Patents

Literature

38results about How to "Reduce the amount of broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

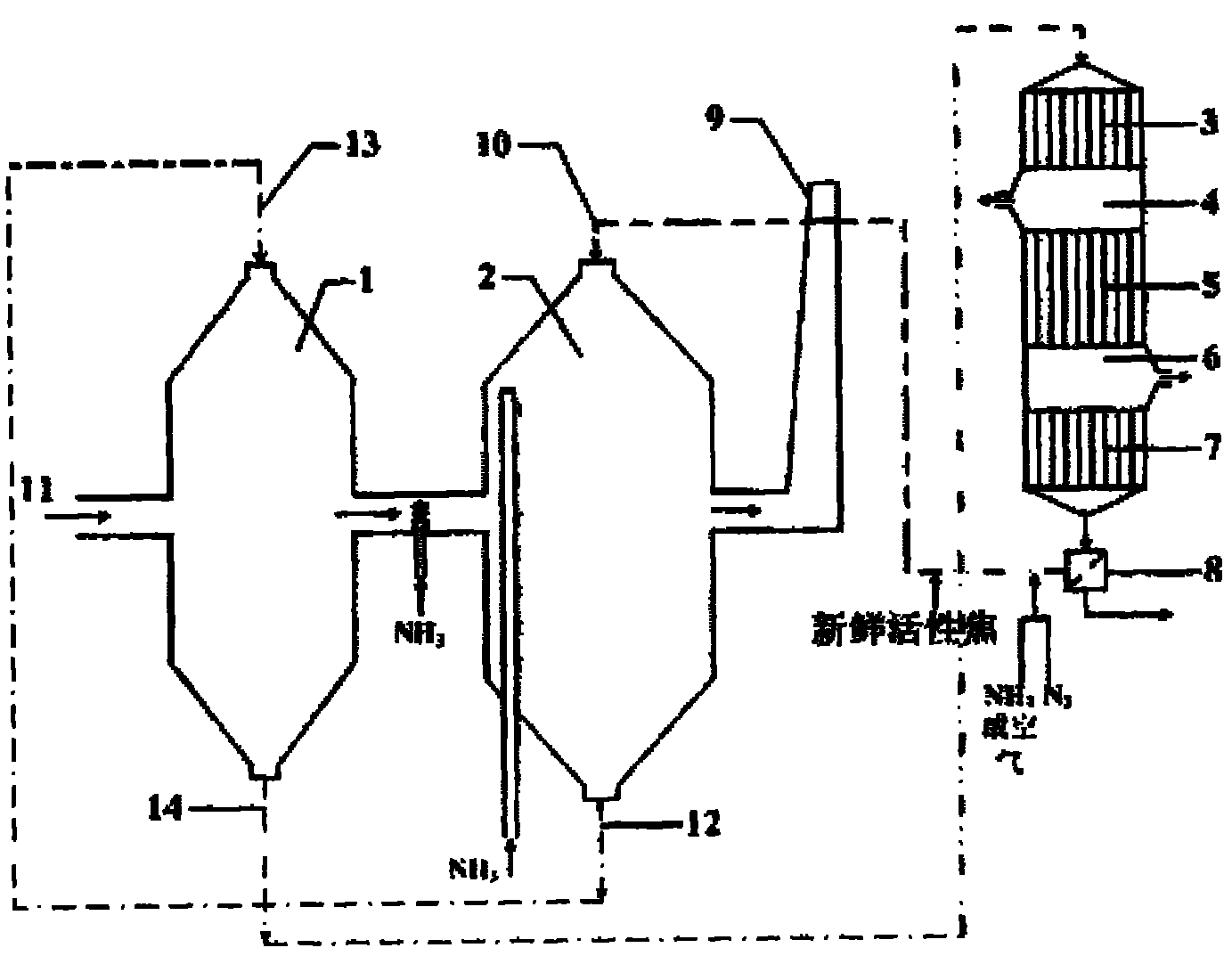

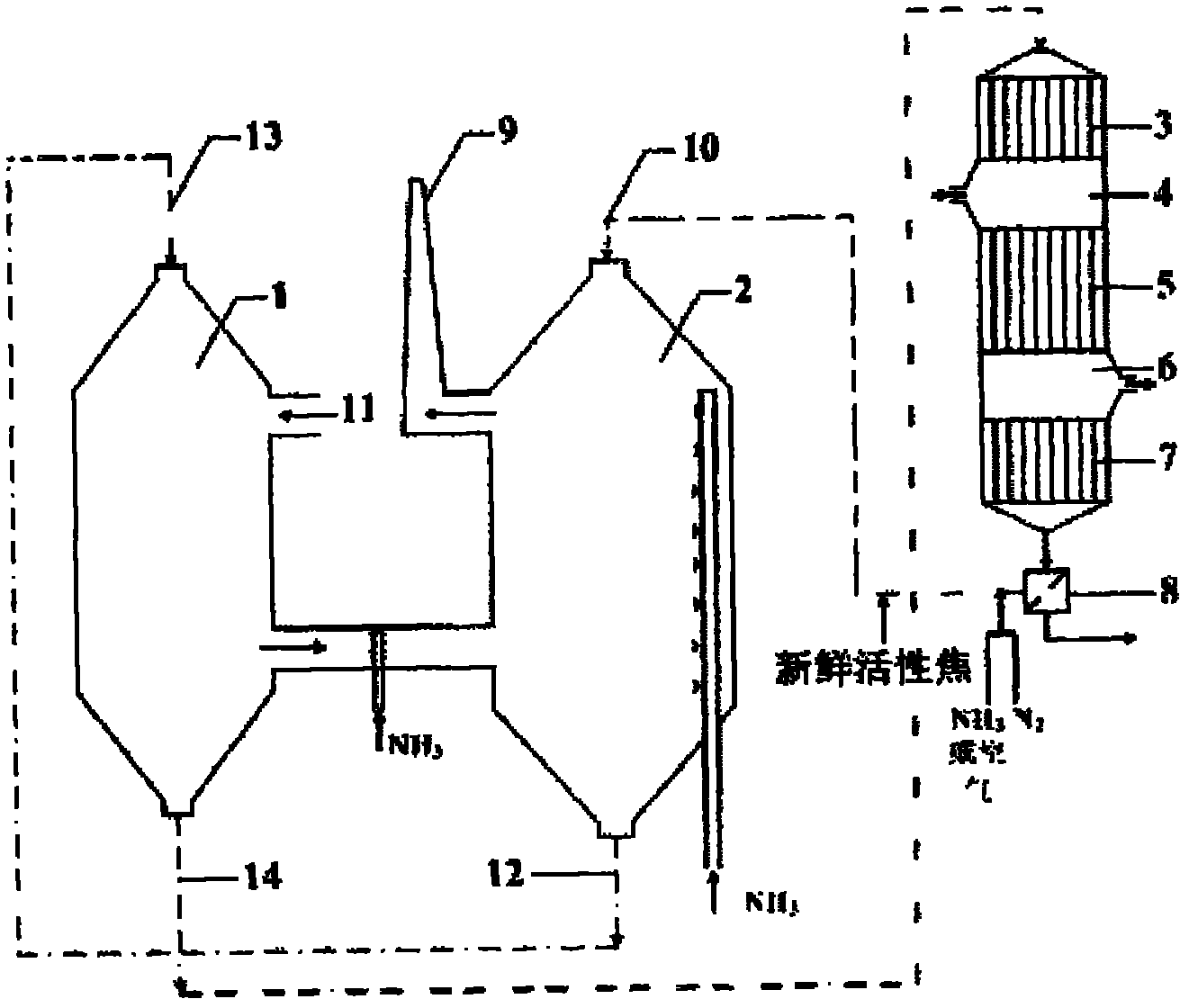

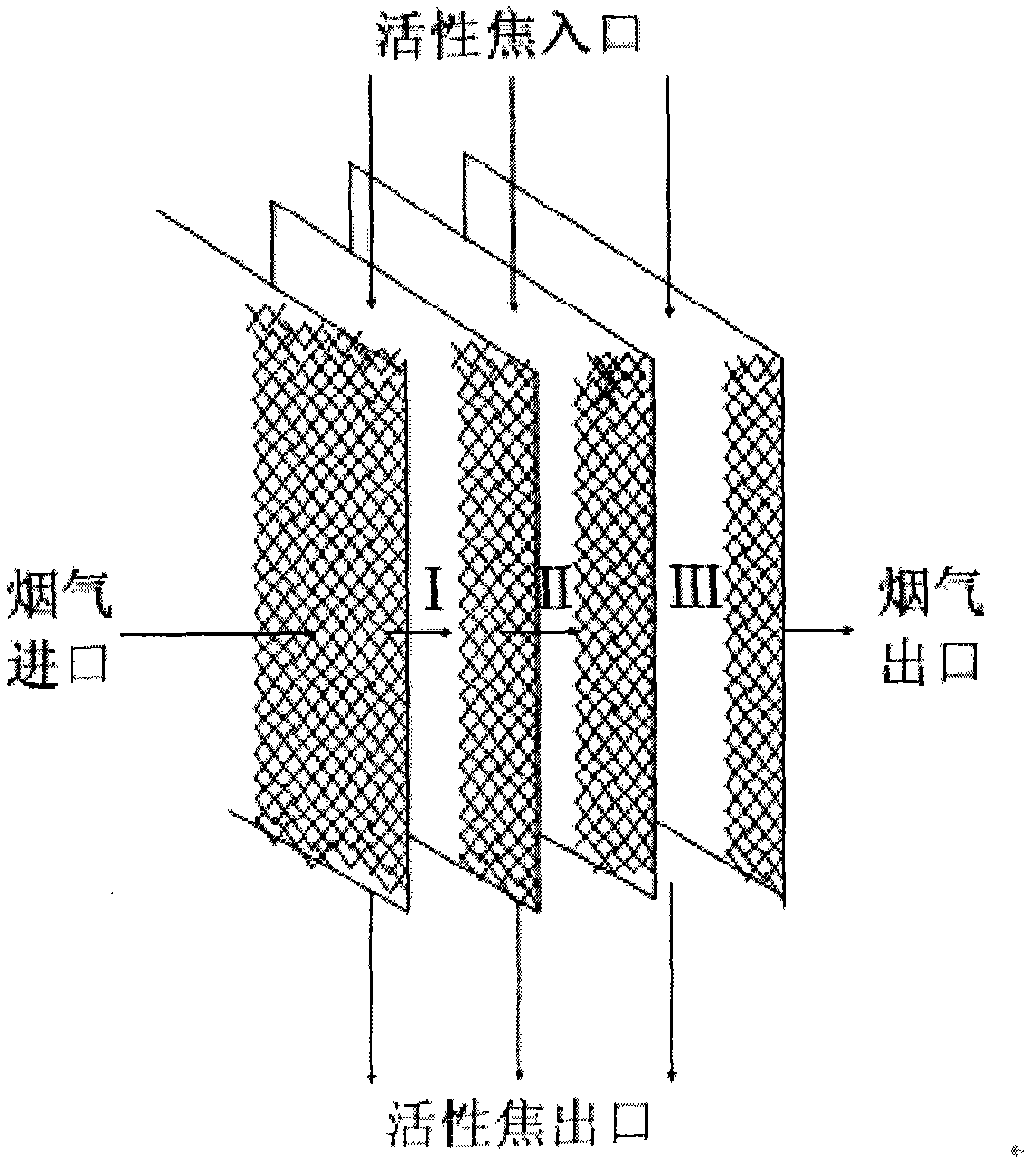

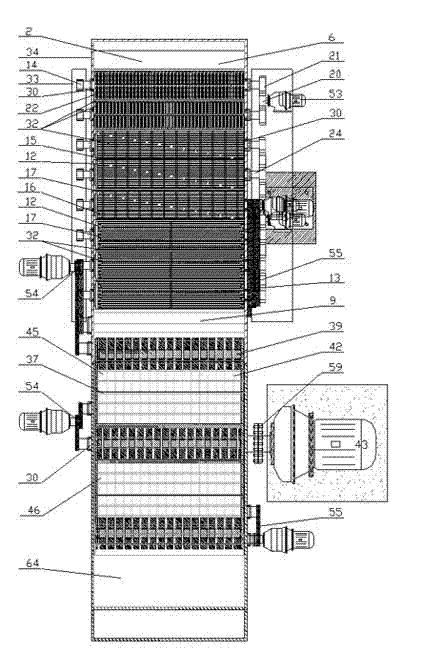

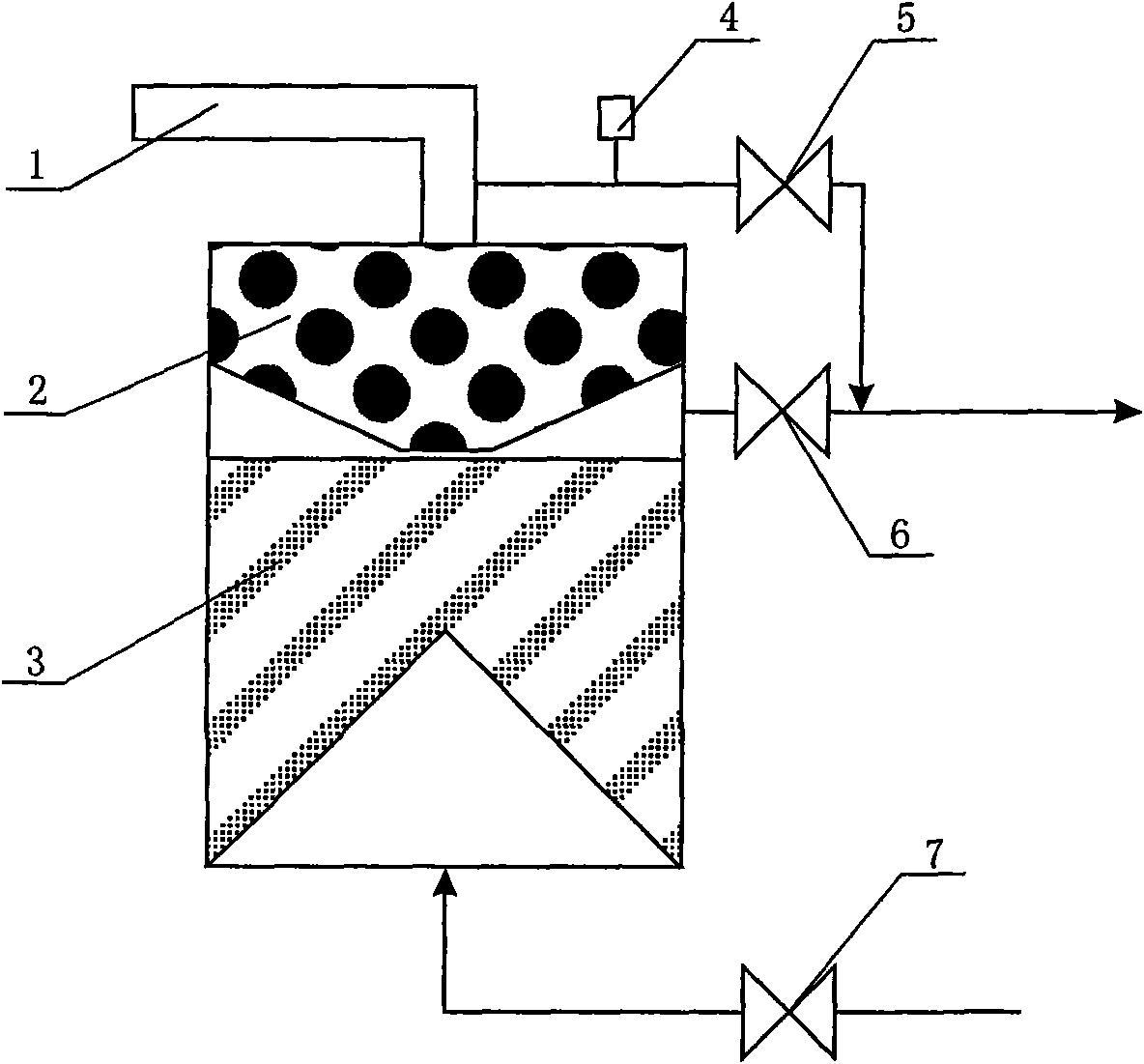

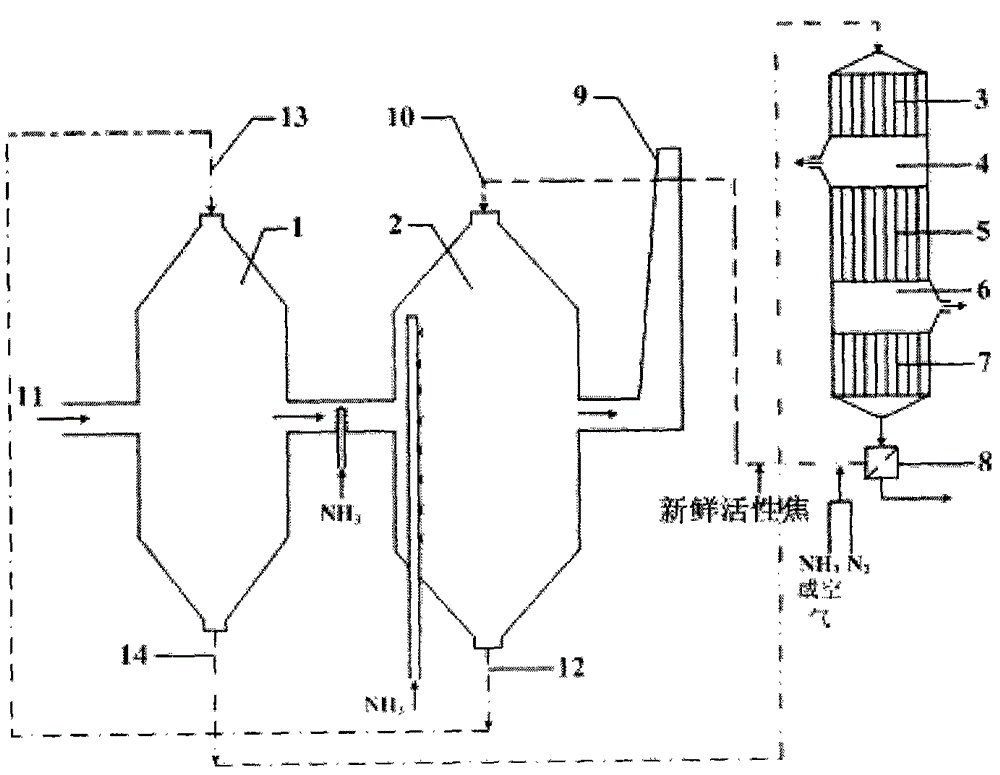

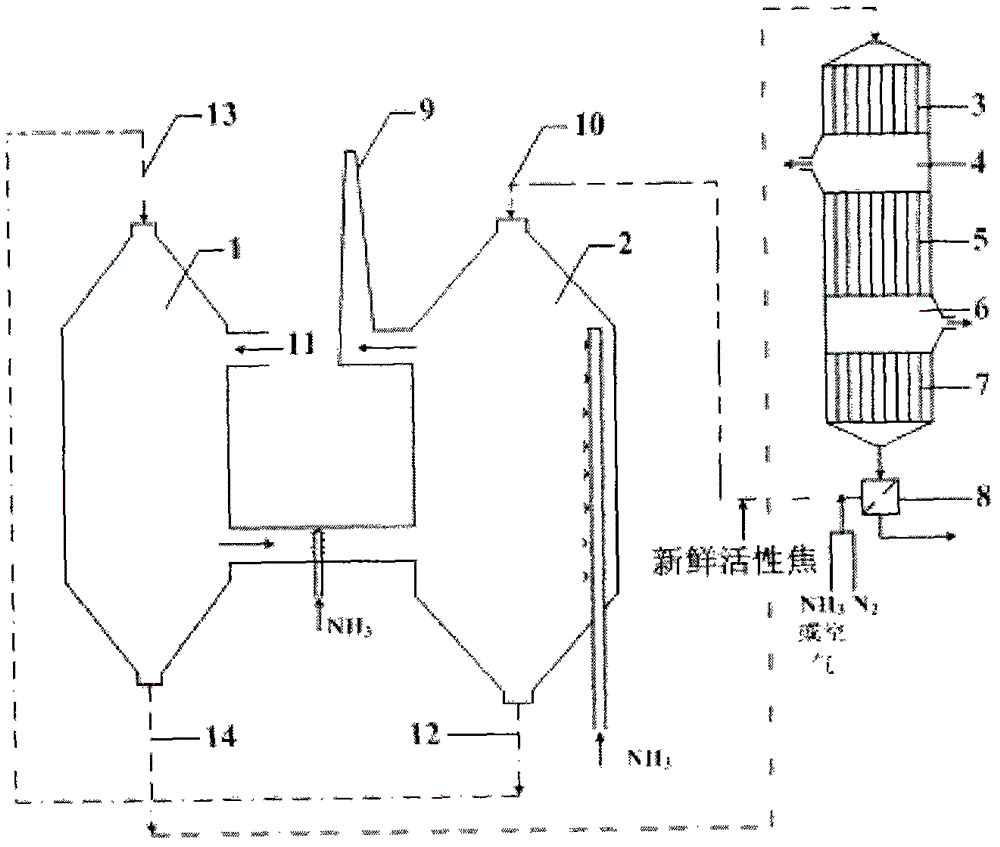

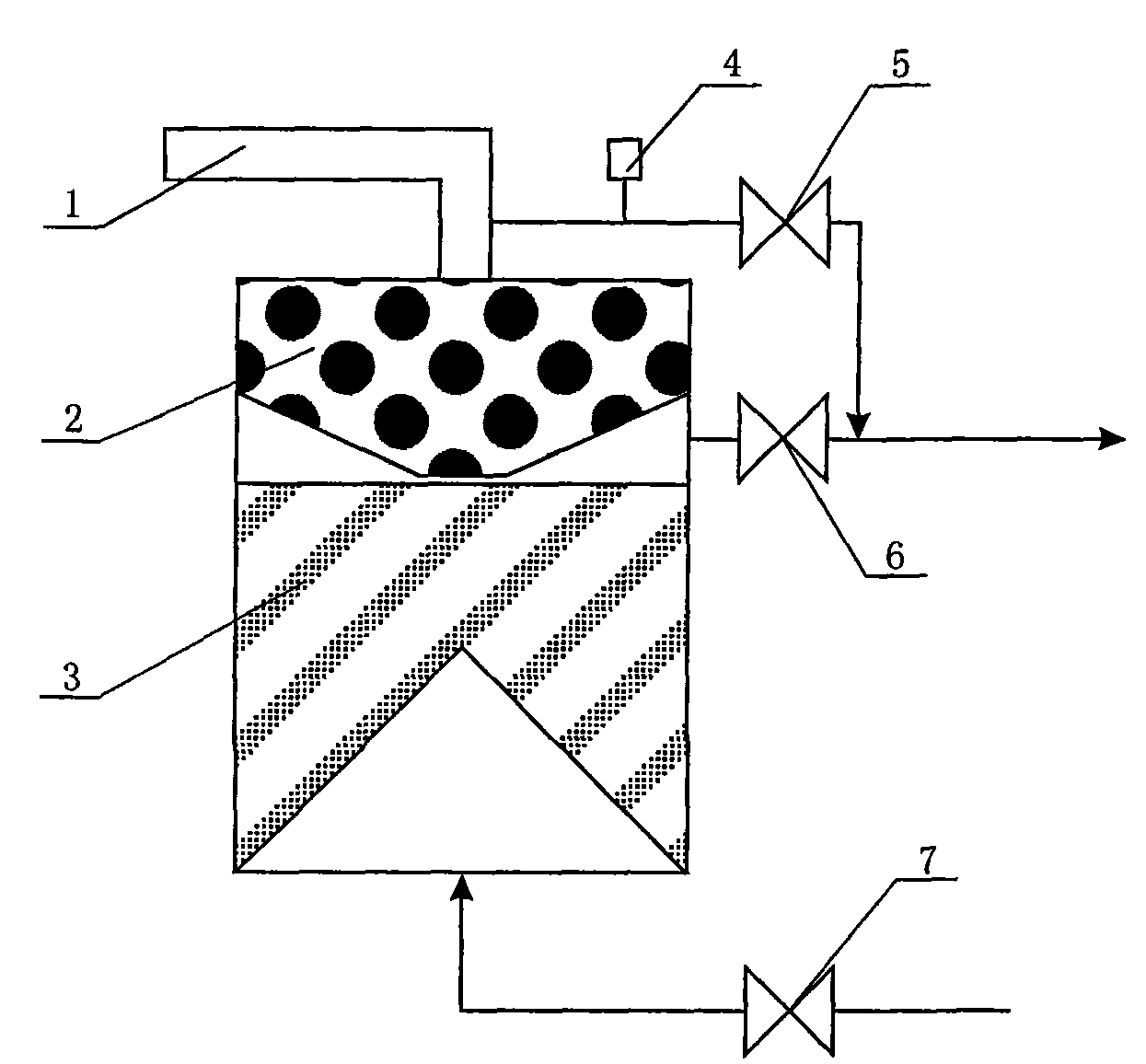

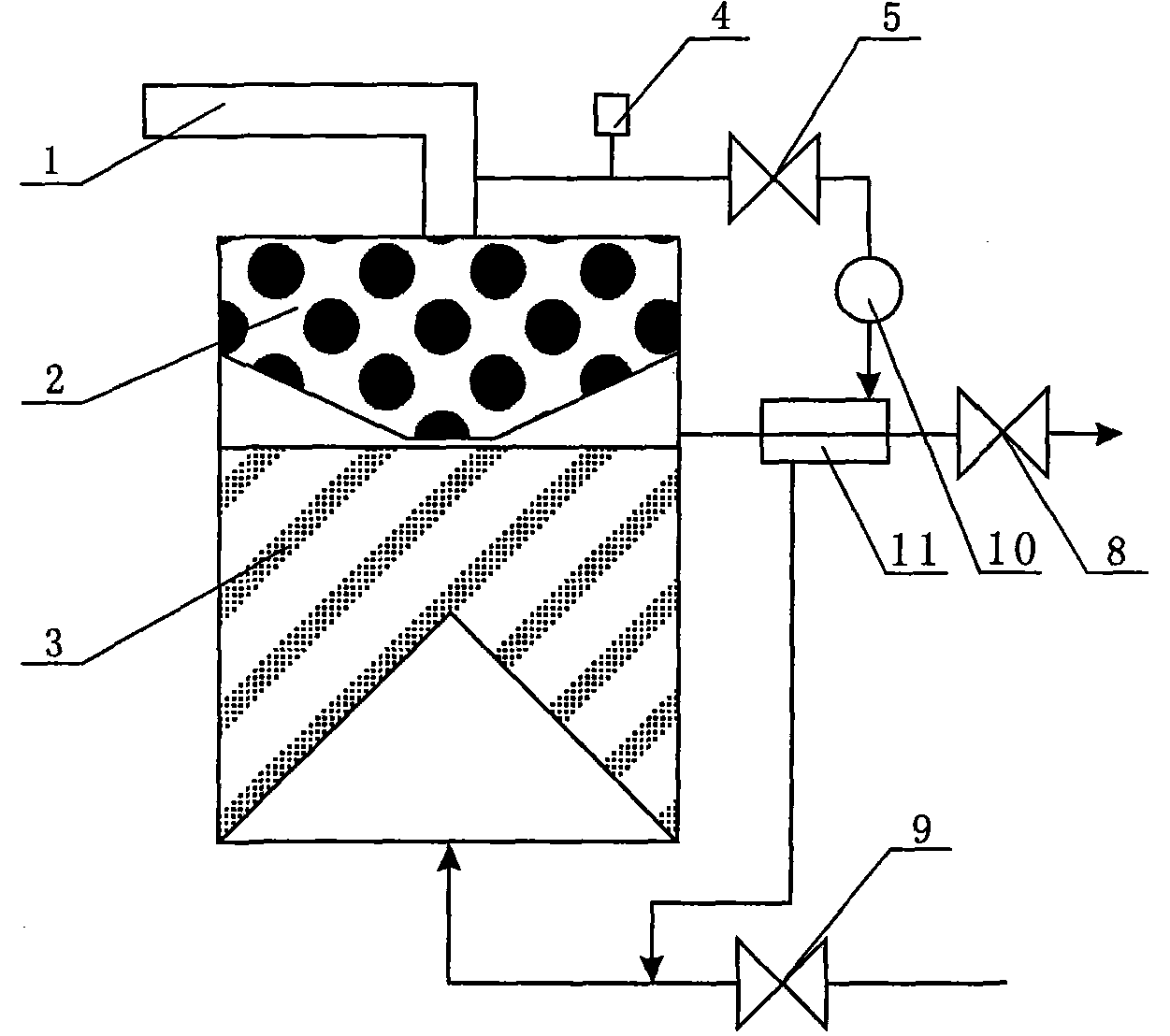

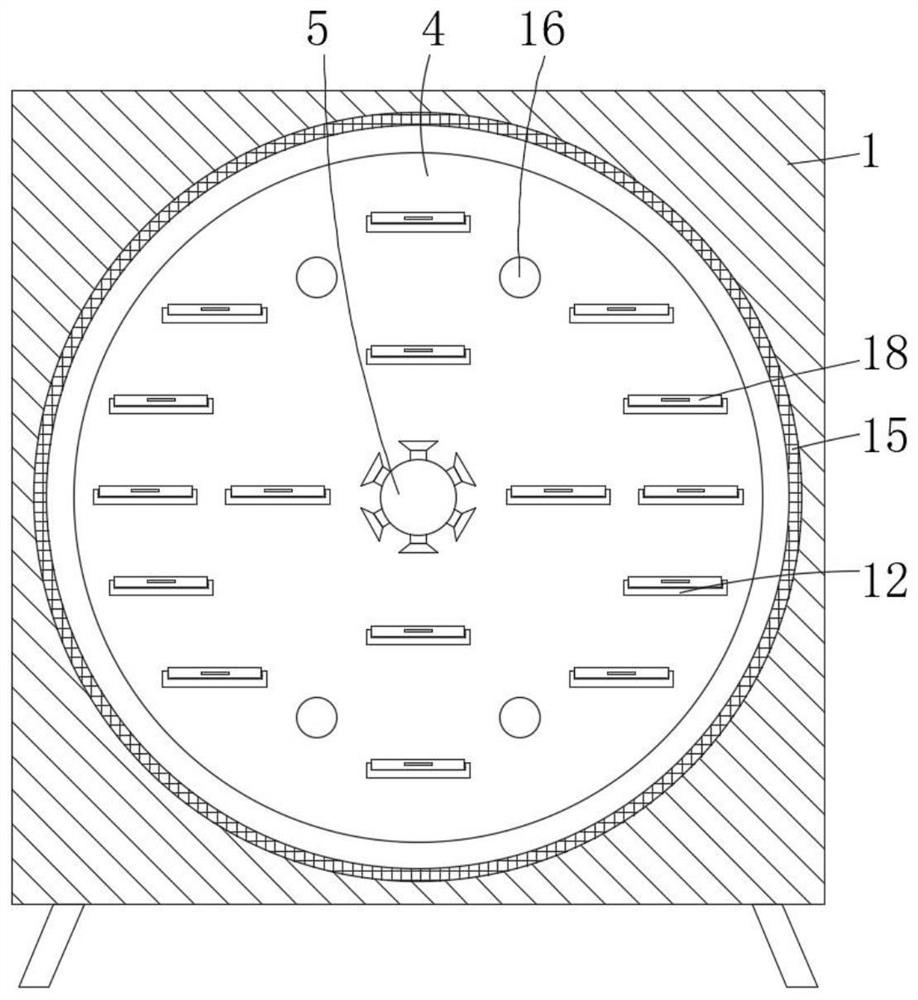

Flue gas-based combined desulfuration and denitration method and special device for method

ActiveCN102019135AImprove distributionImprove denitrification efficiencyDispersed particle separationFlue gasProcess engineering

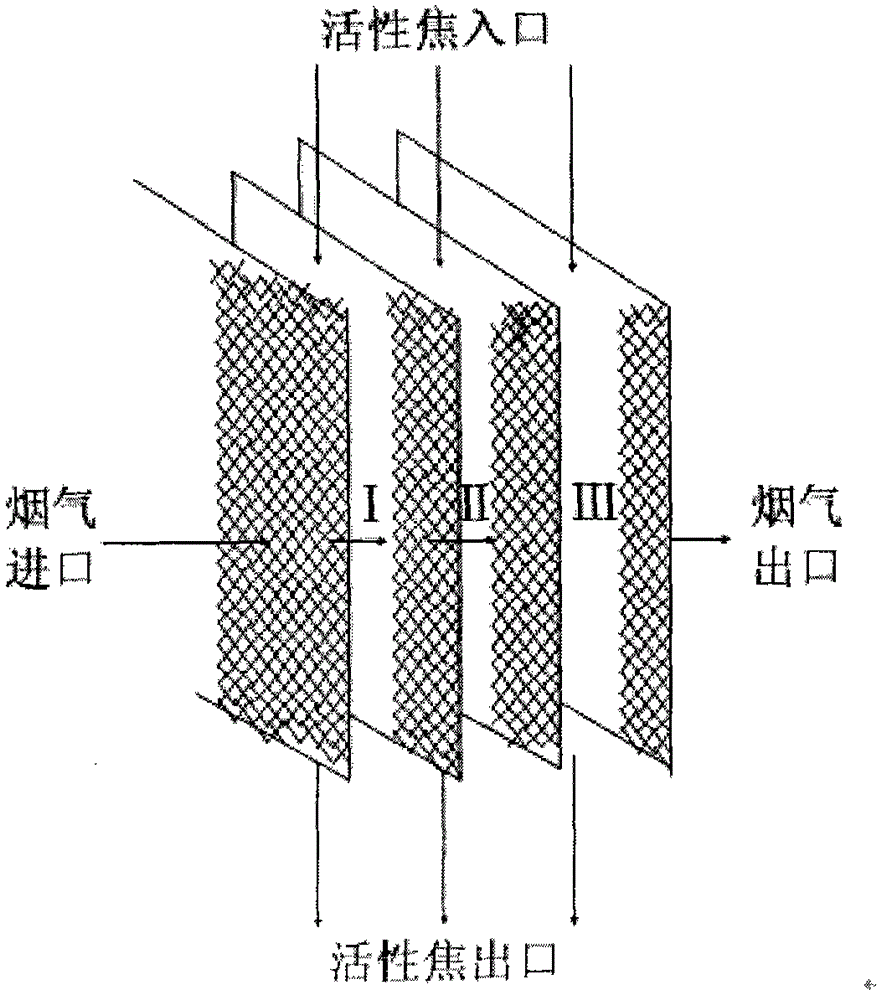

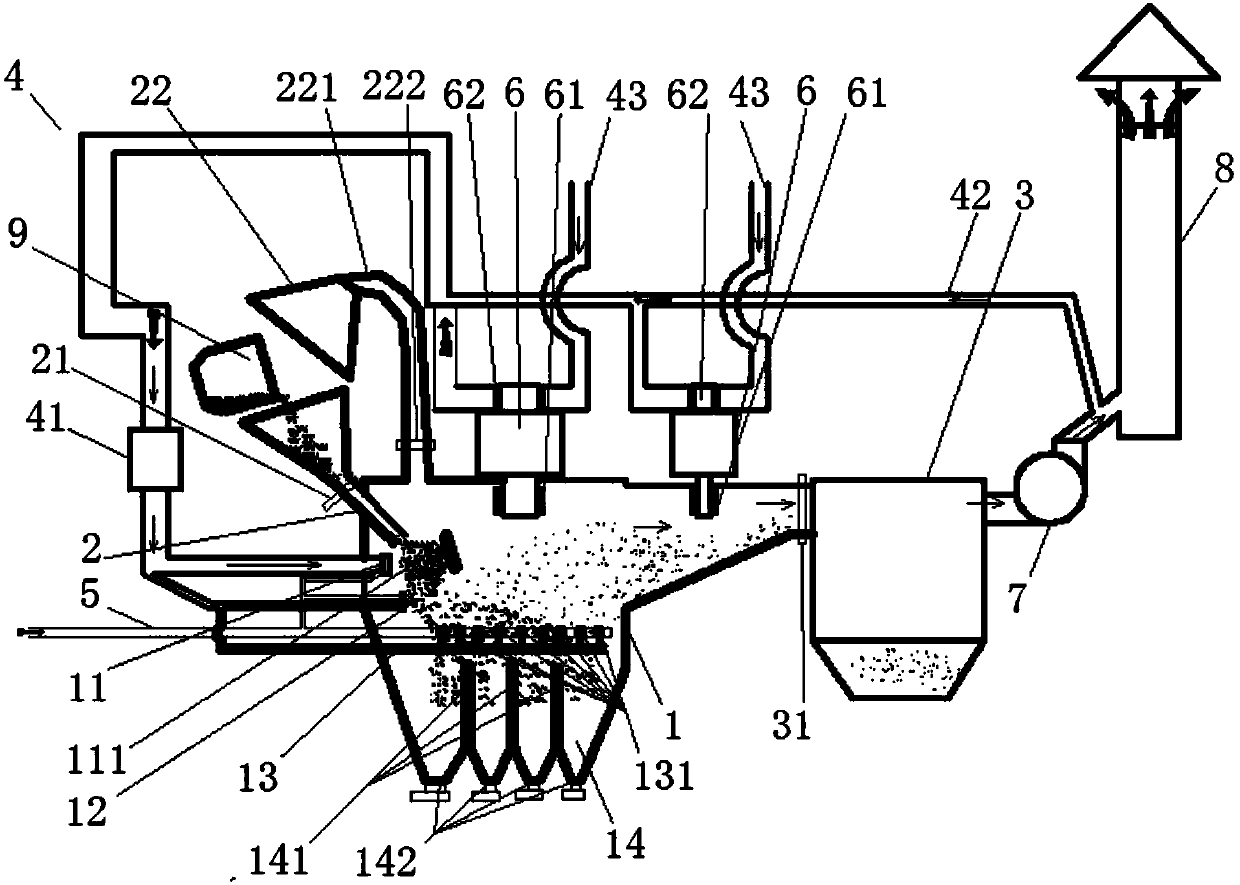

The invention discloses a flue gas-based desulduratoin and denitration method and a special device for the flue gas-based desulduratoin and denitration method. The special device comprises a denitration reactor body and a desulphurization reactor body, wherein the side wall of the desulphurization reactor body is provided with a flue inlet; the desulphurization reactor body and the denitration reactor body are communicated in parallel; the volume of the denitration reactor body is 1-2 times that of the desulphurization reactor body; the communicating position of the desulphurization reactor body and the denitration reactor body is provided with a device for spraying NH3; the top of the denitration reactor body is provided with a denitration reactor inlet for active coke; the bottom of thedenitration reactor is provided with a denitration reactor outlet for the active coke; the top of the desulphurization reactor is provided with a desulphurization reactor inlet for the active coke; the bottom of the desulphurization reactor is provided with a desulphurization reactor outlet for the active coke; and the denitration reactor outlet for the active coke is communicated with a desulphurization reactor inlet for the active coke through a pipeline, and the desulphurization reactor outlet for the active coke is communicated with a regeneration reactor. The invention also provides a method for flue gas desulfurization and denitration by using the device.

Owner:CCTEG CHINA COAL RES INST

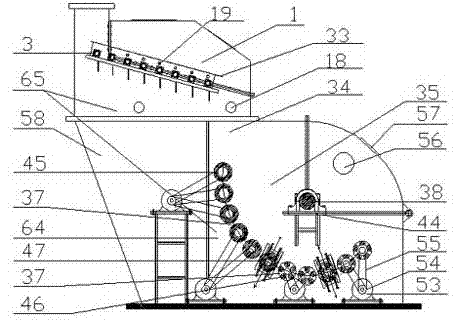

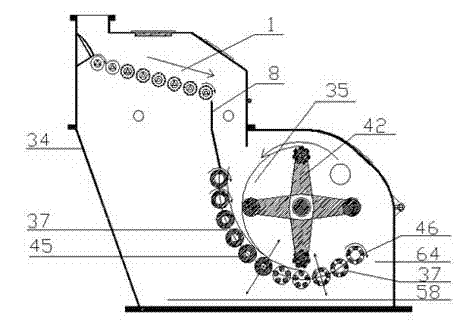

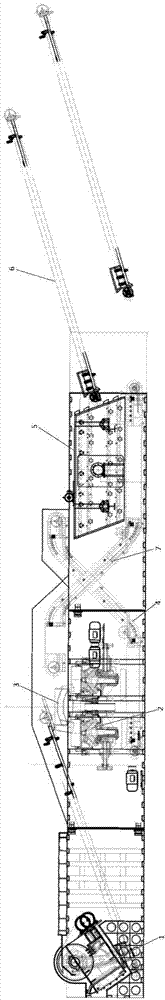

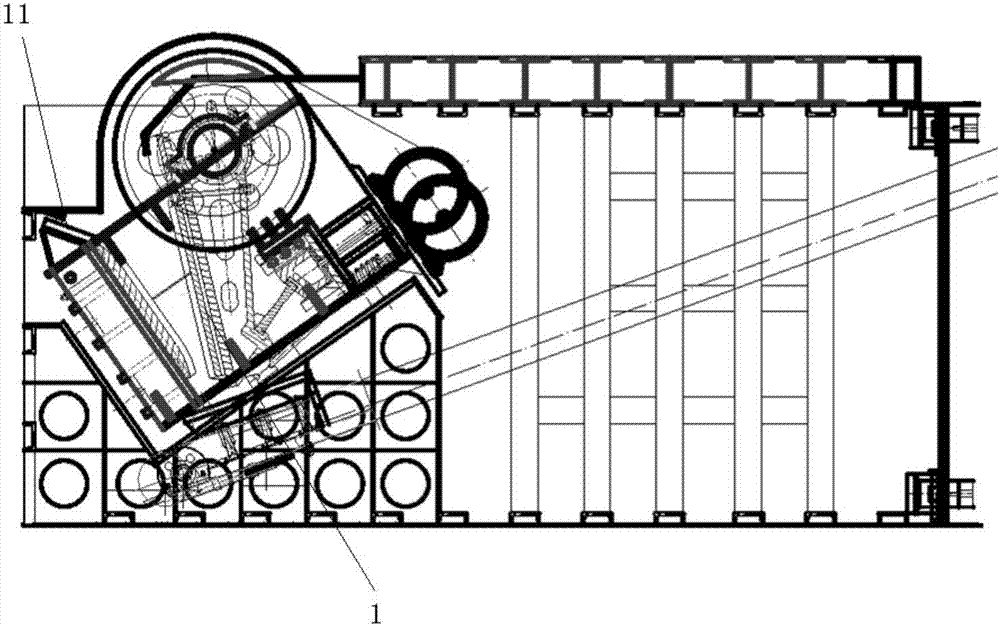

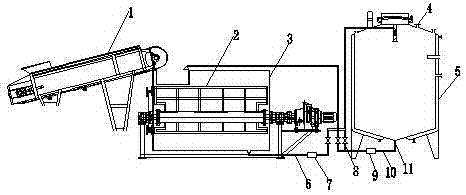

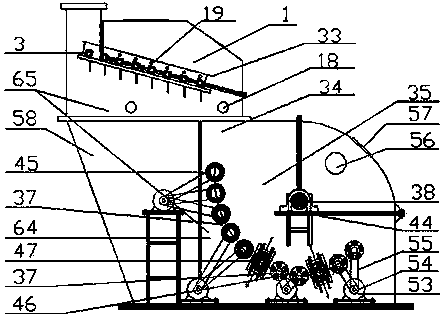

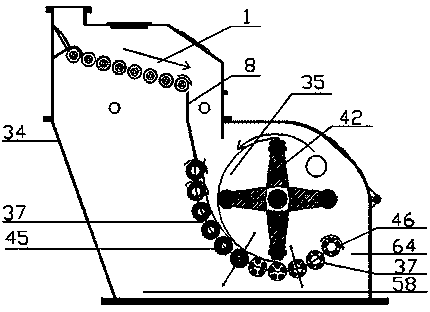

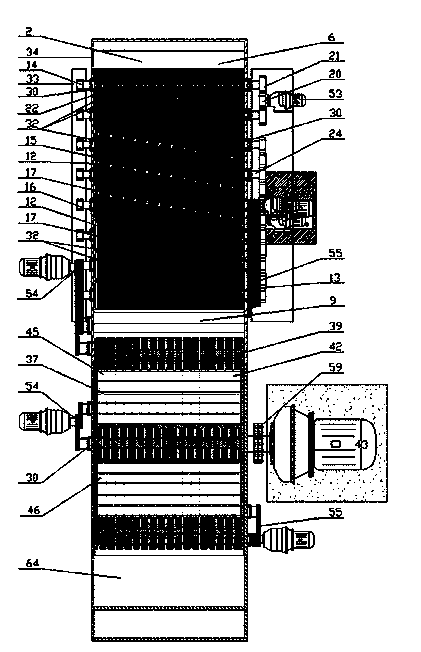

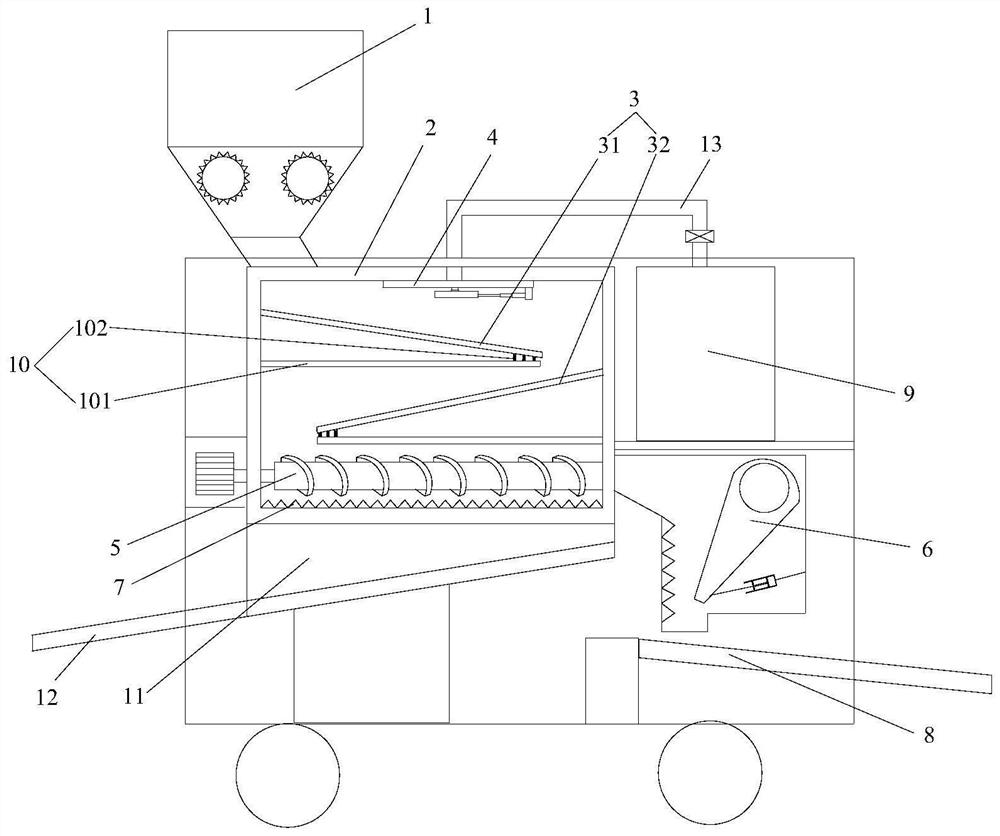

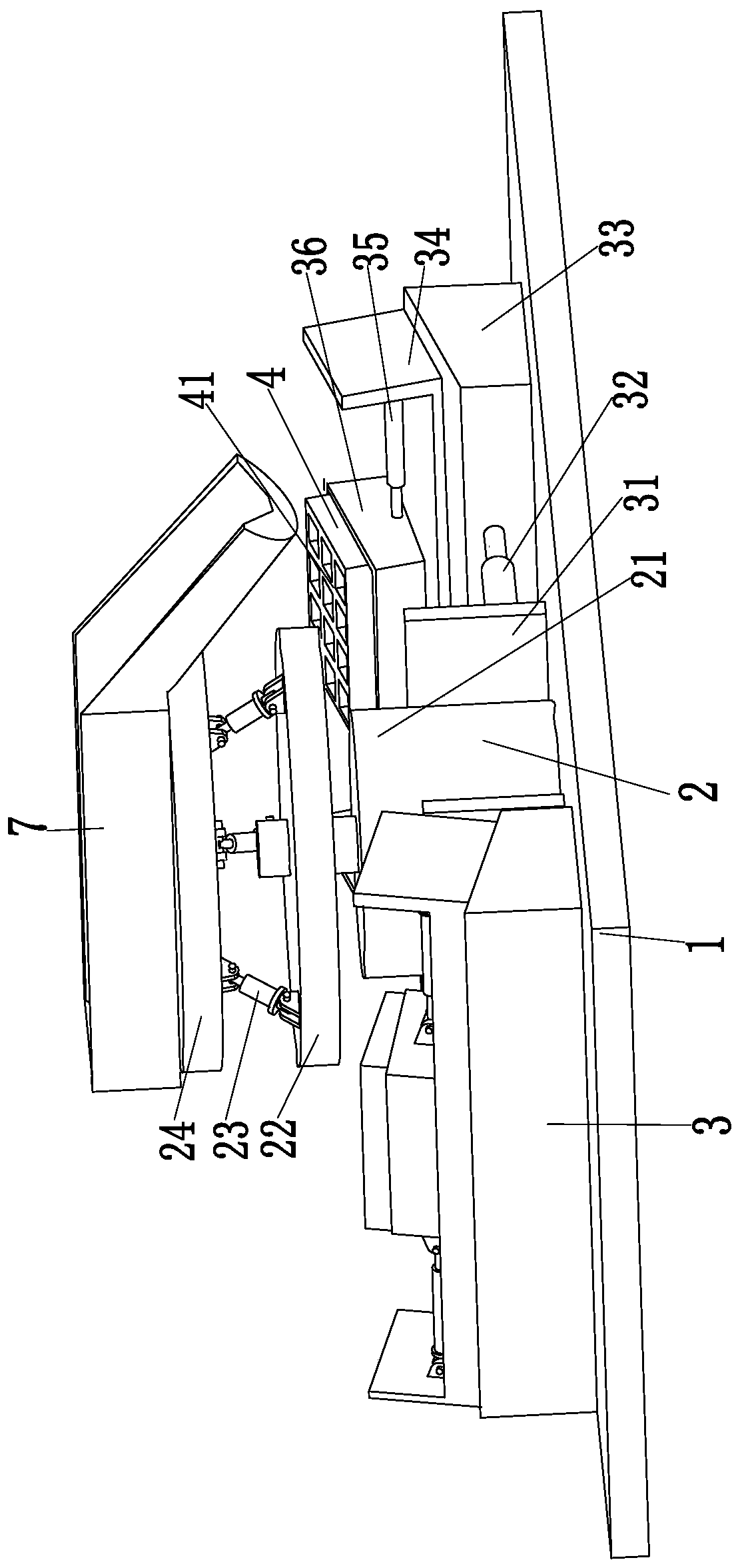

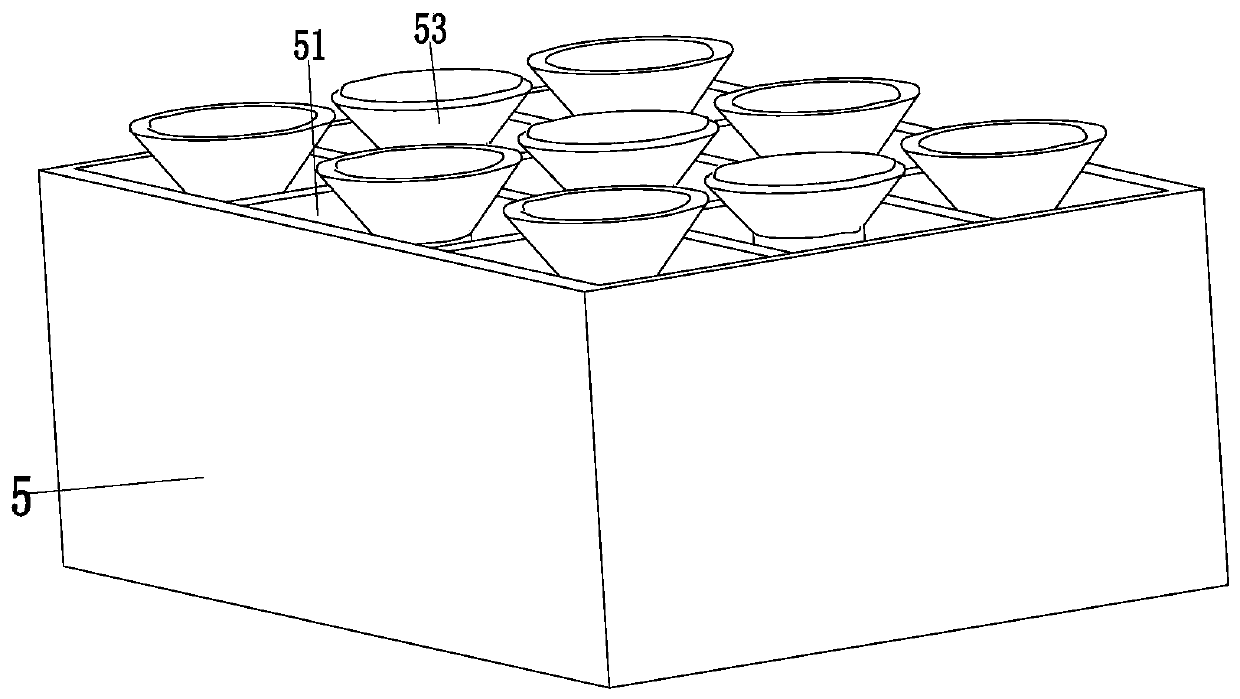

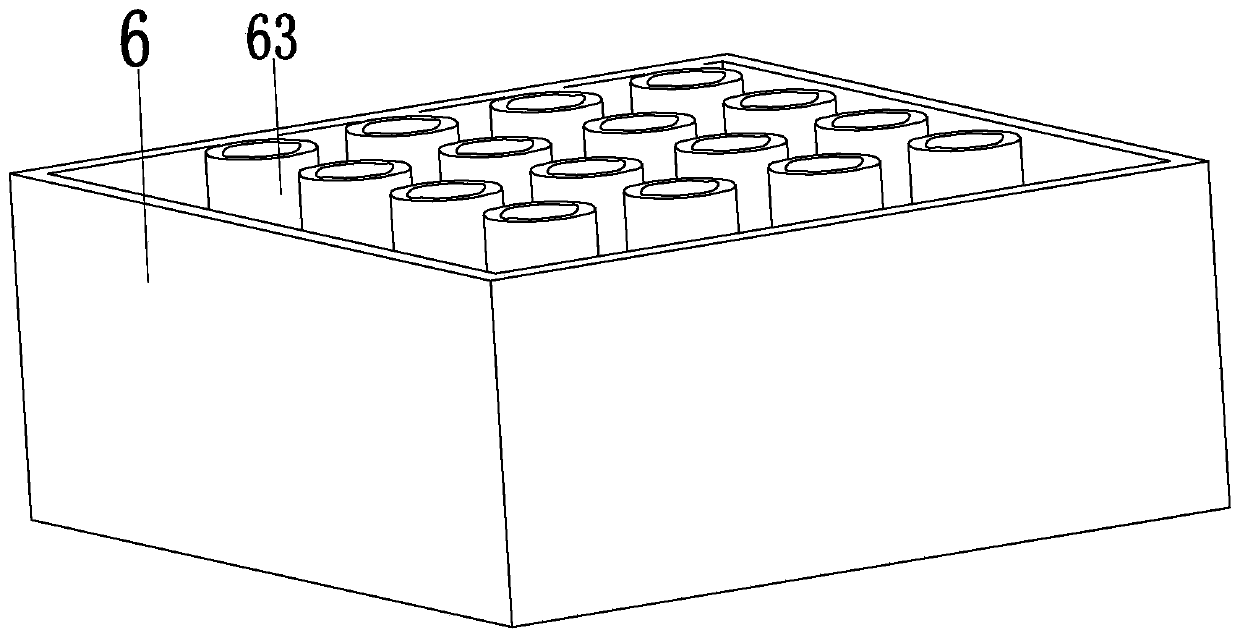

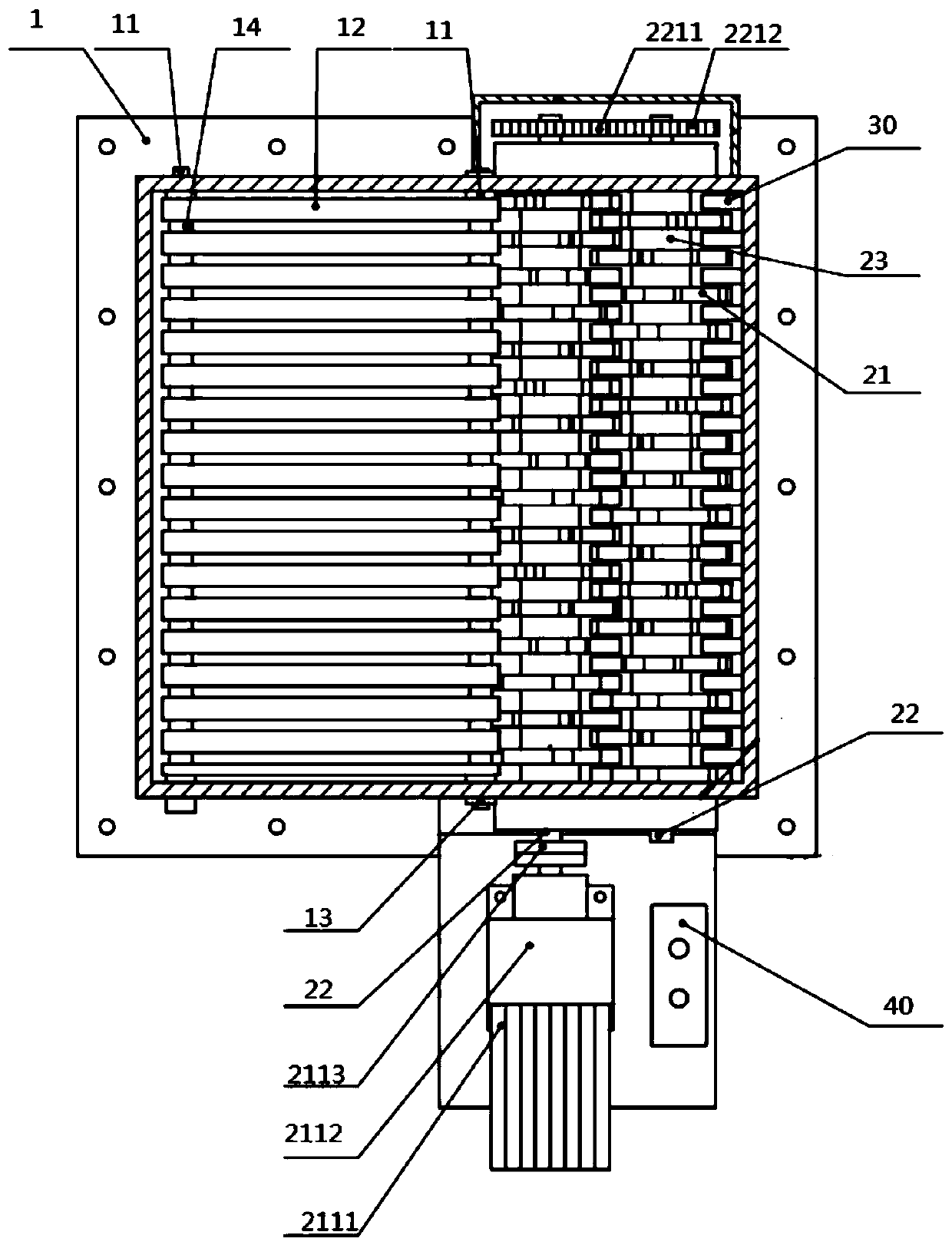

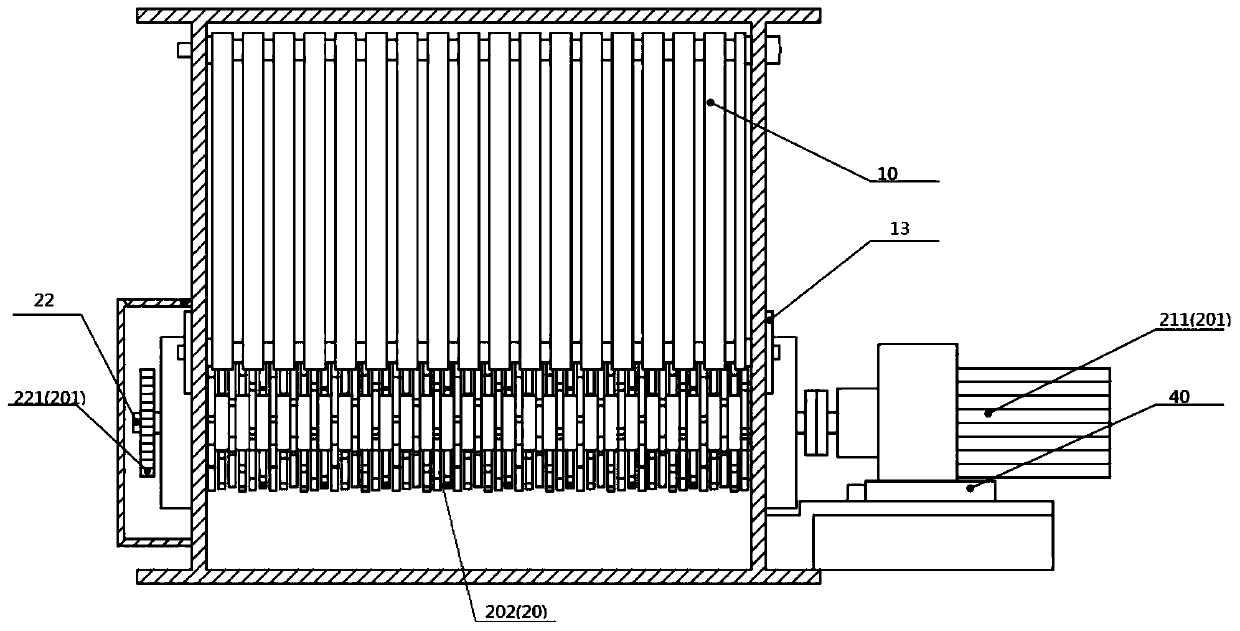

Sieving and crushing integrated machine

ActiveCN102896019AStrong impact resistanceReduces impact and wearSievingScreeningSystem structureProcess engineering

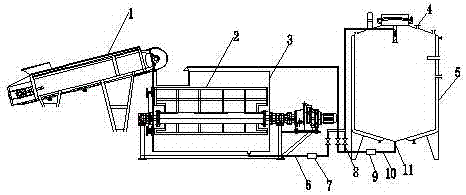

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Low-water-absorption foamed concrete and preparation method thereof

InactiveCN104150951AShort initial setting timeReduced open porosityCeramicwareFoam concreteAluminate

The invention relates to a low-water-absorption foamed concrete and a preparation method thereof. The low-water-absorption foamed concrete is prepared from ordinary Portland cement, sulphoaluminate cement, raw material soil, water, a thickening agent, a water-reducing agent, a foam-stabilizing agent, an accelerator and a foaming agent. Through addition of the sulphoaluminate cement and the accelerator which can accelerate coagulation of the ordinary Portland cement, break of bubbles during an initial setting time is reduced and an opening porosity and water absorption of the foamed concrete are reduced. Through addition of the thickening agent, thickness of the foamed concrete can be adjusted and upward-floating of the bubbles is reduced so that the bubble is distributed uniformly. The foamed concrete is low in water absorption, is uniform in volume weight, is stable in compressive strength and has a better thermal-insulation and temperature-preserving performance, a better mechanical performance and a better freeze-thaw-destroy resistant performance.

Owner:WUHAN UNIV OF TECH

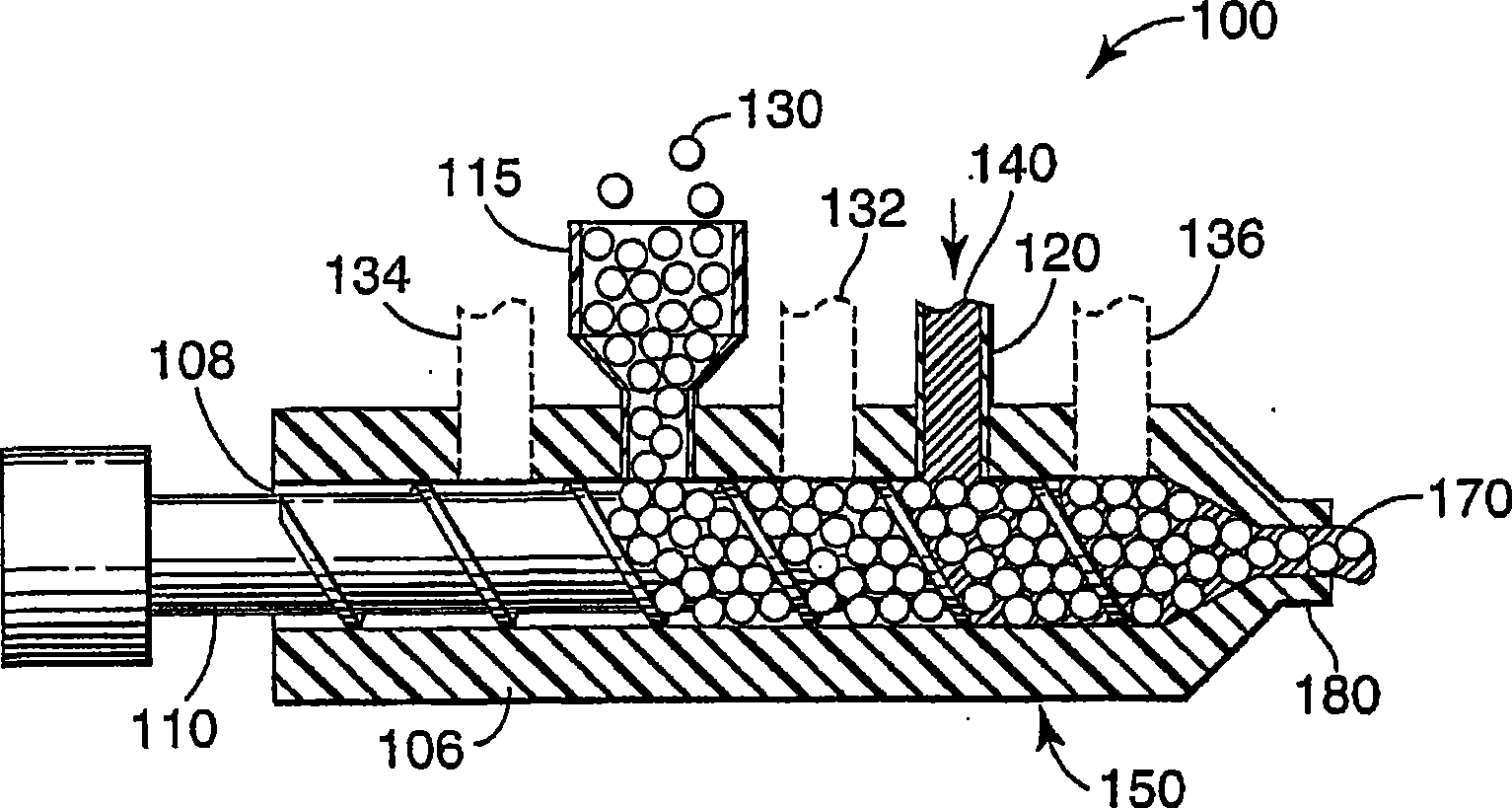

Method of making composite material.

The invention discloses a method of making composite material wherein a molten polymeric material is added to frangible solid particulates within a screw extruder.

Owner:3M INNOVATIVE PROPERTIES CO

Hot braising method for phosphorus removed slag and carbon removed slag

ActiveCN103397120AGood for turning overEasy to crushRecycling and recovery technologiesSlagEconomic benefits

The invention provides a hot braising method for phosphorus removed slag and carbon removed slag. The method comprises the following steps of: pouring hot phosphorus removed slag into a slag braising pit to parch the slag braising pit; pouring the phosphorus removed slag or the carbon removed slag into multiple parched slag braising pits respectively, turning over, dewatering and breaking the slag in each slag braising pit, then pouring another slag respectively, and repeating the operations of turning over, dewatering and breaking the slag till each slag braising pit is full of the slag; and covering the slag braising pits full of the slag with slag braising covers, and braising the slag in a three-section dewatering and braising mode. The hot braising method for the phosphorus removed slag and the carbon removed slag is simple and feasible, can reduce the potential safety hazard of blasting of the slag braising pits and effectively improve the slag braising efficiency and slag braising quality, and has remarkable economic benefits.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

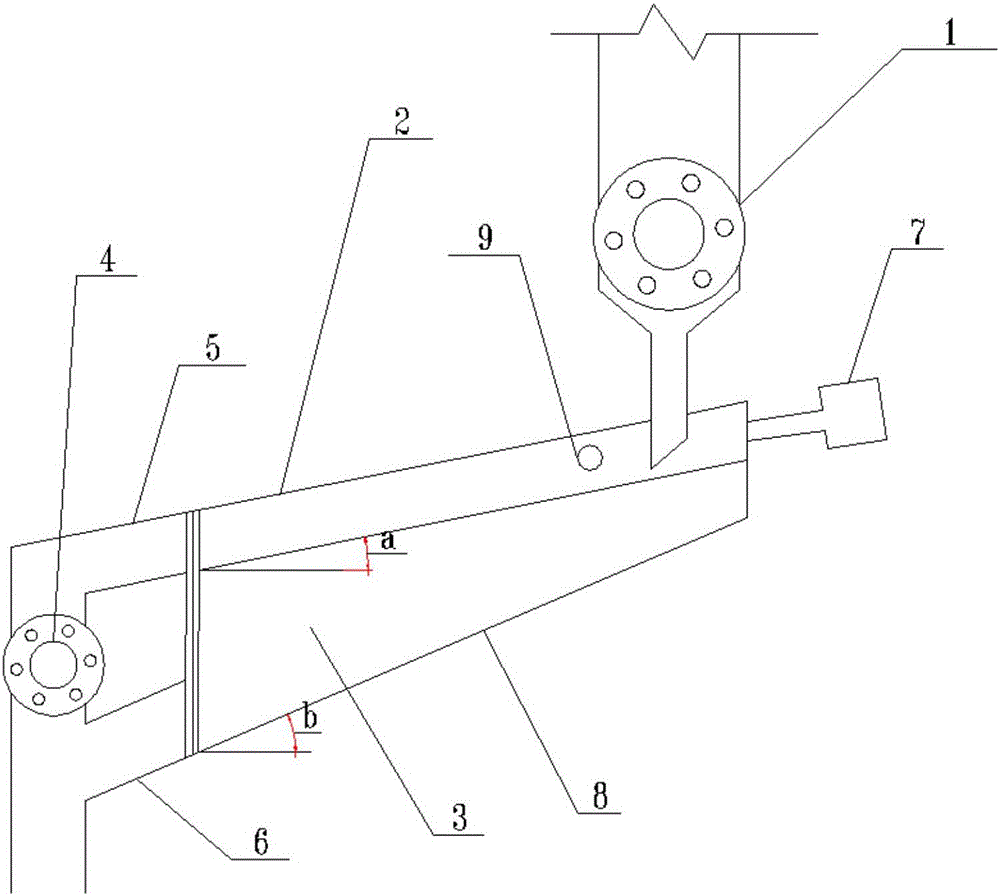

Process for preparing feed gas for synthetic ammonia by two-stage furnace coal gasification taking cold-pressed briquette as raw material

InactiveCN101659395AEasy to manufactureReduce manufacturing costHydrogen productionGranularityProcess engineering

The invention discloses a process for preparing feed gas for synthetic ammonia by two-stage furnace coal gasification taking cold-pressed briquette as raw material. The briquettes after cold extrusion are directly put in a furnace, and then the extruding, the feeding in the furnace and the drying process of the briquettes are continuously finished by adopting a method that the cold-pressed briquettes in the furnace are dried by using the heat of partial air-blowing smoke. Not only the manufacturing process of the briquettes is simplified, but also the manufacturing cost of the briquettes is reduced, and simultaneously, both the strength and the hardness of the cold-pressed briquettes during the process of feeding in the furnace are low, and the difference in dropping height is small, therefore, the process has the advantages of uniform granularity after feeding in the furnace, less crushing quantity, less dust carried from the air blowing smoke, less loss amount of the briquettes, low coal consumption, energy conservation and environmental protection.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD +1

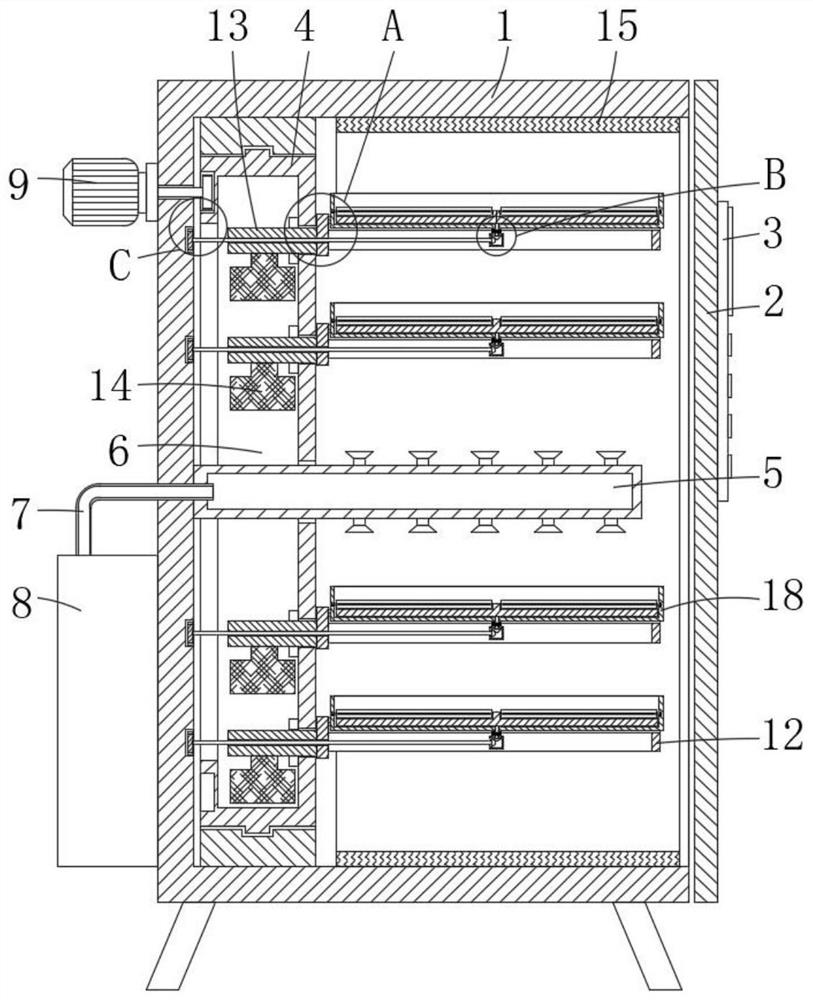

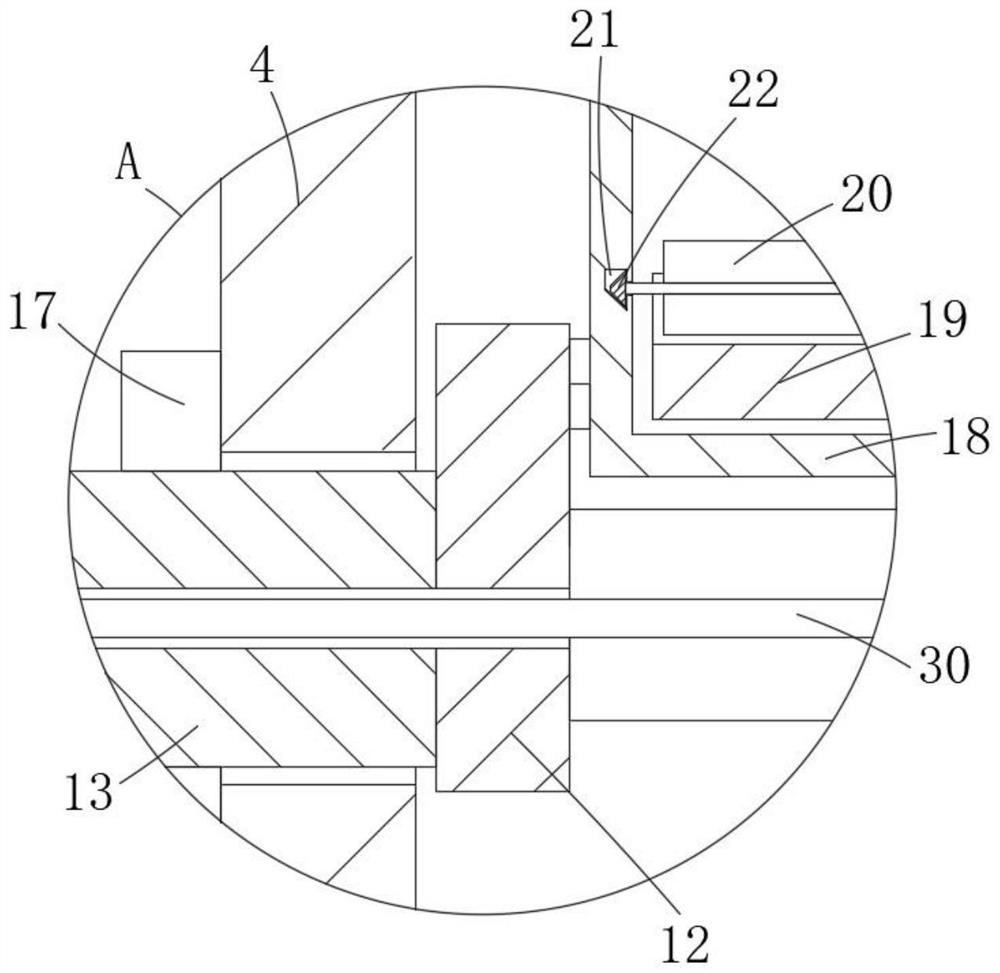

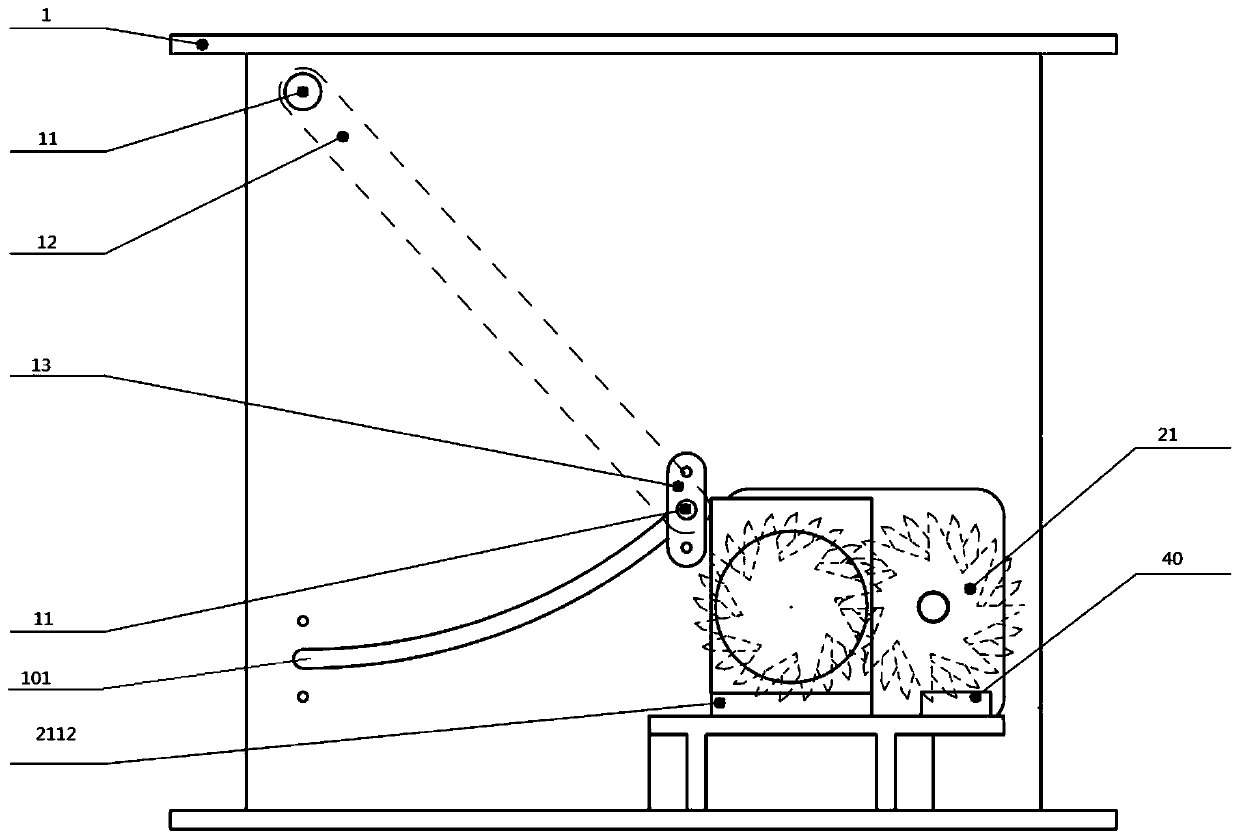

Multistage screening mechanism

PendingCN107282257AReduce the burden onReduce workloadDirt cleaningGrain treatmentsEngineeringMachining

The invention relates to the technical field of material crushing, in particular to a multistage screening mechanism. The multistage screening mechanism comprises a first-stage primary crushing unit and a fine crushing unit arranged on the downstream part of the primary crushing unit, wherein the primary crushing unit and the fine crushing unit each comprise a screening structure which is used for screening out materials with a preset grain diameter so as to avoid over crushing of the materials in the units. According to the multistage screening mechanism, the materials with the preset grain diameter can be screened out of the current crushing units timely in the crushing process and can be prevented from being crushed continuously, and therefore over crushing is avoided, and the machining workload is reduced.

Owner:NENGCHENG GRP

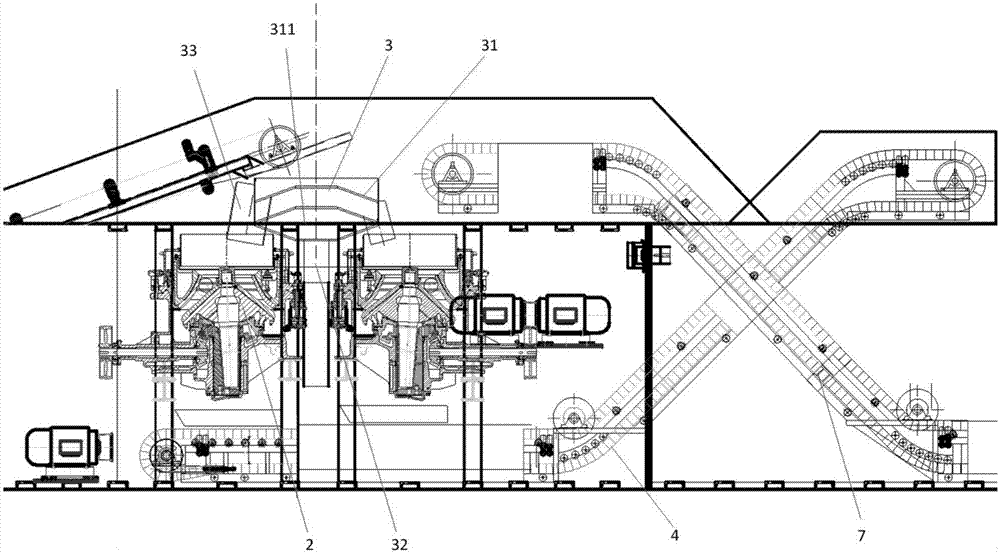

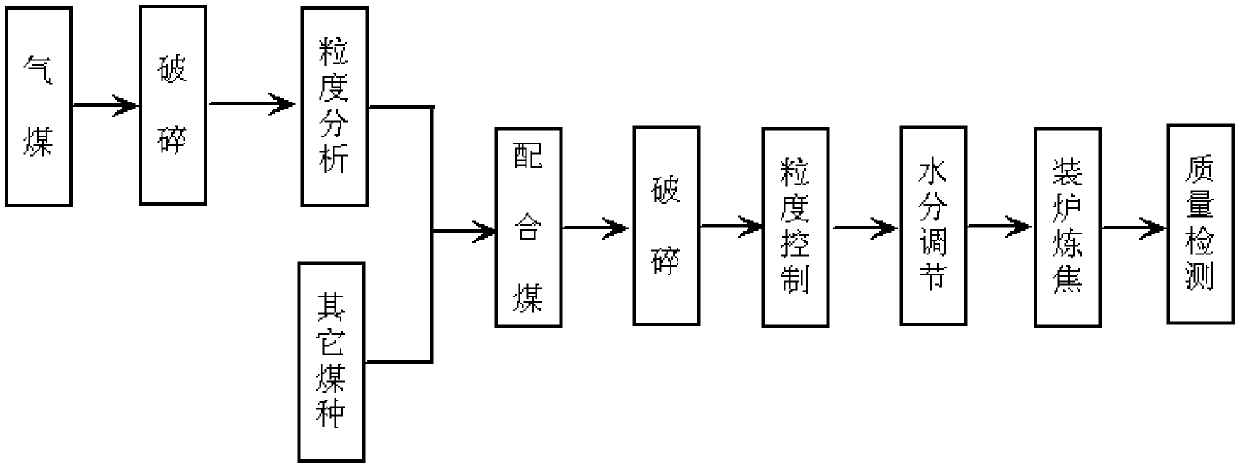

Method for improving cold strength of coke

InactiveCN110607184AIncrease cold strengthImprove quality requirementsCoke ovensMass ratioGranularity

The invention discloses a method for improving the cold strength of coke, which comprises the following steps: 1, gas coal crushing: gas coal with the granularity of less than 6 mm from a production plant is fed into a crusher for crushing, performing screening analysis on the granularity of the gas coal after crushing according to the requirement of the proportion of the granularity of less than3 mm in the crushed gas coal to be 48-53%; 2, blending of blended coal: the crushed gas coal is blended with 1 / 3 coking coal, fat coal and lean coal according to the requirements of coal blending, themass ratio of the gas coal in the whole blended coal is 25.5-27%, the ash content Ad of the blended coal is 8-10%, and the volatile matter VMd of the blended coal is 26-28%; 3, crushing and mixing ofthe blended coal: the blended coal is added into a crusher for repeated crushing, the groove spacing of the crusher is 3-4 mm, and the mass ratio of the blended coal with the particle size smaller than 3 mm after crushing is 84-86%; and 4, moisture adjustment and preparation of high-strength coke.

Owner:BAOSHAN IRON & STEEL CO LTD

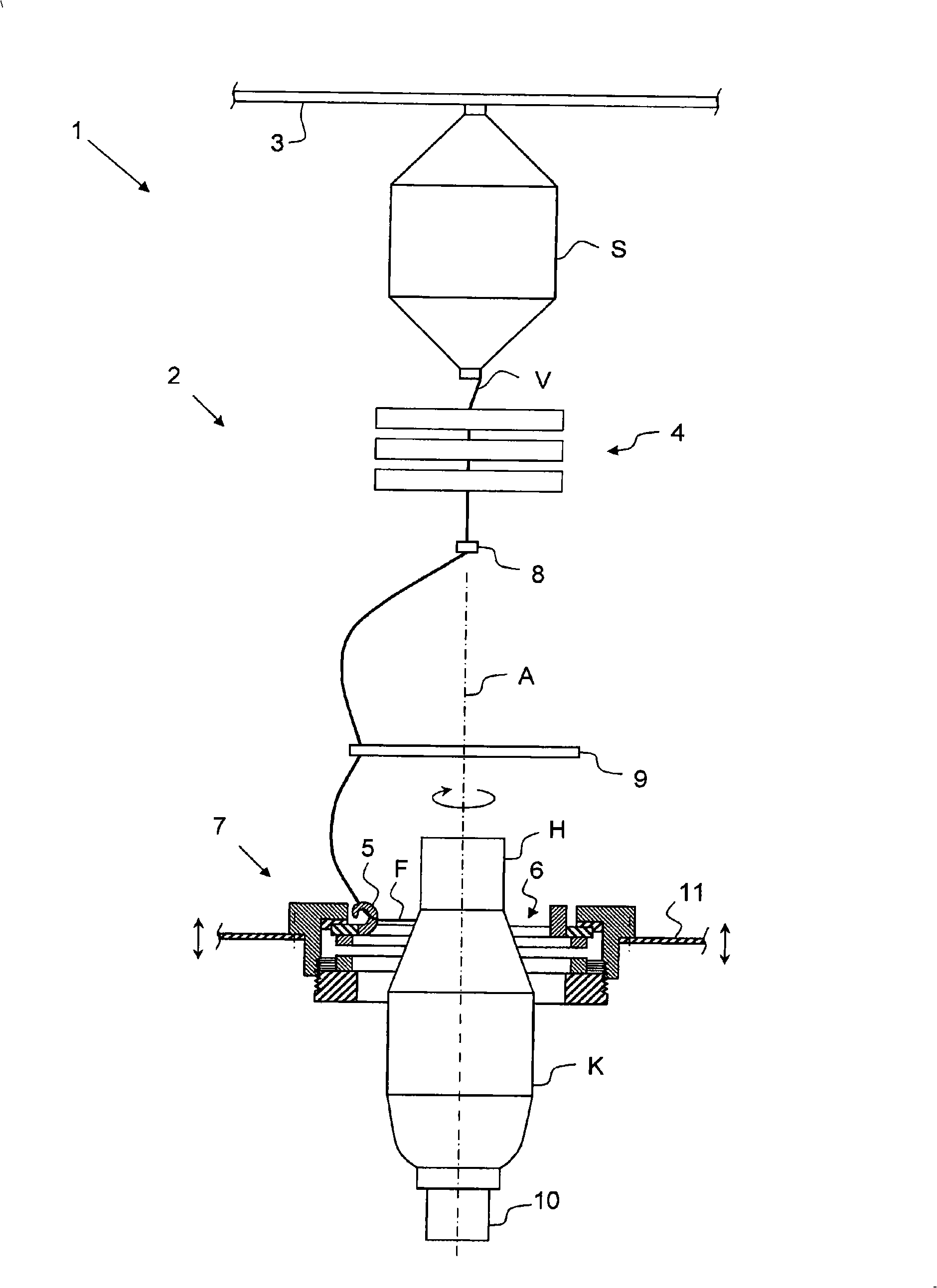

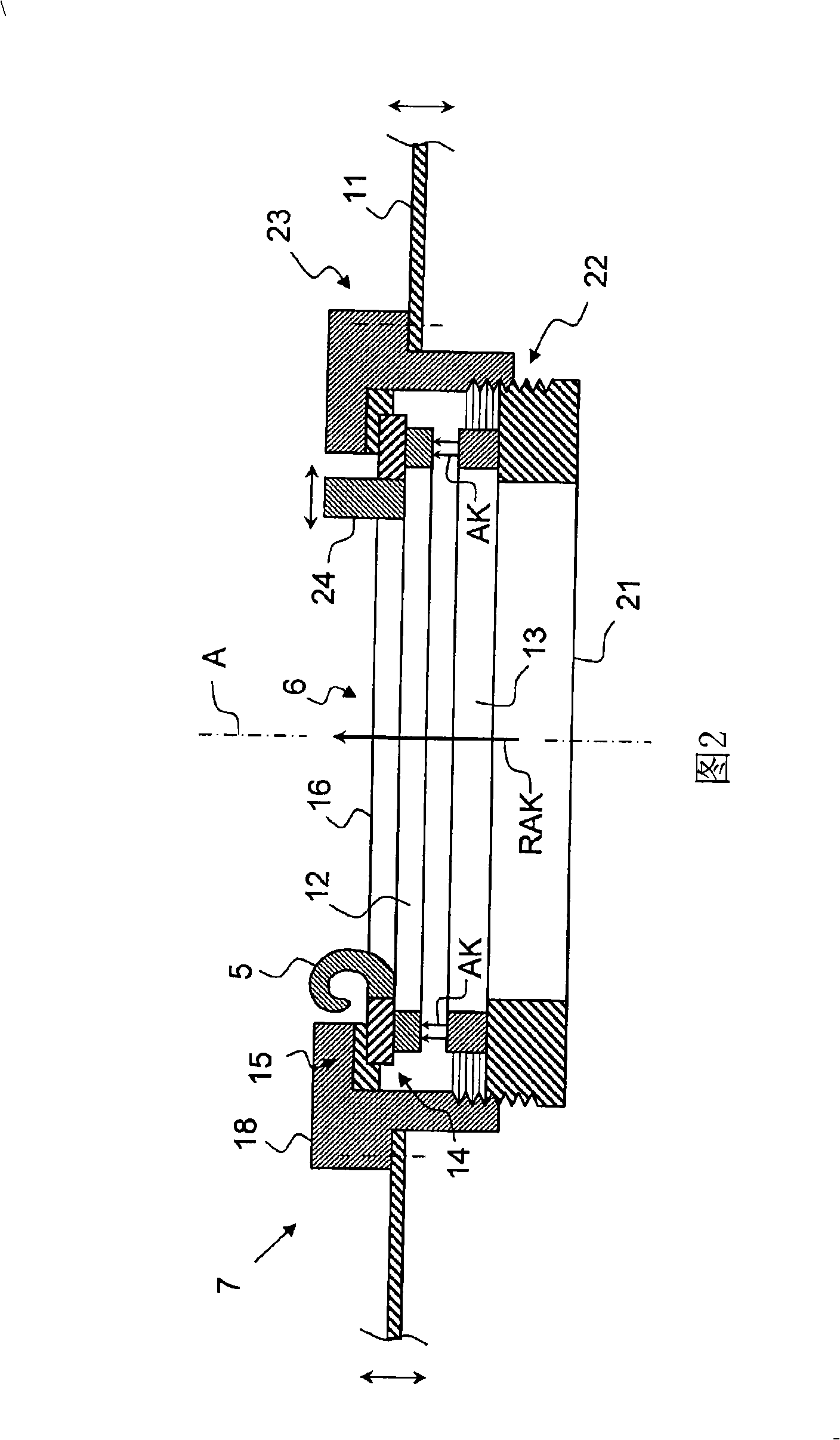

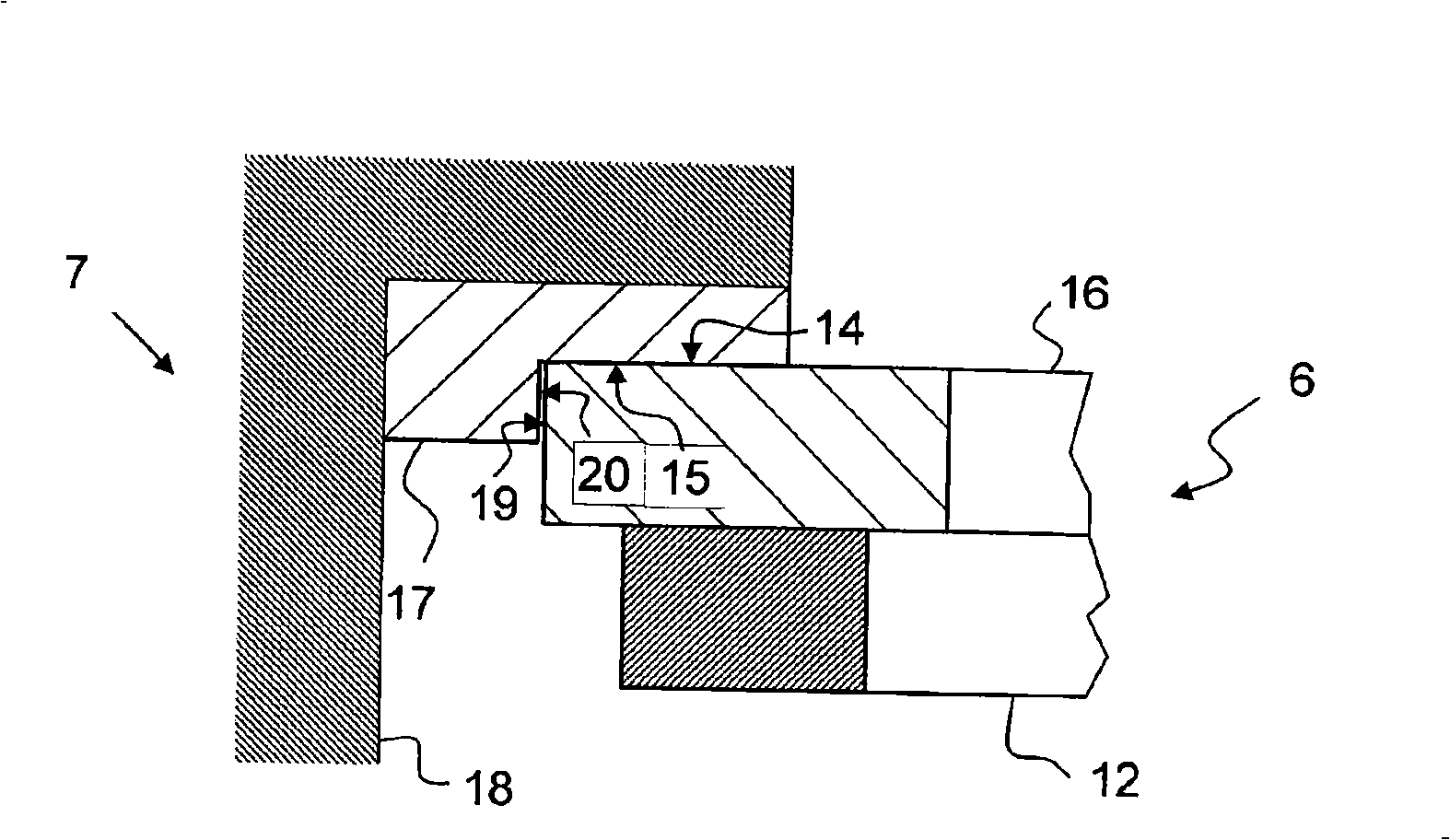

Device and thread guiding ring for a ring spinning machine or twisting machine

The invention relates to a device for ring spinning or twisting machine which is provided with a guide eye (6) the guide parts (5, 5') of which are used for twisting and veer silking (F), and a holding unit (7), the guide eye (6) is arranged on the holding unit (7) and rotates with a given spin axis (A), wherein force generating devices (12, 13; 12', 13'; 28) are used between the axial force (AK) to the guide eye (6), when the device is operated by continuous acting of the force generating devices, a first sliding section (14) formed on the guide eye (6) is bunted on a second sliding section (15)formed on the holding unit (7), thereby providing axial support to the guide eye (6) in that way. The invention also relates to the ring spinning or twisting machine and the guide eye thereof.

Owner:斯图加特德国纺织、纤维研究所

Low-salt tank type fermentation preparation method of Pixian horsebean chili paste

InactiveCN107114690ARealize industrializationFully automatedYeast food ingredientsLactobacillusWater contentChemistry

The invention discloses a low-salt tank type fermentation preparation method of Pixian horsebean chili paste. The method comprises the following steps: adding horsebean paste petals prepared by tank type fermentation and fermented dried chili embryos into a mixing tank according to a mass ratio of 4 to 6, premixing, then adding the material into a chili embryo fermentation tank, uniformly mixing, enabling the concentration of salt in the material to be 9.0-10.5% and enabling the content of water in the material to be 60-65%, then controlling the temperature to be 15-20 DEG C, introducing sterile air for fermenting, adding saccharomycete powder after fermenting for 3-5 days, uniformly mixing, obtaining Pixian horsebean chili paste after fermenting for 75-90 days, then carrying out vacuum dewatering treatment of the Pixian horsebean chili paste to obtain Pixian horsebean chili paste products with water content being less than or equal to 50.00% and salt content being 12.00-15.00%. Through the low-salt tank type fermentation preparation method of Pixian horsebean chili paste, the requirements on the quality can be met; the fragrance and the delicate flavor of the products can be further improved; the problem of pollution in the preparation process is avoided; meanwhile, the special flavor of the conventional Pixian horsebean chili paste is also retained; the method is small in occupation area and is suitable for large-scale industrial production; and the market demand of the Pixian horsebean chili paste is met.

Owner:SICHUAN GAOFUJI FOOD

Dark Pixian County thick broad-bean sauce fermentation preparation method

Owner:SICHUAN GAOFUJI FOOD

Tank type fermentation process for preparing low-salt chili oil thick broad-bean sauce by premixing and feeding

InactiveCN107114689AEasy to manufactureRealize industrializationYeast food ingredientsLactobacillusFlavorChemistry

The invention provides a tank type fermentation process for preparing low-salt chili oil thick broad-bean sauce by premixing and feeding. The tank type fermentation process comprises the following steps: putting a fermented dried chili base material and broad-bean sauce, which are obtained by tank type fermentation, into a premixing groove according to the mass ratio of (7 to 7.5) to (2.5 to 3), and feeding a mixture into a chili base material fermentation tank by adopting an underflow pump; uniformly mixing to enable the salt concentration of the material to be 10 percent to 12 percent and the moisture content to be 70 percent to 75 percent; adding saccharomycete bacterial powder into the tank; keeping constant temperature of 25 DEG C to 40 DEG C and introducing sterile air and fermenting for 4 to 5 days; then adding cooled cooked rapeseed oil into the material subjected to fermentation and dehydration treatment; heating and sterilizing to obtain a chili oil thick broad-bean sauce product. According to the method provided by the invention, the flavor and umami of a product are further improved when the requirements on quality are met; a pollution problem in a production process is avoided; meanwhile, a unique flavor of traditional Pixian thick broad-bean sauce is also kept; an occupied land is small, so that the tank type fermentation process is suitable for large-scale industrial production and the market demand of the Pixian thick broad-bean sauce is satisfied.

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

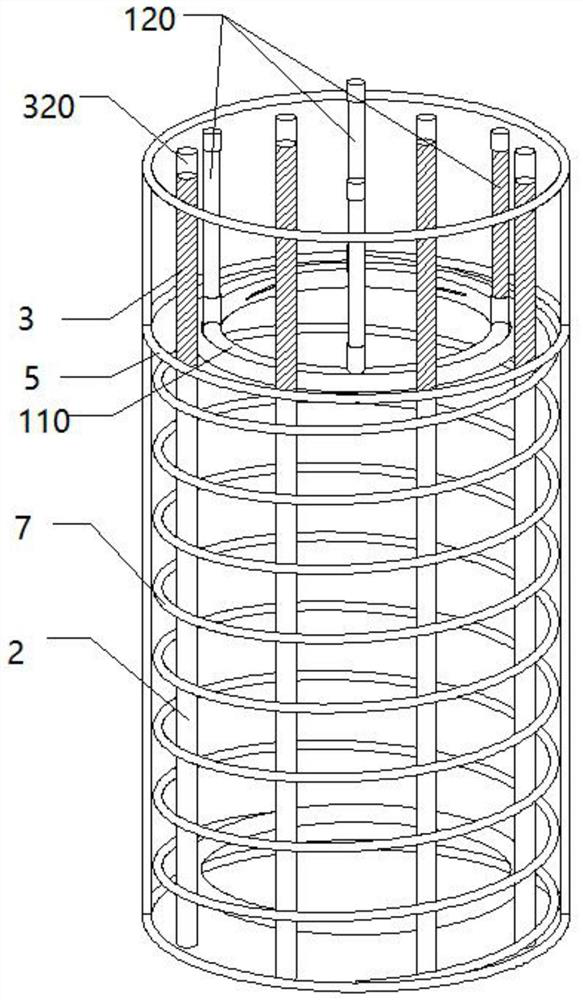

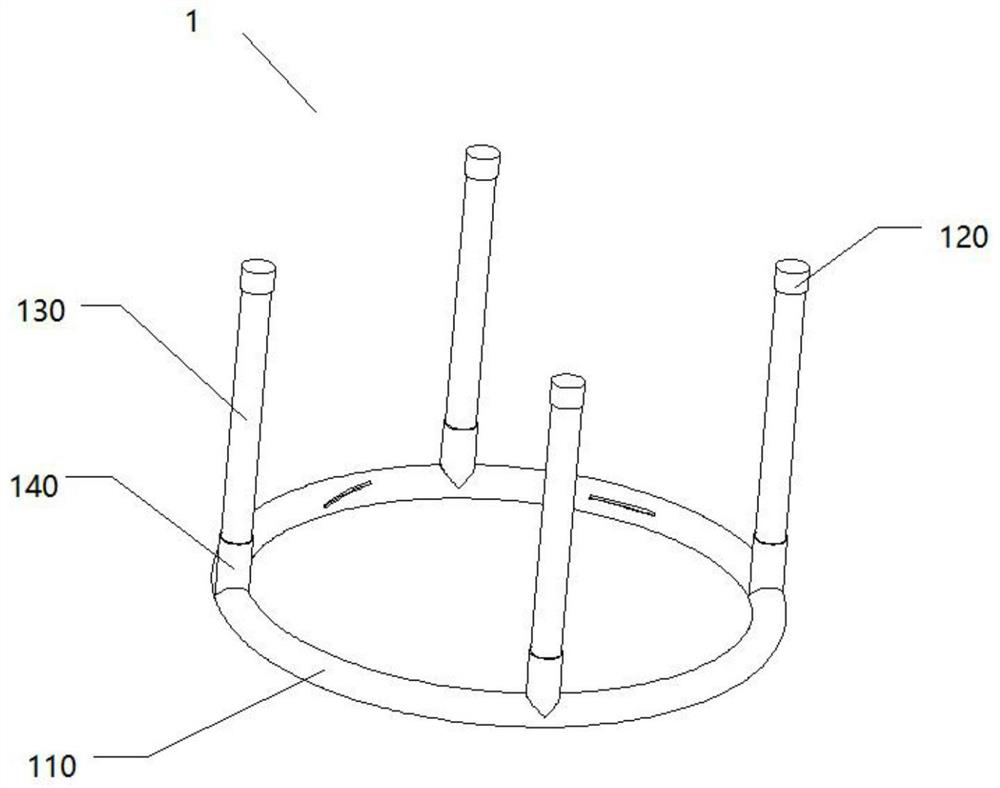

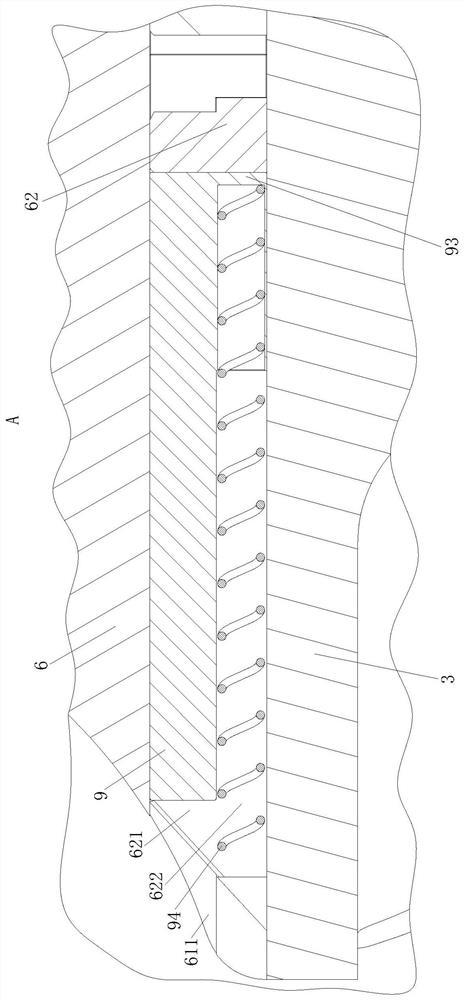

Static breaking construction method for interior of cast-in-situ bored pile head

PendingCN111893992AReduce the amount of brokenReduce noiseBulkheads/pilesPipe fittingArchitectural engineering

The invention discloses a static breaking construction method for the interior of a cast-in-situ bored pile head. The static breaking construction method comprises the following steps that S1, a cast-in-situ pile hole is formed, and a reinforcement cage is manufactured; S2, a pipe fitting is pre-buried in the pile head, a sleeve at the top of the reinforcement cage is installed, and the reinforcement cage is lowered; S3, solid pile concrete is poured; S4, the pile head is excavated and cleaned; S5, the pile head splitting line is cut, and the embedded pipe fitting is poured with an expanding agent; and S6, the interior of the pile head is statically expanded and cracked. The construction method is easy to operate and environmentally friendly, the investment of traditional pile head breaking constructors and machines is greatly reduced, the pile head breaking amount, noise and flying dust are reduced, the pile head breaking construction quality is guaranteed, the pile head breaking construction efficiency is improved, and the construction cost is reduced.

Owner:WUHAN HANYANG MUNICIPAL CONSTR GRP CO LTD +1

Flue gas-based combined desulfuration and denitration method and special device for method

ActiveCN102019135BImprove denitrification efficiencyImprove distributionDispersed particle separationFlue gasProcess engineering

The invention discloses a flue gas-based desulduratoin and denitration method and a special device for the flue gas-based desulduratoin and denitration method. The special device comprises a denitration reactor body and a desulphurization reactor body, wherein the side wall of the desulphurization reactor body is provided with a flue inlet; the desulphurization reactor body and the denitration reactor body are communicated in parallel; the volume of the denitration reactor body is 1-2 times that of the desulphurization reactor body; the communicating position of the desulphurization reactor body and the denitration reactor body is provided with a device for spraying NH3; the top of the denitration reactor body is provided with a denitration reactor inlet for active coke; the bottom of thedenitration reactor is provided with a denitration reactor outlet for the active coke; the top of the desulphurization reactor is provided with a desulphurization reactor inlet for the active coke; the bottom of the desulphurization reactor is provided with a desulphurization reactor outlet for the active coke; and the denitration reactor outlet for the active coke is communicated with a desulphurization reactor inlet for the active coke through a pipeline, and the desulphurization reactor outlet for the active coke is communicated with a regeneration reactor. The invention also provides a method for flue gas desulfurization and denitration by using the device.

Owner:CCTEG CHINA COAL RES INST

Mixed aerial fog steel slag treatment device

PendingCN107723394AShort processReduce consumptionRecycling and recovery technologiesProcess efficiency improvementMolten stateInlet channel

The invention relates to steel slag treatment, and provides a mixed aerial fog steel slag treatment device. The mixed aerial fog steel slag treatment device comprises a slag box, a chute and a dust collector. The dust collector communicates with a chamber of the slag box. The mixed aerial fog steel slag treatment device further comprises an air inlet channel, a water inlet pipe and a first fog spraying pipe. The air inlet channel and the water inlet pipe both communicate to the first fog spraying pipe. The spraying-out path of the first fog spraying pipe intersects with the sliding-out path ofthe chute. A reflection plate allowing steel slag impacting is arranged in the slag box. According to the mixed aerial fog steel slag treatment device, molten red slag is crushed many times in a molten state, the particle size is smaller than the particle size of air quenching method slag treatment, the crushing quantity of subsequent treatment is reduced, even direct application is achieved without secondary treatment, and the subsequent investment and energy consumption are reduced. After the molten red slag is crushed in the molten state, free calcium oxide in the molten red slag is in full contact with aerial fog and steam obtained through aerial fog conversion to be eliminated, elimination of the free calcium oxide is more thorough and faster than elimination of hot stewed slag, theproblem about stability of tail slag is solved more thoroughly, and reutilization of the tail slag is facilitated.

Owner:WISDRI ENG & RES INC LTD

A kind of foam concrete with low water absorption rate and preparation method thereof

InactiveCN104150951BShort initial setting timeReduced open porosityCeramicwarePorosityFreeze thawing

The invention relates to a low-water-absorption foamed concrete and a preparation method thereof. The low-water-absorption foamed concrete is prepared from ordinary Portland cement, sulphoaluminate cement, raw material soil, water, a thickening agent, a water-reducing agent, a foam-stabilizing agent, an accelerator and a foaming agent. Through addition of the sulphoaluminate cement and the accelerator which can accelerate coagulation of the ordinary Portland cement, break of bubbles during an initial setting time is reduced and an opening porosity and water absorption of the foamed concrete are reduced. Through addition of the thickening agent, thickness of the foamed concrete can be adjusted and upward-floating of the bubbles is reduced so that the bubble is distributed uniformly. The foamed concrete is low in water absorption, is uniform in volume weight, is stable in compressive strength and has a better thermal-insulation and temperature-preserving performance, a better mechanical performance and a better freeze-thaw-destroy resistant performance.

Owner:WUHAN UNIV OF TECH

Low-salt-content tank fermentation method of Pixian thick broad-bean chili sauce by using premixed materials

InactiveCN107252054AGood controllability of fermentation conditionsSmall footprintFood scienceWater contentChemistry

The invention discloses a low-salt-content tank fermentation method of Pixian thick broad-bean chili sauce by using premixed materials. The low-salt-content tank fermentation method of the Pixian thick broad-bean chili sauce by using the premixed materials comprises the following steps of putting broad-bean-half paste prepared by carrying out tank fermentation and fermented dried chili pepper bases into a material mixing tank at a mass ratio of 4 to 6, and carrying out premixing; introducing the premixed materials into a chili pepper base fermentation tank by adopting a slurry pump, and carrying out uniform mixing; making salinity of the mixture at 10-12%, and water content of the mixture at 60-65%; controlling the temperature at 15-20 DEG C, and introducing sterile air so as to carry out fermentation; adding yeast powder after 3-5 days of fermentation, and carrying out uniform mixing; carrying out fermentation for 75-90 days so as to obtain the Pixian thick broad-bean chili sauce; and then, performing vacuum dehydration treatment on the Pixian thick broad-bean chili sauce so as to obtain a Pixian thick broad-bean chili sauce product of which the water content is 50.00% or lower, and the salt content is 12.00-15.00%. The low-salt-content tank fermentation method of the Pixian thick broad-bean chili sauce by using the premixed materials meets quality requirements, and further improves aroma and delicious taste of the Pixian thick broad-bean chili sauce; moreover, pollution problems during preparation processes of the Pixian thick broad-bean chili sauce are also avoided. The method also retains unique flavor of traditional Pixian thick broad-bean chili sauce, and is small in floor area and suitable for large-scale industrial production; and thus, market demands for the Pixian thick broad-bean chili sauce is satisfied.

Owner:SICHUAN GAOFUJI FOOD

Sieving and crushing integrated machine

ActiveCN102896019BReasonable layoutReduce power consumptionSievingScreeningEngineeringSystem structure

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

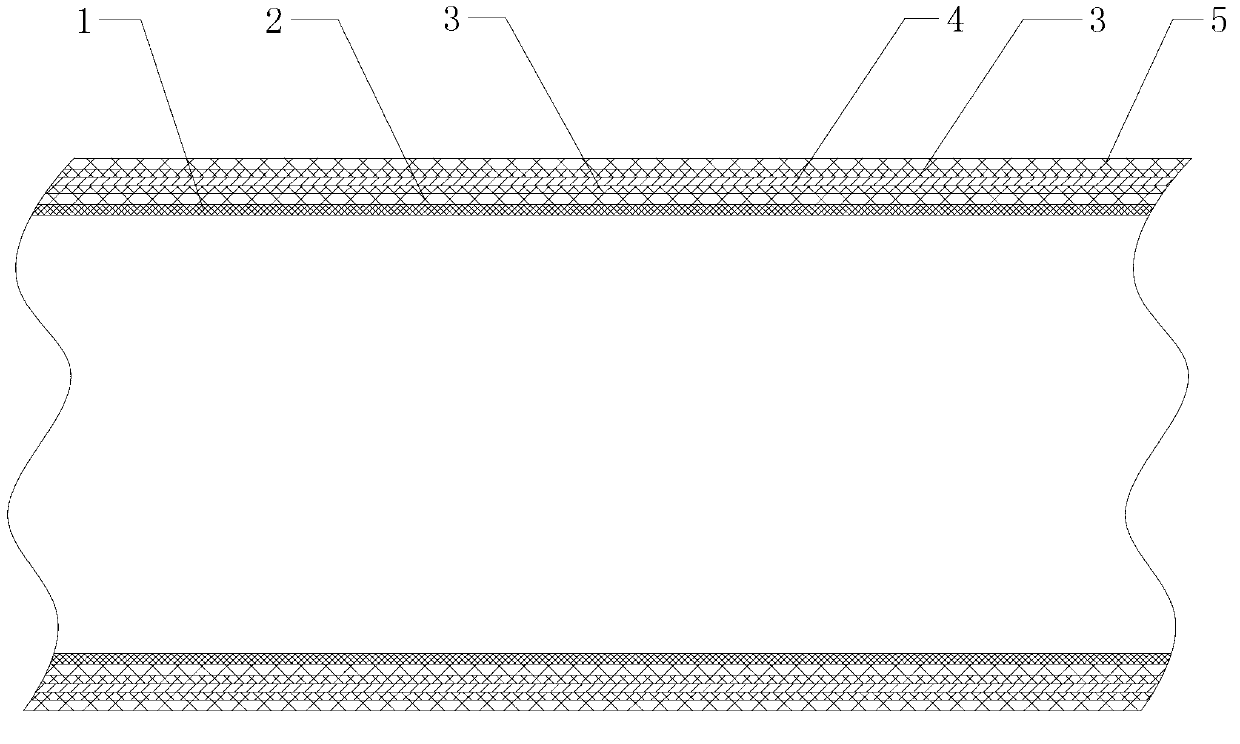

Wear resistant composite tube

InactiveCN103104760AAvoid breakingLow costRigid pipesPipe protection against damage/wearWear resistantTransport medium

The invention discloses a wear resistant composite tube. The inner layer of the composite tube is a wear-resistant layer. The outer portion of the wear-resistant layer is sleeved with an inner plastic layer. A steel skeleton layer is sleeved outside the inner plastic layer. An outer plastic layer is sleeved outside the steel skeleton layer. The steel skeleton layer and the inner plastic layer are pasted through hot melting glue. The steel skeleton layer and the outer plastic layer are pasted through hot melting glue. Due to the fact that the wear resistant layer is added to the inner wall of the composite pipe, the wear resistant composite pipe is capable of transporting medium with a big friction coefficient, is not easy to break and improves service life of tubing. Compared with a steel pipe, the wear-resistant composite tube is low in cost and convenient to install.

Owner:JIANGSU SHUANGTENG PIPE IND CO LTD

A device for treating construction waste in civil engineering

ActiveCN111318357BReduce energy consumptionReduce maintenance costsGrain treatmentsCold treatmentConstruction engineering

Owner:SHANGQIU INST OF TECH

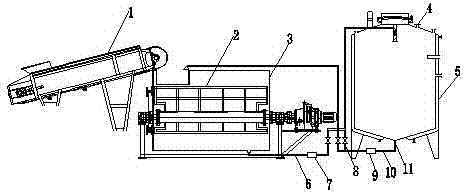

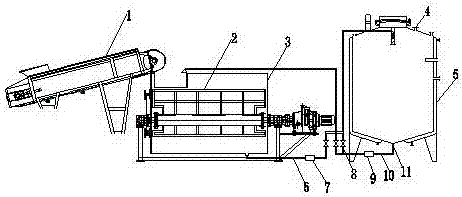

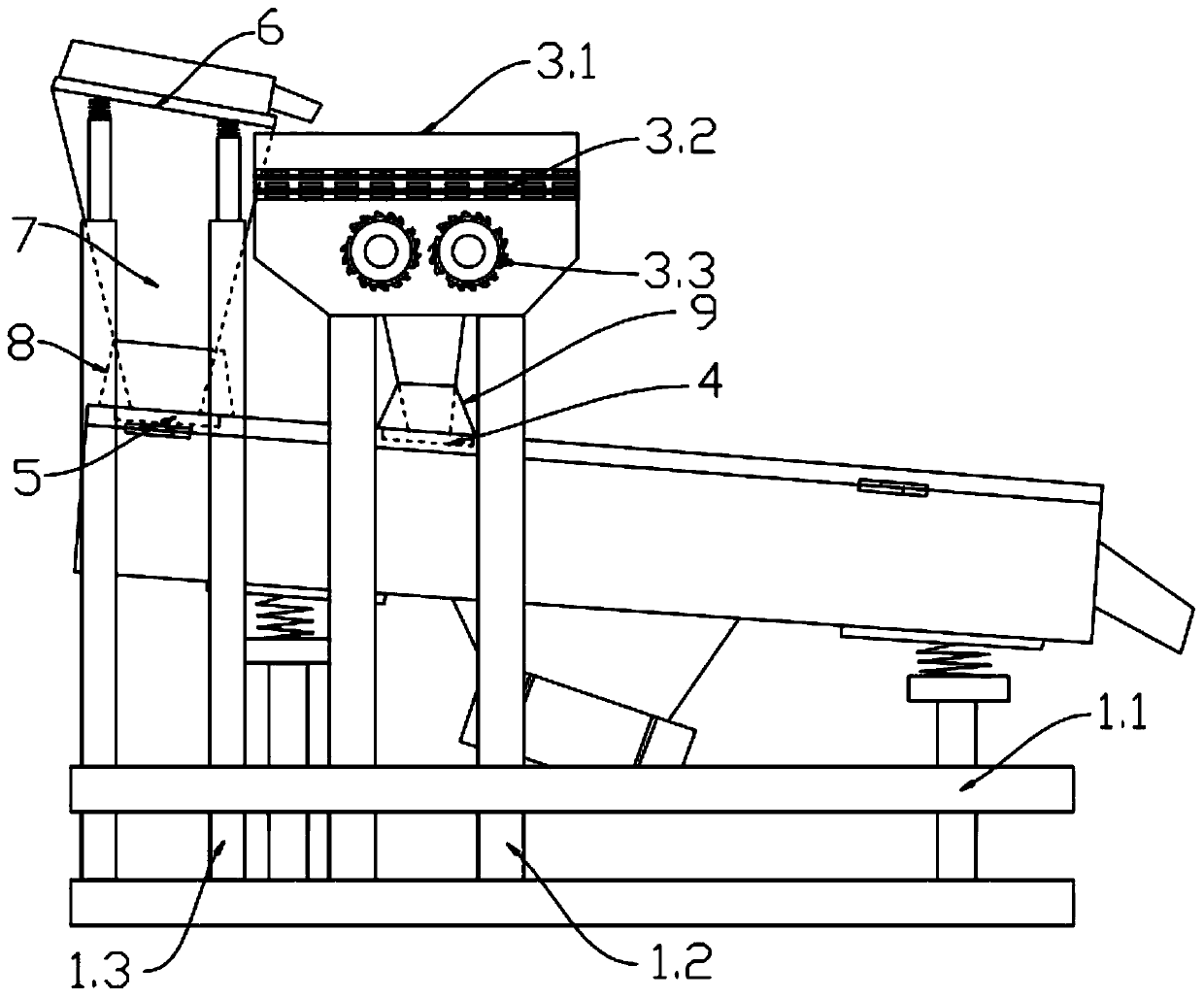

coal crushing and screening machine

Owner:徐州东兴能源有限公司

Raw bauxite secondary crushing device for manufacturing brown fused alumina

InactiveCN106179707AGuaranteed crushing effectReduce the amount of brokenGrain treatmentsEngineeringCrusher

The invention discloses a raw bauxite secondary crushing device for making brown corundum, which comprises a raw bauxite crusher 1 for primary crushing, and a screen is arranged below the raw bauxite crusher 1, and the upper end of the sieve is Align with the outlet of raw bauxite crusher 1, set a storage box at the lower part of the screen, connect the raw bauxite crusher 2 through pipeline 1 at the output end of the screen, and connect the storage box to the raw bauxite crusher through pipeline 2 The connection of the two output ends realizes that the raw bauxite in the sieve and the storage box is closed and flows into the next process. The invention has the advantages of simple structure, convenient manufacture and strong practicability.

Owner:贵州开阳三环磨料有限公司

Process for preparing feed gas for synthetic ammonia by two-stage furnace coal gasification taking cold-pressed briquette as raw material

InactiveCN101659395BEasy to manufactureReduce manufacturing costHydrogen productionGranularityHardness

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD +1

Hot braising method for phosphorus removed slag and carbon removed slag

The invention provides a hot braising method for phosphorus removed slag and carbon removed slag. The method comprises the following steps of: pouring hot phosphorus removed slag into a slag braising pit to parch the slag braising pit; pouring the phosphorus removed slag or the carbon removed slag into multiple parched slag braising pits respectively, turning over, dewatering and breaking the slag in each slag braising pit, then pouring another slag respectively, and repeating the operations of turning over, dewatering and breaking the slag till each slag braising pit is full of the slag; and covering the slag braising pits full of the slag with slag braising covers, and braising the slag in a three-section dewatering and braising mode. The hot braising method for the phosphorus removed slag and the carbon removed slag is simple and feasible, can reduce the potential safety hazard of blasting of the slag braising pits and effectively improve the slag braising efficiency and slag braising quality, and has remarkable economic benefits.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

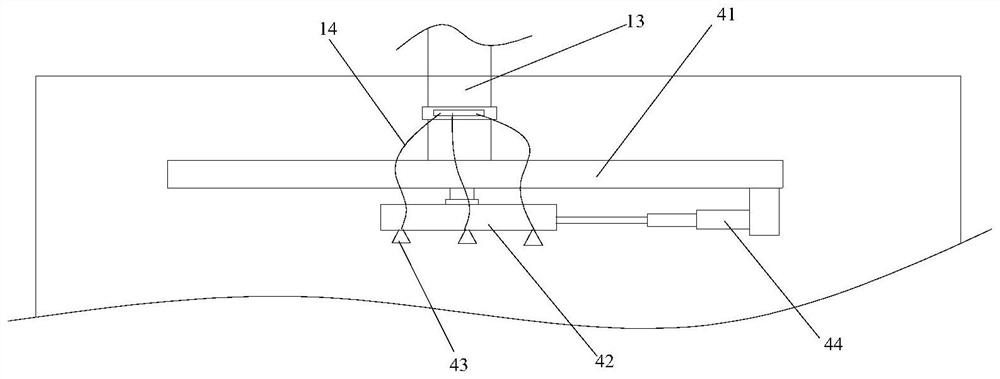

An automated device that efficiently organizes different types of glassware

ActiveCN107416252BReduce the amount of brokenImprove work efficiencyContainers to prevent mechanical damagePackaging bottlesGlass vesselEngineering

The invention relates to automatic equipment capable of finishing different types of glassware efficiently. The automatic equipment comprises a bottom plate, a rotating device is mounted in the middle of the bottom plate, a guiding frame is mounted on the rotating device and can be driven to rotate by the rotating device, and two stacking devices are symmetrically installed at the two ends of the bottom plate; a rectangular bottle collecting frame is placed in each stacking device, and the two stacking devices can drive the rectangular bottle collecting frames to move and evenly collect rectangular glassware in the rectangular bottle collecting frames; and the rotating device and the stacking devices are used cooperatively to finish the glassware finishing process. According to the automatic equipment capable of finishing different types of glassware efficiently, the function of efficient finishing of the glassware with different structures can be achieved, the glassware with different structures are placed in corresponding glassware containers, the crushing amount of the glassware is reduced, manual operation is not required, and the automatic equipment has the advantages of being small in labor intensity and high in working efficiency.

Owner:HAIMEN CHENGJUN GLASS

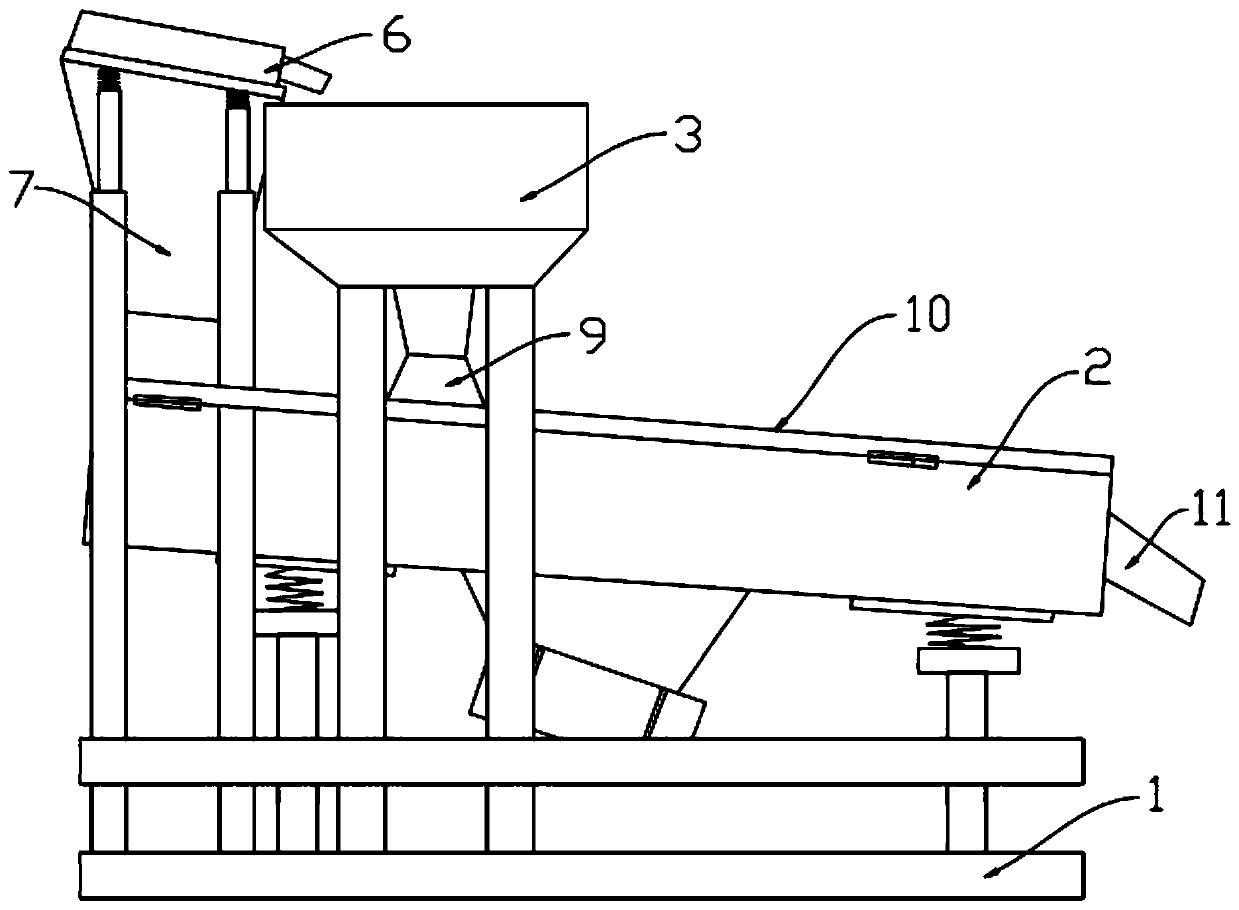

Production process of strip-shaped black tea

PendingCN114271341AReduce the amount of brokenImprove qualityPre-extraction tea treatmentHorticultureEngineering

The invention relates to the technical field of black tea processing, in particular to a strip-shaped black tea making process, and aims to solve the problems of inconvenience in laying and non-uniform oxygen contact in a tea fermentation process in the prior art, the following scheme is provided: the strip-shaped black tea making process comprises the following steps: S1, picking fresh leaves which have one bud and two leaves or one bud and three leaves and are uniform and consistent in tenderness; s2, cleaning the tea leaves obtained in the step S1, and draining off water in the fresh tea leaves; s3, withering the cleaned tea leaves obtained in the step S2 by using a withering machine; s4, shaping and processing the withered tea leaves obtained in the step S3 by using a strip tidying machine; and S5, putting the shaped tea leaves obtained in the step S4 into a fermentation device for fermentation. The device is reasonable and stable in structure and easy to operate, tea leaves are effectively and conveniently laid in the tea leaf fermentation process, uniform fermentation of the tea leaves is guaranteed, the tea leaf crushing amount is effectively reduced, the tea leaf quality is improved, and the device is easy to popularize and use.

Owner:ANHUI JINZHAI JINLONG YUZHU TEA IND

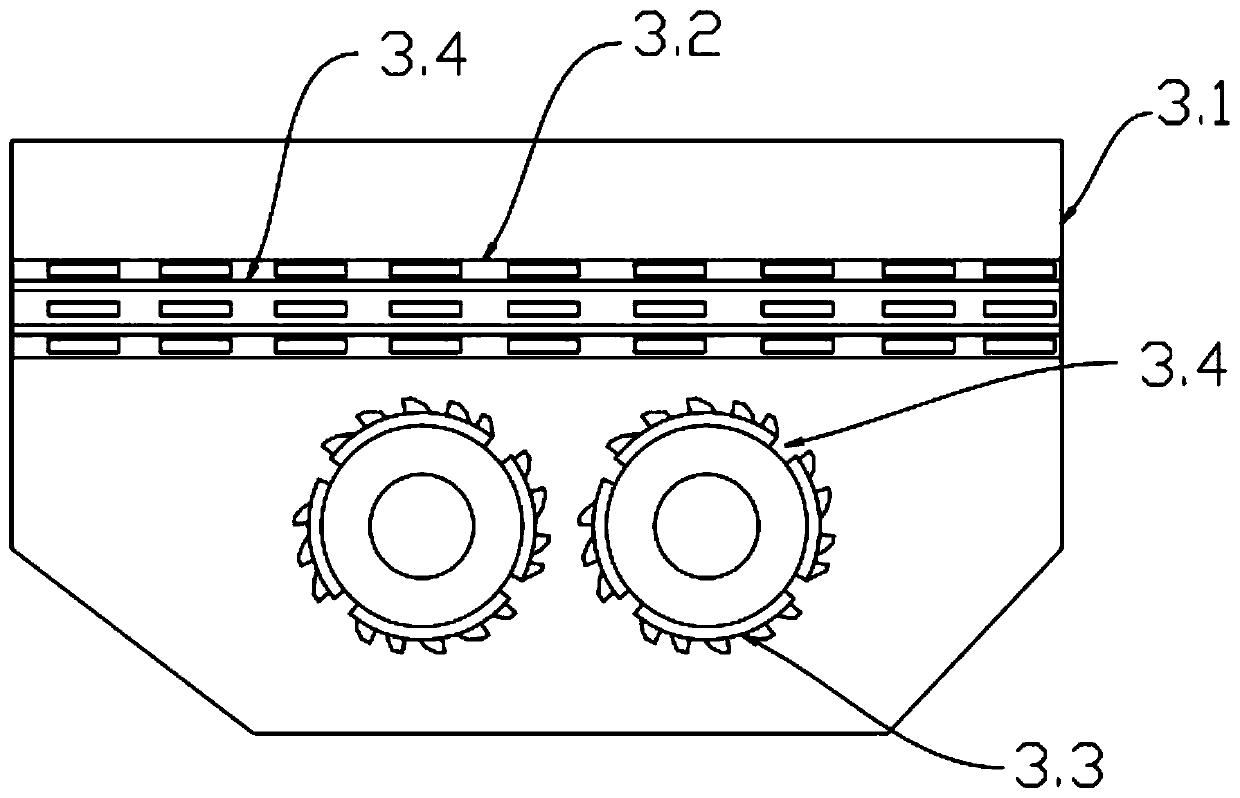

Energy-saving type crushing machine of discharging pipeline of cement bunker

The invention discloses an energy-saving type crushing machine of a discharging pipeline of a cement bunker. The crushing machine is mounted at a discharging opening of the cement bunker and comprisesa screen plate covering the upper part of the discharging opening and a crushing mechanism covering the lower part of the discharging opening. Multiple screen holes allowing cement which is not hardened to pass are evenly distributed in the screen plate, and when hardened cement blocks exist in discharged materials of the cement bunker, the lower end surface of the screen plate is connected withone end surface of the crushing mechanism; and when the hardened cement blocks do not exist in the discharged materials of the cement bunker, the screen plate is collected by the aid of an arc-shapedgroove, the discharging opening is opened, cement materials are directly guided out of the discharging pipeline of the cement bunker without passing the crushing machine, and the crushing mechanism can be stopped at this moment. Multiple crushing knife wheels which are driven by power to rotate and are used for crushing the hardened cement blocks are distributed on the crushing mechanism, the hardened cement blocks which are not screened out by the screen plate slide to the crushing mechanism below under the action of dead weight and are guided out of the cement bunker after being crushed by the crushing mechanism. The crushing machine has the advantages that the total crushing amount of the cement materials at the discharging opening is reduced, meanwhile, when the hardened cement blocksdo not exist in the discharged materials of the cement bunker, the crushing mechanism can be stopped, and the power consumption can be reduced substantially.

Owner:HUAQIAO UNIVERSITY

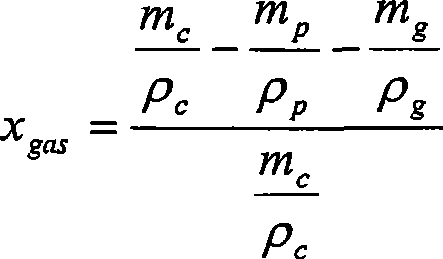

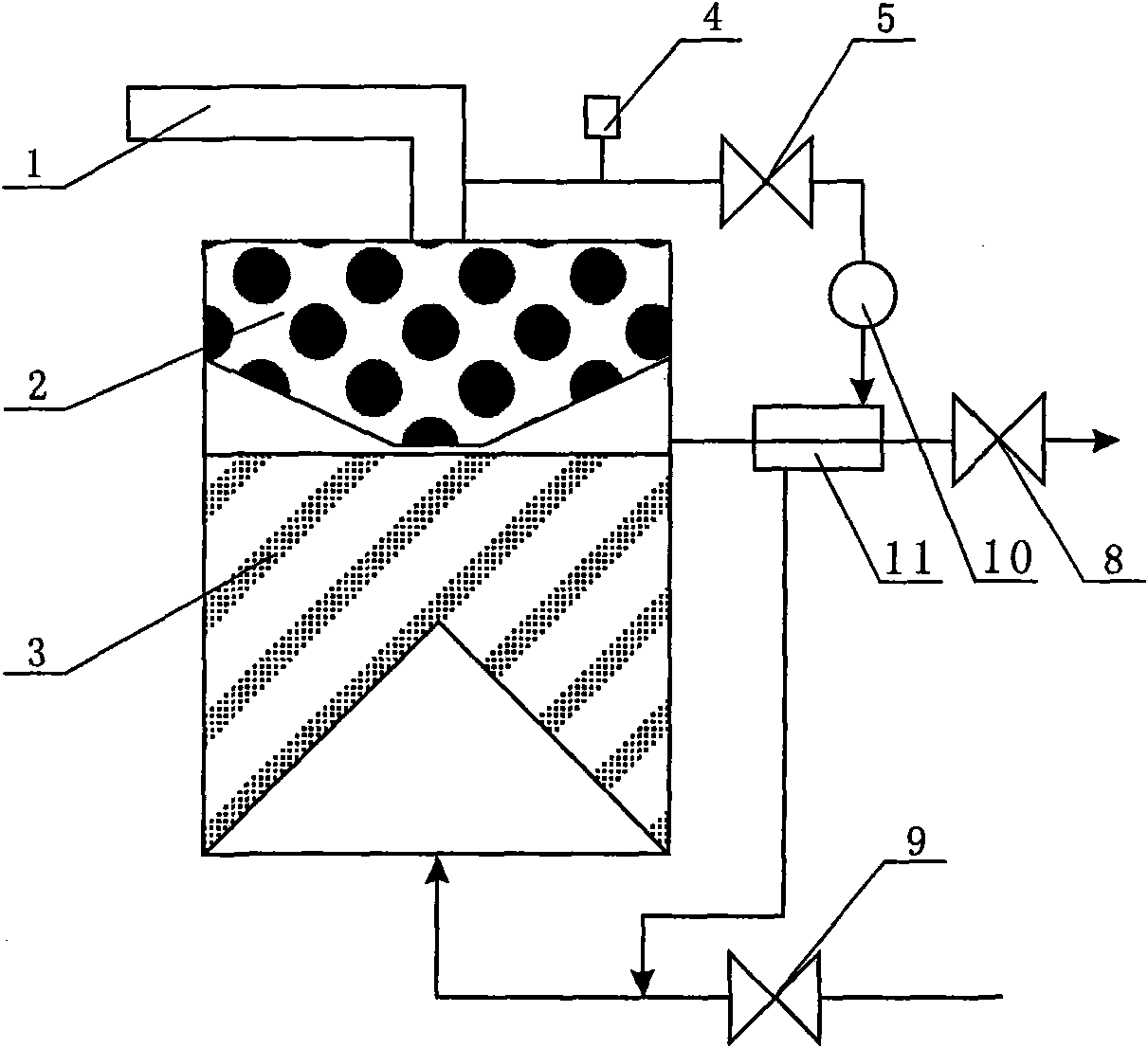

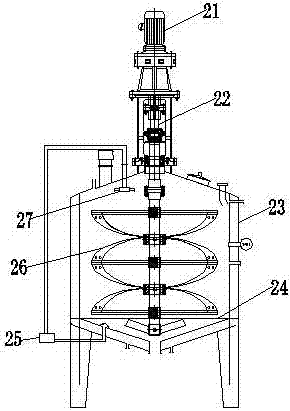

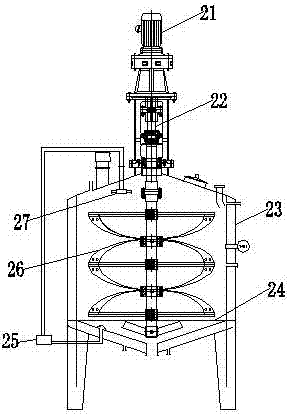

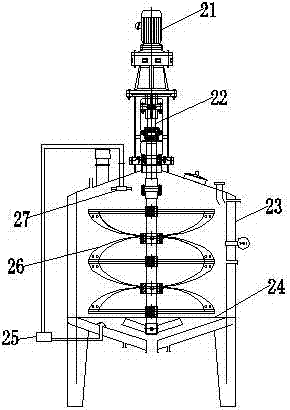

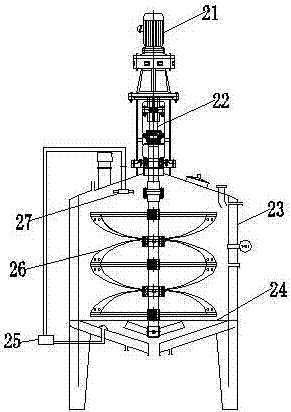

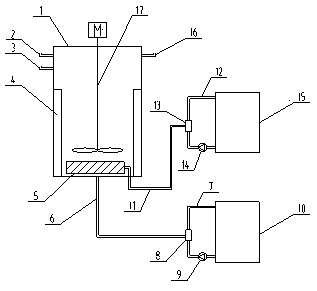

Powder resin desorption regeneration reactor

ActiveCN102489347BImprove hydrodynamic propertiesRealize continuous separation and regeneration operationIon-exchanger regenerationSpecific water treatment objectivesDesorptionPhysical chemistry

A regenerating reactor for desorbing a powdery resin, comprising a reactor (1), a resin separator (5), a desorption liquid tank (15), and a regenerated resin delivery system; the resin separator (5) has one end thereof connected to a discharging pipe for the desorption liquid (11), and the other end of the discharging pipe for the desorption liquid (11) is connected to a suction port of a water ejector (13) of a circulating pipe of the desorption liquid tank which is mounted on the circulating pipe (12) of the desorption liquid tank; an upper outlet of the circulating pipe (12) of the desorption liquid tank is in communication with the desorption liquid tank (15), and a lower outlet thereof is in communication with the desorption liquid tank (15) via a circulating pump (14) for the desorption liquid tank; the regenerated resin delivery system comprises a fully mixed resin reactor (10), a circulating pipe (7) of the fully mixed resin reactor, a water ejector (8) of the circulating pipe of the fully mixed resin reactor and a circulating pump (9) for the fully mixed resin reactor. The reactor can complement any reactor directed to such resins, make full use of the advantages of such resins, and achieve the operations of continuous separation and regeneration of resin in the resin reaction device.

Owner:NANJING UNIV +1

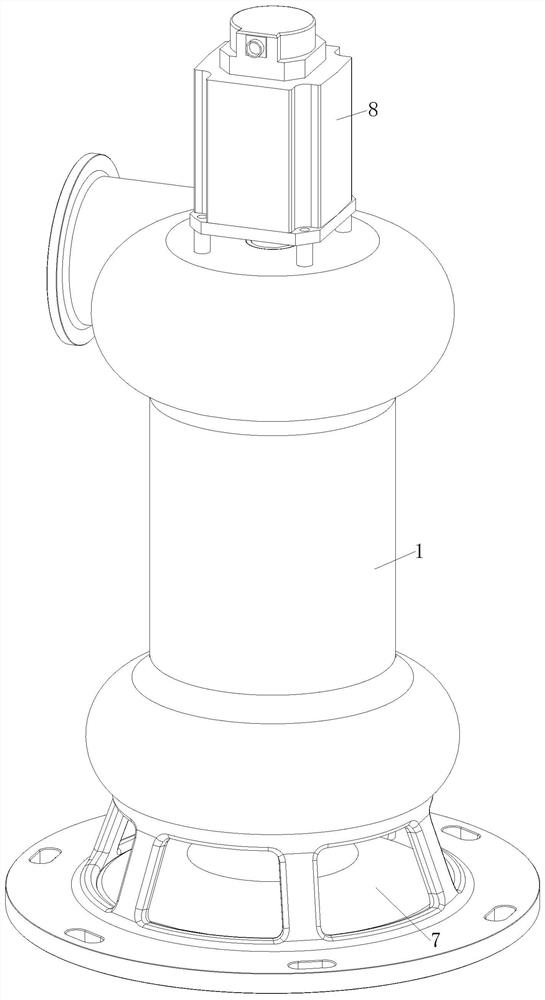

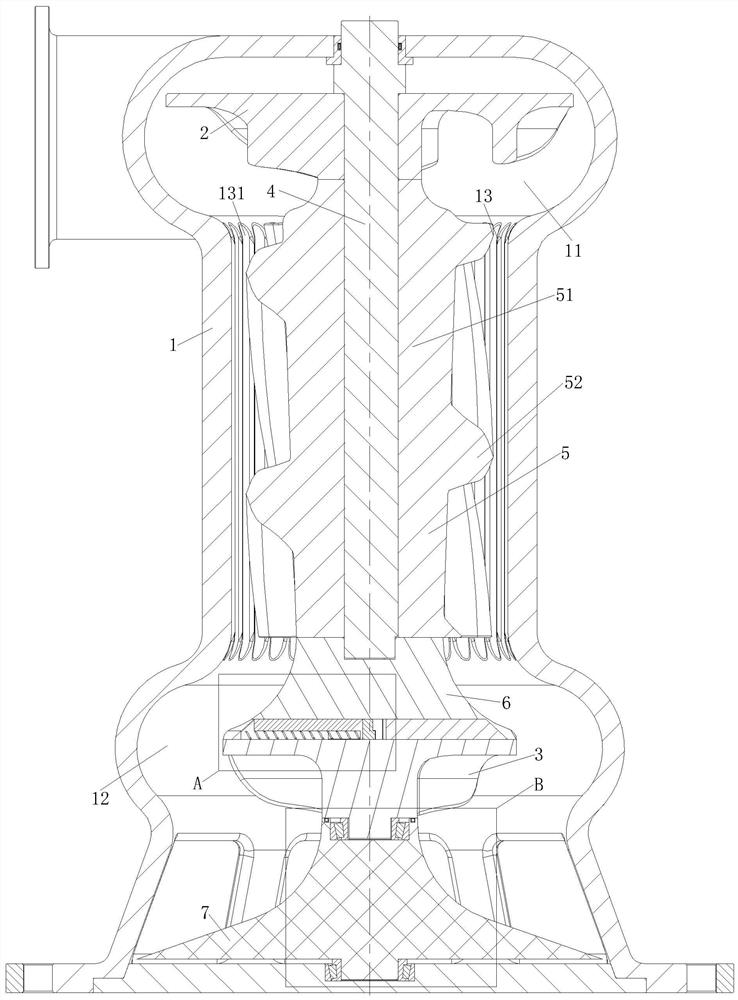

Submersible sewage pump

InactiveCN113864204AReduce wearGuaranteed crushing effectSpecific fluid pumpsPump componentsImpellerSewage discharge

The invention belongs to the technical field of pumps, and particularly relates to a submersible sewage pump. The submersible sewage pump comprises a pump body, a first impeller, a second impeller, a rotating shaft and a crushing part. The first impeller, the crushing part and the second impeller are driven by the rotating shaft to synchronously rotate at a high speed, when the first impeller rotates, sewage in a crushing cavity and a suction cavity is sucked into a discharge cavity, then the sewage enters a sewage discharge pipeline, when the second impeller rotates, the second impeller generates acting force on the sewage between blades, then the sewage in the suction cavity enters the crushing cavity, sewage in a sewage pool is discharged into the sewage discharge pipeline under the combined action of the first impeller and the second impeller, and then sewage conveying is realized; and the crushing part is arranged on the first impeller and the second impeller to crush large-size sundries, then the sewage has a very high flowing speed when the crushing part crushes the sundries, then the influence of the sundries on the flowing speed of the sewage is reduced, and then the sewage discharge efficiency of the sewage pump is guaranteed.

Owner:王培娟

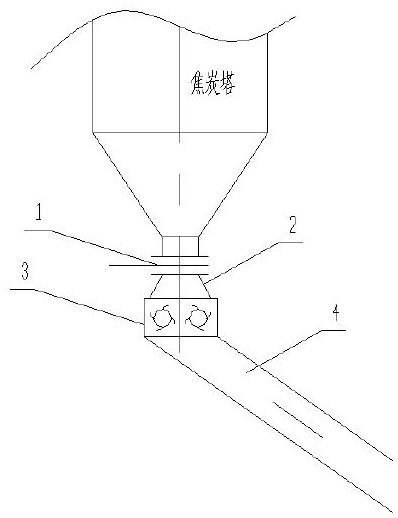

Coke discharging and crushing device

InactiveCN112705340AReduce the amount of instantaneous crushingRealize vertical feeding effectGrain treatmentsCokePetrochemical

The invention discloses a coke discharging and crushing device in the technical field of petroleum refining. The coke discharging and crushing device comprises a bottom cover machine, a flexible connecting section, a crusher and an inclined chute. The device is characterized in that the flexible connecting section is connected under the bottom cover machine and is connected with the upper surface of the crusher; an outlet in the lower surface of the crusher is directly connected with a chute opening of the inclined chute; and the crusher is installed between the bottom cover machine and the inclined chute, and the bottom cover machine is connected with the crusher through the flexible connecting section. By the adoption of the device, the material taking requirement of an original grab crane can be met, the material taking requirement of novel coke taking equipment such as a spiral material taking machine and a belt conveyor can also be met, meanwhile, the probability of locked-rotor and unsmooth feeding of the crusher is reduced, the crushing amount of the crusher is reduced, erosion and impact damage of coke to a chute can be relieved, and the requirements in the fields of petroleum, chemical engineering and the like can be met.

Owner:SINOPEC GUANGZHOU ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com