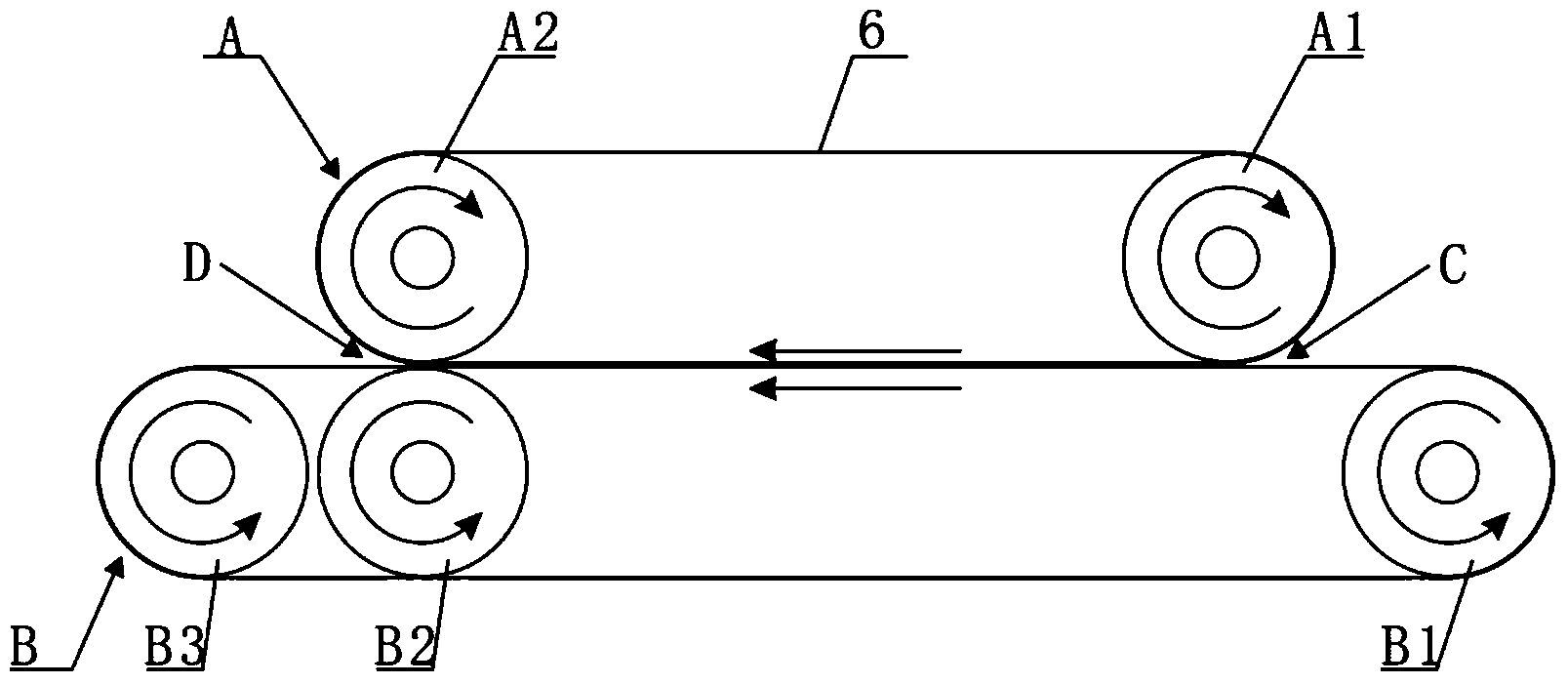

Drum type leather gluing machine and production process thereof

ActiveCN104070764AQuality assuranceAvoid local deformationLaminationLamination apparatusConveyor beltSizing

The invention discloses a drum type leather gluing machine. The drum type leather gluing machine comprises an upper conveyor belt and a lower conveyor belt which are arranged up and down and mutually matched for conveying and compacting leather and lining cloth, wherein a leather conveying channel is formed between the upper conveyor belt and the lower conveyor belt, the lower conveyor belt is longer than the upper conveyor belt, two ends of the lower conveyer belt both exceed the upper conveyor belt, and a lower roller II matched with an upper roller I for extruding the leather and the lining cloth is arranged in a position of the lower conveyor belt, which corresponds to the upper roller I. The invention further discloses a production process of the drum type leather gluing machine. The production process comprises the steps of arranging the leather and the lining cloth to be bonded on the conveyor belts, preheating, conveying into the leather conveying channel, heating, extruding, and cooling and sizing after outputting from the conveying channel. According to the drum type leather gluing machine and the production process thereof, the leather and the lining can be prevented from locally deforming and misplacing so that the leather and the lining cloth are flat and are firmly bonded, and the percent of pass is increased to 100 percent.

Owner:四川非意欧国际皮革制品有限公司

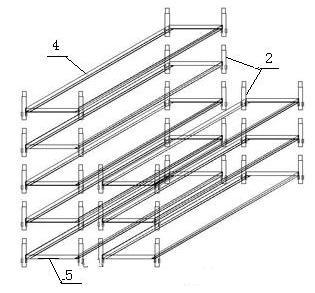

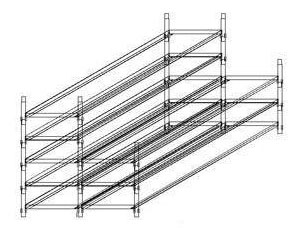

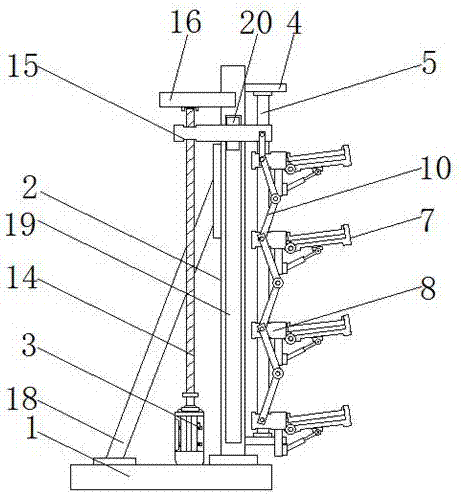

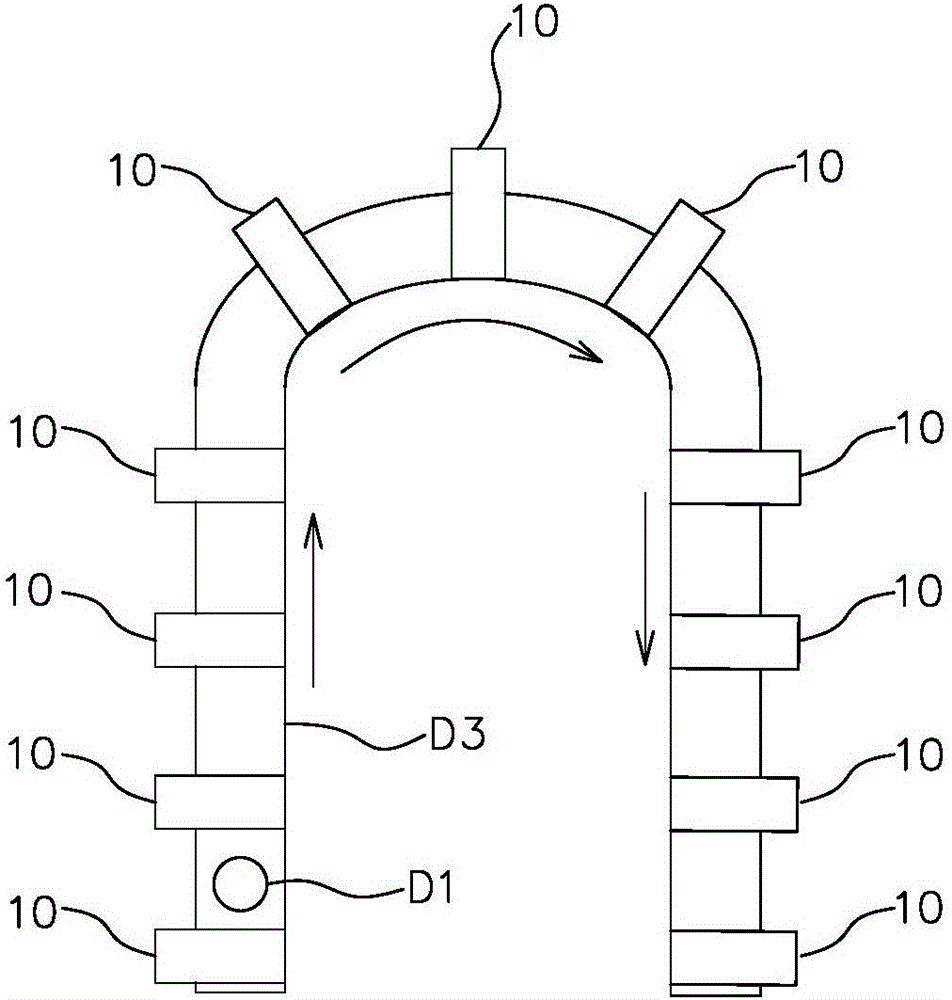

Multi-layer cultivation illumination adjustment frame for flowers and plants

PendingCN107980417AConducive to manual operationAdjustable distanceSaving energy measuresCultivating equipmentsEngineeringDaylight

The invention discloses a multi-layer cultivation illumination adjustment frame for flowers and plants. Two or more multi-layer cultivation illumination adjustment frames for the flowers and plants are used in combination. The frame includes a base, a stabilizer rod and a motor are fixedly connected at the top of the base, and the upper end and the lower end of the stabilizer rod are respectivelyconnected with fixing blocks; a sliding bar is connected between the two fixing blocks, moving blocks are slidably connected with the surface of the sliding bar, support plates are hinged on the moving blocks, fixing plates are arranged on the surfaces of the support plates, seedling frame clamping connecting grooves are formed in the tops of the fixing plates, and fluorescent lamps are arranged on the lower bottom surfaces of the support plates except for the support plate on the bottommost layer; the distances between the fixing plates can be adjusted according to the heights of the plantedflowers and plants during use, and the maximum distance between the fixing plates can be arranged to receive natural illumination to the maximum degree during daytime; at night, the distances betweenthe fixing plates can be shortened so that illumination supplement effects of the fluorescent tubes can be optimized, and electric energy can be saved.

Owner:GUIZHOU JIAOKAN ECOLOGICAL GARDENS

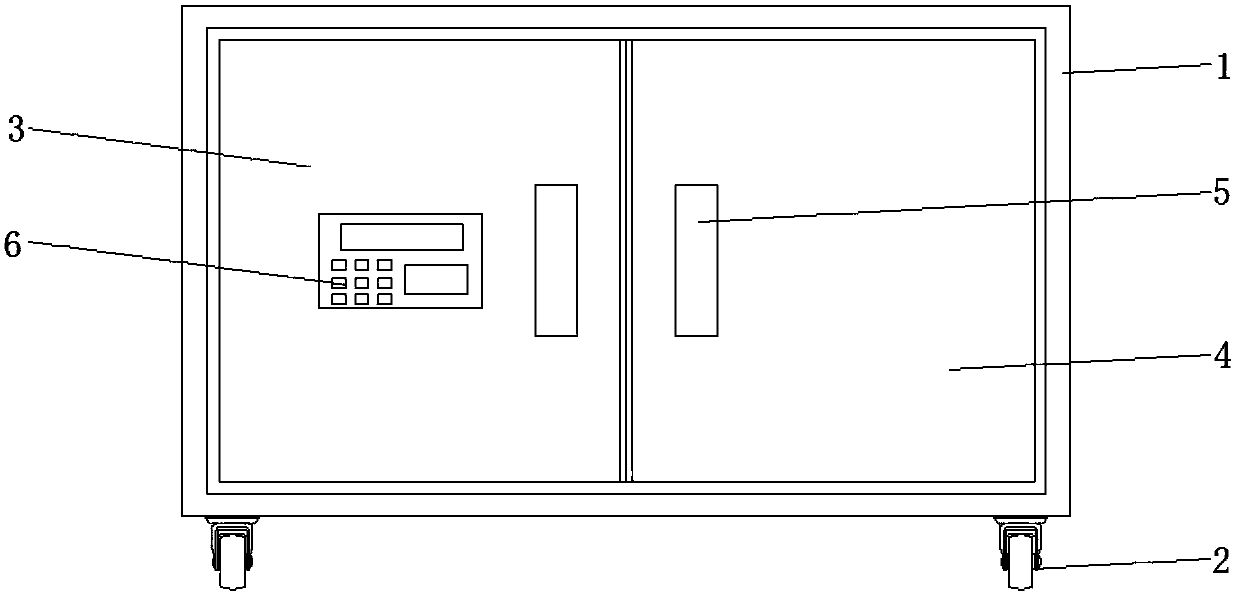

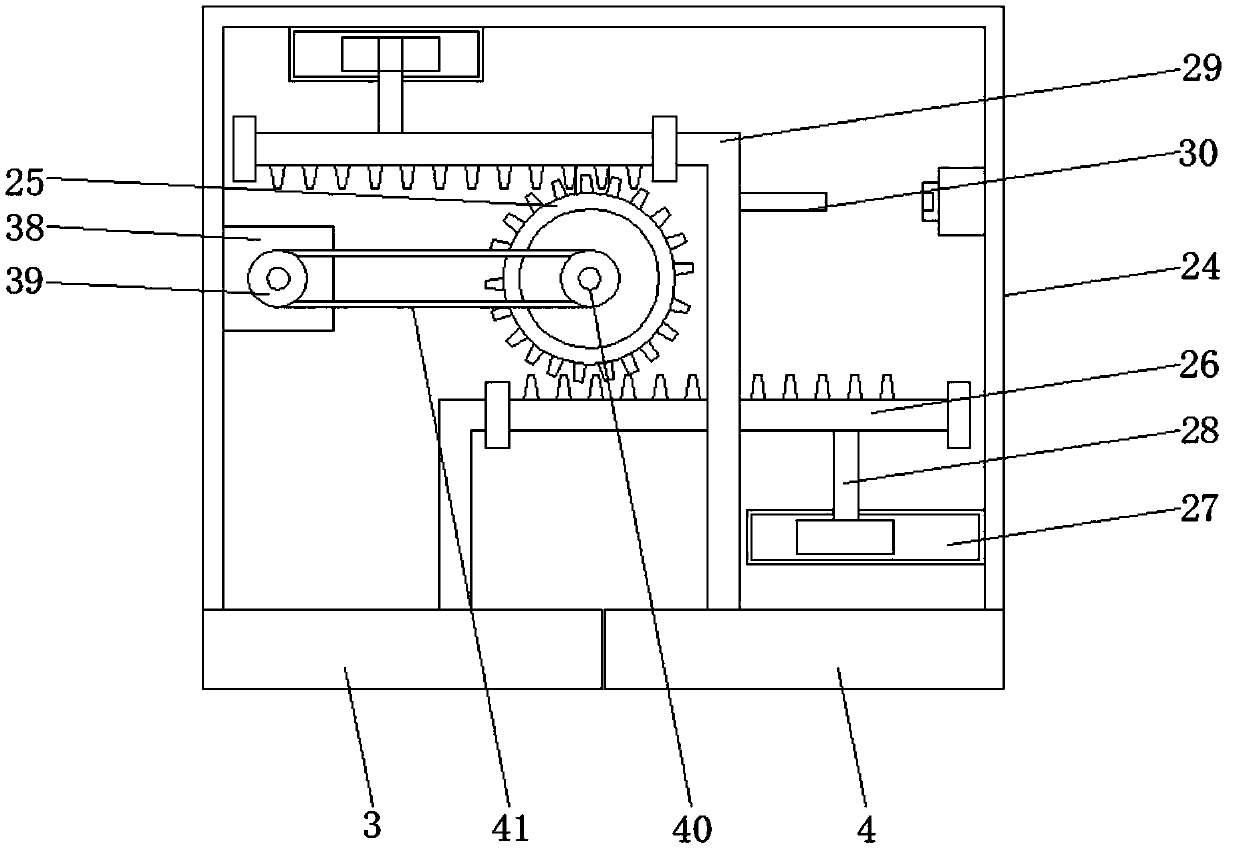

High-safety power distribution cabinet

InactiveCN107946923AImprove securityConducive to manual operationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsSlide platePower apparatus

The invention discloses a high-safety power distribution cabinet. The high-safety power distribution cabinet comprises an outer frame; a safety door switching apparatus is fixedly connected in the interior, close to the two sides of the bottom end, of the outer frame; fire-fighting power apparatuses are fixedly connected to the two sides, close to the middle position, of the interior of the outerframer; the bottom ends of the fire-fighting power apparatuses are fixedly connected with a supporting plate; movable sliding grooves are formed in the two sides of the interior of the outer frame; connecting rods are rotationally connected with the two sides of the bottom end of a push plate respectively; push blocks are fixedly connected with the bottom ends of the corresponding connecting rods;pushing sliding grooves are formed in the two sides of a supporting frame; sliding plates are glidingly connected in the pushing sliding grooves; the middle positions of the bottom ends of the sliding plates are rotationally connected with a rotary shaft; and the bottom end of the rotary shaft is fixedly connected with a refrigerating room. The invention relates to the technical field of electronics. By virtue of the high-safety power distribution cabinet, an illuminating lamp is turned on automatically when the safety door is opened, so that manual operation can be performed conveniently; and meanwhile, uniform heat dissipation is performed in the power distribution cabinet, so that the service life of instruments is prolonged, and full automatic and all-around fire fighting and fire extinguishing of the power distribution cabinet is realized.

Owner:佛山杰致信息科技有限公司

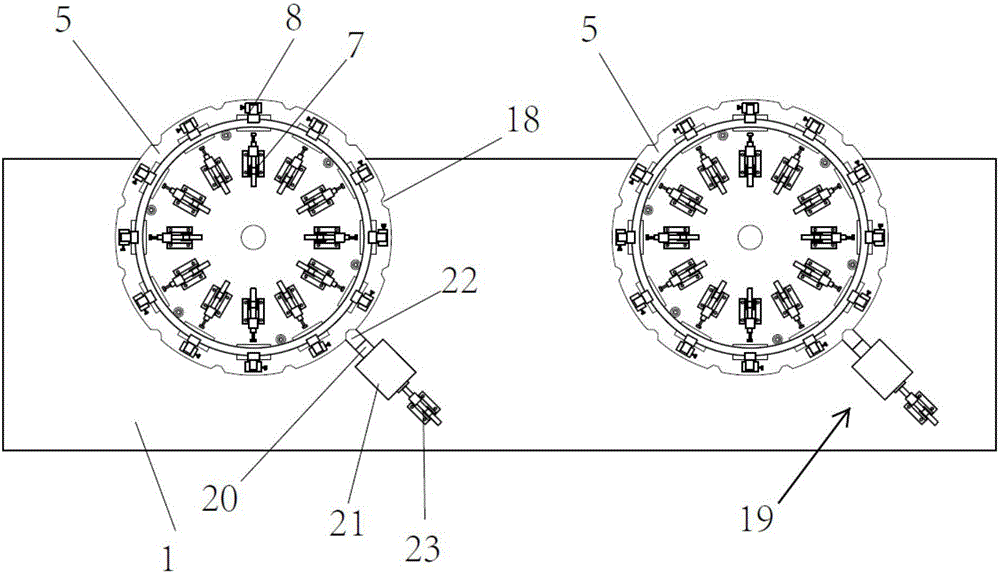

Basket ring spring hook butt welding machine

The invention discloses a basket ring spring hook butt welding machine which comprises a base plate. The base plate is arranged on a mobile support. A first guide assembly and a transmission mechanism are arranged between the base plate and the mobile support, and two loading discs are arranged on the surface of the base plate in the moving direction. The loading discs are connected with the base plate through a rotating assembly, a plurality of first quick clamps are arranged on the surfaces of the loading discs along the same circumference, and a plurality of butting positioning parts are further arranged between the edges of the plurality of first quick clamps and the outer circumferences of the loading discs along the same circumference. The first quick clamps and the butting positioning parts are matched with clamping spring hooks, the loading discs between the first quick clamps and the corresponding butting positioning parts are provided with butt welding avoiding grooves, and the butt welding machine is arranged on one side of each loading disc. The basket ring spring hook butt welding machine can effectively position the spring hooks and is high in welding efficiency and good in quality.

Owner:LIRUIBAO SPORTS EQUIP WUJIANG

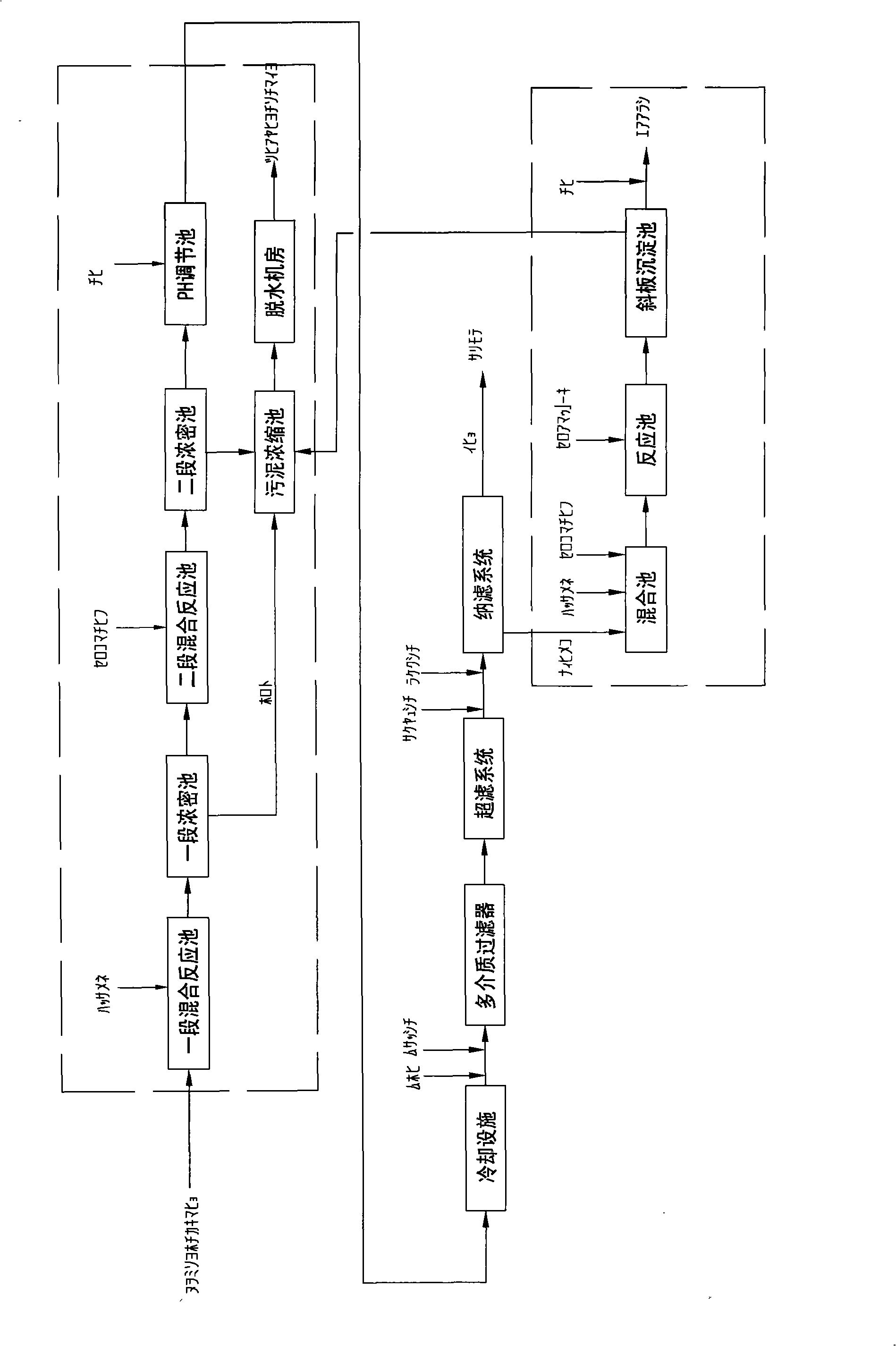

Membrane separation process for lead-zinc smelting wastewater

ActiveCN101492214ALow annual depreciation rateHigh recovery rateWater contaminantsWaste water treatment from metallurgical processIndustrial waste waterUltrafiltration

The invention discloses a membrane separation process for treating lead-zinc smelting wastewater, which comprises the following steps: pretreating lead-zinc smelting industrial wastewater through the processes of a multi-media filter, ultrafiltration, and the like after the wastewater reaches the discharge standard after the treatment of a heavy metal precipitation process; and performing desalinization treatment on the wastewater by a nanofiltration process, wherein water is produced for recycling and a concentrated solution reaches the standard after an intensified coagulation treatment and is discharged. The membrane separation process has the advantages of high wastewater recovery ratio by adopting a membrane process to perform recycling treatment on the lead-zinc smelting wastewater, good recycling water quality, advanced performance and economical practicability, high automation degree, and simple and convenient manual operation.

Owner:CHINA NERIN ENG +1

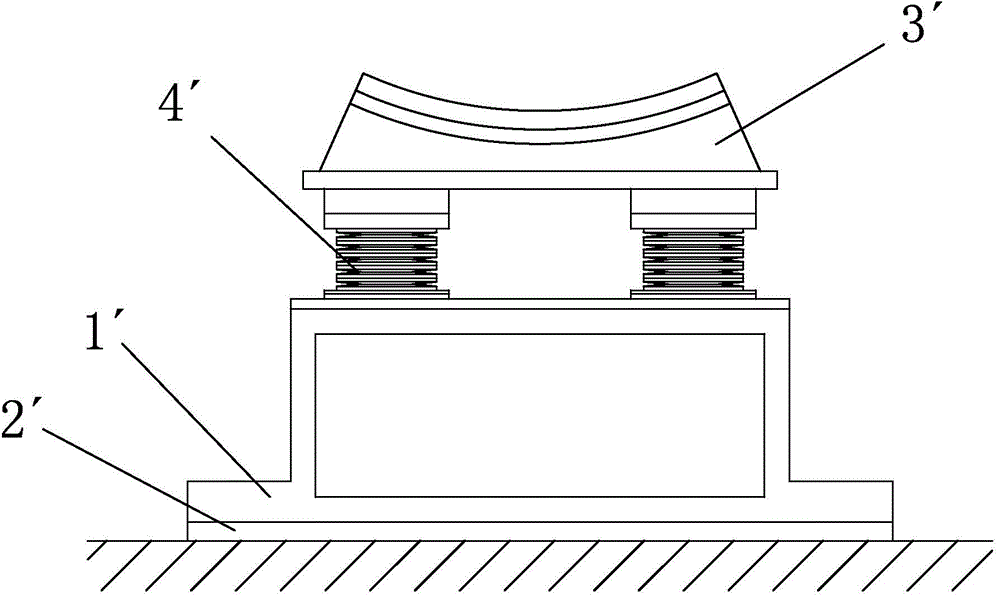

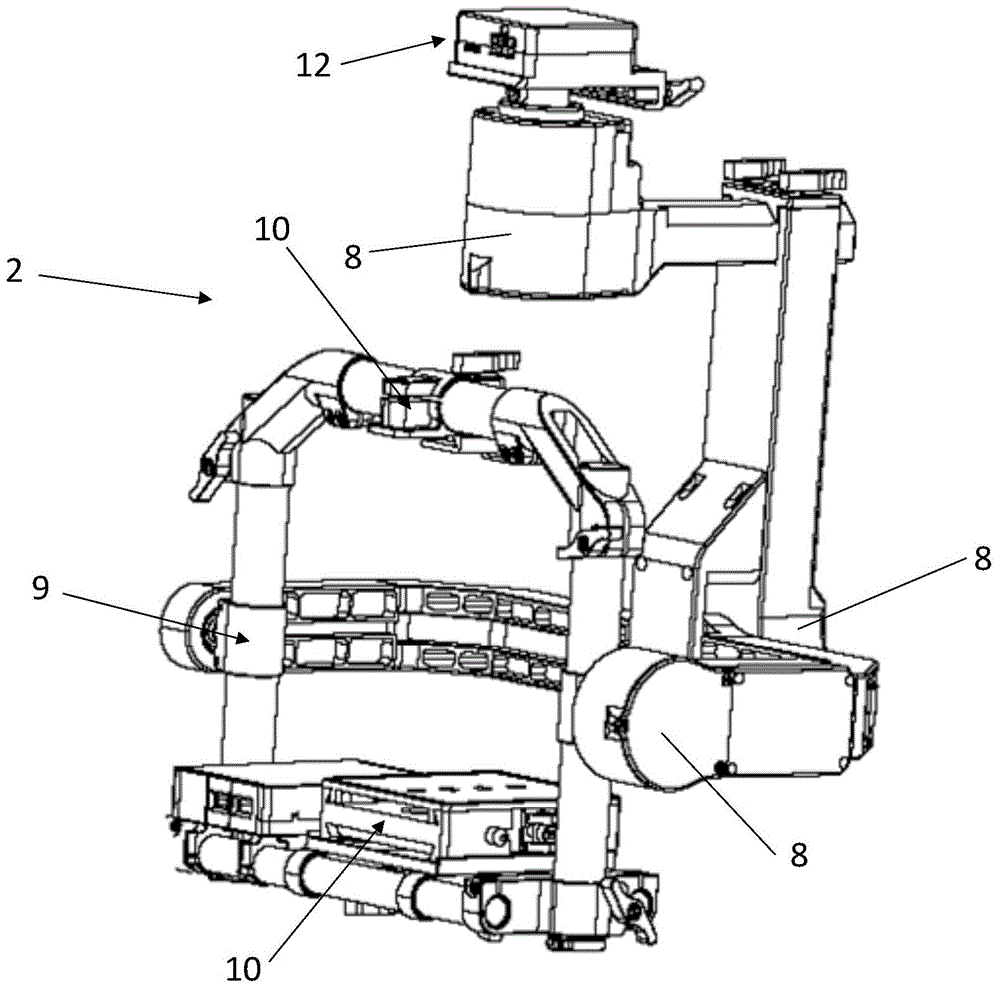

Integrated bionic massage robot based on flexible driving

ActiveCN108670754ARealize closed-loop controlRelieve work stressDiagnosticsSuction-kneading massageCouplingPhysical therapy

The invention relates to an integrated bionic massage robot based on flexible driving, and belongs to the field of flexible driving and bionic machinery. The robot is composed of a bionic massage elbow unit, a bionic massage hand unit, an infrared detection unit, a transmission unit, a control unit and a support base. The bionic massage elbow unit and the bionic massage hand unit based on the pneumatic artificial muscle can simulate the massage actions of the hands and the elbow, such as rubbing, press, knead, pinch and the like. In addition, the flexible sensor integrated in the bionic massage hand unit and the bionic massage elbow unit can measure the tissue hardness of the massage area, and the control unit can select the corresponding massage force according to the specified massage action. The integrated bionic massage robot based on flexible driving has the advantages of high integration degree, excellent rigid and flexible coupling performance, compact structure, and can provideeffective characterization means and evaluation mechanisms for massage quality, further improve the massage effect, and has important application value in the fields of family service robots, medicalrehabilitation and the like.

Owner:JILIN UNIV

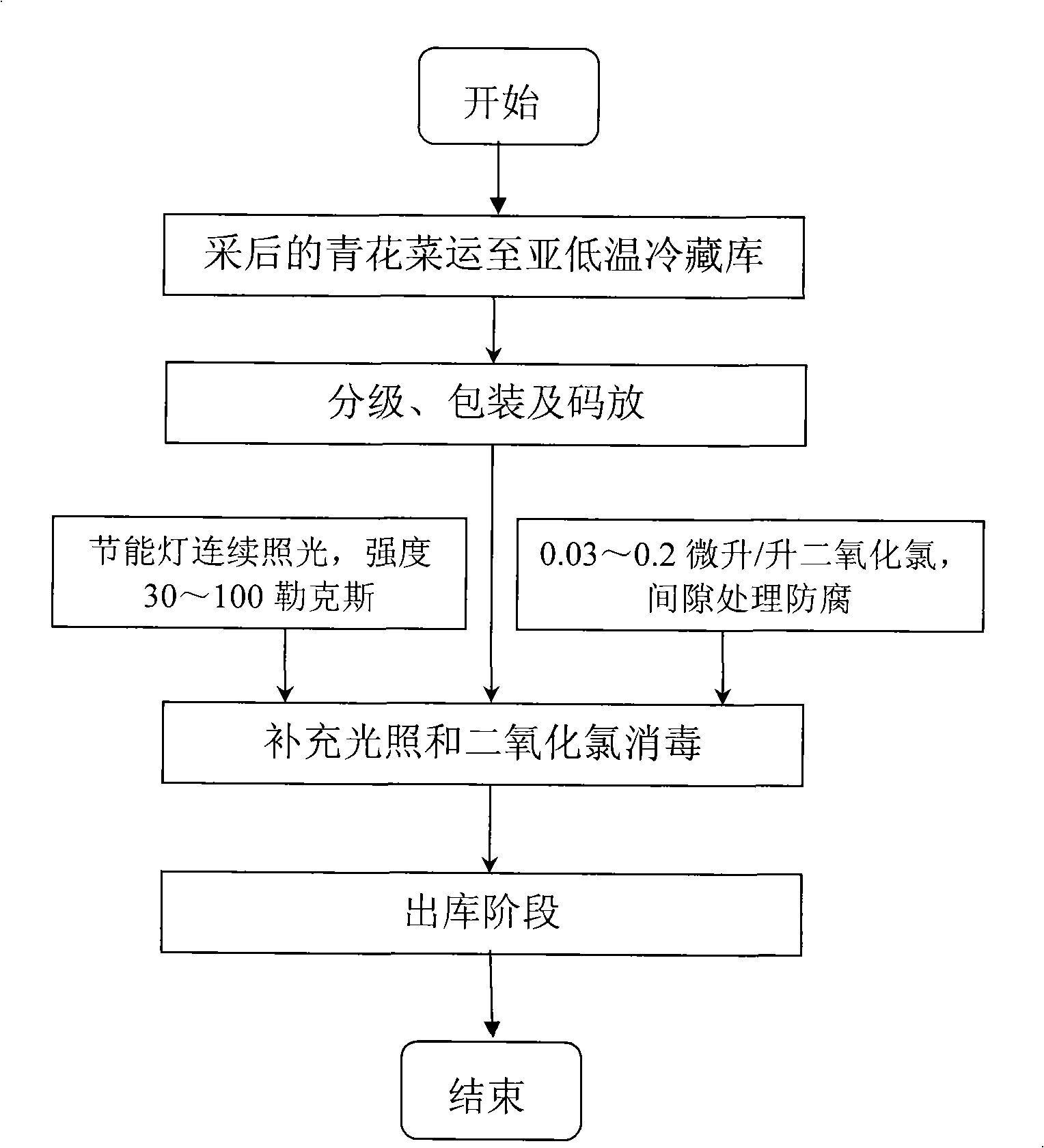

Method for processing broccoli for fresh-keeping using light filling and chlorine dioxide in sub-low-temperature cold-storage

ActiveCN101253881AImprove qualityReduce decay lossFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingPathogenic microorganismChlorine dioxide

The invention discloses a fresh-keeping method of broccoli in the mild hypothermia refrigerator by supplemental lighting and chlorinedioxide. The fresh-keeping method includes the following phases in sequence: transporting the picked broccoli to the mild hypothermia refrigerator; grading, packaging and stacking; lighting and sterilizing; and stocking out. The fresh-keeping method has the advantages that the controllable refrigerating temperature at 3-8 DEG C facilitates manual operation and saves refrigeration energy consumption; the supplemental lighting at a proper dosage and within a proper spectrum enables the stocked broccoli to carry out a weak photometabolism, which facilitates the synthesis and the preservation of the chlorophyll, i.e., the preservation of the greenness, and at the same time remarkably reduces the loss of the vitamin C; The disinfection treatment with the chlorinedioxide at a concentration of 0.03-0.2 MuL / L at intervals is a safe method with an remarkable effect of preventing the broccoli from mustiness, thereby remedying the defect of the mustiness of the broccoli due to a higher temperature set in the refrigerator, deferring decomposing of the broccoli chlorophyll, preserving the greenness and controlling the infection mustiness caused by the pathogenic microorganism.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

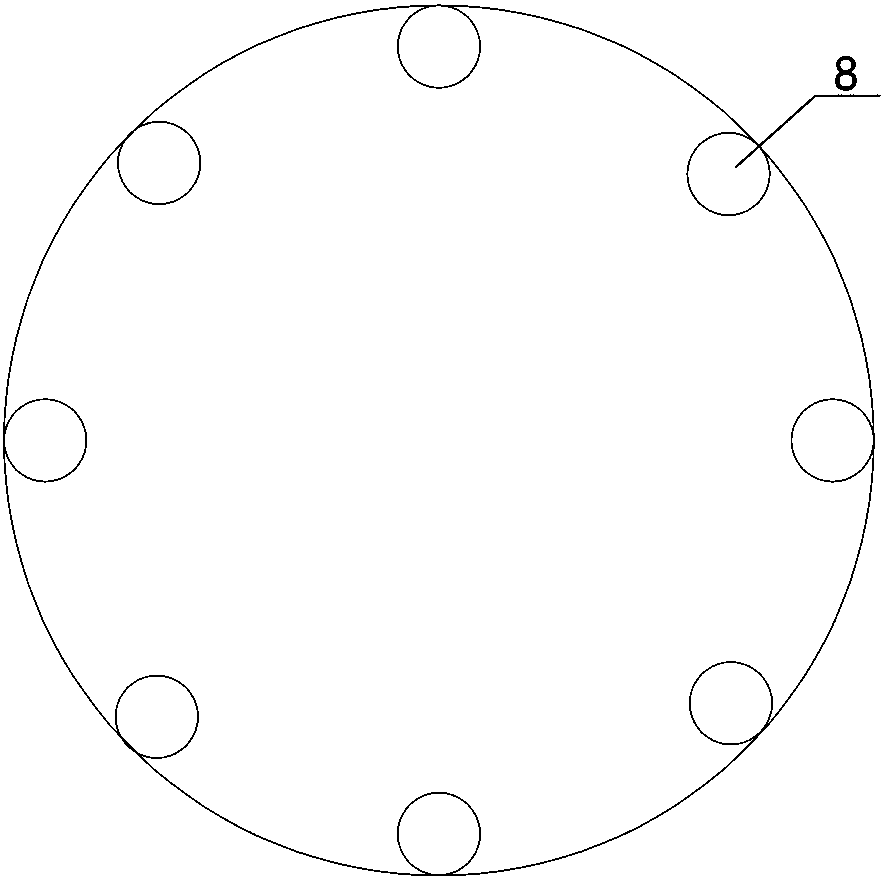

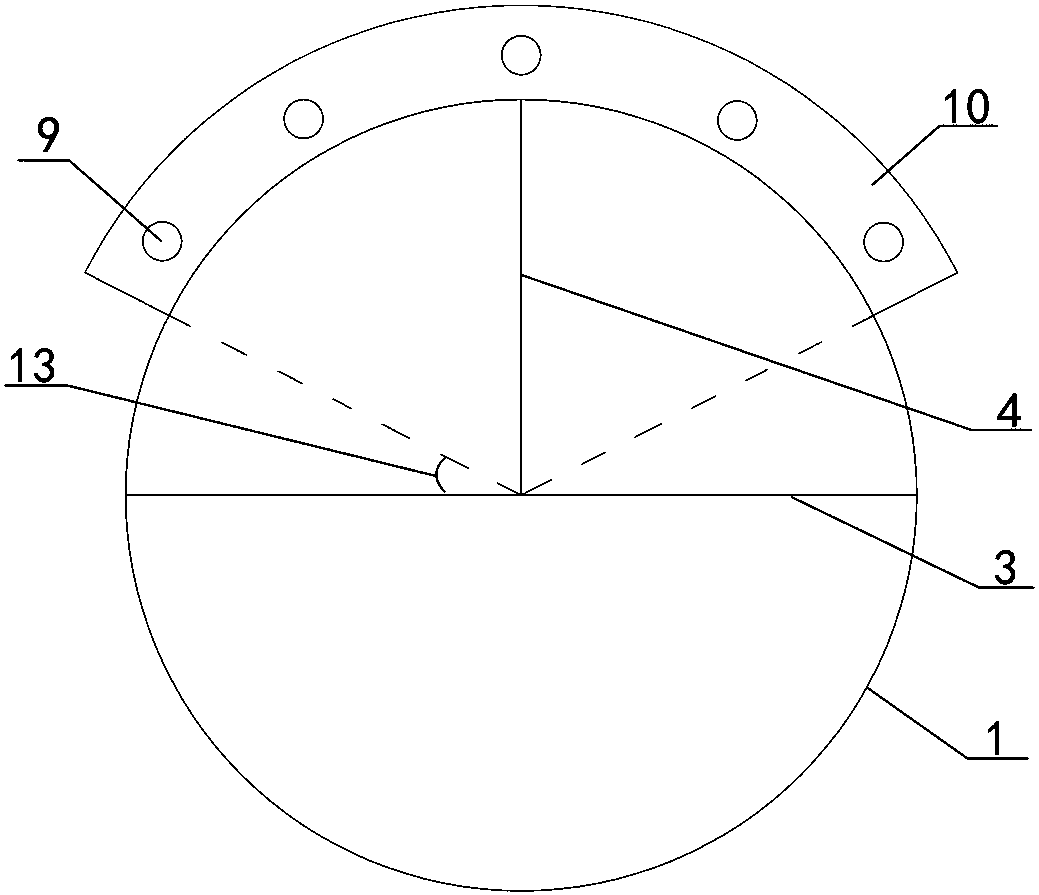

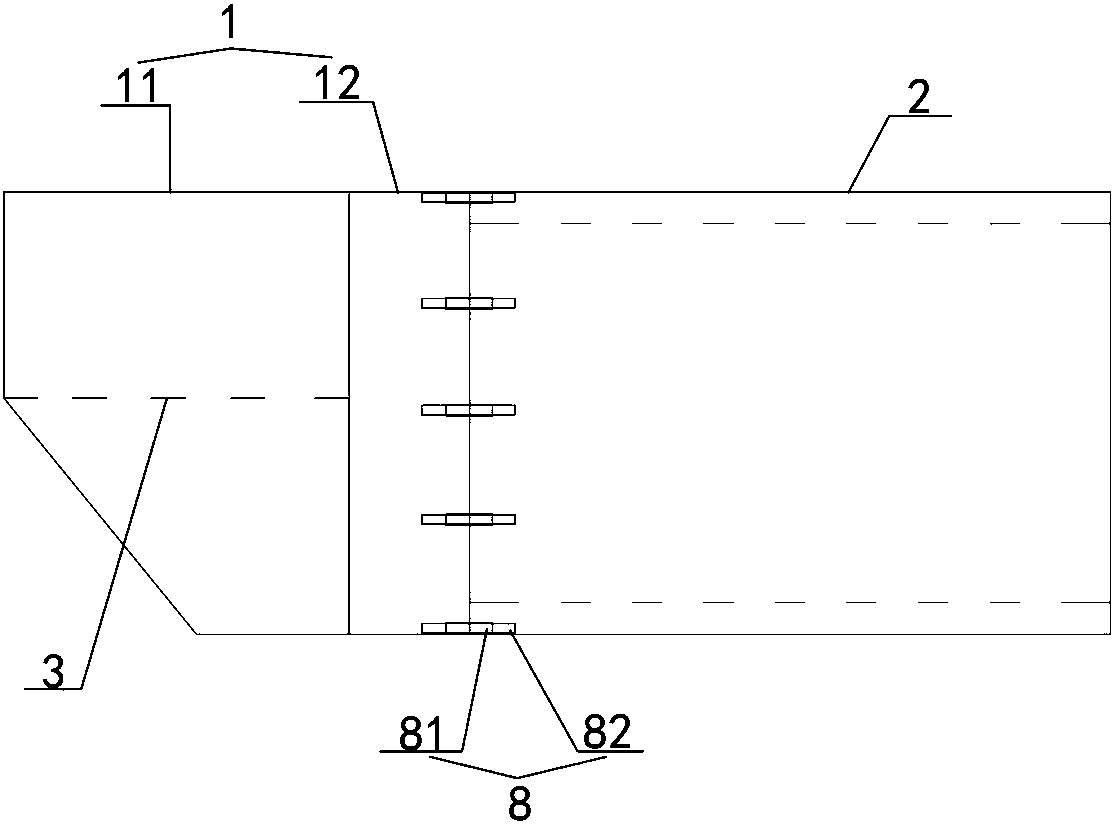

Large-pipe-diameter manual jacking pipe for space-separated excavation and excavation construction method applying jacking pipe

PendingCN108506015AEasy to adjustEasy to correctUnderground chambersTunnel liningBuilding constructionEngineering

The invention discloses a large-pipe-diameter manual jacking pipe for space-separated excavation and an excavation construction method applying the jacking pipe. The jacking pipe includes a tool pipeand a concrete pipe, the tool pipe includes a blade feet section and a rectification section, the internal space of the blade feet section is divided by partition plates, the partition plates are composed of a horizontal middle partition and a vertical middle partition plate, the internal space of a steel pipe of the blade feet section is divided into three parts by the partition plats, specifically, an upper first space, an upper second space and a lower third space, and a rectifying device is fixedly connected into the jacking pipe. Through the transformation of the tool pipe, the problems of difficult jacking, large settlement and being prone to collapsing of a traditional jacking pipe in a sand pebble stratum can be solved effectively; the problems that a conventional tool pipe is large in an excavation tunnel face, secondary disturbance is more frequent in the process of manual excavation, and reinforced soil collapses in a bulk mode and falls down together with ungrouted soil atthe same time are avoided; and the efficiency of continuous work in the process of manual pipe jacking can be improved greatly, and the construction period and cost are saved.

Owner:北京住总集团有限责任公司

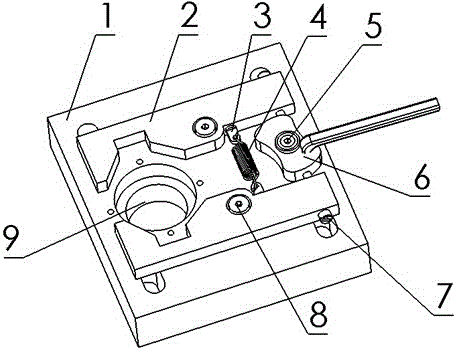

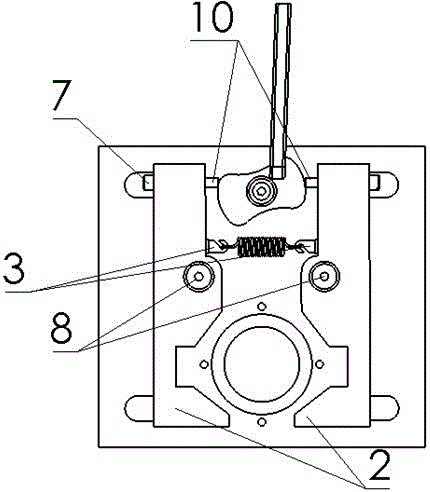

Rapid fixture special for eccentric adjustment of rotary encoder circular grating

The invention relates to a rapid fixture special for eccentric adjustment of a rotary encoder circular grating. The rapid fixture comprises a fixing plate, a clamping plate, a hook-shaped screw, a tension spring, a bolt type cam follower needle roller bearing, a shifting lever cam, an outer thread pin, a step pin and a cylindrical compression spring. In the rapid fixture special for eccentric adjustment of the rotary encoder circular grating, a four-point positioning way is adopted, and the clamping and positioning of an encoder are realized by using the extension and retraction characteristics of the tension spring, the rotation characteristic of a cam mechanism, a lever principle and the like; the rapid fixture special for eccentric adjustment of the rotary encoder circular grating has a simple and reasonable structure, and is convenient and rapid to use; by adopting the rapid fixture, rapid clamping of the rotary encoder is realized, and the efficiency in eccentric adjustment of the rotary encoder circular grating on a production line is increased.

Owner:HARBIN UNIV OF SCI & TECH

Zipper cutting-off mechanism

ActiveCN101255652AHigh strengthHigh impact strengthSlide fastenersSevering textilesReciprocating motionAcoustics

The invention discloses a zipper cut-off mechanism, comprising a fixed arranged mold, an ultrasonic wave head which is on the same axis with the mold and can do reciprocal motion, an ultrasonic generator which is electrically connected with the ultrasonic wave head; a bulge which is arranged on the working surface of the mold corresponding to the working end surface of the ultrasonic wave head, the peak of the bulge is arranged as a blade; when the distance between the ultrasonic wave head and the mold is minimum, a gap kept between the bulge of the mold and the ultrasonic wave head is smaller than the thickness of a zipper cotton tape. The invention is characterized in that the structure is simple, the property is stable, the operation is convenient, and the invention is suitable for various zipper cut-off, punch mechanisms or cloth fabric cut-off, punch mechanisms.

Owner:KEE (GUANGDONG) GARMENT ACCESSORIES LTD

Pipeline cutting equipment on basis of inner side wall expansion clamping principles

InactiveCN108971538ASection flatImprove cutting efficiencyLarge fixed membersExpansion mandrelsEngineeringThreaded rod

The invention provides pipeline cutting equipment on the basis of inner side wall expansion clamping principles. The pipeline cutting equipment comprises a bottom plate. A first movable groove with anupward opening is formed in the bottom plate, a first movable block is arranged in the first movable groove, a first threaded through hole is formed in the first movable block, a first threaded rod is connected into the first threaded through hole in a threaded manner, and two ends of the first threaded rod are rotationally connected with two ends of the first movable groove. The pipeline cuttingequipment has the advantages that a pipeline can be cut by a cutter head after rotating by a circle, the sections of the pipeline are flat, follow-up finishing can be omitted, and the cutting efficiency and cutting effects can be effectively improved; a rotary disc can be driven by a rotary sleeve to rotate, third threaded rods which are matched with the rotary disc can approach a support column,connecting sleeves can be driven by horizontal plates and first arc plates to rotate, second arc plates can be outwardly extended, accordingly, clamping protrusions on clamping plates can be squeezedwith the inner side walls of the pipeline in a contact manner, and the pipeline can be clamped.

Owner:陈晨

Automatic weighing and material preparing system and control method thereof

ActiveCN106644013AImprove configuration efficiencyReduce human inputControllers with particular characteristicsTotal factory controlMixed materialsLoad cell

The invention relates to an automatic weighing and material preparing system and a control method thereof. The automatic weighing and material preparing system comprises a plurality of automatic weighing and fixed-amount material placing devices and a material collecting device. The material collecting device comprises a material receiving container and a conveying device for conveying the material receiving container. The plurality of automatic weighing and fixed-amount material placing devices are used for weighing the different material components respectively; the material receiving container moves along the conveying device and collects the weighed material components that are automatically weighe. The automatic weighing and fixed-amount material placing device includes a material feeding part and a weighing part wherein the material feeding part is an electromagnetic vibration material feeding machine and the weighing part comprises a weighing sensor fixedly connected on a support rod and a bidirectional material hopper fixedly connected with the weighing sensor. The bidirectional material hopper is located under the material feeding part; and through a guiding groove, the bidirectional material hopper forms a bidirectional channel which guides materials into the material receiving container. The invention is suitable for the production and configuration of mixed materials, which greatly increases the configuration efficiency of the mixed materials and reduces the investment of human labor.

Owner:CAS HEFEI INST OF TECH INNOVATION

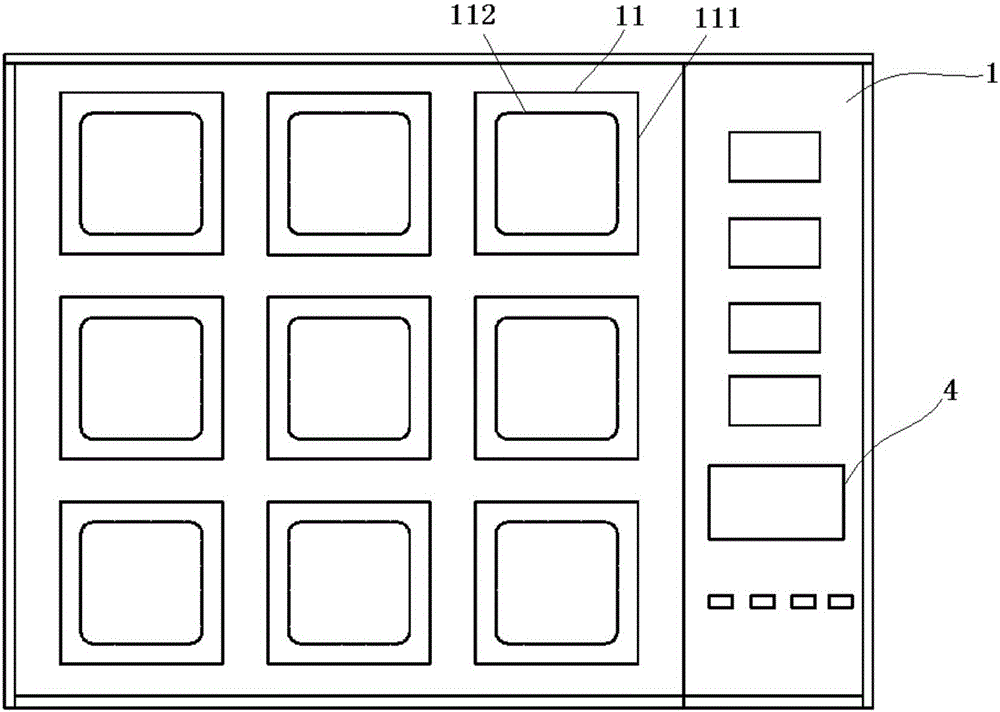

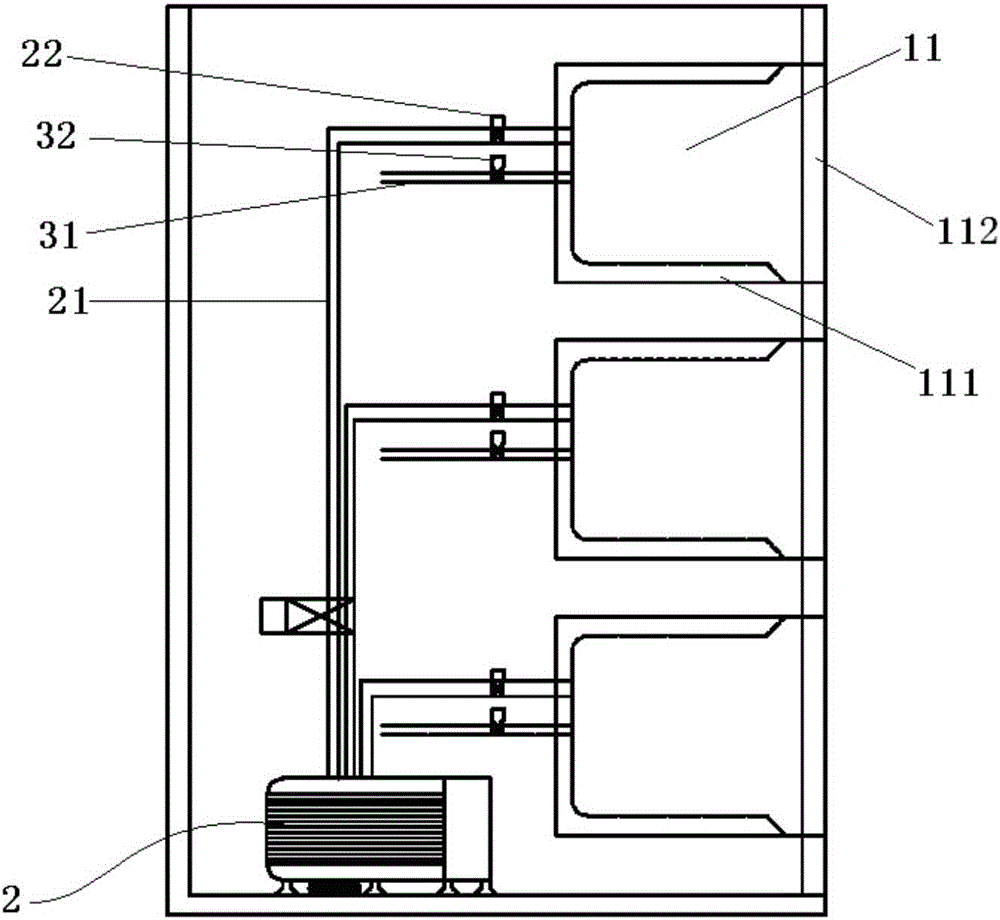

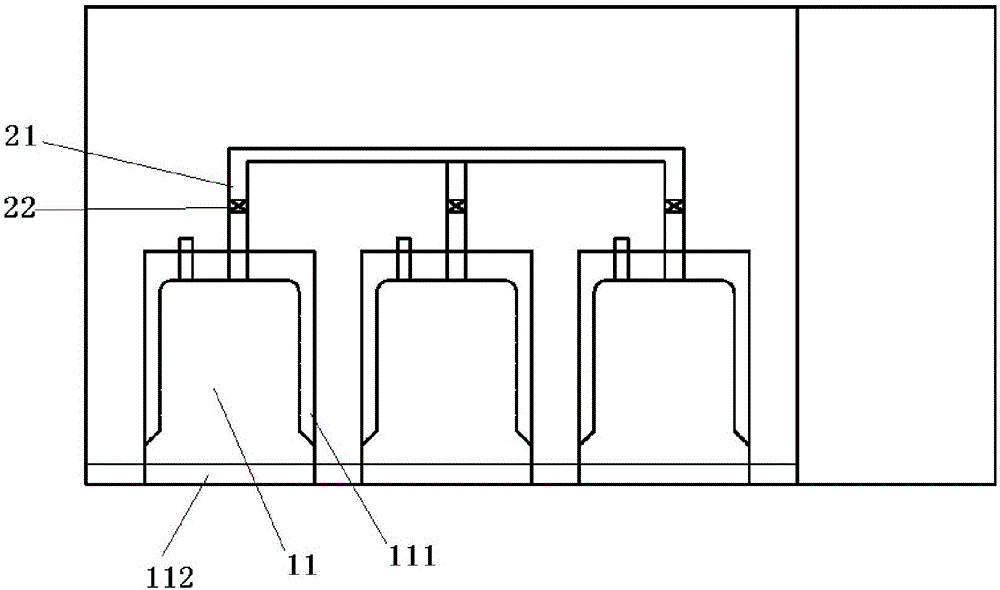

Unit type independent control box body structure

InactiveCN106829201ASolve Oxidation ProblemsLow costLiving organism packagingPackaging under vacuum/special atmosphereEngineeringNitrogen gas

The invention provides a unit type independent control box body structure. An integral type storage cabinet is divided into a plurality of independent chambers. Each chamber communicates with a vacuum pump for vacuuming and a vacuum breaking gas source for breaking vacuum, and an intelligent control system is adopted to realize intelligent control over the process of vacuuming and breaking the vacuum, so that the function of vacuum intelligent wafer storage is achieved. Compared with the traditional nitrogen cabinet, the whole process of wafer storage in the unit type independent control box body structure is in a vacuum state, the oxygen content of 10 ppm can be ensured, the oxidation problem of wafers in the storage process is eliminated completely, and nitrogen is not needed in the wafer storage process, the cost is greatly reduced, accessing operation of each chamber does not affect the other chambers, and the operating cost is reduced; in addition, the control system is more intelligent , the storage historical status can be inquired, and the current or historically stored wafer batch number and the storage time of each chamber can be automatically saved to facilitate the follow-up traceability. A man-machine operation interface adopts a touch screen and a scanning gun, and is easy to operate.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

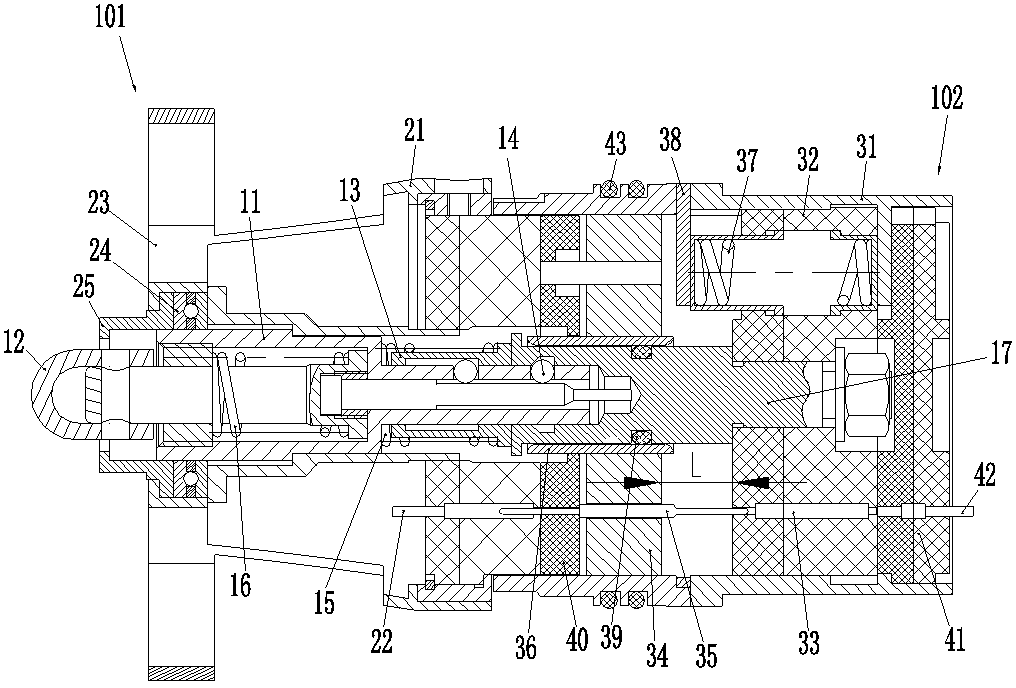

Electric coupler assembly, plug thereof and underwater short-circuit-resistant socket thereof

ActiveCN103259131ASolve the problem of not being able to prevent short circuits underwaterShort circuit will not causeCoupling contact membersTwo-part coupling devicesLocking mechanismUnderwater

The invention relates to the field of electric couplers, in particular to an electric coupler assembly, a plug of the electric coupler assembly and an underwater short-circuit-resistant socket of the electric coupler assembly. The electric coupler assembly comprises the plug and the socket, a mandrel locking mechanism is arranged between the plug and the socket, a socket contact piece comprises a floating contact piece and a change-over contact piece, the portion, behind a fixed insulator, of a floating insulator can be assembled in a socket shell body in a forward and backward floating mode, and a separating spring is arranged at the front end of the floating insulator in an ejecting mode, the floating contact piece is separated from the change-over contact piece under the action of the separating spring, a locking ring is fixedly assembled on the floating insulator and forward penetrates through the fixed insulator, the fixed insulator is matched with the locking ring in a sliding and sealed mode; a rotating piece is arranged on a plug shell body, a mandrel sleeve can be assembled in the plug shell body in a forward and backward sliding mode; the rotating piece and a sliding sleeve form a lead screw nut mechanism which is used for driving the locking ring to move and driving the floating contact piece to be connected with the change-over contact piece in an inserting mode; the problem that a socket of an electric coupler assembly can not be prevented from a short circuit underwater after being separated from a plug is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

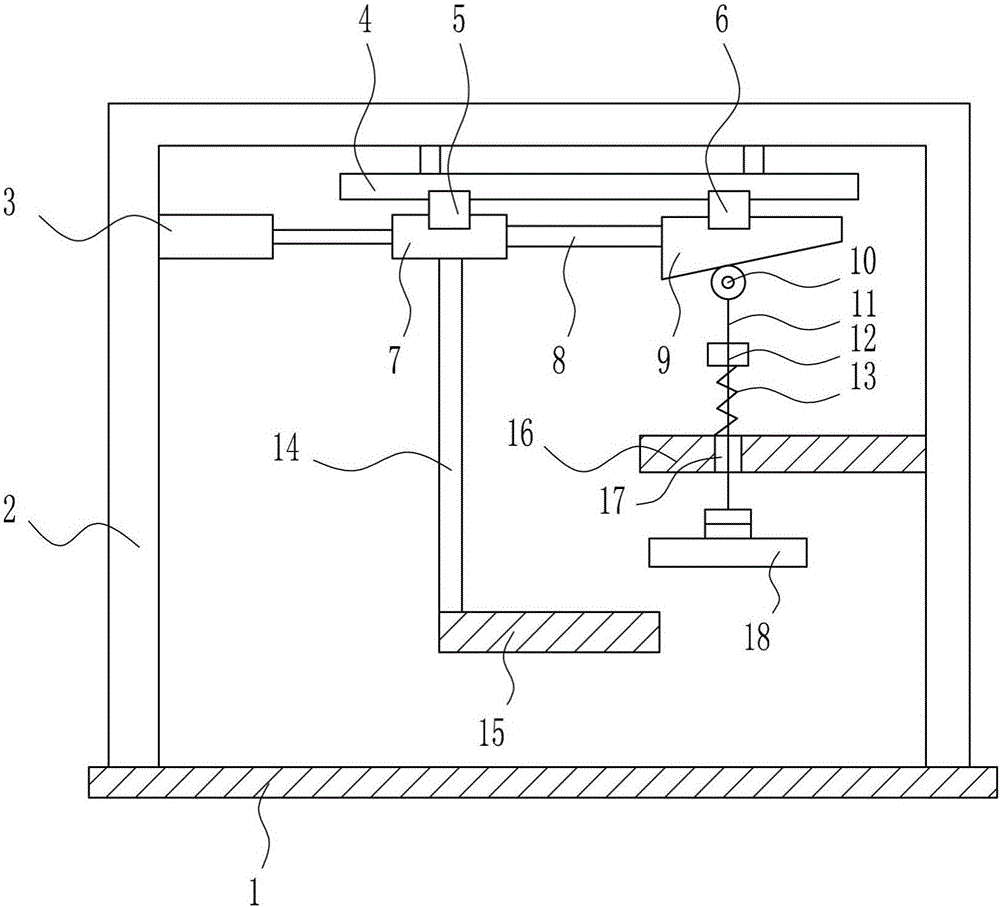

High precision cutting device for photo studios

ActiveCN106346554AHigh precision cuttingConducive to manual operationMetal working apparatusEngineeringMechanical engineering

The invention relates to a cutting device, especially to a high precision cutting device for photo studios. The technique aims to provide is the high precision for cutting device of photo studios. The cutting device adopts the following components to achieve the technical requirements: baseplate, stand, power-driven pusher, sliding rail, the first sliding block, the second sliding block, connecting block, the first connecting rod, wedge block, contact roller, lifting rod, fixed stop, spring, the second connecting rod, cutting table, guide plate and cut-off knife. The baseplate is equipped with stand, the upper inside of left arm of which is installed with power-driven pusher and middle inside of right arm with guide plate. There're guide holes on the guide plate. Sliding rails are provided at the inner top of the stand. The cutting device achieves the cutting device requirements for high precision. The device is simple and efficient but novelty, and convenient for staff in photo studios to operate.

Owner:山东港投投资发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com