Large-pipe-diameter manual jacking pipe for space-separated excavation and excavation construction method applying jacking pipe

A large pipe diameter and pipe jacking technology, which is applied in the construction of pipe jacking excavation and the field of artificial pipe jacking in separate warehouses, can solve the problems of manual pipe jacking difficulties, defective thixotropic mud sleeves, secondary disturbances, etc., and achieve reduction Effects of secondary excavation, reduced grouting volume, and less broken volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

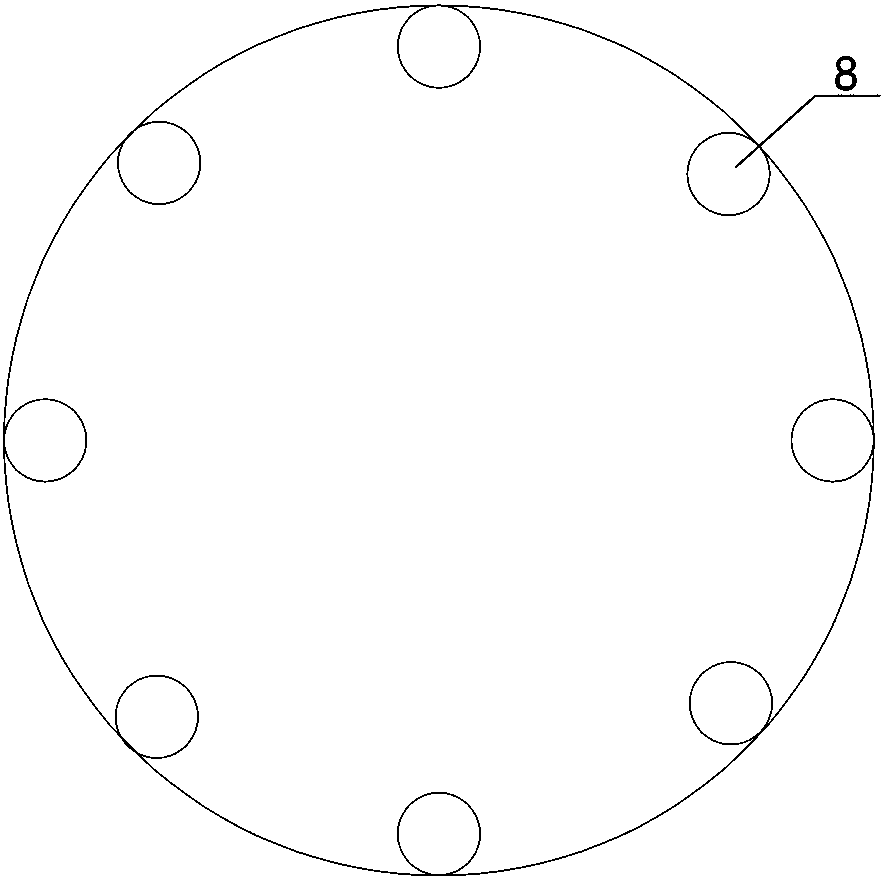

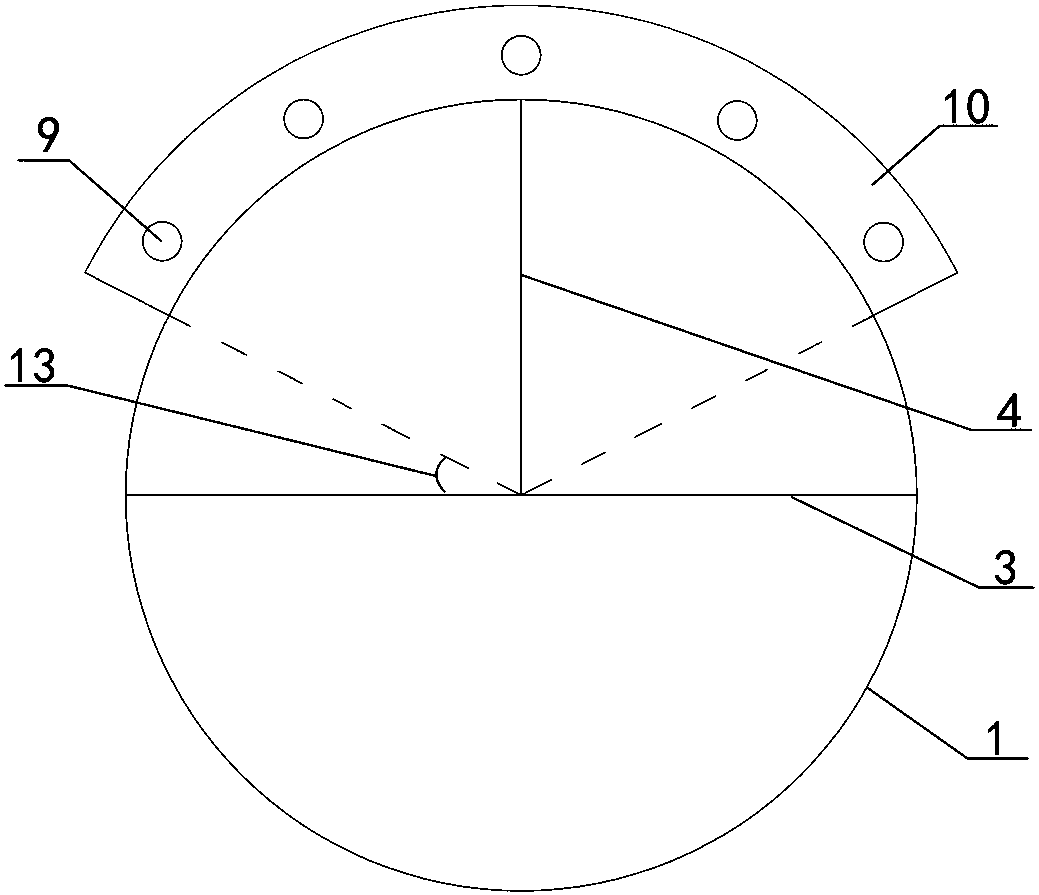

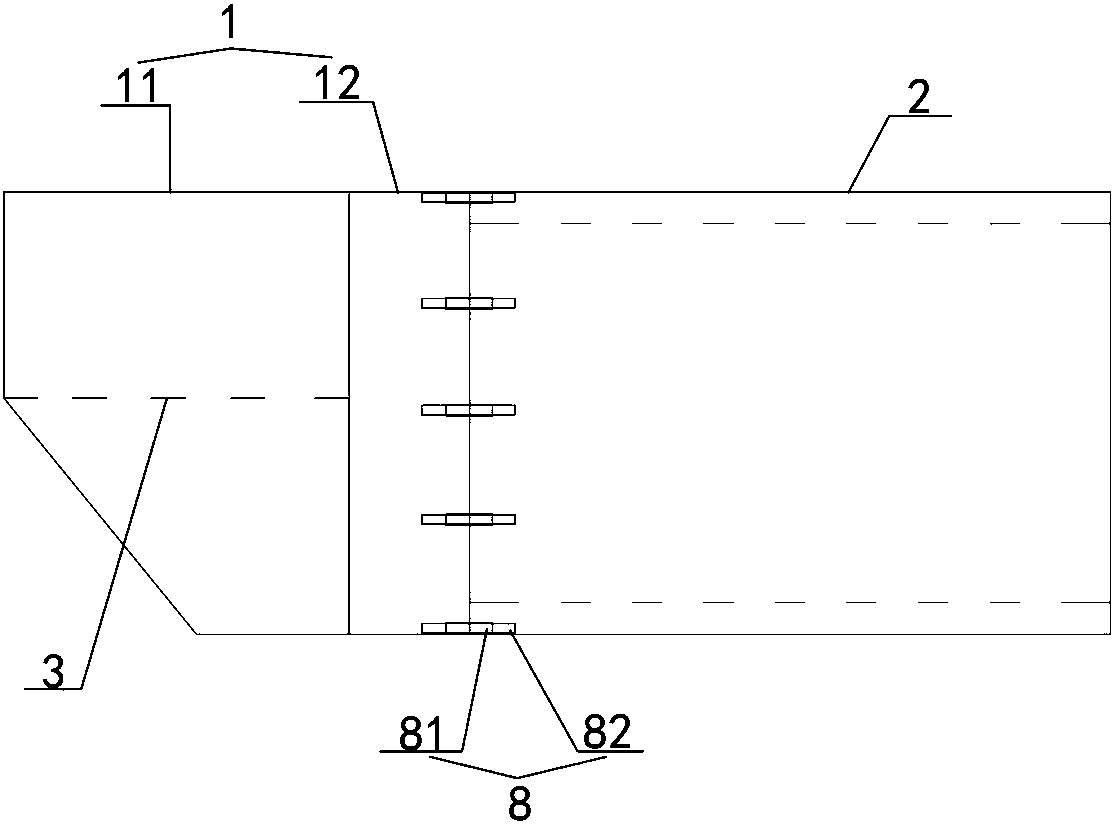

[0045] Examples see Figure 1-4 As shown, a large-diameter sub-bin excavation artificial pipe jacking includes a tool pipe 1 made of steel plates and a concrete pipe 2 connected with the tool pipe. The tool pipe includes a blade foot section 11 and a deflection correction section 12. The internal space of the blade foot section is separated by a partition, and the cross section of the partition is "丄" shape, including a horizontal partition 3 and a vertical partition 4, and the horizontal partition 3 is located at At the position of the horizontal diameter of the cross-section of the blade foot section 11, the end surfaces on both sides of the horizontal intermediate partition 3 are fixedly connected to the inner walls of the left and right sides of the blade foot section 11, and the vertical intermediate partition 4 stands on the side of the horizontal intermediate partition 3. At the position of the upper central axis, the bottom surface of the vertical middle partition 4 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com